Drying agent for mine underground electric apparatus and preparation method thereof

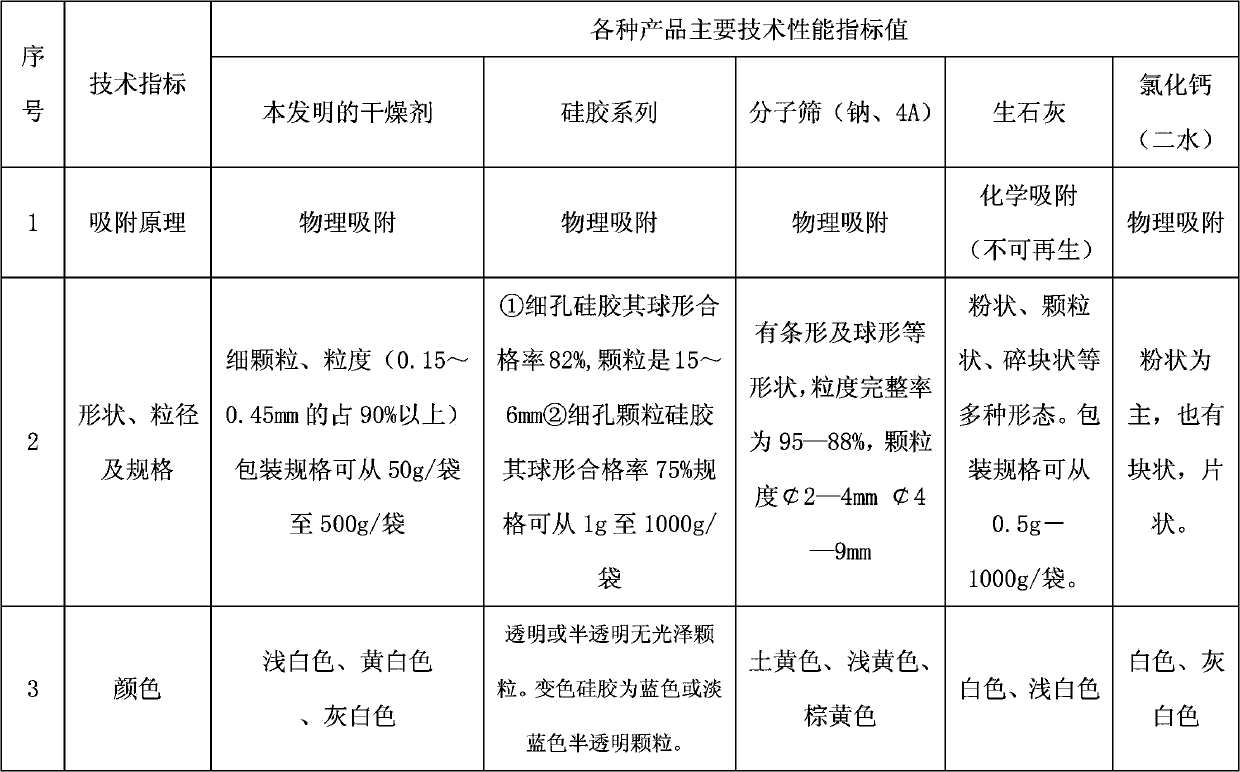

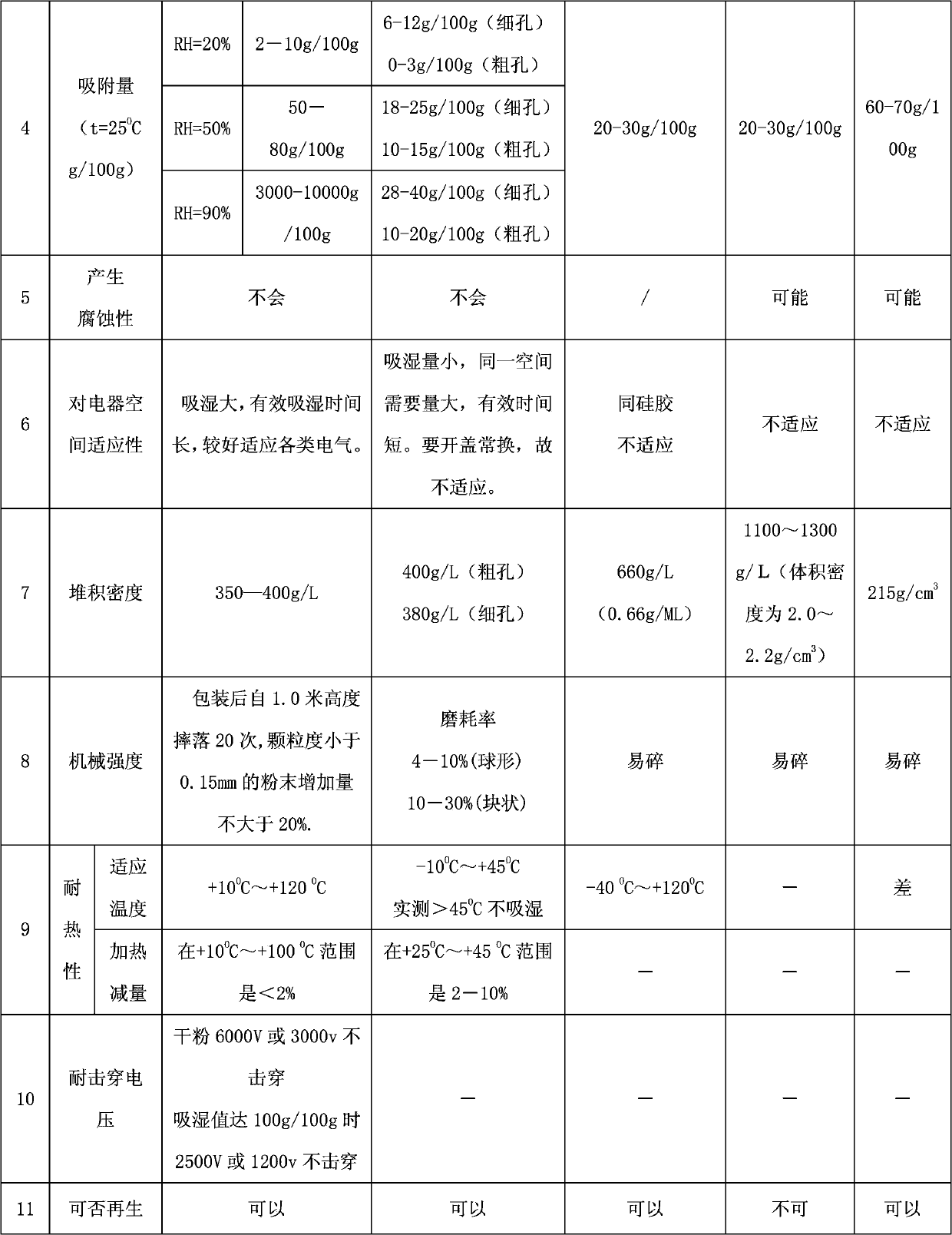

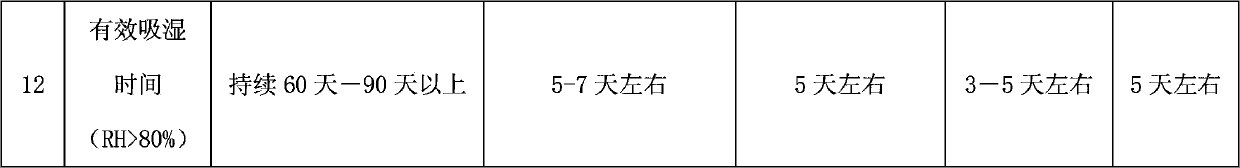

A technology of electrical equipment and desiccant, applied in the field of dehumidification desiccant and moisture absorption, can solve the problems of high use cost, high comprehensive cost, and many maintenance labor.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0080] Embodiment 1, the specific method and situation of using the desiccant of the present invention in a certain coal mine.

[0081] 1) The formula of the desiccant of the present invention is 35 parts of polyacrylate + 15 parts of modified PVA, the particle size of which is 0.2-0.4 mm + silicon (sio 2 ) powder 40 parts, the particle size is 0.3 ~ 0.45mm + 10 parts Nacl for industrial use, the particle size is 0.15 ~ 0.3mm. The colors are all white or off-white.

[0082] 2) The packaging material is non-conductive non-woven fabric. See Table 4 for the packaging size, weight per package, and usage amount.

[0083]3) Placement requirements: Keep a distance of more than 50mm between the desiccant and the charged part of 6KV, and keep a distance of more than 20mm between the charged part of 1140V and below.

[0084] 4) The mine stipulates that the switch and other equipment and desiccant should be inspected once every two months (60 days). If it is found that the weight of t...

Embodiment 2

[0095] Embodiment 2: the concrete method that certain coal mine uses desiccant of the present invention is as follows:

[0096] 1) The desiccant formula of the present invention is 32 parts of polyacrylate + 16 parts of polyacrylamide (both particle sizes are 0.2-0.4 mm) + 40 parts of silica gel waste powder (particle size is 0.25-0.45 mm) + dihydrate chlorine Calcium (cacl 2 .2H 2 O) 7 parts + industrial salt sodium chloride (Nacl) 5 parts (all particle sizes are 0.15 ~ 0.30mm). The color is all white or off-white.

[0097] 2) The packaging material is non-conductive non-woven fabric, and the weight of each package is 50g, 100g, and 200g respectively.

[0098] 3) The specific placement equipment and location are as follows:

[0099] 1. High-voltage explosion-proof switch (PGB53-6): put 2 packs of 200 grams in the switch cavity, and place it in a safe position at the lower part of the switch cavity;

[0100] 2. Mobile transformers (KBSGZY-630, KBSGZY-1600, etc.): put 2 pa...

Embodiment 3

[0108] Embodiment 3, a certain iron mine in my country tried the desiccant of the present invention in April 2010.

[0109] 1) The desiccant formula of the present invention is 35 parts of polyacrylate + 15 parts of modified PVA (both particle sizes are 0.2-0.4 mm); + silicon (sio 2 ) powder 40 parts (particle size 0.3 ~ 0.45mm) + industrial sodium chloride Nacl 10 parts (particle size 0.15 ~ 0.30mm). The color is white or off-white.

[0110] 2) The packaging material is non-conductive non-woven fabric. The packing weight is 50g / pack and 100g / pack.

[0111] 3) The specific placement equipment and location are as follows

[0112] On April 17, the desiccant of the present invention was placed in the power distribution cabinets of three LGY-20 / 8 screw air compressors in the mine, and the dosage was 200 grams per 50 grams x 4 packs, and no other moisture-proof measures were taken. During this period, the weather was rainy and the underground was very humid. After more than a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com