Rubber ultra-thin dialysis cutting machine

A slitting machine, ultra-thin technology, applied in metal processing, preparation of test samples, etc., can solve the problems of unguaranteed product safety, affecting the accuracy of test results, low accuracy of test results, etc., and achieves a small error. , to prevent sheet curling, the effect of a wide range of applications

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further described below in conjunction with accompanying drawing.

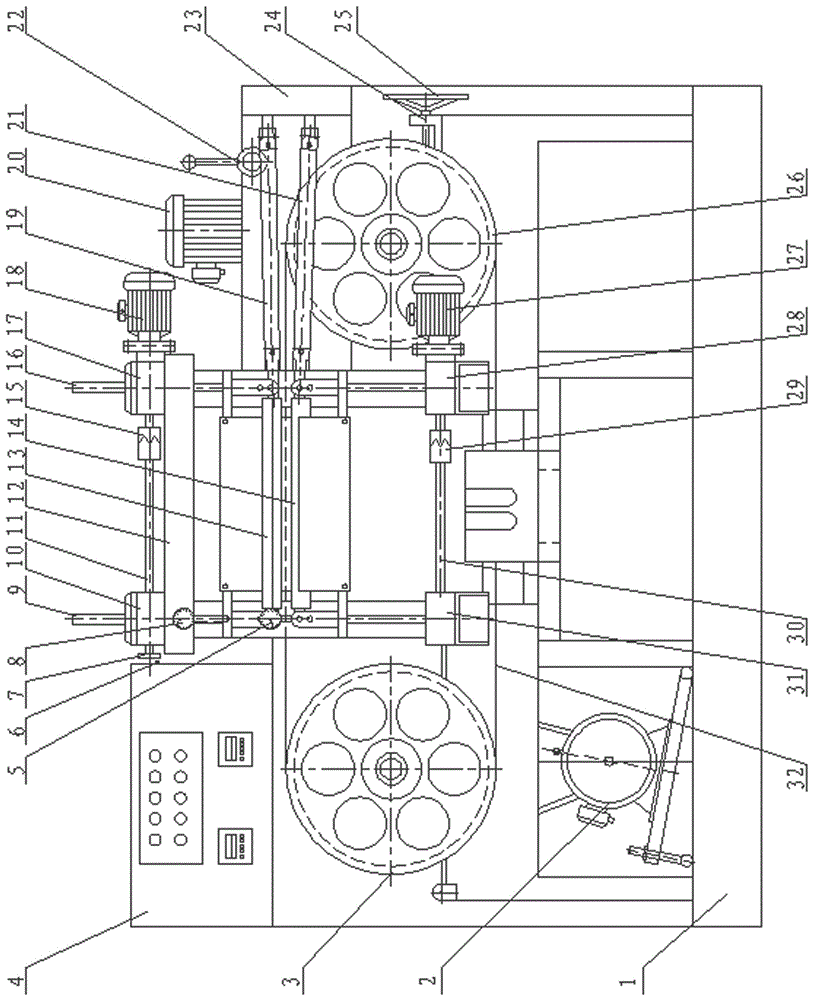

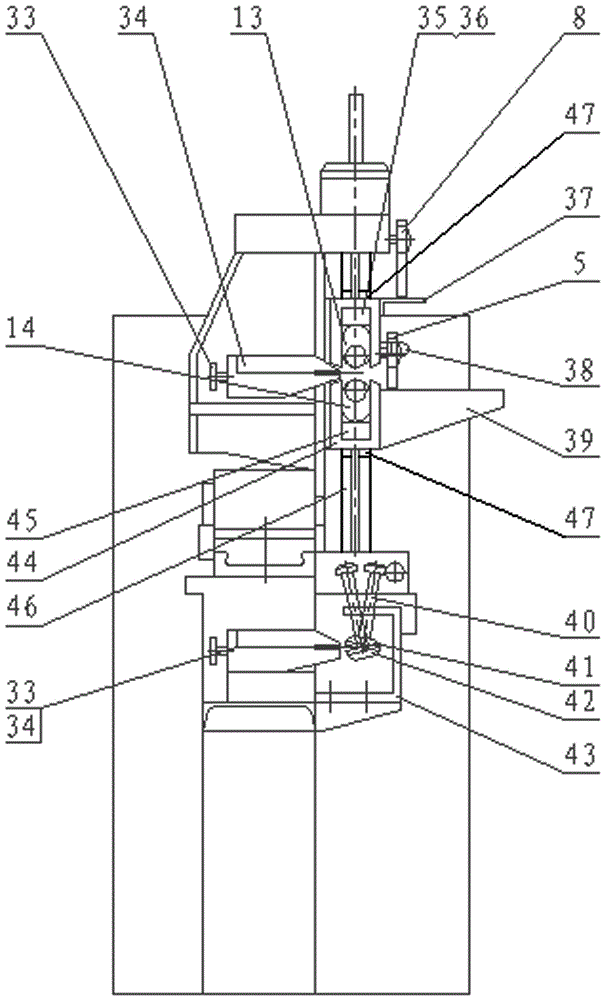

[0021] figure 1 , 2 As shown in the rubber ultra-thin dialysis cutting machine, the upper end of the frame 1 is provided with a control system 4 . The main cutter wheel 3 and the auxiliary cutter wheel 26 are respectively arranged on the left and right sides of the frame 1. The main cutter wheel 3 is connected to the motor 2 with a knife in the frame 1 through a belt connection, and the auxiliary cutter wheel 26 is connected with a hydraulic pump valve through a bearing. 25 of the carriage bearing block 24, the main cutter wheel 3 and the auxiliary cutter wheel 26 are provided with a belt cutter 32; the frame 1 between the main cutter wheel 3 and the auxiliary cutter wheel 26 is provided with a support 42, and the support 42 is provided with a screw rod 40, The screw rod 40 is connected to the grinding wheels 41, 42 through bearings, and the screw rod 40 is installed at a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com