An omnidirectional wheel and an omnidirectional mobile platform using the omnidirectional wheel

An omnidirectional wheel and hub technology, applied in the direction of wheels, transportation and packaging, vehicle parts, etc., can solve the problems of poor strength, inability to use high-speed moving occasions, easy to fail, etc., to eliminate stress concentration, solve poor strength, and improve strength. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

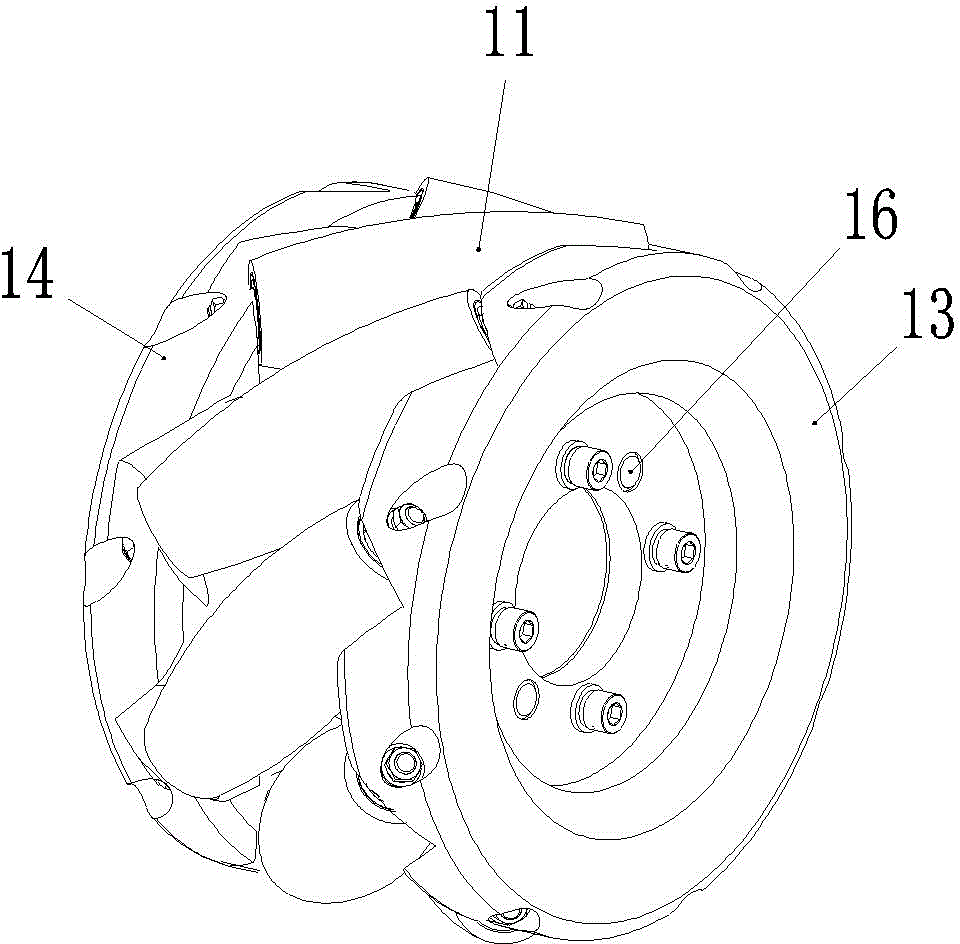

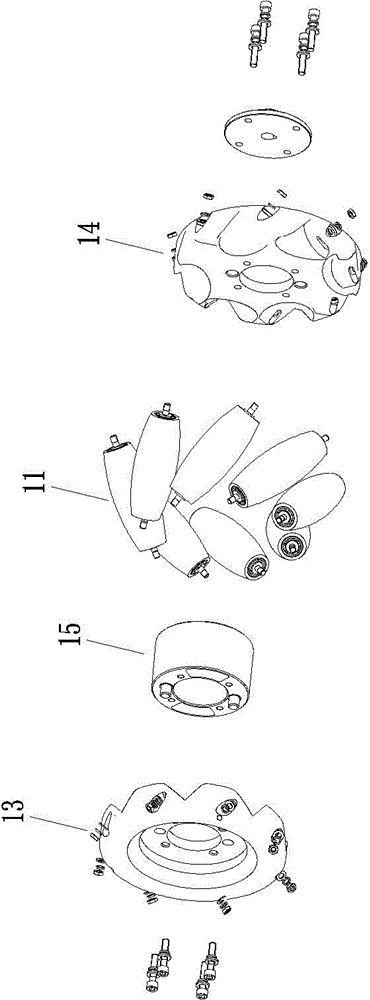

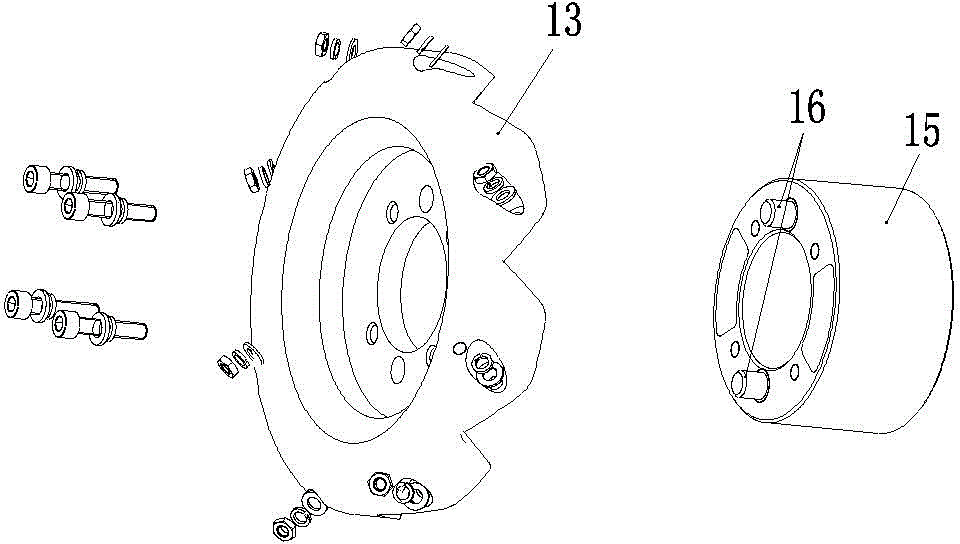

[0028] Embodiment 1 of the omnidirectional wheel of the present invention, as Figure 1-6As shown, it includes a hub and an integral roller 11, the roller 11 is assembled on the hub through the corresponding roller shaft 12, the roller 11 and the corresponding roller shaft 12 are assembled together through bearings and both ends of the roller shaft 12 protrude At both ends of the corresponding roller, the part protruding from the roller is provided with an external thread. In addition, the axis of the roller shaft 12 and the axis of the hub are at an angle of 45°. The hub includes a left supporting turntable 13, The right support turntable 14 and the axle sleeve 15 connected between the left and right support turntables, the axle sleeve 15 fixes the left and right support turntables together on the one hand, and plays the role of connecting with the corresponding wheel axle on the other hand. In the example, the left and right supporting turntables are all detachably connected...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com