Vacuum relay

A technology of vacuum relays and vacuum chambers, applied in the direction of relays, electromagnetic relays, detailed information of electromagnetic relays, etc., to achieve the effect of increasing insulation distance and improving voltage resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

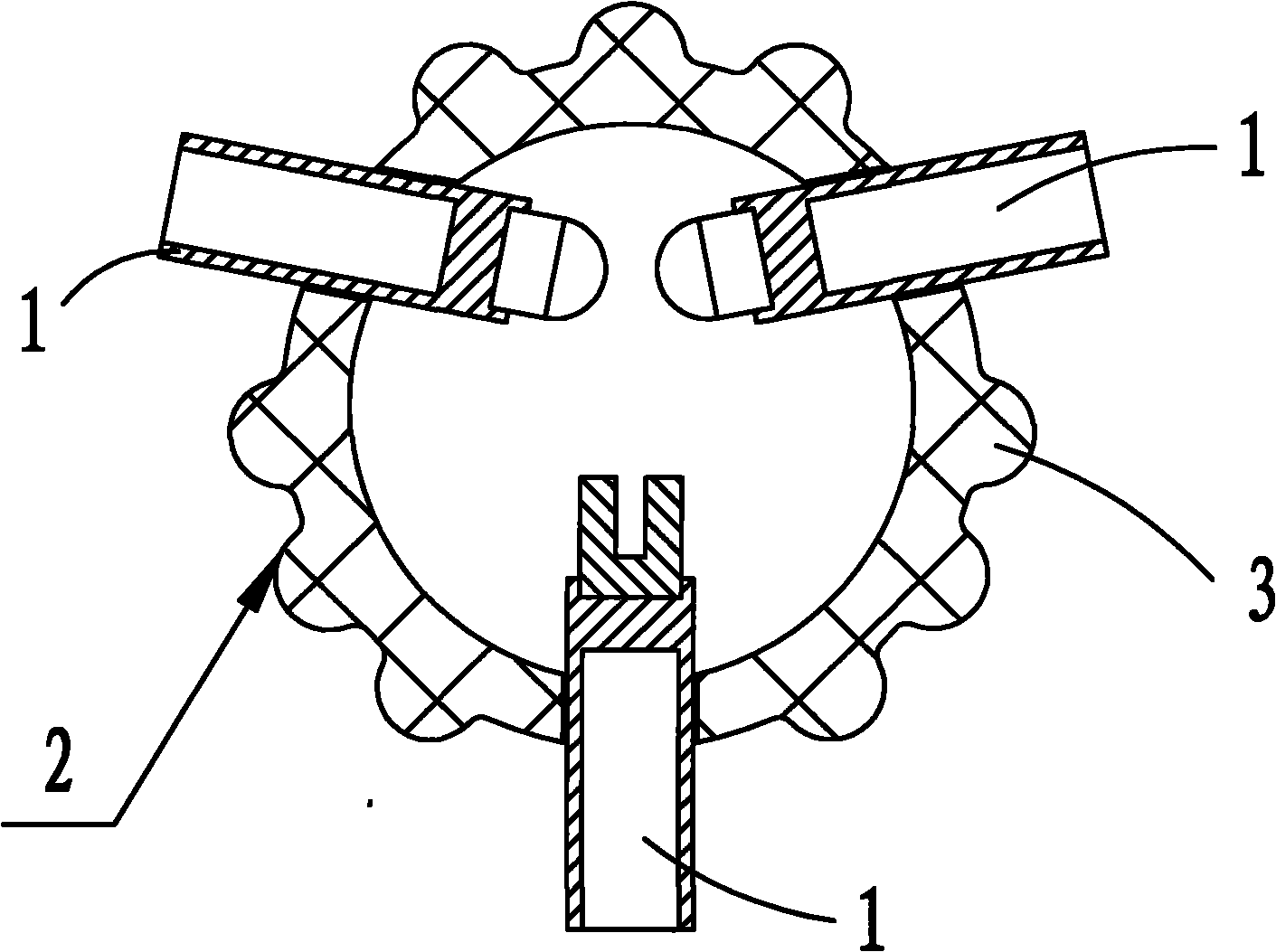

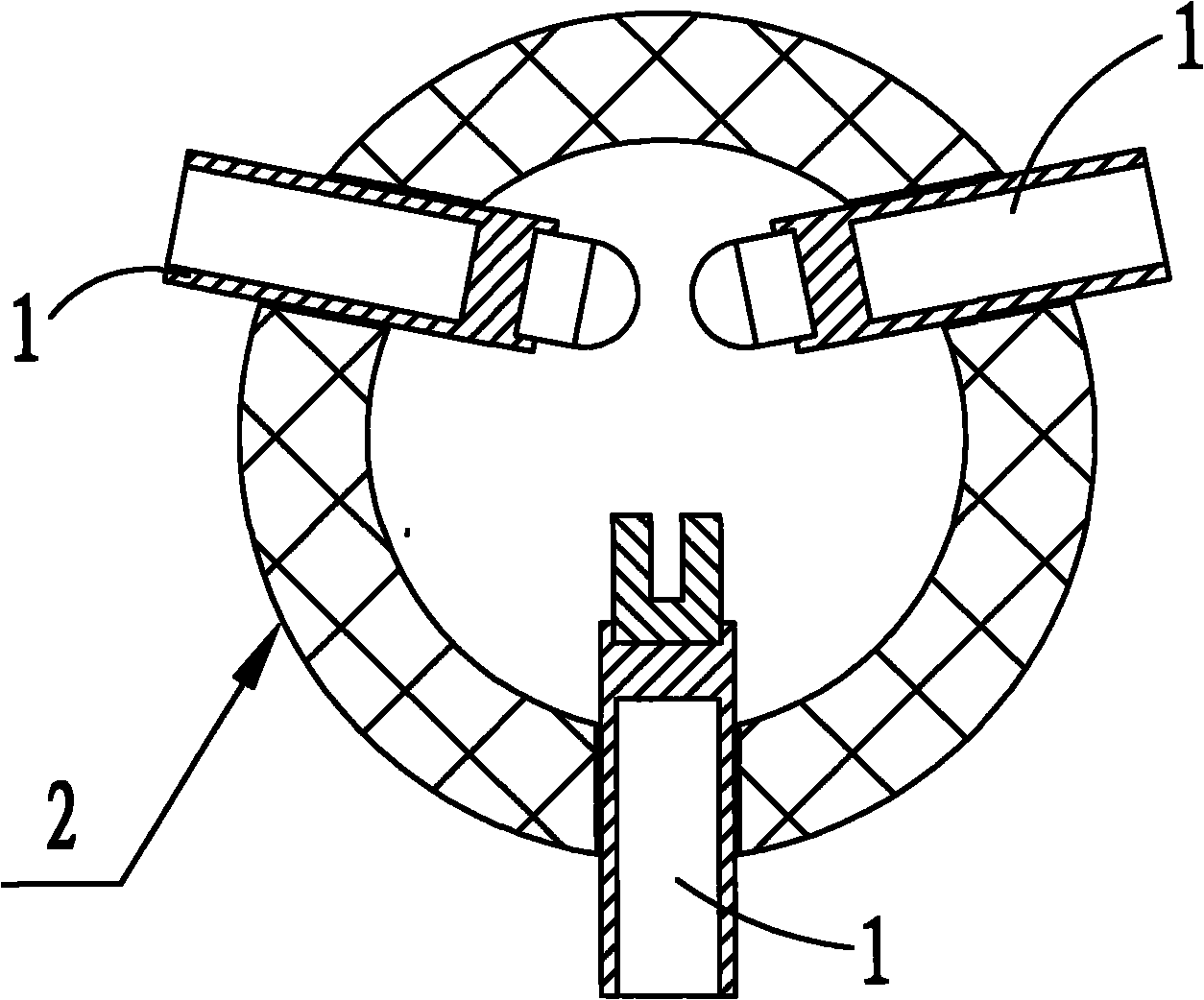

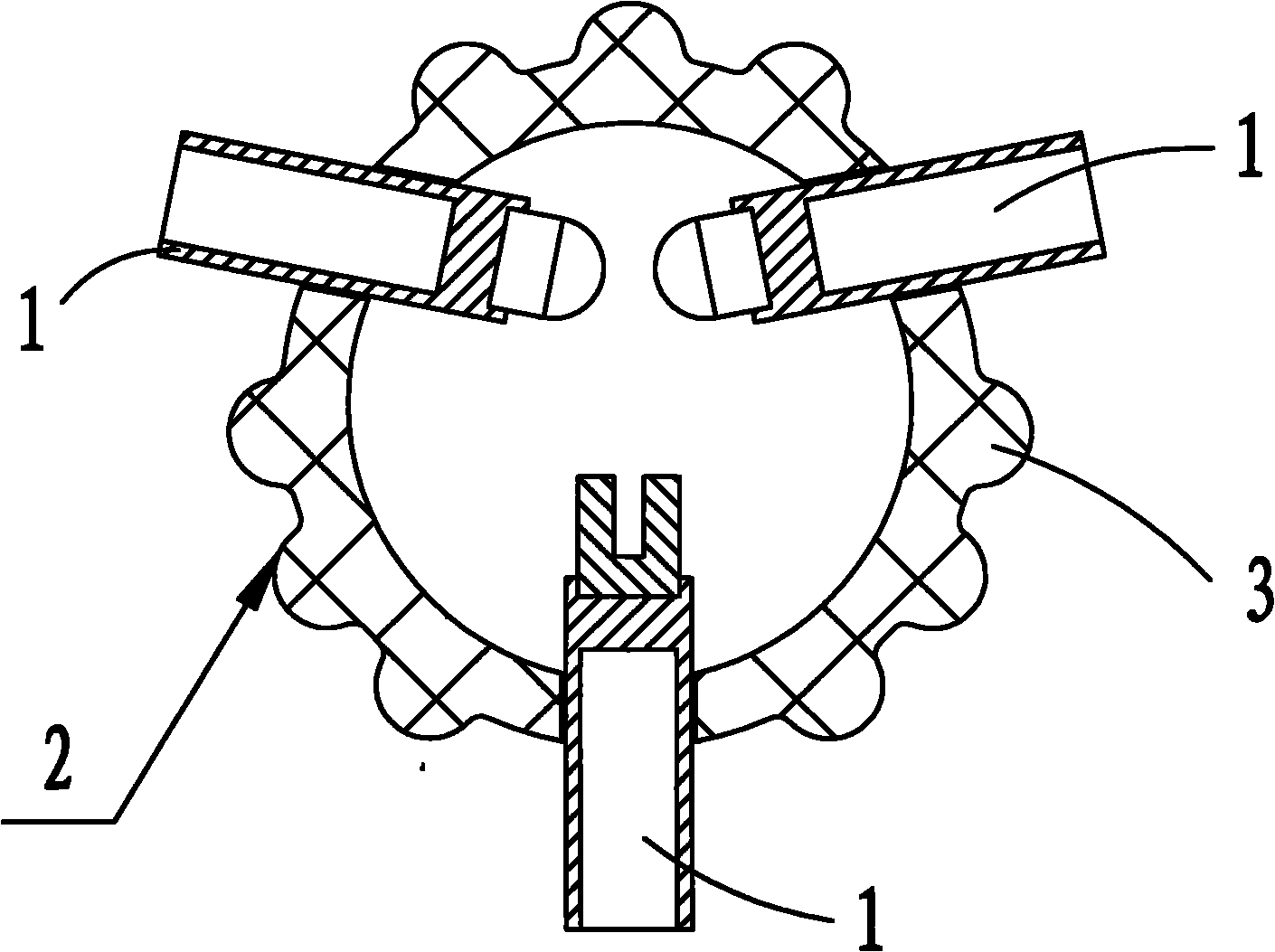

[0010] Embodiment: a vacuum relay, including a vacuum chamber, a number of contact point rods 1 are sealed and installed on the side wall of the vacuum chamber 2, based on the assembly direction, a number of longitudinal The convex rib 3, the outer peripheral section of the side wall of the vacuum chamber 2 between the contact point rods 1 is corrugated.

[0011] Three contact point rods 1 are pierced on the side wall of the vacuum chamber 2 .

[0012] There are three convex ribs 3 on the outside of the side wall of the vacuum chamber 2 between the contact point rods 1 .

[0013] Since some longitudinal convex ribs 3 are formed on the outside of the side wall of the vacuum chamber 2 between the contact point bars 1, the outer peripheral section of the side wall of the vacuum chamber 2 between the contact point bars 1 becomes corrugated, so that the outer contact point of the vacuum chamber 2 The insulation distance between the rods 1 is changed from the original flat arc dist...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com