A preparation method and fermentation medium of a Shenzimycin fermentation medium

A fermentation medium and the technology of Shenzimycin, applied in the field of pesticides, can solve the problems of low potency, high cost, unfavorable industrialization development, etc., and achieve the effect of eliminating antagonism and improving resource utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

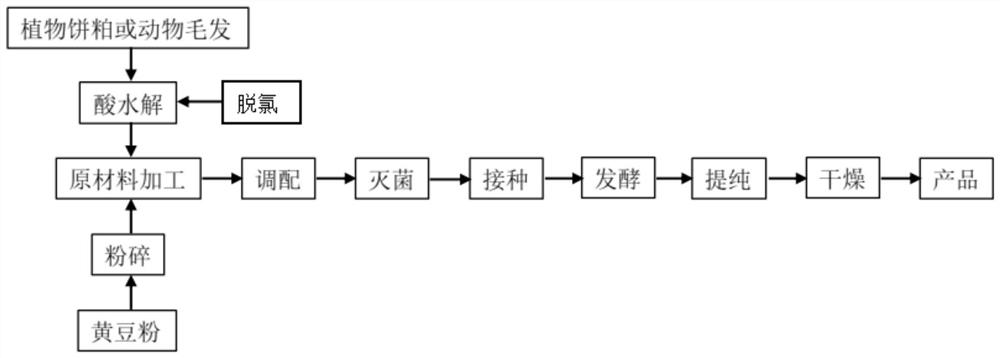

Method used

Image

Examples

Embodiment 1

[0033] A high-yielding shenzamycin fermentation medium formula and preparation method, the specific steps are as follows:

[0034](1) Preparation of soybean powder and soybean meal amino acid liquid: soybeans are pulverized by a grinder for 30 seconds, passed through a 100-mesh sieve, and ground for use immediately; soybean meal is hydrolyzed with 6mol / L hydrochloric acid at 110°C for 24 hours to obtain soybean meal hydrolyzed amino acid solution; The amino acid liquid is distilled under reduced pressure to obtain a dechlorinated hydrolyzed amino acid liquid. The vacuum distillation steps are as follows: open the vacuum to 0.1MPa, distill at 110°C until the hydrochloric acid steaming speed slows down, and after recovery, a dechlorinated hydrolyzed amino acid solution with a chloride ion content of 8% (dry basis of the remaining material) is obtained.

[0035] (2) Preparation of fermentation medium: soybean powder 5g / L, corn steep liquor 5g / L, soybean meal dechlorination hydrol...

Embodiment 2

[0040] A high-yielding shenzamycin fermentation medium formula and preparation method, the specific steps are as follows:

[0041] (1) Preparation of soybean flour and soybean meal amino acid liquid: soybeans are pulverized by a grinder for 30 seconds, passed through a 100-mesh sieve, and ground for use immediately; soybean meal is hydrolyzed with 6mol / L hydrochloric acid at 110°C for 24 hours to obtain soybean meal hydrolyzed amino acid solution; The hydrolyzed amino acid liquid is distilled under reduced pressure to obtain the dechlorinated hydrolyzed amino acid liquid. The steps of vacuum distillation are as follows: open the vacuum to 0.1MPa, distill at 110°C until the hydrochloric acid distilling speed slows down, and after recovery, soybean meal dechlorinated hydrolyzed amino acid solution with a chloride ion content of 8% (the remaining material on a dry basis) is obtained.

[0042] (2) Preparation of fermentation medium: soybean powder 8g / L, corn steep liquor 11g / L, so...

Embodiment 3

[0048] A high-yielding shenzamycin fermentation medium formula and preparation method, the specific steps are as follows:

[0049] (1) Preparation of soybean flour and soybean meal amino acid liquid: soybeans are pulverized by a grinder for 30 seconds, passed through a 100-mesh sieve, and ground for use immediately; soybean meal is hydrolyzed with 6mol / L hydrochloric acid at 110°C for 24 hours to obtain soybean meal hydrolyzed amino acid solution; The hydrolyzed amino acid liquid is distilled under reduced pressure to obtain the dechlorinated hydrolyzed amino acid liquid. The vacuum distillation steps are as follows: open the vacuum to 0.1MPa, distill at 110°C until the hydrochloric acid steaming speed slows down, and after recovery, a dechlorinated hydrolyzed amino acid solution with a chloride ion content of 8% (dry basis of the remaining material) is obtained.

[0050] (2) Preparation of fermentation medium: soybean powder 10g / L, corn steep liquor 16g / L, soybean meal dechlo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com