Self-temperature-adjusting faucet, control method of self-temperature-adjusting faucet and water supply system

A faucet and faucet technology, applied in sliding valves, valve details, multi-way valves, etc., can solve problems such as inaccurate temperature values

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

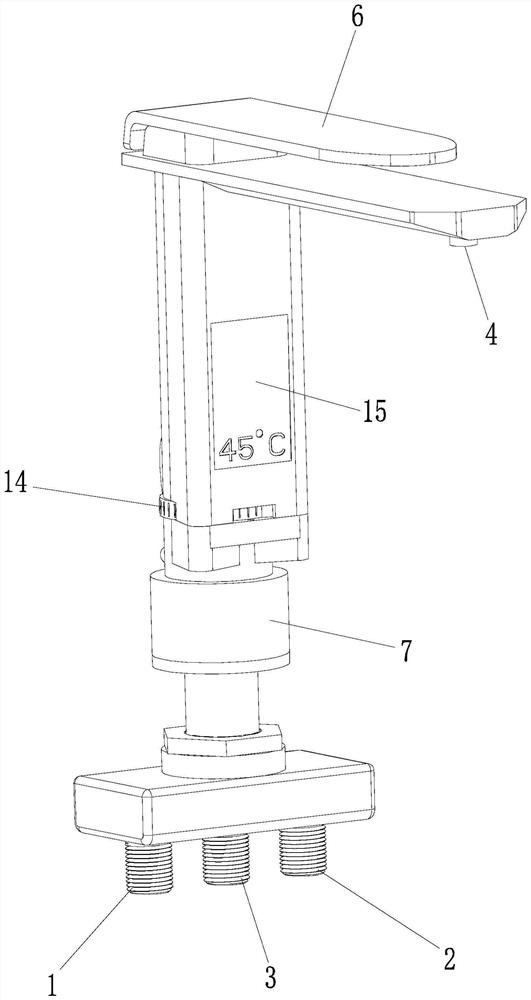

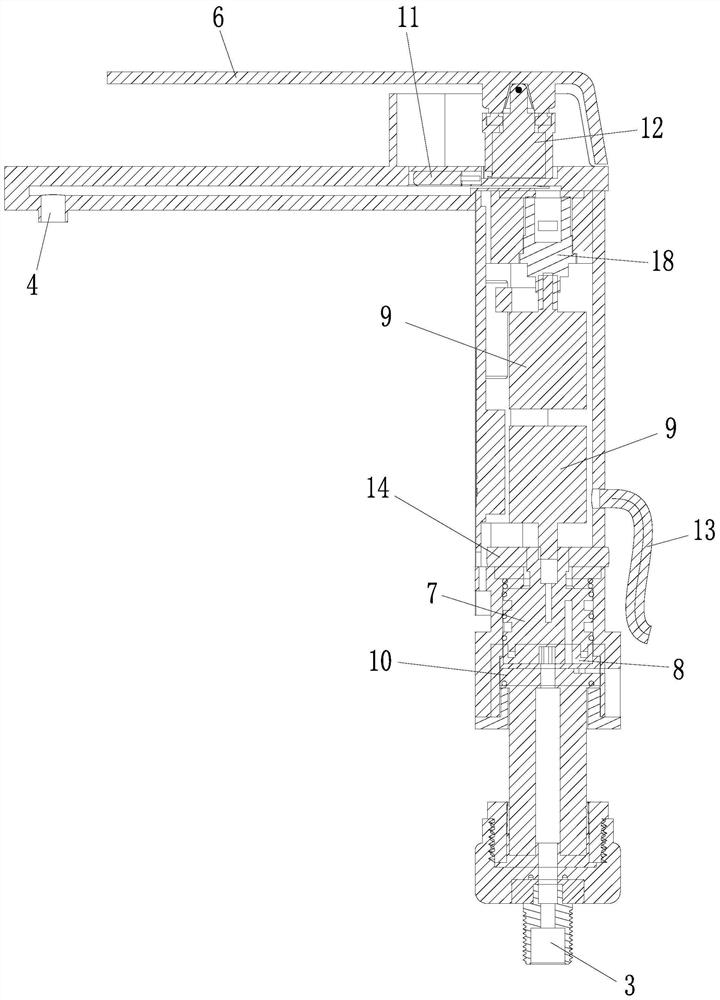

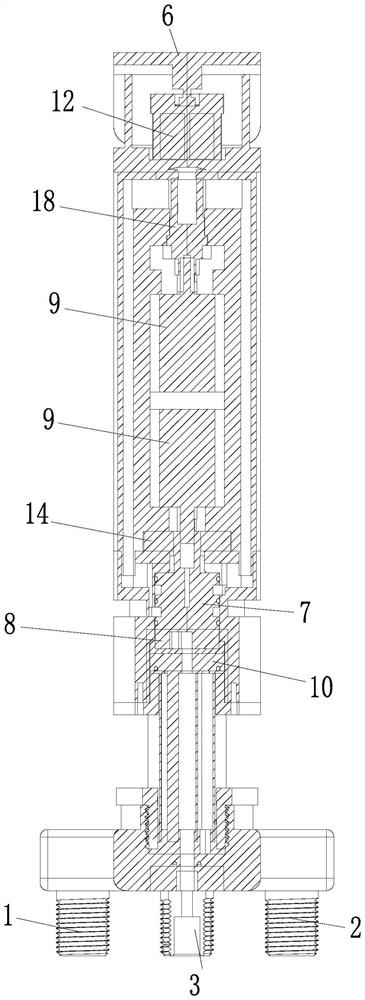

[0109] Example 1: faucet

[0110] Figure 1 to Figure 23 Another faucet is shown, which includes a faucet body of a traditional faucet. A water flow channel is provided in the faucet body. The water flow channel includes: a cold water flow channel for cold water, a hot water flow channel for hot water, and a cold water flow channel. The confluence waterway in which the water outlet of the flow channel and the water outlet of the hot water flow channel are connected. In actual application, the cold water in the cold water channel and the hot water in the hot water channel are combined in the confluence channel. The bottom of the faucet body is provided with a cold water connection 1 connected to the cold water flow channel and a hot water connection 2 connected with the hot water flow channel, and the cold water connection 1 is set at the water inlet end of the cold water flow channel, and the hot water connection 2 is set at the hot water flow water inlet end of the road. I...

Embodiment 2

[0160] In the above embodiment, if the first motor 9 driving the movable valve body 802 is self-locked after power off, rotating the handwheel 14 will not be able to rotate the movable valve body 802, and thus the faucet cannot be used after power off. For this reason, Figure 24 to Figure 27 It shows the second specific embodiment of the faucet of the present application. The faucet of this embodiment has basically the same structure as that of Embodiment 1, the main difference is that: this embodiment is provided with a Clutch 24.

[0161] Above-mentioned clutch 24 has adopted the manual clutch that can artificially adjust " off and on " state. During normal operation, the user adjusts the clutch 24 to a tight state, and the motor 9 can drive the valve body 802 to rotate. After the power is cut off, the clutch 24 is adjusted to a disengaged state. Even if the motor 9 is self-locking, the user can rotate the hand wheel 14 to drive the valve body 802 to rotate.

[0162]Obvi...

Embodiment 3

[0165] Example 3: faucet

[0166] Figure 28 to Figure 39 It shows the third specific embodiment of the faucet of the present application. Different from the above four embodiments, this embodiment uses another method to solve the problem of using the faucet when the power is off. It is not equipped with a rotating handwheel and a clutch. Instead, it is configured: across the movable valve body 802, to communicate with the upstream cold water channel of the movable valve body 802 and the downstream water flow channel of the movable valve body (the downstream water flow channel can be the cold water flow channel or the converging water channel downstream of the movable valve body) The cold water bypass bypasses the movable valve body 802 to communicate with the upstream hot water channel of the movable valve body 802 and the downstream water flow channel of the movable valve body (the downstream water flow channel may be a hot water flow channel or a confluence channel downstre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com