Patents

Literature

64results about How to "Satisfy processability" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

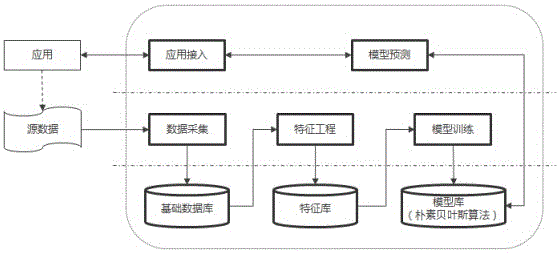

Real-time recommendation system and method of financial products of banks based on Naive Bayesian classification

InactiveCN106600369AImprove experienceIncrease stickinessMathematical modelsFinanceData setData mining

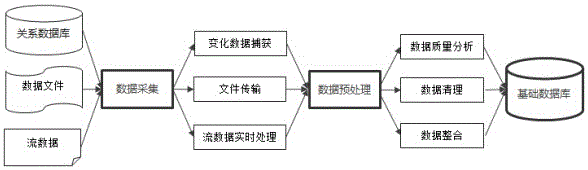

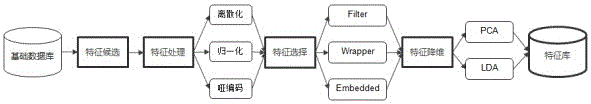

The invention discloses a real-time recommendation system and method of financial products of banks based on Naive Bayesian classification wherein the method comprises: acquiring the data of a bank business system, a peripheral system, and an internet / mobile internet; processing and storing the data in a basic database; conducting characteristic processing to the data attributes of the customers in a certain area; converting for data characteristics to develop a characteristic database; classifying the data in the characteristic database as a training data set and a verification data set which are used respectively for the training and estimating of a Naive Bayesian classification algorithm model; obtaining a model base after several times of iteration; identifying the characteristics of customers and in combination with the Naive Bayesian classification algorithm model base, matching the customers with the financial products they are mostly likely to purchase in real time; and recommending to the customers the financial products that are forecasted and matched by the models. The recommendation system and method of the invention are capable of helping customers to find out suitable products, therefore, increasing the user experience and the bonding effect of the customers to the financial products, lifting up the transferring rate of the products and making the bank more competitive.

Owner:广东奡风科技股份有限公司

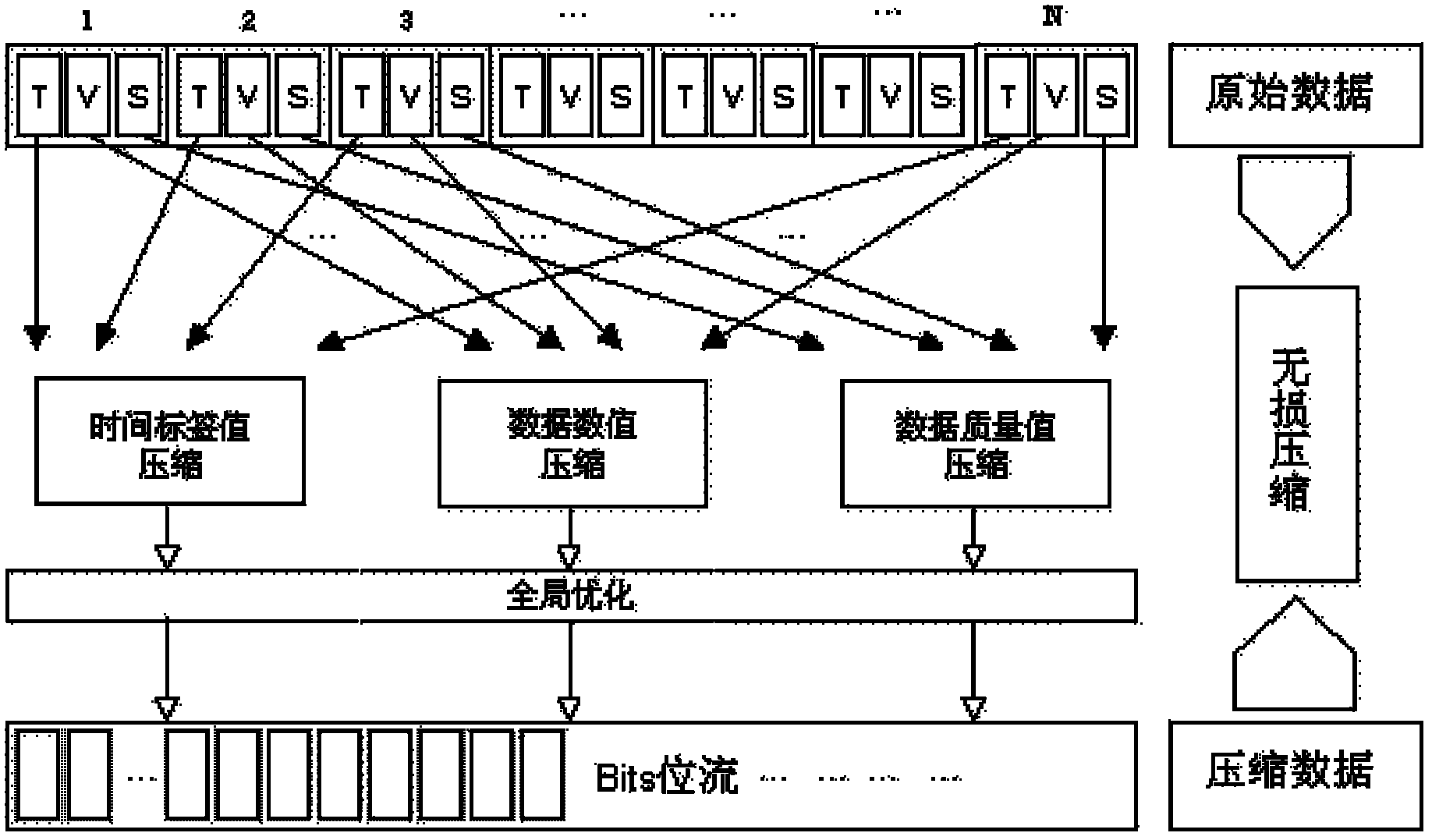

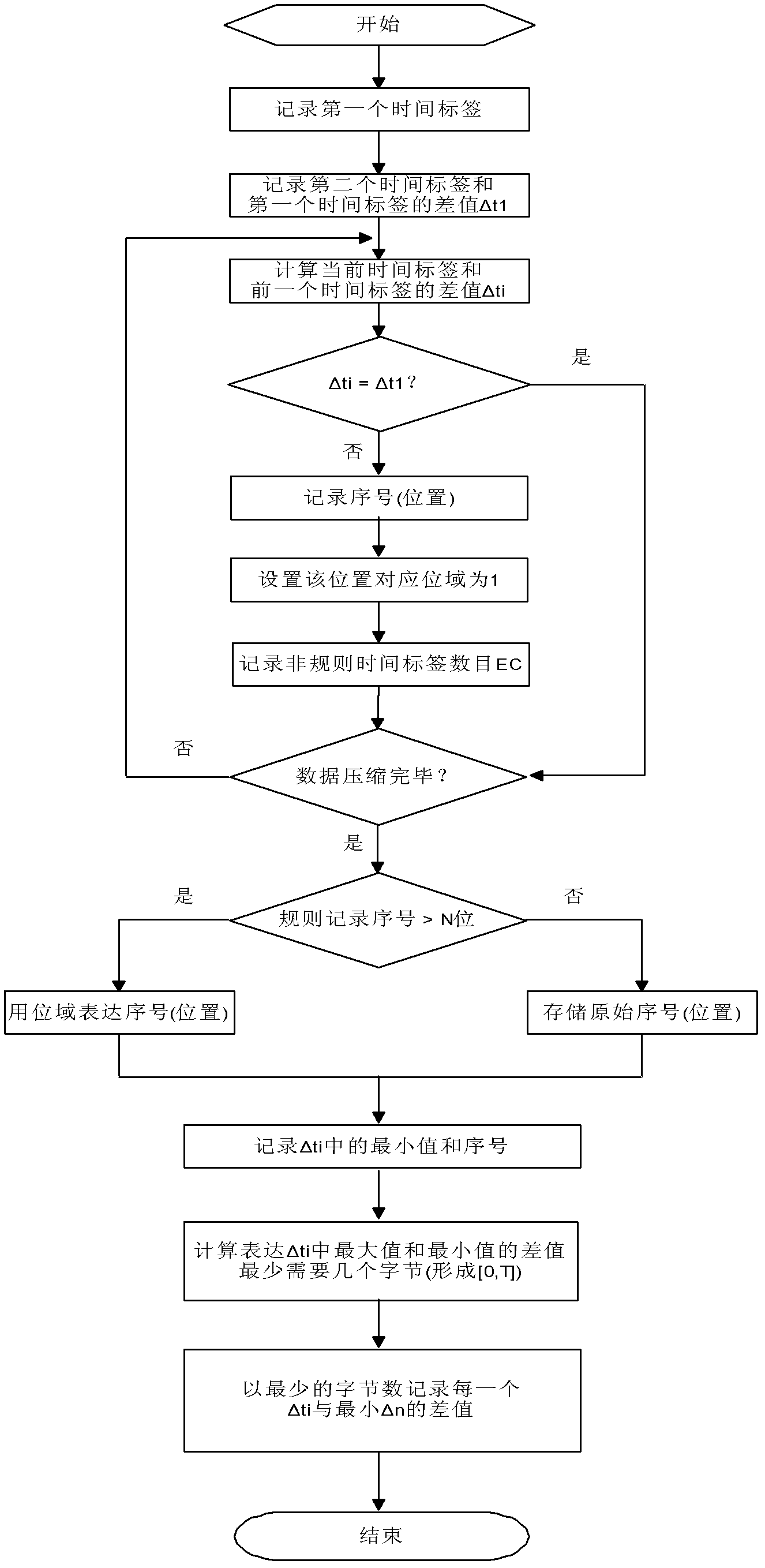

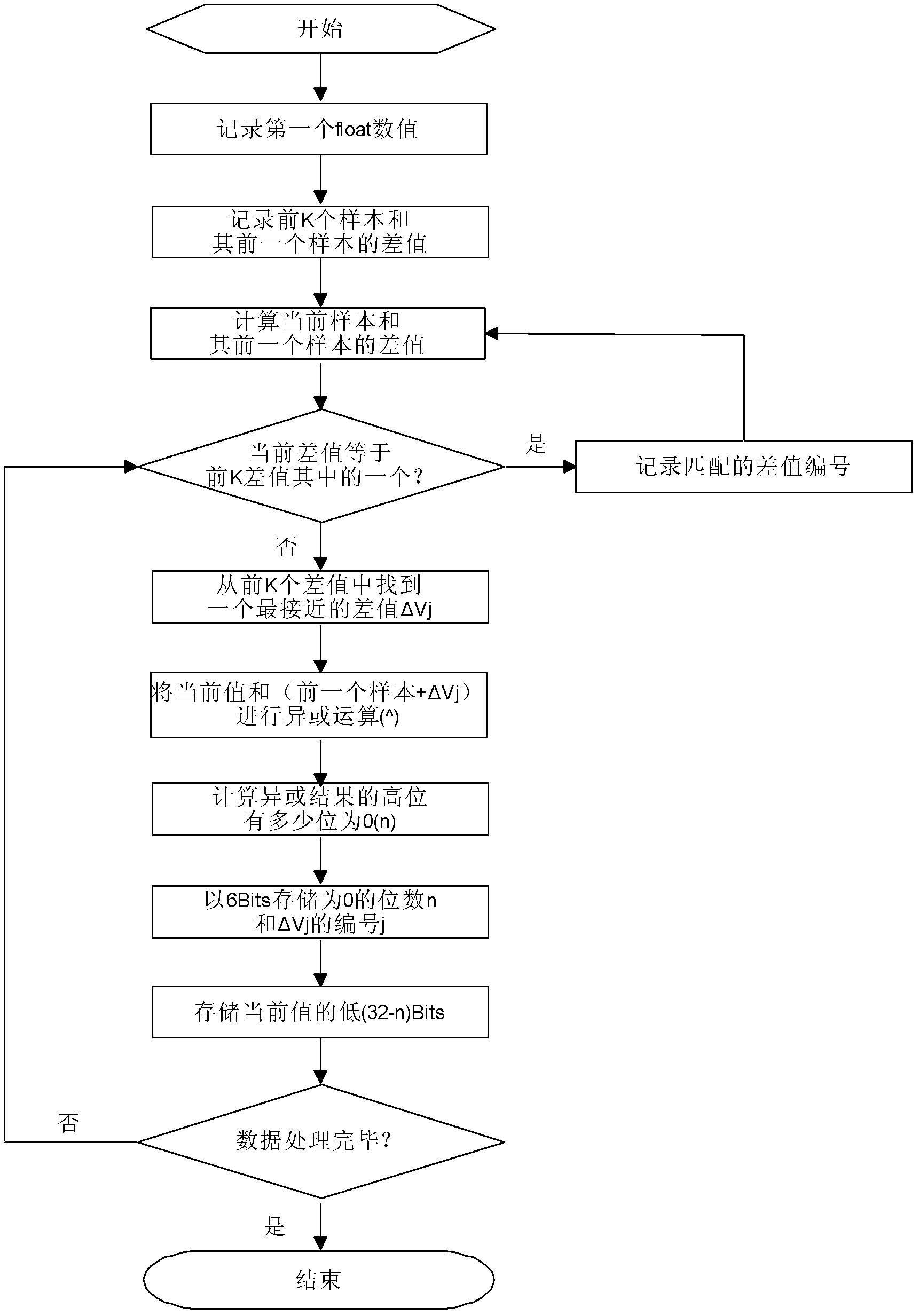

Real-time holographic lossless compression method for productive time sequence data

The invention discloses a real-time holographic lossless compression method for productive time sequence data, which comprises the steps of: respectively independently compressing three numerical ranges of each data in N productive time sequence data: a time label, a data value and data quality; respectively forming time label compression data, data value compression data and data quality compression data; and combining the three compression data into a complete compression data. In the method, productive time sequence data and files of each industry can be efficiently compressed in a lossless mode; and urgent demands of industries with enormous productive data, such as basic industry, electrics, telecommunication, chemical engineering, steel and the like for transmission, distribution, computing processing and storage of time sequence data can be satisfied.

Owner:ELECTRIC POWER RES INST OF GUANGDONG POWER GRID

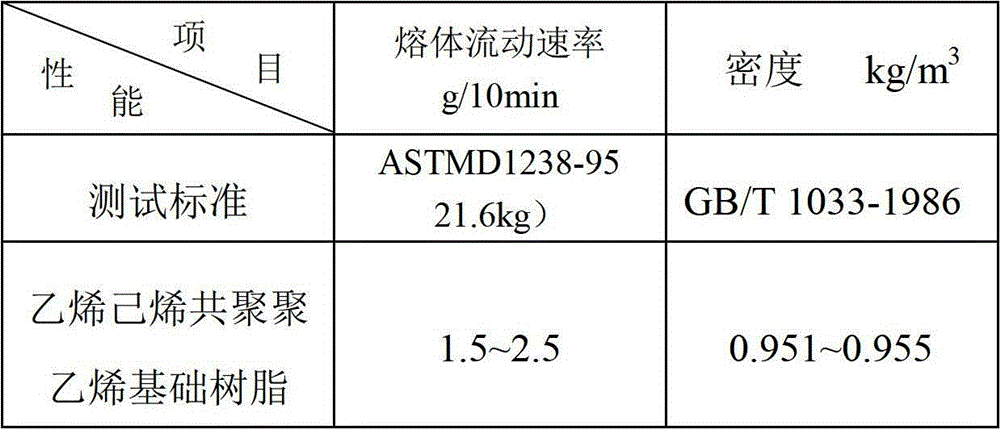

Large hollow container blow molding material and preparation method thereof

The present invention discloses a large hollow container blow molding material, which comprises the following raw materials, by weight, 99.9-100.0 parts of an ethylene hexene copolymerization polyethylene base resin, 0.05-0.10 part of an antioxidant, 0.07-0.12 part of a co-antioxidant, and 0.03-0.05 part of a slip agent. The present invention further discloses a preparation method for the large hollow container blow molding material. The large hollow container blow molding material has characteristics of low fusion index, large molecule weight, high strength, and the like, and is suitable for blowing of large size containers, wherein the product has prominent rigidity and toughness balancing capacity, creep resistance, excellent ESCR and good chemical resistance.

Owner:CHINA PETROLEUM & CHEM CORP

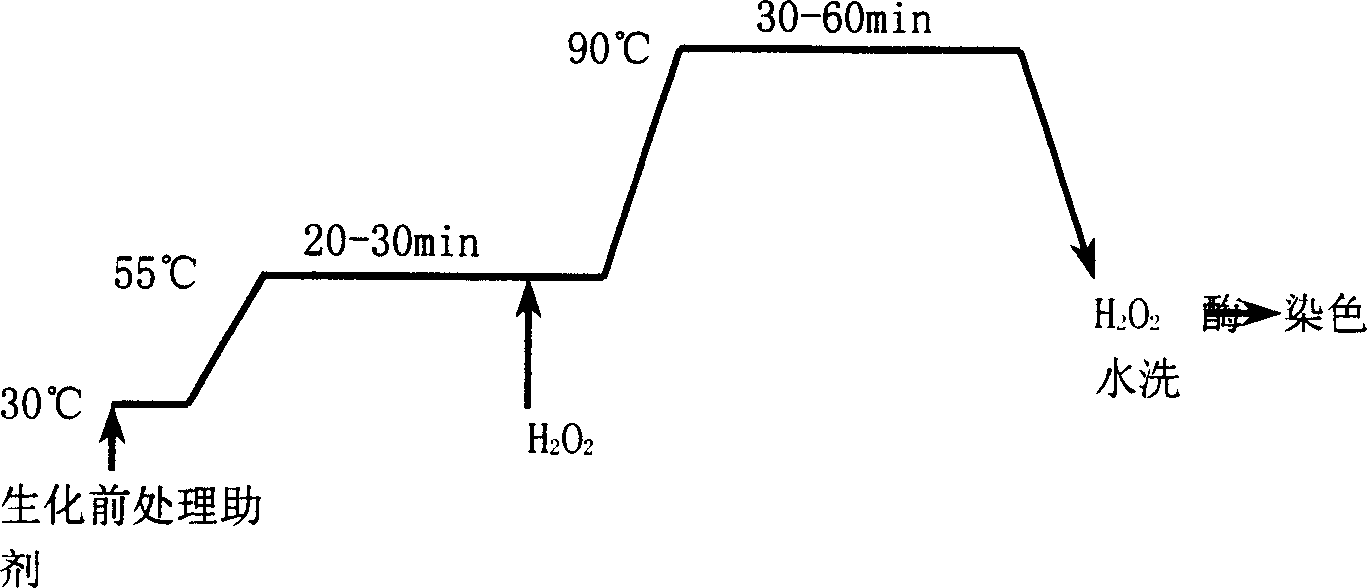

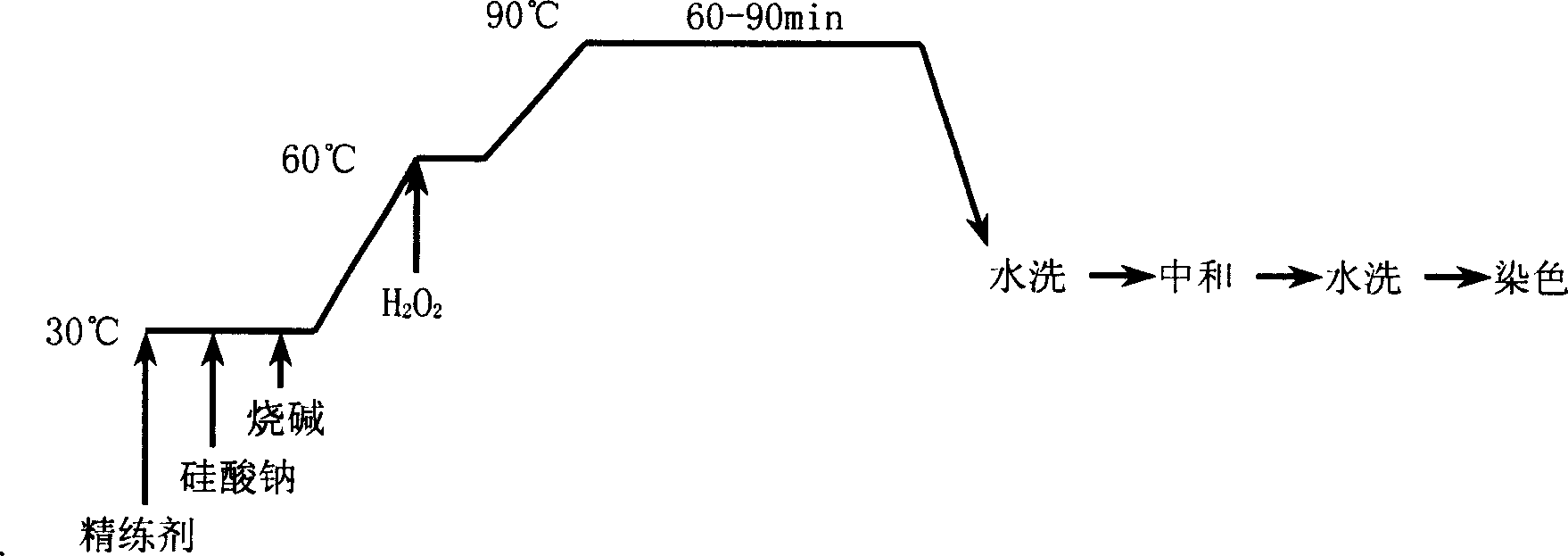

Cellulose fibre, textile assistant for union biochemical pretreatment, perparing method and use

The invention relates to the method to use special biology enzyme (pectic enzyme, fibrin enzyme, lipase, albumen enzyme, lacquer enzyme, xylan enzyme, polysaccharide enzyme, and catalase) and environment-friendly effective surfactant to produce aid fitting the biochemical pretreatment of fibrin fiber, and its fabric, and its processing technology. The aid for short flow of zoology pretreatment made of a host of biology enzyme and environment-friendly surfactant can fit the short flow of zoology pretreatment of fibrin fiber and its fabric. The invention advances the quality of the production. At the same tie, it reduces pollution to the environment, and it achieves the process of pretreatment of fibrin fiber and its fabric with the interreaction with biology enzyme and surfactant. Moreover, thep rocess does little harm to the fiber and it has an effective removement of residue. Additionally, it is friendly to the environment.

Owner:DONGHUA UNIV +1

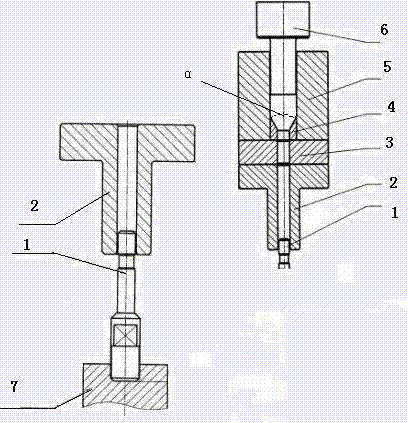

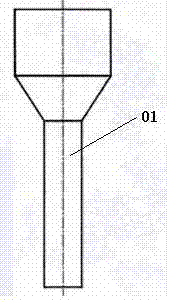

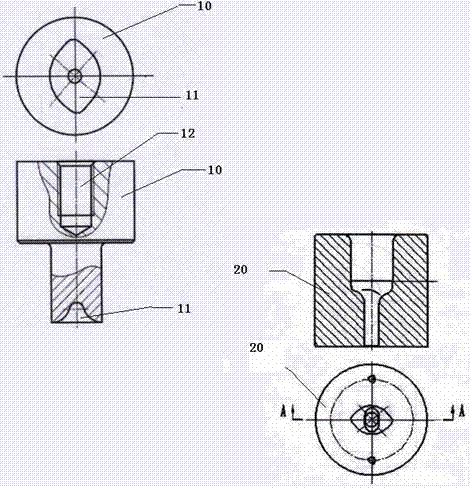

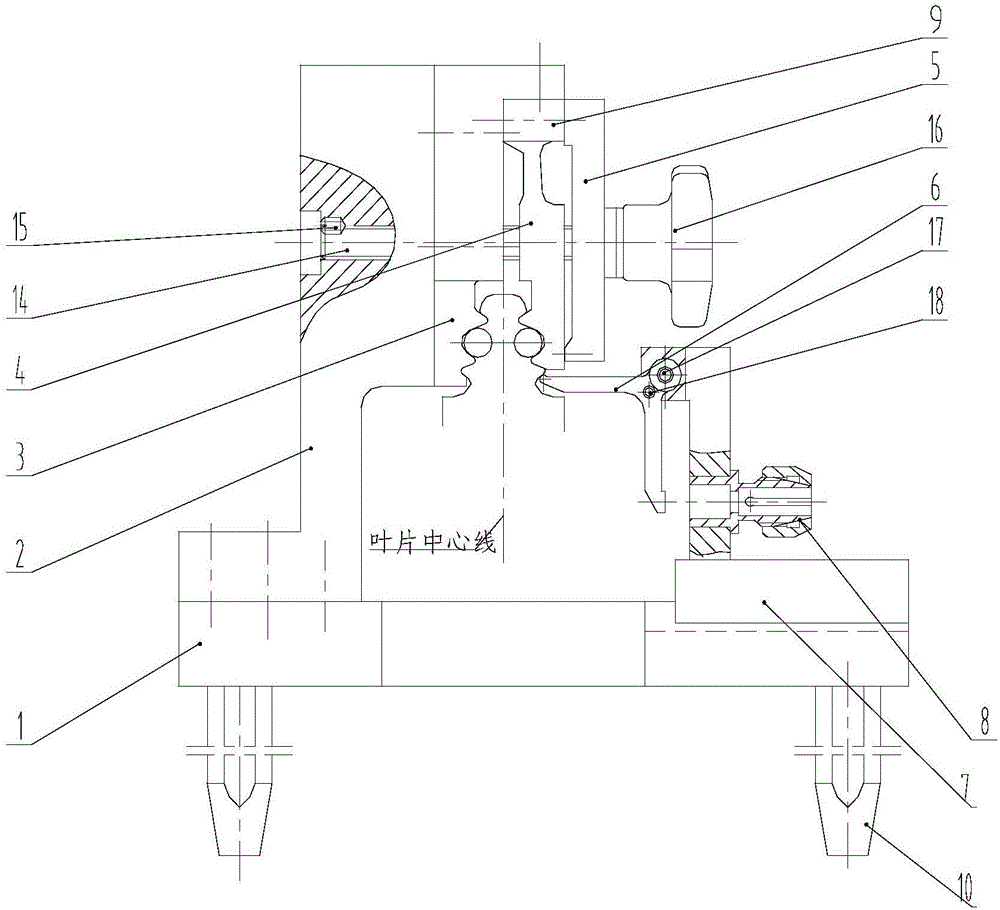

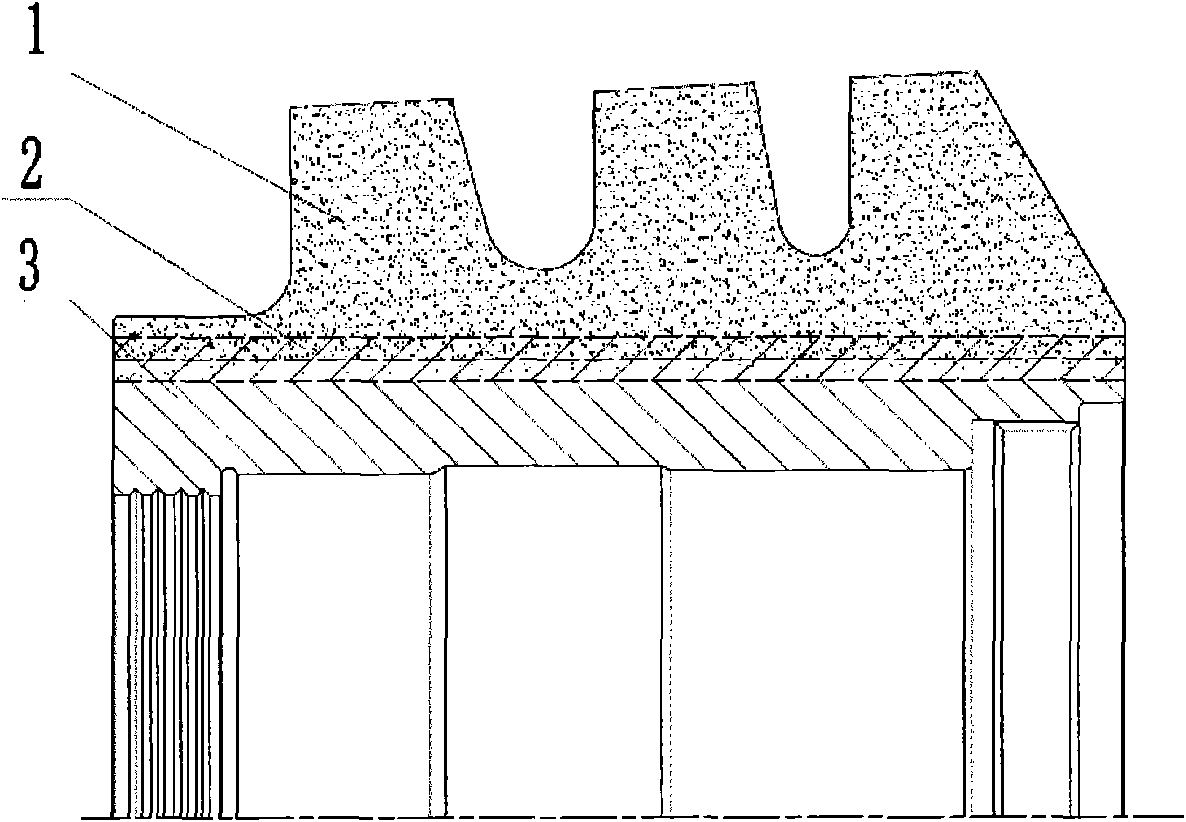

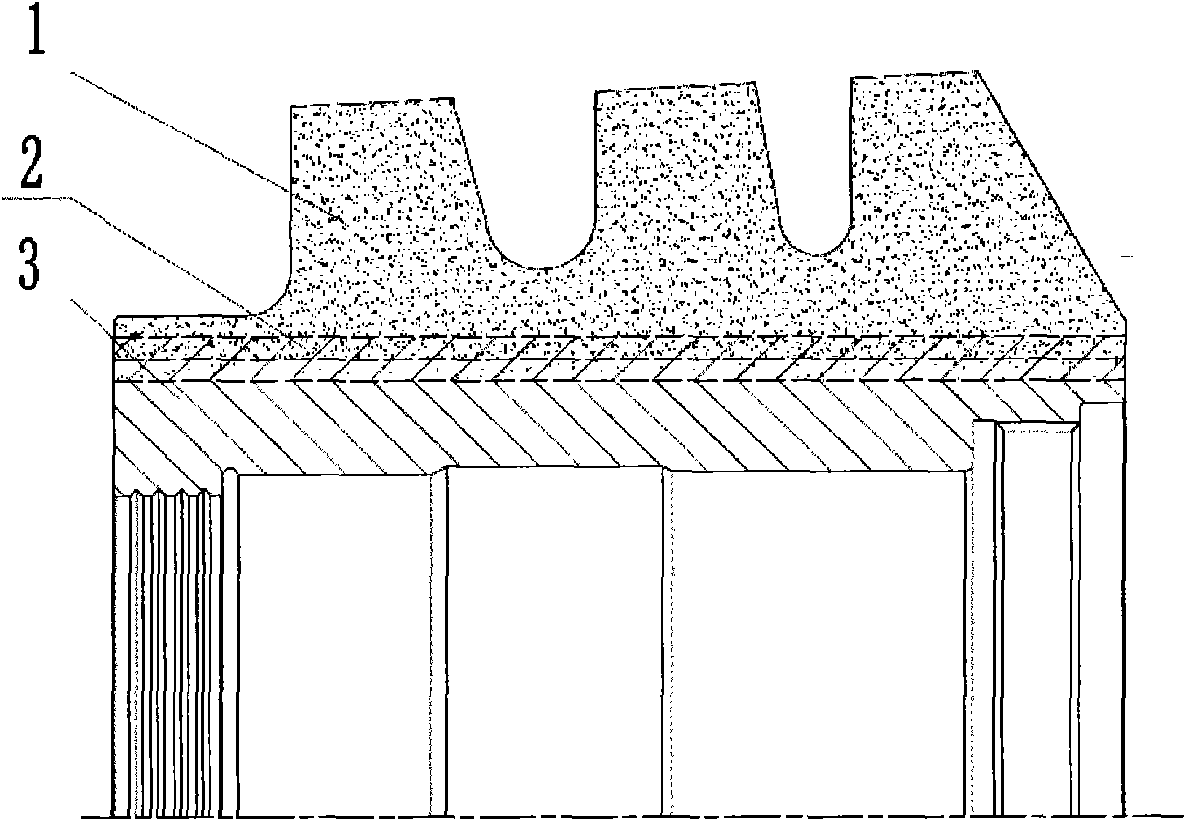

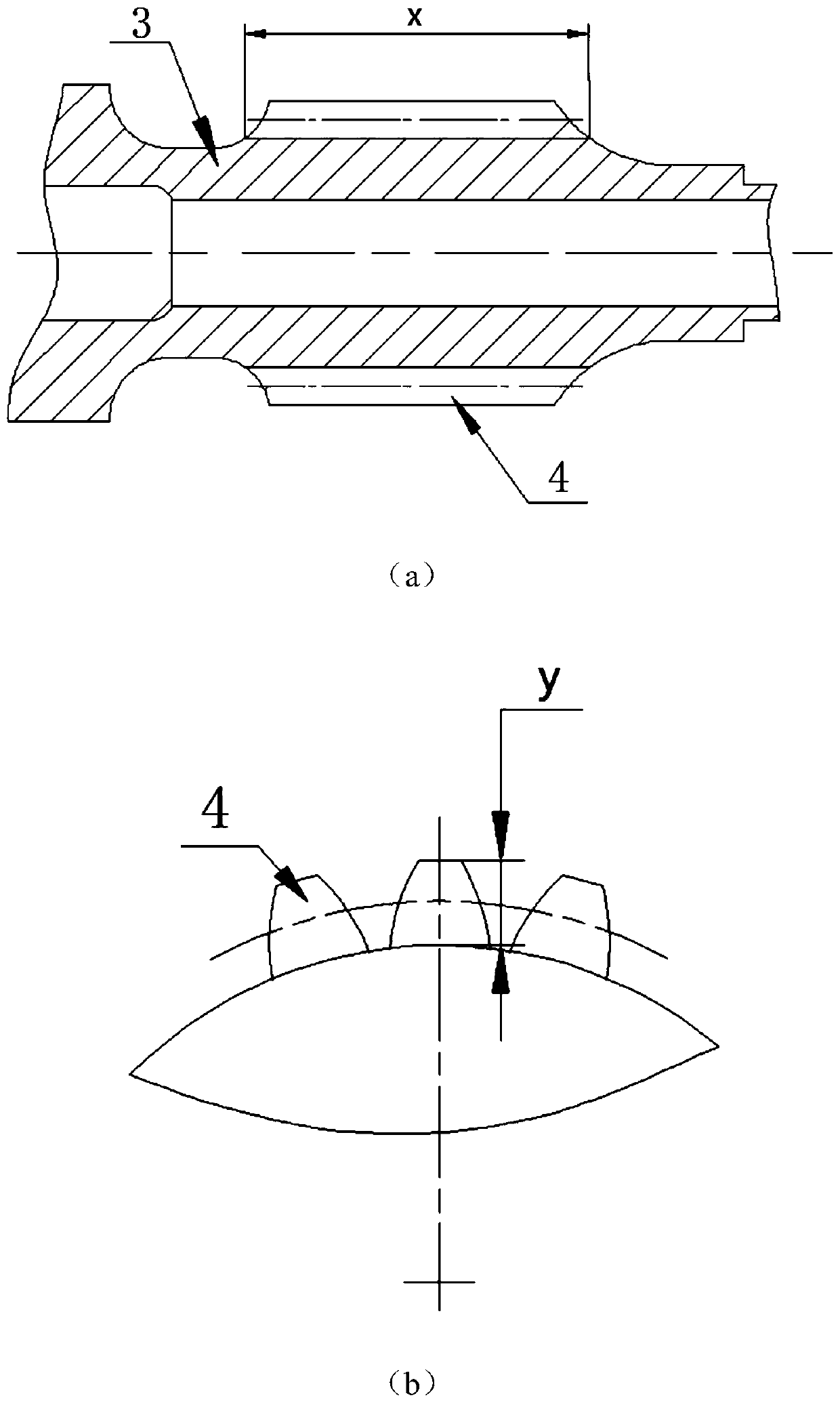

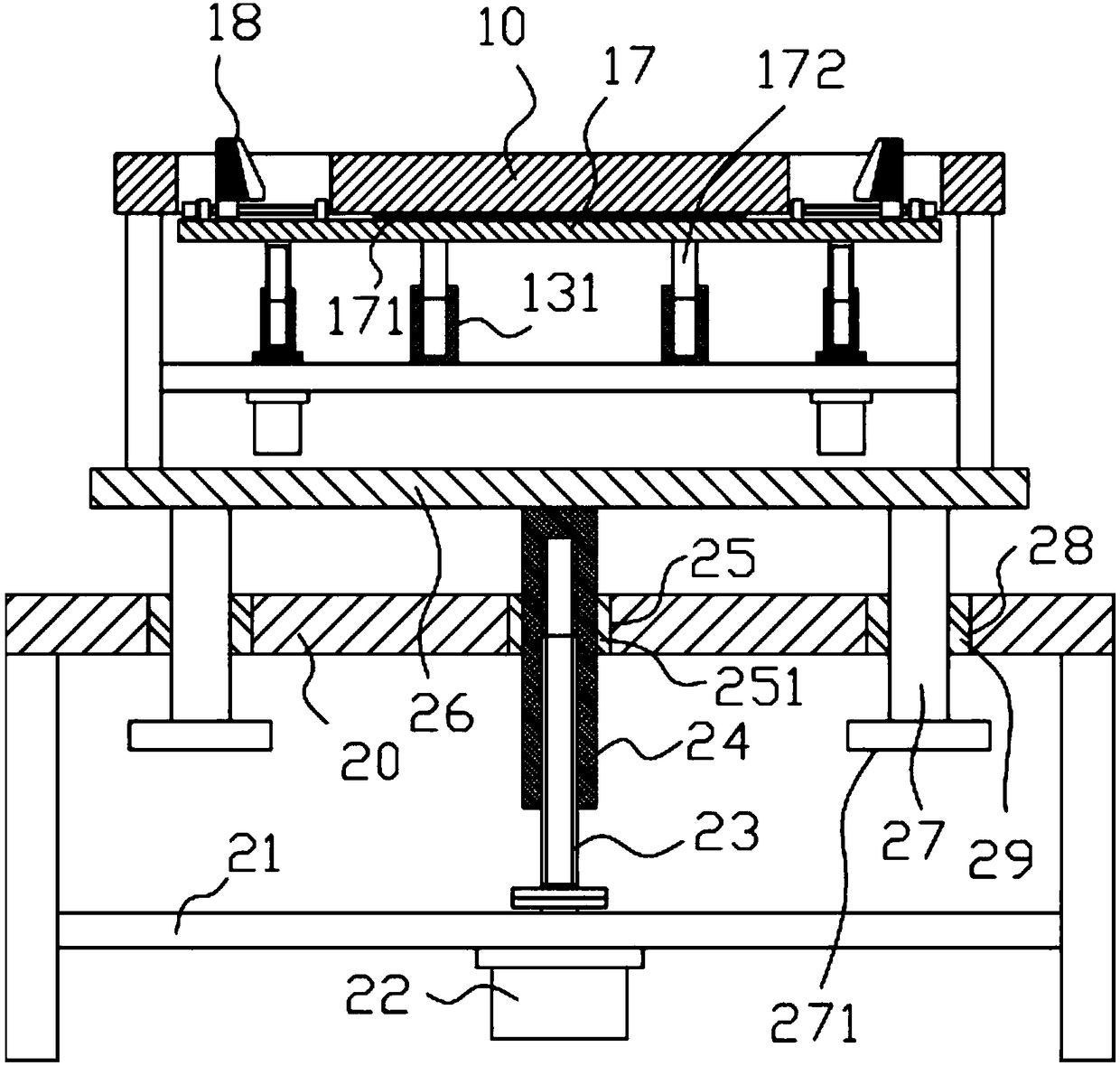

Die in alloy blade precision forging process

InactiveCN102310154AImprove mechanical propertiesEasy to useForging/hammering/pressing machinesAlloyMechanical property

The invention provides a die in an alloy blade precision forging process, and particularly provides a rod squeezing die and a forging die. The die is characterized in that the rod squeezing die comprises an ejector rod (1), an ejector rod guide sleeve (2), a cushion block (3), an insert (4), a squeezing cylinder (5) and a punch head (6); and the forging die comprises a male die (10) and a female die (20). The blanking die squeezing die and forging die are adopted for blanking so as to realize precision forging with the blade singe-face allowance of 0.3-0.7mm, the requirements of a cold rolling process on processing allowance, size precision and surface quality of forge pieces are met, the metal streamline direction of a blade body is reasonable, and the mechanical properties and the use performance of the blade are improved.

Owner:SHENYANG LIMING AERO-ENGINE GROUP CORPORATION

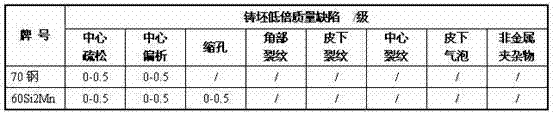

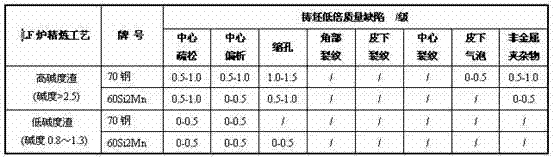

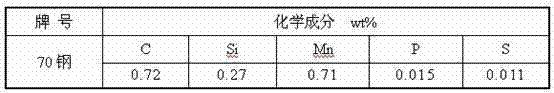

Ladle furnace low alkalinity slag refining process

The invention provides ladle furnace low alkalinity slag refining process. According to the process, bottom blowing of argon to ladles is carried out in the whole course of steel making and tapping, and ferrosilicon, silicon-calcium-barium and high carbon ferromanganese are sequentially added into the ladles for deoxidation and alloying; under the condition that argon flow is 30 to 50 NL / min, argon is blown to the liquid steel for two to three minutes, electrodes are inserted to melt slag, and the slag is modified; the liquid steel is heated to a temperature of 1580 to 1600 DEG C, and alkalinity of the slag is controlled to be 0.8 to 1.3; under the condition that argon flow is 20 to 30 NL / min, argon is blown to the liquid steel for 25 to 30 minutes, and components of the slag are controlled. Therefore, compound inclusion particles with a low melting point and good plastic deformation are formed in the liquid steel and float upward rapidly, which is beneficial for effective removal of inclusions in the liquid steel, thereby substantially improving cleanliness of the liquid steel, obviously enhancing quality of billets, enabling defects of billets like looseness, cracks, segregationand non-metallic inclusions to be greatly reduced, the content of micro inclusions, especially inclusions of B type oxides and D type oxides, in steel products to be substantially reduced and the steel products to meet subsequent processing requirements of 70 high carbon steel wires and 60 Si2Mn spring steel.

Owner:WUKUN STEEL

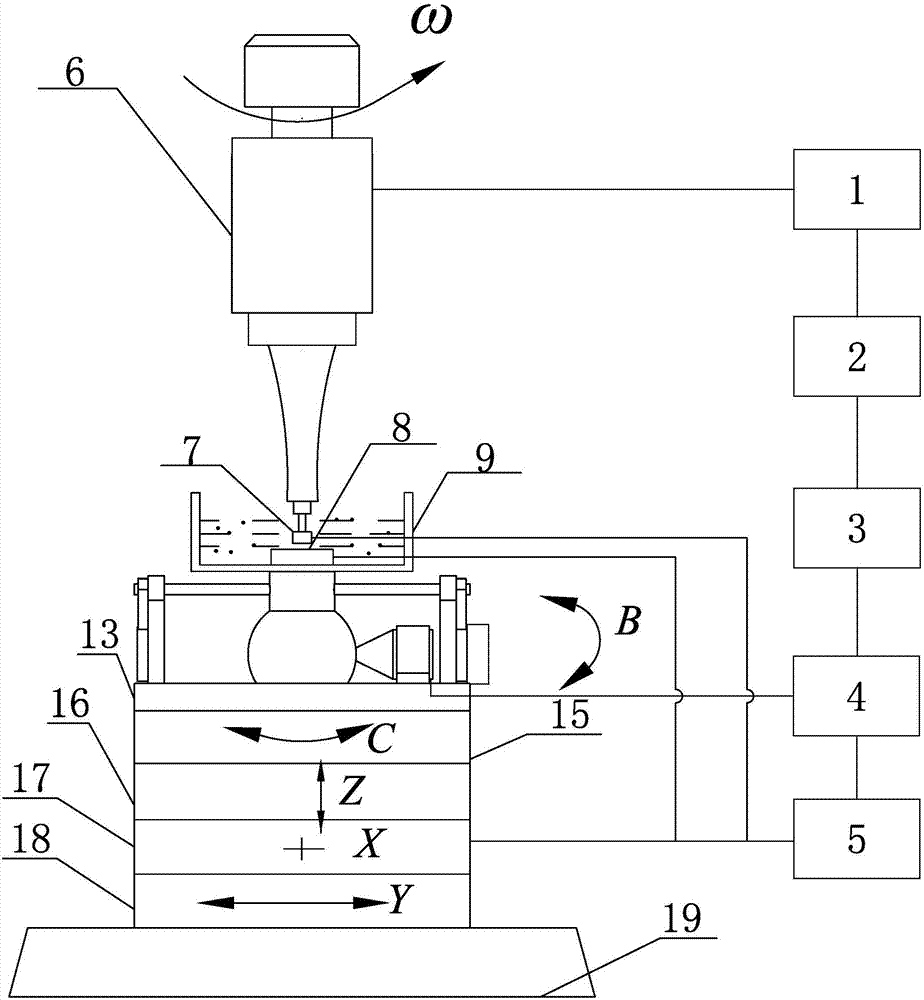

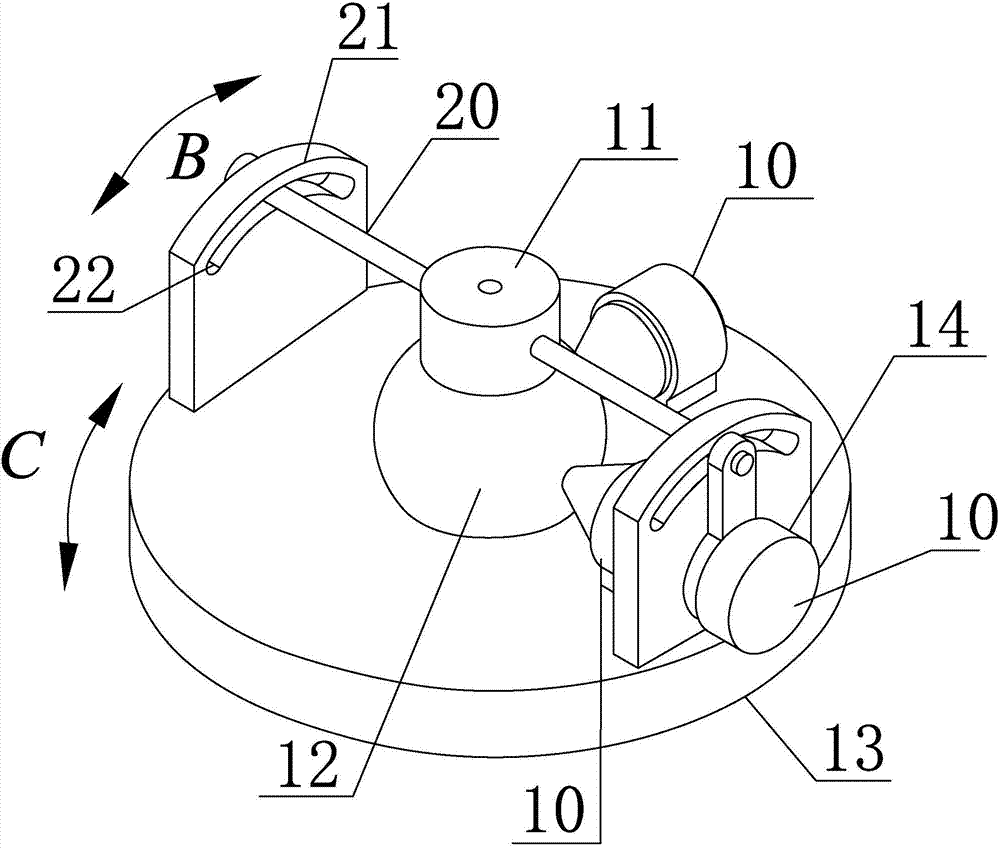

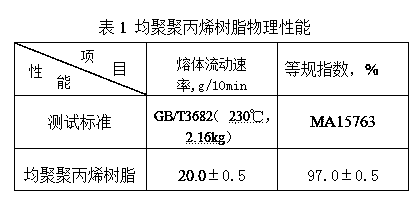

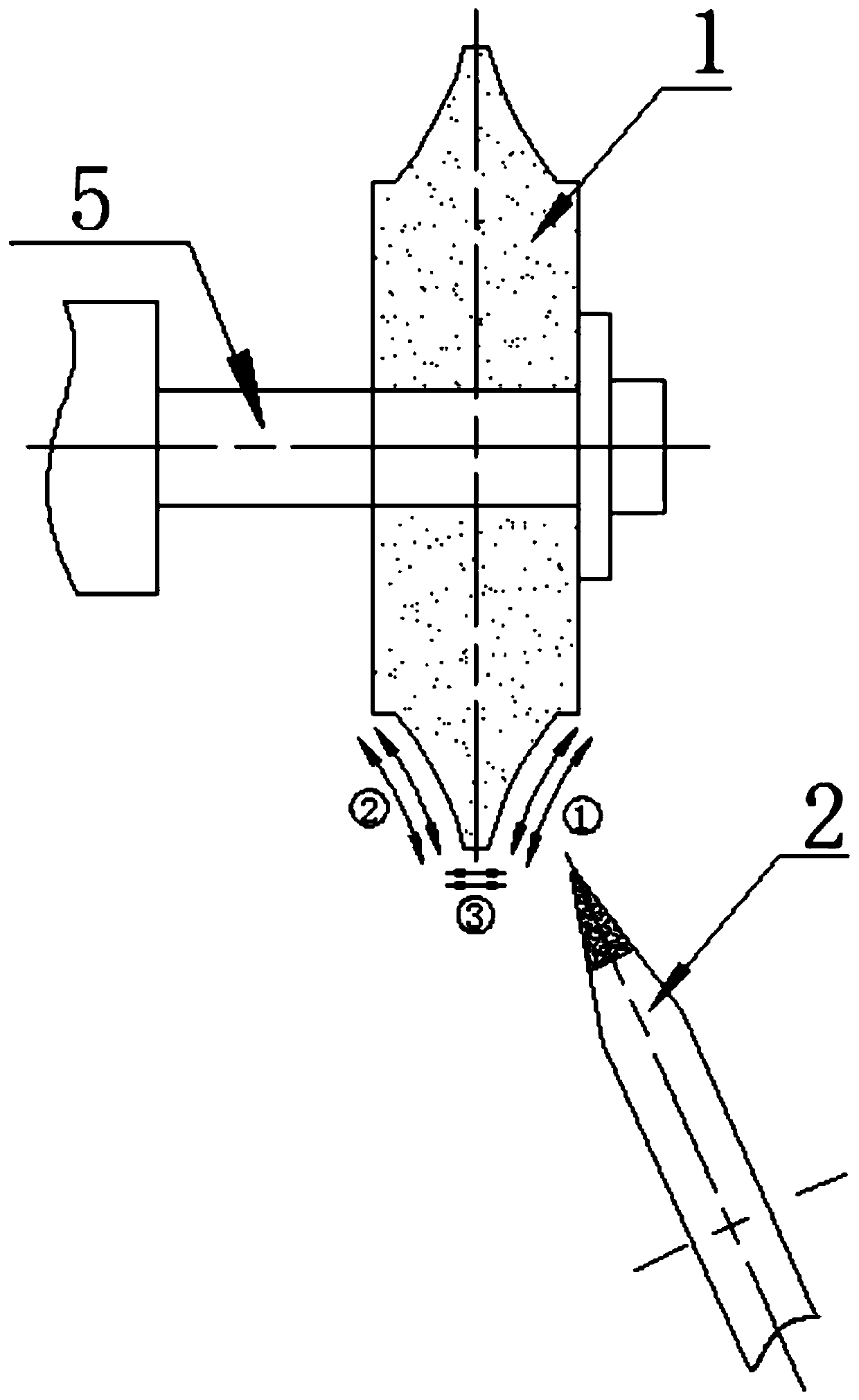

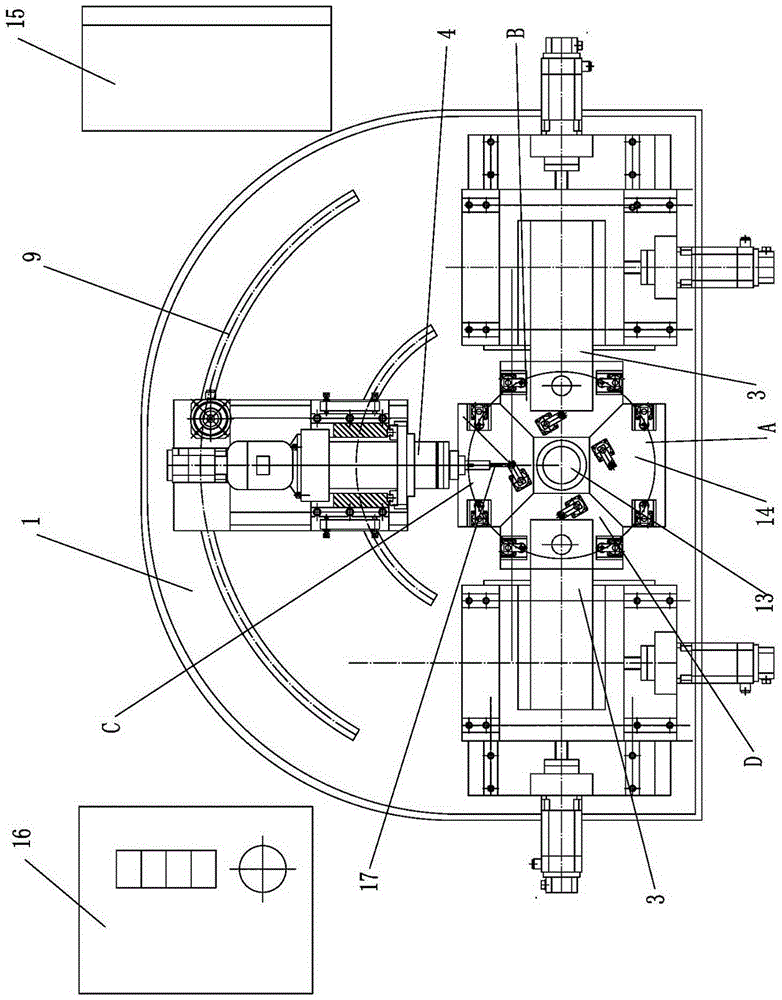

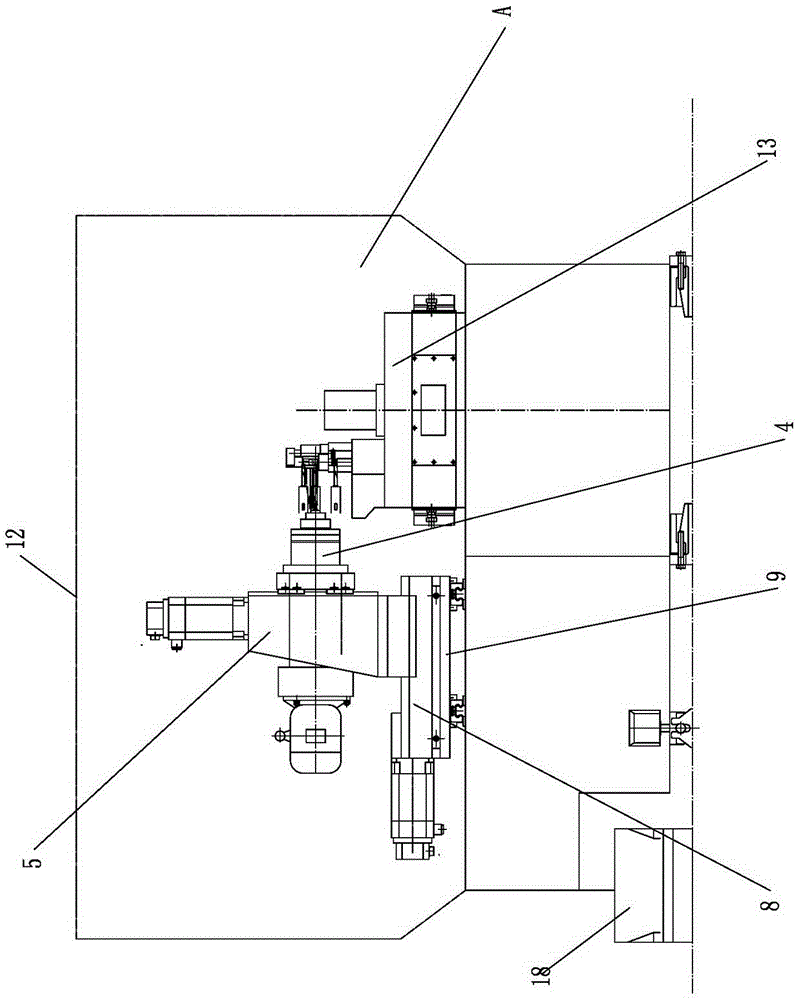

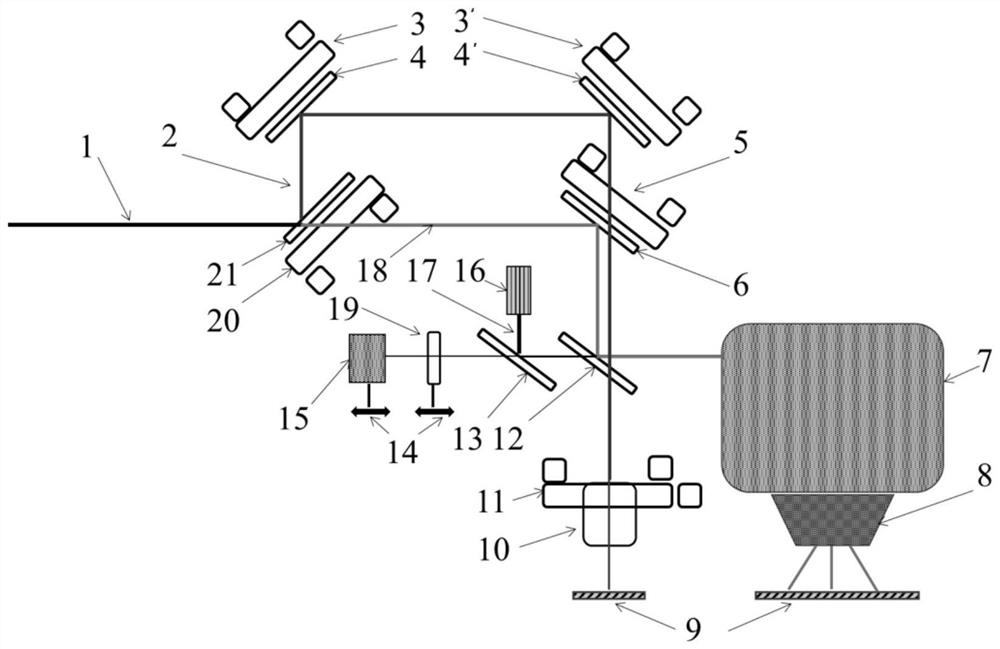

Multidimensional rotation ultrasound generating machining mechanism and machining method thereof

ActiveCN107378655ASimple manufacturing processSatisfy processabilityGrinding carriagesGrinding feed controlVibration amplitudeNumerical control

Disclosed is a multidimensional rotation ultrasound generating machining mechanism and a machining method thereof. By using coupling action of axial rotation ultrasound and double radial ultrasound, component space molded surface generating machining is conducted in a stimulating mode. The multidimensional ultrasound vibration and axial rotation motion can remarkably enhance effects such as ultrasound impacting, polishing and cavitation. The removing efficiency of crisp and hard materials, cycling updating of abrasive material working fluid and timely excluding of machining products are accelerated. Parameters such as ultrasound vibration parameters, gaps between tools and workpieces and temperature are detected on-line, computer operation processing and control are used, real-time adjusting and multi-axis linkage feeding amount control are conducted on the key parameters such as multidimensional ultrasound vibration amplitude and the machining gaps, the reasonable amplitude and the machining gaps of an ultrasound system in generating feeding machining are maintained, the machining efficiency of the crisp and hard materials can be remarkably improved, and the machining precision is improved. The multidimensional rotation ultrasound generating machining mechanism is novel and unique, the multidimensional rotation ultrasound vibration and multi-axis linkage feeding motion can be effectively achieved, the machining method is in conquering the unyielding with the yielding mode and used for generating motion flexible machining forming, the technical advantages of multidimensional ultrasound machining and multi-axis linkage numerical control are achieved, and the machining difficult problem of special-shaped curved surface components of all kinds of crisp and hard materials can be effectively solved.

Owner:YANGZHOU UNIV

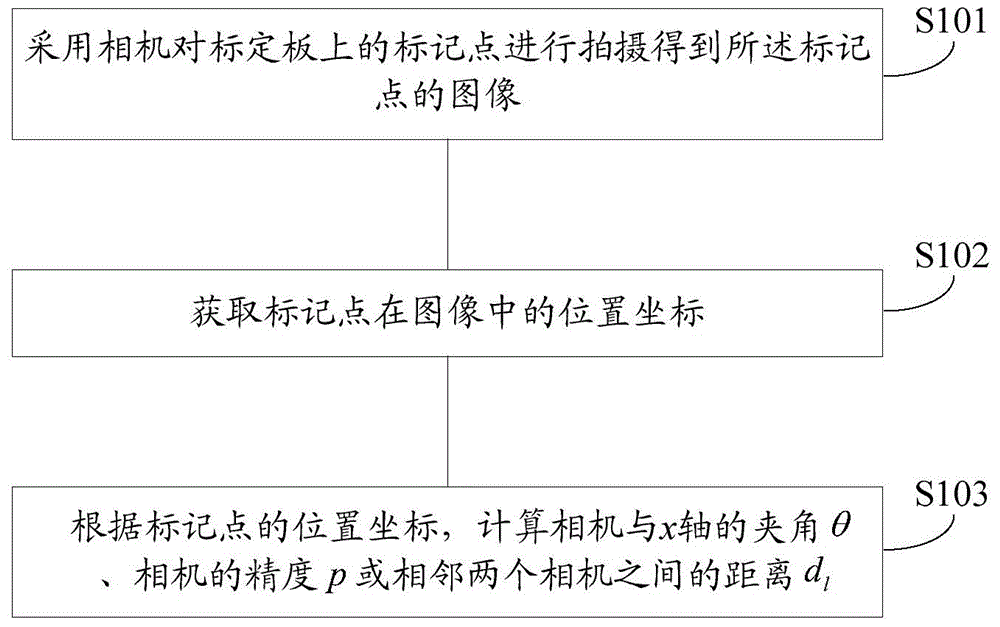

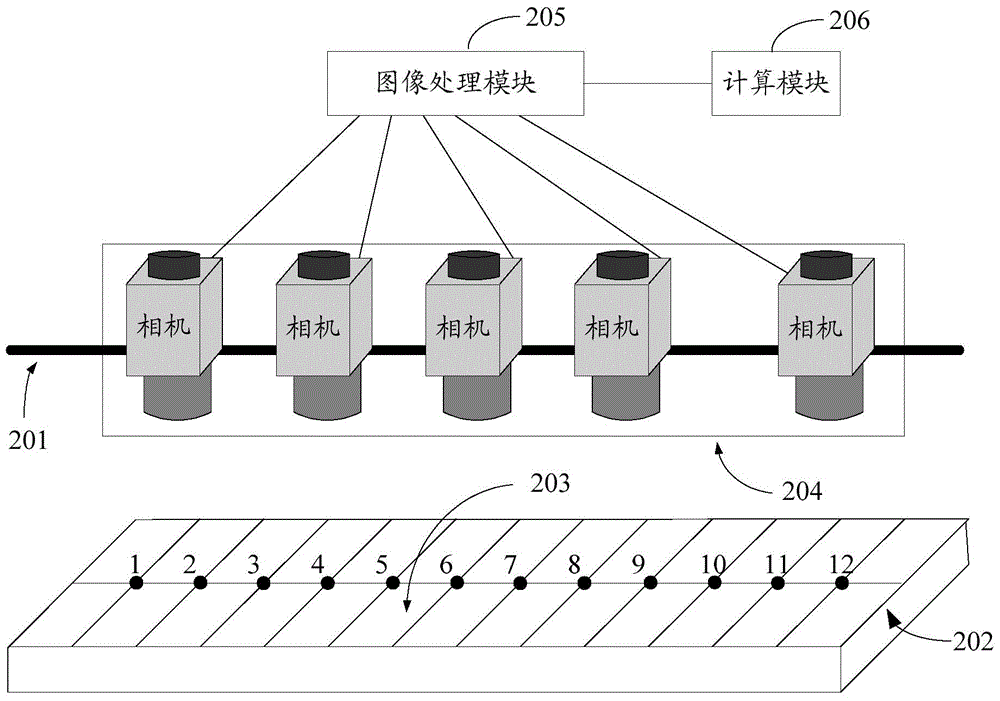

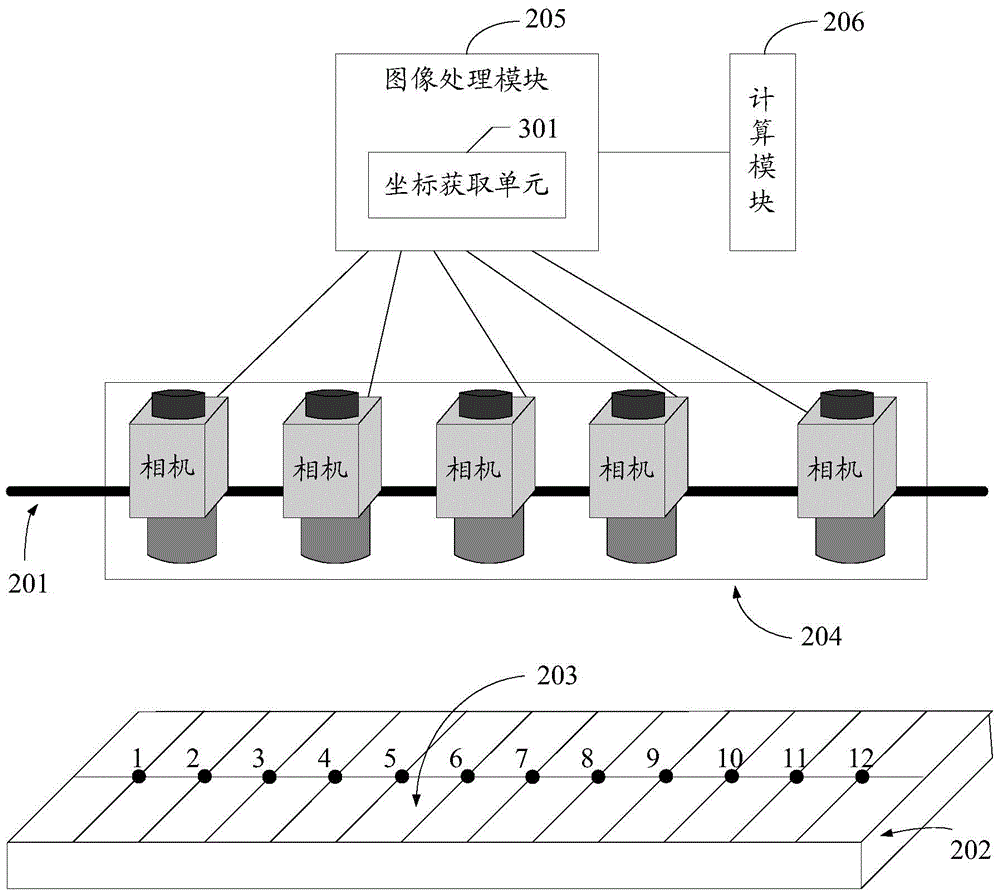

Method and system for calibrating camera parameters of one-dimensional area array camera set

ActiveCN104463833AImprove accuracyGuaranteed accuracyImage analysisComputer graphics (images)Computer vision

The invention discloses a method and system for calibrating camera parameters of a one-dimensional area array camera set. By means of the method and system, the camera parameters needed when a device is assisted for conducting operation such as positioning, machining and detecting can be obtained. The method includes the steps that pictures are taken by cameras for mark points on a calibrating board to obtain pictures of the mark points, and an x motion platform bears the one-dimensional area array camera set; position coordinates of the mark points in the pictures are obtained; according to the position coordinates of the mark points, included angles theta between the cameras and the x axis, the accuracy p of the cameras or the distance d1 between every two adjacent cameras are calculated. By means of the method in the embodiment, the obtained parameters have the relatively-high accuracy degree, so that when a visual system is used for assisting in the device for conducting the operation such as positioning, machining and detecting, the accuracy of positioning, machining and detecting is sufficiently guaranteed, and the high-accuracy positioning, machining and detecting requirements under certain scenes can be met.

Owner:深圳市大族机器人有限公司

Environmental-friendly tourmaline composite home decoration material and preparation method thereof

ActiveCN104386982AChanging the Potential Threat QuestionPlay the environmentSolid waste managementOxygen ionsFar infrared

The invention discloses an environmental-friendly tourmaline composite home decoration material. The environmental-friendly tourmaline composite home decoration material comprises the following raw materials in parts by weight: 2-20 parts of tourmaline powder, 20-80 parts of slag, 2-10 parts of activated carbon, 5-40 parts of a binding agent, 1-40 parts of an accessory and 0.1-0.3 part of an air entraining agent. The invention further discloses a preparation method of the material. By mainly utilizing various excellent characteristics of tourmaline, the prepared home decoration material has functions of releasing negative oxygen ions and emitting a far infrared ray, the problem of potential threats to a human body caused by an existing home decoration material is greatly changed, a great number of negative oxygen ions can be released, formaldehyde, peculiar smells and the like can be absorbed, dust and other small molecule compounds in air can be adsorbed, and the effects of purifying indoor environment and killing and inhibiting bacteria are achieved; moreover, a main body part is prepared by using the flag and Portland cement, and the material is low in price, easy to obtain, high in mechanical strength, light in weight, reusable, wide in application prospect and suitable for popularization and application.

Owner:CHENGDU SHANGKE KITCHEN EQUIP

Preparation method of high-density polyethylene IBC inner container blow molding material

The invention discloses a preparation method of a high-density polyethylene IBC inner container blow molding material. The method comprises the following steps that 1, in the single-loop slurry process polythene production technology, on the condition that diluents are always in a circulating state, ethylene and hexene-1 are placed in a reaction container, a polymerization reaction is performed on the condition that a catalyst exists to generate ethylene-hexene-copolymerization polyethylene resin with the melt flow rate of 5.60-7.0 g / 10 min, the density of 0.943-0.947 kg / m<3>, the weight-average molecular weight of 250-290 thousands, the molecular weight distribution of 13-18 and the hexene-1content of 0.3%-0.6%, and the reaction temperature in the reaction container is set at 92.0+ / -2.0 DEG C; 2, the ethylene-hexene-copolymerization polyethylene resin, antioxidants, antioxidant aids and light stabilizers are taken to be mixed evenly, and then extruding and pelleting are performed to obtain the granular high-density polyethylene IBC inner container blow molding material. According to the IBC inner container blow molding material prepared through the method, molecular weight distribution is wide, the comonomer hexene content is high, the processing property and the moldability are good, and a blow-molded IBC inner container product has the outstanding rigid-tough balance capacity, antioxidant capacity and anti-corrosion and environmental stress cracking resistance properties and the good rebound resilience.

Owner:CHINA PETROLEUM & CHEM CORP

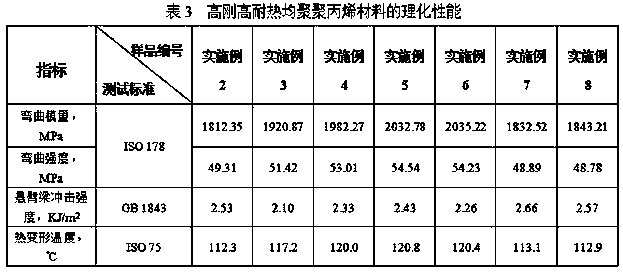

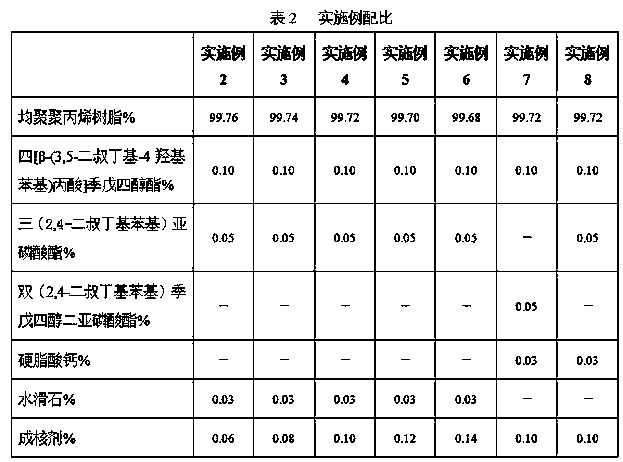

High-rigidity high-heat-resistance homo-polypropylene material and preparation method thereof

ActiveCN103554660AImprove adjustabilityImprove melt fluidityHeat deflection temperaturePtru catalyst

The invention discloses a high-rigidity high-heat-resistance homo-polypropylene material which is prepared from the following raw materials: a homo-polypropylene resin, an antioxidant, a halogen absorbent and a nucleating agent. The homo-polypropylene resin is prepared by the following steps: adding the raw material propylene into a loop reactor, adding the catalyst, cocatalyst, electron donor and antistatic agent, and uniformly stirring, wherein the reaction temperature in the loop reactor is controlled at 70+ / -1 DEG C, the reaction pressure is controlled at 3.4-3.8 MPa, and the hydrogen concentration is controlled at 3500-4500 ppm. The invention also discloses a preparation method of the high-rigidity high-heat-resistance homo-polypropylene material. The high-rigidity high-heat-resistance homo-polypropylene material has higher melt index, bending modulus and heat-deformation temperature, and can satisfy the raw material requirements of injection molding manufacturers of small home appliances, automobiles and the like.

Owner:CHINA PETROLEUM & CHEM CORP

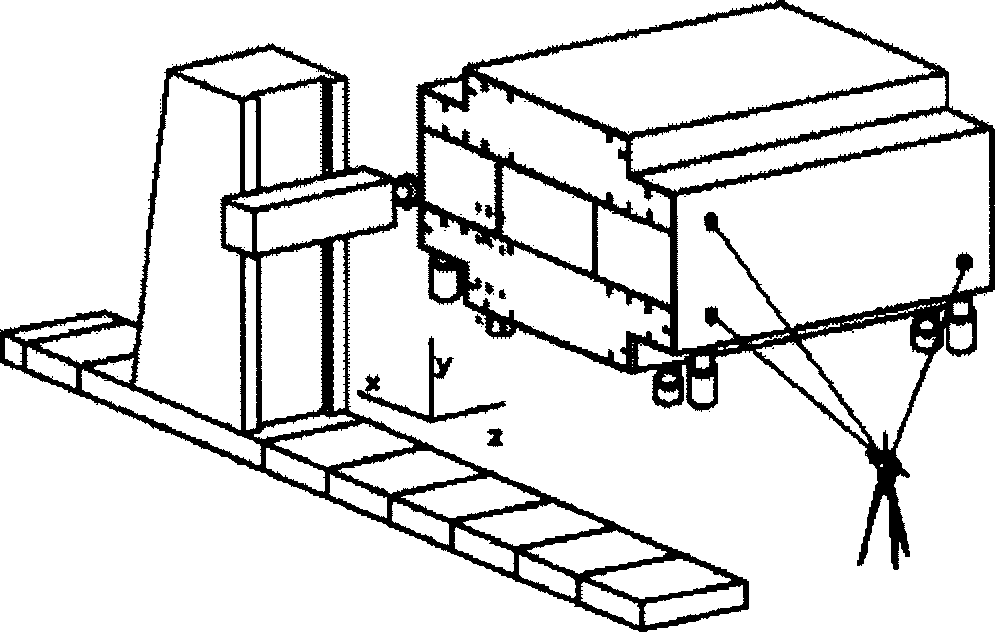

Machining alignment and location method of cable tower segment

InactiveCN1868668AImprove efficiencySatisfy processabilityMeasurement/indication equipmentsPositioning apparatus3d trackingEngineering

A centering and locating method for machining the end face of the segment of steel cable tower includes such steps as using numeral controlled hydraulic locating system to support said segment and locate it to a machining position, centering the first end face by using 3D tracking measurer to measure machine and 3 laser markers for determining the position relation between machine and workpiece and regulating and locking the position of workpiece, centering the second end face by transporting the segment to machining position, creating the coordinate system of machine, measuring and processing the machined first end face, and checking its position in said coordinate system.

Owner:CHINA RAILWAY BAOJI BRIDGE GRP

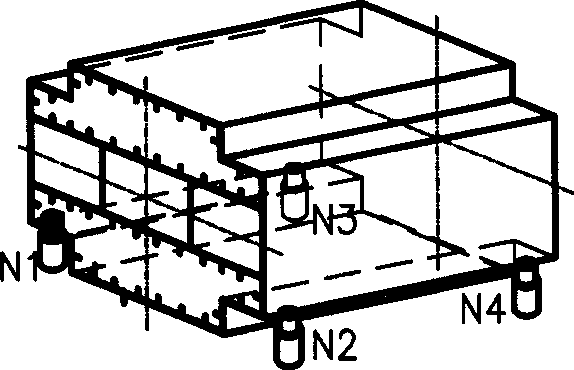

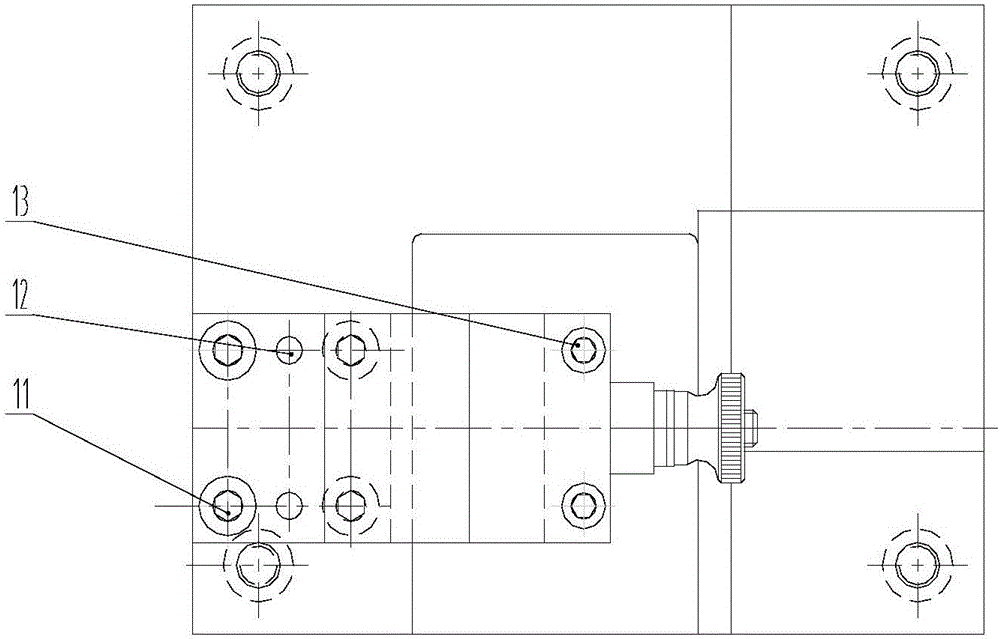

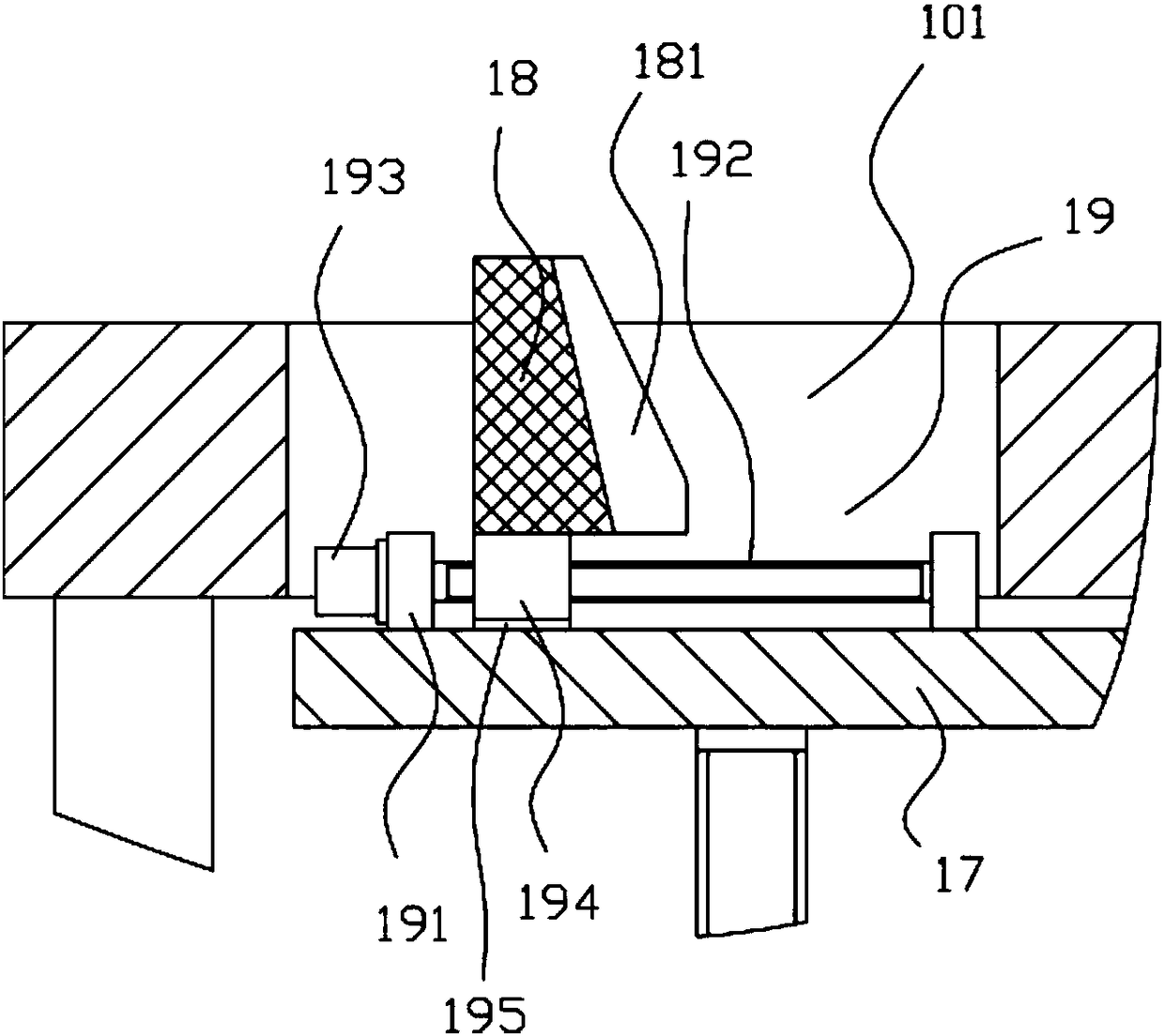

Detection device and detection method for detecting tenon staggered teeth of turbine blade

InactiveCN106247887AMeet detectionSatisfy processabilityMechanical measuring arrangementsTurbine bladeCompression device

The invention relates to a detection device and a detection method for detecting the tenon staggered teeth of a turbine blade. The device comprises a bottom plate. A support plate is fixedly arranged on the bottom plate. The support plate is provided with a fixed tooth-shaped block and an elastic tooth-shaped block which are used for being matched with each other to compress the tenon of the turbine blade. The opposite side surfaces of the fixed tooth-shaped block and the elastic tooth-shaped block are provided with tooth profiles matched with the tenon of the turbine blade. The upper end of the elastic tooth-shaped block is fixedly connected with the support plate. The side surface of the elastic tooth-shaped block, with its back onto the fixed tooth-shaped block, is connected with a compression device. A sliding plate capable of sliding is arranged on the bottom plate. A lever and a gauge clamp used for being connected with a dial indicator are installed on the sliding plate. The lever is of a right-angle turning-shaped structure composed of a transverse rod and a vertical rod, wherein the end part of the transverse rod can be abutted against the tenon of the turbine blade. The end part part of the vertical rod is connected with the dial indicator. According to the technical scheme of the invention, during usage, all the teeth of the tenon of the turbine blade can be positioned. The entire blade body and the blade crown part of the turbine blade are suspended to push the detection sliding plate for detection. Therefore, the operation is simple and convenient, and detection data are stable and reliable.

Owner:AECC AVIATION POWER CO LTD

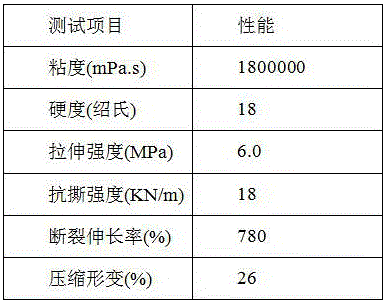

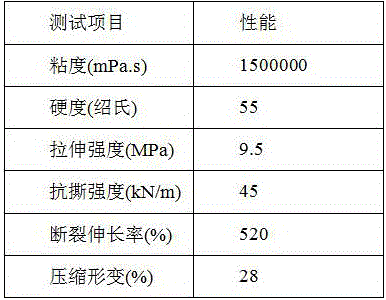

Medical two-component addition-type liquid silicone rubber and preparation method thereof

The invention discloses medical two-component addition-type liquid silicone rubber. The liquid silicone rubber comprises a component A and a component B in a mass ratio of 1: 1, wherein the component A comprises the following raw materials in parts by mass: 50 to 70 parts of vinyl polysiloxane, 3 to 10 parts of a silane coupling agent, 20 to 45 parts of fumed silica and 0.1 to 1 part of a platinum catalyst; the component B comprises the following raw materials in parts by mass: 50 to 70 parts of vinyl polysiloxane, 2 to 5 parts of a silane coupling agent, 20 to 45 parts of fumed silica, 2 to 20 parts of low hydrogen containing polysiloxane, and 0.1 to 0.5 part of an inhibitor. The liquid silicone rubber prepared by the invention has high transparency and high mechanical properties, meets medical requirements of FDA and the like, and further can meet the processing performance and the molding cycle of liquid injection molding silicone rubber.

Owner:JIANGSU TIANCHEN NEW MATERIALS

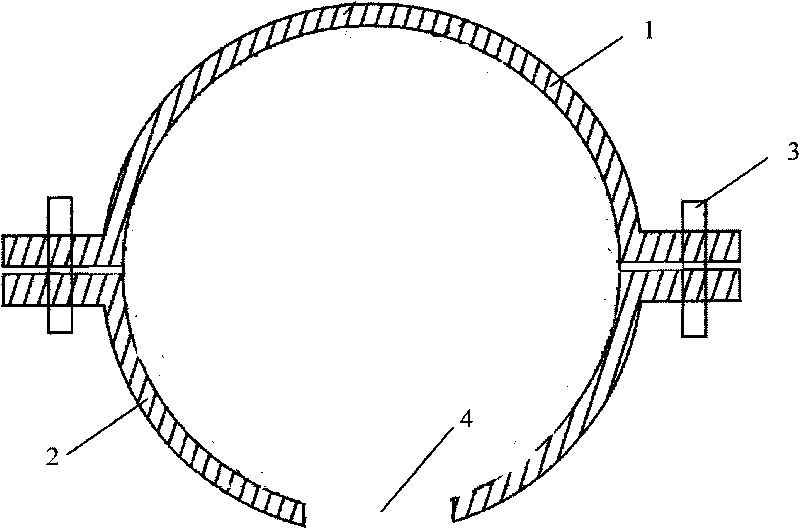

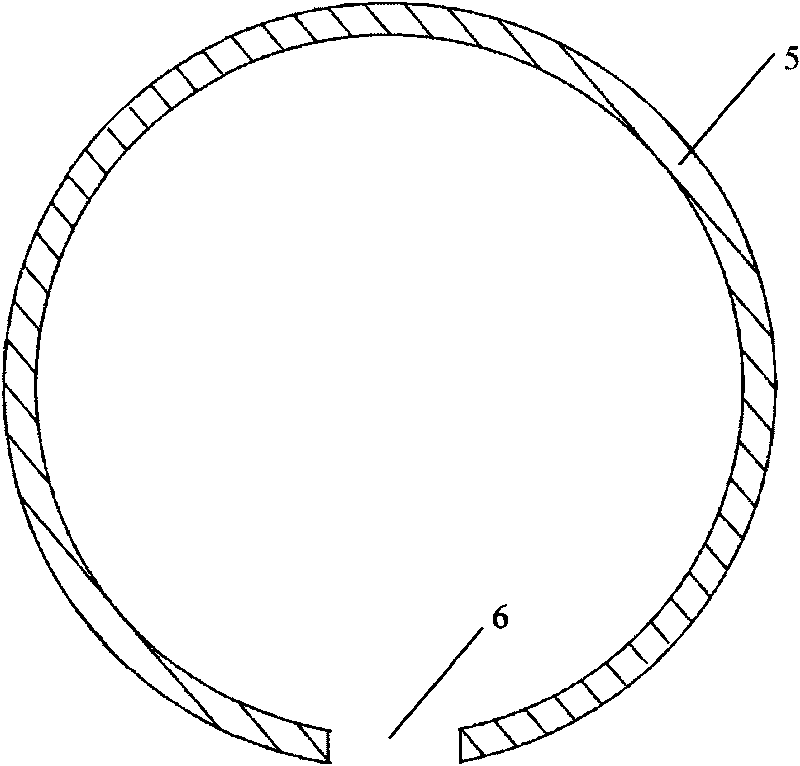

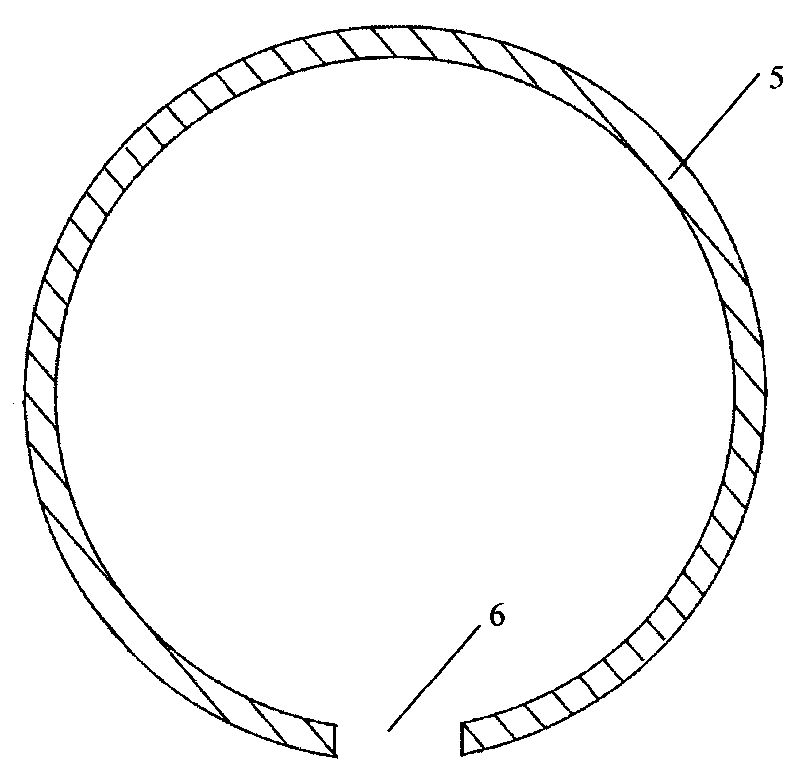

Spherical projecting screen and manufacturing method

The invention discloses a seamless spherical projecting screen and a manufacturing method thereof. A mould sinking type spherical mould is subjected to rotational moulding treatment by adopting a rotational moulding machine, so that rotational moulding materials positioned in the mould are uniformly diverted and solidified under a certain temperature and time, thereby achieving the purpose that the projecting screen is processed at one time and wholly formed and avoiding the defects that the prior optical additive spherical projecting screen is required to be spliced, and splicing seams on the surface influence the projection effect. Because the rotational moulding materials are dispersed in a resin body with a certain thickness, the projection effect is better than the effect of a thin coating layer, and an image is clear and is not distorted. The processed finished projecting screen has smooth and level surface, attractive appearance and remarkably improved projection effect and projection quality and is particularly suitable for occasions with special display effect.

Owner:深圳市蓝宝石球显科技有限公司

Centrifugal casting process for shell of bimetal compound metallurgical wedge hob

The invention relates to a centrifugal casting process for the shell of a bimetal compound metallurgical wedge hob, which sequentially comprises the steps of moulding, shell modification, spraying, mold shell assembling, molten steel smelting, deoxidization and slag removing, pouring, heat preservation and coring, blasting and sand removal, processing and finishing, heat treatment and the like. The wedge hob produced through the process above not only has the advantages of high hardness, good abrasion-resistance and the like, but also has good comprehensive mechanical properties such as stiffness, toughness and the like, thereby satisfying the requirements for strength and wear resistance of cutter teeth of the wedge hob, ensuring the manufacturability of the hob body, improving the service time of the cutter teeth of the wedge hob, and reducing the production cost.

Owner:BEIJING CHINA COAL MINE ENG CO LTD

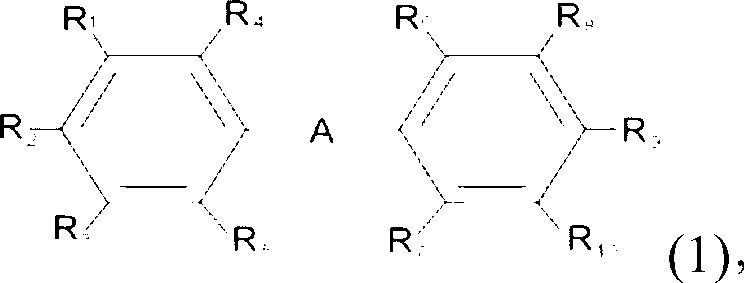

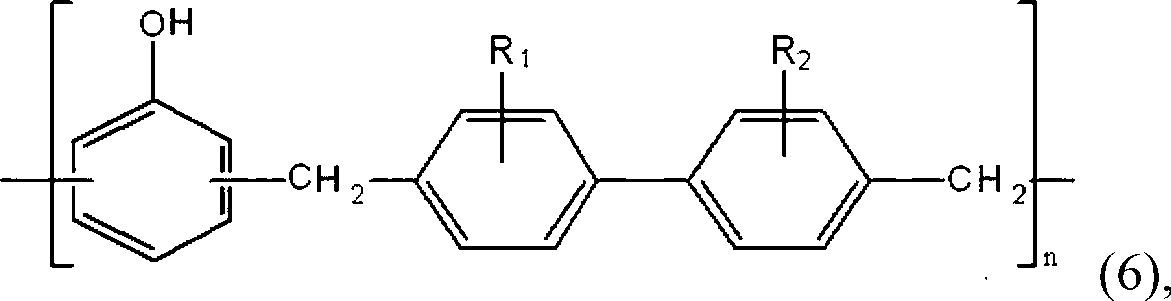

Adhesive composition for semiconductor, adhesive film and semiconductor device

InactiveCN103184014APlasma process omittedAdequate adhesionNon-macromolecular adhesive additivesSemiconductor/solid-state device detailsAdhesion processSemiconductor

The invention relates to an adhersive composition for a semiconductor, an adhesive film and a semiconductor device. More specifically, the invention relates to the adhersive composition. Through highly adhersive features of the adhersive composition, a PCB curing process and a PCB plasma process can be omitted through improvement of the curing rate, and partial curing, if being applied to an on-line process, can be conducted during a lead adhesion process so as to reduce the process time, so that a curing process (or a semi-curing process or a B step) can be omitted or minimized. For the adhersive composition, phenolic film and amine-cured resin both serve as curing agents to allow the curing process to be omitted or minimized, and an imidazole curing agent or a micro-capsule potential curing agent is adopted to serve as the curing agent so that the curing rate is improved.

Owner:CHEIL IND INC

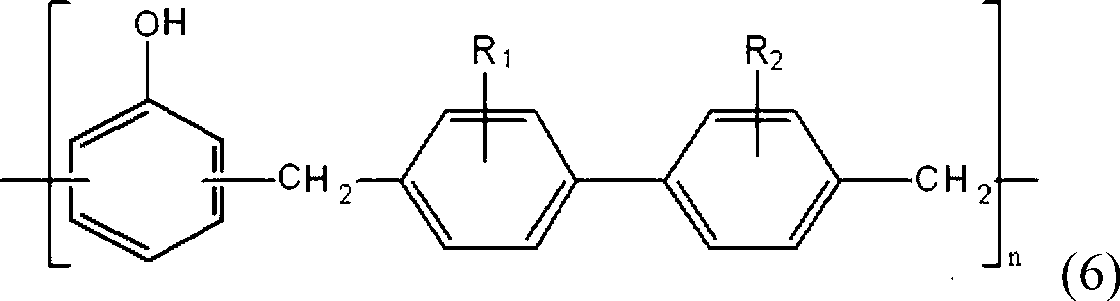

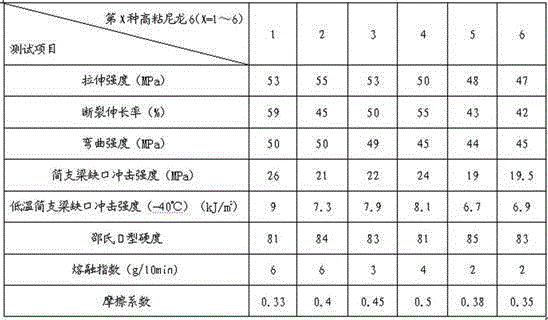

High-viscosity nylon 6 and preparation method thereof

The invention provides high-viscosity nylon 6, made from nylon 6, low temperature resistant toughener, wear-resistant agent, antioxidant, black masterbatch, and chain extender according to a reasonable ratio. The high-viscosity nylon 6 is high in molecular weight, high in viscosity and good in mechanical property. The invention further provides a preparation method of the high-viscosity nylon 6. The preparation method includes sequential steps of blending, mixing, drying and the like; the preparation method is simple and high in response speed; the defect that high viscosity of materials in later period of reaction causes difficulty of stirring and byproduct spreading is overcome. The preparation method is applicable to the preparation of the high-viscosity nylon 6 and is further applicable to processing and application of spring guards for heavy-duty trucks.

Owner:河北北田工程塑料有限公司

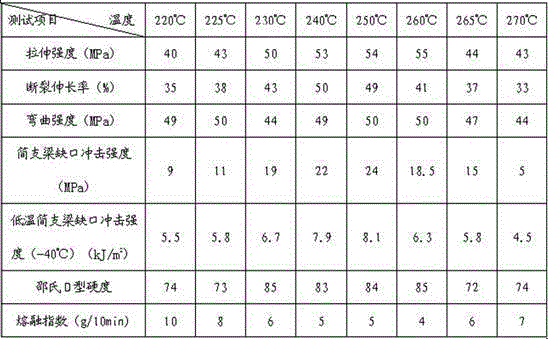

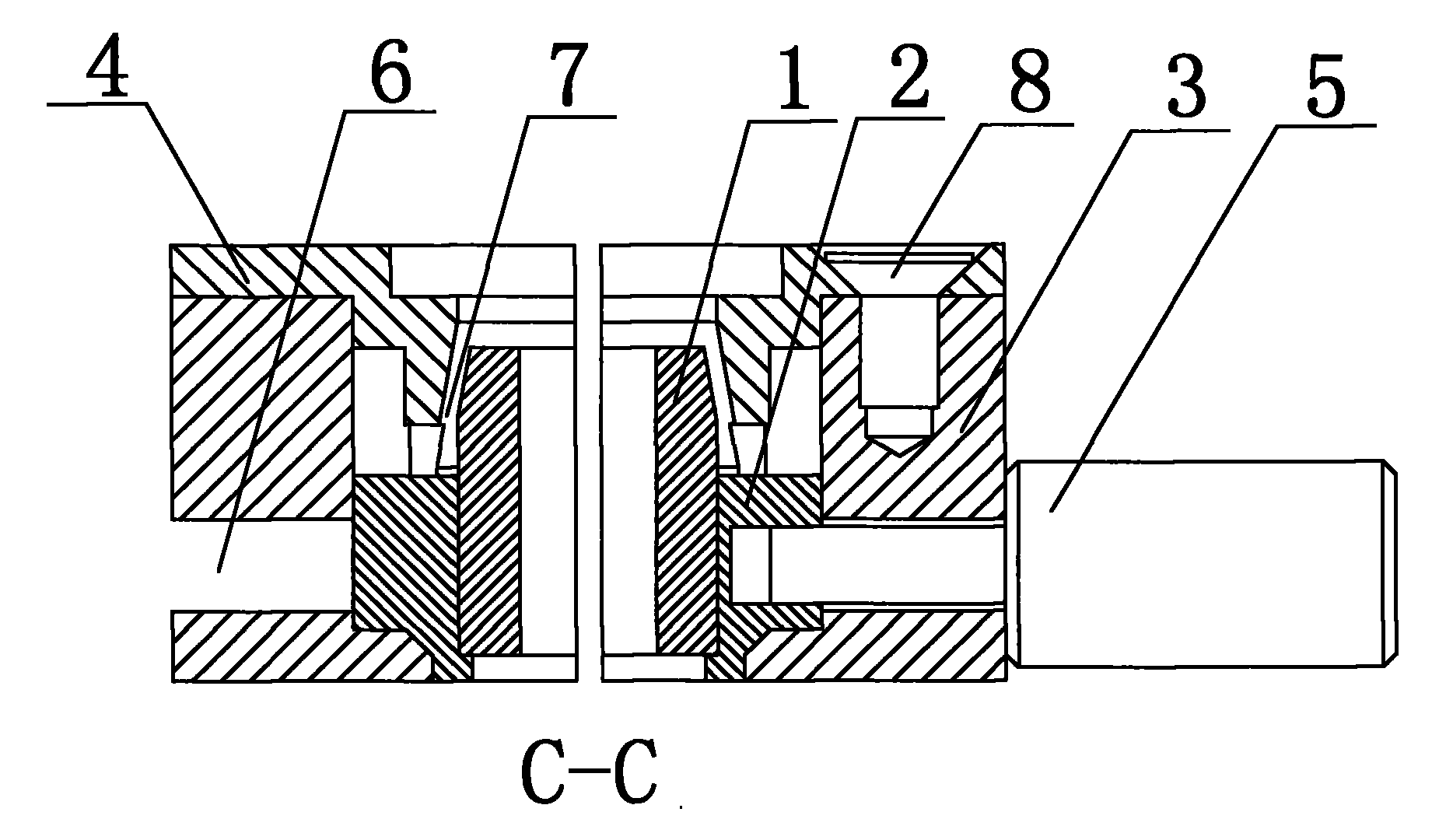

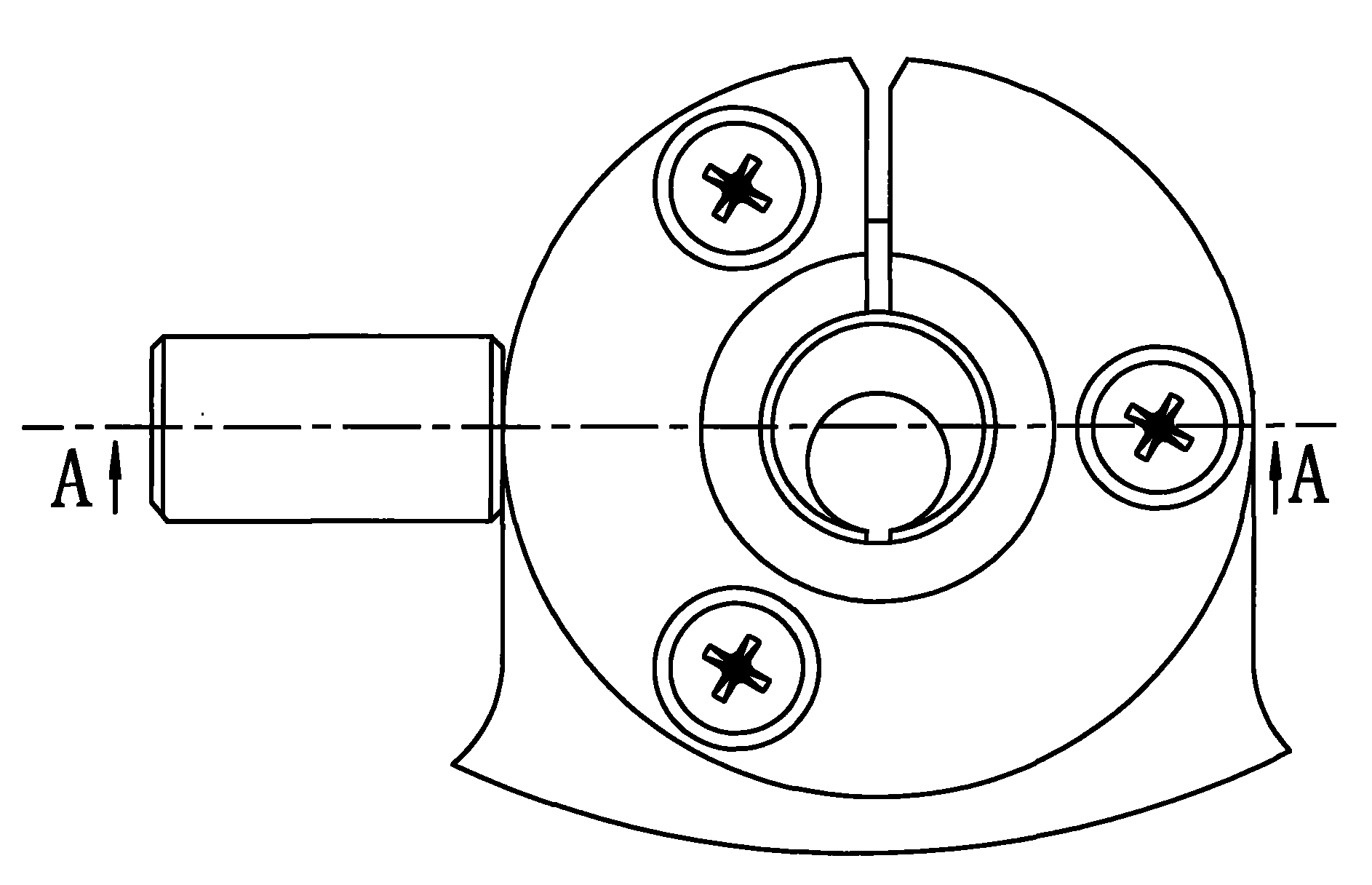

Nozzle device of linear cutting machine

ActiveCN101780573AReduce irregular vibrationImprove Mechanical StreaksElectrical-based auxillary apparatusEngineeringMachine tool

The invention discloses a nozzle device of a linear cutting machine, which comprises a nozzle seat and a nozzle head, wherein the nozzle head has an eccentric cylindrical sleeve structure; one end of the nozzle head is arranged in the nozzle seat which is arranged in a nozzle body; the nozzle body is provided with an annular groove in which an adjustment element is arranged in a screwing way; the adjustment element slides in the annular groove and drives the nozzle seat and the nozzle head to rotate in the nozzle body; the end part of the nozzle body is fixedly provided with a nozzle end cover; and the centre of the nozzle end cover is provided with a jet-flow outlet which forms an annular cavity with the other end of the nozzle head. The nozzle device uniformly sprays a liquid flow out in a way that the nozzle head serves as the centre to cover the wire electrodes to reduce irregular vibration produced by the impact of the liquid flow on the wire electrodes so as to improve mechanical stripes on surfaces, can simultaneously meet the two states of straight-wall machining and conical machining without detaching and replacing parts, is simple to operate, improves working efficiency, reduces the dynamic flexibility of the wire electrodes because bearing distances of the wire electrodes between upper and lower idler pulleys are shortened, and improves the quality of the surfaces.

Owner:SANGUANG ELECTRIC WORKING SUZHOU

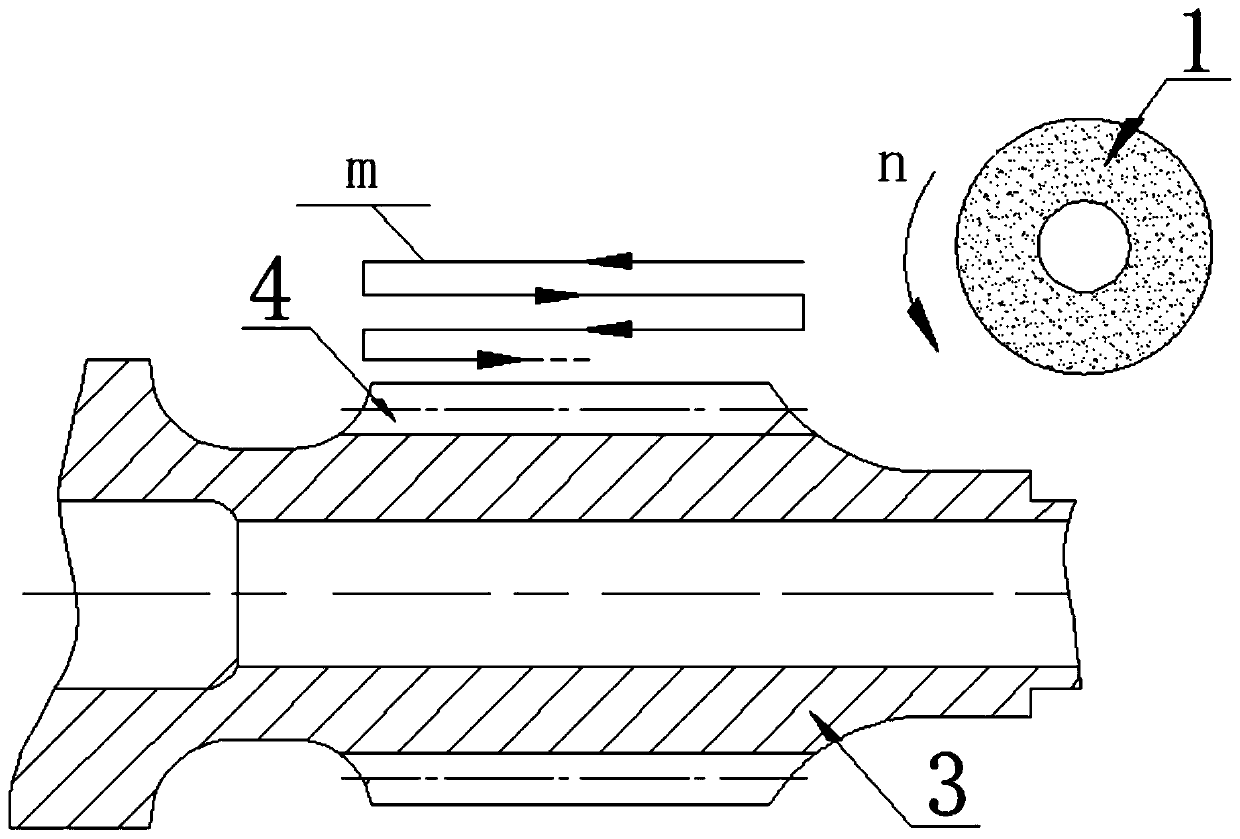

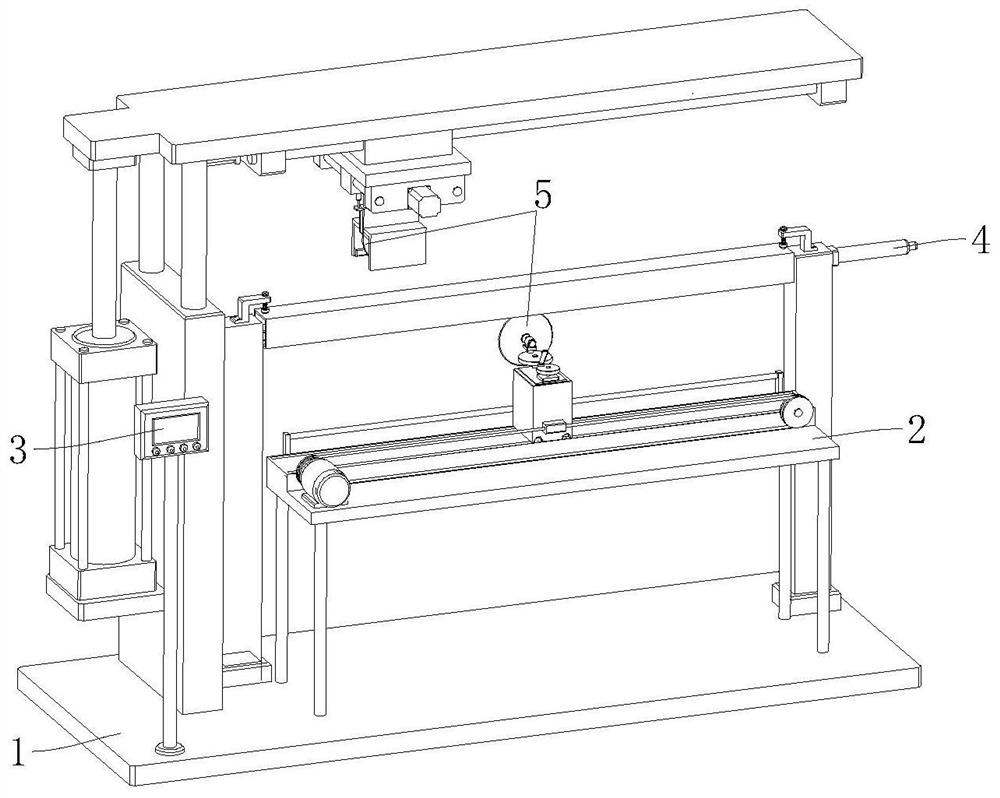

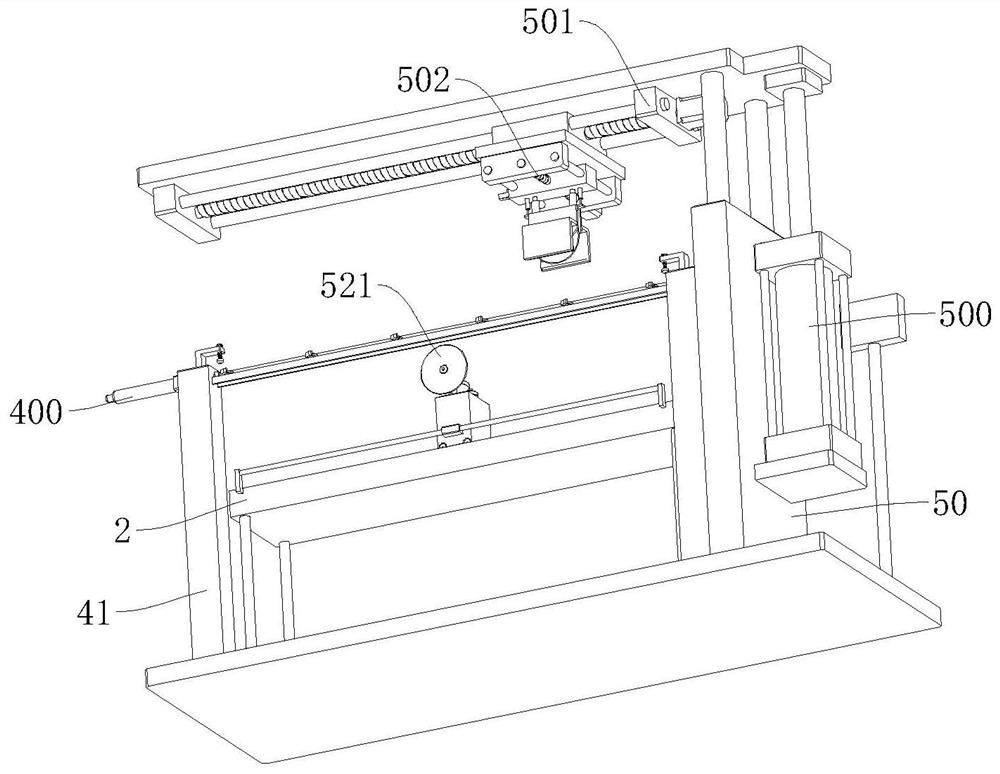

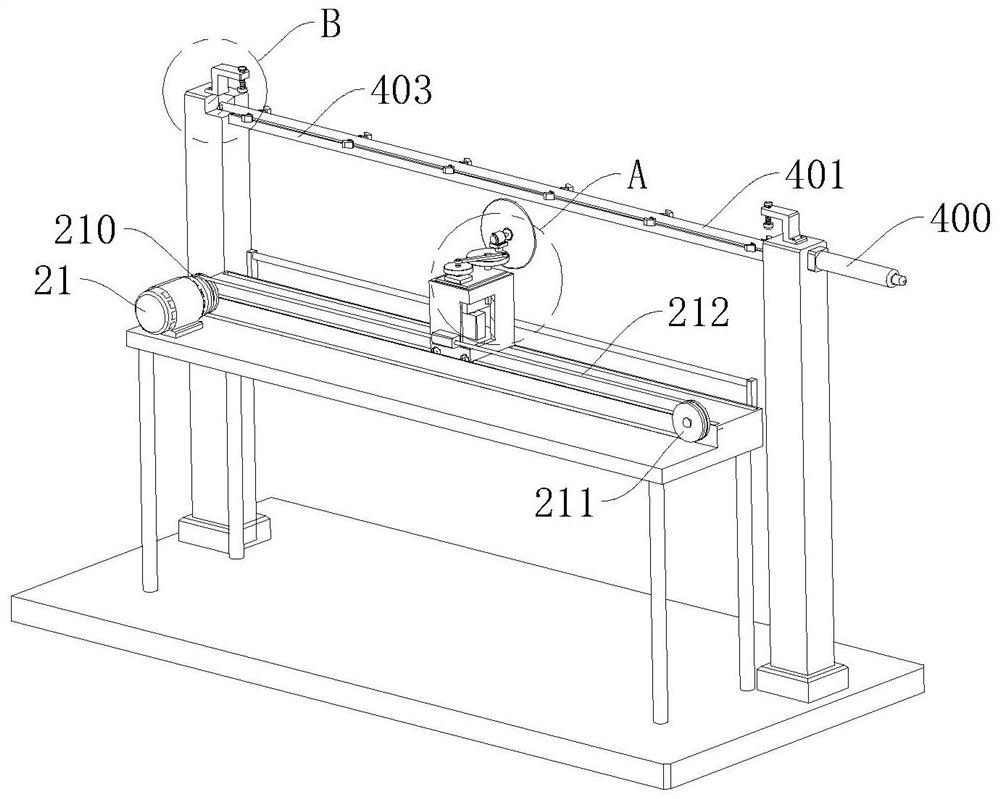

Forming grinding method of turbine long shaft spline teeth

ActiveCN110193785AIncreased accuracy levelImprove machining accuracyAbrasive surface conditioning devicesGear teethSurface roughnessAlloy

The invention discloses a forming grinding method of turbine long shaft spline teeth. Firstly, the molded surface of a grinding wheel is directly finished into the shape correspondingly opposite to the tooth shapes of involute spline straight teeth on a turbine long shaft part, and the machining allowances of the involute spline straight tooth portions are pre-machined on the turbine long shaft part for layering; and then the grinding wheel with the finished molded surface is adopted for directly carrying out forming grinding on all layers until the spline teeth meeting the design requirementsare finally formed. The machining precision and the surface roughness of the part spline teeth can be greatly improved, and the requirements of high-precision machining and high surface roughness ofthe high-temperature alloy turbine long shaft part of an advanced aeroengine on the shapes, the directions and the like of the involute spline teeth are met.

Owner:AECC AVIATION POWER CO LTD

C-shaped steel structure automatic processing equipment

ActiveCN111673164ARealize automatic resetGuaranteed smoothShearing machinesShearing machine accessoriesEngineeringAutomatic processing

The invention relates to the technical field of steel structure processing, in particular to C-shaped steel structure automatic processing equipment. The equipment comprises a base and a supporting platform, and further comprises a controller, a fixing mechanism and a cutting mechanism; the controller is fixedly arranged at the top of the base; the fixing mechanism is arranged at the top of the base and is used for fixing C-shaped steel; the fixing mechanism comprises a bearing assembly, two supporting pillars and two pressing assemblies; the cutting mechanism is arranged on the base and is used for cutting the C-shaped steel; the cutting mechanism comprises a vertical plate, an upper cutting assembly and a lower cutting assembly; and the bearing assembly, the upper cutting assembly and the lower cutting assembly are electrically connected with the controller. The C-shaped steel structure automatic processing equipment and an operation method can conduct automatic adjustment based on offset deviation when position deviation of a cutting tool occurs, realize resetting of the cutting tool, and always maintain that the cutting tool meets the cutting requirements; at the same time, when the C-shaped steel is fixed, the speed is fast, the operation is convenient and processing efficiency can be effectively improved.

Owner:永盟绿建科技(南通)有限公司

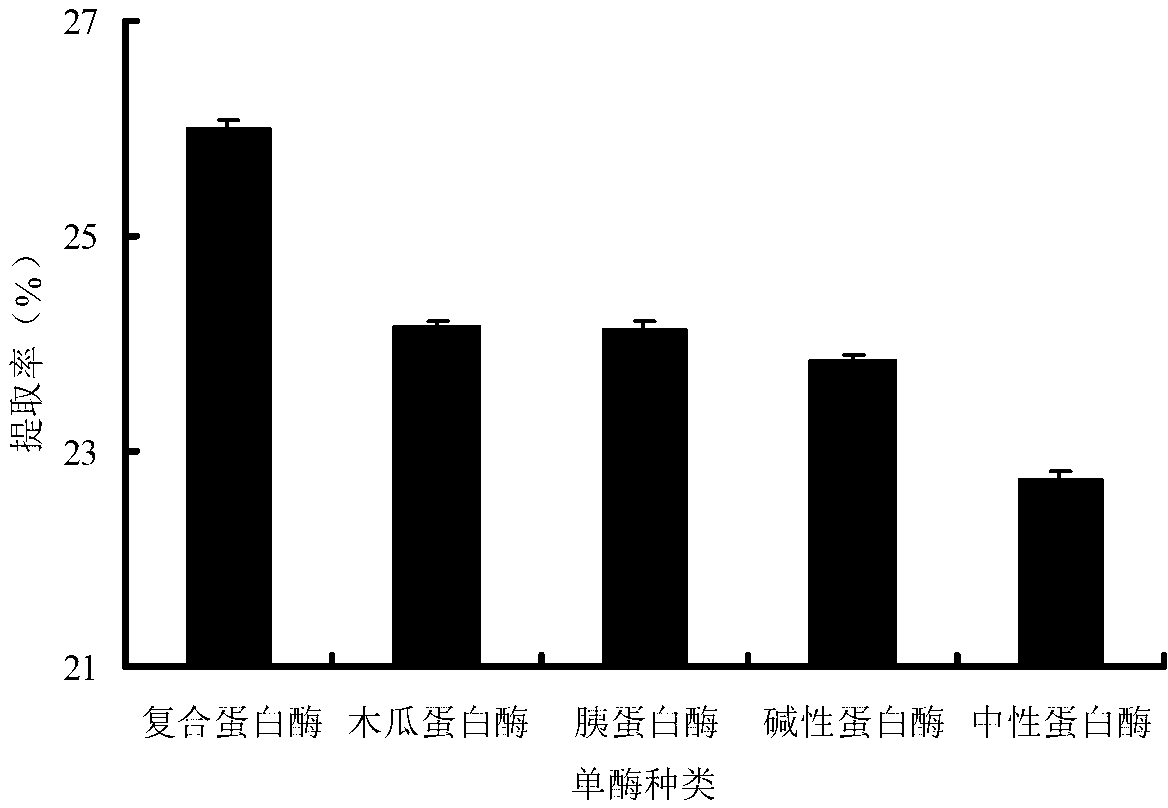

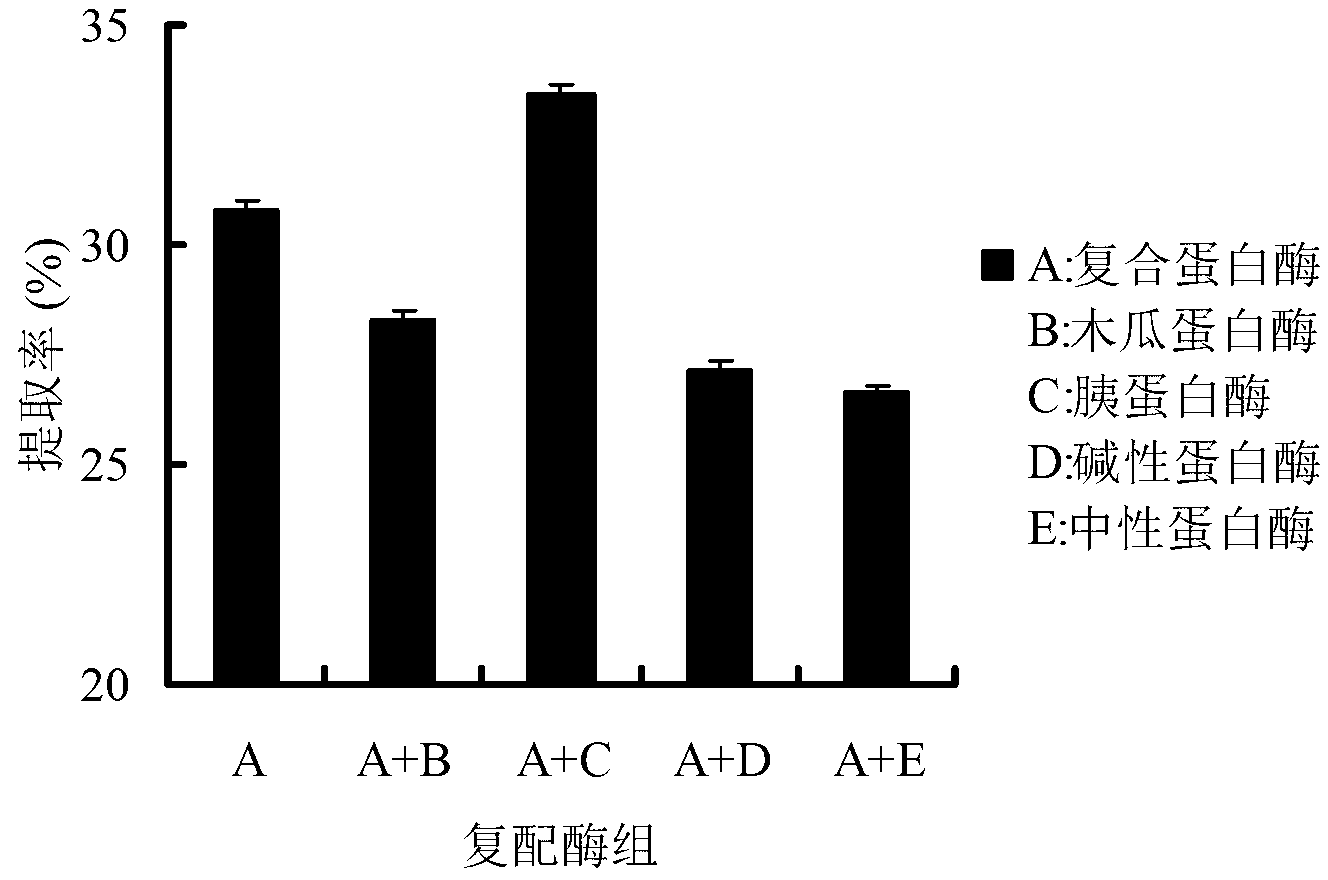

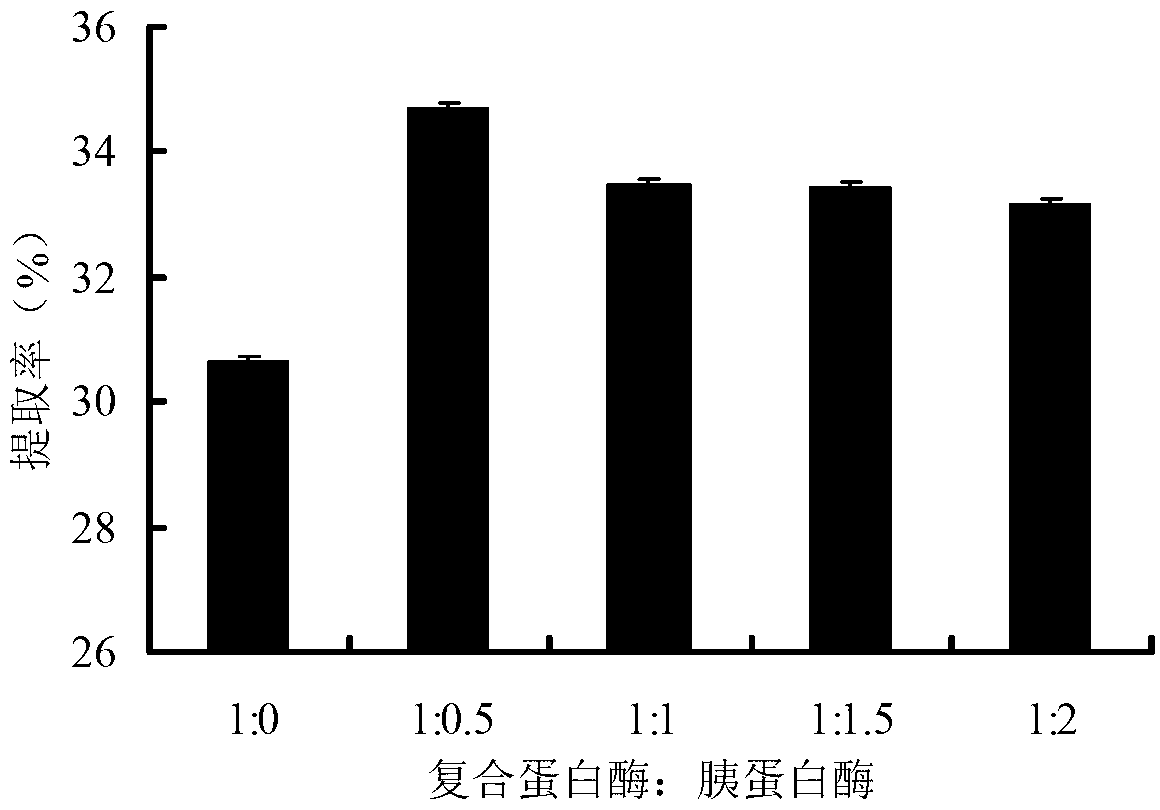

Extracting method of duck chondroitin sulfate by compound enzymolysis

ActiveCN103243079AProcess environmental protectionSatisfy securityHydrolasesProteinase activityChemical composition

The invention discloses an extracting method of duck chondroitin sulfate by compound enzymolysis. A basic formula of novel compound protease, which is used for extracting duck chondroitin sulfate, is designed according to chemical composition of the duck breast cartilage; and the compound enzyme is utilized to prepare duck chondroitin sulfate; the process comprises the following four steps of: preparing duck breast cartilage powder, extracting the duck breast cartilage powder by enzymolysis; settling protein; and preparing chondroitin sulfate powder. The extracting method can be used for extracting chondroitin sulfate of the duck breast cartilage by adopting a compound enzymolysis method; the novel compound protease and trypsin are compounded, so that an alkaline extraction step is omitted, and the use of the compound enzyme is optimized, and therefore, the yield is improved by about 20% compared with the yield achieved by adoption of other methods, and the product purity reaches 90%-95%. The compound enzyme can be used for substituting dilute alkali or thick alkali for decomposing the cartilage, so that the pollution to the environment is greatly lowered, the production period can be effectively shortened, the production cost is lowered, the product quality is improved, and the blank in the field is filled.

Owner:QINGDAO AGRI UNIV

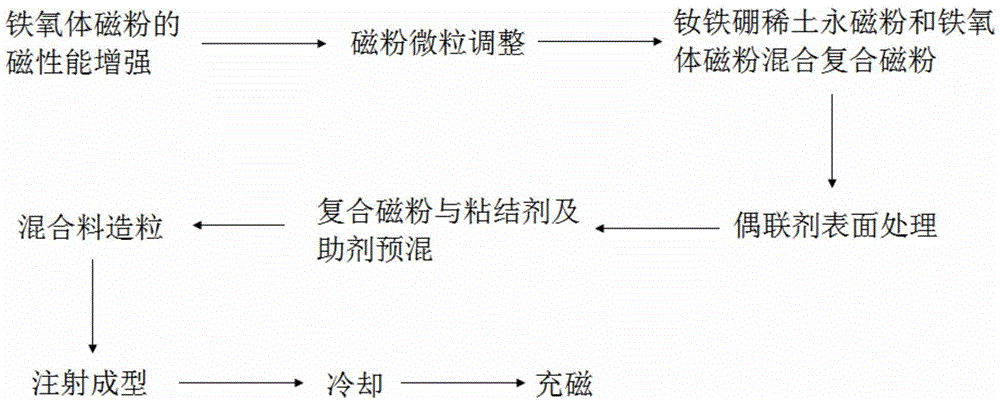

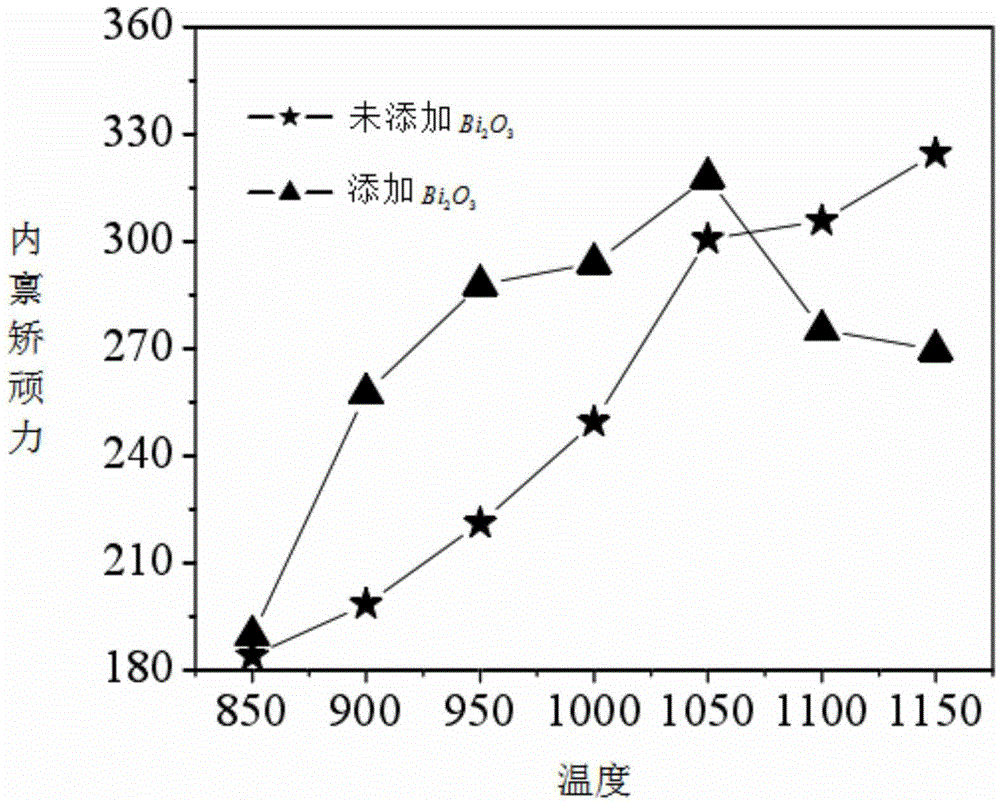

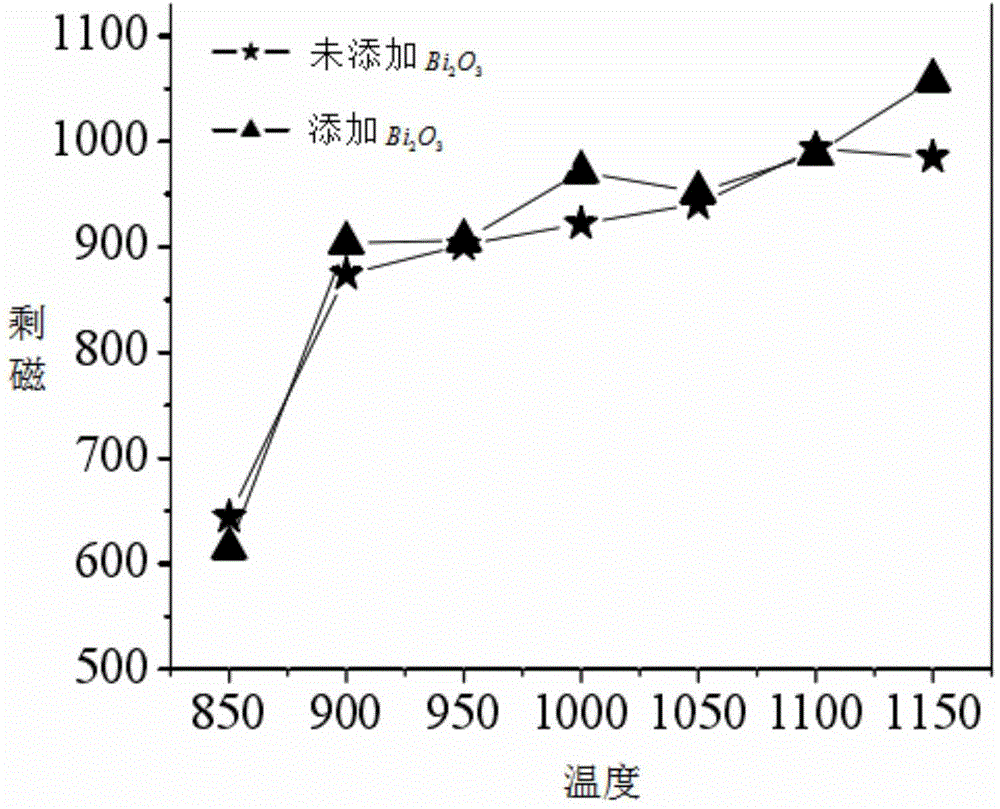

Anisotropic bonded magnet and production process thereof

ActiveCN104616882AStrong magnetismImprove mechanical propertiesInorganic material magnetismInductances/transformers/magnets manufactureState of artRare earth

The invention discloses an anisotropic bonded magnet and a production process thereof. An appropriate amount of anisotropic neodymium iron boron lanthanon permanent magnet powder and ferrite magnetic powder is mixed in proportion to form composite magnet powder, mixing pelleting, injection moulding, cooling curing and other processes are carried out on the composite magnet powder, binding agents with proper components and other assistants, and the anisotropic bonded magnet with good magnetic performance, mechanical performance, oxidation resistance and heat resisting performance is manufactured. The defects that the heat performance of an anisotropic neodymium iron boron bonded magnet in the prior art is poor, and the magnetic performance of a ferrite bonded magnet is insufficient are overcome.

Owner:HEYE HEALTH TECH CO LTD

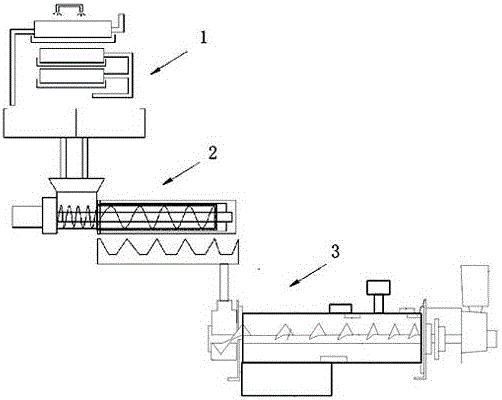

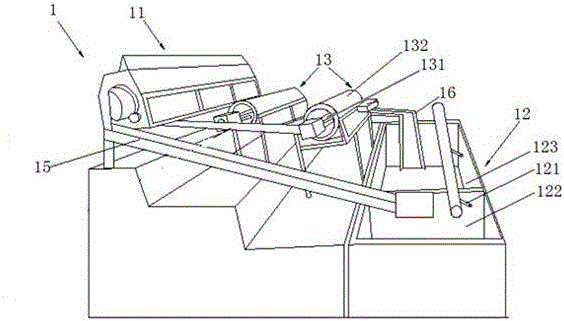

Fully-automatic fish fresh preparation device and method

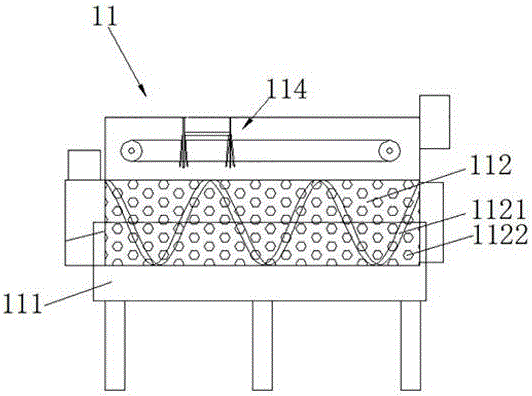

The invention relates to a fully-automatic fish fresh preparation device and method. The preparation device comprises a rinsing device, a fine filtering device and a dewatering device which are communicated with one another in sequence; the rinsing device comprises a rotary screen, a rinsing tank and a filtering roller; a spray head is arranged above the rinsing tank; the rinsing tank comprises a first rinsing tank and a second rinsing tank; the rotary screen conveys fish flesh to the first rinsing tank through an oblique slideway; the filtering roller conveys the fish flesh to the second rinsing tank through an L-shaped slideway; the rotary screen comprises a water tank, a hollow rotating drum is arranged in the water tank, a spiral convex channel is formed in the inner wall of the rotating drum, and water outlets are densely formed in the surface of the rotating drum; the bottom of the water tank is communicated with the filtering roller through a water pipe; a water spray device is arranged above the rotary screen; the filtering roller comprises a rotating shaft and a roller body wrapped with filter cloth.

Owner:ZHOUSHAN TENGXIN FOOD CO LTD

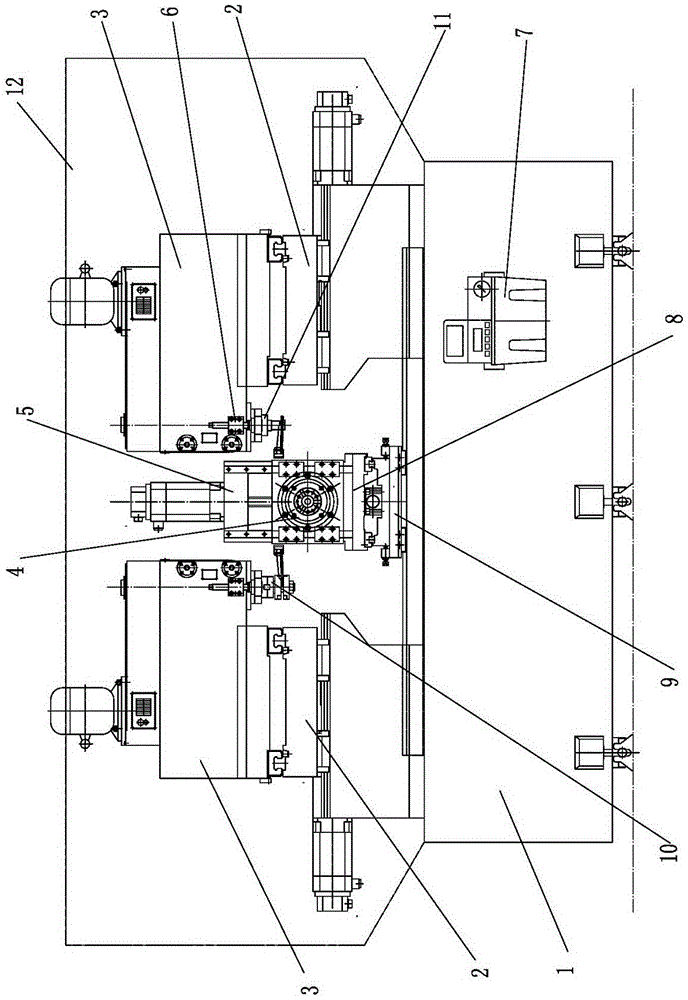

Combined machining device special for shifting fork

InactiveCN105458710AClamping does not affectSatisfy processingGearing controlOther manufacturing equipments/toolsNumerical controlElectrical control

The invention provides a combined machining device special for a shifting fork. The combined machining device special for the shifting fork comprises a complete lathe body, a hydraulic rotating workbench, two numerical control cross sliding tables, two vertical milling power heads, a boring power head, four hydraulic clamps, an electrical control system, a hydraulic system, a concentrated lubricating device and a cooling and chip removing device. A clamping station is arranged on the front side of the hydraulic rotating workbench; an open gear milling station and a shifting fork flat part milling station are arranged on the corresponding side faces of the two vertical milling power heads fixed to the numerical control cross sliding tables; and a hole drilling station is correspondingly arranged behind the boring power head, and therefore four stations are formed. Four parts can be clamped by the combined machining device special for the shifting fork at a time, the three procedures of milling an opening gear, milling a shifting fork flat part and drilling a hole can be completed through one time of clamping, clamping of the parts is not affected in the machining process, and the deformation quantity of the shifting fork is eliminated through hydraulic pressing; and the machining tact is short, and production efficiency is greatly improved.

Owner:湖北华阳汽车变速系统股份有限公司

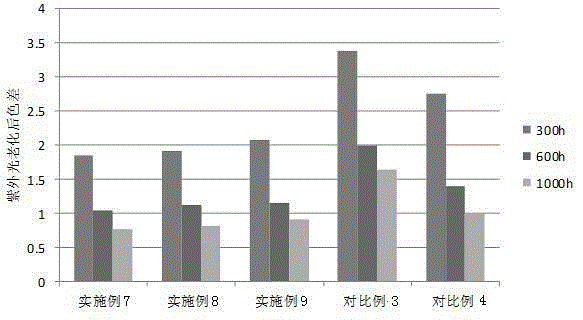

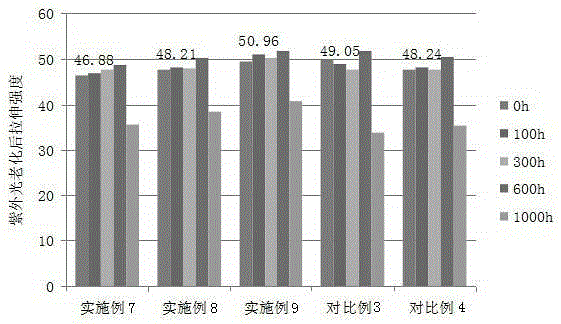

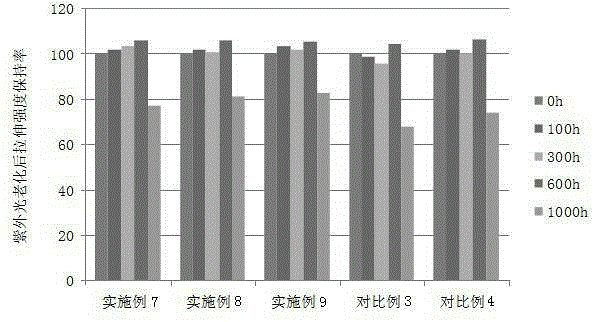

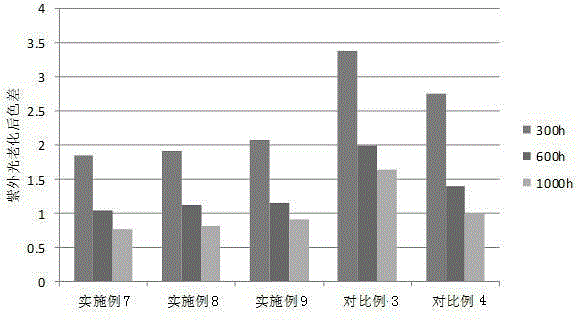

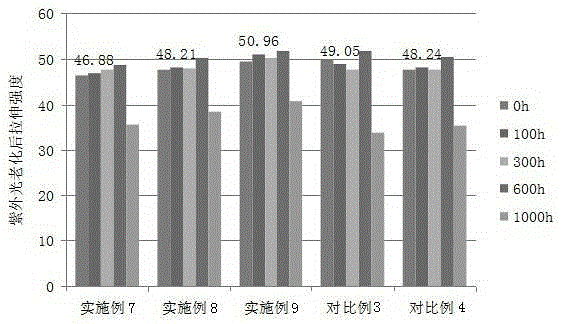

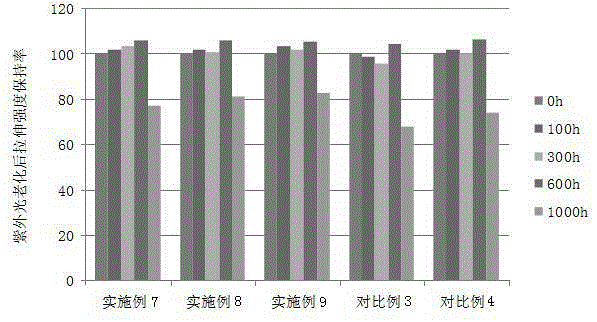

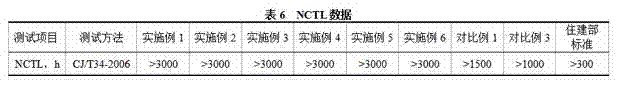

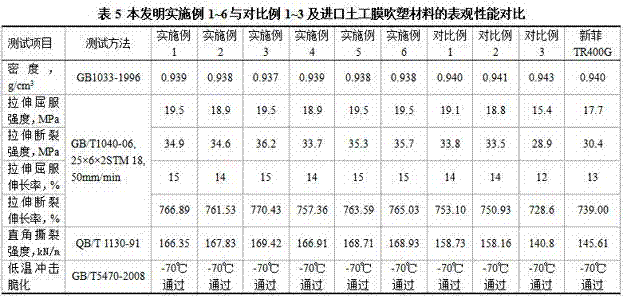

Ultraviolet-light-ageing-resistant high-intensity polyethylene IBC inner container material and preparation method

The invention discloses an ultraviolet-light-ageing-resistant high-intensity polyethylene IBC inner container material and a preparation method. The ultraviolet-light-ageing-resistant high-intensity polyethylene IBC inner container material is mainly prepared from, by mass, 100 parts of ethylene hexylene copolymer polyethylene resin, 0.05-0.1 part of antioxidant, 0.05-0.1 part of antioxidant aid and 0.15-0.20 part of composite light stabilizer. The invention further discloses a preparation method of the material. An IBC bucket inner container manufactured through the material is good in formability, excellent in environmental stress cracking resistance and light stability, and all mechanical properties are stable.

Owner:CHINA PETROLEUM & CHEM CORP

Automobile lifting fixing frame for automobile production examination

The invention discloses an automobile lifting fixing frame for automobile production examination. The automobile lifting fixing frame comprises an upper top plate and a lower fixing frame body. The upper top plate is located over the lower fixing frame body. A transverse fixing plate is arranged under the lower fixing frame body. A main adjusting motor is fixed to the middle of the bottom face ofthe transverse fixing plate. An output shaft of the main adjusting motor penetrates through the transverse fixing plate and is connected with a vertical main screw through a coupling. A main adjustingthreaded sleeve is in threaded connection with the vertical main screw. The middle of the main adjusting threaded sleeve is inserted into and sleeved with a central through hole formed in the middleof a top plate of the lower fixing frame body. The top end of the main adjusting threaded sleeve is fixed to the bottom face of a main lifting plate. A plurality of supporting legs are fixed to the top face of the main lifting plate. The top faces of the supporting legs are fixed to the bottom face of the upper top plate. The side walls of a middle horizontal plate are fixed to the inner side walls of the supporting legs. The lifting plate can be lifted, thus, four limiting blocks are lifted for positioning an automobile body, positioning is rapid and convenient, the efficiency is high, the effect is good, meanwhile, the automobile body is lifted, and the machining or detection height requirements are met.

Owner:FOSHAN HUAPU RUILIAN ELECTROMECHANICAL TECH CO LTD

Preparation method of high-hexene grafted high-density polyethylene geomembrane blow molding material

ActiveCN104744795AImprove conversion efficiencyIncrease the amount of graftingBulk chemical productionBlow moldingPtru catalyst

The invention discloses a preparation method of a high-hexene grafted high-density polyethylene geomembrane blow molding material. The method comprises the following steps: (1) when a diluting agent is always under a circulation state, placing monomer ethylene and 1-hexene in a reaction vessel; adding an antistatic agent and an catalyst subjected to an activation treatment; adjusting the reaction temperature in the reaction vessel to 92-98 DEG C until the melt flow rate of a reaction product is 10.0-13.0g / 10min and the density of the reaction product is 0.937-0.939kg / m<3>, thereby obtaining ethylene-hexene polyethylene copolymer base resin with weight average molecular weight of 200,000 to 300,000, 1-hexene content of not less than 1.20% and crystallinity of 46.5-49.5%; (2) uniformly mixing 99.5-99.8 parts of the ethylene-hexene polyethylene copolymer base resin and 0.20-0.50 part of an antioxidant; and adding the mixture to a mixer for extrusion granulation, so as to obtain the geomembrane blow molding material. According to the method, a high-activity novel chromium catalyst is adopted, the equipment limitation of a loop slurry process is overcome, and high-hexene grafted high-density polyethylene is produced. With the method, reaction scale is effectively ameliorated, a reactor wall attachment phenomenon is reduced, production is smooth, and the productivity of the special material is high.

Owner:CHINA PETROLEUM & CHEM CORP

Rubber composition, vulcanized rubber, and applications of vulcanized rubber

The invention discloses a rubber composition. The rubber composition comprises ethylene propylene rubber, an activator, a reinforcing agent, a paraffin oil, a vulcanization accelerator, and a vulcanizing agent; the vulcanization accelerator is composed of 2-mercaptobenzothiazole, N-cyclohexyl-2-benzothiazole sulfonamide, diethyldiphenylthiuram disulfide, and tellurium diethyldithiocarbamate. The rubber composition contains no toxic raw material, possesses excellent physical properties, processing performance, and smell, and can be used for producing green passenger vehicle rubber sealing strips.

Owner:CHINA PETROLEUM & CHEM CORP +1

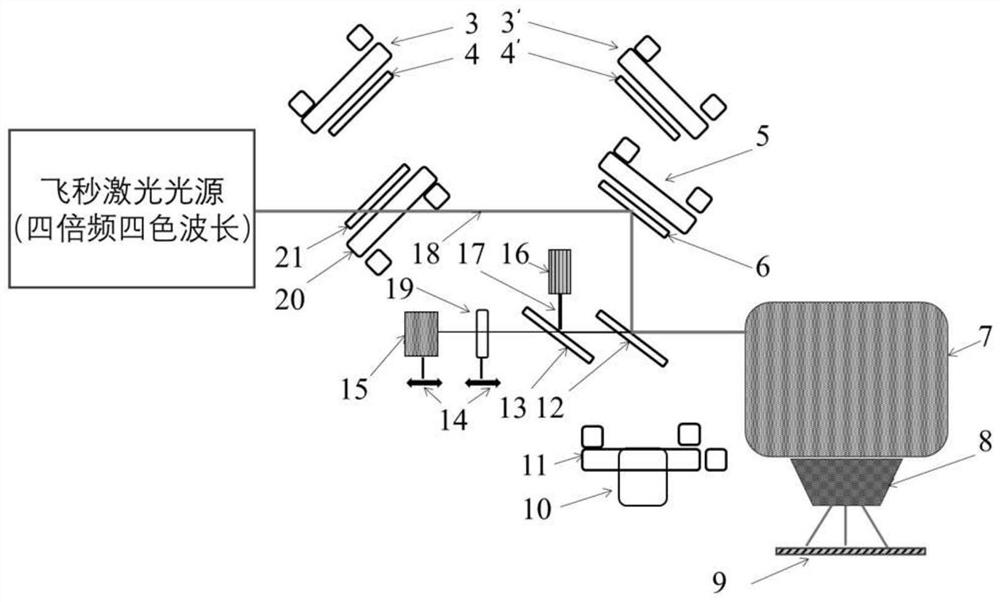

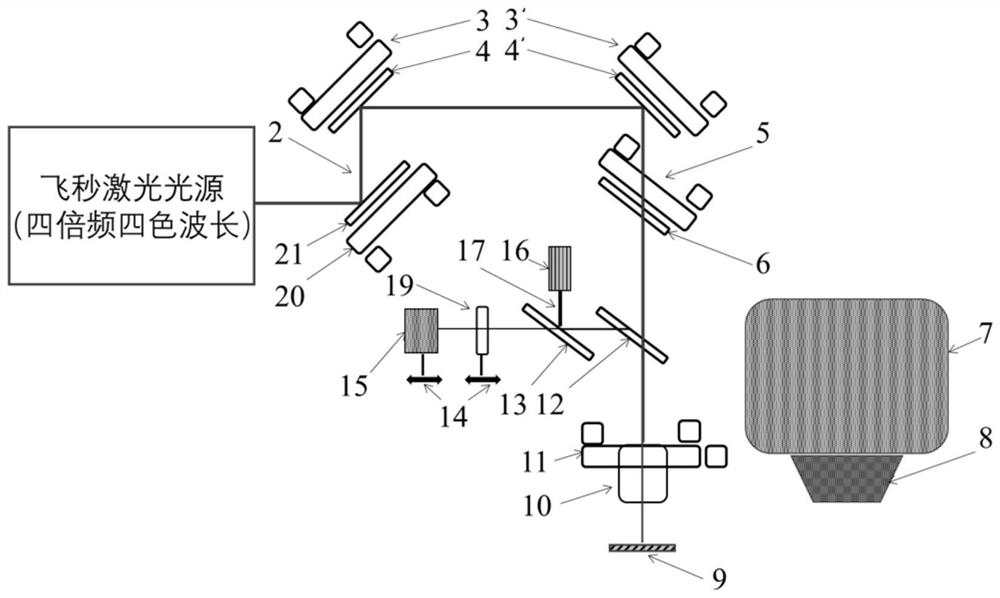

Three-waveband laser double-focusing-head laser processing system and method

ActiveCN111604582AClear imagingObserve clearlyLaser beam welding apparatusLaser processingUltraviolet lights

The invention relates to a three-waveband laser double-focusing-head laser processing system and method. Through three-waveband laser beam splitting processing and double-focusing-head design, one device can be matched with ultraviolet, visible and infrared three-waveband laser transmission and processing at the same time; a composite light beam is used for illumination, visible light and infraredlight are used for illumination during ultraviolet light processing, ultraviolet light is used for illumination during visible light and infrared light processing, light captured by a CCD only comprises illumination light and does not comprise processing light at the moment, and a processing position can be imaged and observed more clearly; by means of a plurality of precise two-dimensional adjusting frames and a translation support, precise adjustment and imaging control of the transmission direction of the laser beam are facilitated, the requirement for adjusting the direction of the incident laser beam is lowered, and the processing and imaging requirements of various laser light sources and various specifications of focusing mirrors or field lenses are met.

Owner:青岛昆仑天峰航空科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com