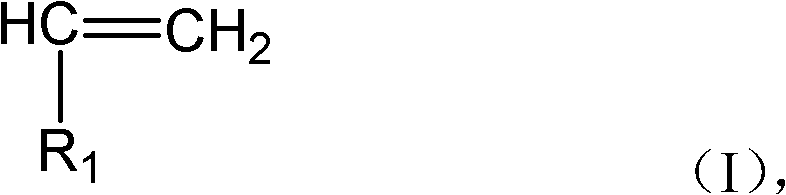

Conjugated diene/monovinyl aromatic hydrocarbon copolymer and continuous polymerization production method thereof as well as and oil-extended rubber and preparation method thereof

A monovinyl aromatic hydrocarbon and conjugated diene technology, which is applied in the production of conjugated diene/monovinyl aromatic hydrocarbon copolymer and its continuous polymerization, and the fields of oil-extended rubber and preparation thereof, can solve the problem of narrow molecular weight distribution and processing performance. Poor and other problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0036] According to the preparation method of the oil-extended rubber of the present invention, the method comprises mixing and contacting the copolymer with the extender oil, wherein, based on the total amount of the oil-extended rubber, the amount of the copolymer used is 66-80% by weight, so The amount of the extender oil is 20-34% by weight, wherein the copolymer is the 1,3-conjugated diene / monovinylarene copolymer prepared by the method of the present invention.

[0037] According to the preparation method of the oil-extended rubber of the present invention, the present invention has no special requirements on the conditions for mixing and contacting the copolymer and the extending oil. The copolymer solution after polymerization of the present invention can be mixed with the extender oil in a continuous contact manner, or the copolymer solution can be mixed with the extender oil in a discontinuous contact manner. Preferably, the copolymer solution after polymerization of...

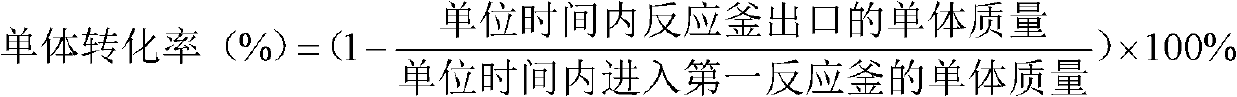

Embodiment 1

[0049] The continuous polymerization process was adopted in the experiment, and the reaction was carried out in two 5-liter polymerization reactors connected in series. Under the protective atmosphere of high-purity nitrogen, the pressure in the polymerization tank is controlled at 0.7MPa (gauge pressure), and a mixed solvent of 700g of cyclohexane and n-hexane (cyclohexane and n-hexane, the weight ratio is 88:12) is added to the first tank. , after heating up to 100°C through the jacket, continuously add 35°C mixed solvent of cyclohexane and n-hexane (hexanaphthene and n-hexane, weight ratio is 88:12) and monomers to the first kettle, various reactions The feed rate of raw materials is: cyclohexane and n-hexane (hexanaphthene and n-hexane, weight ratio is 88: 12) 3538g / h, 1,3-butadiene 669g / h, styrene 329g / h, ethyl 2.268g / h of tetrahydrofurfuryl ether, 0.2201g / h of n-butyllithium and 0.1996g / h of 1,2-butadiene. The reaction pressure of each polymerization tank is 0.6-0.80Mpa...

Embodiment 2

[0051] Using the same experimental conditions as in Example 1, the only difference is that the feed rate of 1,2-butadiene is 0.1497 g / h. The data of styrene-butadiene copolymer and oil-extended rubber are shown in Table 1 and Table 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com