Electronic tensile machine for testing performance of carbon fiber composite

A composite material and carbon fiber technology, which is applied in the direction of analyzing materials, applying stable tension/pressure to test the strength of materials, measuring devices, etc., can solve the problems of easy deviation, small contact area, and inaccurate detection results, etc., and achieve shortening Clamping process, the effect of increasing the contact area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] In order to have a further understanding and understanding of the structural features of the present invention and the achieved effects, the preferred embodiments and accompanying drawings are used for a detailed description, as follows:

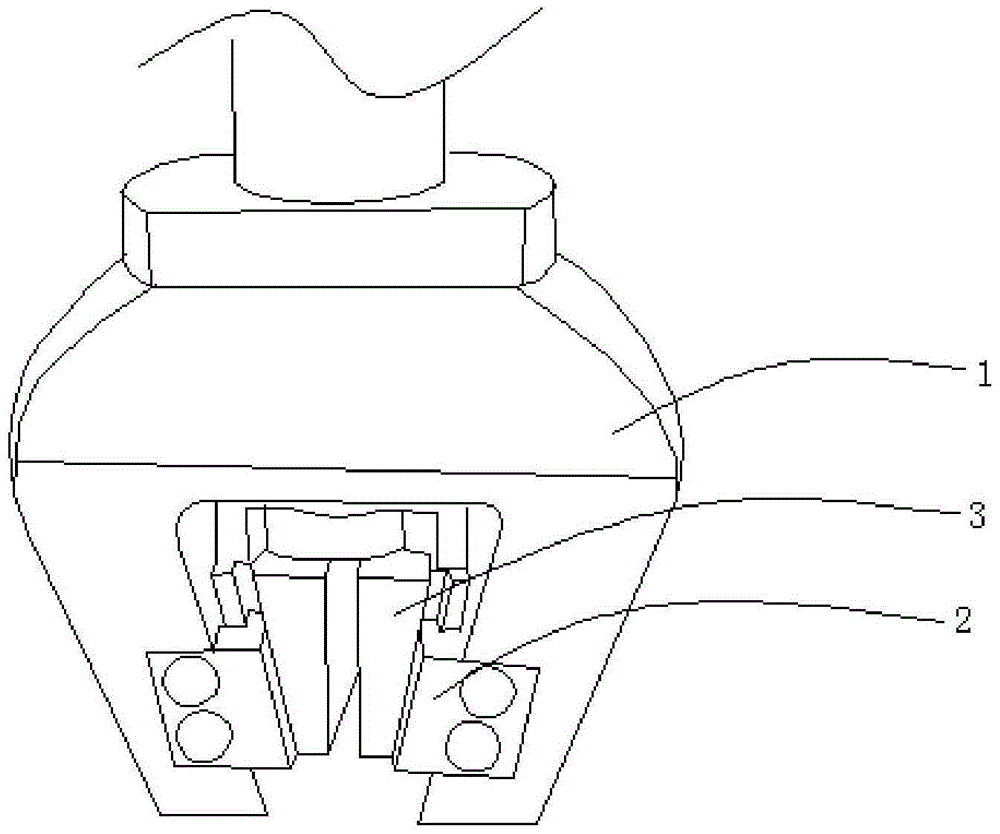

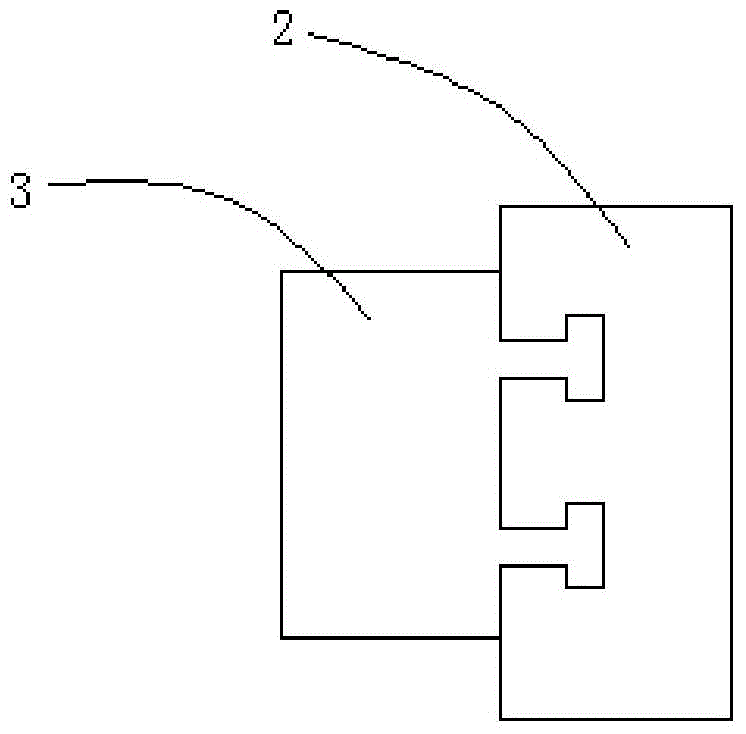

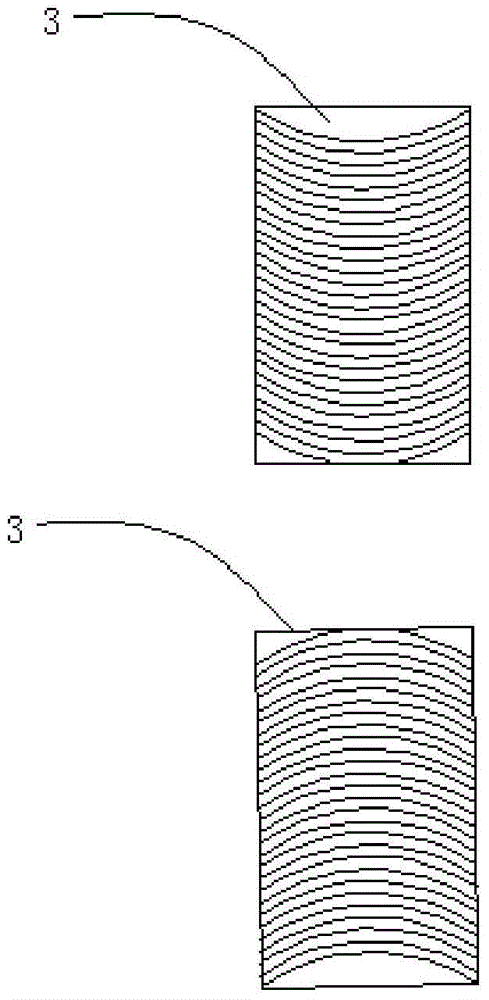

[0027] like figure 1 As shown, an electronic tensile machine for performance testing of carbon fiber composite materials, including a clamping mechanism. The clamping mechanism includes a base 1, a clamping body 2, and a wedge-shaped slider 3; the base 1 is U-shaped; the inner walls on both sides of the base 1 are respectively fixed with a clamping body 2 near the opening; two clamping bodies 2 The opposite surfaces of the two clamping bodies are all inclined surfaces; wedge-shaped sliders 3 are respectively fixed on the inclined surfaces of the two clamping bodies 2; the wedge-shaped sliders 3 slide up and down relative to the clamping body 2; The contact surface is a sliding surface, and the surface opposite to the sliding surface ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com