Anti-displacement breast implant forming method based on 3D printing and breast implant

A breast prosthesis, 3D printing technology, applied in other home appliances, household appliances, applications, etc., can solve problems such as breast prosthesis displacement, achieve the effect of solving rupture or penetration, reducing the possibility, and avoiding displacement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The specific implementation of the present application will be described in further detail below in conjunction with the accompanying drawings.

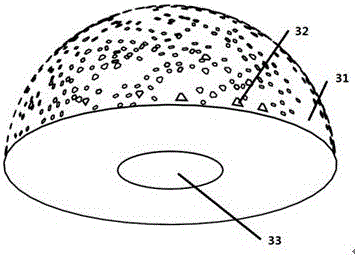

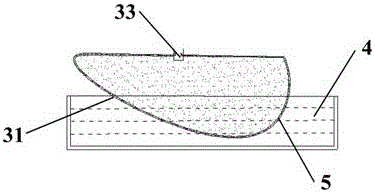

[0023] This application aims to provide a 3D printing-based anti-displacement breast prosthesis molding method and breast prosthesis. A plurality of grooves are designed on the surface of the breast prosthesis mold, and the breast prosthesis capsule prepared according to the breast prosthesis mold, The inner surface of the breast prosthesis has many protrusions. These protrusions can avoid the displacement of the filler inside the breast prosthesis during extrusion, and solve the technical problem of easy displacement of the existing breast prosthesis after extrusion.

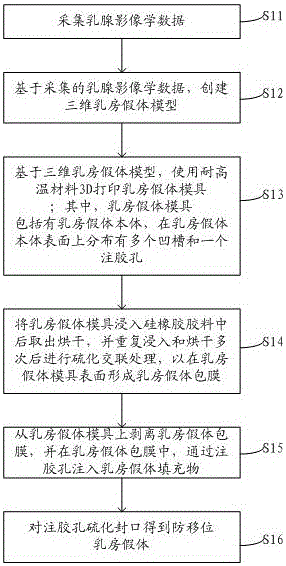

[0024] Such as figure 1 As shown, the 3D printing-based anti-displacement breast prosthesis molding method proposed in this application includes the following steps:

[0025] Step S11: Collect breast imaging data.

[0026] By collecting breast imaging data and obtainin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| depth | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com