Automated metal piece machining device

A processing device and a technology for metal parts, applied in the field of metal parts processing, can solve the problems of time-consuming and cutting efficiency reduction, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

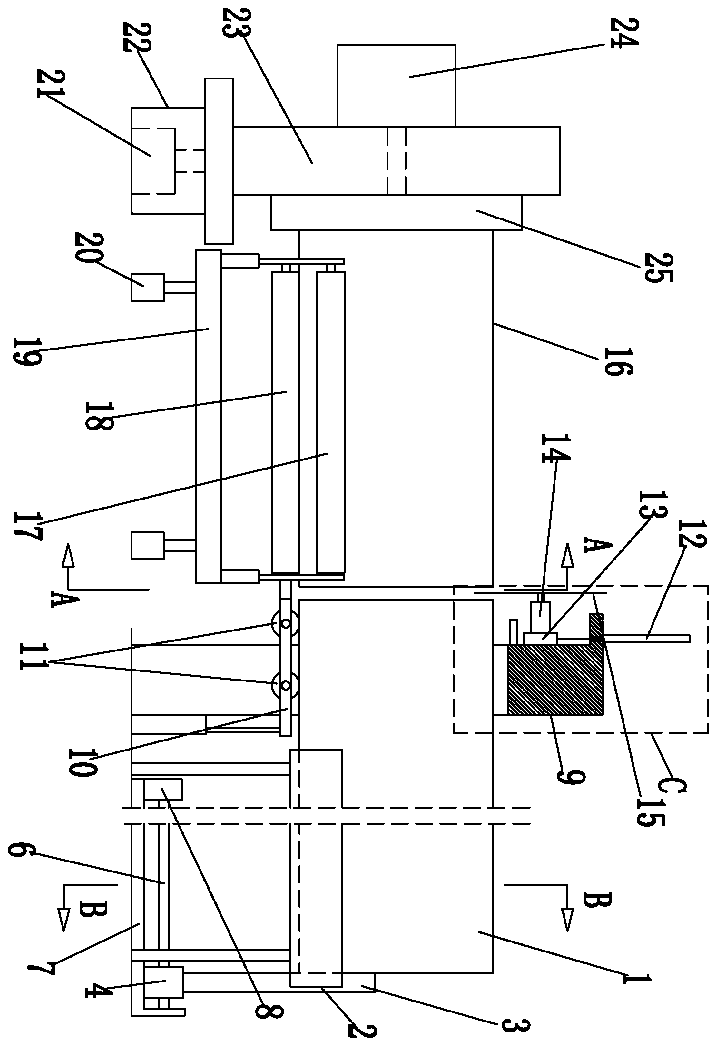

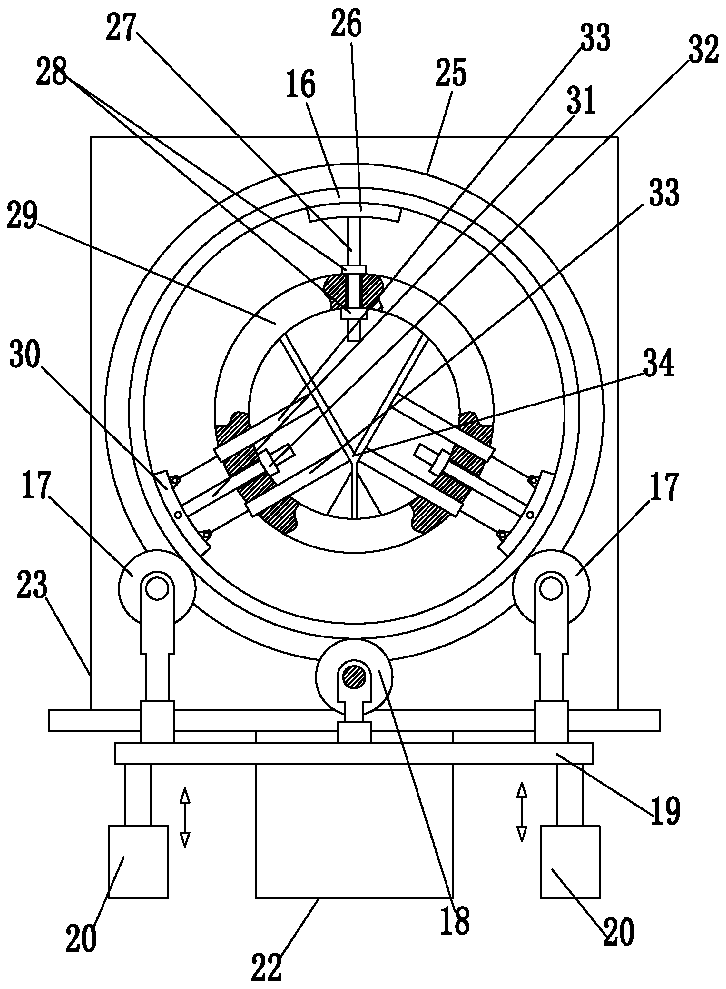

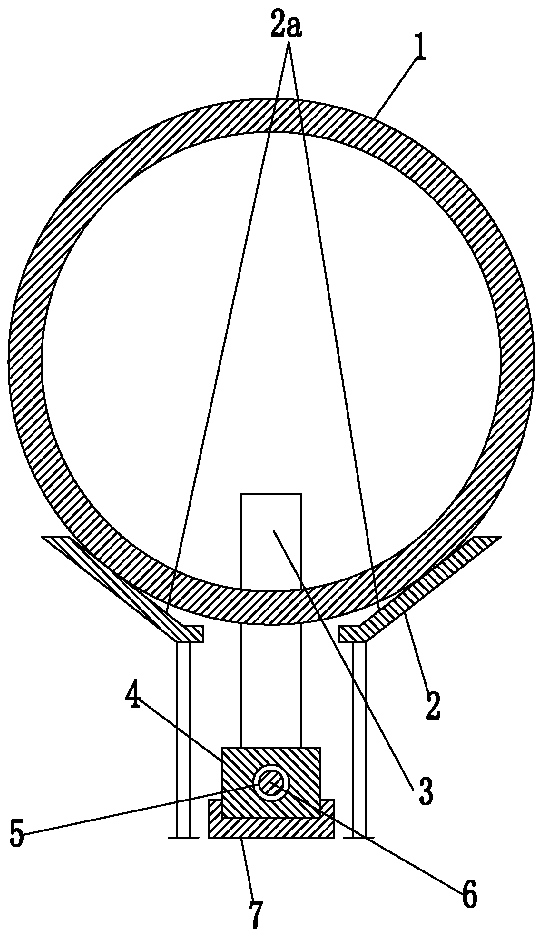

[0020] like Figure 1-6 As shown, an automatic metal parts processing device includes a conveying part for conveying the blank tube 1, a cutting part for cutting the blank tube 1, a transfer part for transferring the cut finished tube 16, and It includes a PLC controller 35, and the conveying parts, cutting parts, and transfer parts are arranged sequentially according to the conveying process, and the conveying parts include a pair of side brackets 2 that are spaced from each other and set opposite to each other, and whose extension direction is consistent with the conveying direction of the blank tube 1, The opposite sides of the two side brackets 2 are provided with inclined side bracket slopes 2a for supporting the outer peripheral wall of the blank tube 1, and the conveying part also includes a magnetic support for abutting against the non-cut side shaft end of the blank tube 1. The magnetic abutment bar 3 also includes a feed linear drive mechanism installed on the ground...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com