Production system of lead acid battery PE separators

A lead-acid battery, production system technology, applied in battery pack parts, circuits, electrical components, etc., can solve the problems of substrate burr piercing short circuit, reduced PE separator elongation, large temperature difference between rollers, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0079] The technical solutions in the embodiments of the present invention will be clearly and completely described below in conjunction with the drawings in the embodiments of the present invention.

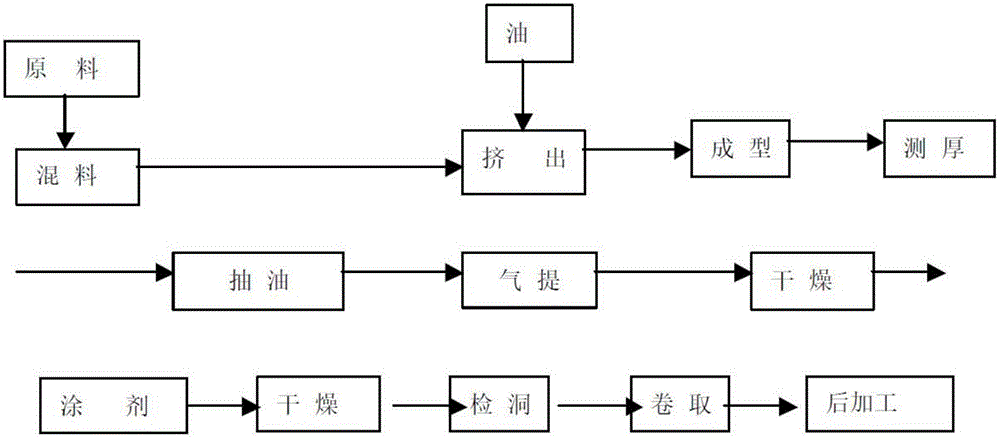

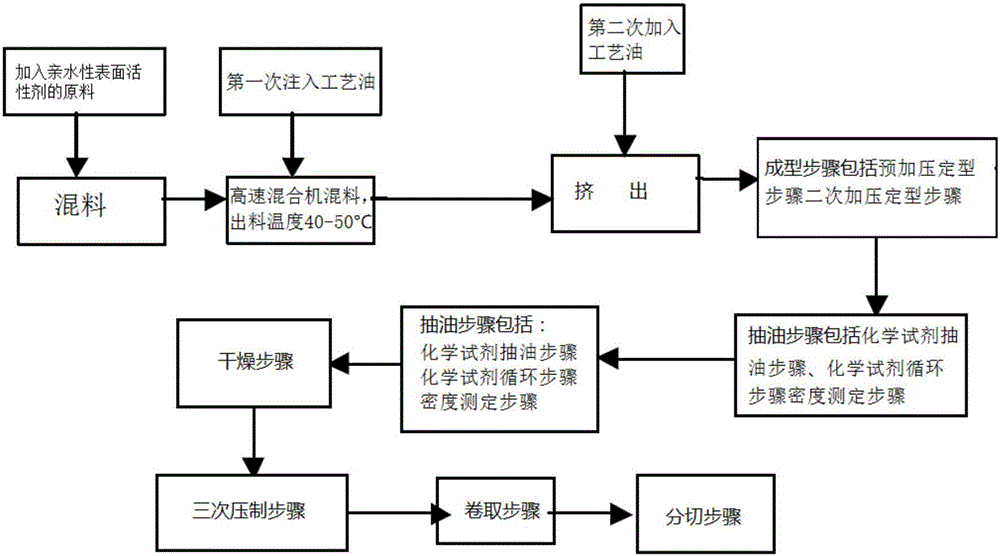

[0080] The system flow chart of the first embodiment is as follows image 3 As shown,

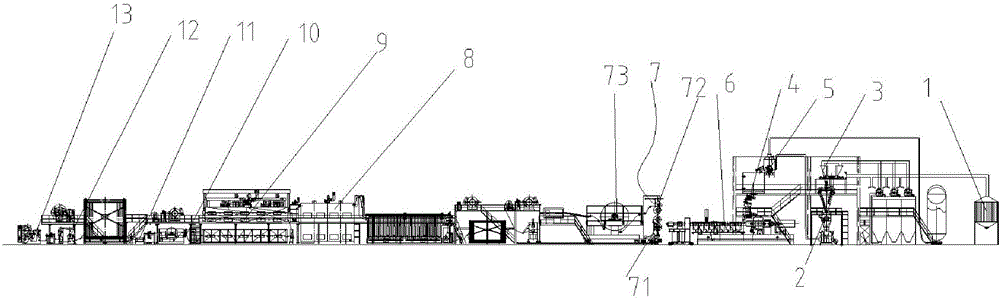

[0081] A production system of PE isolation board for lead-acid battery, including the following devices:

[0082] Mixing device 1, adding a surfactant during the mixing process to increase the hydrophilicity of the PE separator produced;

[0083] Low-speed stirring device, mixing the mixture at low speed;

[0084] High-speed stirring device 2, the mixture is fed into a high-speed mixer for high-speed stirring, and process oil at a temperature of 30-40°C is added to the mixture through the first process oil filling device 3. The temperature of the material is between 50-60℃;

[0085] Extrusion device 4, said extrusion device includes:

[0086] The weighing device controls the amount of mixed material en...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com