Preparation method of special blow molding material for automobile plastic fuel tank resistant to environmental stress cracking

A technology that is resistant to environmental stress and fuel tanks, applied in the field of blow molding plastics, can solve problems such as high safety performance requirements, expensive raw materials, and difficulty in ensuring supply, and achieve outstanding low-temperature impact resistance, excellent rigidity and toughness balance, and excellent Effect of environmental stress cracking resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

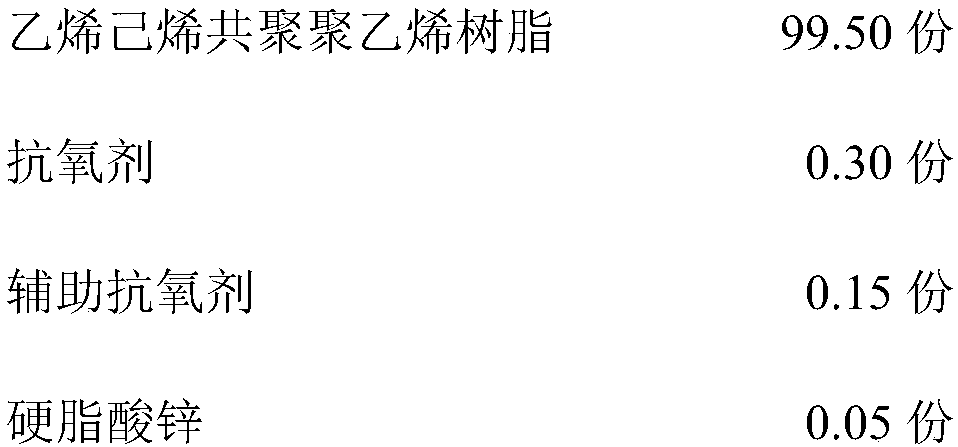

Embodiment 1

[0036] Raw materials for ethylene-hexene copolymerized polyethylene resin:

[0037] 1) The feed rate of polymer grade ethylene is 30t / h

[0038] 2) Catalyst: Chromium catalyst 963, adding amount 112kg / h

[0039] 3) The amount of 1-hexene added is 457kg / h

[0040] 4) diluent isobutane 36kg / h

[0041] The preparation method of ethylene-hexene copolymerized polyethylene:

[0042] The diluent isobutane is always in a circulating state. The ethylene and 1-hexene are injected into the loop reactor respectively, the ethylene-hexene feed ratio is strictly controlled, and the activated catalyst is added to control the reaction temperature in the reactor to 94.8 ℃, the ethylene feed rate is 30t / h, the 1-hexene feed rate is 457kg / h, the catalyst feed rate is 112kg / h, the melt flow rate of ethylene and 1-hexene reaction is 6.2g / 10min, and the density is 0.945g / h cm 3 The ethylene-hexene copolymerized polyethylene resin has a molecular weight distribution of 15.3 and a weight average ...

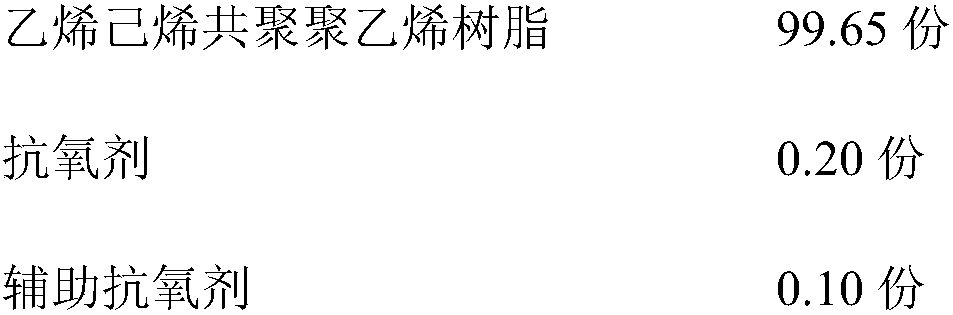

Embodiment 2

[0050] Raw materials for ethylene-hexene copolymerized polyethylene resin:

[0051] 1) The feed rate of polymer grade ethylene is 38t / h

[0052] 2) Catalyst: Chromium catalyst 963, adding amount 149kg / h

[0053] 3) The amount of 1-hexene added is 795kg / h

[0054] 4) diluent isobutane 36.8kg / h

[0055] The preparation method of ethylene-hexene copolymerized polyethylene resin:

[0056] The diluent isobutane is always in a circulating state, inject ethylene and 1-hexene into the loop reactor respectively, strictly control the feed ratio of ethylene and hexene, and add a pre-activated catalyst to control the reaction temperature in the reactor to 98.2 ℃, the feed rate of ethylene is 38t / h, the feed rate of 1-hexene is 795kg / h, the feed rate of catalyst is 149kg / h, the melt flow rate of ethylene and 1-hexene is 5.4g / 10min, and the density is 0.945 g / cm 3 The ethylene-hexene copolymerized polyethylene resin has a molecular weight distribution of 16.8 and a weight average mol...

Embodiment 3

[0065] Raw materials for ethylene-hexene copolymerized polyethylene resin:

[0066] 1) The feed rate of polymer grade ethylene is 33.8t / h

[0067] 2) Catalyst: Chromium catalyst 963, adding amount 196.1kg / h

[0068] 3) The amount of 1-hexene added is 842.8kg / h

[0069] 4) diluent isobutane 35.8kg / h

[0070] The preparation method of ethylene-hexene copolymerized polyethylene resin:

[0071] The diluent isobutane is always in a circulating state, inject ethylene and 1-hexene into the loop reactor respectively, strictly control the feed ratio of ethylene and hexene, and add a pre-activated catalyst to control the reaction temperature in the reactor to 95 ℃, the ethylene feed rate is 33.8t t / h, the 1-hexene feed rate is 842.8kg / h, the catalyst feed rate is 196.1kg / h, and the melt flow rate obtained by the reaction of ethylene and 1-hexene is 5.5g / 10min. The density is 0.945g / cm 3 The ethylene-hexene copolymerized polyethylene resin has a molecular weight distribution of 19...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com