Automatic winding device for reactor coil

A technology of winding device and reactor, which is applied in coil manufacturing, inductance/transformer/magnet manufacturing, circuits, etc. It can solve the problems affecting the quality of coil winding, wire pressing, and inconvenient demoulding, etc., and achieves good clamping effect, Easy demoulding and lower production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

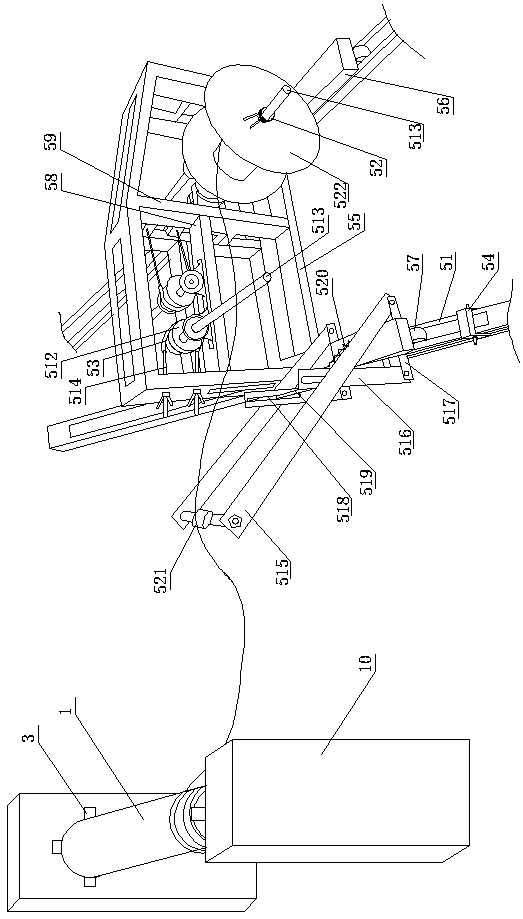

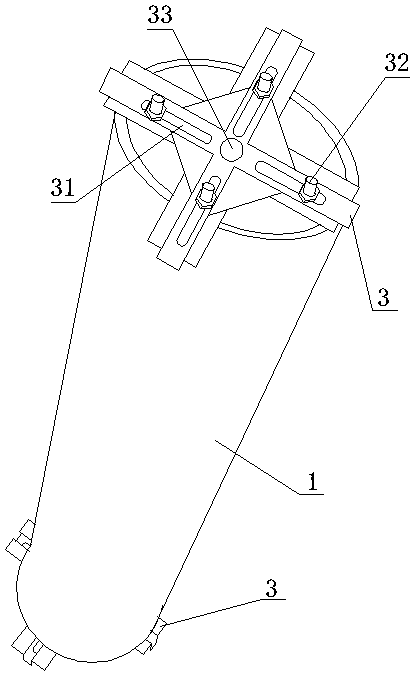

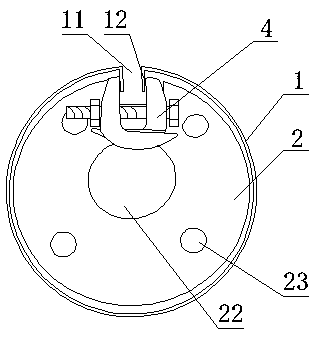

[0031] Such as Figure 1 to Figure 9 As shown, the automatic winding device of a kind of reactor coil of the present invention comprises a pay-off mechanism and a winding mechanism, and the pay-off mechanism includes a pay-off rack and a wire reel 522, and the wire reel 522 is installed on the wire reel shaft of the pay-off rack, The spool shaft 513 is also provided with a clamp 52 for preventing the spool from falling off. The winding mechanism includes a winding machine 10 and a winding tool. The winding machine 10 is provided with two opposite tops 101. The winding tool is installed on Between the two tops 101; a guide rail 51 is installed on the ground at the bottom of the pay-off rack, and the guide rail 51 is arranged parallel to the axis of the top 101. The pay-off rack is slidably connected in the guide rail 51 by a pulley 57 arranged at the bottom of the pay-off rack, and the guide rail 51 is provided with a locking slider 54 for locking the pulley, the locking slider...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com