High-rigidity high-heat-resistance homo-polypropylene material and preparation method thereof

A technology of homopolypropylene and high heat resistance, which is applied in the field of preparation of high rigidity and high heat resistance homopolypropylene materials, which can solve problems such as inability to assemble and use, affect normal use of products, and high shrinkage and warpage of products, and achieve Good melt fluidity and rigidity, reduced shrinkage and warpage, and high isotactic index

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

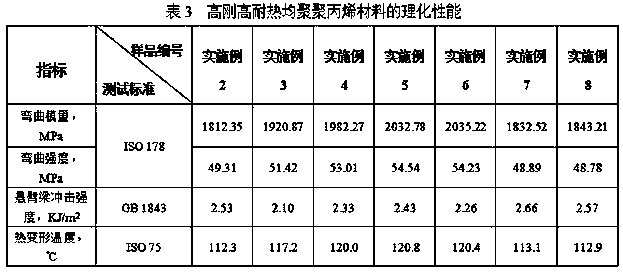

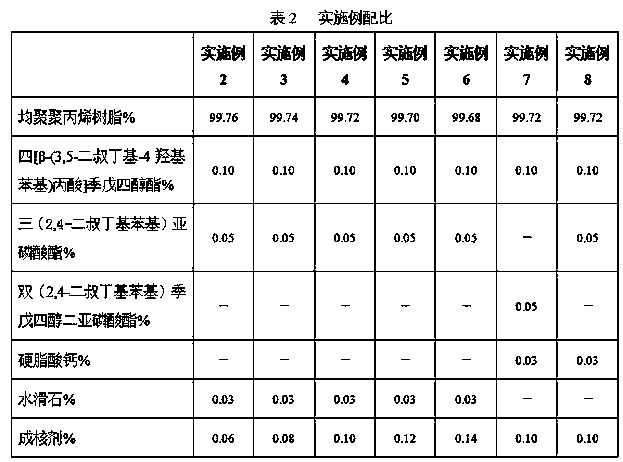

Examples

Embodiment 1

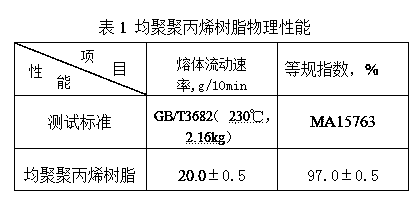

[0023] Embodiment one: the preparation of homopolypropylene resin:

[0024] 1. The raw materials for the production of base resin are the following substances:

[0025] 1) Polymer grade propylene

[0026] project purity% Water content 10 -6 CO content10 -6 CO 2 Content 10 -6 index ≥99.35 ≤5 ≤0.2 ≤4

[0027] 2) Catalyst DQC-401, cocatalyst TEAL, electron donor DONOR, antistatic agent Atmer163

[0028] 3) Hydrogen

[0029] project purity% Water content 10 -6 CO content10 -6 Total Sulfur Content10 -6 index ≥95 ≤5 ≤5 ≤1

[0030] Add propylene to the loop reactor, and add catalyst DQC-401, cocatalyst triethylaluminum (TEAL), electron donor DONOR, antistatic agent Atmer163. Among them: catalyst DQC-401 is added according to the output of 40kg / ton; TEAL / C 3 (Propylene) = 0.16; TEAL / DONOR=10; antistatic agent Atmer163 is 2~3kg / h. Stir evenly, control the reaction temperature in the loop reactor to 70±1°C, the re...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| flexural modulus | aaaaa | aaaaa |

| heat deflection temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com