Large hollow container blow molding material and preparation method thereof

A large hollow, raw material technology, applied in the field of blow molding plastics, can solve the problems of difficult granulation, long-term stable supply, inconvenient production process, etc., to meet processing performance and various physical and mechanical properties, excellent environmental stress cracking resistance , The effect of good rigidity, toughness and balance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

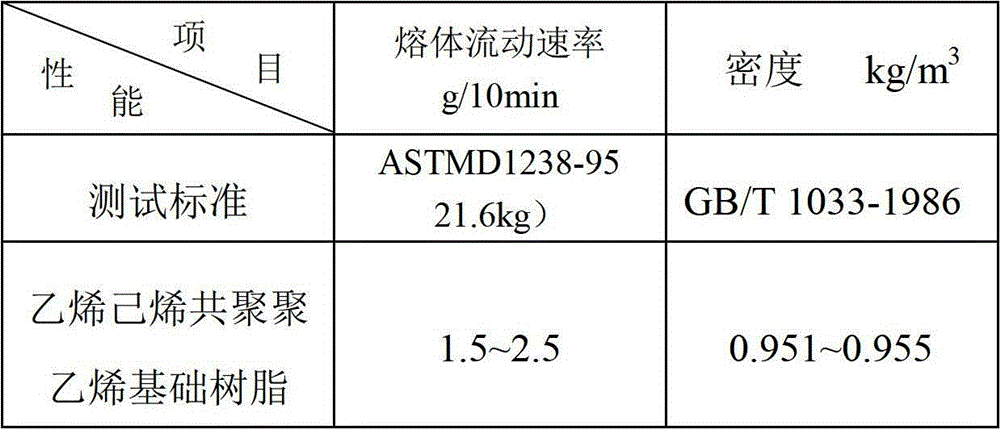

[0039] Raw materials for ethylene-hexene copolymerized polyethylene base resin:

[0040] The raw materials for the production of base resins are the following substances:

[0041] 1) The feed rate of polymer grade ethylene is 33.5 tons / hour

[0042] project

Purity %

Water content 10 -6

CO content10 -6

o 2 Content 10 -6

indicators

≥99.2

≤1

≤1

≤2

[0043] 2) Catalyst: NTR-973 dosage 246kg / hour

[0044] 3) 1-hexene addition 100kg / hour

[0045] project

Purity %

Water content 10 -6

CO content10 -6

Isomerized alpha olefins

indicators

≥98.5

≤20

≤5

≤1%

[0047] The preparation method of ethylene-hexene copolymerized polyethylene base resin:

[0048]The diluent isobutane is always in a circulating state, inject ethylene and hexene into the loop reactor respectively, strictly control the feed ...

Embodiment 2

[0059] Raw materials for ethylene-hexene copolymerized polyethylene base resin:

[0060] The raw materials for the production of base resins are the following substances:

[0061] 1) The feed rate of polymer grade ethylene is 35 tons / hour

[0062] project

Purity %

Water content 10 -6

CO content10 -6

o 2 Content 10 -6

indicators

≥99.2

≤1

≤1

≤2

[0063] 2) Catalyst: NTR-973 dosage 300kg / hour

[0064] 3) The amount of 1-hexene added is 140kg / hour

[0065] project

Purity %

Water content 10 -6

CO content10 -6

Isomerized alpha olefins

indicators

≥98.5

≤20

≤5

≤1%

[0066] 4) An appropriate amount of diluent isobutane.

[0067] The preparation method of ethylene-hexene copolymerized polyethylene base resin:

[0068] The diluent isobutane is always in a circulating state, inject ethylene and hexene into the loop reactor r...

Embodiment 3

[0079] Raw materials for ethylene-hexene copolymerized polyethylene base resin:

[0080] The raw materials for the production of base resins are the following substances:

[0081] 1) Polymerization grade ethylene feed rate 30 tons / hour

[0082] project

Purity %

Water content 10 -6

CO content10 -6

o 2 Content 10 -6

indicators

≥99.2

≤1

≤1

≤2

[0083] 2) Catalyst: NTR-973 dosage 200kg / hour

[0084] 3) 1-hexene addition 90kg / hour

[0085] project

Purity %

Water content 10 -6

CO content10 -6

Isomerized alpha olefins

indicators

≥98.5

≤20

≤5

≤1%

[0086] 4) An appropriate amount of diluent isobutane.

[0087] The preparation method of ethylene-hexene copolymerized polyethylene base resin:

[0088] The diluent isobutane is always in a circulating state, inject ethylene and hexene into the loop reactor respectively, stric...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com