Water-based copper and aluminum wiredrawing oil composite and preparation method thereof

The technology of drawing oil and composition is applied in the field of water-based copper-aluminum drawing oil composition and its preparation field, which can solve the problems that lubricating oil is not easily biodegradable, difficult to achieve lubricating effect, poor environmental friendly benefit, etc., and achieves good light stability and storage stability, excellent UV and storage stability, and ensure the effect of safe use environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

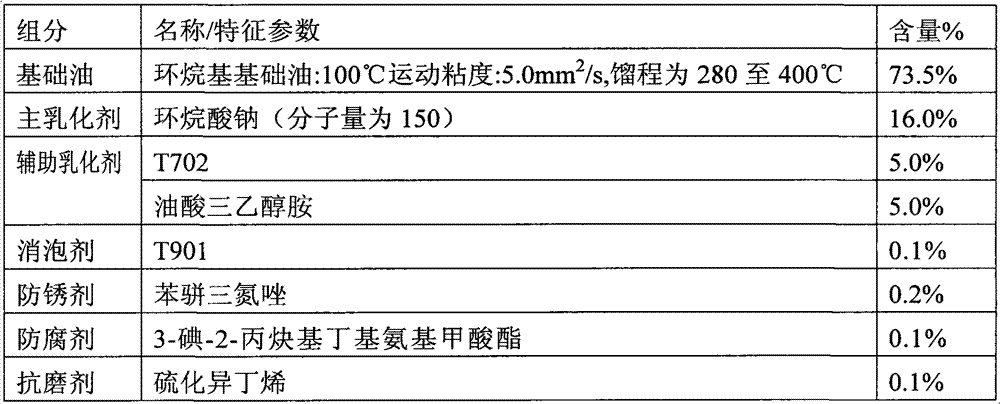

[0020] In Example 1, the composition of the water-based copper-aluminum wire drawing oil composition according to the weight percentage of raw materials is:

[0021]

[0022] The specific preparation method is as follows: first add the base oil to the reactor, stir and heat to 50°C, add the main emulsifier and auxiliary emulsifier, stir for 45 minutes at a temperature of 55°C; then add the defoamer and antirust Agents, preservatives and anti-wear agents, stirred at a temperature of 60 ℃ until completely dissolved, stop heating and wait for cooling to be the finished product.

[0023] The performance evaluation of the above-mentioned finished wire drawing oil after preparing 45% wire drawing oil-water emulsion is as follows:

[0024]

Embodiment 2

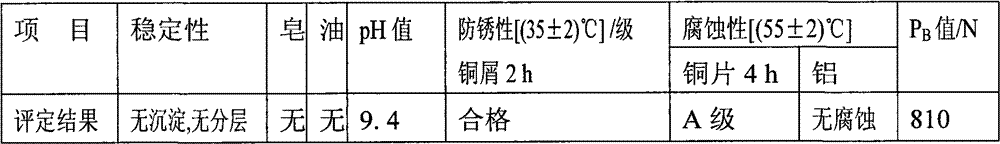

[0025] In Example 2, the composition of the water-based copper-aluminum wire drawing oil composition according to the weight percentage of raw materials is:

[0026]

[0027] The specific preparation method is as follows: first add the base oil to the reactor, stir and heat it to 55°C, add the main emulsifier and auxiliary emulsifier, stir at 60°C for 40 minutes; then add the defoamer and anti-rust Agents, preservatives and anti-wear agents, stir until completely dissolved at a temperature of 60 ℃, stop heating and wait for cooling to be the finished product.

[0028] The performance evaluation after the above-mentioned finished wire drawing oil is formulated into a 20% wire drawing oil-water emulsion is as follows:

[0029]

Embodiment 3

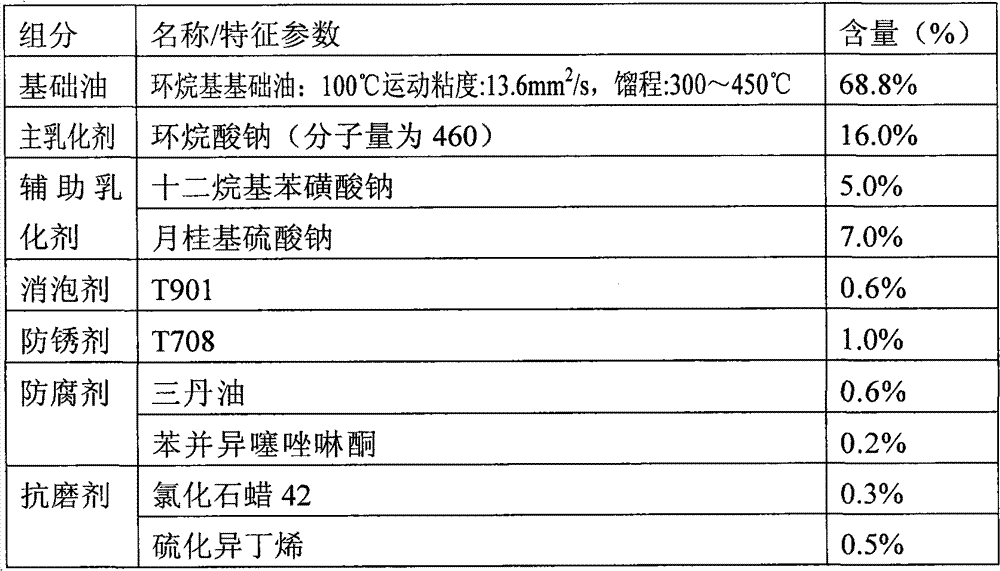

[0030] In Example 3, the composition of the water-based copper-aluminum wire drawing oil composition according to the weight percentage of the raw material is:

[0031]

[0032] The specific preparation method is as follows: first add the base oil into the reactor, stir and heat it to 50°C, add the main emulsifier and auxiliary emulsifier, stir at 50°C for 60 minutes; then add the defoamer and antirust Agents, preservatives and anti-wear agents, stir until they are completely dissolved at a temperature of 50°C, stop heating and wait for cooling to become the finished product.

[0033] The performance evaluation of the above-mentioned finished wire drawing oil after mixing into 12% wire drawing oil-water emulsion is as follows:

[0034]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com