Patents

Literature

50results about How to "Reduced Possibility of Displacement" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

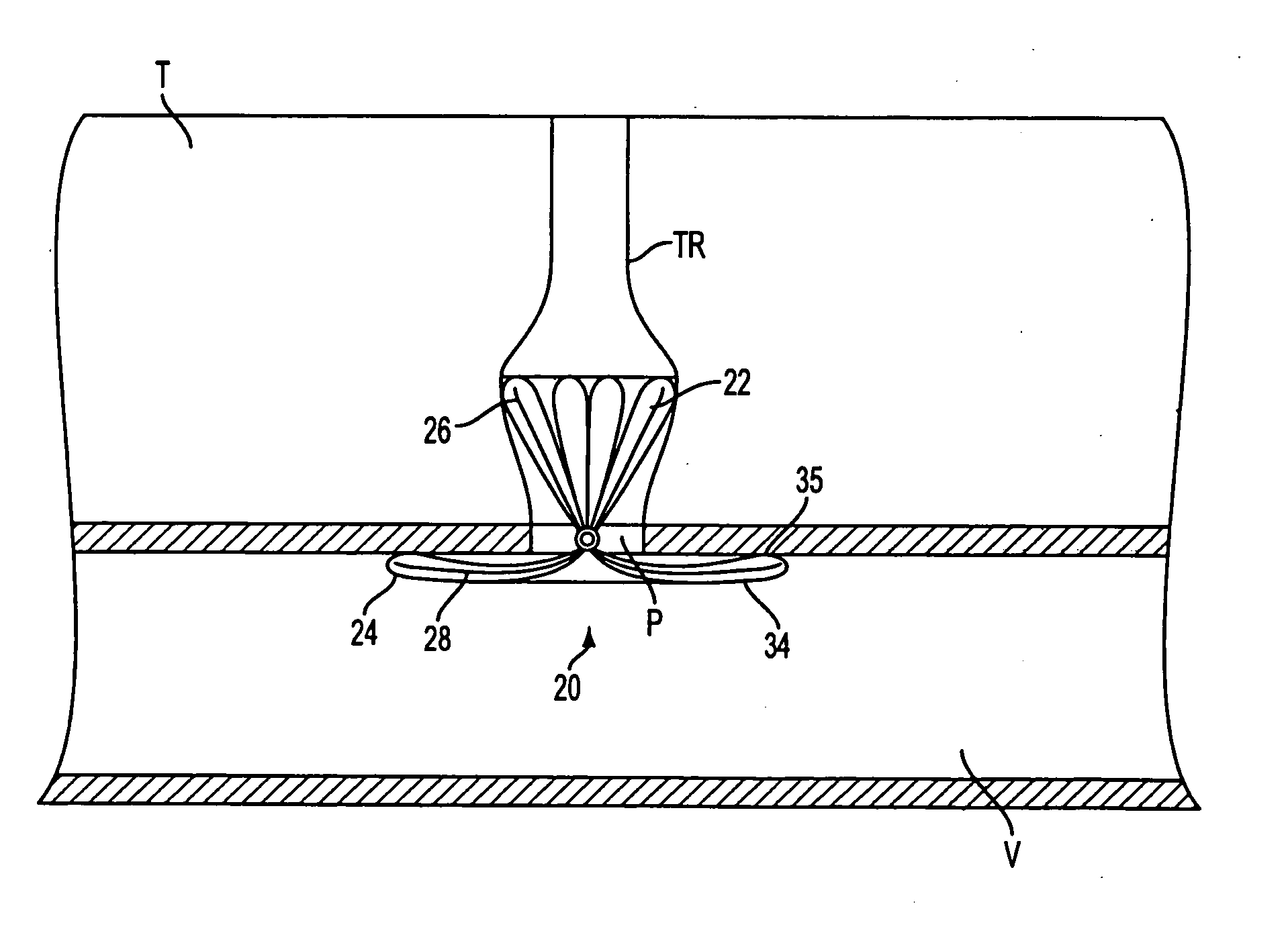

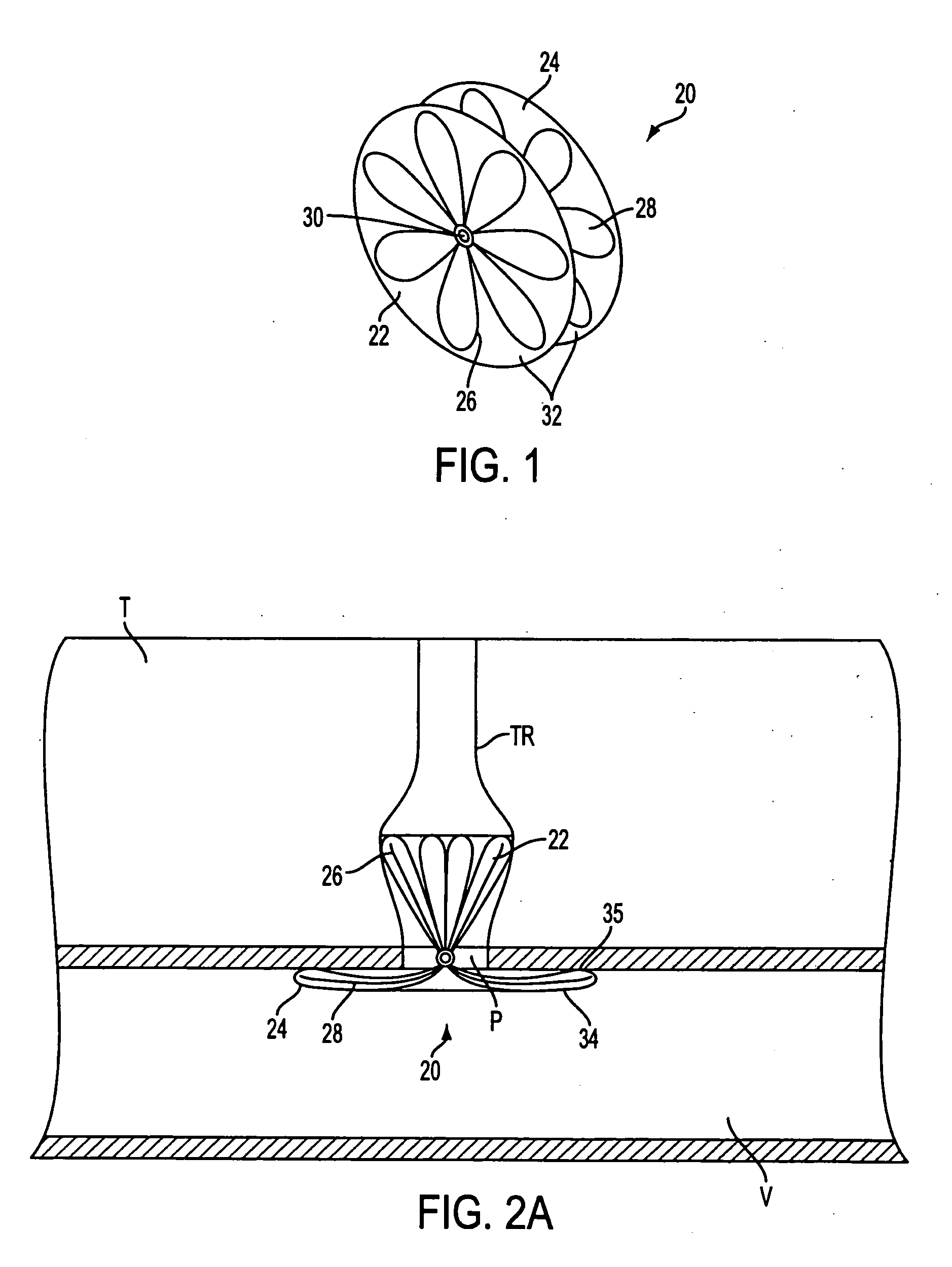

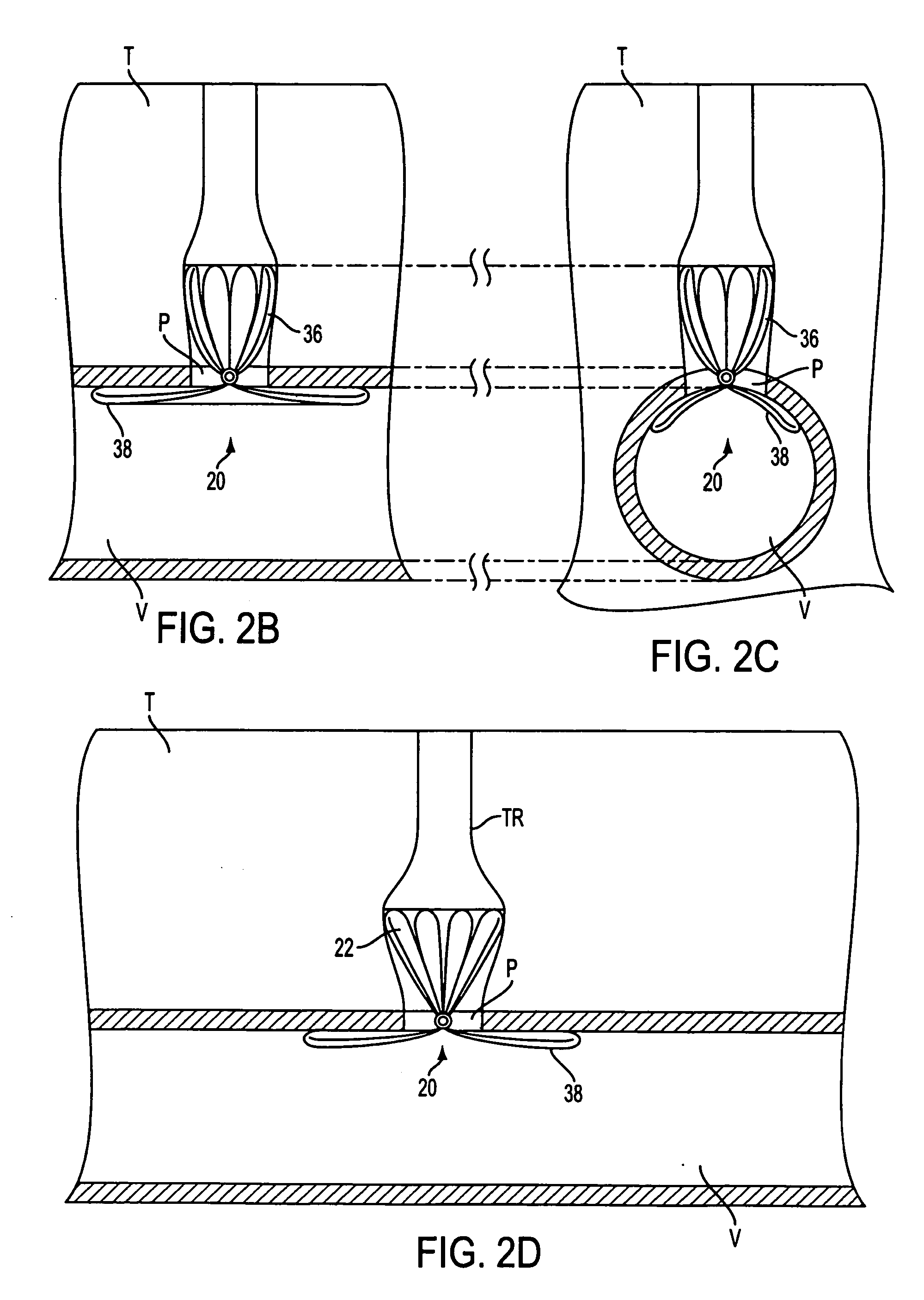

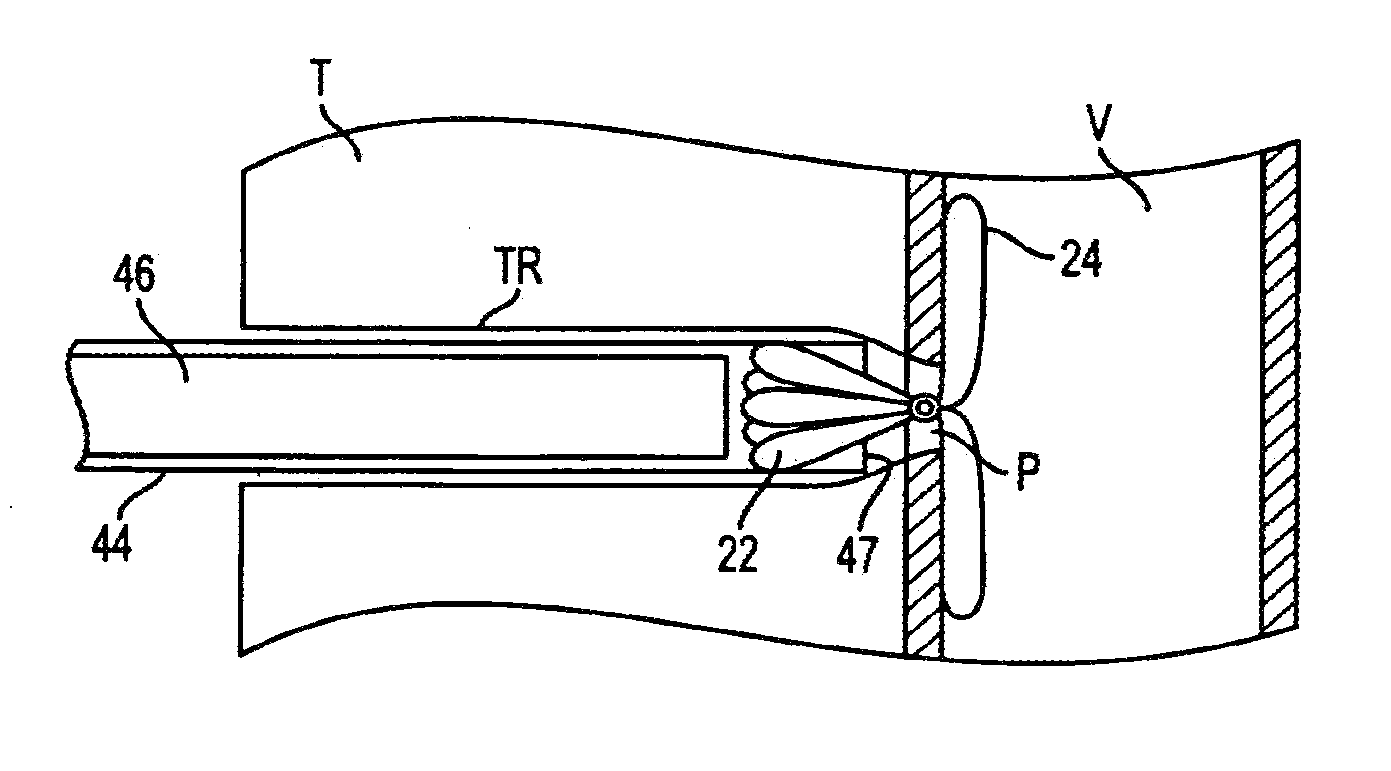

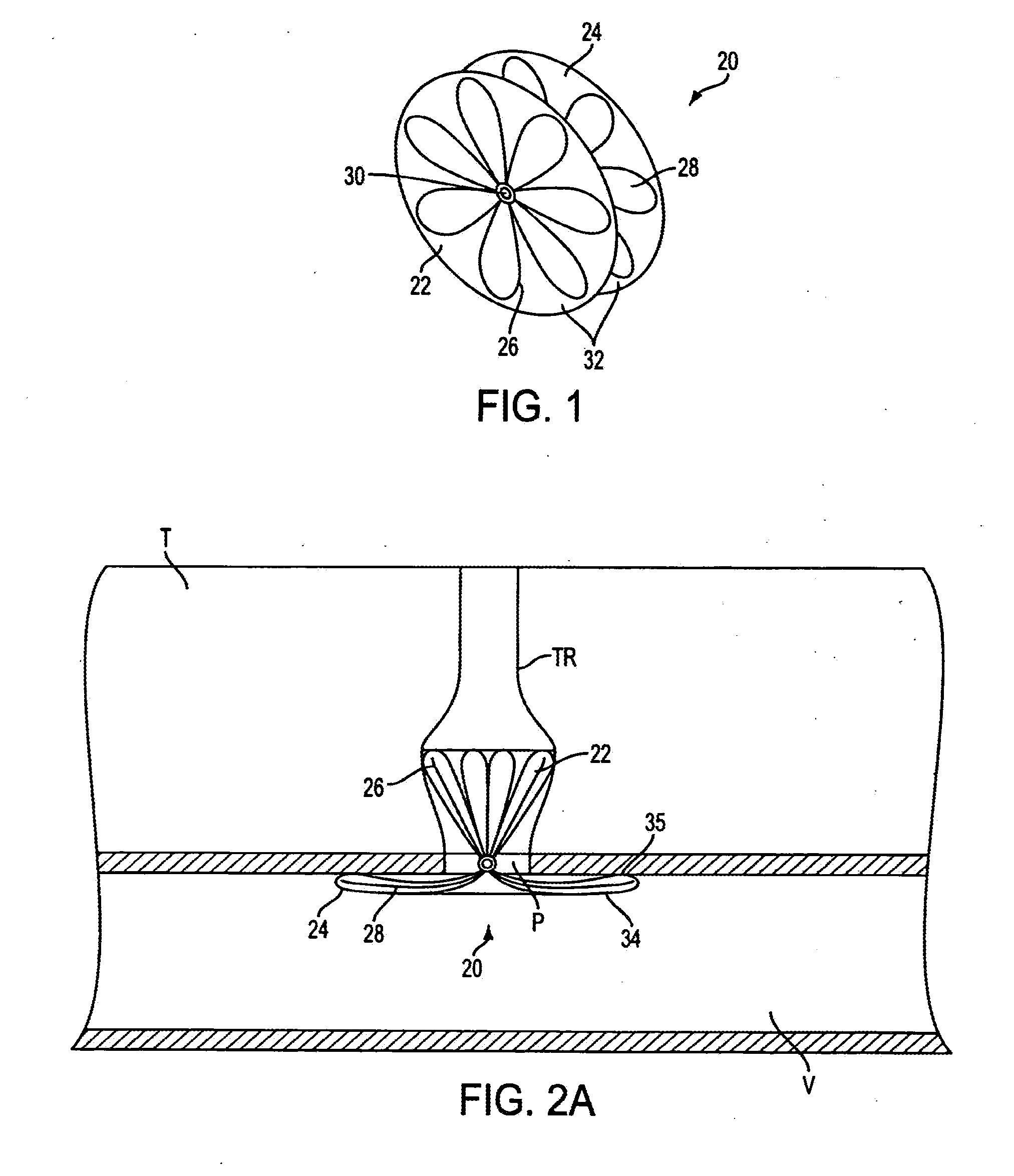

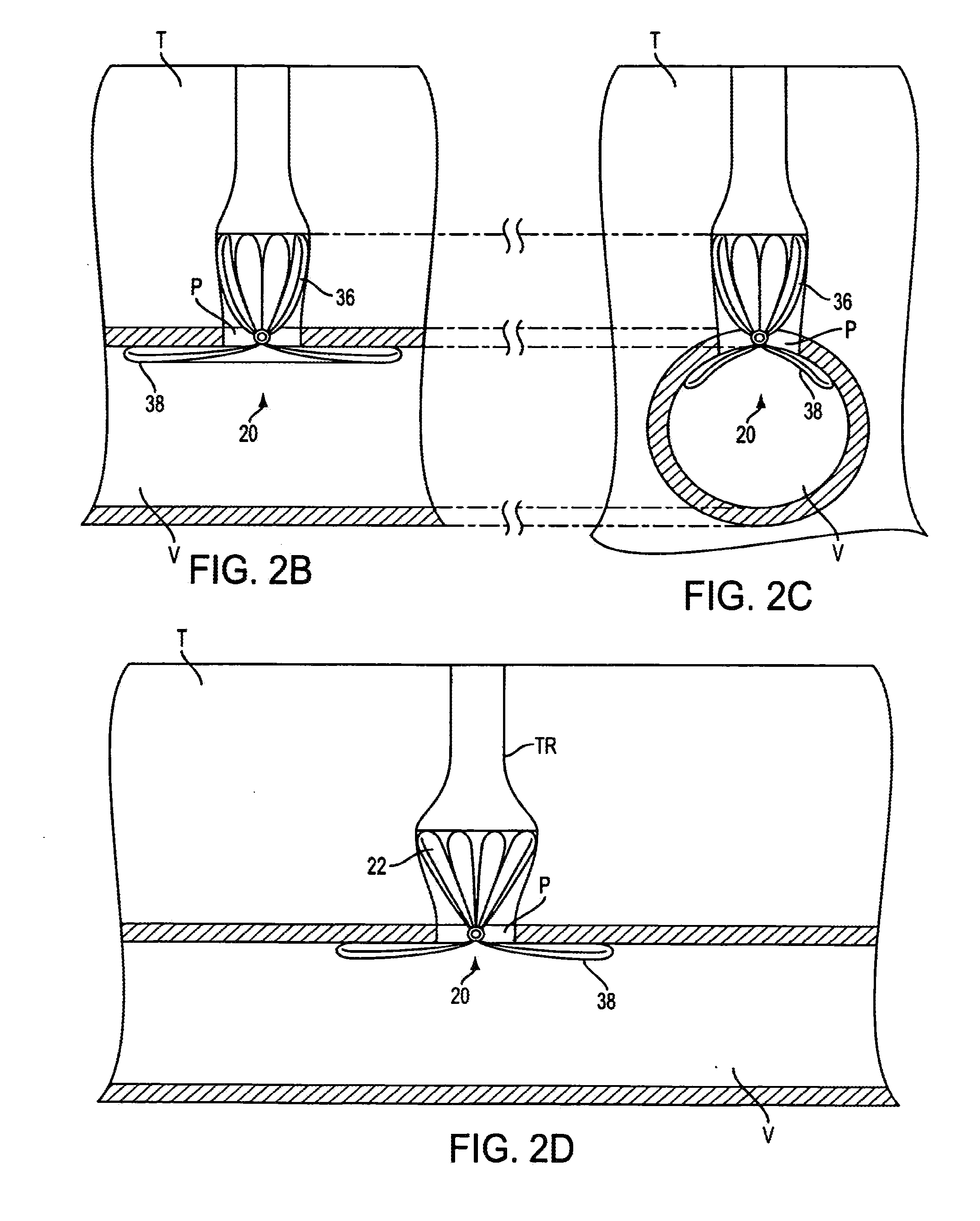

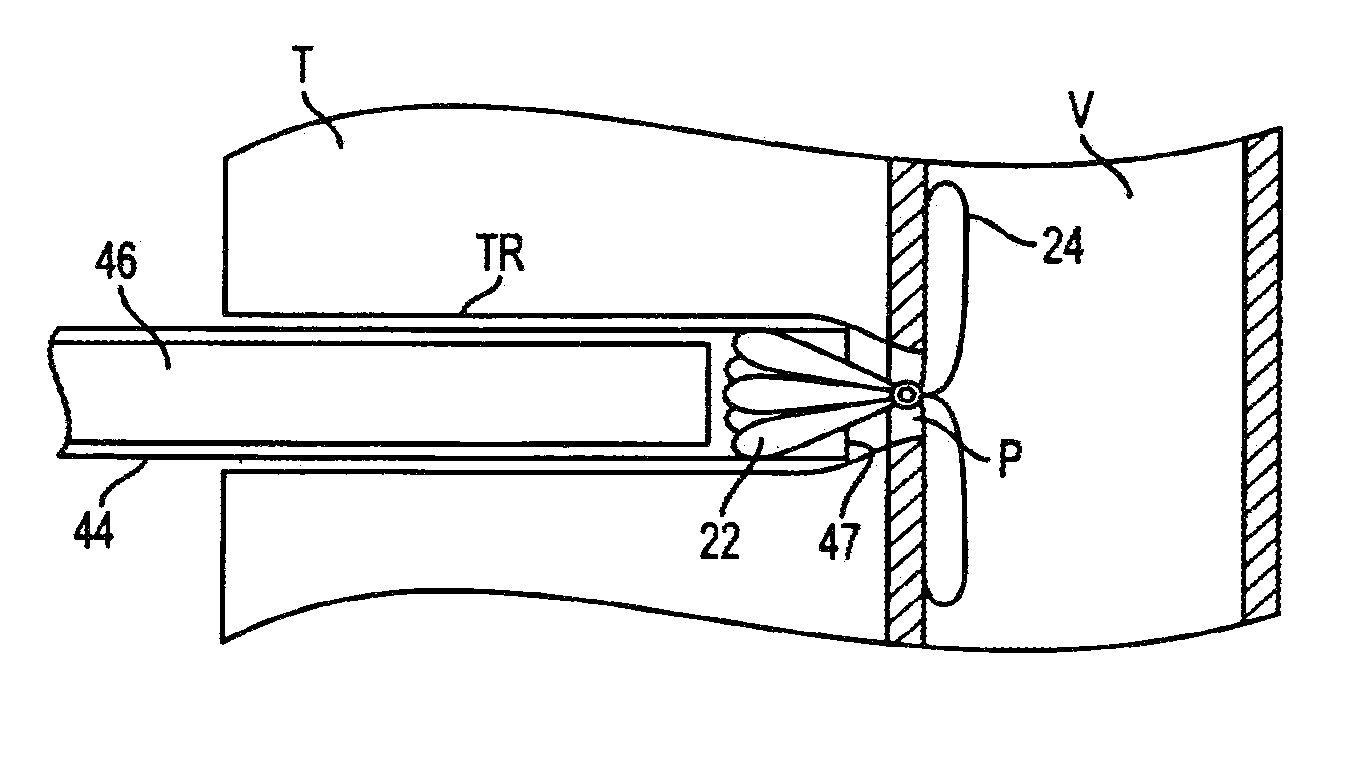

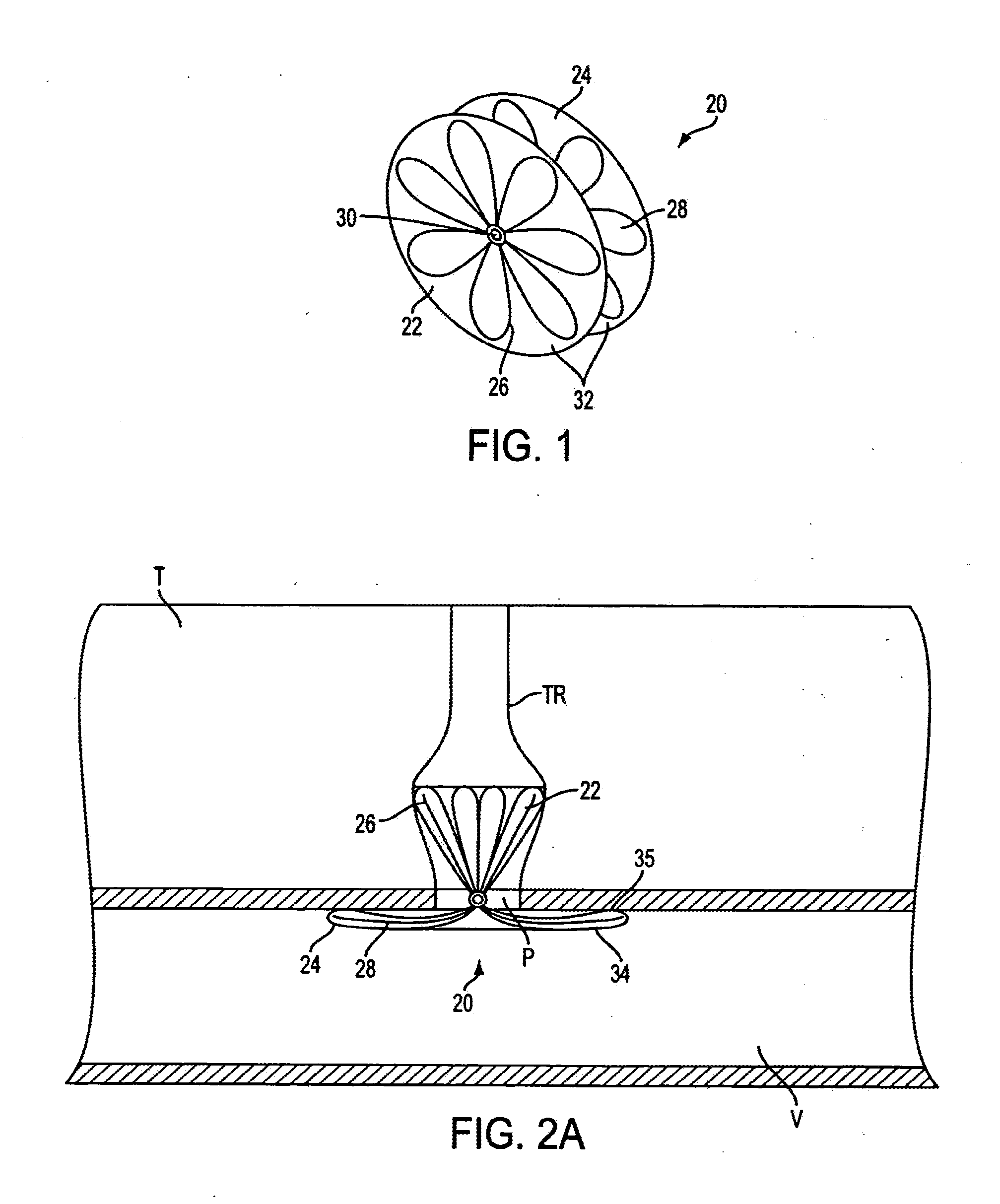

Apparatus for sealing surgical punctures

ActiveUS20060106418A1Low profileReduced Possibility of DisplacementStaplesNailsBlood vesselSurgical puncture

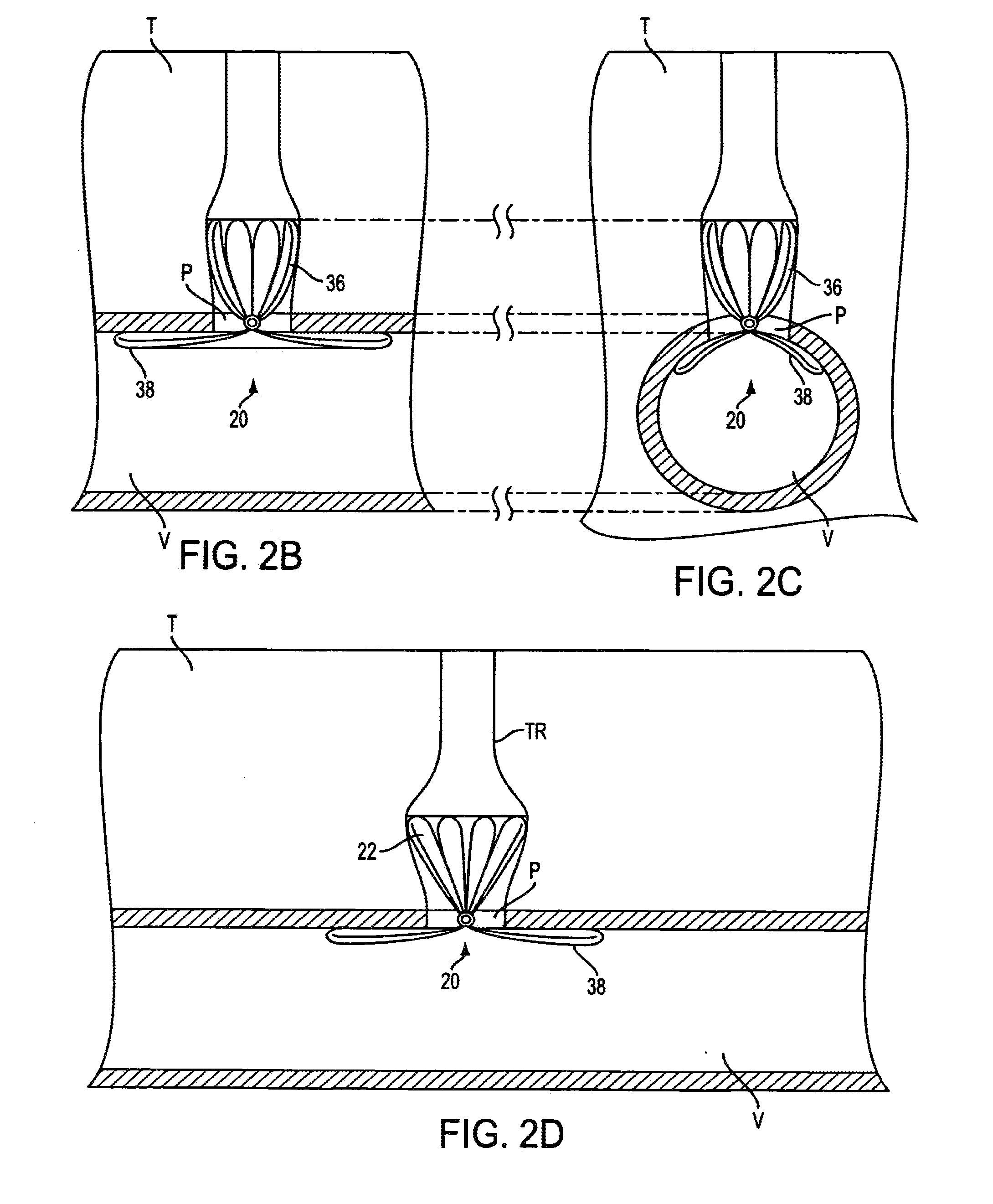

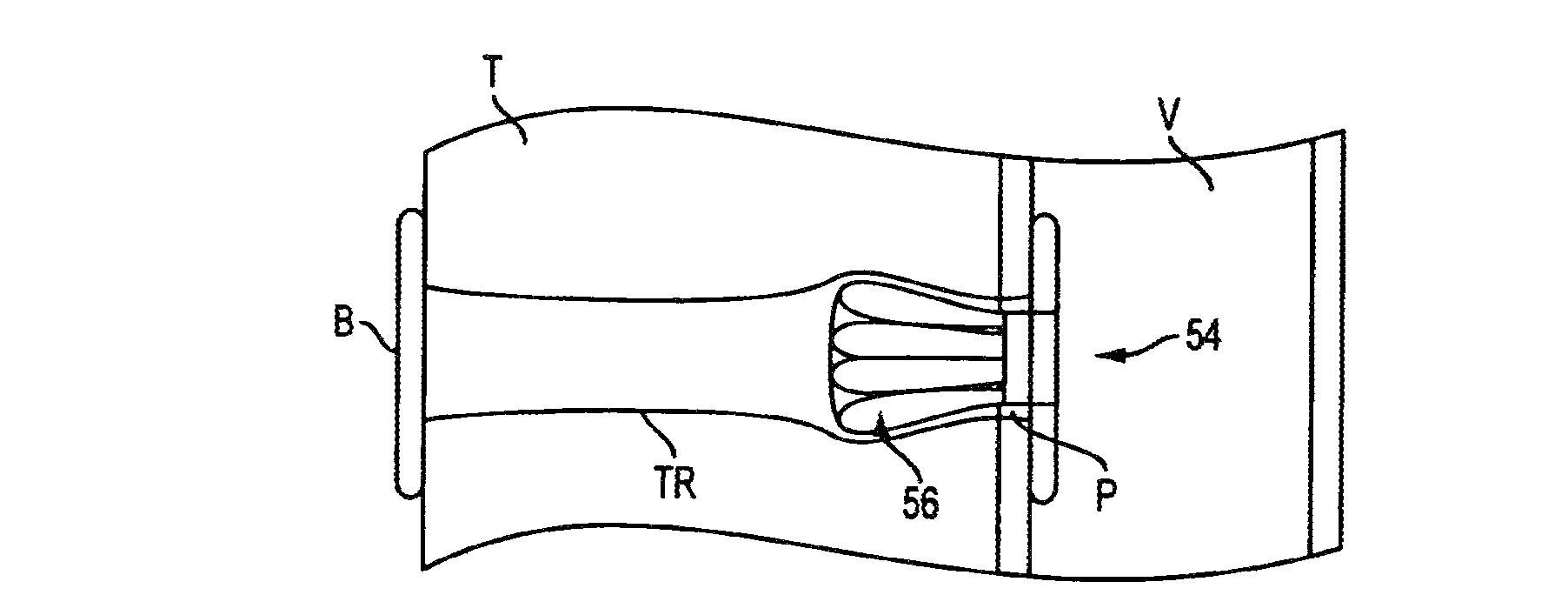

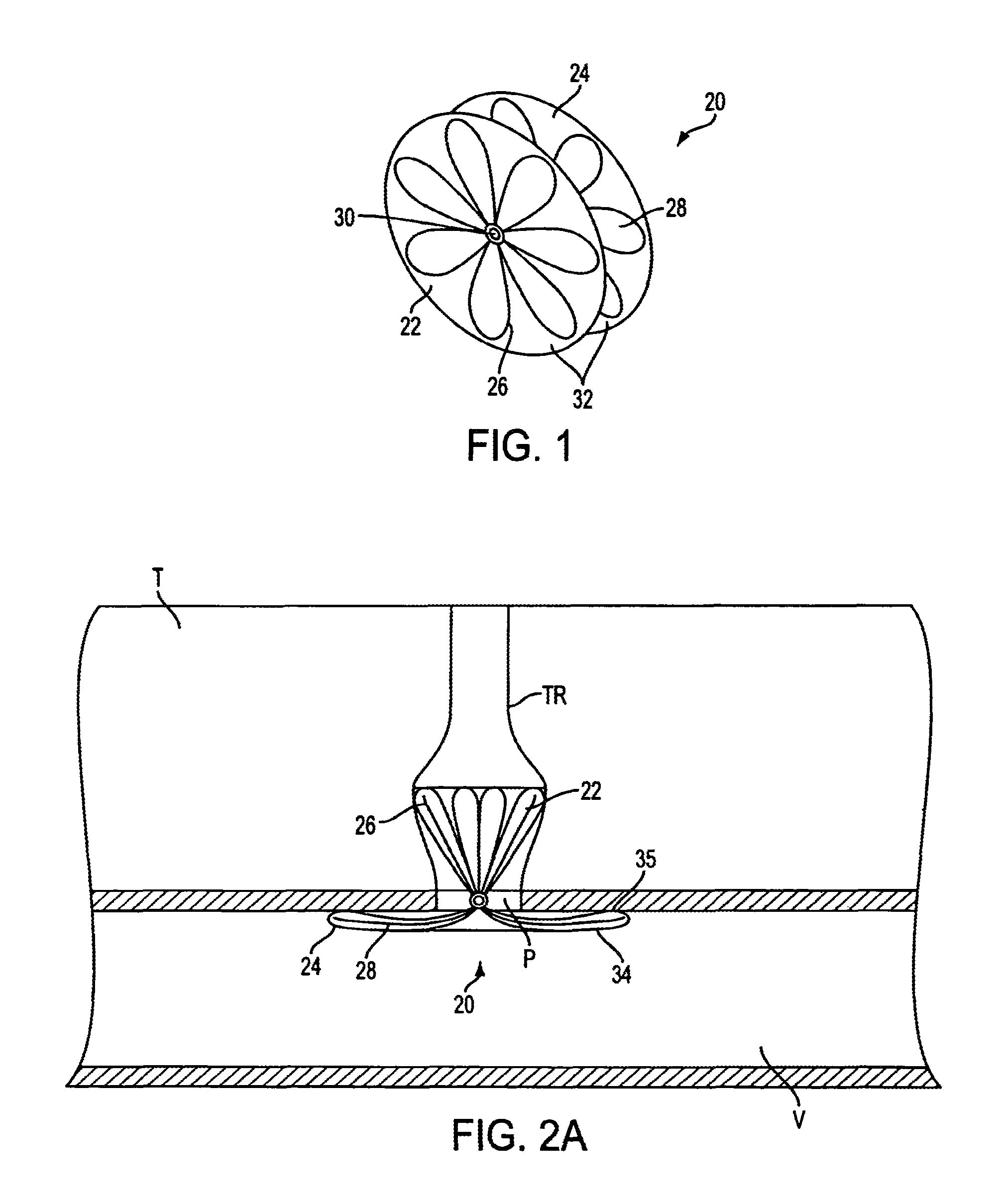

Apparatus is provided for sealing a puncture within a vessel or tissue to provide hemostasis, comprising a first disk coupled to either a second disk or a spring, and sealingly engaged to the vessel or tissue surrounding the puncture. At least the first disk is preferably configured to substantially conform to the profile of the vessel or tissue when deployed. In one embodiment, the disks may be released from engagement with the vessel or tissue to reposition the disks after deployment.

Owner:ABBOTT LAB VASCULAR ENTERPRISE

Apparatus for sealing surgical punctures

Apparatus is provided for sealing a puncture within a vessel or tissue to provide hemostasis, comprising a first disk coupled to either a second disk or a spring, and sealingly engaged to the vessel or tissue surrounding the puncture. At least the first disk is preferably configured to substantially conform to the profile of the vessel or tissue when deployed. In one embodiment, the disks may be released from engagement with the vessel or tissue to reposition the disks after deployment.

Owner:ABBOTT LAB VASCULAR ENTERPRISE

Apparatus for sealing surgical punctures

Apparatus is provided for sealing a puncture within a vessel or tissue to provide hemostasis, comprising a first disk coupled to either a second disk or a spring, and sealingly engaged to the vessel or tissue surrounding the puncture. At least the first disk is preferably configured to substantially conform to the profile of the vessel or tissue when deployed. In one embodiment, the disks may be released from engagement with the vessel or tissue to reposition the disks after deployment.

Owner:ABBOTT LAB VASCULAR ENTERPRISE

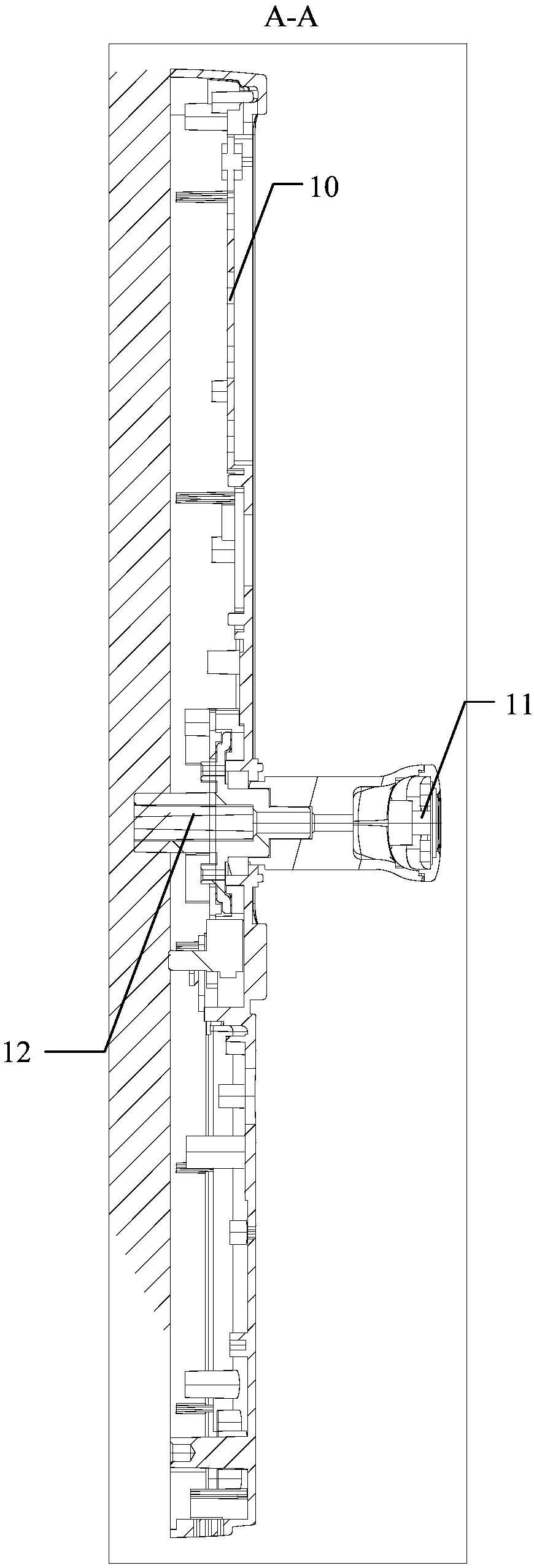

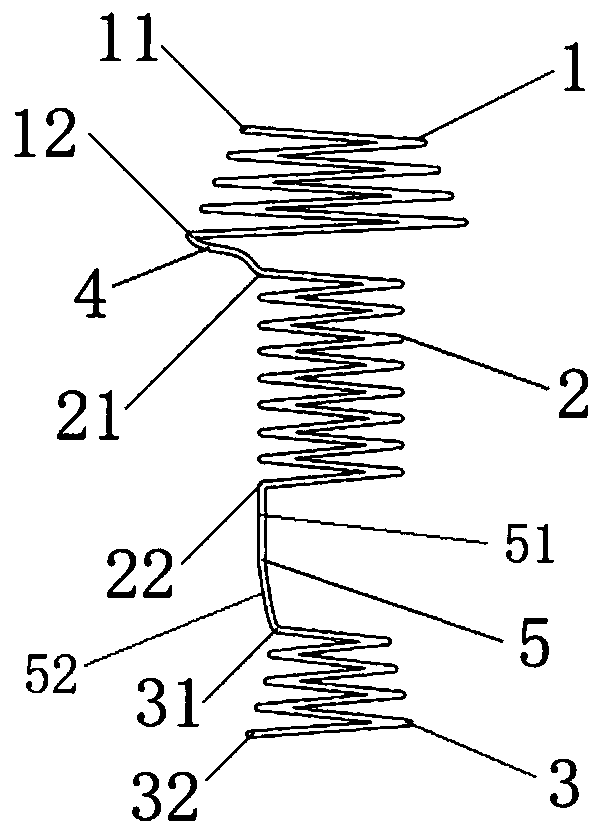

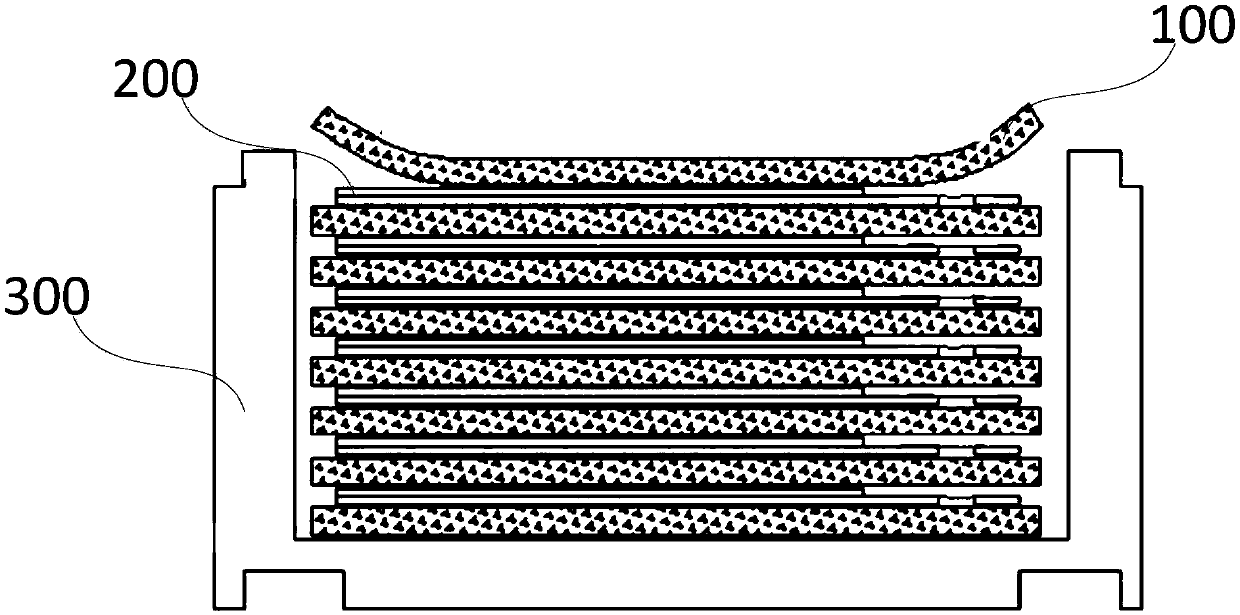

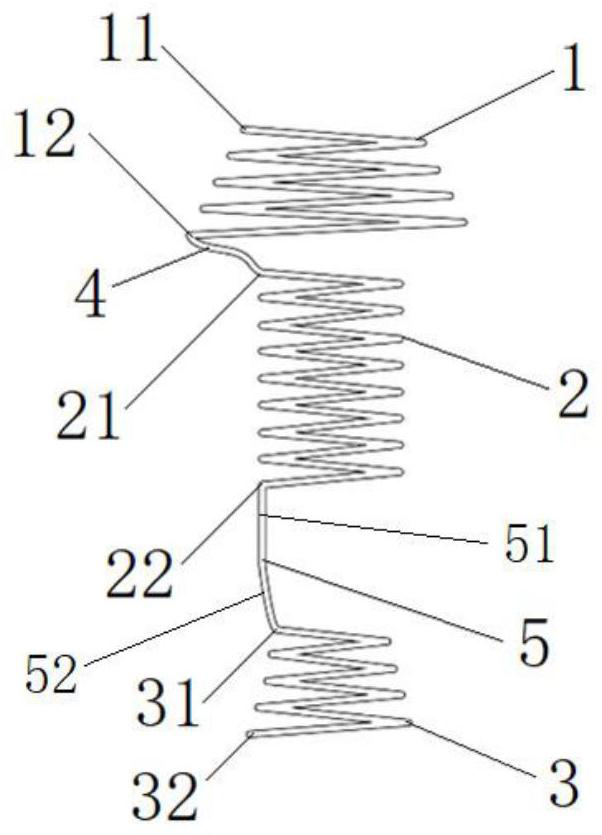

Combined membrane-covered stent capable of being bent in any direction

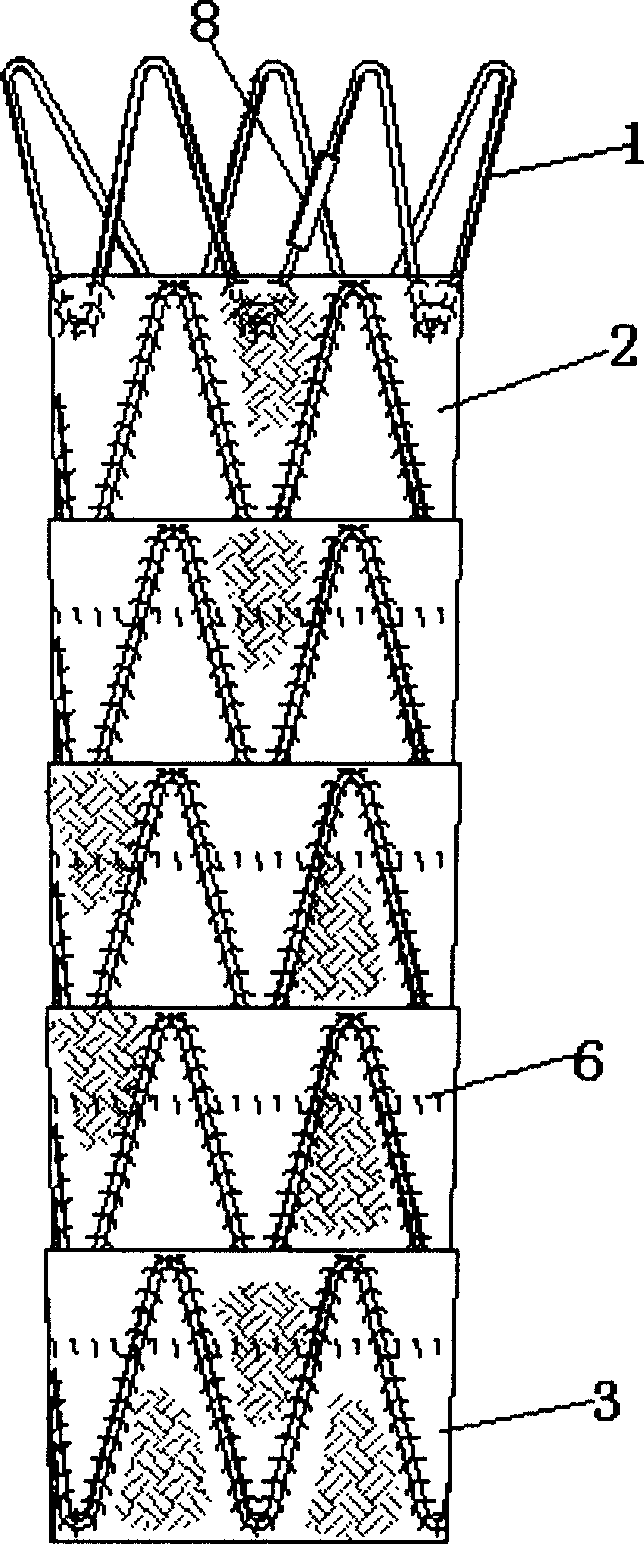

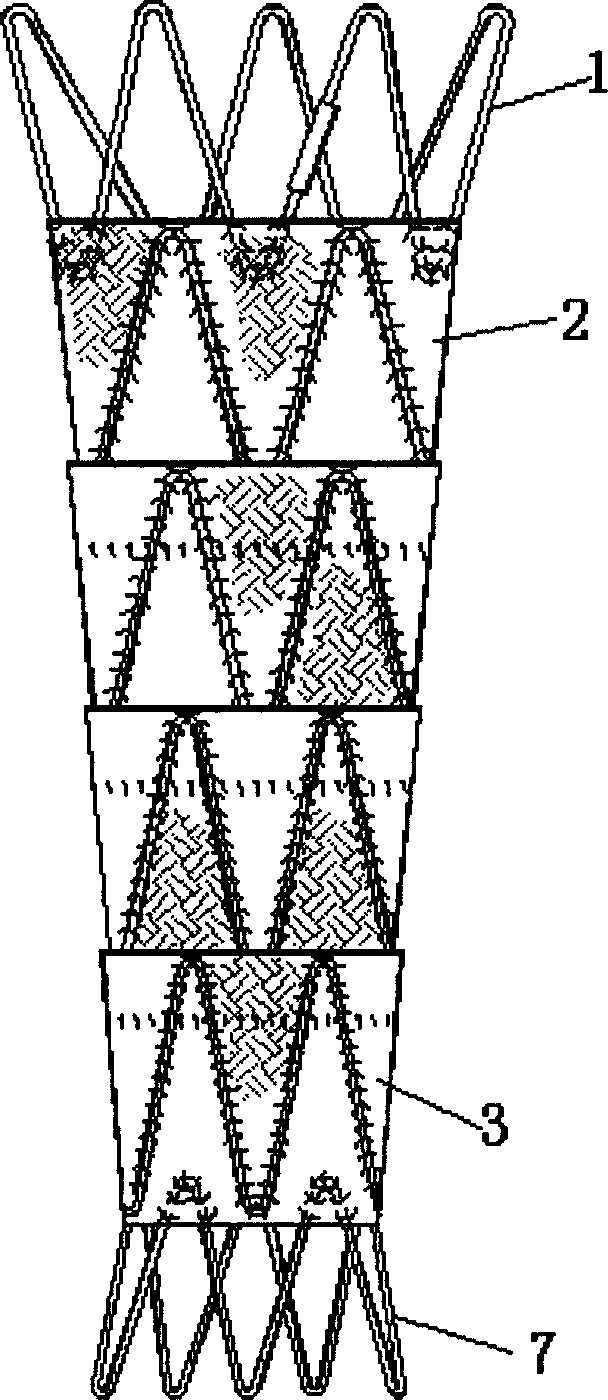

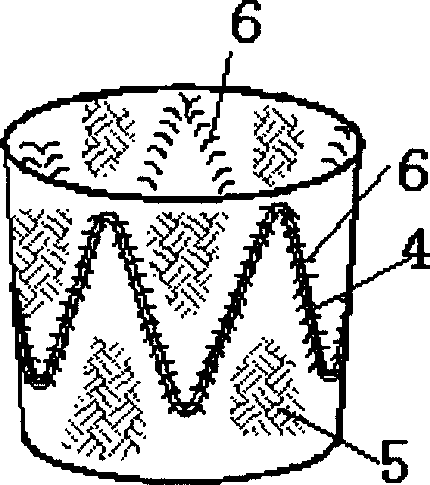

The invention discloses a composite tectorial support of random orientation bending for intracavity insulating therapy of human pathology vessel, which consists of several intermediate tectorial support units and a tail tectorial support unit, wherein each tectorial support unit contains tubular tectorial unit and support unit fixed on the tectorial unit by suture, wherein the support unit concludes several sealing column structure of alloying filament fabrication. There is an overlapping part between adjacent tectorial support units, which stitches by the suture. The invention overcomes the directional defect of congeneric product with the advantages of the following: steady structure, random orientation bending, smooth inwall and so on, which is applied in the human pathology therapy of artery, vein or other lumen, especially in the pathology therapy of aorta-vessel.

Owner:SHANGHAI MICROPORT ENDOVASCULAR MEDTECH (GRP) CO LTD

Apparatus for sealing surgical punctures

Owner:ABBOTT LAB VASCULAR ENTERPRISE

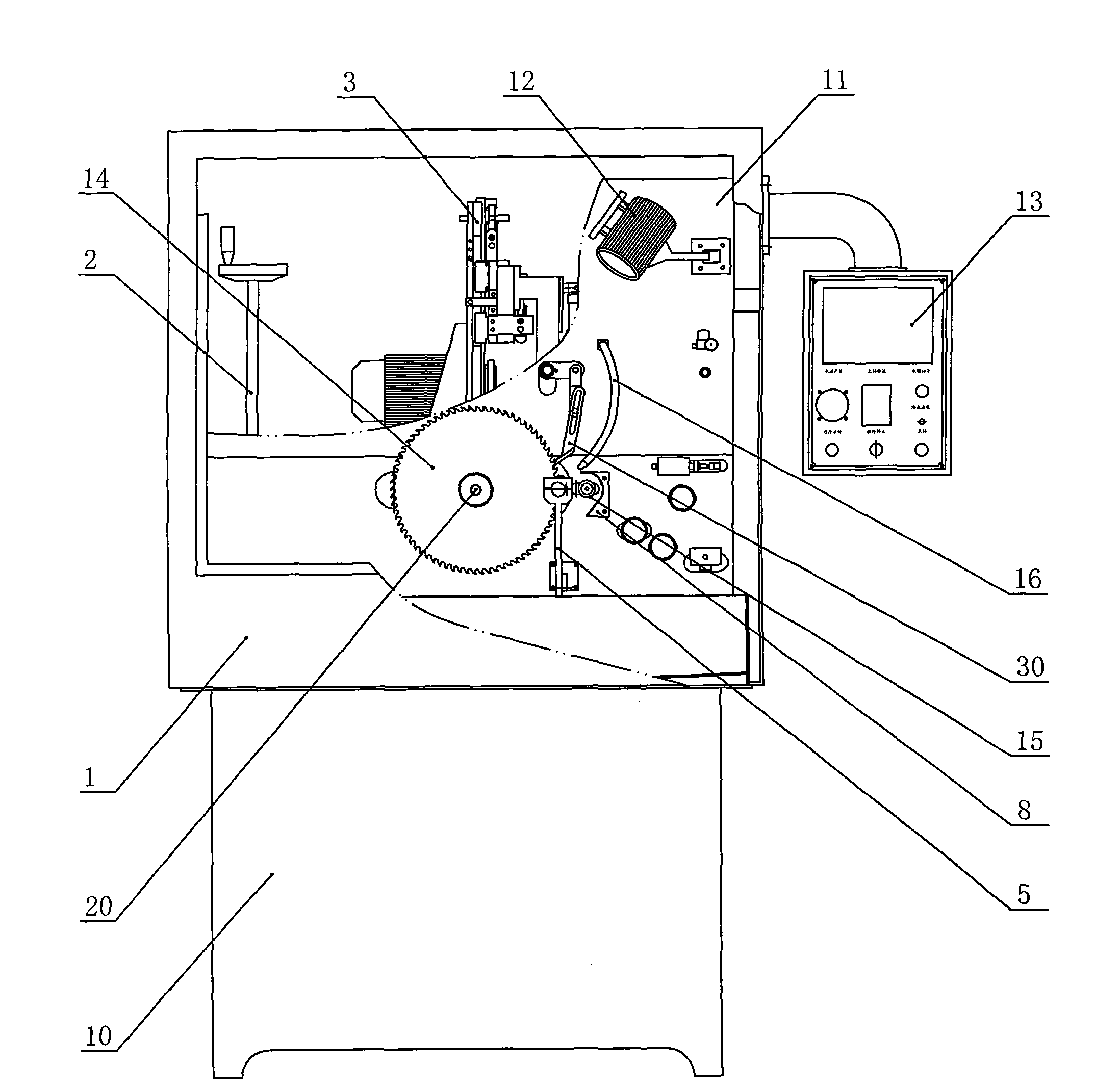

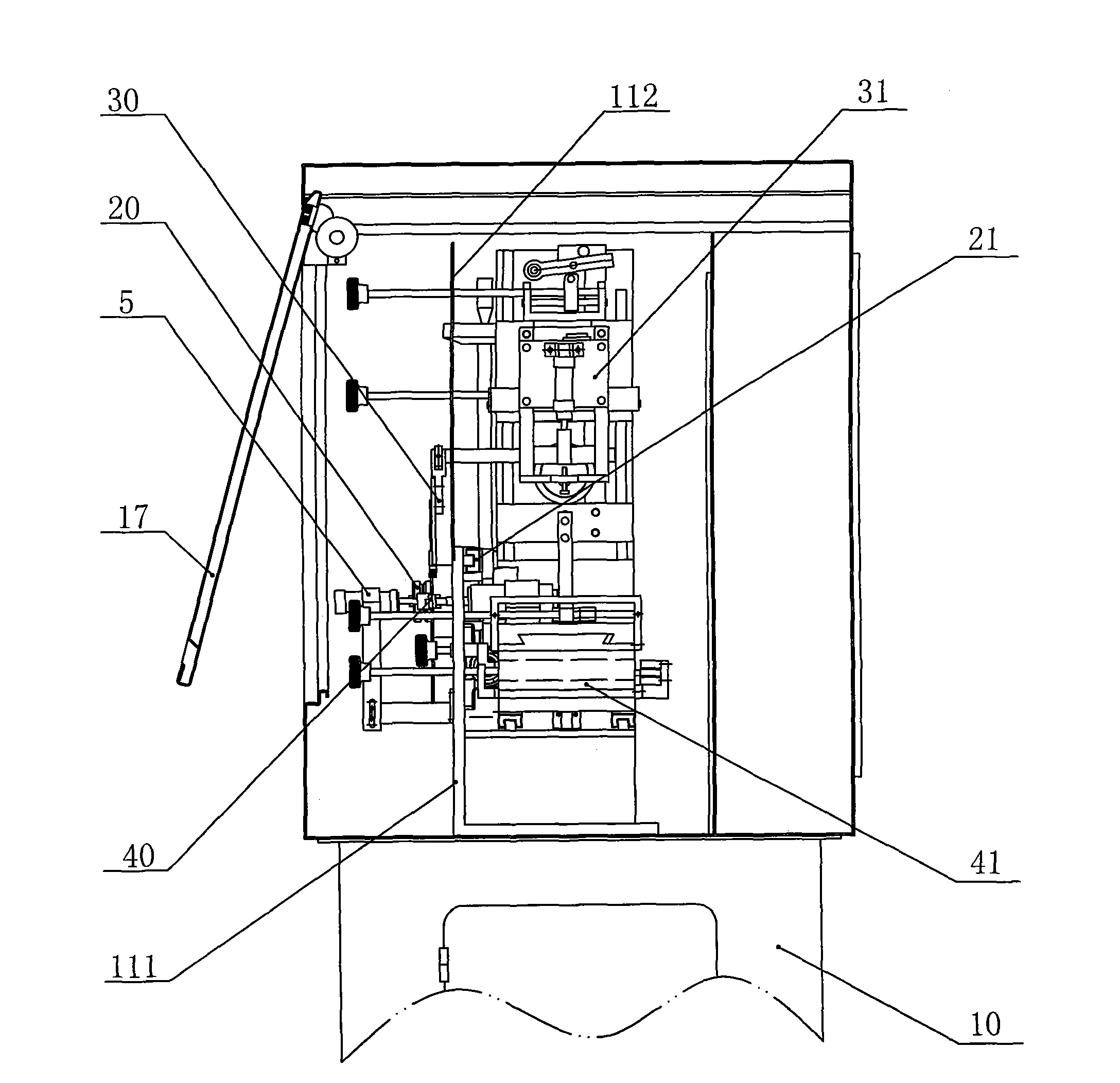

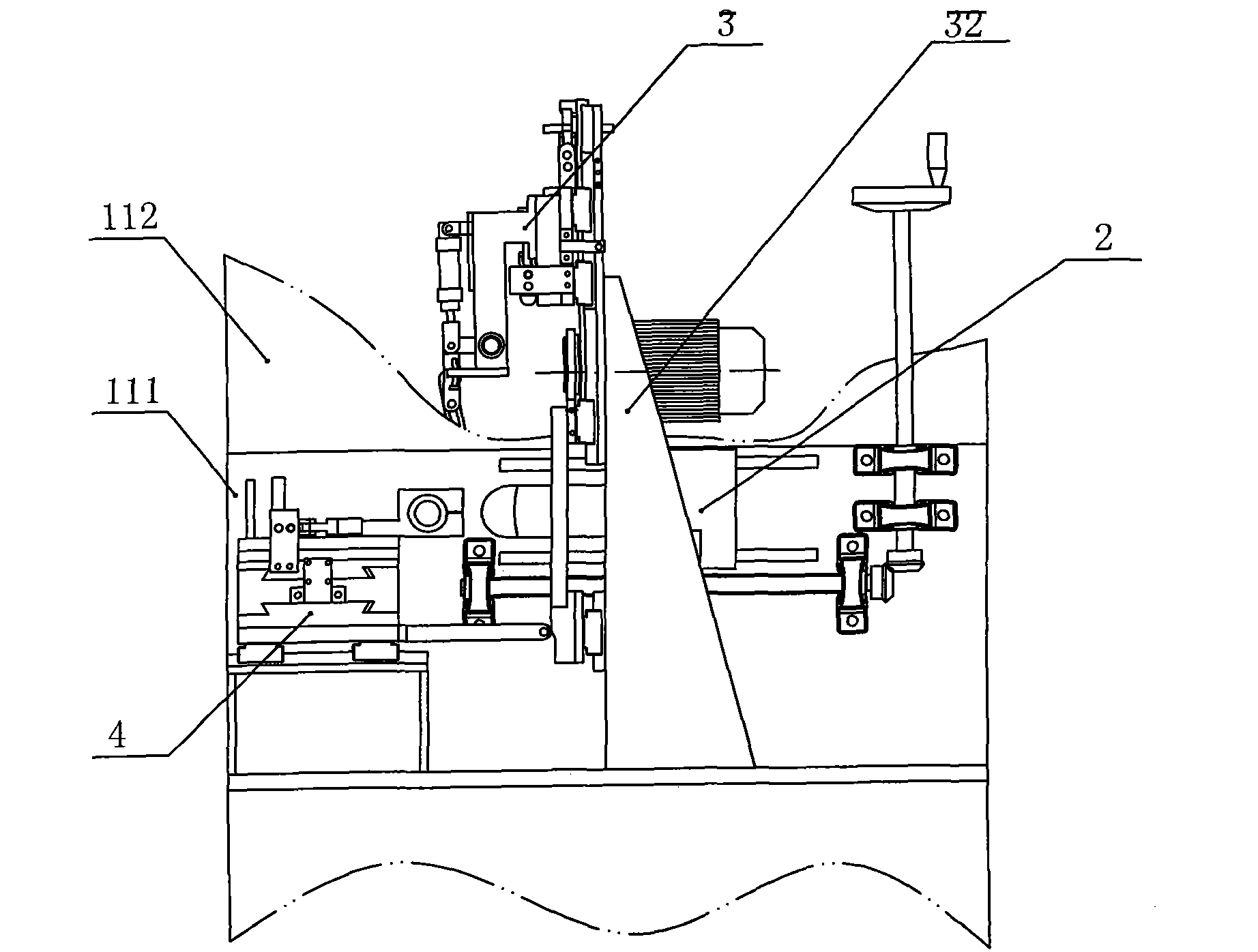

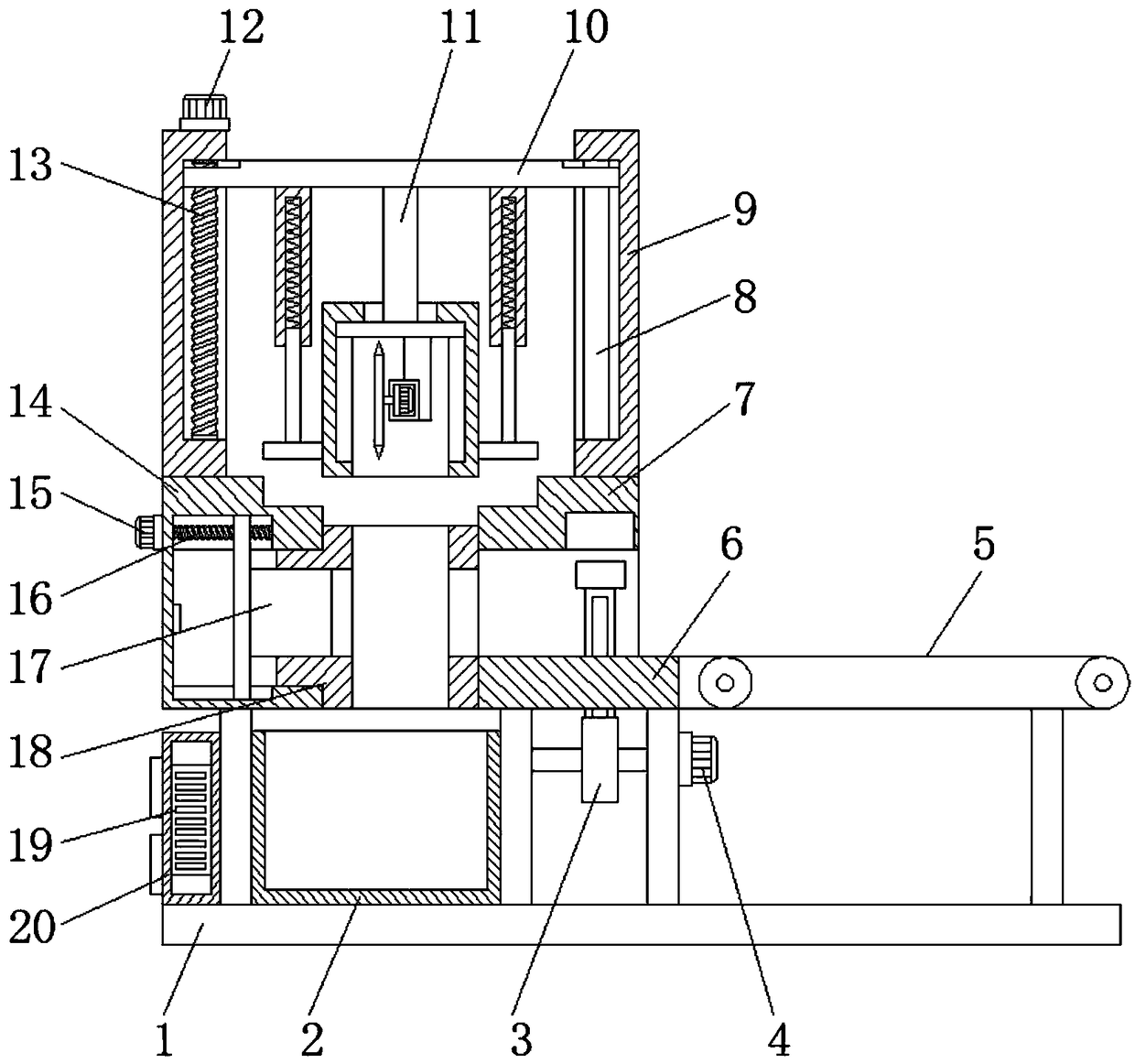

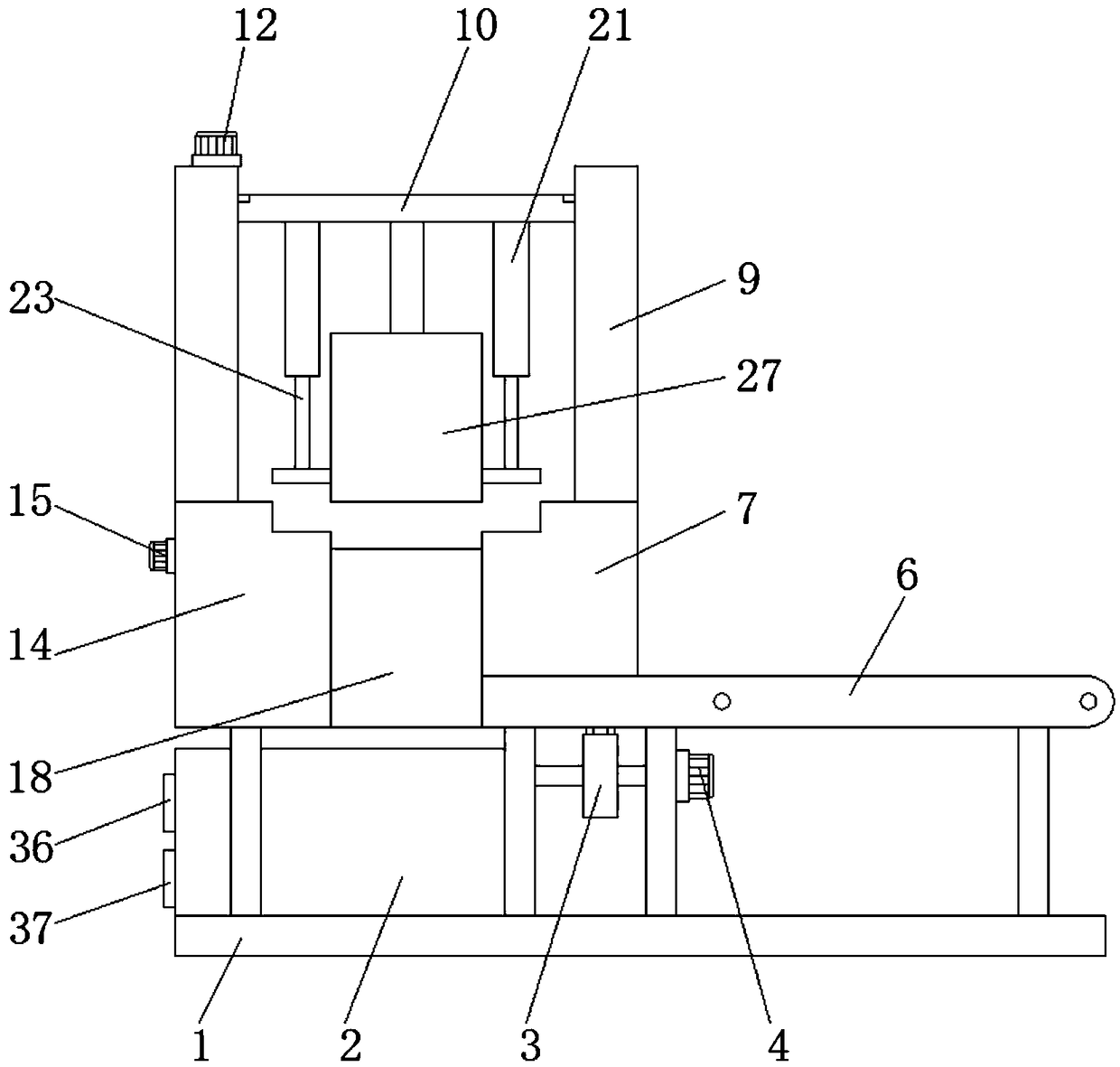

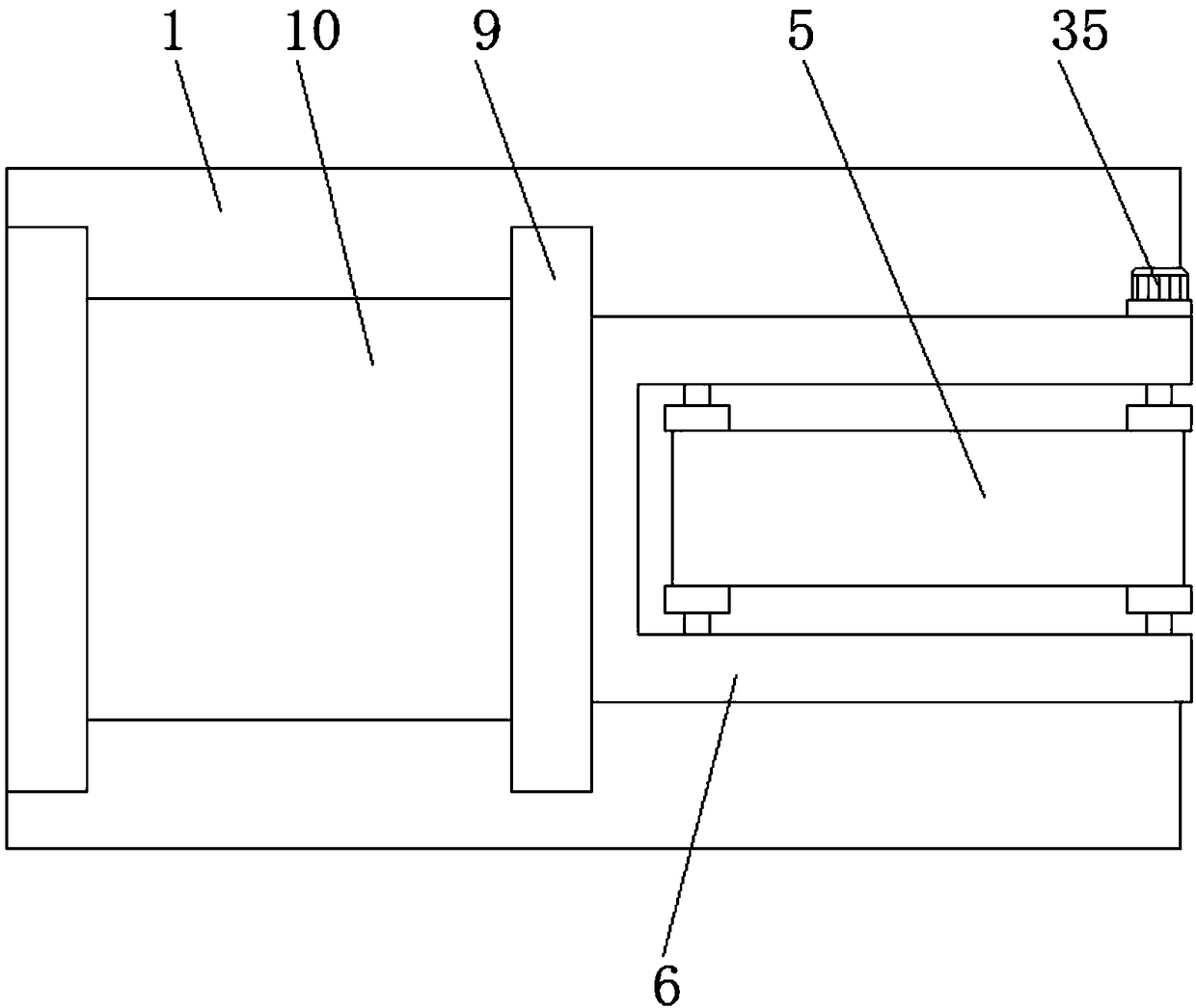

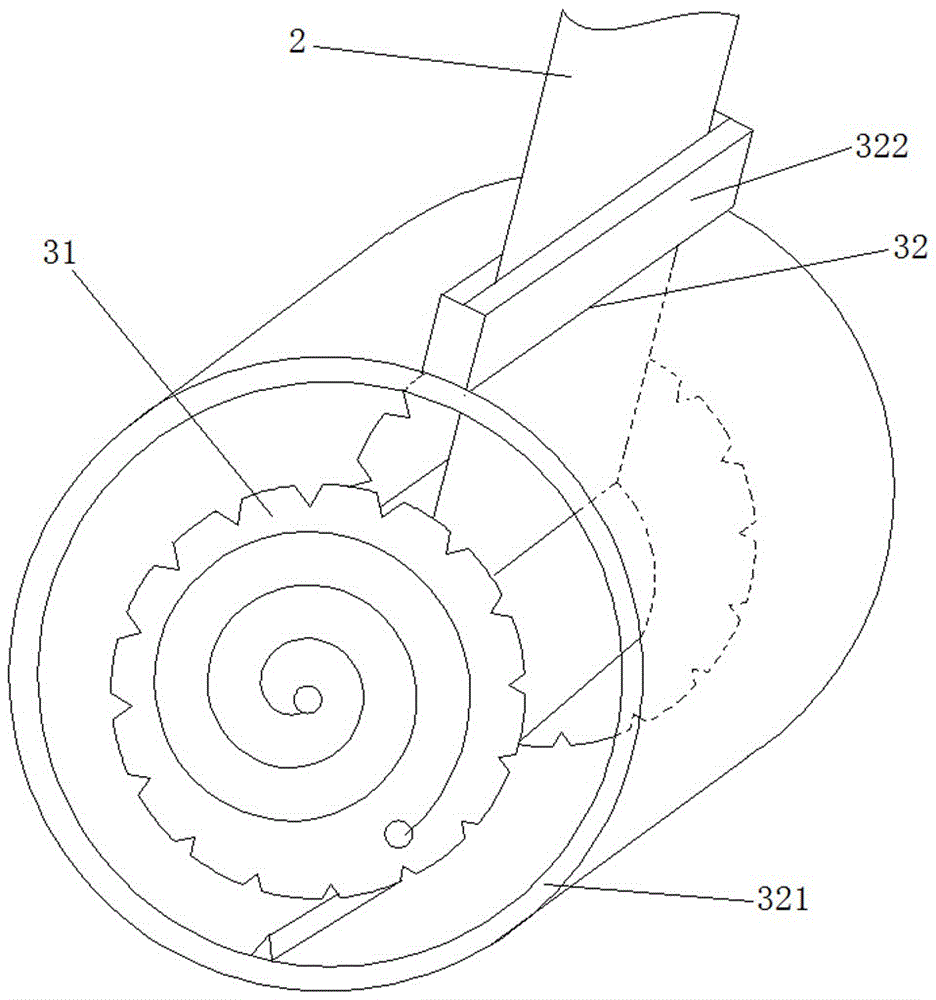

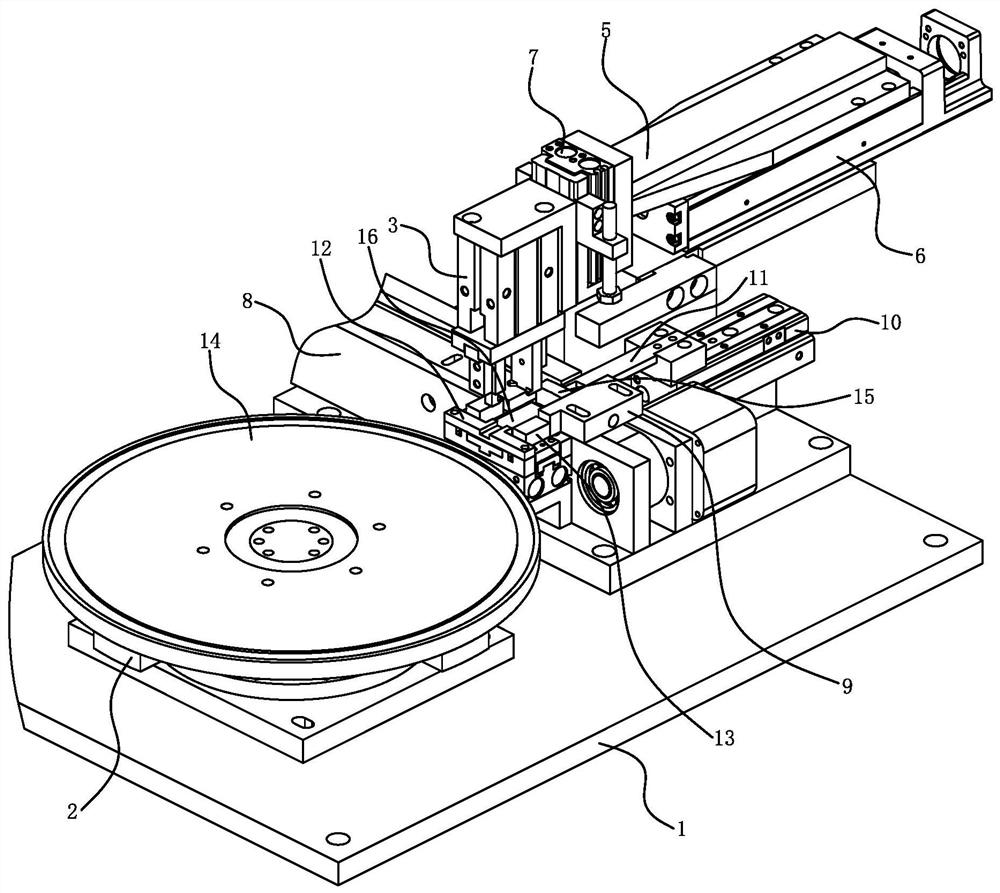

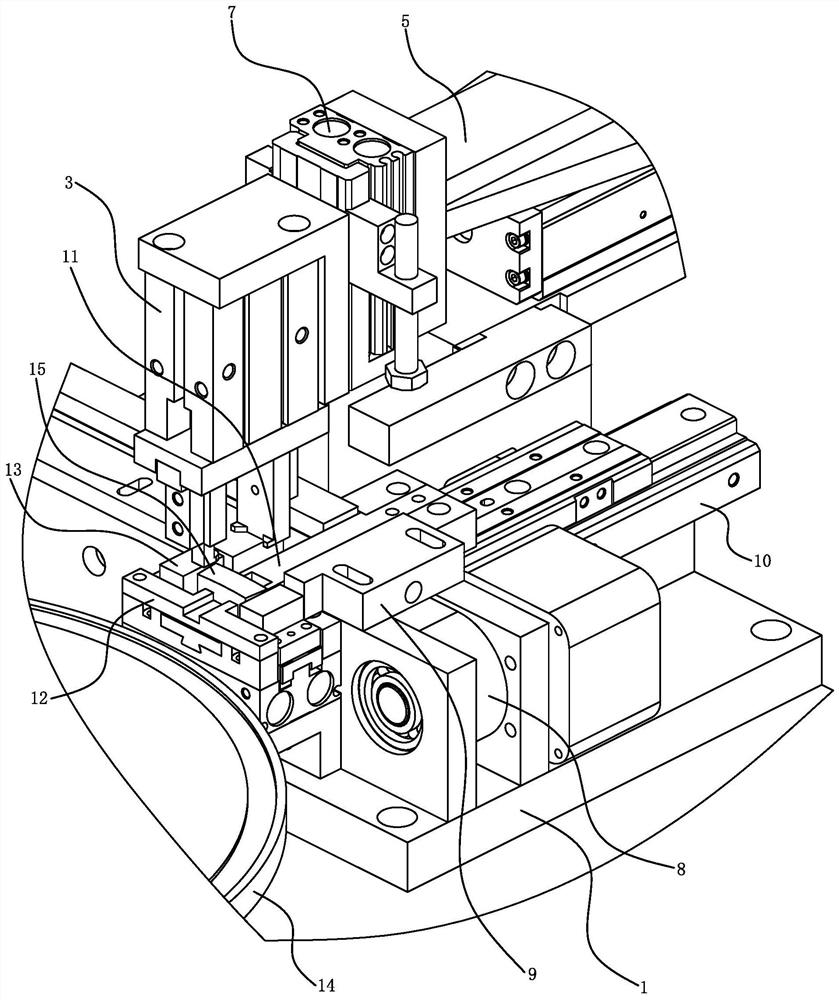

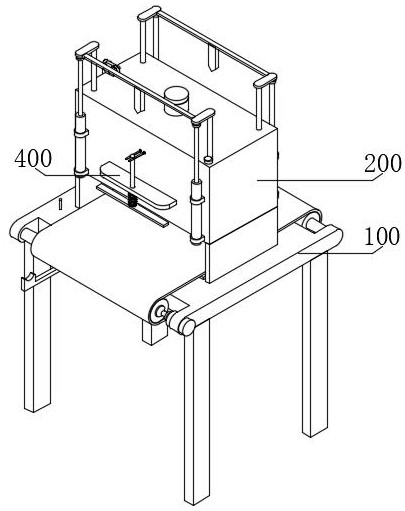

Grooving machine for metal circular saw blades

ActiveCN101579757AEasy to pass throughEasily pass through the screen panels and attachMetal sawing tool makingCircular sawEngineering

The invention relates to a grooving machine for metal circular saw blades, which comprises a stander, a saw blade positioning device, a saw blade step driving device and a grooving cutter driving device, wherein the saw blade positioning device comprises a saw blade fixing base and a saw blade clamping head; the saw blade step driving device comprises a step driving main body and a step pawl; and the grooving cutter driving device comprises a cutter driving main body and a cutter clamping head. The grooving machine also comprises a screen plate fixedly connected to the stander, the saw blade fixing base, the step driving main body and the cutter driving main body are arranged on the inner side edge of the screen plate, and the saw blade clamping head, the step pawl and the cutter clamping head are arranged on the outer side edge of the screen plate; and the grooving machine also comprises a saw blade pressing device and a saw blade cushion block, and the saw blade pressing device comprises a cylinder fixing base and a pressing cylinder. By using the grooving machine, the grooving work is safe and simple and has high efficiency and accurate positioning. The grooving machine can be applied to grooving the top end faces of peripheral sawteeth of the metal circular saw blades.

Owner:广东捷泰克智能装备有限公司

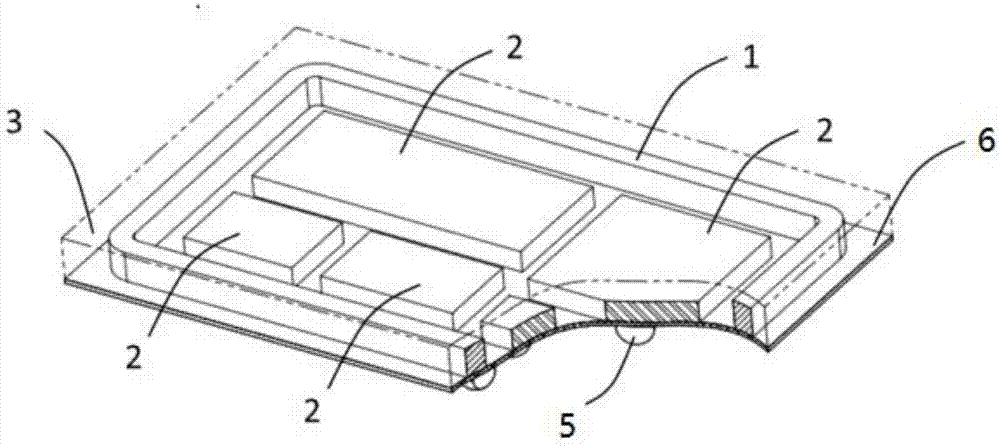

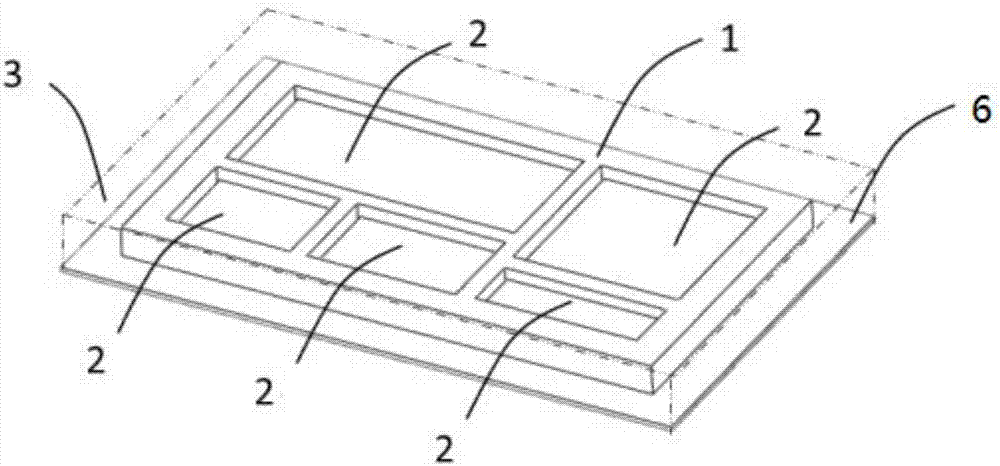

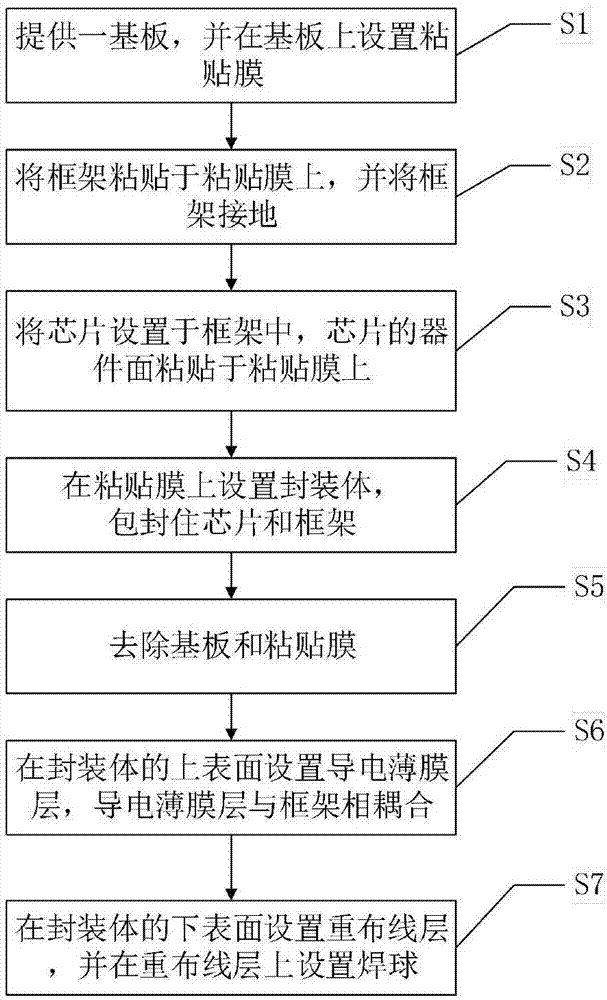

Wafer-grade fan-out packaging structure and method

ActiveCN107481977AImprove electrical performanceReduce electromagnetic interferenceSemiconductor/solid-state device detailsSolid-state devicesElectrical conductorEngineering

The present invention discloses a structure and method of wafer-grade fan-out packaging with electromagnetic shielding. The structure comprises: a frame which is internally provided with one or more than one chips, wherein the frame is connected with a ground wire; a packaging body, wherein the frame and the one or more than one chips are packaged in the packaging body, and the lower surface of the packaging body, the lower surface of the frame and the devices of the one or more than one chips are located at the same plane. A metal conductor and the frame made of ceramic material and having a surface plated with metal are earthed to allow the packaging body and the frame in the wafer-grade fan-out packaging structure to form a complete loop so as to reduce the possibility of electromagnetic wave interference of the packaging structure itself and the external portion of the packaging structure on the wafer-grade packaging and the one or more than one chips at the internal portion of the structure and improve the electrical properties of the wafer-grade fan-out packaging structure.

Owner:NAT CENT FOR ADVANCED PACKAGING

Slicing device with high safety performance and suitable for agricultural product and byproduct processing

ActiveCN109109042AWork lessReduce the phenomenon of accidental accidents caused by chip splashingMetal working apparatusEngineeringSlide plate

The invention belongs to the technical field of agricultural product and byproduct processing, and particularly relates to a slicing device with high safety performance and suitable for agricultural product and byproduct processing. The slicing device aims to solve the problem that when an existing slicing device performs slicing, cuttings splash and are likely to cause safety accidents. Accordingto the following proposed scheme, the slicing device comprises a base; a clamping table and an adjusting table are fixed to the two sides of the outer wall of the top of the base through screws; cutting tanks are fixed to the outer walls of the sides, opposite to each other, of the clamping table and the adjusting table through screws; sliding plate sliding grooves are formed in the two sides ofthe outer wall of the top of the clamping table; sliding plates are slidably connected to the inner walls of the two sliding plate sliding grooves; and clamping plates are fixed to the outer walls ofthe tops of the two sliding plates through screws. By means of the slicing device, the occurrence probability of the phenomena that workers are injured by cutters by accident and the cuttings splash to cause accidents is reduced advantageously, the slicing thickness can be adjusted conveniently according to machining demands, the application range of the slicing device is expanded advantageously,the possibility that raw materials shift in the slicing process can be reduced, and the product quality is improved advantageously.

Owner:宜川三物农产品有限责任公司

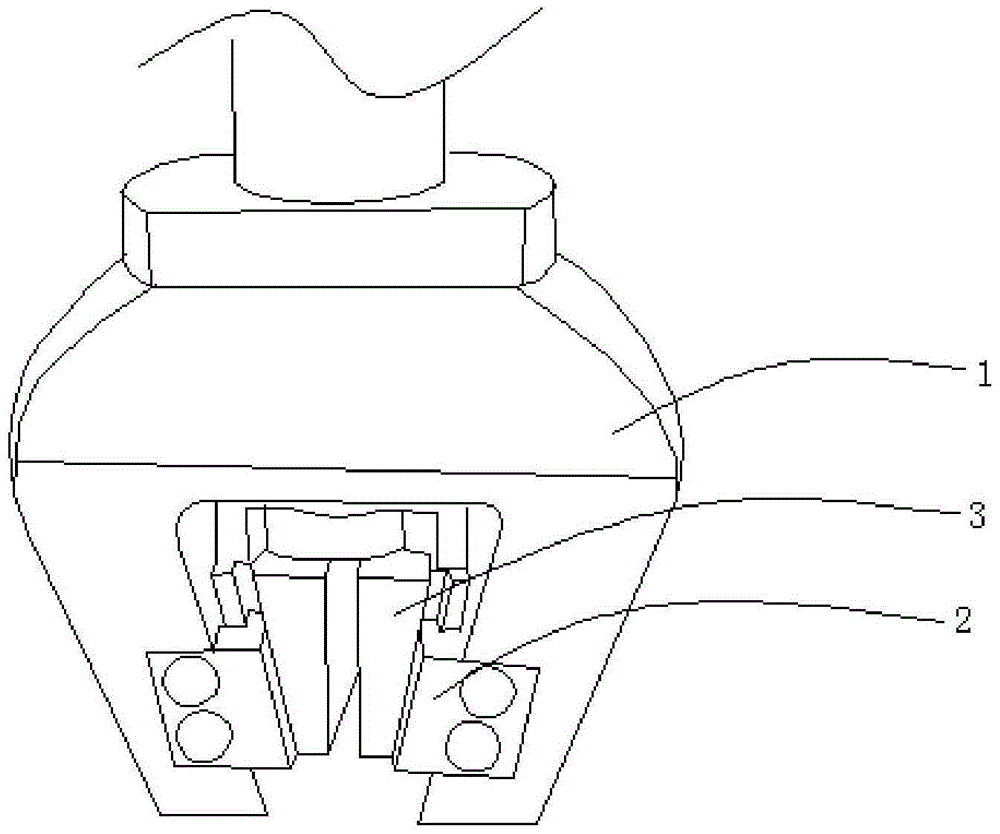

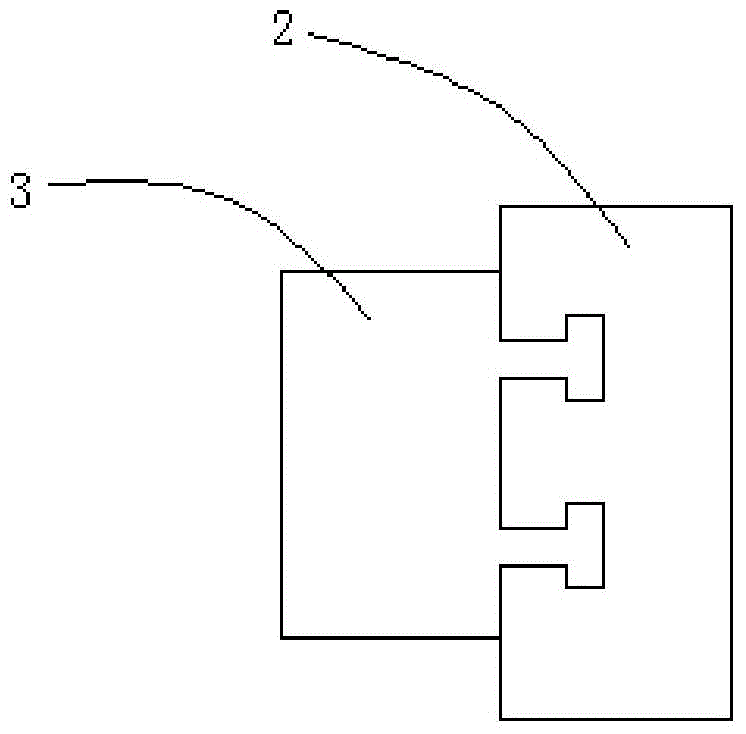

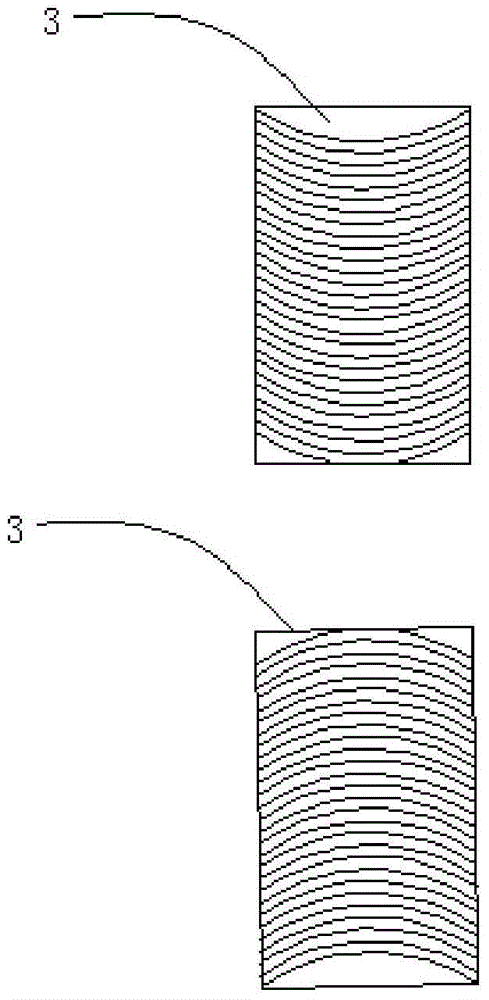

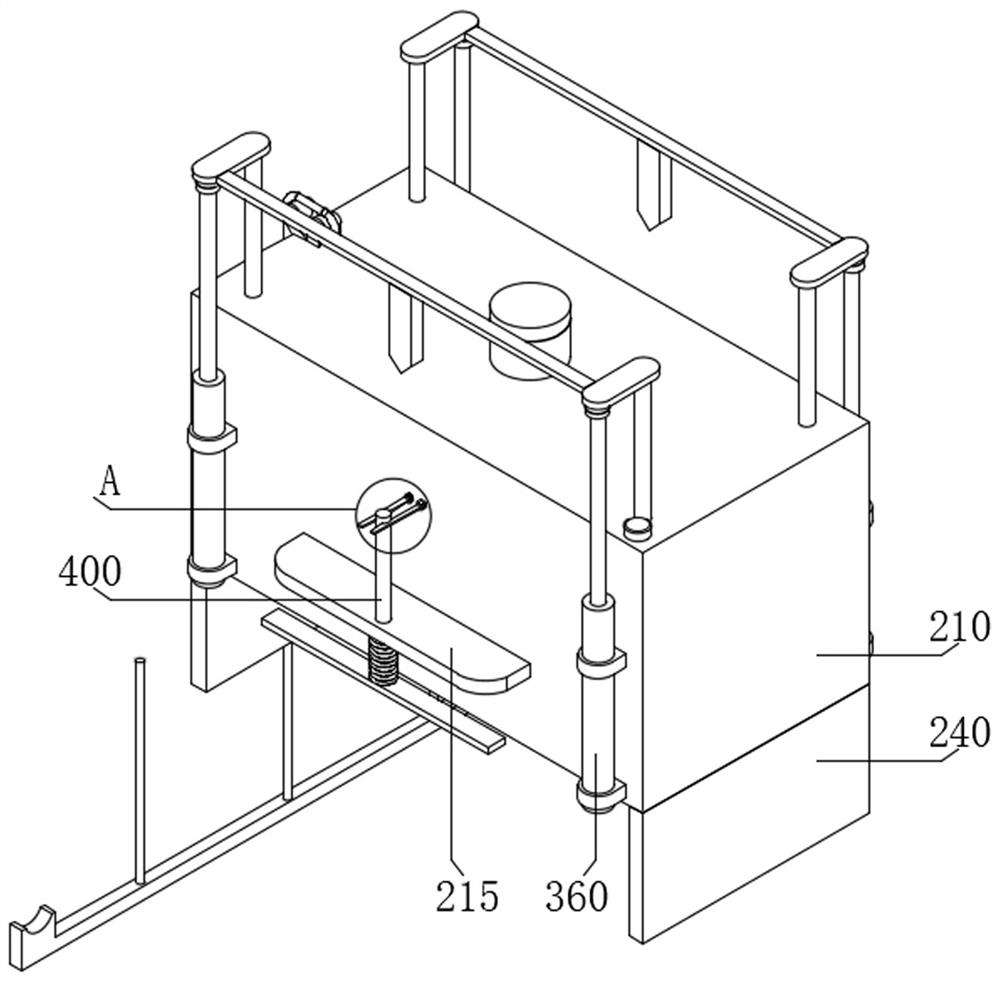

Electronic tensile machine for testing performance of carbon fiber composite

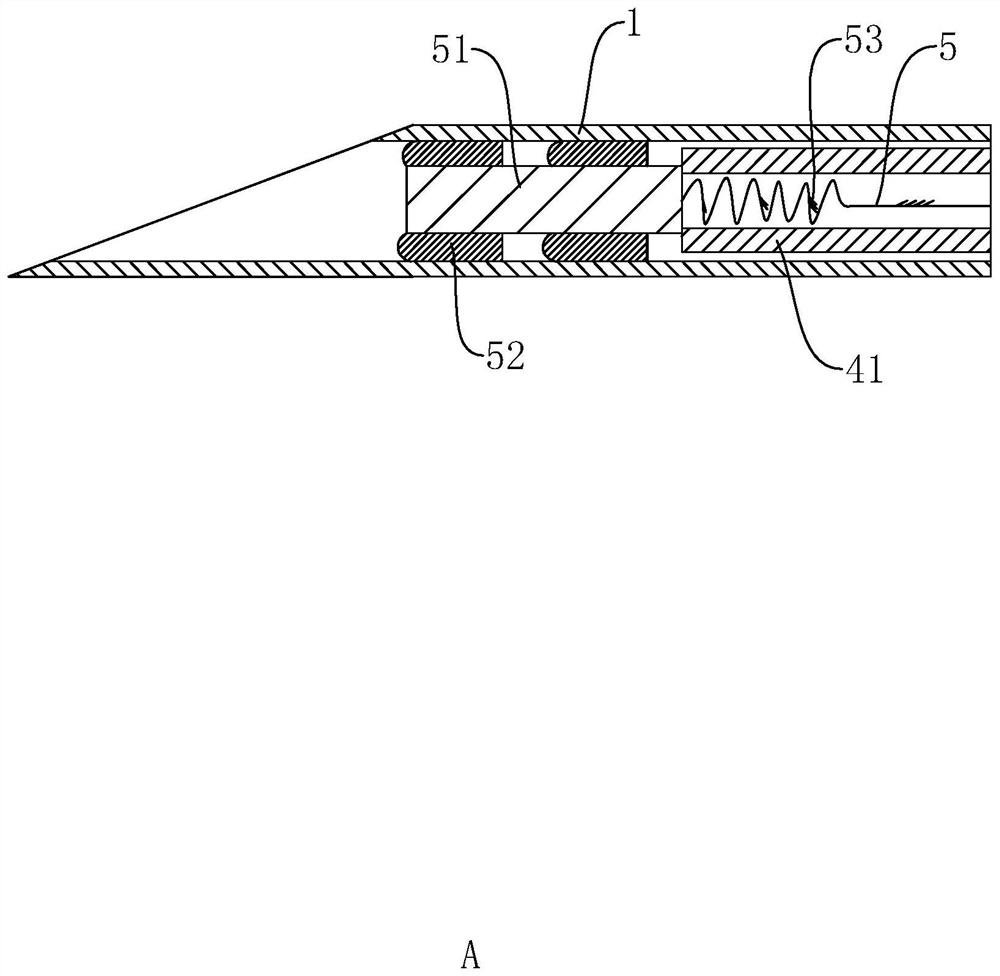

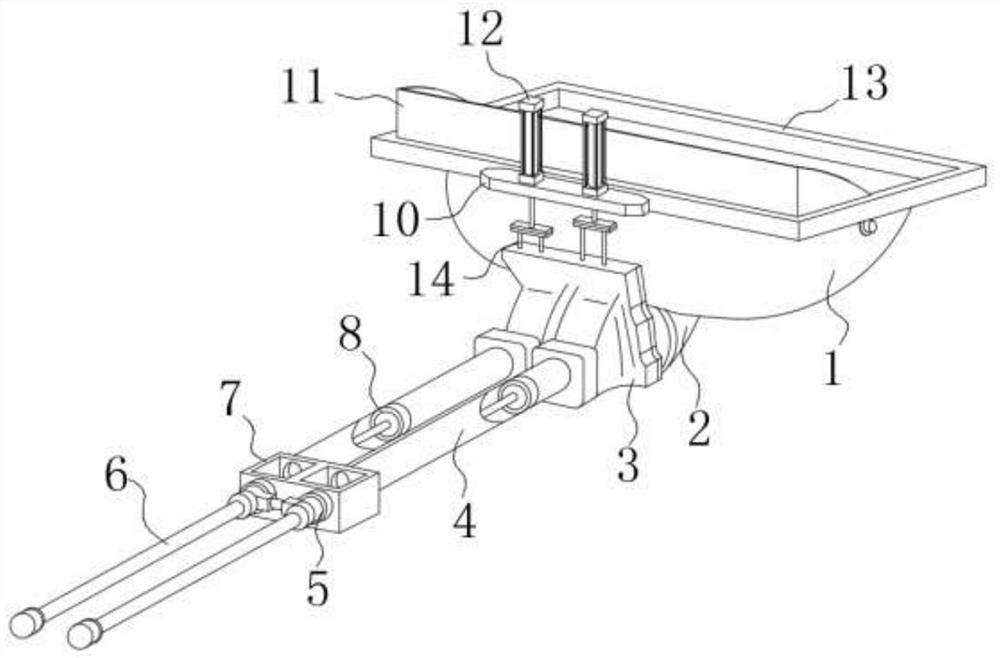

InactiveCN105203397AReduce clampingReduced Possibility of DisplacementMaterial strength using tensile/compressive forcesTest performanceMechanical engineering

The invention provides an electronic tensile machine for testing performance of a carbon fiber composite. The electronic tensile machine comprises a clamping mechanism, wherein the clamping mechanism comprises a U-shaped base, clamping bodies and wedge-shaped sliding blocks, and the clamping bodies are fixed in positions, close to an opening, of inner walls of two sides of the base respectively; opposite surfaces of the two clamping bodies are inclined surfaces; the wedge-shaped sliding blocks are fixed on the inclined surfaces of the two clamping bodies respectively; the wedge-shaped sliding blocks slide up and down relative to the clamping bodies; surfaces, contact with the clamping bodies, of the wedge-shaped sliding blocks are sliding surfaces, surfaces opposite to the sliding surfaces are clamping surfaces, the clamping surfaces are vertical surfaces, and included angles formed by the sliding surfaces and the clamping surfaces are 20-40 degrees; when the two wedge-shaped sliding blocks slide towards the opening of the U-shaped base, the distance between the clamping surfaces of the two wedge-shaped sliding blocks is shortened. Compared with the prior art, the electronic tensile machine has the advantages that the inclination degree of the wedge-shaped sliding blocks is increased, the process for clamping furnace pieces is shortened, and the probability of sliding and displacement of the furnace pieces is reduced.

Owner:ANHUI JIALIQI AEROSPACE CARBON FIBER CO LTD

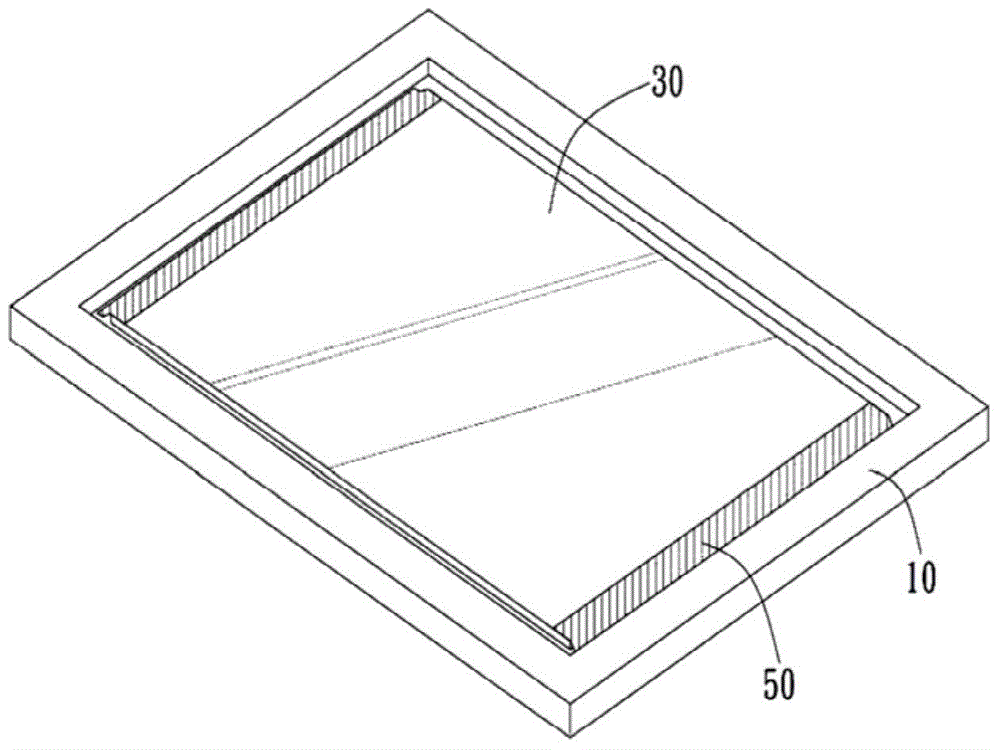

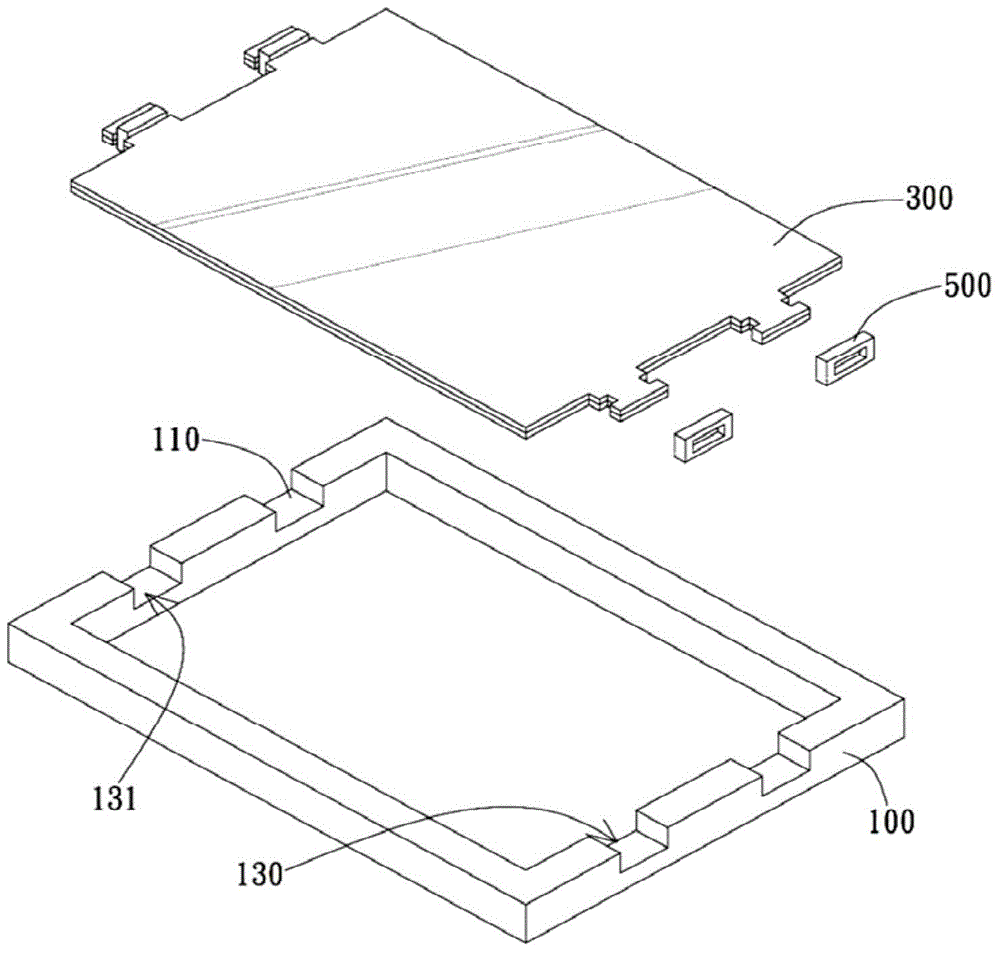

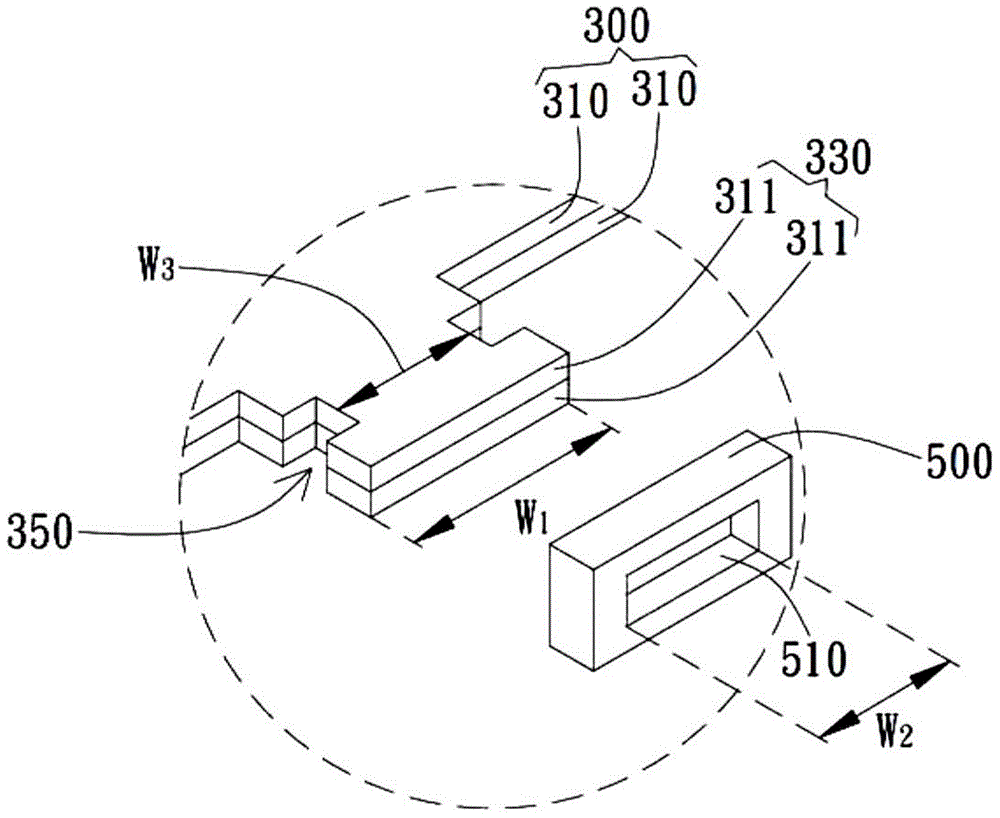

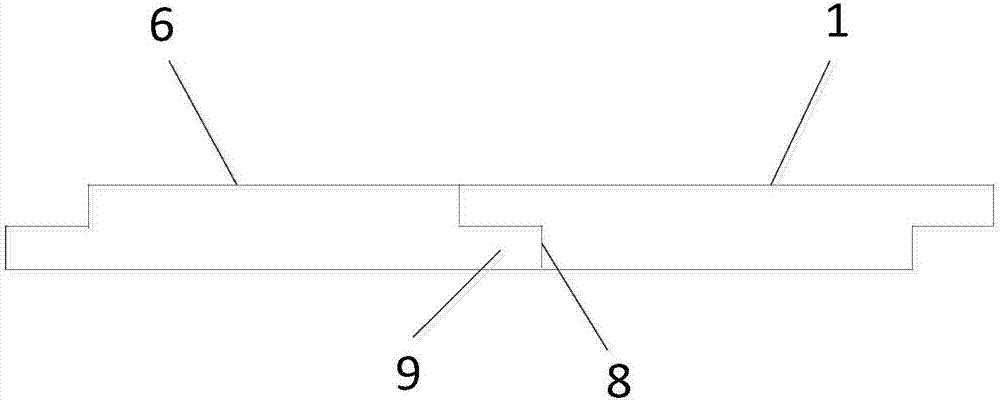

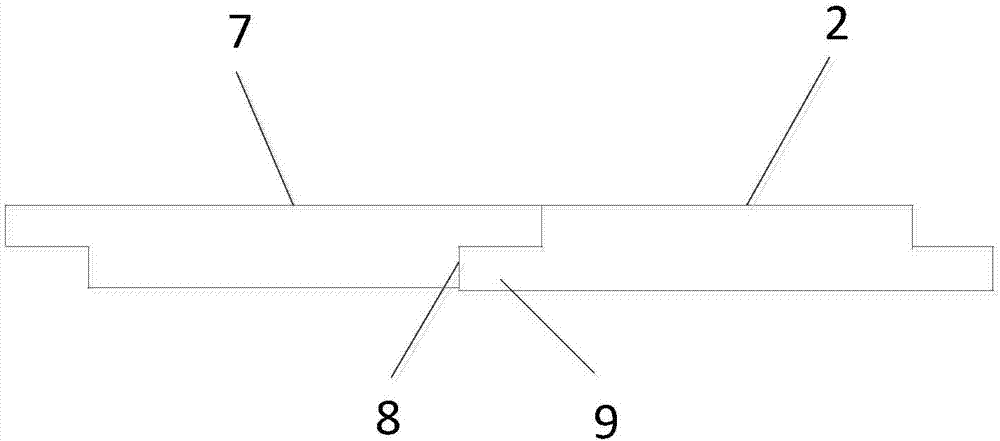

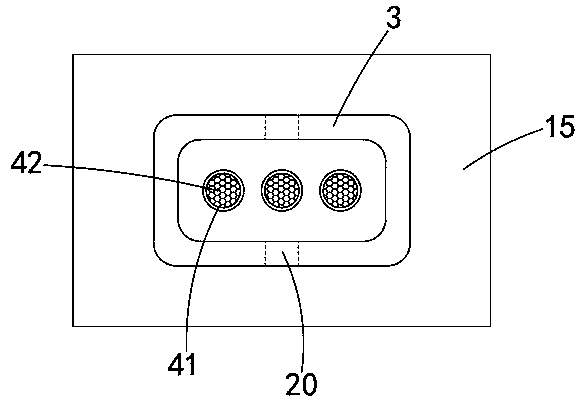

Backlight module

InactiveCN104696833AReduce the degree of relative displacementImprove integrityLight fasteningsFixed installationComputer moduleEngineering

The invention provides a backlight module comprising a frame, an optical film group and a fixed ring; the optical film group is arranged in the frame, so the optical film group is surrounded by the frame or matched with the frame; the optical film group comprises lug directly or indirectly supported by a support face of the frame; the support face supports the lug, so the frame can support the optical film group; two sides of the lug are respectively provided with at least one groove; the fixed ring hoops the lug, and at least part of the fixed ring is clamped in the groove.

Owner:AU OPTRONICS CORP

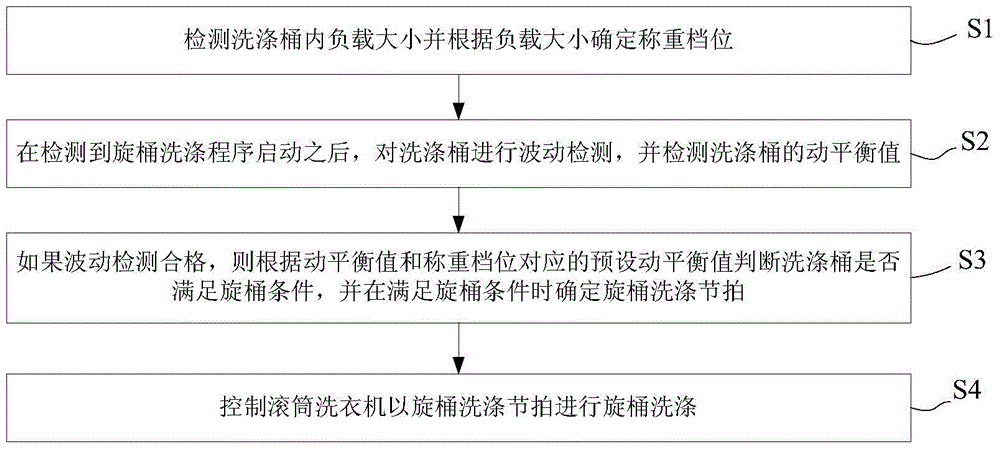

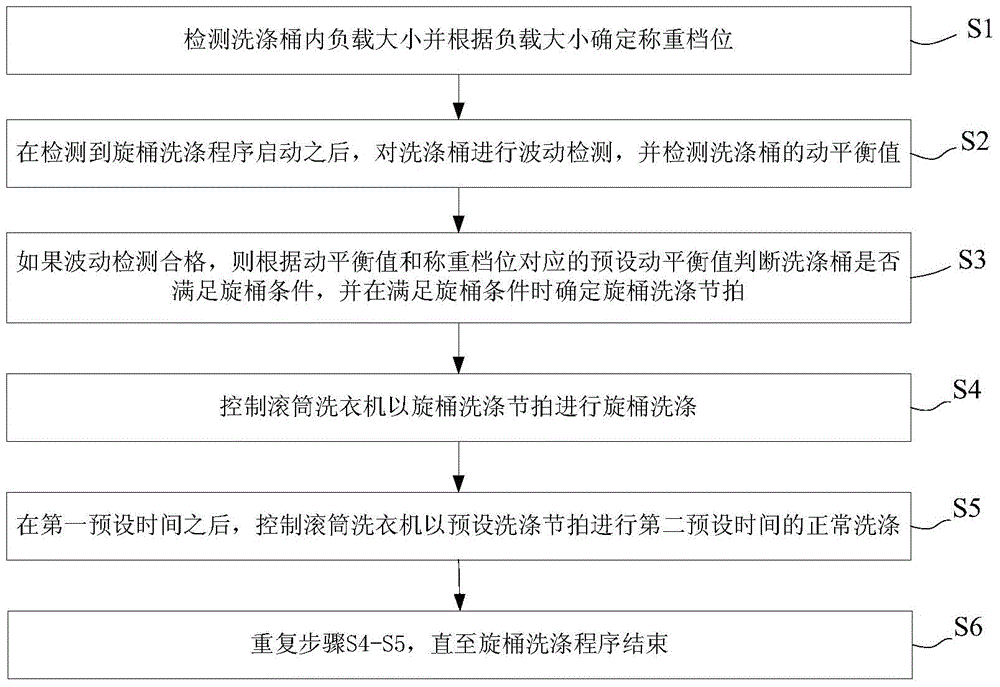

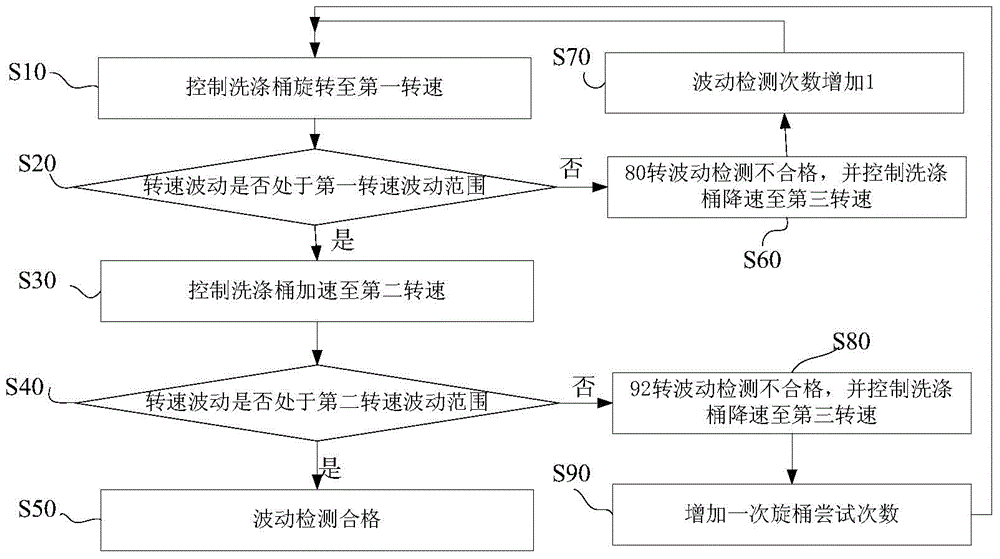

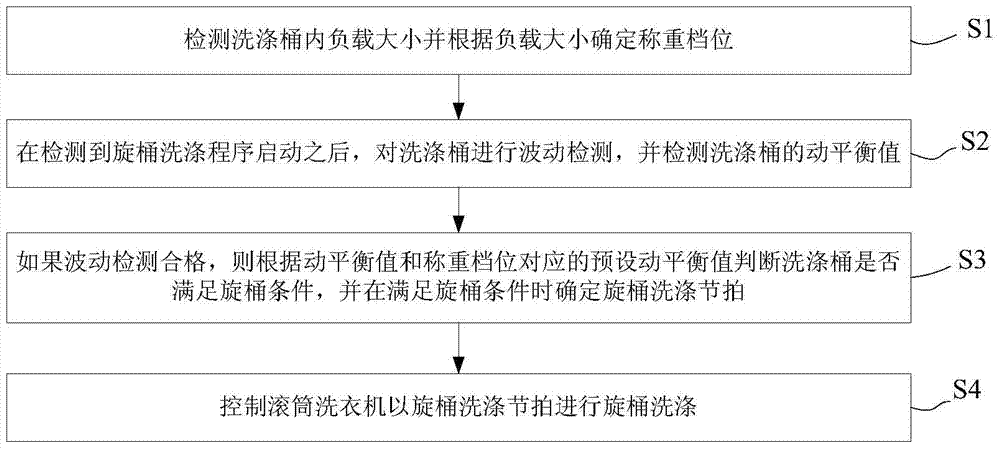

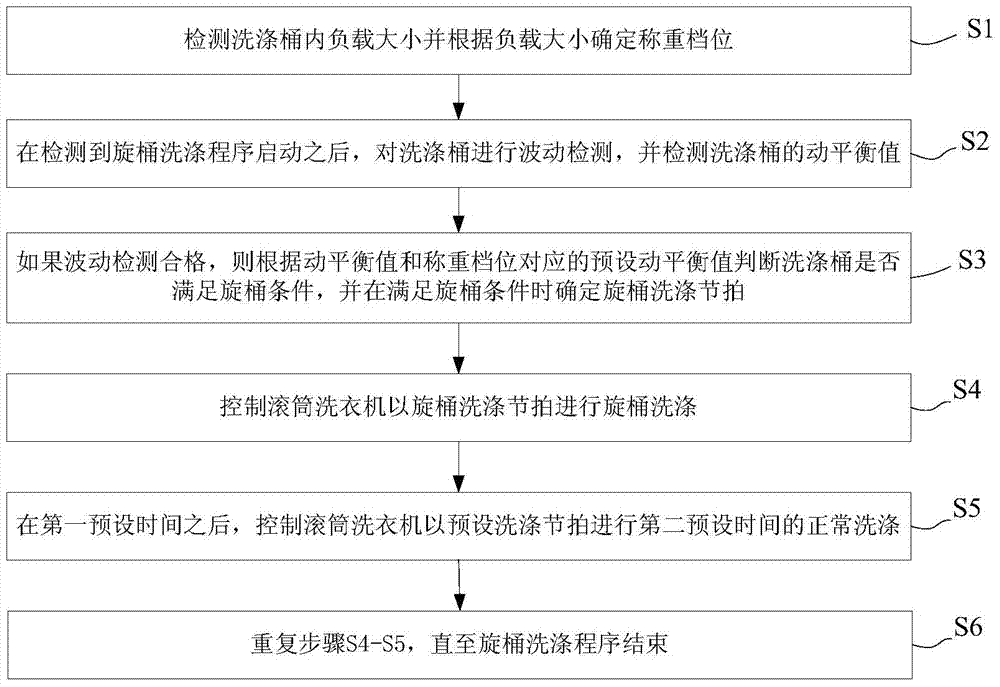

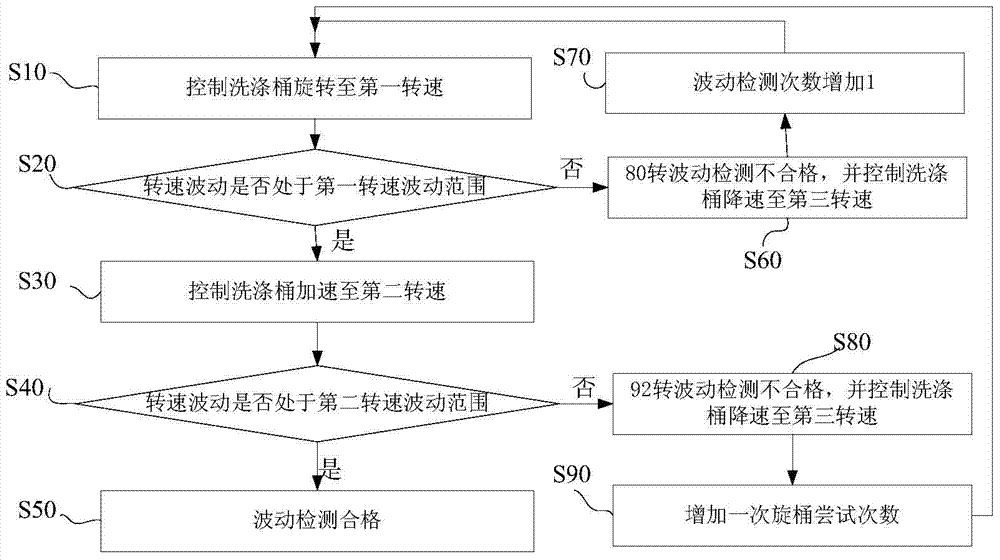

Control method for rotational washing of front-loader washing machine

ActiveCN105088645AGuaranteed stabilityReduced Possibility of DisplacementControl devices for washing apparatusTextiles and paperProcess engineeringDynamic balance

The invention discloses a control method for rotational washing of a front-loader washing machine. The control method comprises the following steps of S1. ,detecting the load in a washing drum and determining a weight level according to the load; S2. detecting fluctuation of the washing machine after detecting a rotational washing routine is started, and detecting a dynamic balance value of the washing drum; S3. determining whether the washing drum meets a rotational condition according to the dynamic balance value and a preset dynamic balance value corresponding to the weight level if the fluctuation is qualified, and determining a beat of rotational washing if the rotational condition is met; and S4 controlling the front-loader washing machine to rotationally wash according to the beat of rotational washing. By adopting the control method for rotational washing of a front-loader washing machine, shifts can be reduced during rotational washing, and the smoothness of rotational washing can be improved.

Owner:WUXI LITTLE SWAN ELECTRIC CO LTD

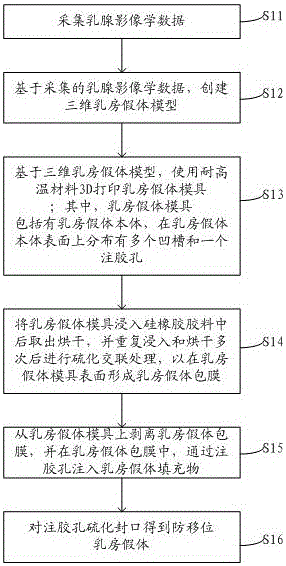

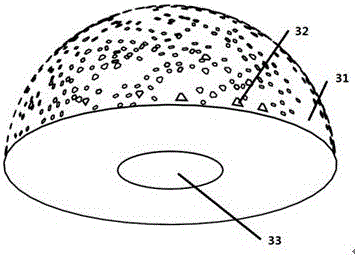

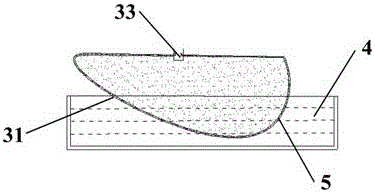

Anti-displacement breast implant forming method based on 3D printing and breast implant

The invention discloses a 3D printing-based anti-displacement breast prosthesis forming method and a breast prosthesis, which solve the technical problem of extrusion and displacement of the existing breast prosthesis. Including collecting breast imaging data; creating a three-dimensional breast prosthesis model based on the collected breast imaging data; There are multiple grooves and a glue injection hole distributed on the surface of the breast prosthesis body; the breast prosthesis mold is immersed in the silicone rubber material, taken out and dried, and repeated immersion and drying several times before vulcanization. The obtained breast prosthesis capsule is peeled off from the breast prosthesis mold, and the breast prosthesis filler is injected through the glue injection hole; the glue injection hole is vulcanized and sealed to obtain a displacement-proof breast prosthesis. Because the inner surface of the capsule of the breast prosthesis has multiple protrusions, it can avoid displacement of the internal filler after the breast prosthesis is squeezed.

Owner:青岛三缔生物科技有限公司

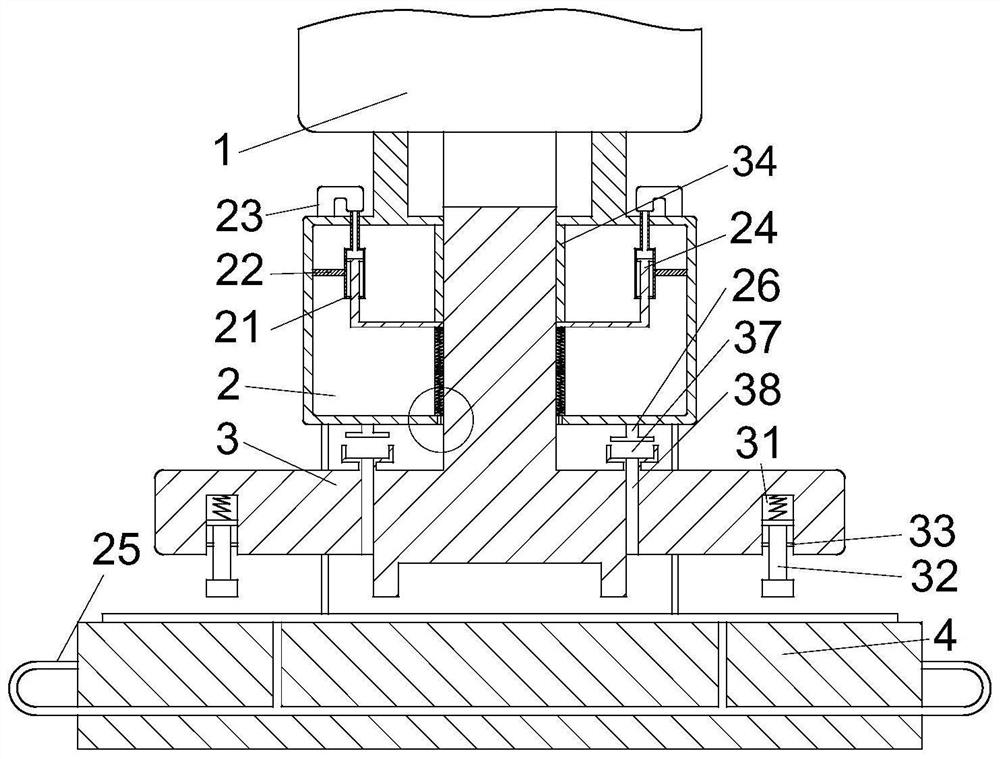

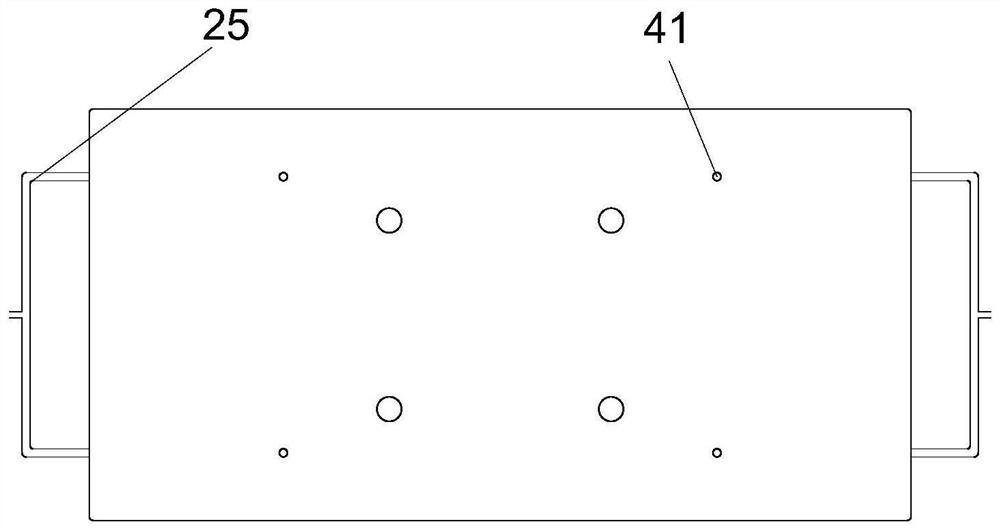

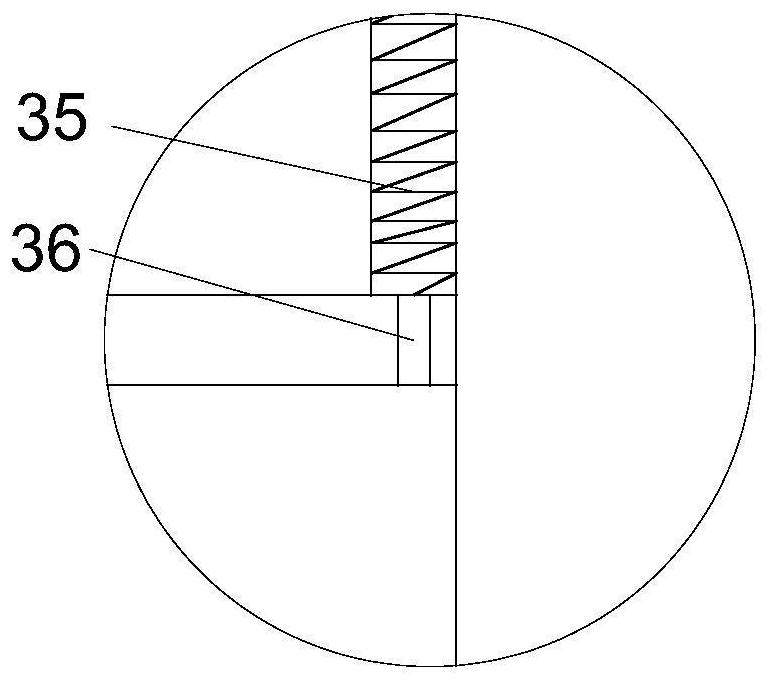

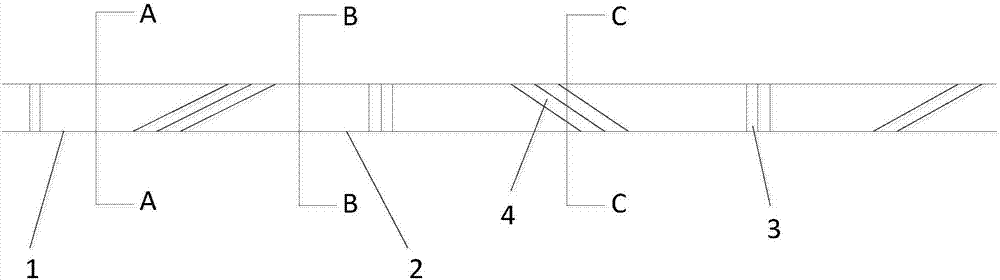

Aluminum foil product production forming stamping die

PendingCN114192662AReduce displacementStamping quality declineShaping toolsMetal-working feeding devicesHydraulic cylinderEngineering

The invention belongs to the technical field of stamping dies, and particularly relates to an aluminum foil product production forming stamping die which comprises a hydraulic cylinder, a box body, an upper die base and a lower die base. The box body is fixedly connected below the hydraulic cylinder; the upper die base is fixedly connected with the output end of the hydraulic cylinder, and the output end of the hydraulic cylinder penetrates through the box body. A lower die holder is arranged below the upper die holder; the lower die holder is fixedly connected with the base; an air cylinder is arranged in the box body and is fixedly connected to the inner wall of the box body through a connecting rod; an air outlet in the air cylinder communicates with a first air pipe, and the first air pipe communicates with a second air pipe. The second air pipe communicates with air holes in the upper surface of the lower die base. A piston rod is arranged at the end, away from the upper air outlet, in the air cylinder. The other end of the piston rod is fixedly connected with the upper die base. A cavity with a downward opening is formed in the upper die base. A positioning block is arranged in the cavity, a check block is arranged in the cavity, a spring is arranged between the positioning block and the upper die base, the possibility of displacement of aluminum foil is reduced, and the stamping quality is improved.

Owner:刘博

Sand-plastic floor convenient to mount

The invention relates to the technical field of building materials, in particular to a sand-plastic floor convenient to mount. The sand-plastic floor comprises a first sand-plastic floor body and a second sand-plastic floor body which are connected in the length direction, and further comprises the first sand-plastic floor body and a third sand-plastic floor body which are connected in the width direction as well as the second sand-plastic floor body and a fourth sand-plastic floor body which are connected in the width direction. A pair of edges of the first sand-plastic floor body in the length direction is arranged to be a vertical edge and an oblique edges correspondingly, and a pair of edges of the second sand-plastic floor body in the length direction are arranged to be a vertical edge and an oblique edge correspondingly. The vertical edge and the oblique edge of the first sand-plastic floor body are each provided with at least one sliding groove provided with a plurality of protruding parts, and the vertical edge and the oblique edge of the second sand-plastic floor body are each provided with at least one sliding block matched with the corresponding sliding groove. A pair ofedges of the first groove sand-plastic floor body, the second sand-plastic floor body, the third sand-plastic floor body and the fourth sand-plastic floor body in the width direction are arranged tobe mounting grooves and convex blocks correspondingly. According to the sand-plastic floor convenient to mount, every two adjacent floor bodies are firmly connected in the horizontal direction and thevertical direction, and after long-term using, firm connection can also be guaranteed even if slight deformation occurs.

Owner:BEIJING RECHSAND SCI & TECH GRP

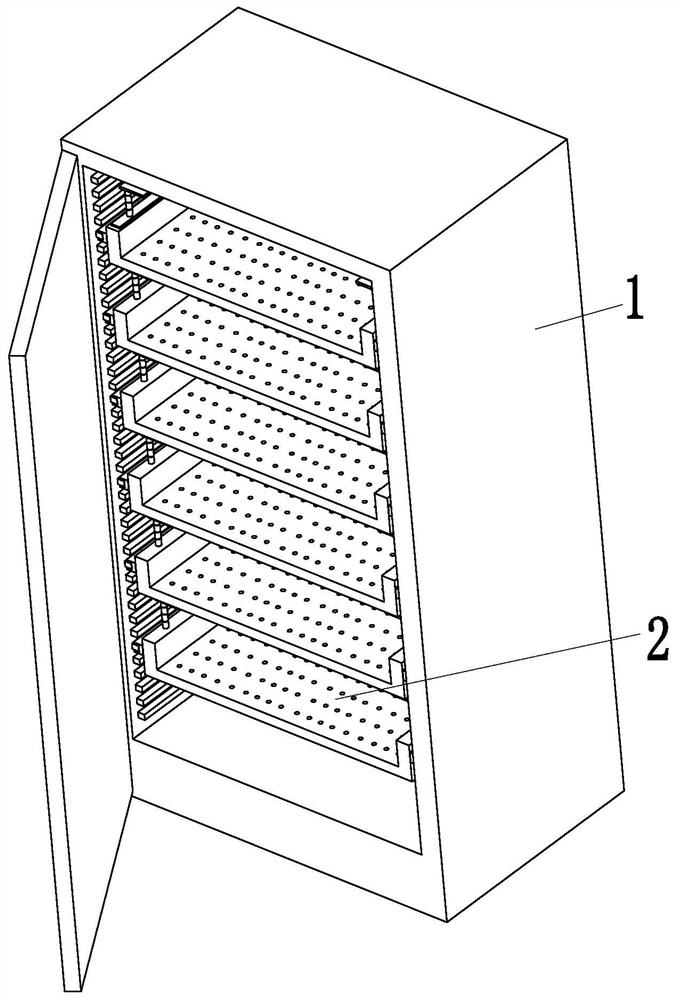

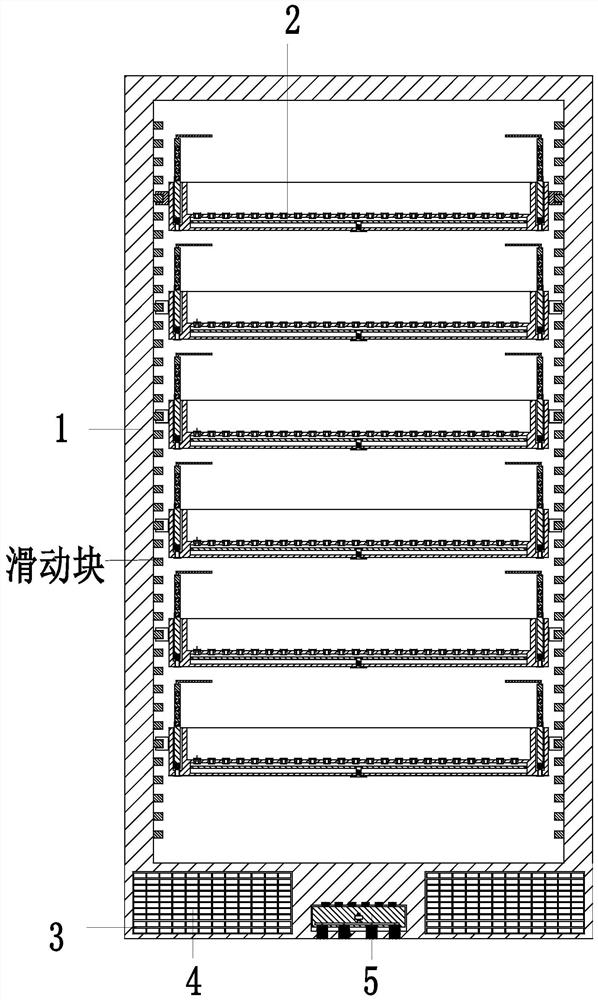

Low-voltage switch cabinet

InactiveCN112864880ASufficient processing timeAvoid damageSubstation/switching arrangement casingsAnti-seismic devicesClassical mechanicsMechanical engineering

The invention relates to a low-voltage switch cabinet. The low-voltage switch cabinet comprises a cabinet body, drawer devices, containing cavities, gravity blocks and an anti-seismic device; the drawer devices are evenly installed on the cabinet body; the containing cavities are symmetrically formed in the left side and the right side of the lower end of the cabinet body; the gravity blocks are placed in the containing cavities; the anti-seismic device is installed in the middle of the lower end of the cabinet body. The internal structure of an existing cabinet body is fixed, when box bodies containing electrical components need to be arranged in the cabinet body, the box bodies containing the electrical components can only be placed according to the structure in the cabinet body, and as a result, gaps between the box bodies which are adjacently arranged along a vertical direction tend to be large, the space utilization rate is low; an existing low-voltage switch cabinet does not have an anti-seismic function, when an earthquake occurs, the conditions that the cabinet body collapses and the box bodies internally provided with the elements deviate and misplace possibly occur, and the parts may be damaged due to the fact that sufficient processing time can be hardly give to workers due to instant collapse. With the low-voltage switch cabinet of the invention adopted, the above problems can be solved.

Owner:安晓明

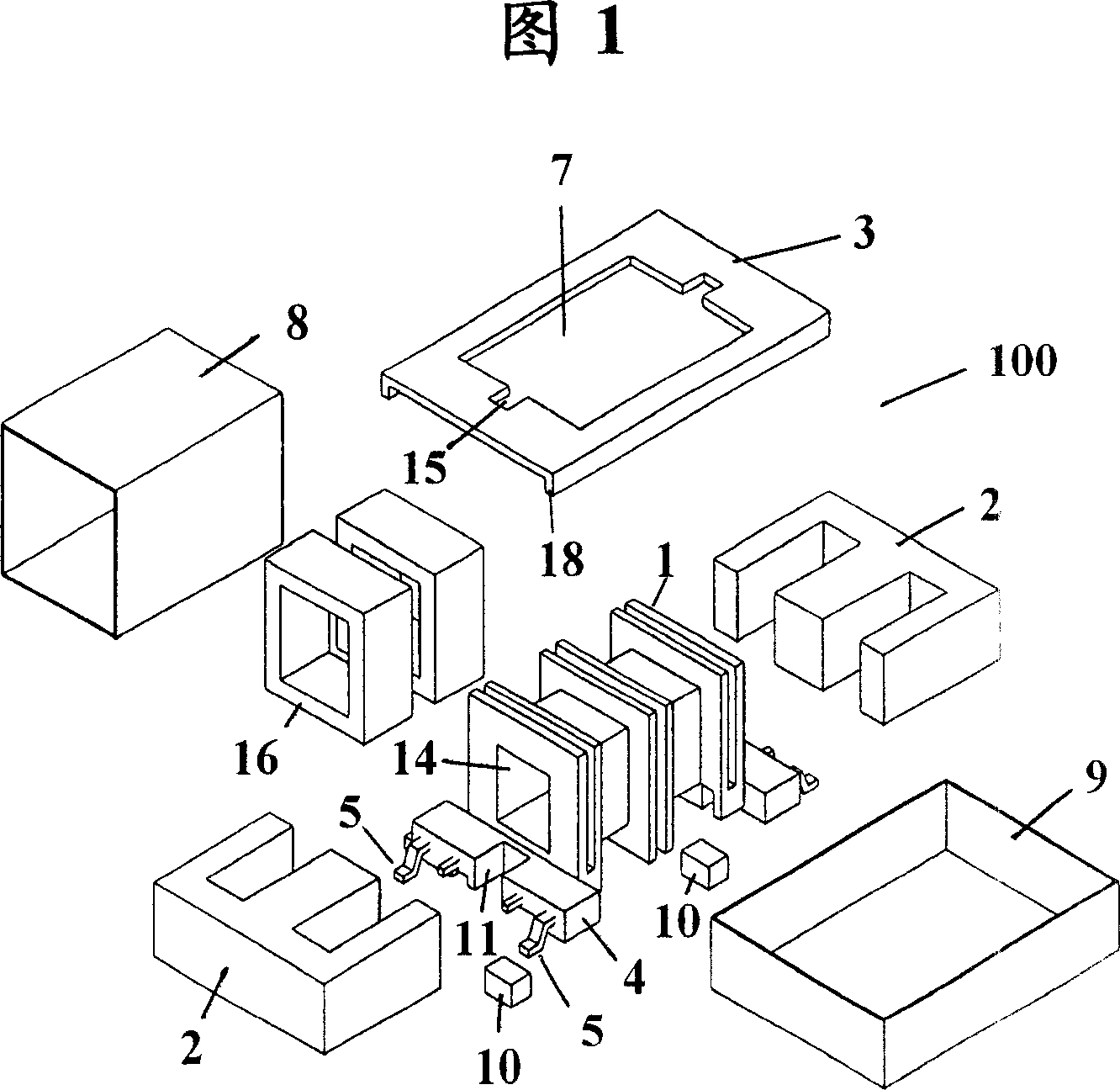

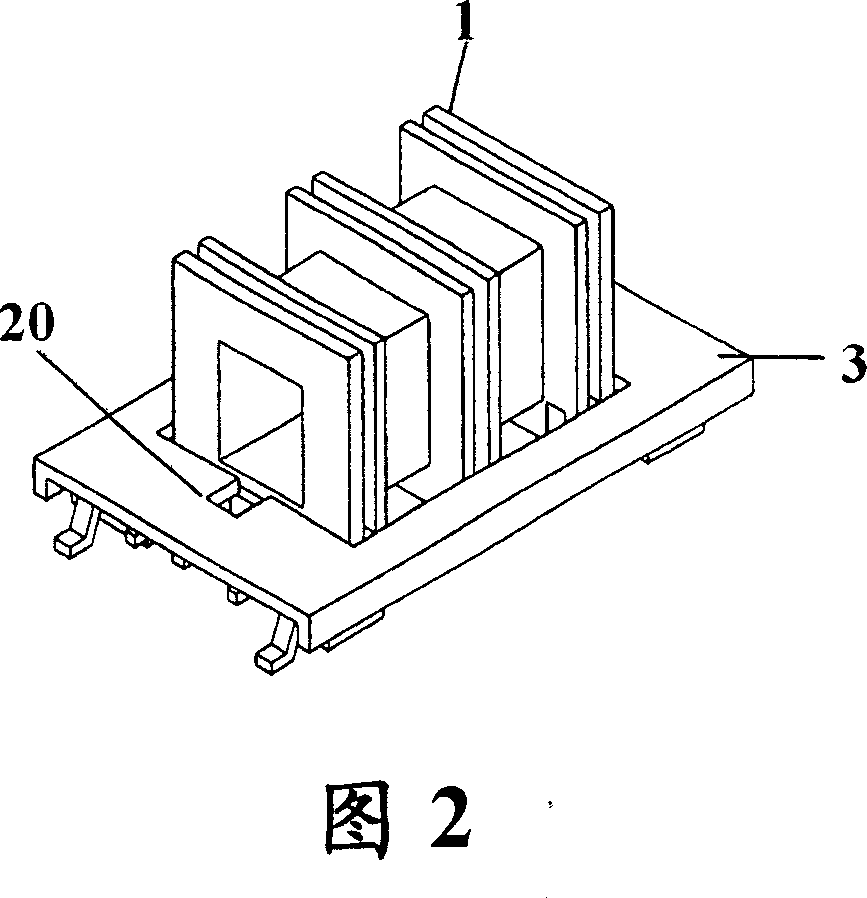

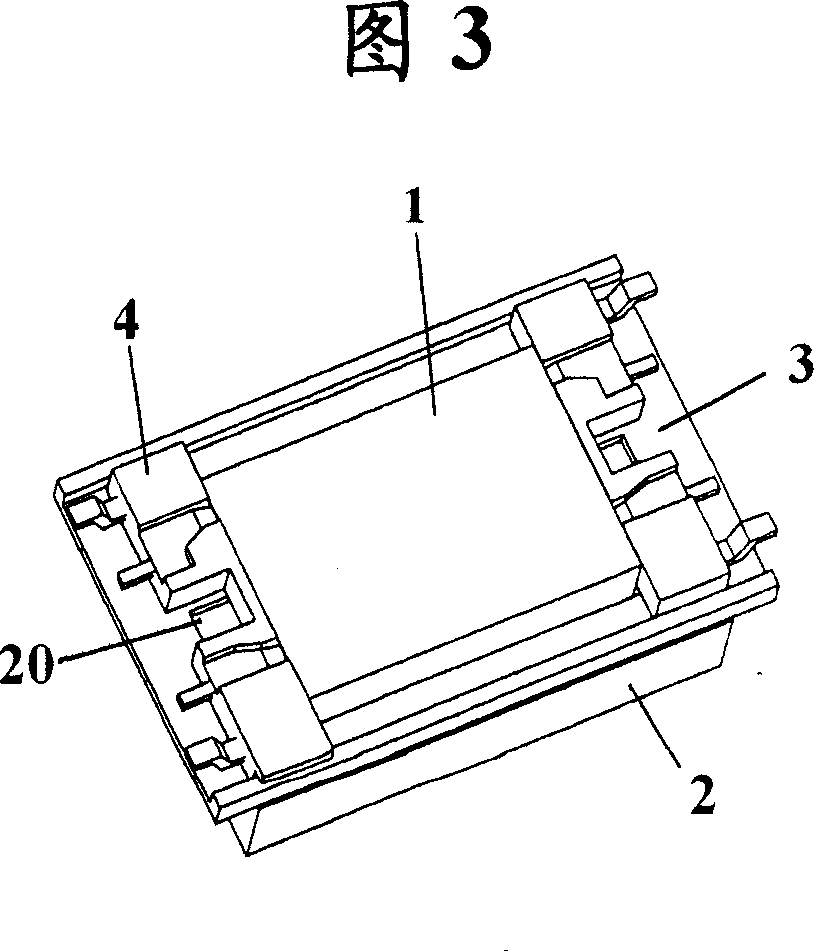

Magnetic element

InactiveCN1967746AIncrease insulation distanceGuaranteed miniaturizationTransformers/inductances coils/windings/connectionsFixed transformersEngineeringConductor Coil

The invention relates to a magnetic element, which comprises winding support with terminal base; winding coiled on the winding support; insulated baffle plate with hollow open to cover the base via the winding support; and the magnetic corn inserted into the winding support, wherein said base has the first positioning part; the baffle plate has second positioning part; the first and second positioning part can form adhesive stuff part through to the magnetic corn via mounting winding support, magnetic corn and insulated baffle plate together; therefore, it only needs to fill stuff into stuff part, to fix winding support, magnetic corn and baffle plate together. The invention can reduce cost and simplify process.

Owner:SUMIDA ELECTRIC H K COMPANY

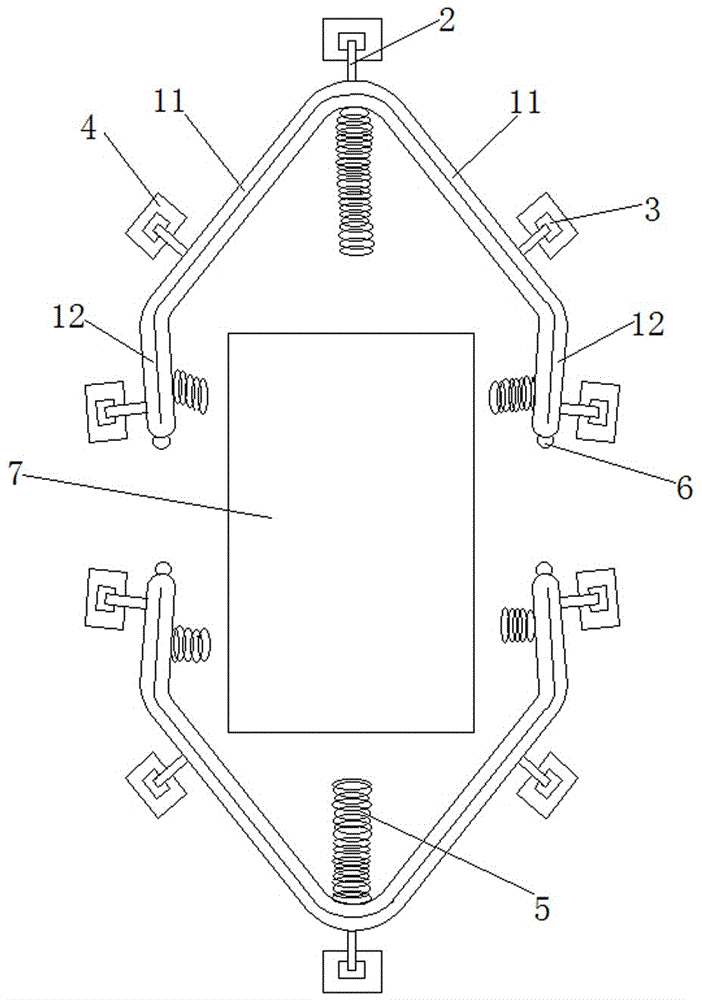

Liftable and lowerable bridge pier anti-collision protection devices

InactiveCN105821807APlay a stabilizing roleReduced Possibility of DisplacementClimate change adaptationShipping equipmentWater flowStops device

The invention discloses liftable and lowerable bridge pier anti-collision protection devices. The liftable and lowerable bridge pier anti-collision protection devices comprise protection barriers, first protection barrier arms, second protection barrier arms, pulling ropes, lock-up retractors, stopping devices, stopping rings, friction plates, counter-weights, springs, inverted-T-shaped pulling rings and a bridge pier. The protection devices provided by the invention have the beneficial effects that the protection devices are arranged around the bridge pier and the inverted-T-shaped pulling rings of one protection device are connected with the inverted-T-shaped pulling rings of the other protection device by ropes, so that the bridge pier is surrounded with the protection devices; the protection barriers are of a hollow interior and rubber sealed structure to float on the water, so that the protection devices are subjected to certain steadiness action, and the possibility that the protection devices are displaced under the action of water flow or crash of a ship is reduced.

Owner:CHENGDU XINZHU ZHUANBO ENVIRONMENTAL PROTECTION TECH

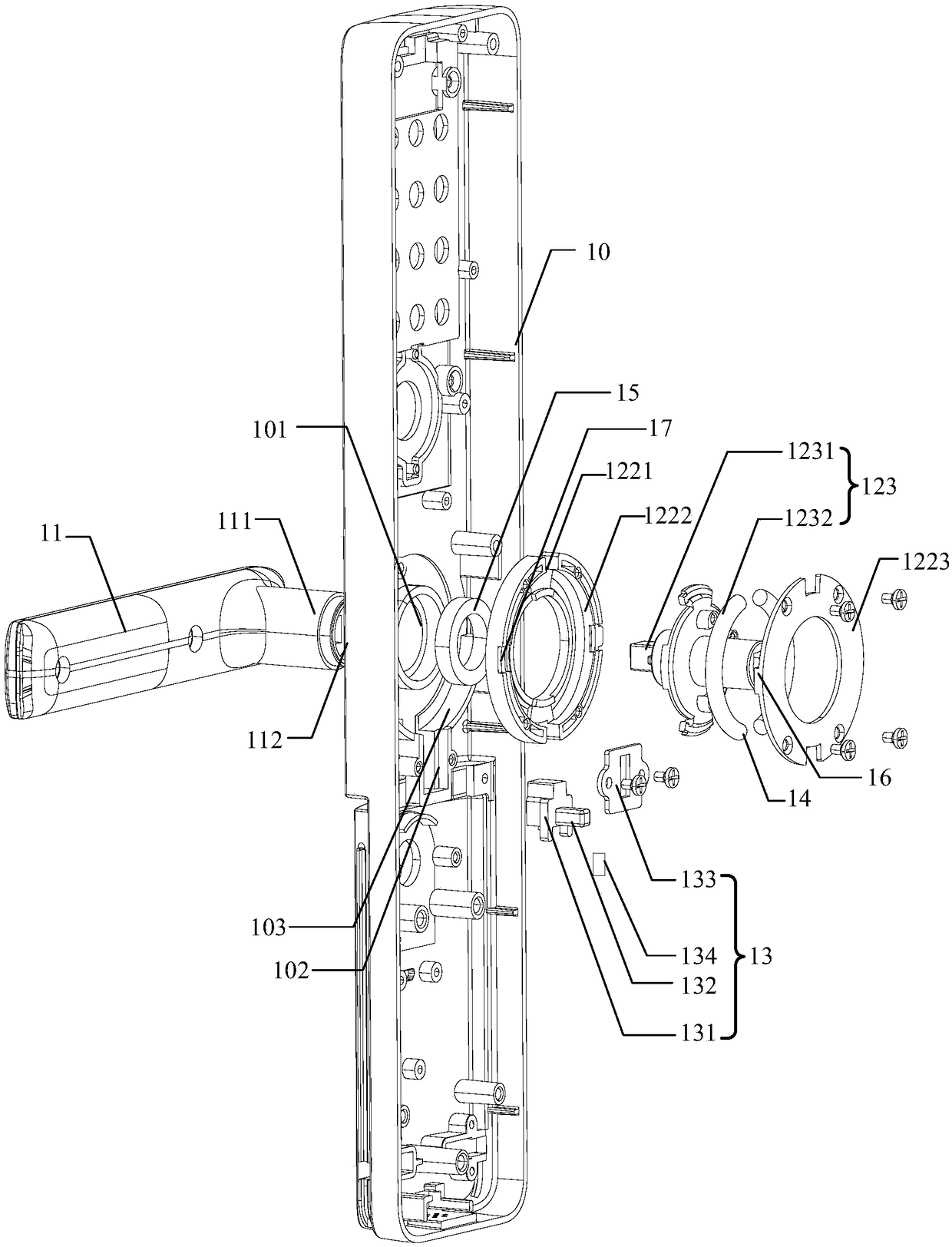

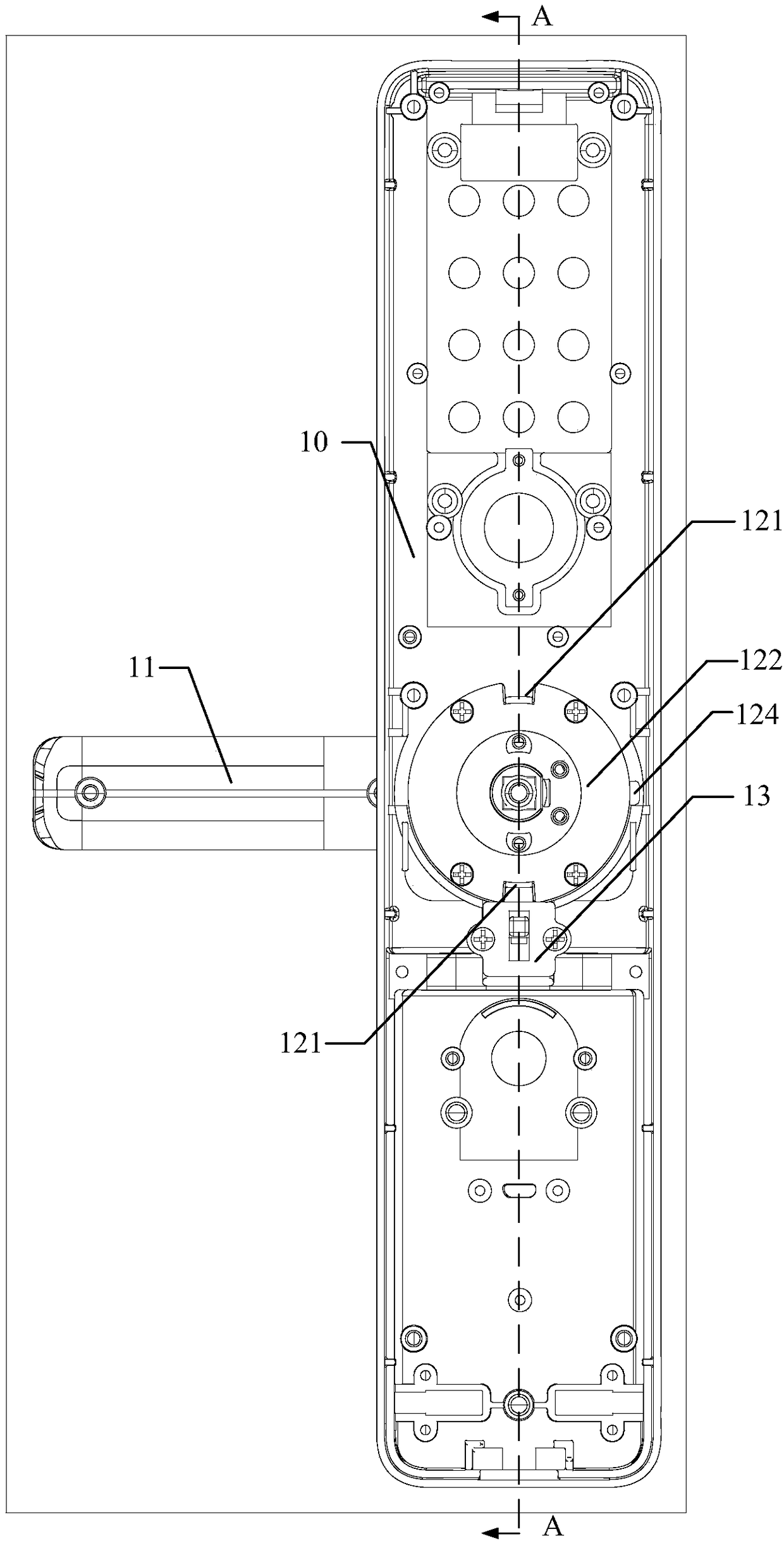

Door lock

PendingCN108468484AAchieve regulationRealize commutationBuilding locksHandle fastenersElectrical and Electronics engineeringSteering system

The invention provides a door lock which comprises a door lock panel, a handle, a steering assembly and a positioning block. A through hole is formed in the door lock panel, the handle is arranged onone side of the door lock panel, a connection shaft of the handle is sleeved with the through hole, the steering assembly is opposite to the handle and arranged on the other side of the door lock panel, the steering assembly is in transmission connection with the handle, the steering assembly is provided with multiple positioning concave holes, the positioning block and the steering assembly are arranged on the same side of the door lock panel, the positioning block is matched with the positioning concave holes, and therefore the rotation of the steering assembly is limited when the positioning block stretches into the positioning concave holes. According to the door lock in the scheme, by means of the cooperation of the positioning concave holes and the positioning block, fixing of the steering assembly at multiple positions in the rotation circumferential direction of the handle is achieved, the rotating position of the handle can be adjusted by adjusting the positioning concave holes matched with the positioning block, steering of the handle is achieved, the handle can be installed without correcting forward and reverse directions, and reversing is convenient.

Owner:MIDEA INTELLIGENT LIGHTING & CONTROLS TECH CO LTD

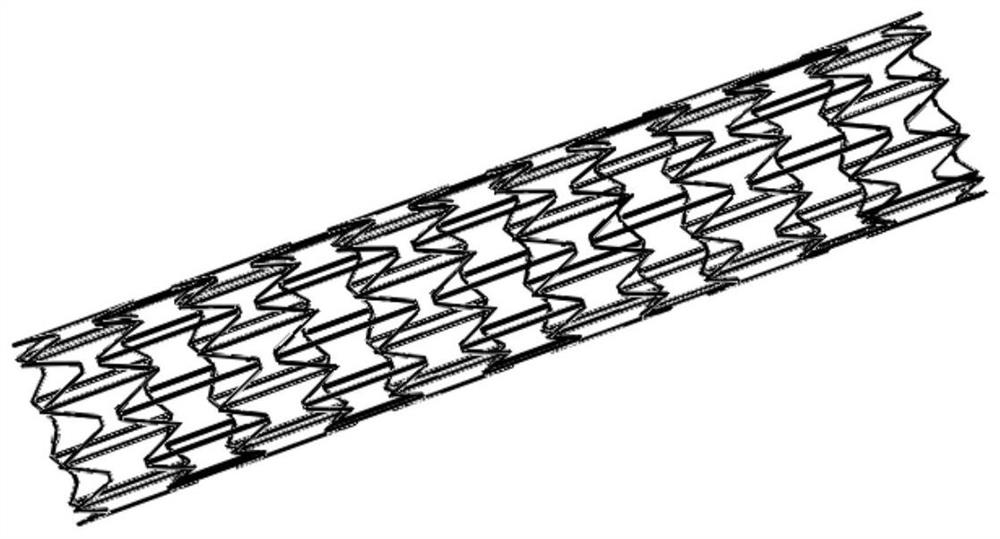

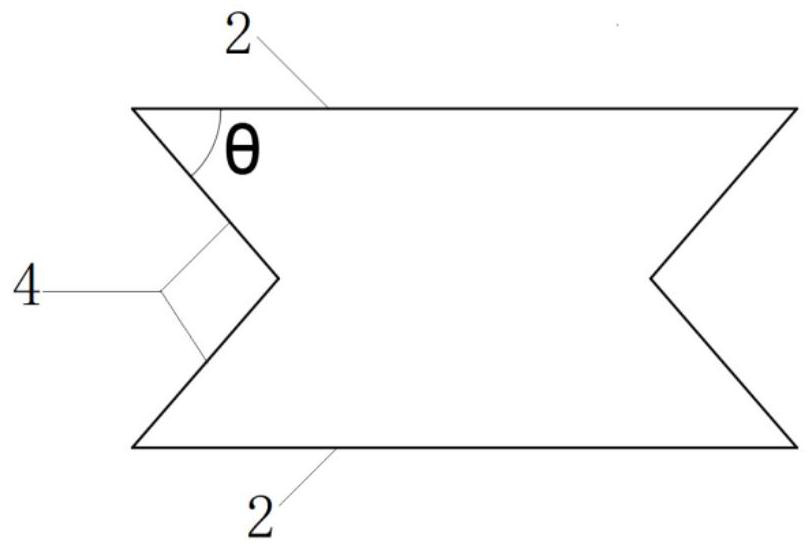

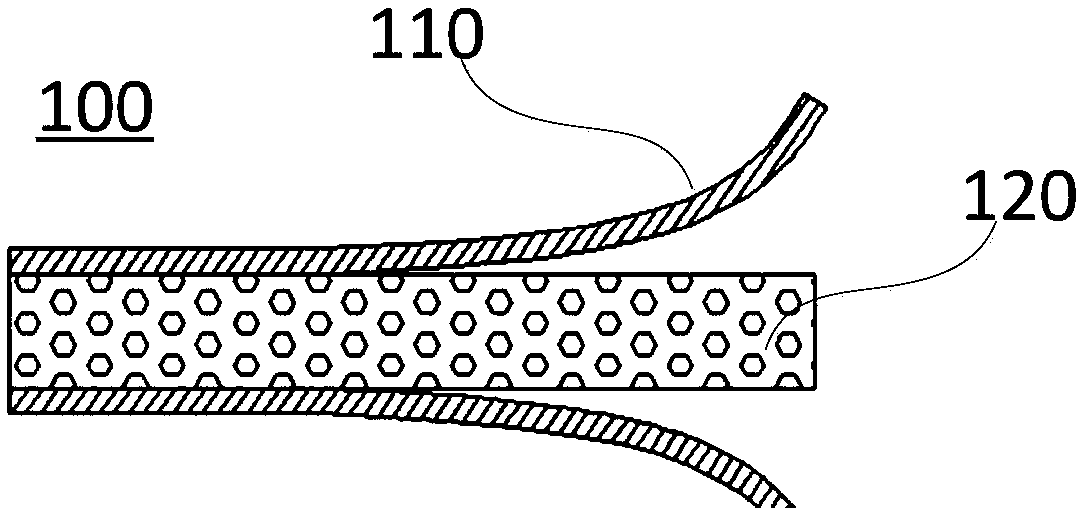

Stent suitable for urethral bent part

ActiveCN112107401AReduce problems such as restenosisEasy implantationStentsAdditive manufacturing apparatusUrethral stentsHuman body

The invention provides a stent suitable for a urethral bent part. A body of the urethral stent is of a tubular structure made of a degradable or non-degradable material; the tubular structure is in astraight tube state before being implanted; at least one part of the tubular structure is bent after being implanted into a human body; the tube wall of the tubular structure is formed by arranging and combining concave hexagonal structures; and, in the concave hexagon at the bent position after being implanted into the human body, the included angle theta formed by the straight edges and the inclined edges of the concave hexagons sequentially arranged from the bent outer side to the bent inner side is gradually increased. After the urethral stent in the invention is implanted into a urethralstenosis part, both the inner diameter and the length of the stent can be increased by means of balloon dilatation and the like; furthermore, the stent can be bent at the same time after being implanted so as to adapt to physiological bending of a urethral membrane part, a ball part and a pubis anterior bending part; and thus, the problems of intimal hyperplasia, stent restenosis and the like caused by urethral straightening due to overlarge rigidity of the stent are solved.

Owner:BEIHANG UNIV

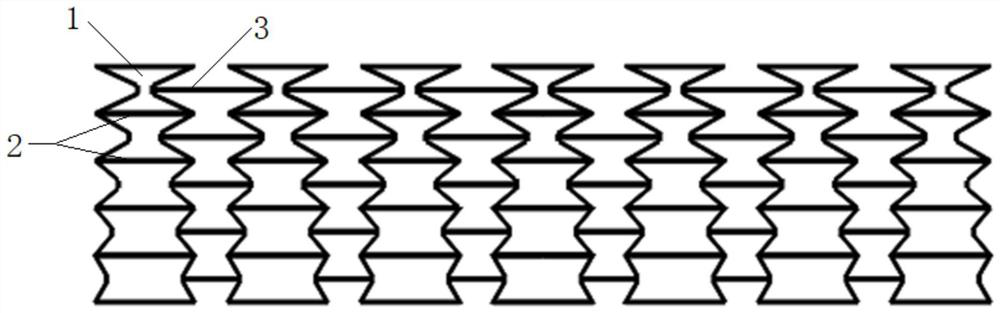

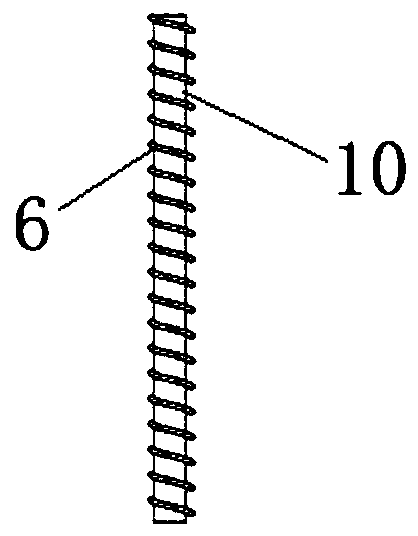

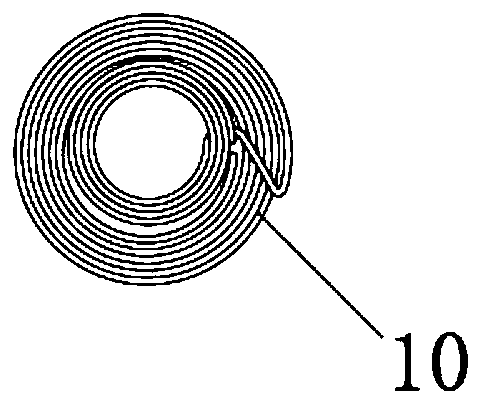

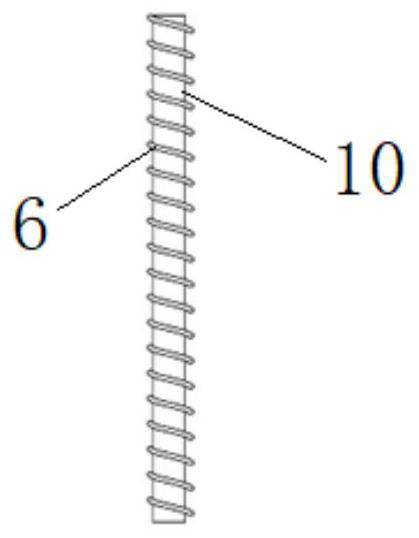

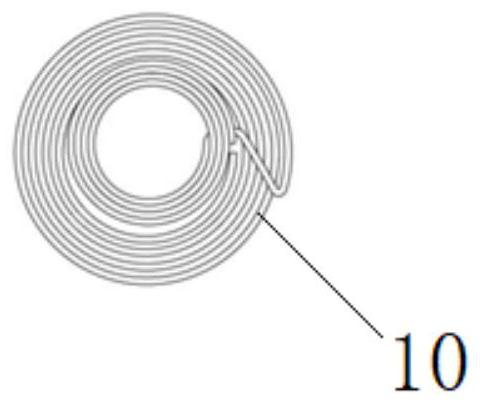

Urethral stent for non-invasive surgery and preparation method thereof

ActiveCN110974500AReduce the difficulty of surgeryImprove comfortStentsSurgeryUrethral stentsInvasive surgery

The invention provides a urethral stent for non-invasive surgery. The urethral stent comprises a main body structure made of a polydodecyl glyceride (PGD) material and a degradable alloy wire, whereinthe main body structure is in a thin strip shape at normal temperature and is converted into a spiral structure after being implanted into a human body; and the degradable alloy wire is coiled on theouter surface of the main body structure. The main body structure of the stent is made of polydodecyl glyceride, and the main body structure is in a slender strip shape at normal temperature, so thatthe main body structure is convenient to insert into a urethra in an operation process; and the polydodecyl glyceride has a memory effect at body temperature, can deform after being implanted into ahuman body to become a spiral structure, and plays a role in expanding the urethra, so that operation difficulty is obviously reduced, and comfort of the implanted stent is improved. According to theinvention, the degradable alloy wire rod is coiled on the main body structure, so that the stent structure can be supported, and meanwhile, the stent structure can be deformed together with the PGD material to play a role in expanding the urethra.

Owner:BEIHANG UNIV

Gasket for display panel and package box

InactiveCN109649839AReduce stressAvoid warpingContainers to prevent mechanical damageInternal fittingsEngineeringDensity difference

The invention provides a gasket for a package box of a display panel. The gasket is rectangular and comprises a gasket body and a protecting film layer covering the surface of the gasket body. At least one edge of all edges of the gasket is provided with trimming grooves distributed uniformly. The trimming grooves penetrate through the gasket body and the protecting film layer. One end of each trimming groove is opened and penetrates through the edge, where the trimming grooves are located, of the gasket, and the other end of each trimming groove extends into the gasket and is provided with ananti-tear hole communicating the corresponding trimming groove. According to the gasket, the trimming grooves are formed in the edge of the gasket, stress generated by the density difference betweenthe gasket body and the gasket film layer on the periphery of the gasket is effectively eliminated, warpage deformation of the gasket is avoided, and the possibility that during production, the gasketis blown away by the wind due to warpage is reduced.

Owner:HUIZHOU CHINA STAR OPTOELECTRONICS TECHNOLOGY CO LTD

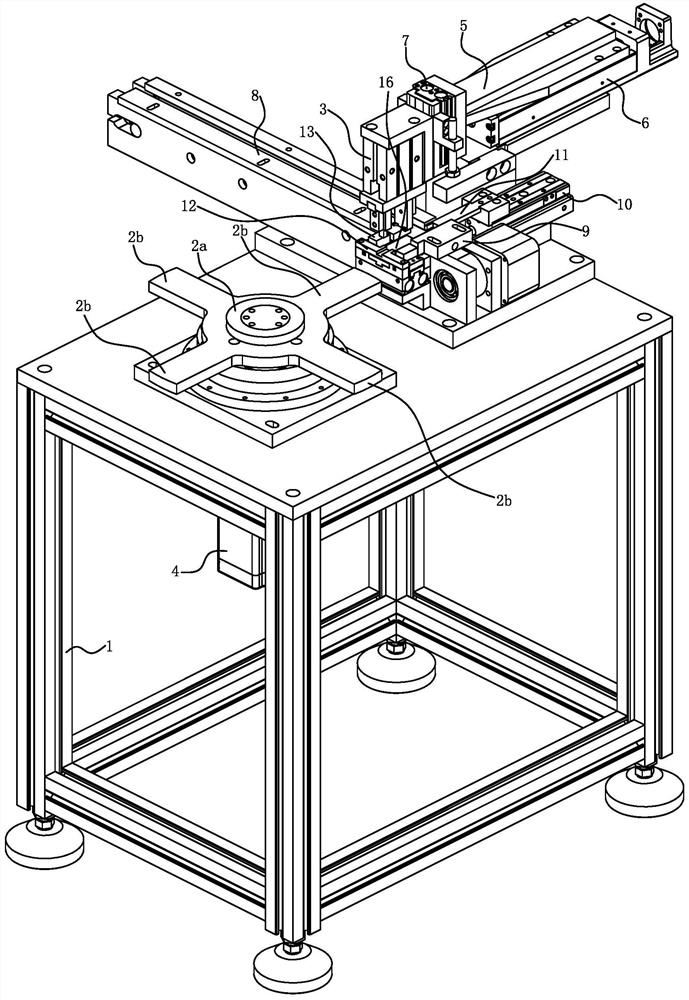

Automatic grinding disc cutter head placement device

PendingCN111889843ASame radial positionHorizontal travel is the sameSoldering auxillary devicesTool bitCircular disc

The invention provides an automatic grinding disc cutter head placement device, and belongs to the technical field of machine tools. The automatic grinding disc cutter head placement device solves theproblems that in existing manual grinding disc cutter head placement manners, the labor intensity is large, and production efficiency is low. The automatic grinding disc cutter head placement devicecomprises a rack, a grinding disc locating tool and a cutter head clamping assembly. A rotating drive assembly connected with the grinding disc locating tool is mounted on the rack. When a disc body of a grinding disc is mounted on the grinding disc locating tool, the center line of the disc body is vertically arranged, and the disc body can rotate around the center line through the rotating driveassembly. A cutter head locating seat is fixed to the rack and is located on one side of the grinding disc locating tool. A mechanical arm assembly connected with the cutter head clamping assembly ismounted on the rack. The mechanical arm assembly can drive the cutter head clamping assembly to do ascending and ascending moving and to horizontally move in the direction of the radial line of the disc body mounted on the grinding disc locating tool. The automatic grinding disc cutter head placement device has the advantages of being high in universality, simple in structure and low in manufacturing cost.

Owner:台州市圣西亚金刚石设备有限公司

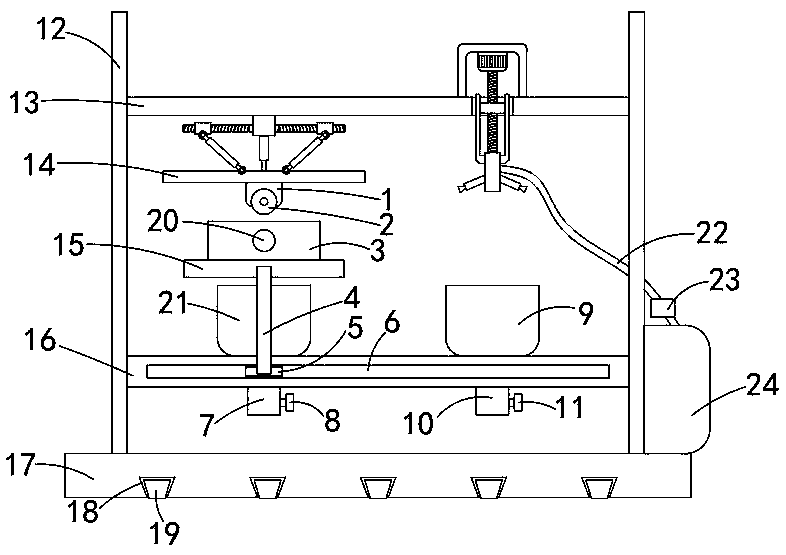

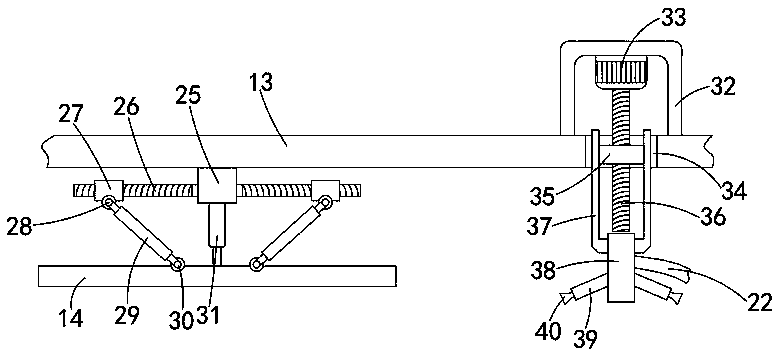

Convenient-to-clean splashing-prevention bone sawing device for orthopedics

The invention discloses a convenient-to-clean splashing-prevention bone sawing device for orthopedics, which comprises a base, two vertical plates are fixedly installed on the upper surface of the base symmetrically, Between that two vertical plate, a horizontal plate and a support plate are arranged from top to bottom in sequence, the left and right ends of the horizontal plate and the support plate are fixedly connected with two vertical plates, a first waste liquid barrel and a second waste liquid barrel are sequentially arranged on the upper surface of the support plate from the left to the right, The front and rear surfaces of the support plate are symmetrically provided with sliding grooves, sliding blocks are respectively slidably connected in the two sliding grooves, connecting plates are fixedly connected on the side walls of the two sliding blocks, a bottom plate is arranged between the two connecting plates, and the bottom plate is positioned directly above the first waste liquid barrel. The invention avoids the splash phenomenon of blood and flesh caused in the operation process by forming the encirclement between the lifting plate and the storage chamber, and the storage chamber can be cleaned thoroughly by the filtering action of the flushing mechanism and the filter screen.

Owner:孙胜房

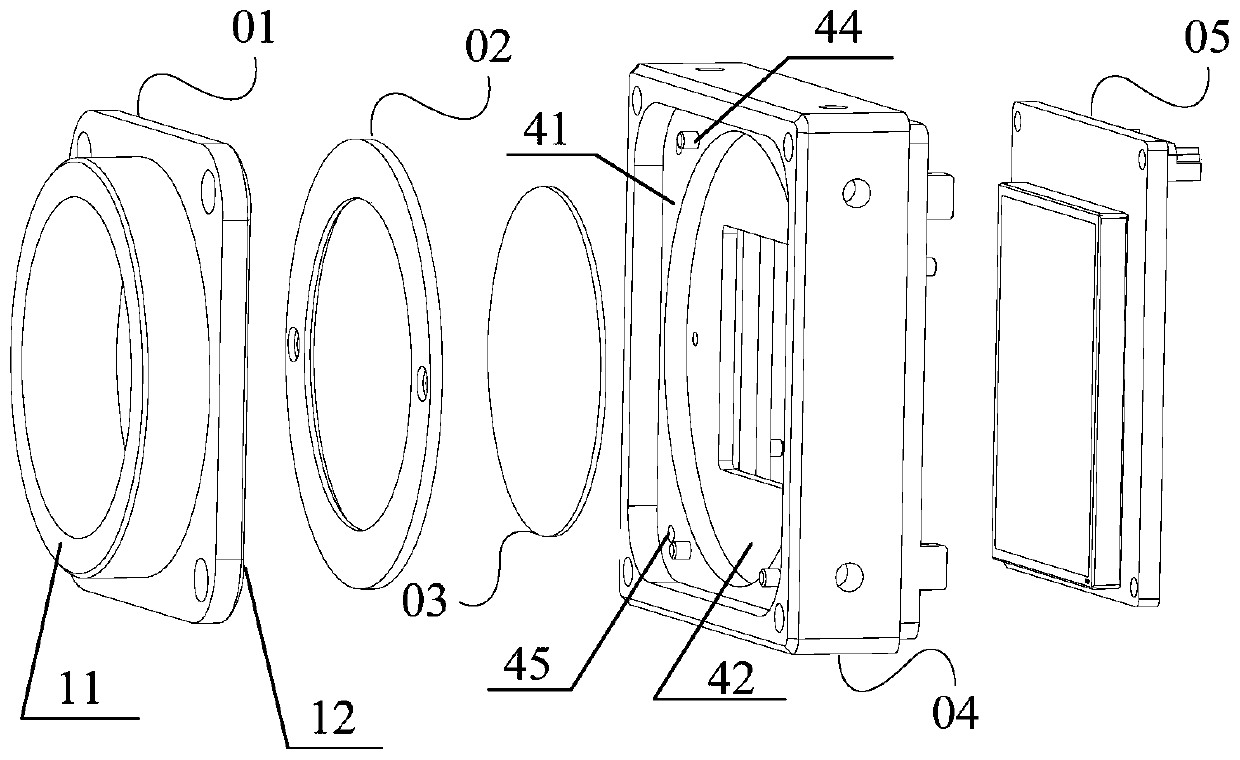

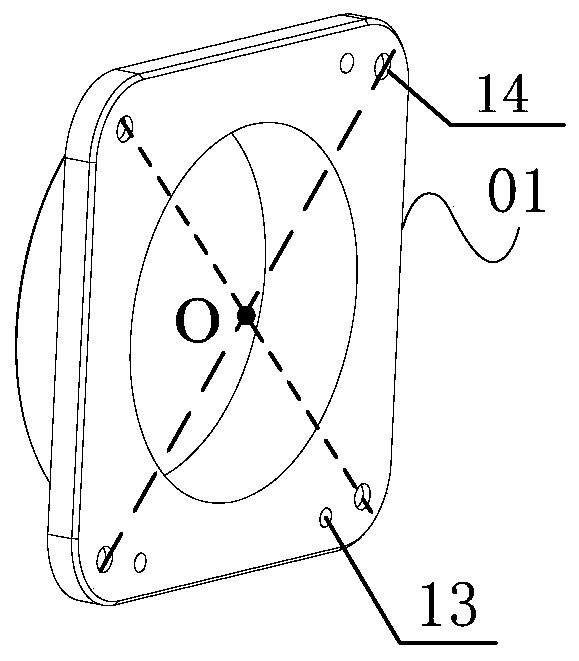

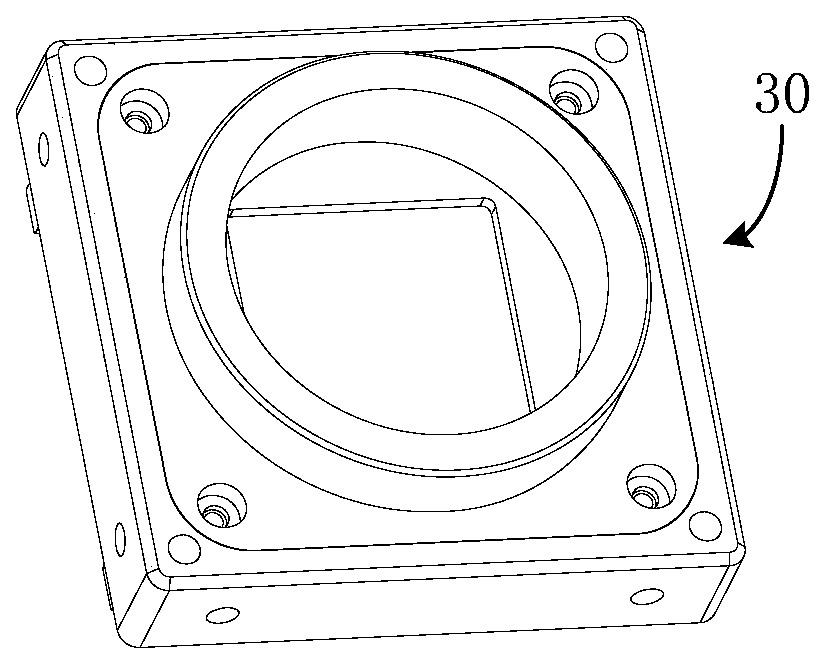

A high parallelism installation method and camera of a large target surface sensor

ActiveCN109167897BImprove installation accuracyImprove parallelismTelevision system detailsColor television detailsEngineeringMechanical engineering

The application discloses a high parallelism installation method of a large target surface sensor and a camera. The installation method includes: step 1, fixing the front shell and the lens flange on the processing platform respectively, Parallelism processing, wherein, the processing plane of the front shell includes the third plane and the fourth plane, and the processing plane of the lens flange includes the first plane and the second plane; step 2, according to the first positioning hole and the first positioning post, the The processed front shell and the processed lens flange are assembled, which is recorded as an assembly; step 3, based on the first plane of the lens flange, fix the assembly on the processing platform; step 4, the front shell The sensor mounting surface is processed for parallelism, and the processed sensor mounting surface is parallel to the first plane of the lens flange. Through the technical solution in this application, it is beneficial to reduce the cumulative error of the parallelism between the sensor assembly surface and the lens, thereby improving the imaging effect of the image sensor.

Owner:BEIJING DAHENG IMAGE VISION +1

A urethral stent for non-invasive surgery and its preparation method

The present invention provides a urethral stent for non-invasive surgery. The urethral stent includes: a main structure made of polyglyceryl dodecanoate (PGD), the main structure is in the shape of a long and thin strip at normal temperature, After being implanted in the human body, it transforms into a helical structure; the degradable alloy wire is coiled on the outer surface of the main structure. The main structure of the stent in the present invention is made of polylaurin, and the main structure is in the shape of a slender strip at room temperature, which is convenient to be placed in the urethra during surgery. The polylaurin has a memory effect at body temperature, After it is implanted into the human body, it can deform and become a helical structure, which can expand the urethra, thereby significantly reducing the difficulty of the operation and improving the comfort of the stent after implantation. In the present invention, the degradable alloy wire is coiled around the main structure, which can deform together with the PGD material while providing support for the stent structure, so as to expand the urethra.

Owner:BEIHANG UNIV

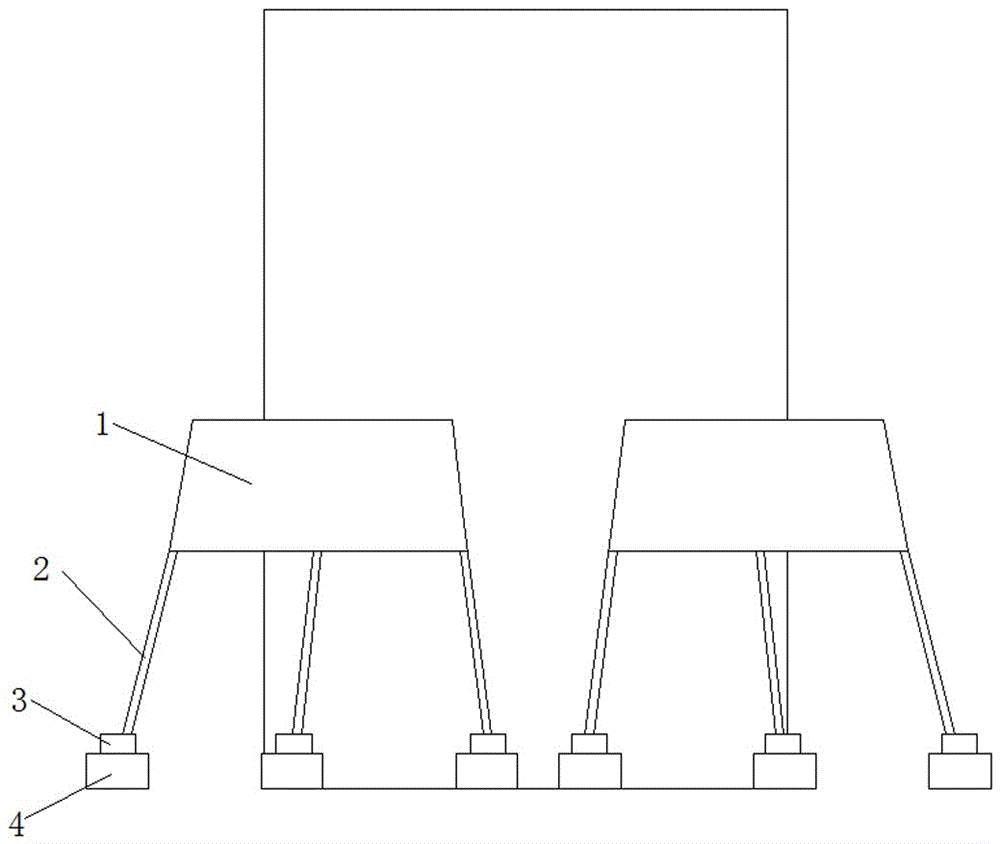

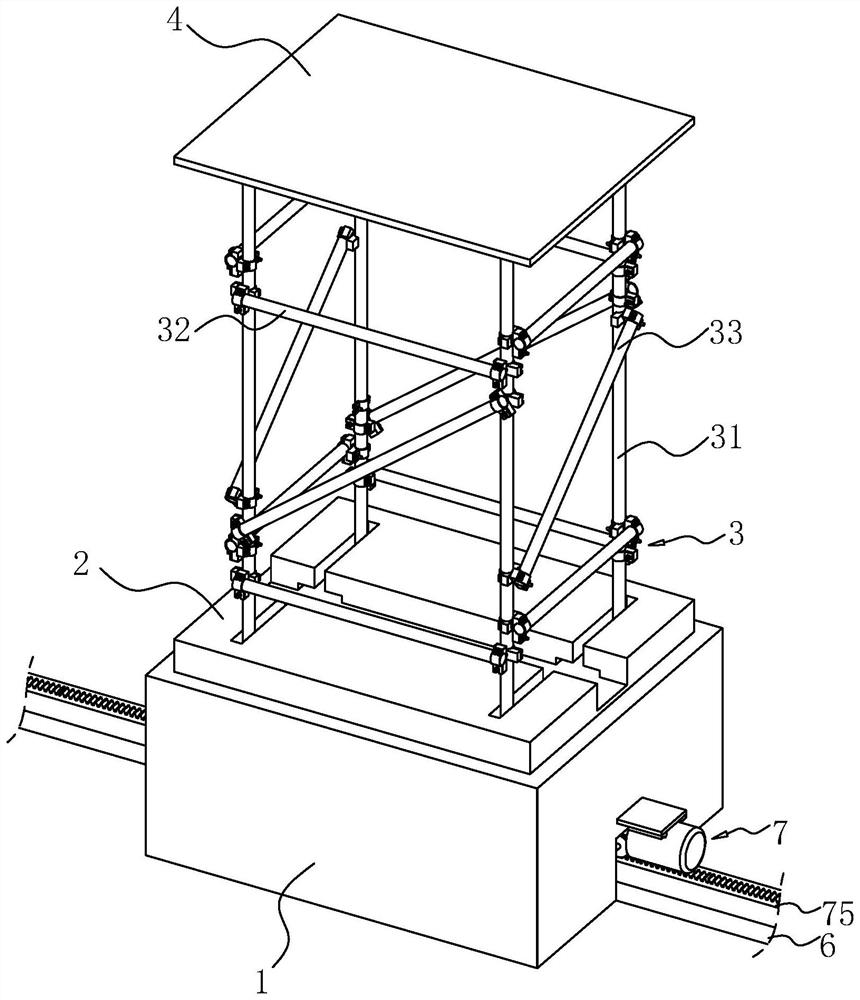

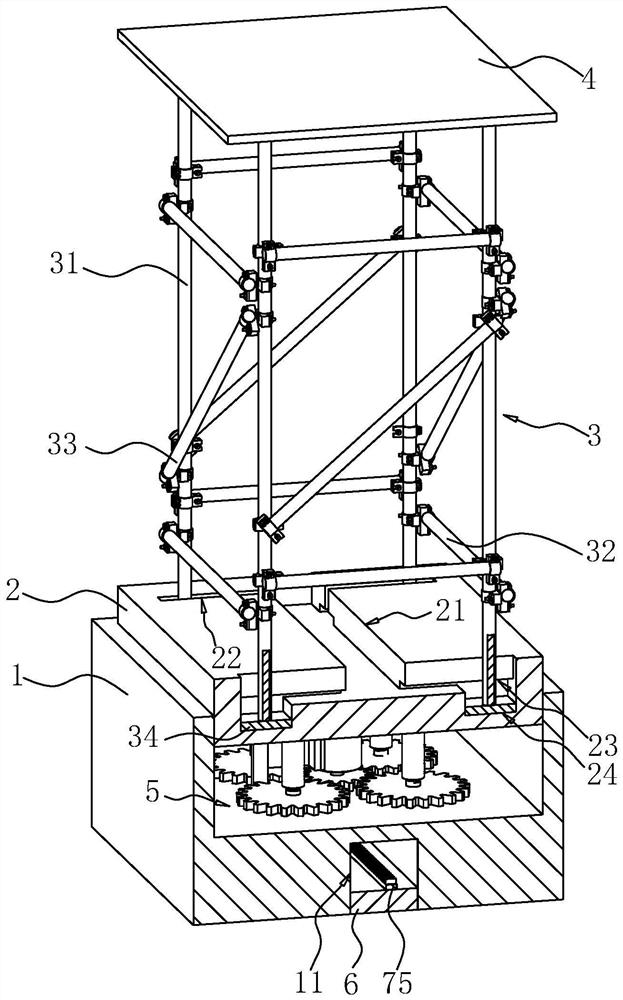

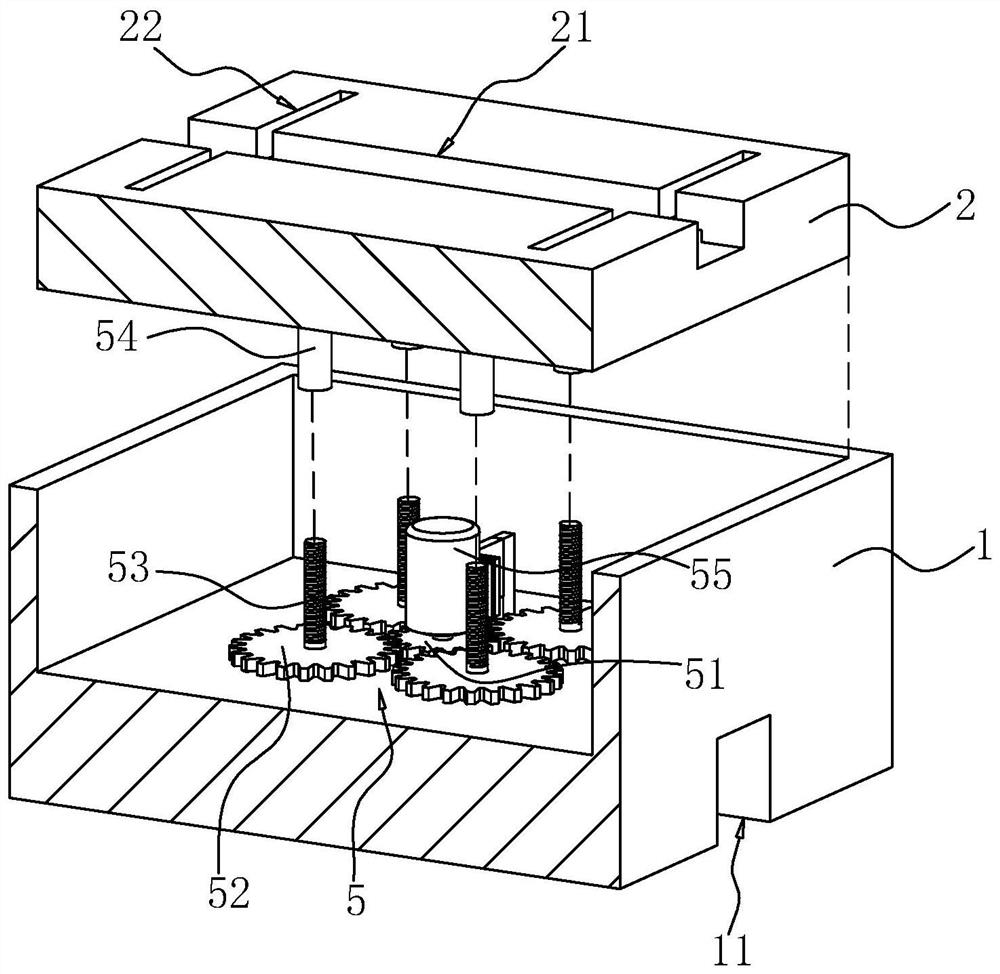

Cast-in-place bridge formwork support system device and bridge cast-in-place rapid construction method

PendingCN114108468AEasy transferReduce the situation of demolition and decompositionBridge erection/assemblySupporting systemGear wheel

The invention relates to a cast-in-place bridge formwork support system device, and relates to the field of constructional engineering.The formwork support system comprises a plurality of formwork supports and a plurality of sliding box bodies, a bayonet socket is slidably inserted into each sliding box body, the formwork supports are installed on the bayonet sockets, formworks are installed on the formwork supports, a pouring mold is built on the formworks, and the formwork supports are connected with the sliding box bodies through bolts. A plurality of rails are laid on the ground of the bridge construction position, a mounting groove is formed in the bottom face of the sliding box body, the rail corresponding to the sliding box body is inserted into the mounting groove, a worm is rotationally connected into the mounting groove, a worm wheel meshed with the worm is rotationally connected into the mounting groove, and a sliding block is arranged in the worm wheel. A rotating shaft of the worm gear is fixedly connected with an intermediate gear, the upper surface of the track is fixedly connected with a rack, the intermediate gear is meshed with the rack, and the sliding box body is fixedly connected with a transmission motor for driving the worm to rotate. The construction method has the effect of improving the construction efficiency.

Owner:SHANDONG LUQIAO CONSTR

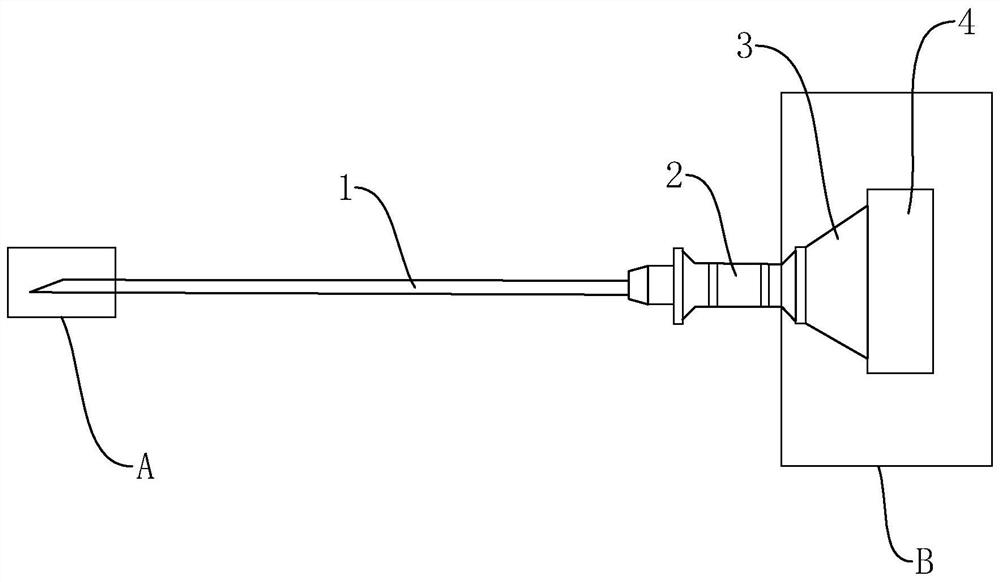

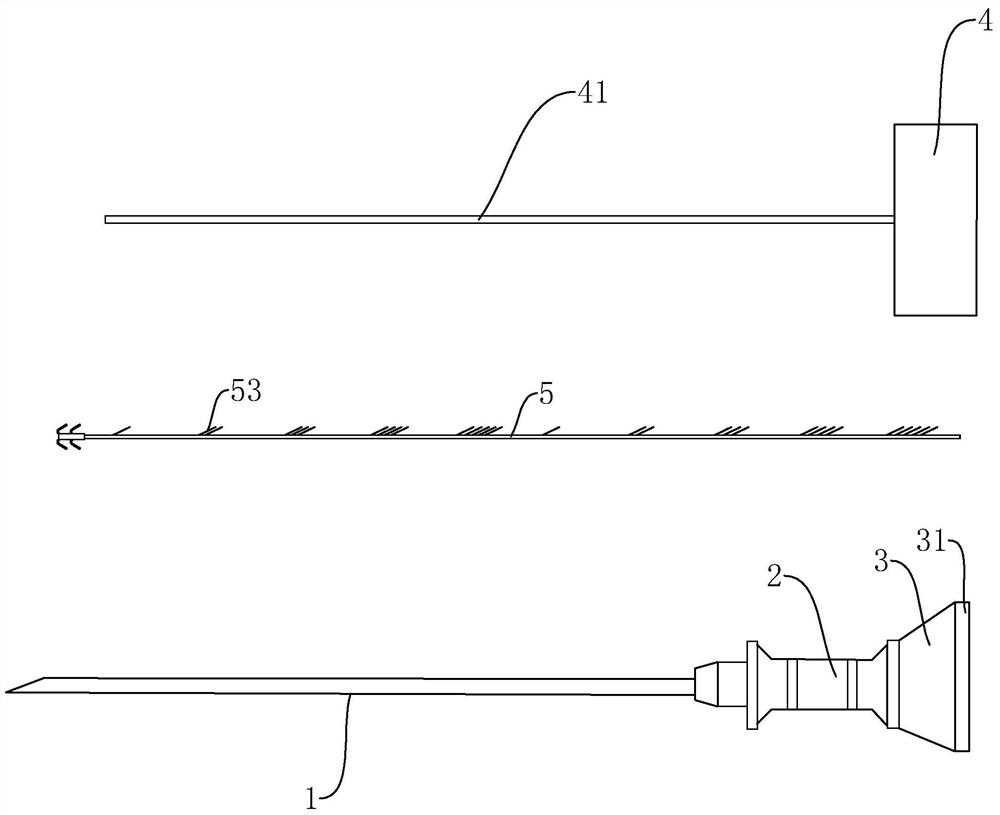

Pulmonary nodule positioning puncture needle

PendingCN113648074AImprove gripReduced Possibility of DisplacementSurgeryDiagnostic markersPulmonary noduleAnatomy

The invention discloses a pulmonary nodule positioning puncture needle, relates to the technical field of medical puncture positioning instruments, and aims to solve the problems that the depth of a focus is judged through color block distribution on a positioning line, the judgment precision is low, hands are not easy to master, and a positioning mark moves. According to the technical scheme, at least one set of markers are distributed on a positioning line in the axial direction of the positioning line, each marker comprises a plurality of barb sets distributed in the axial direction of the positioning line, each barb set comprises barbs of different numbers, and openings of the barbs face the direction away from an anchoring positioning pin. In the same group of markers, the number of barbs contained in the barb groups in the direction far away from the anchoring positioning needle forms an arithmetic progression, and the first barbs, close to the anchoring positioning needle, in each barb group are uniformly distributed on the positioning line. The depth of the focus can be judged by simply counting the number of the barbs, the operation is fast, and the accuracy is guaranteed due to the anchoring effect of the barbs on the positioning line.

Owner:南京普立蒙医疗科技有限公司

Rotary drum washing control method of drum washing machine

ActiveCN105088645BReduced Possibility of DisplacementImprove stabilityControl devices for washing apparatusTextiles and paperDynamic balanceProcess engineering

The present invention discloses a method of controlling a spin washing tub of a drum washing machine, the control method comprising the steps of: S1, magnitude of the load detecting the washing tub and weighed to determine the load size based on the gear; S2, upon detection of the spin tub washing program starts Thereafter, the washing tub is detected fluctuates, and balancing the detection value of the washing tub; S3, if the fluctuation is qualified, it is determined whether the spin tub washing tub satisfies the condition according to the preset value and the balancing balancing weighed value corresponding to the gear , when the spin tub and the spin tub washing condition is satisfied is determined rhythm; and S4, the control drum washing machine to spin spin tub washing tub washing beats.The possibility of displacement when rotating the washing tub of the drum washing machine control method of the present invention, a spin tub washing can be reduced, improving stability of the washing tub rotation.

Owner:WUXI LITTLE SWAN ELECTRIC CO LTD

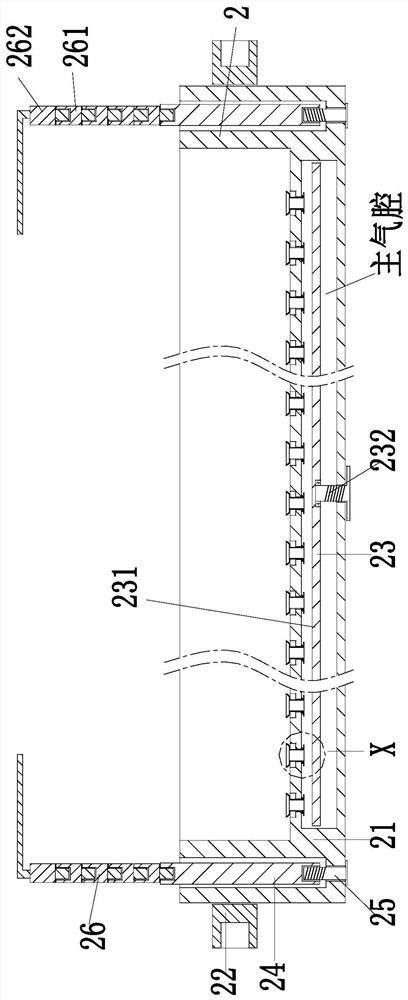

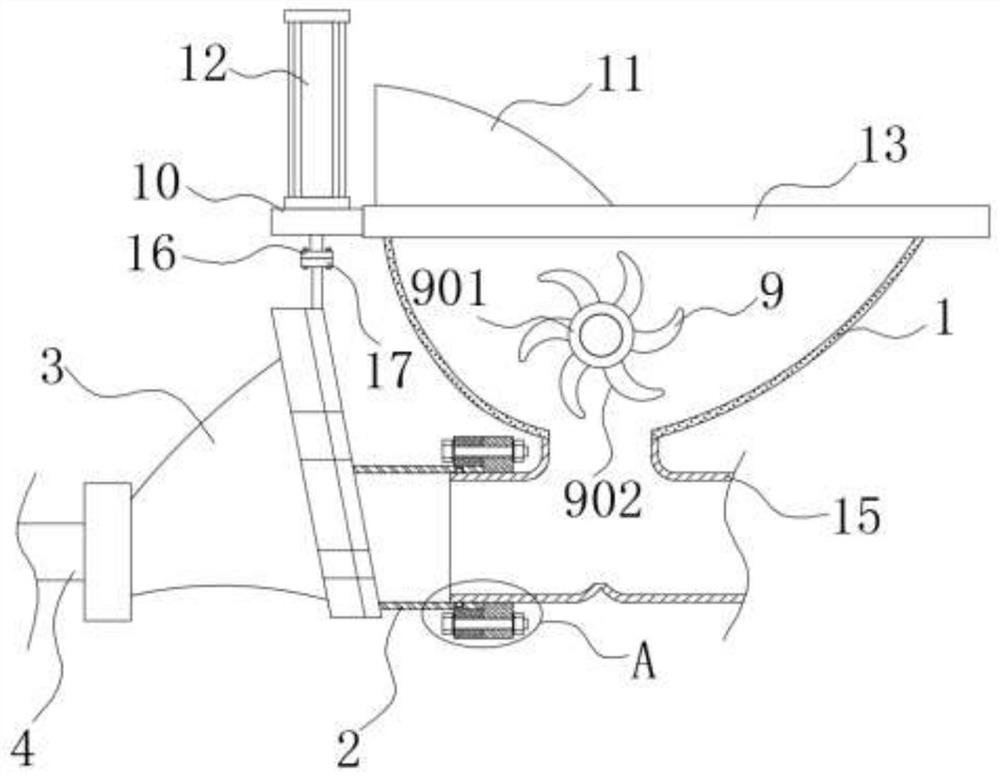

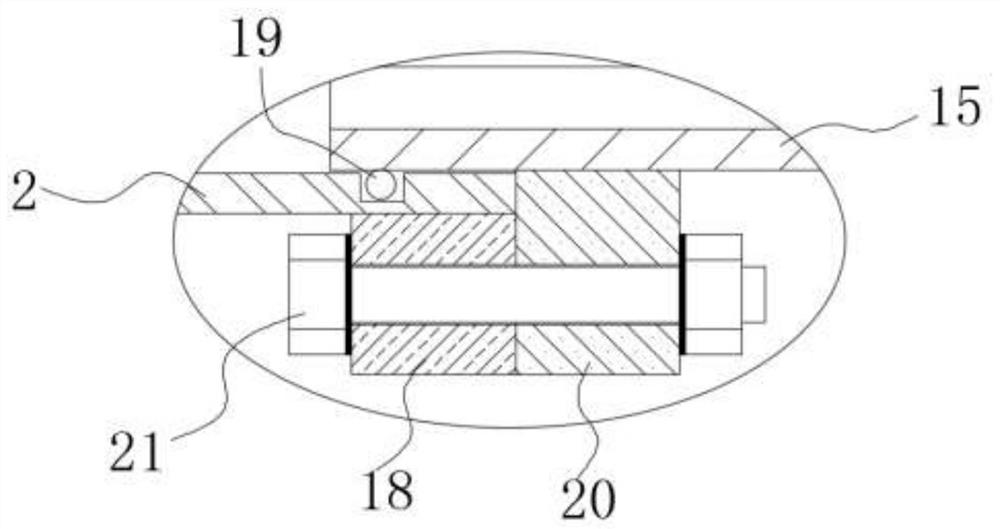

An installation structure of a concrete pumping mechanism hopper and a concrete pump truck

ActiveCN109989586BClosely connectedReduced Possibility of DisplacementBuilding material handlingStructural engineeringMechanical engineering

Owner:QINGDAO CO NELE GRP CO CO LTD

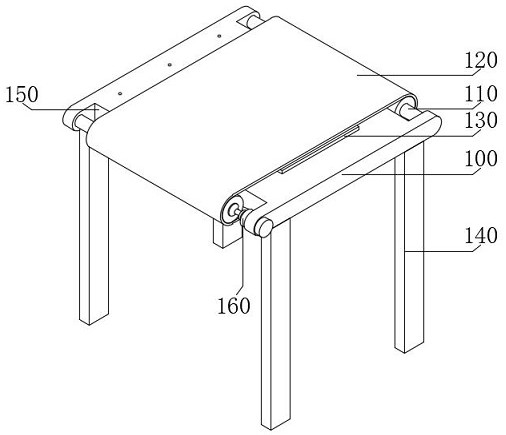

Jean fabric production device and process thereof

InactiveCN113930924AReduced Possibility of DisplacementLower the altitudeTextile treatment machine arrangementsTextile treatment carriersProcess engineeringIndustrial engineering

The embodiment of the invention provides a jean fabric production device and a process thereof, and relates to the technical field of fabric production. The jean fabric production device comprises a table plate and a dyeing device, wherein conveying rollers are rotationally mounted on the two sides of the table plate and are in transmission connection through a conveying belt; the conveying belt is arranged on the surface of the table plate in a sleeving mode; the dyeing device is fixed to the surface of the table plate; a supporting body is mounted on the upper end face of the table plate; and the upper end face of the supporting body is tightly attached to the inner wall of the conveying belt. According to the jean fabric production device and the process thereof provided by the invention, through cooperation of the conveying rollers and the conveying belt, a semi-finished jean fabric to be dyed can be conveyed, in the conveying process, the semi-finished jean fabric can be dyed through the dyeing device, and during dyeing, the supporting body on the surface of the table plate can support the semi-finished jean fabric by supporting the conveying belt, so that the possibility of shaking of the semi-finished jean fabric is reduced, and the dyeing stability is improved.

Owner:山东大统服饰有限责任公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com