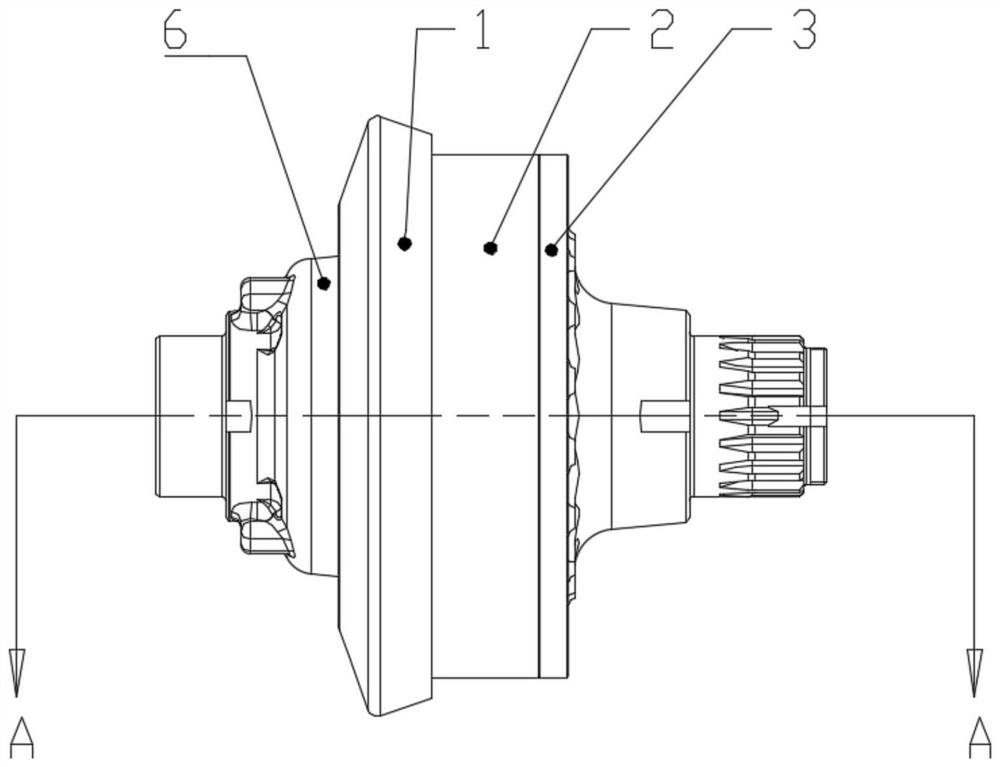

Low-cost inter-wheel differential structure

An inter-wheel differential, a low-cost technology, applied in the direction of differential transmission, belt/chain/gear, mechanical equipment, etc., can solve the problem of uncoordinated ratio of driven bevel gear long diameter direction, low material utilization rate, gear Problems such as poor rigidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

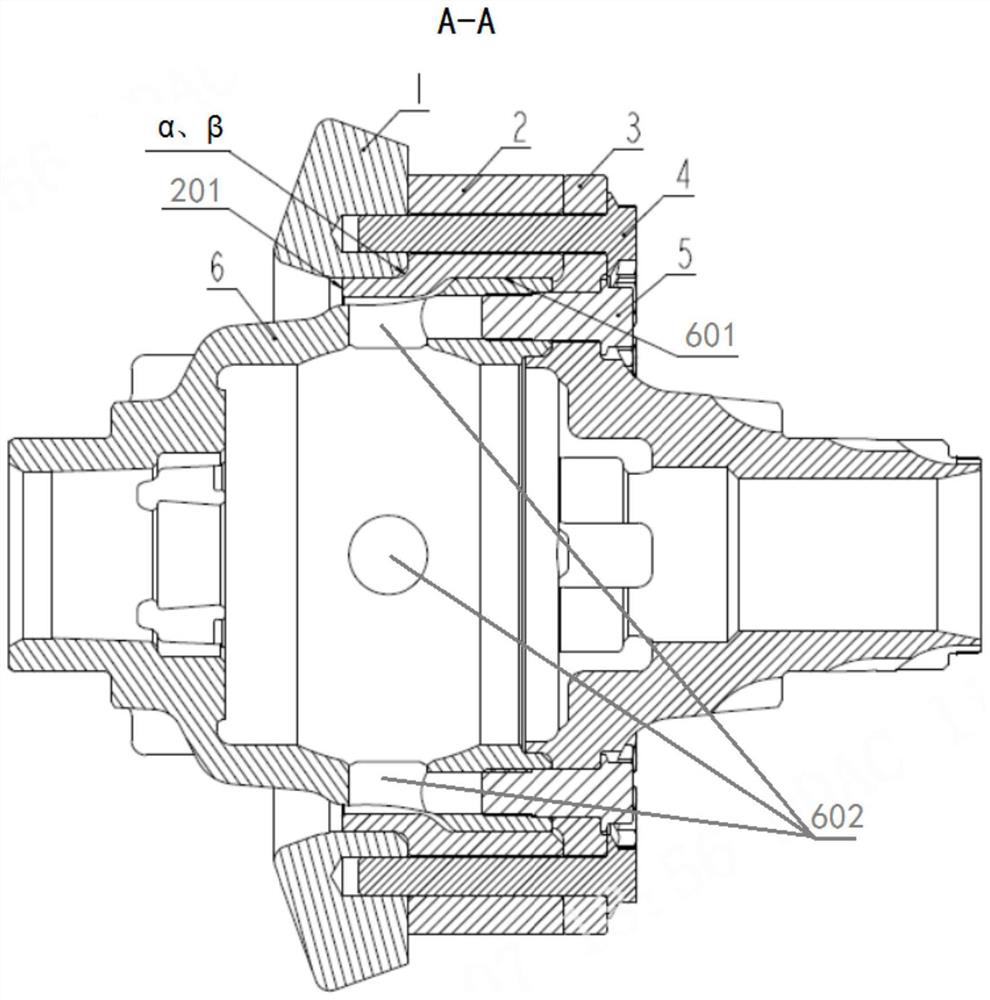

[0033] The principles and features of the present invention are described below in conjunction with the accompanying drawings, and the examples given are only used to explain the present invention, and are not intended to limit the scope of the present invention.

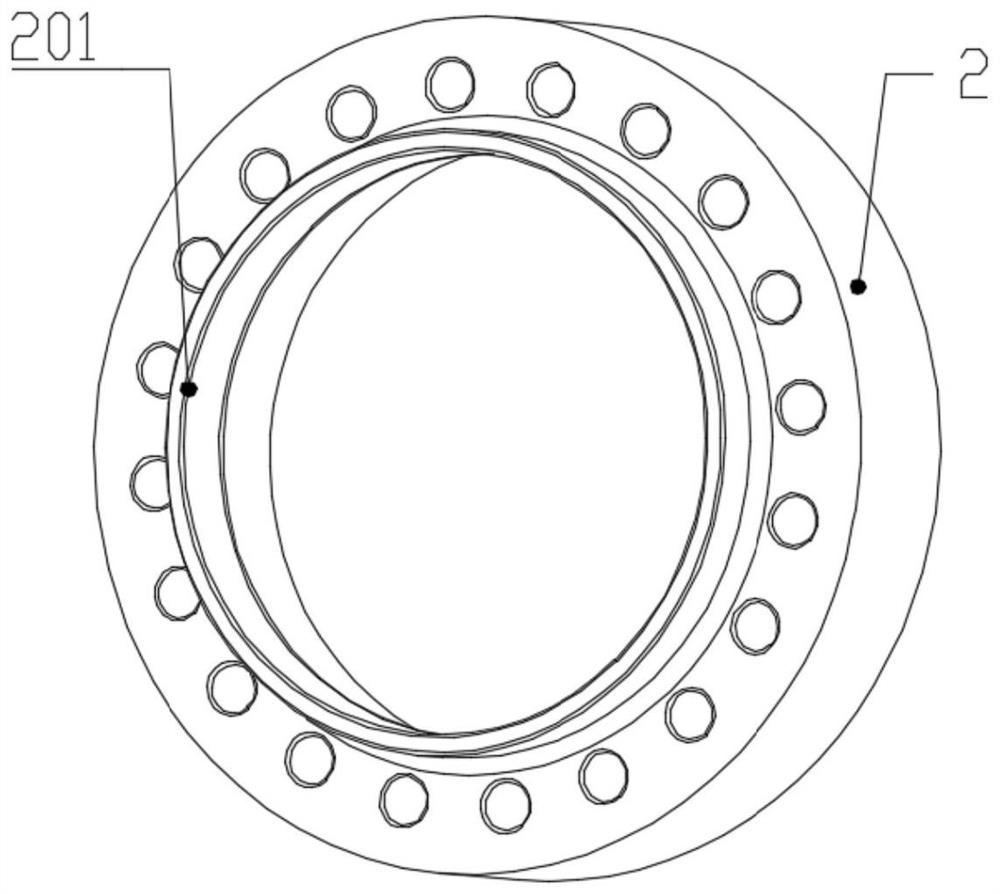

[0034] Such as Figure 4 Shown is the composition structure of the conventional inter-wheel differential mentioned in the background art. It includes driven bevel gear 1, left differential case 3, driven bevel gear connecting bolt 4, right differential case 6, left and right differential case connecting bolt 5, side gear, planetary gear 8, cross shaft 7. The left differential case 3 and the right differential case 6 are connected with the connecting bolts 5 of the left and right differential cases through radial spigot fit, forming the overall installation framework of the differential. The driven bevel gear 1 is matched with the right differential case 6 through a radial spigot, and the installation end face of th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com