Production process for PE isolation plate of lead-acid storage battery

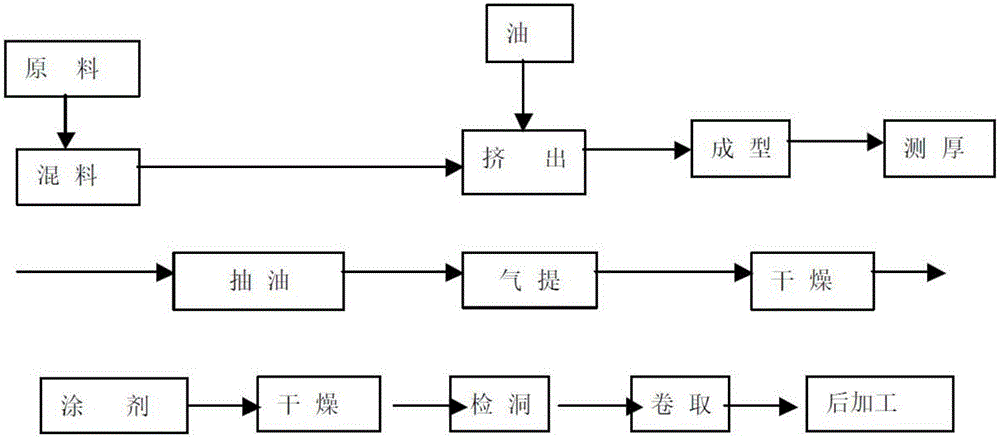

A lead-acid battery and production process technology, applied in battery pack parts, circuits, electrical components, etc., can solve problems such as reduced elongation of PE separators, shrinkage and deformation of PE separators, and substrate burrs and short circuits.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

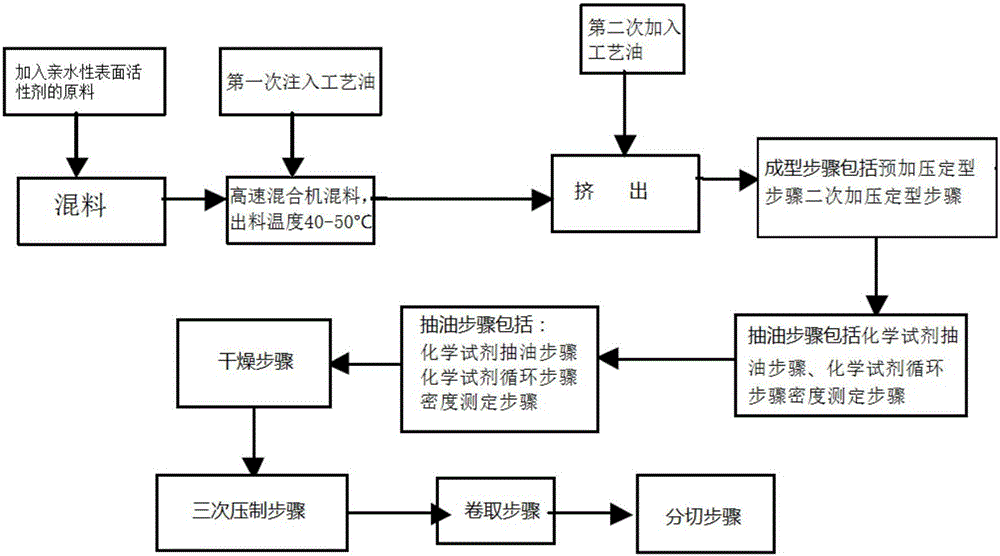

[0077] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the drawings in the embodiments of the present invention.

[0078] The process flow diagram of present embodiment one is as figure 2 as shown,

[0079] A kind of production technology of lead-acid storage battery PE separator, comprises the steps:

[0080] Step 1: a mixing step, adding a surfactant during the mixing process to increase the hydrophilicity of the produced PE separator;

[0081] Step 2: a low-speed stirring step, stirring the mixture at a low speed;

[0082] Step 3: high-speed stirring step, low-speed stirring step The mixed material obtained in the step is sent to a high-speed mixer for high-speed stirring, and process oil with a temperature of 30-40 ° C is added to the mixed material, and the temperature of the mixed material after stirring is 50 Between -60°C;

PUM

| Property | Measurement | Unit |

|---|---|---|

| elongation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com