Patents

Literature

50results about How to "Reasonable molecular weight distribution" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

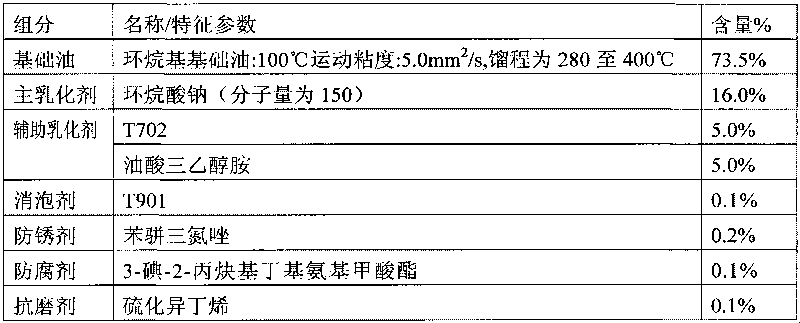

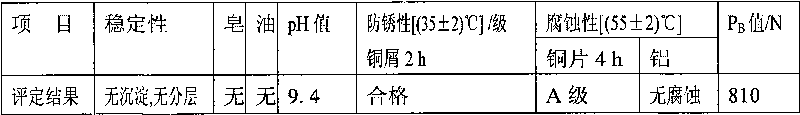

Water-based copper and aluminum wiredrawing oil composite and preparation method thereof

The invention relates to an oil-based lubricating composite and a preparation method thereof, in particular to a water-based copper and aluminum wiredrawing oil composite and a preparation method thereof. The water-based copper and aluminum wiredrawing oil composite comprises base oil, an emulsifier, an auxiliary emulsifier, a defoaming agent, a rust-proof agent, an antiseptic and an antiwear agent. The preparation method comprises the following steps of: configuring the water-based copper and aluminum wiredrawing oil composite into 3 percent to 45 percent water-based emulsion according to weight percentage; and spraying the water-based emulsion into a wiredrawing die cavity in the copper and aluminum wiredrawing process. The water-based copper and aluminum wiredrawing oil composite has the advantages of excellent lubricating property, great optimal light stability and storage stability, low cost, good cooling effect, fast heat transfer, little temperature increase in the using process, difficult combustion and easy cleaning and ensures the safety of the service environment; and in addition, a copper wire and an aluminum wire drawn by the method have the advantages of uniform wireshape, bright surfaces, difficult corrosion, good ultraviolet and storage stability and good stability.

Owner:PETROCHINA KARAMAY PETROCHEMICAL CO LTD

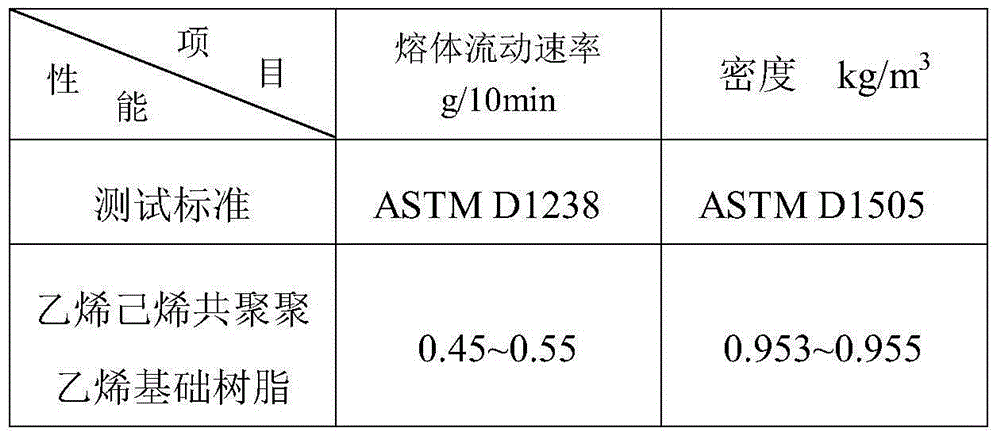

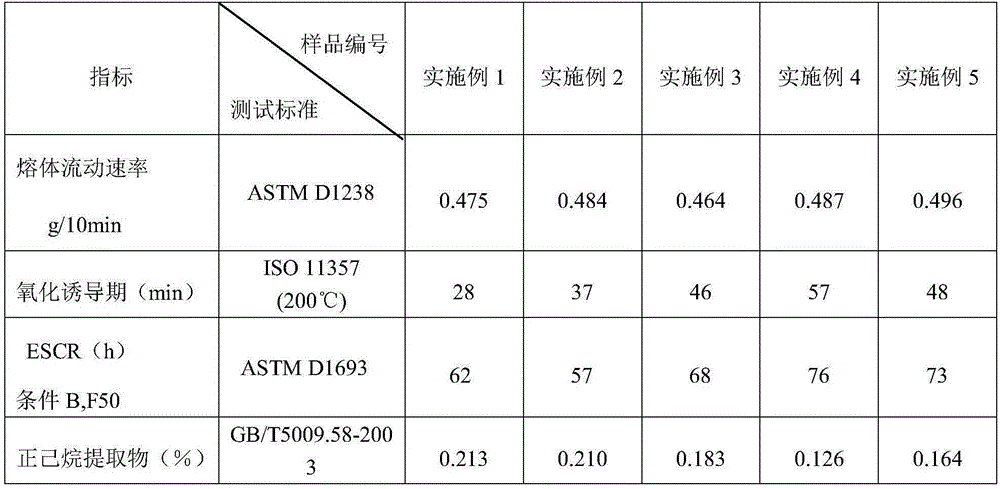

Large hollow container blow molding material and preparation method thereof

The present invention discloses a large hollow container blow molding material, which comprises the following raw materials, by weight, 99.9-100.0 parts of an ethylene hexene copolymerization polyethylene base resin, 0.05-0.10 part of an antioxidant, 0.07-0.12 part of a co-antioxidant, and 0.03-0.05 part of a slip agent. The present invention further discloses a preparation method for the large hollow container blow molding material. The large hollow container blow molding material has characteristics of low fusion index, large molecule weight, high strength, and the like, and is suitable for blowing of large size containers, wherein the product has prominent rigidity and toughness balancing capacity, creep resistance, excellent ESCR and good chemical resistance.

Owner:CHINA PETROLEUM & CHEM CORP

Process for preparing active peptide using fish skin collagen step directional enzynolysed by composit enzyme

InactiveCN1560270AReasonable molecular weight distributionObjective and simple measurementFermentationAlkaline proteaseFreeze-drying

The invention is a method of preparing active peptides by making step oriented enzymolysis of compound enzyme on fish skin collagen, and its characteristic: putting the fish skin collagen in a phosphatic buffer solution to prepare a solution at 0.04-0.06kg / l, adding in pineapple proteinase at 40-50 deg.C in the proportion of 3000-5000 U / g substrate, stirring at constant temperature, making enzymolysis for 3-5 hours, then killing the enzyme at 95-110 deg.C for 4-6 minutes, cooling to normal temperature and freeze-drying. It produces the active peptides of reducing blood pressure and easy to obtain the active peptides with more reasonable molecular weight distribution.

Owner:OCEAN UNIV OF CHINA

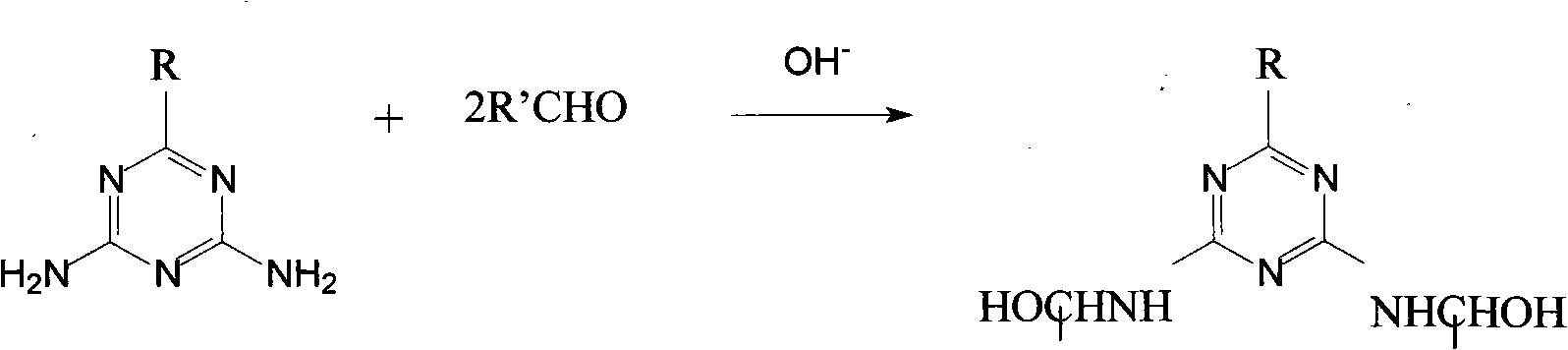

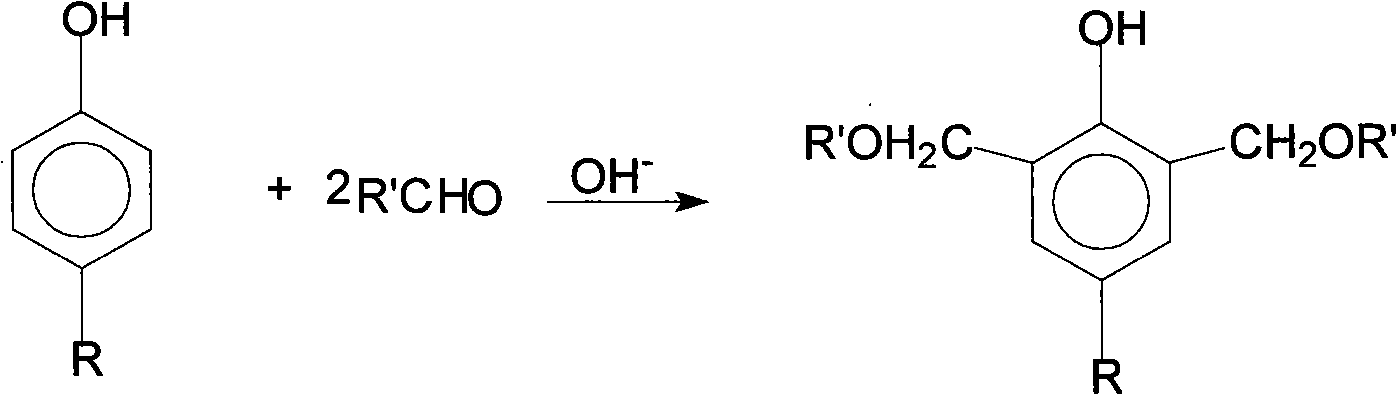

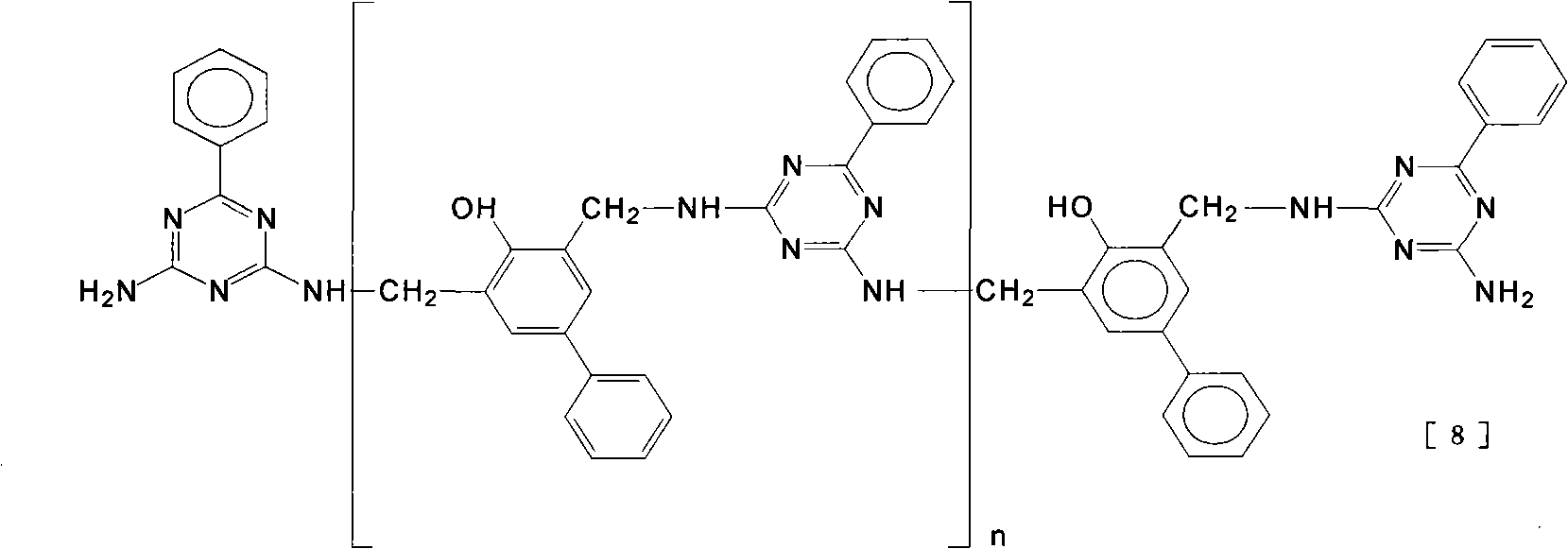

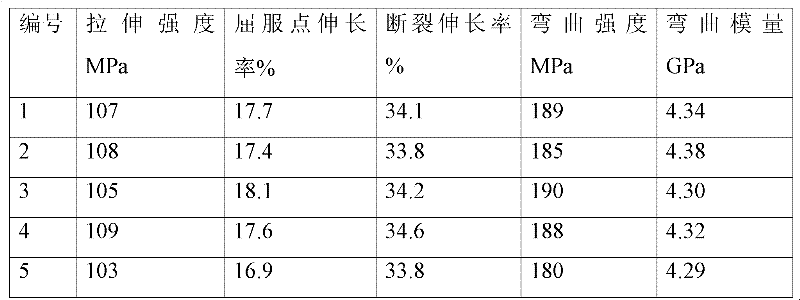

Synthetic method of nitrogen-containing flame-retardant phenolic resin

InactiveCN101323658AModerate molecular weightReasonable molecular weight distributionSolution systemOrganic base

The invention pertains to the technical field of preparing a modified phenolic resin and particularly relates to a synthetic method of a nitrogen-containing and flame-retarding phenolic resin; the synthetic method of the invention comprises the following steps: the monosubstituted melamine monomer and the aldehyde monomer with a mole ratio of 1:2 to 5 are blended and put in to an organic base adjusting solution system with the pH value of 8 to 11 to carry out a hydroxymethylation at a temperature of 65 DEG C to 90 DEG C; the para-orienting organic phenol monomer and the aldehyde monomer with mole ratio of 1:2 to 5 are added into the reaction system; the hydroxymethylation lasts for 0.5 hours to 2 hours at a temperature of 65 DEG C to 90 DEG C; then a condensation polymerization is carried out at the temperature of 75 DEG C to 100 DEG C; an organic solvent is added for the purpose of pressure reduction and azeotropy; the reflow temperature is kept at 60 DEG C to 80 DEG C; after the moisture in the reaction system is removed, an organic solvent is added to dilute, prepare and obtain nitrogen-containing and flame-retarding phenolic resin with a thiotrzinone structure unit, which can be used for producing non-halogen and flame-retarding phenolic resin laminates of grade FV0 and applied as epoxy resin hardeners.

Owner:北京新福润达绝缘材料有限责任公司

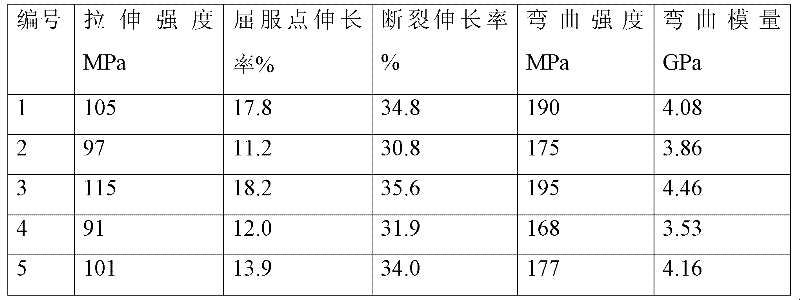

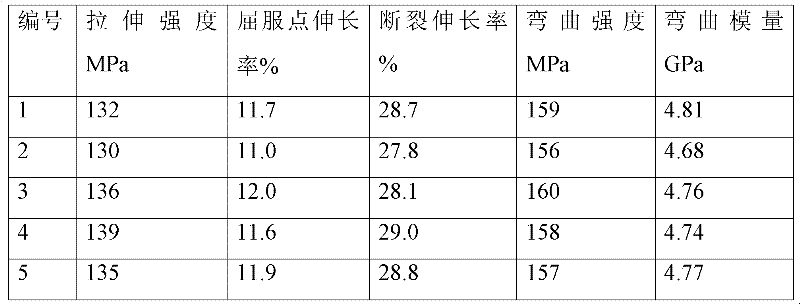

Preparation method of polyether ketone/sulfone high-temperature resistant material

The invention discloses a preparation method of a polyether ketone / sulfone high-temperature resistant material, which comprises the following steps that: firstly, a reactive monomer, a solvent and an inorganic alkali are put into a first reactor, are mixed at a temperature of 40 to 90 DEG C by stirring, and are dissolved; secondly, the mixture is transferred to a second reactor, is added with a water-carrying agent, and is stirred at a temperature of 150 to 280 DEG C to be subjected to salt formation dehydration; and a material after being subjected to salt formation dehydration is introducedinto a third reactor, and is stirred at a temperature of 230 to 330 DEG C to be subjected to polymerization to obtain a product. The synthesis process of the polyether ketone / sulfone material is reacted in three reactors with different temperatures, so that an intermediate product prepared in each step is more sufficient and uniform, the obtained product has a gel content reduced to less than 3% and molecular weight distribution which is more reasonable and reaches the range of 2.42 to 2.45 without changing the comprehensive performance of the product, and thereby the quality of the resin product is improved; and the preparation method is suitable for continuous production, and production cost reduction, energy consumption reduction in a production process and stable quality of the obtained product are achieved.

Owner:KINGFA SCI & TECH CO LTD +2

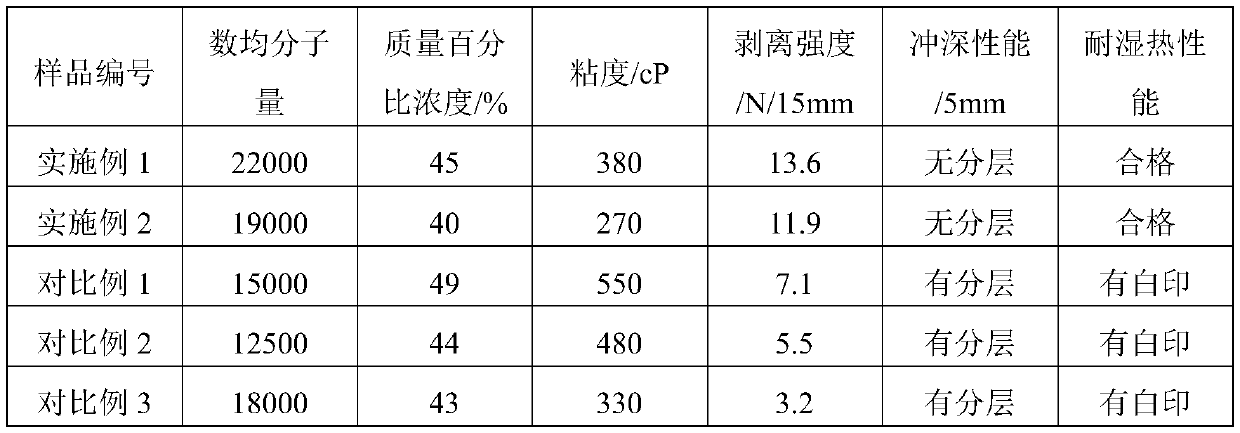

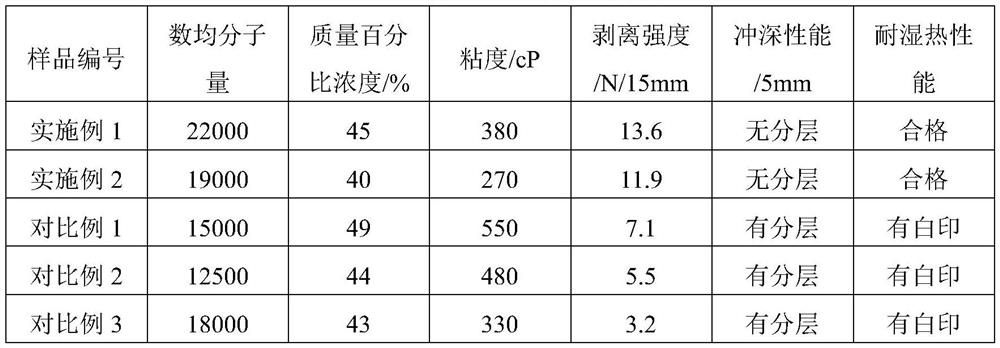

Preparation method of adhesive for outer layer of aluminum plastic film of lithium battery

ActiveCN109851763AMeet application performance requirementsEasy to operateAdhesivesPolymer scienceAdhesive

The invention belongs to the field of organic synthesis, relates to a polymer polymerization technology, and specifically relates to a preparation method of an adhesive for the outer layer of an aluminum plastic film of a lithium battery. Under the action of an antioxidant, aliphatic dihydric alcohols, aliphatic dibasic acids, and aromatic dibasic acids carry out esterification reactions in inertgas with a normal pressure. Then aliphatic polyol is added to carry out polycondensation reactions, under the action of a catalyst, water and micromolecular polymers generated in polycondensation reactions are removed at a high temperature in vacuum, and the reactants are dissolved by a solvent to obtain a solution of polymer with a molecular weight of 10,000 to 30,000. The operation is simple andconvenient, the molecular weight distribution is reasonable, the product quality and application performance are stable; and the product has the advantages of crystallization resistance, good flexibility, good anti-tensile performance, good hydrolysis resistant performance, good caking property, and good impact resistant performance. The prepared adhesive can totally meet the application requirements of a lithium battery aluminum plastic film outer layer adhesive.

Owner:SHENYANG RES INST OF CHEM IND

Preparation method of ultrahigh molecular weight phenolic resin

The invention discloses a preparation method of ultrahigh molecular weight phenolic resin. The preparation method comprises the following steps of: (1) weighing phenol and aldehyde in a molar ratio of 1: (0.8-1.0) respectively, and weighing acid in a mass ratio of the acid to the phenol of (0.5-4): 100; (2) mixing the phenol, partial aldehyde and partial acid, heating till boiling, and refluxing for 2 to 4 hours, wherein the partial aldehyde or the partial acid accounts for 75 to 95 percent of the total adding amount of the aldehyde or the acid; (3) heating and dehydrating the reactants of the step (2), cooling the reactants to the temperature of between 80 and 100 DEG C, adding the rest aldehyde and the rest acid, heating till boiling, and refluxing for 1 to 3 hours; and (4) detecting the melting viscosity of the reactants in the refluxing process of the step (3), adding alkali when the viscosity reaches 2,000 to 4,500MPa.s / 100 DEG C, regulating the pH value to be between 4 and 7, heating and dehydrating to obtain the ultrahigh molecular weight phenolic resin. The weight-average molecular weight of the prepared phenolic resin can reach 14,000 to 30,000, the softening point is 120 to 140 DEG C, and the molecular weight distribution is 13 to 19.

Owner:SHANDONG SHENGQUAN NEW MATERIALS CO LTD

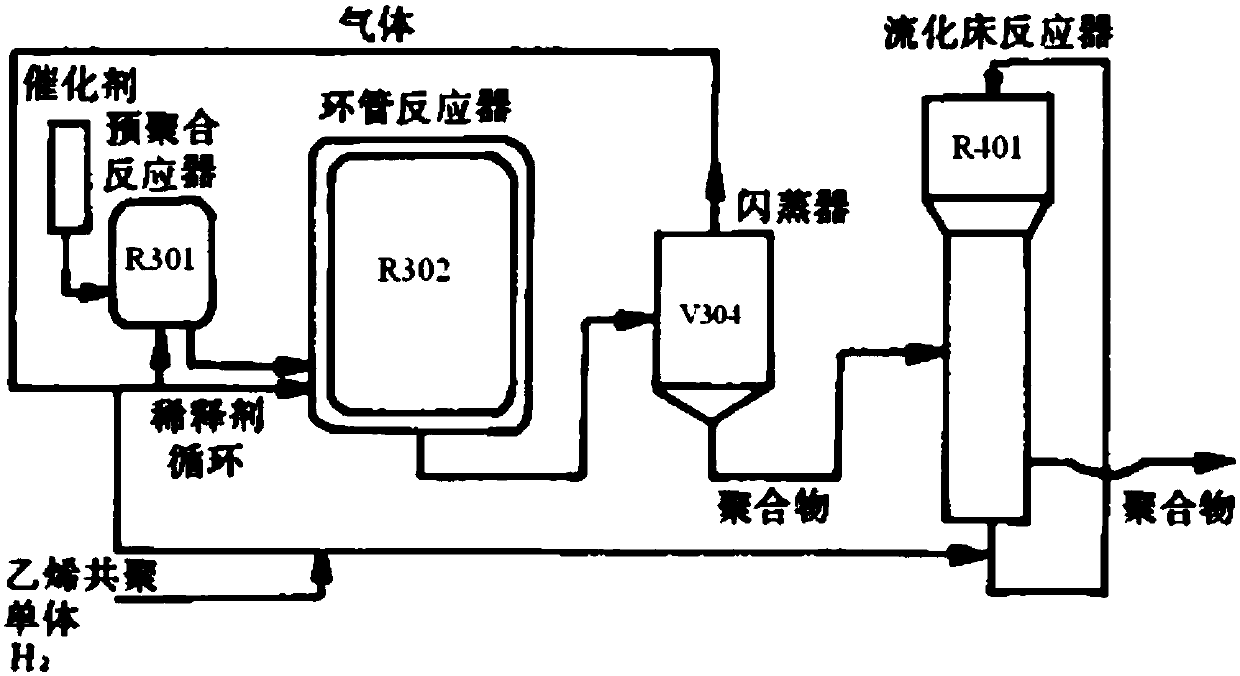

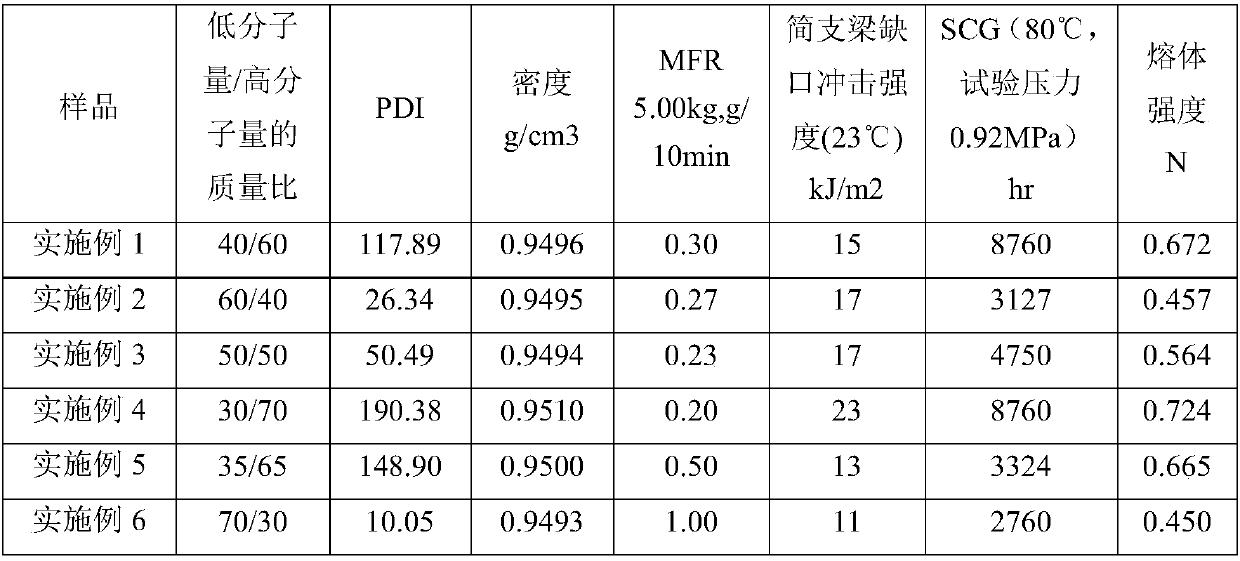

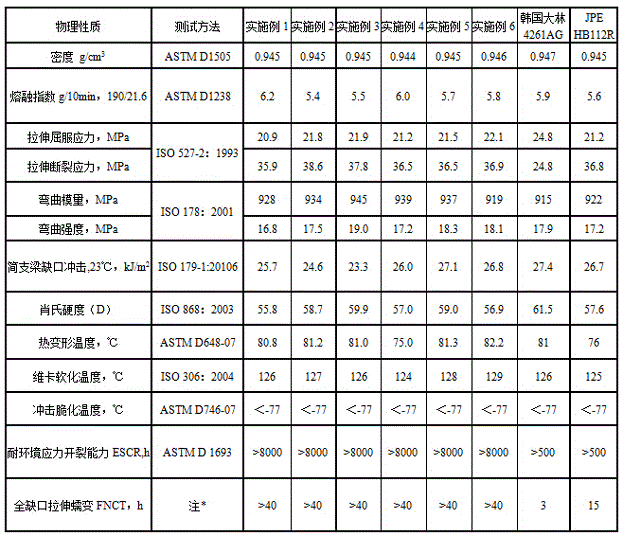

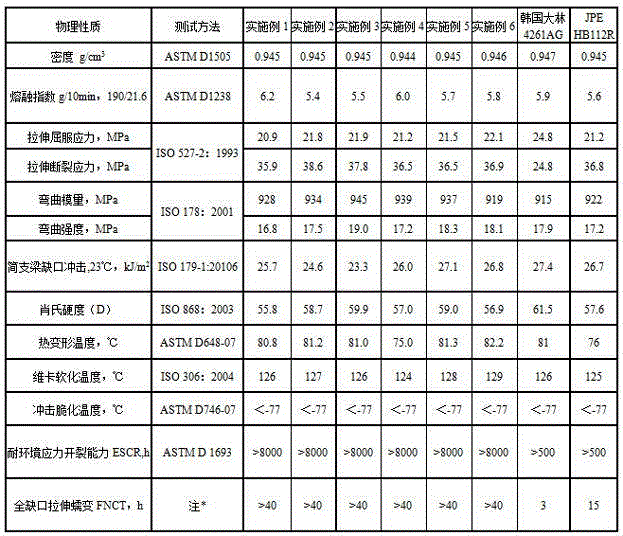

Bimodal polyethylene resin for large-caliber thick-wall low-sag pipes and preparation method of bimodal polyethylene resin

InactiveCN111100362ADistribution controllableReasonable molecular weight distributionPolymer scienceFluidized bed

The invention provides a bimodal polyethylene resin for large-caliber thick-wall low-sag pipes and a preparation method of the bimodal polyethylene resin. The resin comprises a high-molecular-weight part and a low-molecular-weight part, and the mass ratio of the low-molecular-weight part to the high-molecular-weight part is 3: 7-7: 3; wherein the number-average molecular weight Mn of the resin ranges from 2000 to 10000, the weight-average molecular weight Mw of the resin ranges from 100000 to 400000, the Mw / Mn of the resin ranges from 10 to 200, the melt flow rate MFRs of the resin ranges from0.2 to 1.0g / 10min, and the resin density ranges from 0.945g / cm<3> to 0.960g / cm<3>. The bimodal polyethylene resin provided by the invention can be prepared by a reactor formed by connecting a loop reactor and a fluidized bed reactor in series. The bimodal polyethylene resin has improved mechanical properties, excellent processability and excellent strength and sag resistance, and is suitable forpreparing large-caliber thick-wall low-sag pipes.

Owner:CHINA PETROLEUM & CHEM CORP +1

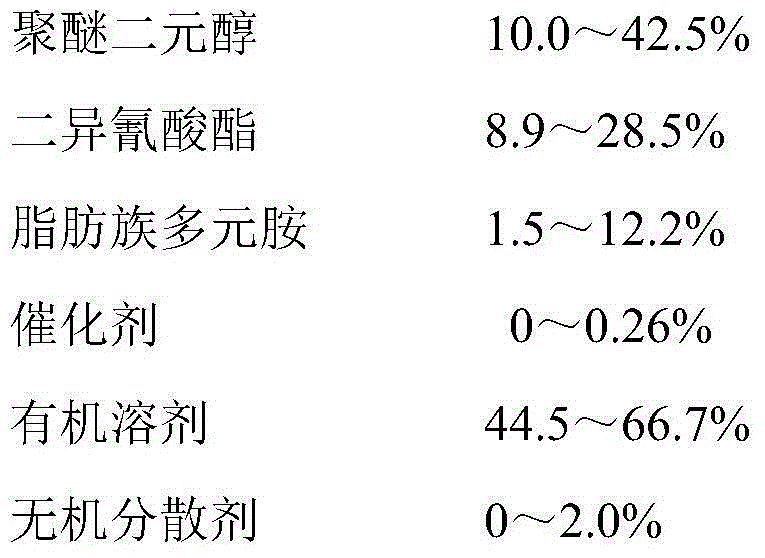

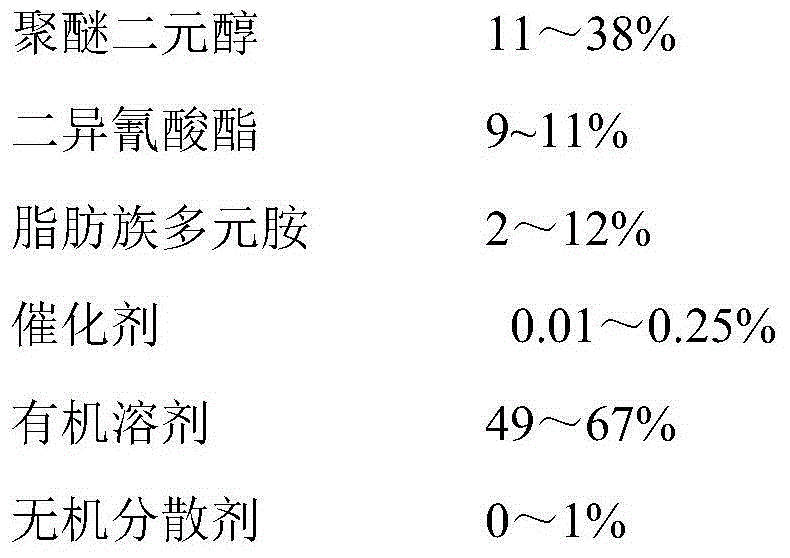

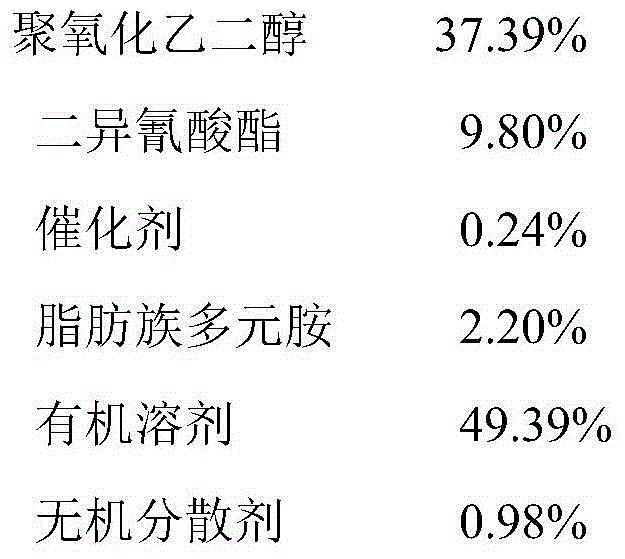

Preparing method for amino-terminated polyurethane for improving tenacity of cured epoxy material

The invention discloses a preparing method for amino-terminated polyurethane for improving tenacity of a cured epoxy material. The preparing method includes the following steps that 1, in the presence of a catalyst, polyether glycol and diisocyanate are polymerized in the nitrogen atmosphere; 2, the product is cooled to room temperature, and a viscosity modifier is added to obtain a prepolymer solution; 3, the temperature is kept at 2-10 DEG C, the product in the step 2 is added into an aliphatic polyamine solution, the mixture is heated to 40-50 DEG C, the temperature is kept for 1-3 h, and amino-terminated polyurethane for improving tenacity of the cured epoxy material is collected from a reaction product. The method is simple, polyamine terminal seal with primary amine and secondary amine is involved, the application range is wider, the polymerization success rate is up to 95%, the gel crosslinking phenomenon occurs rarely, the prepared amino-terminated polyurethane molecular chain is uniform and regular, molecular weight distribution is reasonable, and the average molecular weight approaches the theoretical value.

Owner:SHANGHAI CHLOR ALKALI CHEM

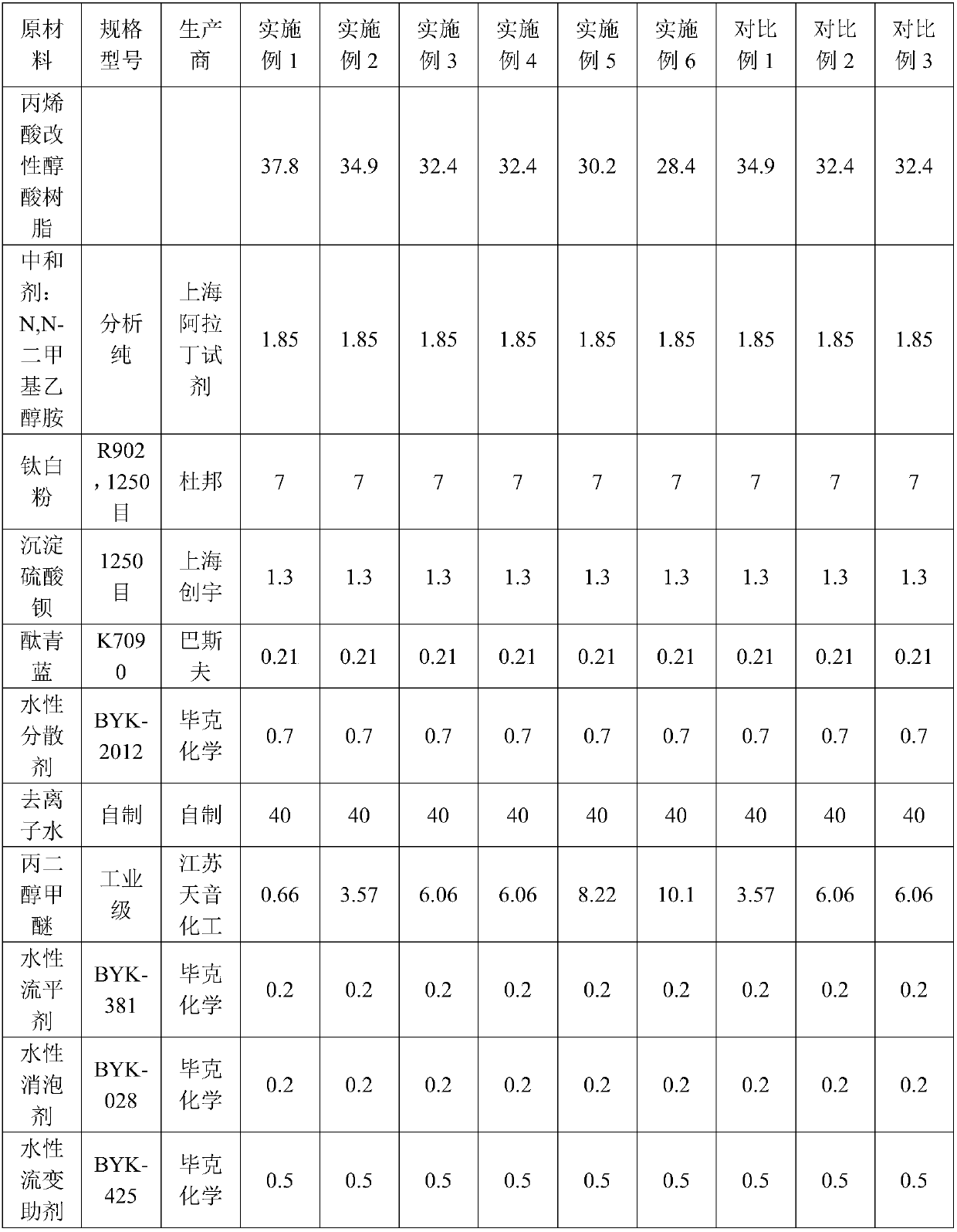

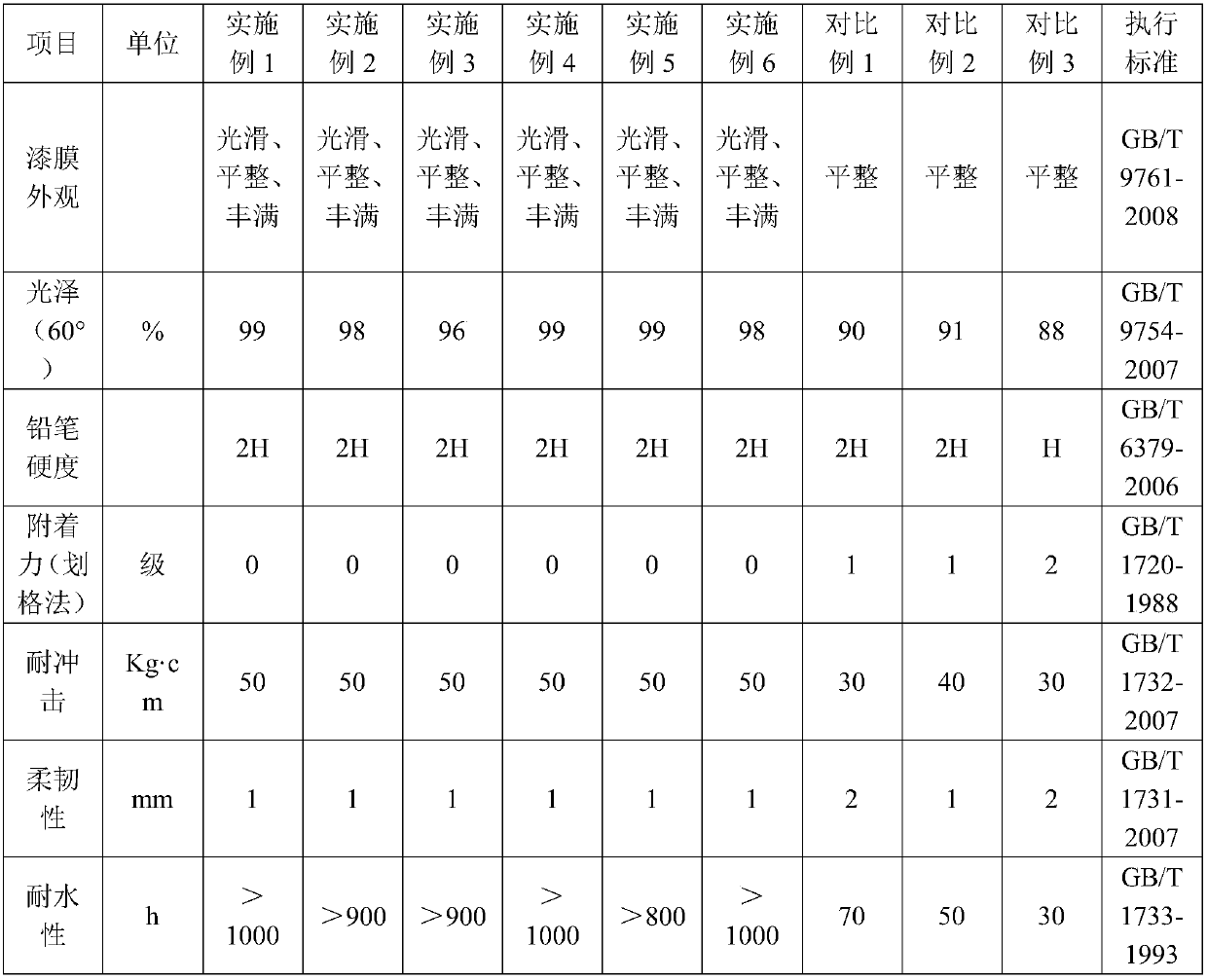

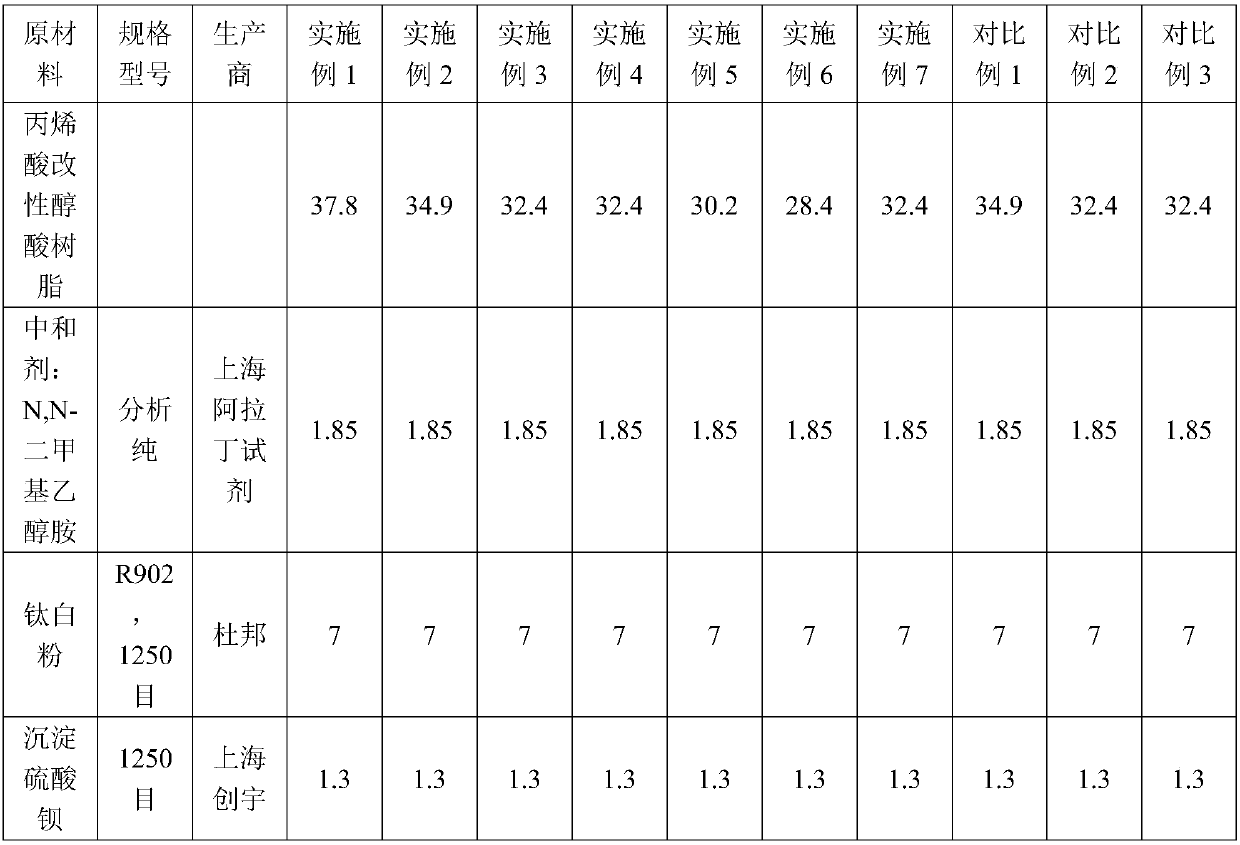

Alkyd resin preparation method and prepared resin thereof, and acrylic acid modified alkyd resin preparation method and prepared resin thereof

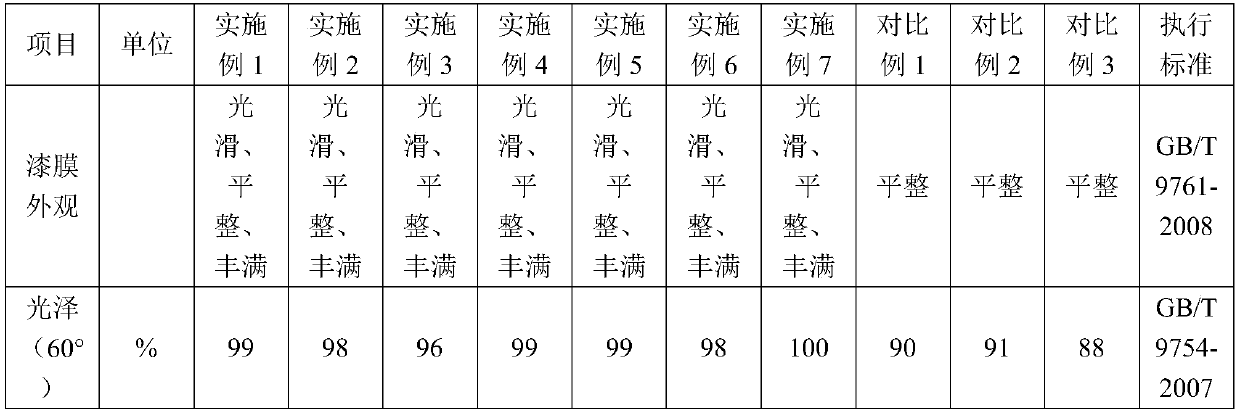

The invention provides an alkyd resin preparation method and the prepared resin thereof, and an acrylic acid modified alkyd resin preparation method and the prepared resin thereof. According to the alkyd resin preparation method, unsaturated carboxylic acid and / or unsaturated anhydride are / is added step by step to improve the structure of the alkyd resin. According to the acrylic acid modified alkyd resin preparation method, a unsaturated monomer is fed step by step, and the feeding time is controlled, so that the unsaturated monomer is uniformly grafted on an alkyd resin, and the molecular weight distribution is narrow. The acrylic acid modified alkyd resin prepared by the preparation method is applied to water-based coating materials, so that a paint film has the advantages of high drying speed, high glossiness, good fullness, low VOC emission, excellent comprehensive performance and the like.

Owner:WANHUA CHEM BEIJING +1

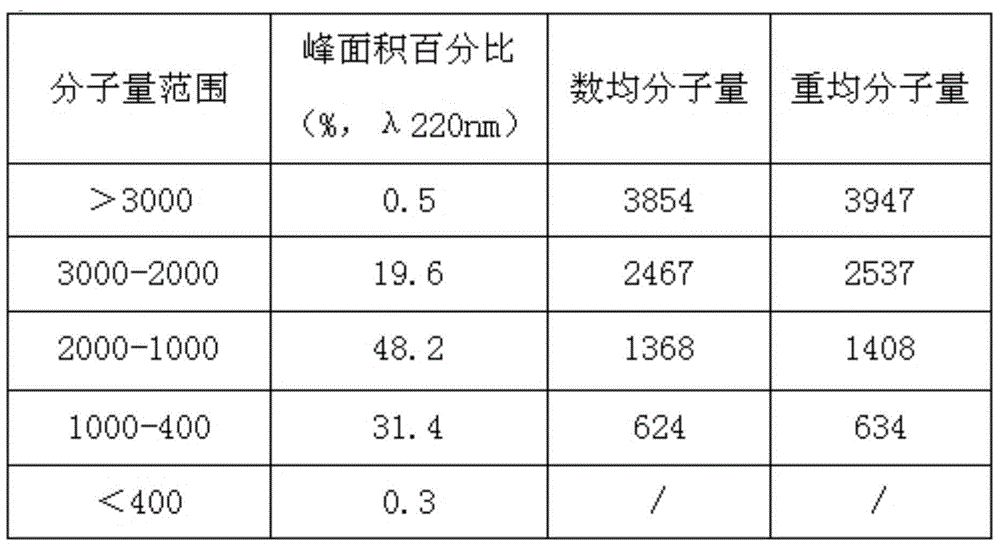

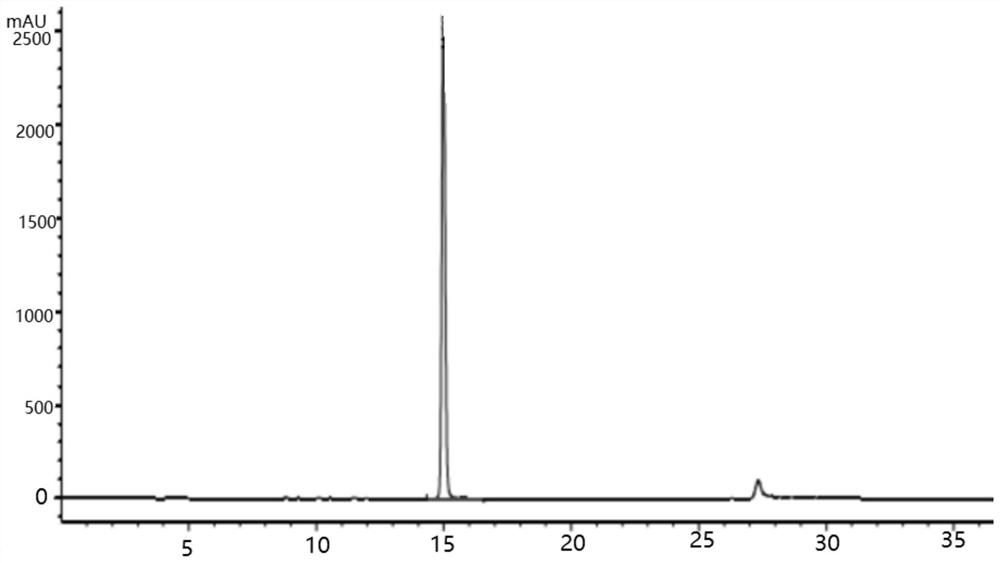

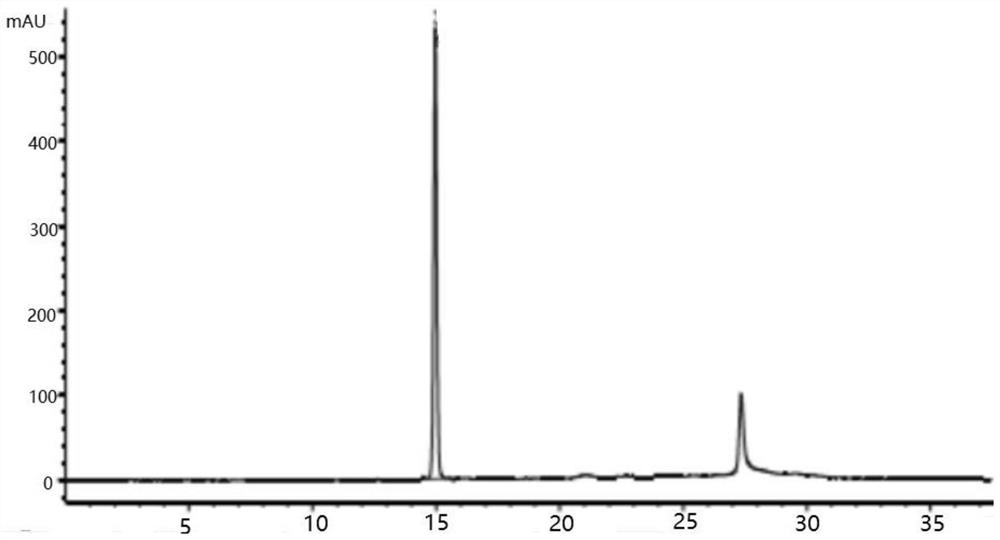

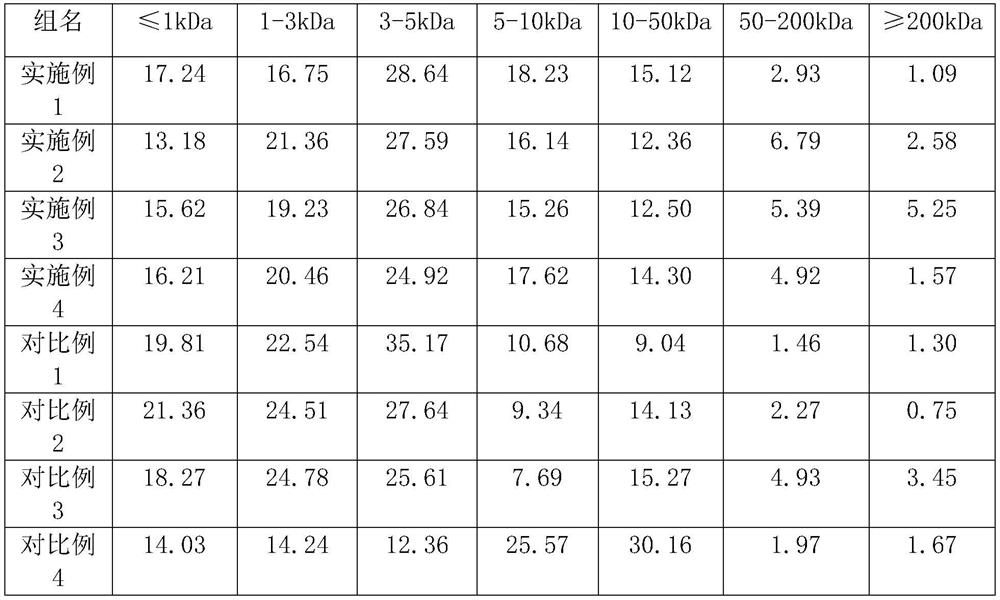

A kind of preparation method of deep-sea fish skin collagen polypeptide

ActiveCN103805665BAdvances in enzymatic hydrolysis preparation technologyMolecular weight controllablePeptide preparation methodsFermentationActivated carbonUltrafiltration

The invention discloses a preparation method of deep-sea fishskin collagen polypeptide. The method comprises the following steps: adding a crude collagen protein liquid into a compound proteinase to carry out enzymolysis at the temperature of 55 DEG C; filtering many times by using an ultrafiltration membrane in the enzymolysis process; then, after decoloring and deodorizing the enzymatic hydrolysate by using composite activated carbon by virtue of a multi-step adsorption method, carrying out nanofiltration and drying to obtain the powdery collagen polypeptide. According to the invention, an enzymolysis and ultrafiltration separation combined process is adopted to truly realize the artificial control for reaction conditions, so that the molecular weight of the deep-sea fishskin collagen polypeptide is controllable and is reasonably distributed, and furthermore, various physicochemical properties of the deep-sea fishskin collagen polypeptide are better.

Owner:QINGDAO HUAKE BIOLOGICAL TECH CO LTD

Preparation method of optical adhesion agent and AB glue protecting film

InactiveCN108977161ALess side effectsImprove wear resistancePolyureas/polyurethane adhesivesPressure sensitive film/foil adhesivesPolypropylene glycolNitrogen

The invention discloses a preparation method of an optical adhesion agent. The method comprises synthesis of an acrylate reactive prepolymer. The synthesis of the acrylate reactive prepolymer comprises the following steps: S1, respectively dehydrating hydroxy functionalized acrylate and polypropylene glycol; S2, adding polypropylene glycol into diisocyanate under the protection of nitrogen, heating to 53-55DEG C, reacting until the content of NCO in reaction liquid is maintained to be unchanged; S3, adding hydroxy functionalized acrylate, a polymerization inhibitor and a first active diluent into the reaction system of S2, heating to 72-75DEG C, and reacting until the content of NCO is zero, so as to obtain the acrylate reactive prepolymer. Diisocyanate is formed by combining 2,4-toluene diisocynate with dicyclohexyl methane diisocyanate. Combined diisocyanate is few in byproduct reaction, the obtained prepolymer is moderate in viscosity and reasonable in molecular weight distribution.The invention also provides an AB glue protecting film.

Owner:JIANGYIN TONGLI OPTOELECTRONICS TECH

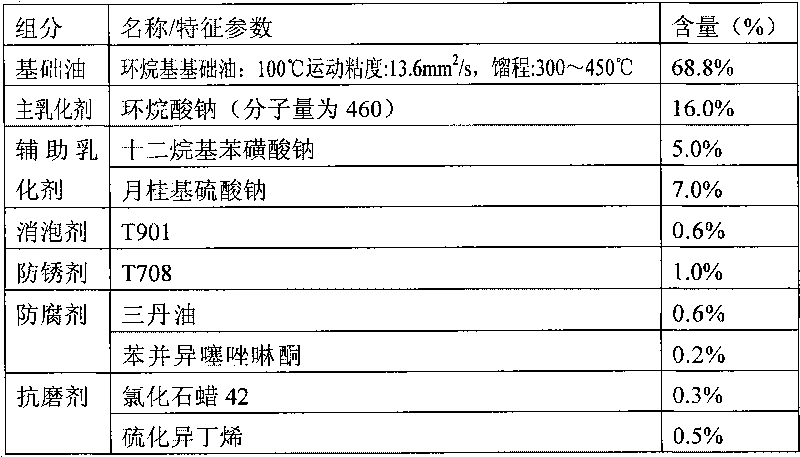

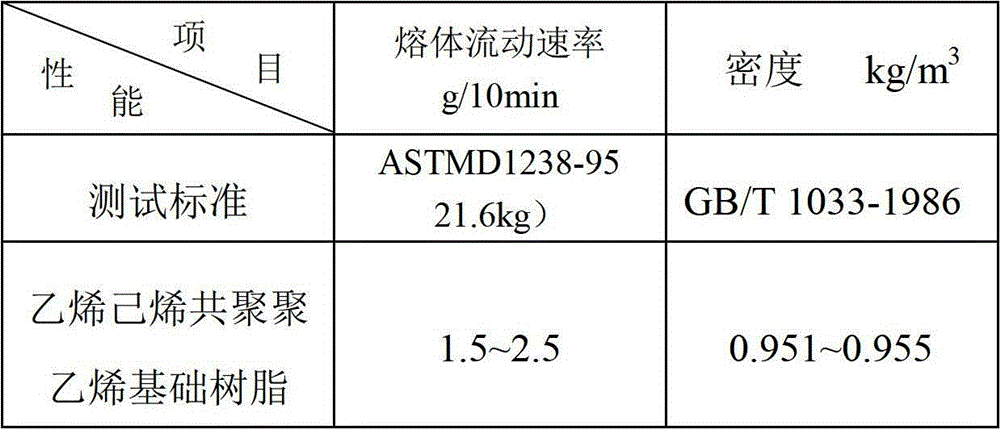

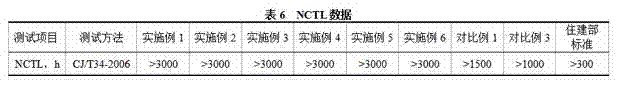

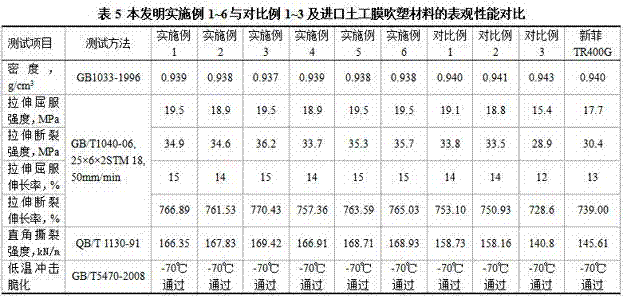

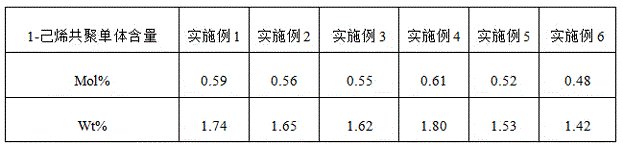

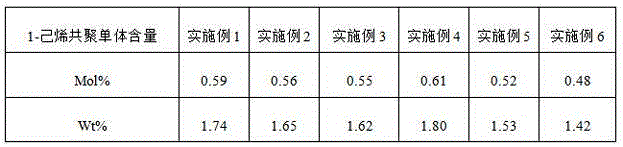

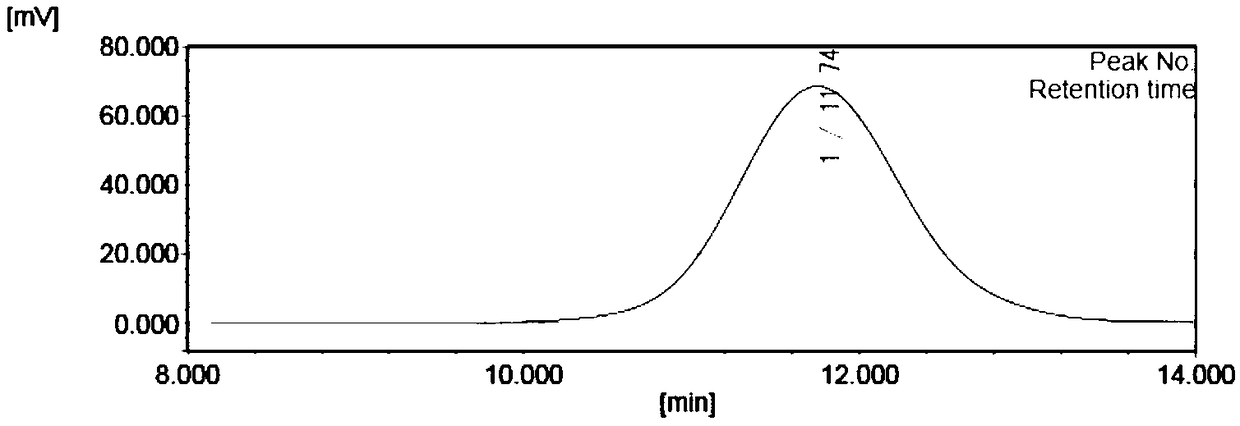

Preparation method of high-hexene grafted high-density polyethylene geomembrane blow molding material

ActiveCN104744795AImprove conversion efficiencyIncrease the amount of graftingBulk chemical productionBlow moldingPtru catalyst

The invention discloses a preparation method of a high-hexene grafted high-density polyethylene geomembrane blow molding material. The method comprises the following steps: (1) when a diluting agent is always under a circulation state, placing monomer ethylene and 1-hexene in a reaction vessel; adding an antistatic agent and an catalyst subjected to an activation treatment; adjusting the reaction temperature in the reaction vessel to 92-98 DEG C until the melt flow rate of a reaction product is 10.0-13.0g / 10min and the density of the reaction product is 0.937-0.939kg / m<3>, thereby obtaining ethylene-hexene polyethylene copolymer base resin with weight average molecular weight of 200,000 to 300,000, 1-hexene content of not less than 1.20% and crystallinity of 46.5-49.5%; (2) uniformly mixing 99.5-99.8 parts of the ethylene-hexene polyethylene copolymer base resin and 0.20-0.50 part of an antioxidant; and adding the mixture to a mixer for extrusion granulation, so as to obtain the geomembrane blow molding material. According to the method, a high-activity novel chromium catalyst is adopted, the equipment limitation of a loop slurry process is overcome, and high-hexene grafted high-density polyethylene is produced. With the method, reaction scale is effectively ameliorated, a reactor wall attachment phenomenon is reduced, production is smooth, and the productivity of the special material is high.

Owner:CHINA PETROLEUM & CHEM CORP

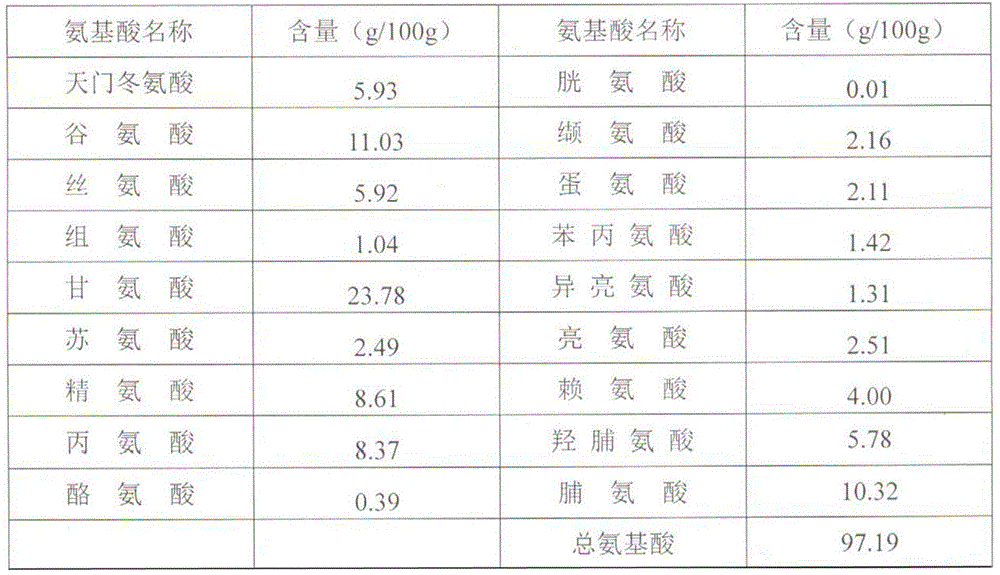

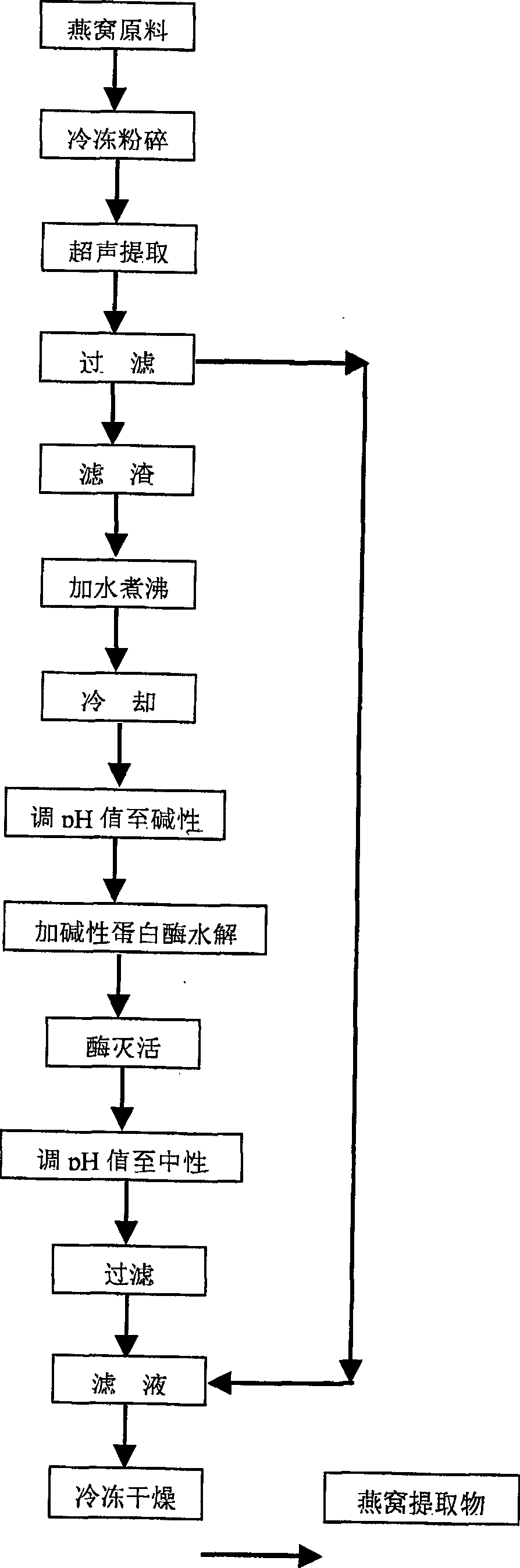

Process for preparing edible bird's nest extraction used for cosmetics

ActiveCN100531708CReasonable molecular weight distributionEasy to operateCosmetic preparationsToilet preparationsSolubilityWater baths

The invention discloses a method for preparing cubilose extract used in cosmetics. Steps are as follows: (1) cryogenic grinding cubilose, sieving, adding water 20 times the weight of the dry cubilose, ultrasonic extracting at room temperature for 1h, filtering, (2) adding water 30 times the weight of the dry cubilose into the filter cake, boiling for 60 minutes under mechanical stirring, (3) cooling to room temperature, regualting pH to 9.8 with Na2CO3 solution, adding alkali protease 1.5% the weight of the dry cubilose, carrying out hydrolysis in water bath at 55deg.C under mechanical stirring, (4) deactivating enzyme at 85deg.C for 20min, (5) cooling to room temperature, regulating pH to neutrality with thin HCl, (6) filtering, combining the filtrate with ultrasonic extract, and freeze drying to obtain powdered cubilose extract. The invention has simple process, good extract water-solubility, high extraction yield, rational product molecular weight distribution, good wetness protection, high product whitening activity, and good product stability; and avoid the influence of boiling to the thermo instable active ingredient in hydrolysis technology. The obtained cubilose extract is suitable for using as cosmetic compounding.

Owner:ZHEJIANG UNIV +1

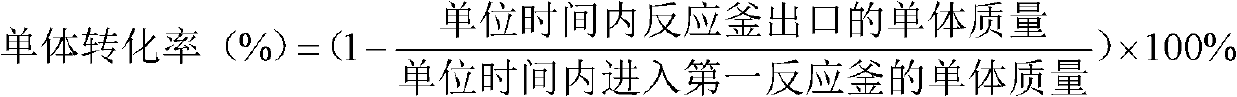

Conjugated diene/monovinyl aromatic hydrocarbon copolymer and continuous polymerization production method thereof as well as and oil-extended rubber and preparation method thereof

The invention relates to a 1,3-conjugated diene / monovinyl aromatic hydrocarbon copolymer and a continuous polymerization production method thereof. The method comprises the following steps of: continuously feeding reaction materials containing monomers a, an organic solvent, 1,2-butadiene, alkyl tetrahydrofurfuryl ether and organic lithium into a reaction kettle, and polymerizing the monomers a for 30-270 minutes under the conditions of a reaction temperature in the range from 130 to 150 DEG C and reaction pressure in the range from 0.5 to 0.9 MPa, thereby obtaining the copolymer, wherein the monomers a refer to monovinyl aromatic hydrocarbon and conjugated diene, and on the basis of the weight of the monomers a, the dosage of the 1,2-butadiene is 75-225 ppm. The copolymer obtained by the method provided by the invention has high vinyl content, high molecular weight distribution and high Mooney viscosity, and rational gel content. The invention also relates to oil-extended rubber and a preparation method thereof. The oil-extended rubber provided by the invention is suitable for subsequent processing.

Owner:CHINA PETROLEUM & CHEM CORP +1

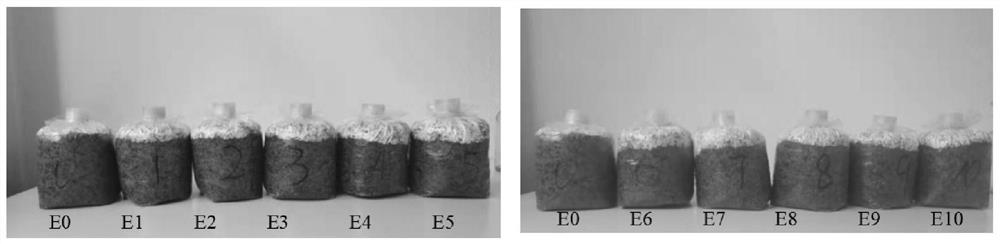

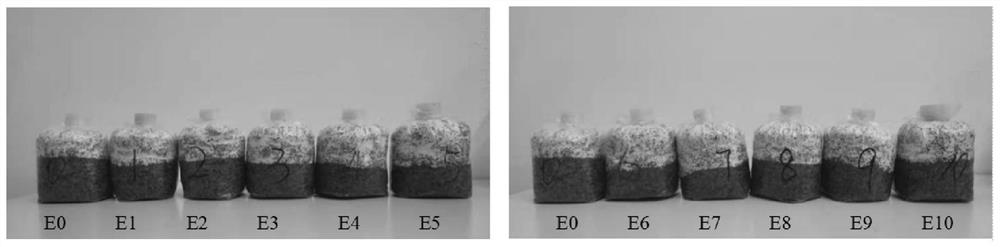

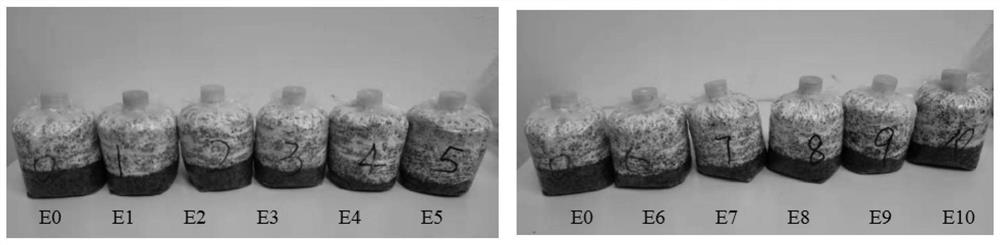

Application of high-substrate-concentration fermented corn steep liquor product in cultivation and production of edible mushrooms

ActiveCN113455286AInhibit the growth of bacteriaHigh nutritional valueFood processingCultivating equipmentsNutrientProtein protein

The invention provides application of a high-substrate-concentration fermented corn steep liquor product in cultivation and production of edible mushrooms, and belongs to the field of deep processing of agricultural and sideline products. According to the invention, a high-concentration corn steep liquor fermented product is prepared by taking the corn steep liquor as a raw material and adopting a microorganism high-concentration liquid fermentation technology, macromolecular protein in the corn steep liquor can be moderately degraded, so that the corn steep liquor has reasonable molecular weight distribution and has the characteristics of quick-acting and medium-long-acting nitrogen source nutrition supply; nutrient substances in the high-concentration corn steep liquor fermented product can activate synthesis and secretion of enzyme systems of the edible mushrooms and accelerate decomposition of cellulose, lignin and the like in a mushroom bag matrix, so that edible mushroom mycelia can quickly absorb nutrient substances which cannot be utilized in a normal state in the initial vegetative growth stage, generation of various induction enzymes is accelerated, the mycelia are robust and rapidly enter stages of culture medium material decomposition, absorption and resynthesis, and the beneficial effects of high mycelium growing speed, tidy fruiting, improvement of the yield and quality of sporocarp and the like are achieved.

Owner:QIQIHAR UNIVERSITY

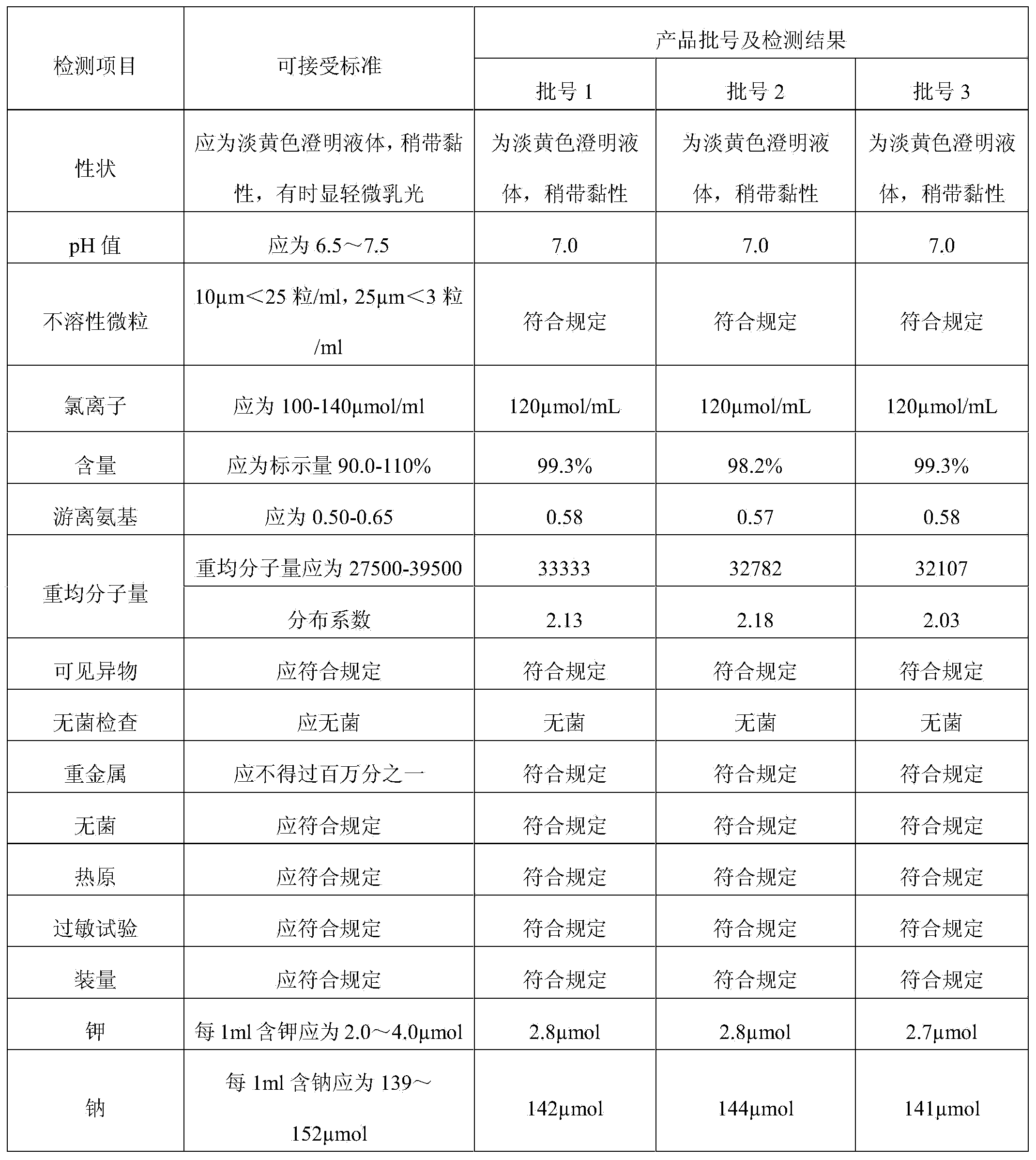

Method for preparing donkey-hide gelatin plasma substitute injection

InactiveCN103432567AReasonable molecular weightReasonable molecular weight distributionHydrolysed protein ingredientsPharmaceutical delivery mechanismPotassiumBlood plasma

The invention relates to a method for preparing a donkey-hide gelatin plasma substitute injection. According to the method, degradation terminal points of donkey-hide gelatin can be controlled through monitoring relative viscosity of a donkey-hide gelatin solution to ensure polypeptide molecular weight and reasonable molecular weight distribution after the donkey-hide gelatin solution is degraded, so as to enable osmotic pressure of the prepared donkey-hide gelatin plasma substitute injection to be close to that of human plasma, and a relatively good capacity expansion effect is realized in clinic practice; succinic anhydride is used for performing acylation modification on the degraded donkey-hide gelatin solution, a polypeptide chain of the modified donkey-hide gelatin solution is relatively stable, so that the polypeptide molecular weight and the molecular weight distribution are effectively controlled, and the safety and the availability of a product are improved; in a process of preparing plasma substitutes, an appropriate amount of electrolytes such as sodium chloride, potassium chloride and calcium chloride are added so as to ensure that when the donkey-hide gelatin plasma substitutes are injected in quantity, electrolyte disturbance can be avoided; under different PH value conditions, through double adsorption of diatomite and activated carbon, heat sources, impurities and colors can be sufficiently removed, so that adverse reactions in clinical use can be avoided.

Owner:武汉华龙生物制药有限公司

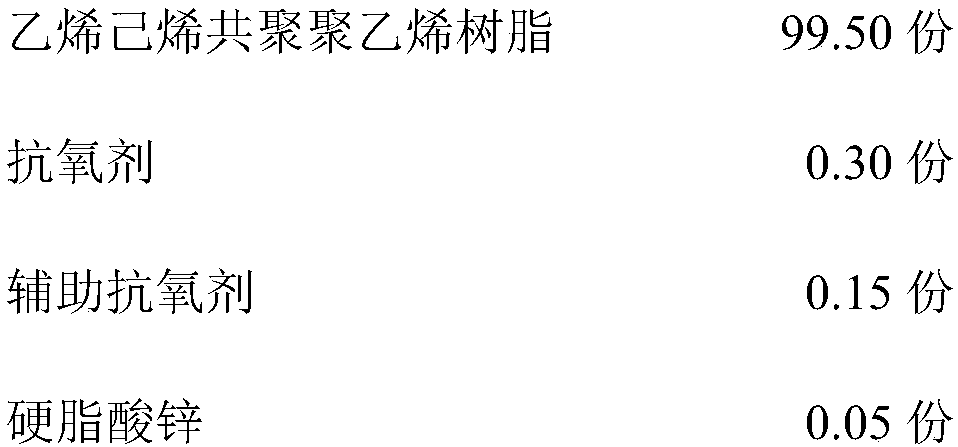

Preparation method of environment stress cracking resistant blow molding material special for auto plastic fuel tank

ActiveCN105462048AHigh molecular weightReasonable molecular weight distributionPtru catalystReaction temperature

The invention discloses a preparation method of an environment stress cracking resistant blow molding material special for an auto plastic fuel tank. The preparation method comprises the following steps: (1) under the condition that a diluent is always in a circulating state and in the presence of a catalyst, placing raw materials including ethylene and 1-hexene into a reaction vessel for reacting, wherein the reaction temperature is 94 to 100 DEG C, and the reaction is stopped when the melt flow rate of a reaction product reaches 5.3 to 6.5g / 10min and the density is 0.943 to 0.947kg / m<3>, so as to obtain ethylene hexene copolymerization polyethylene resin; (2) taking and uniformly mixing 99.50 to 99.80 parts of ethylene hexene copolymerization polyethylene resin, 0.05 to 0.35 part of antioxidant, 0.03 to 0.15 part of auxiliary antioxidant and 0.02 to 0.06 part of zinc stearate, then adding the same into a mixing mill for extrusion pelletization, and cooling particles in cooling water; the obtained blow molding material special for the auto plastic fuel tank has relatively high melt strength, excellent environment stress cracking resistance and creep resistance, and good chemical corrosion resistance, and is suitable for machine shaping of single-layer and multilayer auto plastic fuel tanks.

Owner:CHINA PETROLEUM & CHEM CORP

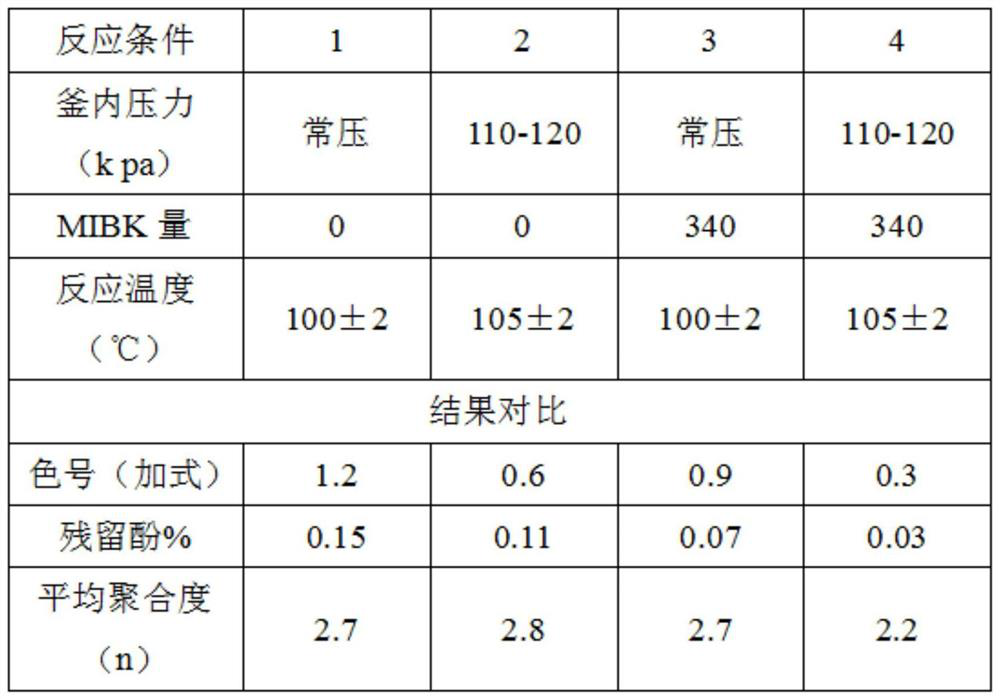

Synthetic process of phenolic resin

ActiveCN111978499AHigh synthesis efficiencyUniform molecular weight distributionOXALIC ACID DIHYDRATEEngineering

The invention discloses a synthetic process of phenolic resin in the technical field of fine chemical synthesis. The synthetic process comprises the following steps: sequentially adding raw materialsincluding phenol, formaldehyde, oxalic acid and MIBK into a reaction kettle; starting to raise the temperature to 100 DEG C; closing the reaction kettle and emptying; starting to adjust the pressure in the kettle to 110kpa-120kpa; opening steam of the reaction kettle to keep reflux in the kettle; starting to time for 2-5 hours; after the reflux is finished, starting to recycle phenol and MIBK; keeping the reaction kettle to continuously raise the temperature to 160 DEG C and keeping the vacuum degree to be below 5kpa; and after the recycling is finished, sampling and detecting. According to the synthetic process disclosed by the invention, quantitative MIBK is added and then the temperature is raised; certain pressure is kept and reaction is carried out under micro-positive pressure; in the phenolic resin produced by the manner, the synthetic efficiency is higher and the molecular weight distribution of the obtained phenolic resin is more uniform and more reasonable; the requirements on gelation time of phosphorus-containing epoxy industry are met; and the positive pressure reaction is adopted and air is isolated, so that the color and luster are lighter.

Owner:山东德源环氧科技有限公司

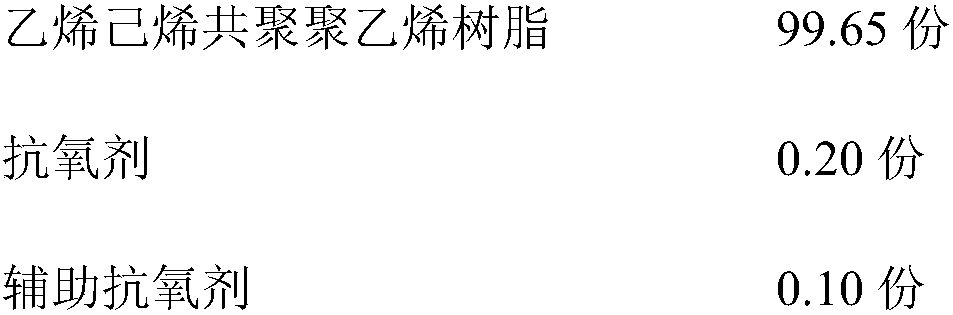

Blow moulding material being resistant to environmental stress cracking and being specially used for automobile plastic fuel tank

ActiveCN105419076AHigh molecular weightReasonable molecular weight distributionFuel tankChemical corrosion

The invention discloses a blow moulding material being resistant to environmental stress cracking and being specially used for automobile plastic fuel tanks. The blow moulding material has environmental stress cracking resistance being more than 8000 h. The blow moulding material is mainly prepared from following raw materials, by weight: 99.50-99.80 parts of ethylene-hexylene polymerized polyethylene resin, 0.05-0.35 parts of an anti-oxidant, 0.03-0.15 parts of an auxiliary anti-oxidant and 0.02-0.06 parts of a demoulding agent. The blow moulding material is high in melt strength, excellent in environmental stress cracking resistance and creep resistance, and excellent in chemical corrosion resistance, and is suitable for processing and moulding single-layer and multi-layer automobile plastic fuel tanks.

Owner:CHINA PETROLEUM & CHEM CORP

A kind of small hollow container blow molding material and preparation method thereof

The invention discloses a small hollow blown material. The material is prepared from the following raw materials in parts by weight: 99.95-98.80 parts of ethylene hexylene copolymerized polyethylene base resin, 0.02-0.4 part of antioxidant, and 0.03-0.8 part of co-antioxidant. The invention also discloses a method for preparing the small hollow blown material. According to the blown material for small hollow containers, the ethylene hexylene copolymerized polyethylene base resin is adopted and has good environmental stress cracking resistance, outstanding oxidation resistance and good corrosion resistance; low n-hexane extract is contained, so that the blown material is suitable for blowing various corrosion resistance small hollow containers, such as small package containers for filling chemical solvent, pesticide, herbicide, detergent and industrial lubricant, also can be used for food and medicine packages with strict requirement for hygiene, the product is easy to granulate and stable in supply.

Owner:CHINA PETROLEUM & CHEM CORP

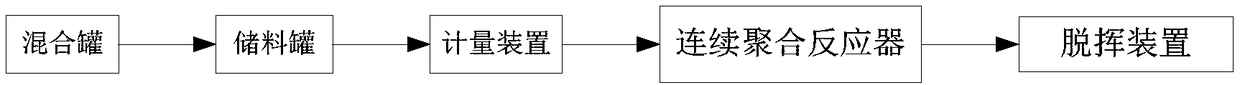

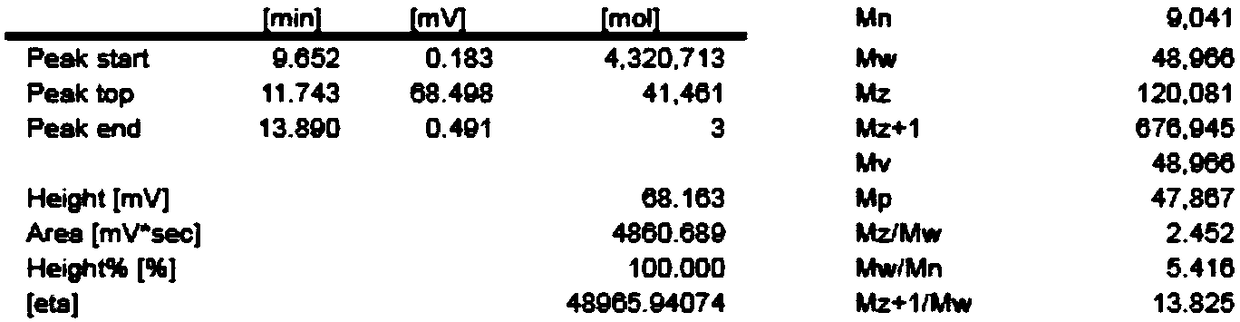

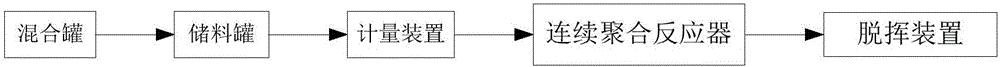

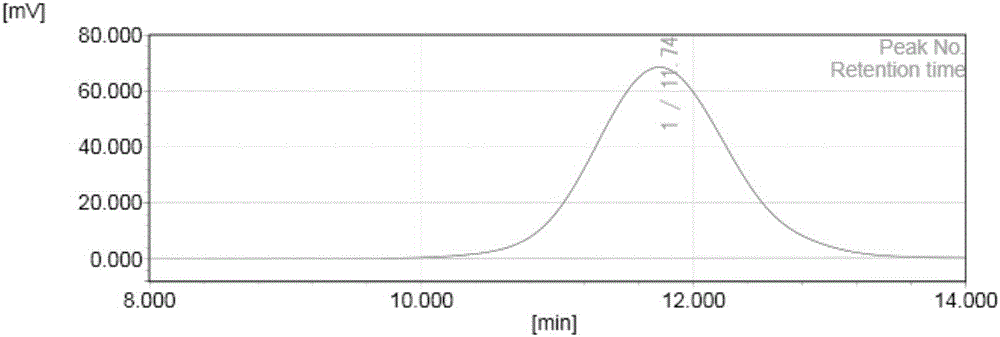

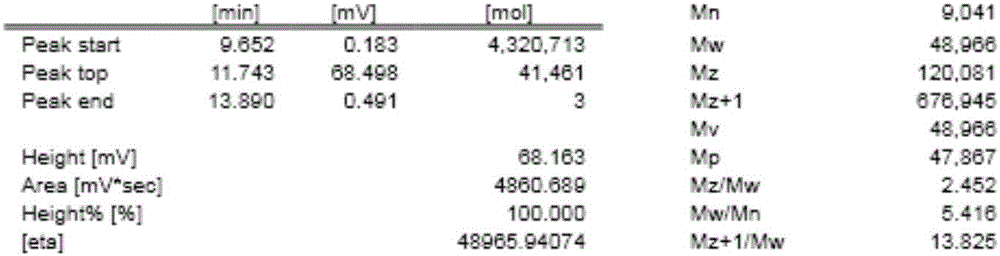

A kind of optical grade pmma continuous bulk polymerization method and production system thereof

The invention provides an optical-grade PMMA (polymethyl methacrylate) continuous bulk polymerization method and production system. The method comprises the following steps: mixing reaction raw materials methyl methacrylate, initiator and assistant according to proportions to obtain mixed solution, performing metering, then injecting the mixed solution into a continuous polymerization reactor to perform polymerization reaction and continuous extrusion, and performing devolatilization treatment after extrusion to obtain a PMMA solid material. By dispersing and thinning the materials through screw-type shaft body rotation and shearing, the molecular weight of the materials is enabled to be reasonably distributed, the mixing uniformity of reaction components is improved, the reaction components are enabled to exchange heat with a machine barrel wall and a shaft outer wall in time, the entire process is continuous, the material retention time is reduced, the probability of heat accumulation is reduced, the temperature gradient between the materials is reduced, the problem of reaction heat control of bulk polymerization is solved and finally the continuous extrusion of the product in the reaction process is realized.

Owner:CENTURY OPTICOMM CO LTD

Optical-grade PMMA (polymethyl methacrylate) continuous bulk polymerization method and production system

The invention provides an optical-grade PMMA (polymethyl methacrylate) continuous bulk polymerization method and production system. The method comprises the following steps: mixing reaction raw materials methyl methacrylate, initiator and assistant according to proportions to obtain mixed solution, performing metering, then injecting the mixed solution into a continuous polymerization reactor to perform polymerization reaction and continuous extrusion, and performing devolatilization treatment after extrusion to obtain a PMMA solid material. By dispersing and thinning the materials through screw-type shaft body rotation and shearing, the molecular weight of the materials is enabled to be reasonably distributed, the mixing uniformity of reaction components is improved, the reaction components are enabled to exchange heat with a machine barrel wall and a shaft outer wall in time, the entire process is continuous, the material retention time is reduced, the probability of heat accumulation is reduced, the temperature gradient between the materials is reduced, the problem of reaction heat control of bulk polymerization is solved and finally the continuous extrusion of the product in the reaction process is realized.

Owner:CENTURY OPTICOMM CO LTD

A kind of preparation method of lithium battery aluminum-plastic film outer layer adhesive

ActiveCN109851763BMeet application performance requirementsEasy to operateAdhesivesPtru catalystOrganic synthesis

The invention belongs to the field of organic synthesis, relates to a polymer polymerization technology, and in particular relates to a method for preparing an adhesive for the outer layer of an aluminum-plastic film of a lithium battery. The aliphatic dihydric alcohol, the aliphatic dibasic acid and the aromatic dibasic acid are subjected to an esterification reaction under the action of an antioxidant in an inert gas under normal pressure; Under the action of a catalyst, the water and small molecular polymers generated by the polycondensation reaction are removed under high temperature and high vacuum conditions, and a solvent is added to the reactants to dissolve, thereby obtaining a polymer solution with a molecular weight of 10,000-30,000. The invention has simple operation process, reasonable molecular weight distribution, stable product quality and application performance, is not easy to crystallize, has good flexibility, excellent tensile performance, and has good hydrolysis resistance, cohesiveness and impact resistance. The adhesive product prepared by the invention can fully meet the application performance requirements of the aluminum-plastic film of the lithium battery for the outer layer adhesive.

Owner:SHENYANG RES INST OF CHEM IND

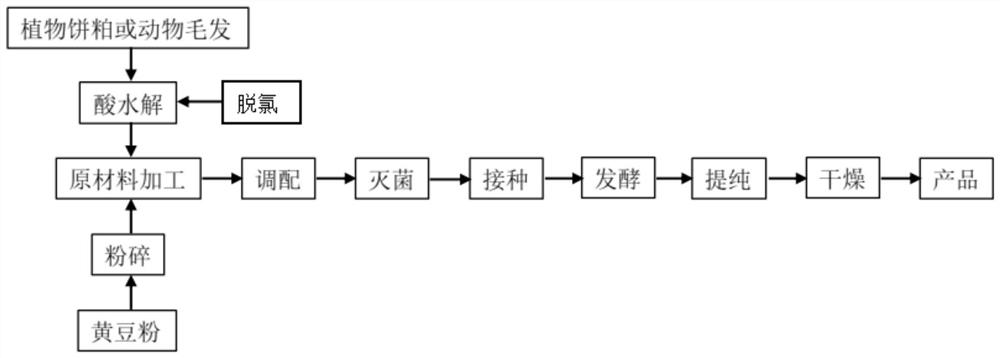

A preparation method and fermentation medium of a Shenzimycin fermentation medium

ActiveCN111485009BImprove resource utilizationGood source of nitrogenBacteriaMicroorganism based processesBiotechnologyMonosodium glutamate

The invention discloses a method for preparing a fermentation medium of Shenzimycin and the fermentation medium. After the raw materials are processed and prepared according to the medium formula, water is added and evenly placed in a fermentation tank. Cooling; add the Shenzimycin fermentation strain into the fermenter under aseptic conditions, cultivate it at 26-28°C and 200-300r / min for 68-72 hours, and then purify to obtain high-yield Shenzimycin; Among them, the medium formula is: soybean powder 5-10g / L, corn steep liquor 5-16g / L, plant cake hydrolyzed amino acid solution 20-30g / L, glucose 10-15g / L, glycerin 20-25g / L, grain Sodium phosphate 5~15g / L, the solvent is water. The production capacity of the shenzimycin in the fermentation medium of the invention is increased by 2.4 to 2.75 times, and the recovery rate of the shenzimycin reaches 78% to 80%.

Owner:SHANGHAI NONGLE BIOLOGICAL PROD

Liquid phase synthesis method of high isotactic polybutene-1

Owner:山东省滕州瑞达化工有限公司

Method for producing polyglucose

The invention relates to a method for producing polyglucose, which comprises the following steps: (1) blending glucose, sorbitol and citric acid in a weight percent range of 80-90: 1-5: 9-15, then performing stirring reaction on the mixture for 3 to 8 hours in a reaction kettle at the temperature of between 150 and 200 DEG C under the negative pressure of between 0.02 to 0.06MPa, and performing polymerization reaction on the mixture to obtain a polymer; (2) adsorbing and decoloring the polymer; and (3) spray-drying the polymer to obtain a finished product of the polyglucose. The producing method solves the difficult problems of complex existing production process, incomplete polymerization reaction, low product purity, poor color and luster and the like, and has the advantages of rich rawmaterial source, simple process, high purity of the finished product, adaptability for large-scale industrialized production and the like; and electric heating is adopted during processing, and the water vapor produced in the polymerization reaction is condensed and discharged, so the whole production process reflects the advantages of no waste gas emission, no pollution, little consumed energy, simple process and energy conservation.

Owner:TIANJIN UNIV OF SCI & TECH

Special peptone for producing inosine through fermentation as well as preparation method and application of peptone

PendingCN114058666AReasonable molecular weight distributionPromote growth and reproductionFermentationInosine synthesisMass propagation

The invention discloses special peptone for producing inosine through fermentation as well as a preparation method and application of the peptone, belonging to the field of peptone preparation. The preparation method for special peptone used for producing inosine through fermentation comprises the following steps: (1) adding various enzymes into fishbone soup to obtain a concentrated fishbone peptone solution; (2) adding various enzymes into a bovine bone soup to obtain a concentrated bovine bone peptone solution; (3) adding various enzymes into a soybean meal filtrate to obtain a concentrated soybean meal peptone solution; and (4) mixing the above three concentrated solutions in proportion, and conducting drying into powder to obtain the special peptone for fermentation production of inosine. The peptone prepared by the method is reasonable in molecular weight distribution, effectively controls a strain fermentation metabolism speed while promoting mass propagation and growth of strains, prolongs inosine synthesis time, increases inosine yield, and lays an important foundation for large-scale inosine fermentation production.

Owner:淄博锦源生物科技股份有限公司

Preparation method of special blow molding material for automobile plastic fuel tank resistant to environmental stress cracking

ActiveCN105462048BHigh molecular weightReasonable molecular weight distributionCrack resistanceAntioxidant

Owner:CHINA PETROLEUM & CHEM CORP

Alkyd resin preparation method and resin prepared by the same, and acrylic acid modified alkyd resin preparation method and resin prepared by the same

The invention provides an alkyd resin preparation method and a resin prepared by the same, and an acrylic acid modified alkyd resin preparation method and a resin prepared by the same. According to the alkyd resin preparation method, vegetable oil is used as a raw material, and unsaturated carboxylic acid and / or unsaturated anhydride are / is added step by step, so that the structure of the alkyd resin is improved. According to the preparation method of the acrylic acid modified alkyd resin, a unsaturated monomer is fed step by step, and the feeding time is controlled, so that the unsaturated monomer is uniformly grafted on an alkyd resin, and the molecular weight distribution is narrow. The acrylic acid modified alkyd resin prepared by the preparation method is applied to water-based coating materials, so that a paint film has the advantages of high drying speed, high glossiness, good fullness, low VOC emission, excellent comprehensive performance and the like.

Owner:WANHUA CHEM BEIJING +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com