Patents

Literature

52results about How to "Meet the mechanics" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method for preparing seamless titanium alloy tube for aircraft engine

The invention discloses a method for preparing a seamless titanium alloy tube for an aircraft engine. The seamless titanium alloy tube for the aircraft engine which meets corresponding requirements is manufactured by improving the technological plasticity of the titanium alloy tube material. The method comprises the following steps of: firstly, smelting a spongy cast ingot to introduce interstitial elements as little as possible; secondly, cogging and forging heated cast ingot at large deformation and repeatedly upsetting and stretching the cast ingot to ensure that as-cast coarse grains are completely crushed and thinned, thermally processing formed tube billet under vacuum to eliminate residual stress produced during tube billet extrusion so as to improve the plasticity of the tube billet; thirdly, cogging and rolling the tube billet at large deformation and further thinning the grains; and finally, annealing at a low temperature after cold rolling of intermediate rolling and finished product rolling to effectively control the coarsening of the grains. Therefore, full recrystallization can be ensured by prolonging the heating time, and mechanical property and processing property required by material consumption of the aircraft engine can be met under the condition that the tube structure is fully recrystallized.

Owner:WESTERN TITANIUM TECH

Halogen-free intumescent flame-retardant polypropylene/ethylene vinyl acetate cable material

ActiveCN101649088AImprove insulation performanceImprove mechanical propertiesPlastic/resin/waxes insulatorsInsulated cablesExtensibilityUv absorber

The invention relates to a halogen-free intumescent flame-retardant polypropylene / ethylene vinyl acetate cable material which is characterized by comprising the following components by weight part: 20-40 parts of polypropylene, 60-80 parts of ethylene vinyl acetate, 45-65 parts of compound flame retardant, 5-15 parts of grafting agent, 1.0-2.0 parts of antioxidizer, 1.0-2.0 parts of ultraviolet absorbent and 1.0-3.0 of processing aid. With the advantages of favorable flexibility, high breakage extensibility, favorable tensile strength, excellent electrical insulating property and good flame retardant, the material favorably meets the requirements on the burning property, the mechanical property and the heat property of the cable material and is mainly used as the outer coating material ofcables.

Owner:应急管理部四川消防研究所

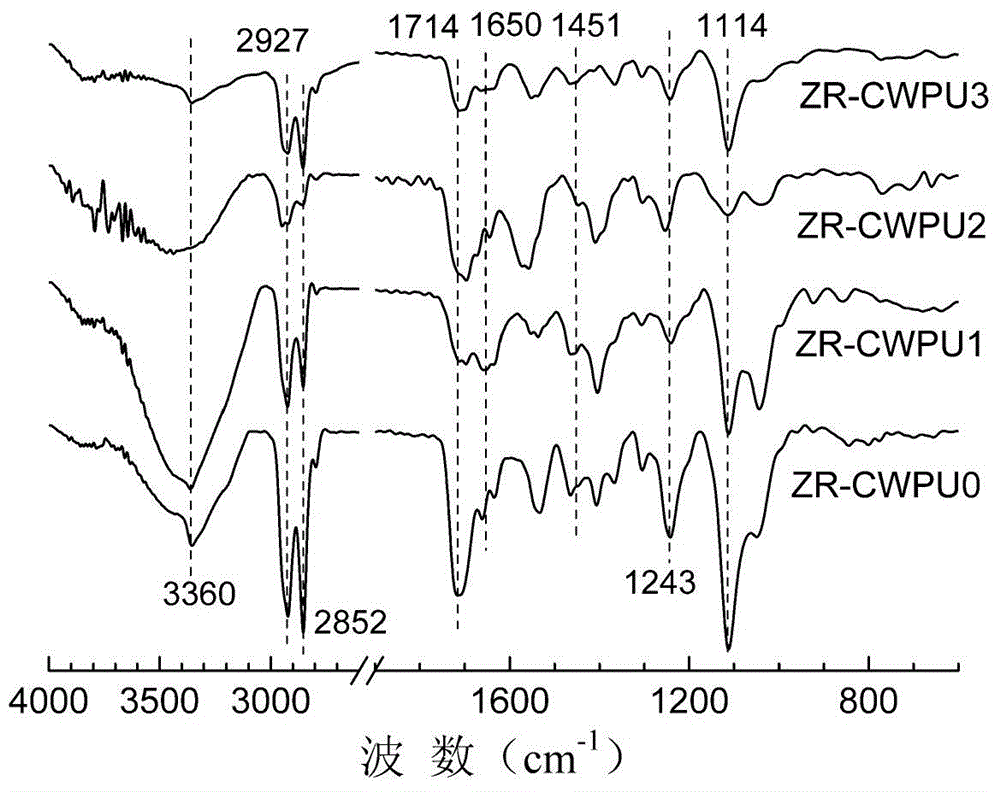

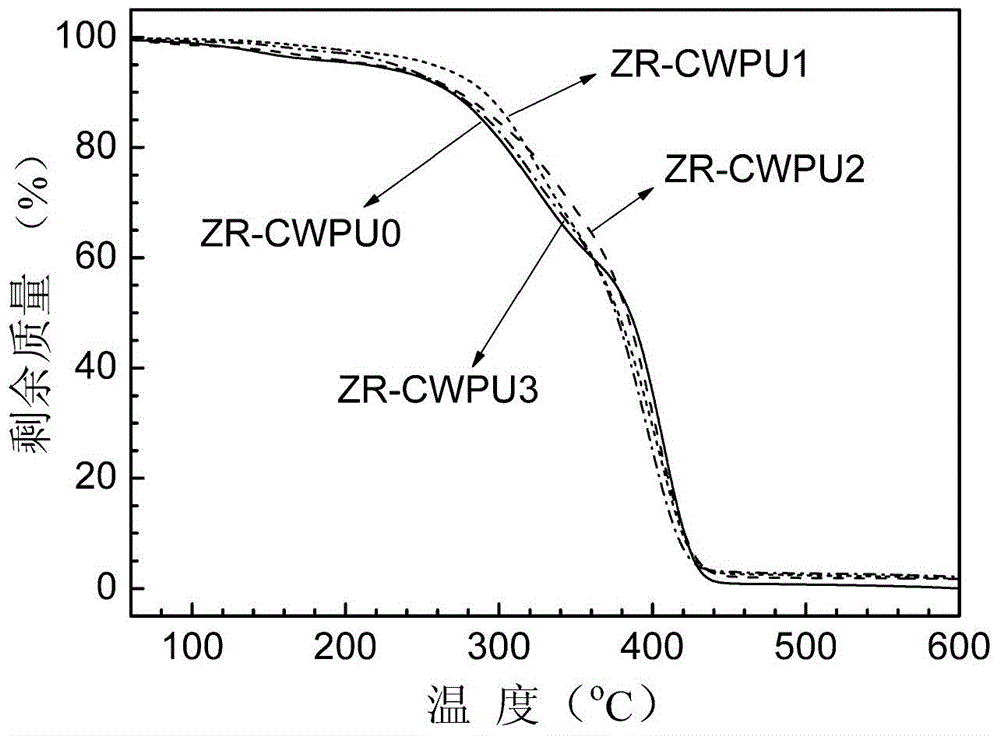

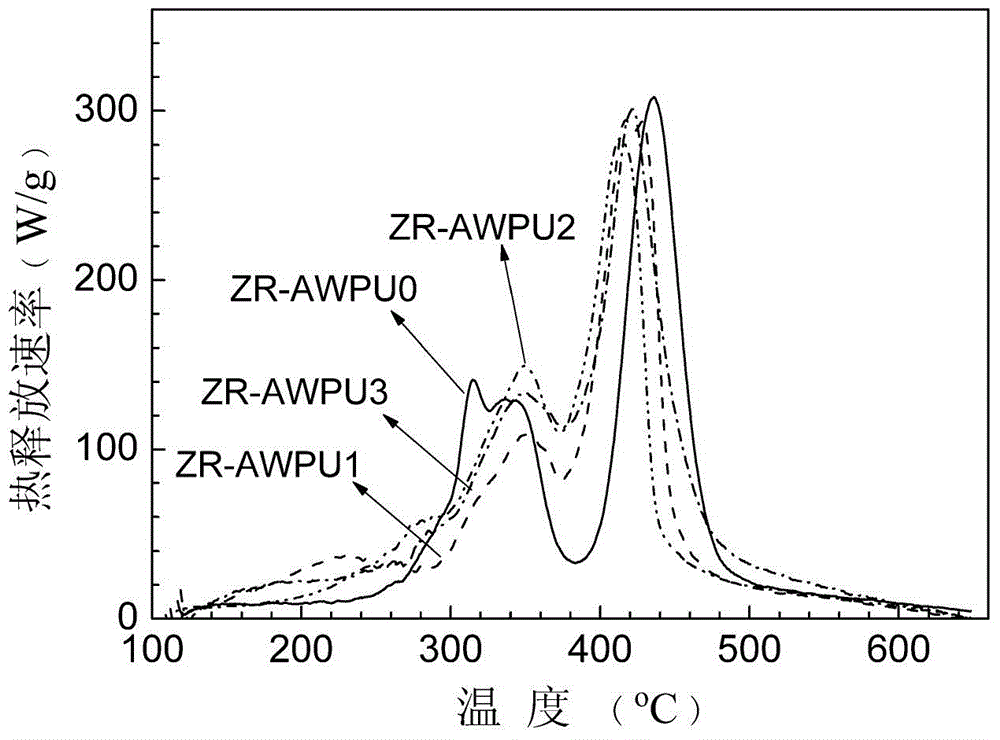

Method for preparing flame-retardant waterborne polyurethane containing phosphaphenanthrene and/or phenyl phosphate groups

InactiveCN104592475ANon-corrosive generationEvenly distributedGroup 5/15 element organic compoundsPolymer scienceAlcohol

The invention discloses a method for preparing flame-retardant waterborne polyurethane containing phosphaphenanthrene and / or phenyl phosphate groups. The method is characterized by comprising the following step of reacting dihydric alcohol as a reactant which contains phosphaphenanthrene and / or phenyl phosphate groups and of which the hydroxyl groups are symmetric with diisocyanate, macromolecular dihydric alcohol, anionic or cationic hydrophilic chain extender and the like to synthesize flame-retardant waterborne polyurethane. According to the method, since flame-retardant dihydric alcohol is used as one of chain extenders, flame-retardant dihydric alcohol ca partially or totally substitute other small molecular chain extenders, phosphorus-containing flame-retardant groups are controllable in content and difficult to migrate and are evenly distributed, and the flame-retardant property of waterborne polyurethane can be enduringly retained. According to the structural characteristics of selected flame-retardant dihydric alcohol, by virtue of one and a combination of two or more of flame-retardant groups, phosphorus in the flame-retardant groups can be alone located at a main chain, side chains or simultaneously located at the main chain and the side chains of the polyurethane molecule chain as desired so as to meet the requirements of different flame-retardant properties or other properties such as mechanics, toughness and plasticity.

Owner:UNIV OF SCI & TECH OF CHINA

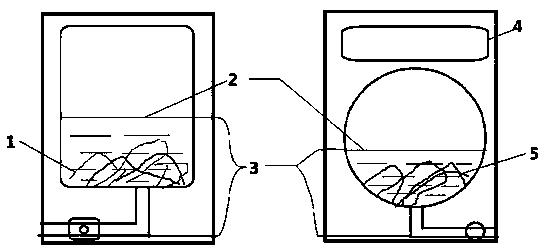

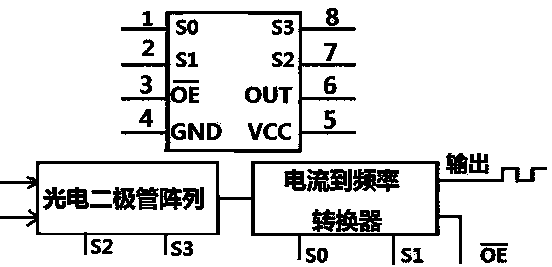

Anti-fading washing control method

ActiveCN104195787AResolve detectionSolve the disadvantages of missed alarmOther washing machinesControl devices for washing apparatusLaundry washing machineControl engineering

The invention discloses an anti-fading washing control method. According to the method, an impeller type washing machine or a tumbling-box washing machine is included. The washing machine comprises a washing machine body. An inner washing barrel, an outer barrel and a controller are mounted in the washing machine body. The washing machine body is further provided with a color sensor. The color sensor detects washing water in the washing process and feeds back a detected result to the controller. The controller analyzes the detected result and then judges whether follow-up operation for preventing fading and mutual dyeing needs to be conducted. The anti-fading washing machine can judge whether woven products fade or not accurately in time.

Owner:HISENSE(SHANDONG)REFRIGERATOR CO LTD

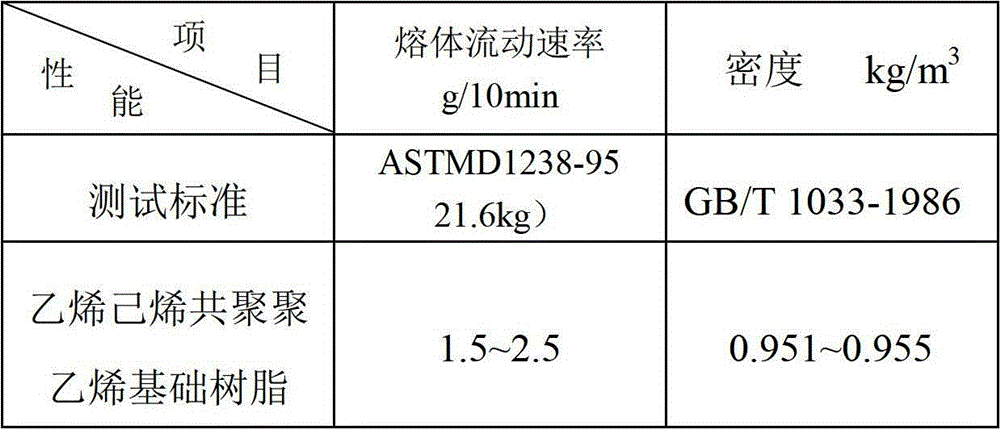

Large hollow container blow molding material and preparation method thereof

The present invention discloses a large hollow container blow molding material, which comprises the following raw materials, by weight, 99.9-100.0 parts of an ethylene hexene copolymerization polyethylene base resin, 0.05-0.10 part of an antioxidant, 0.07-0.12 part of a co-antioxidant, and 0.03-0.05 part of a slip agent. The present invention further discloses a preparation method for the large hollow container blow molding material. The large hollow container blow molding material has characteristics of low fusion index, large molecule weight, high strength, and the like, and is suitable for blowing of large size containers, wherein the product has prominent rigidity and toughness balancing capacity, creep resistance, excellent ESCR and good chemical resistance.

Owner:CHINA PETROLEUM & CHEM CORP

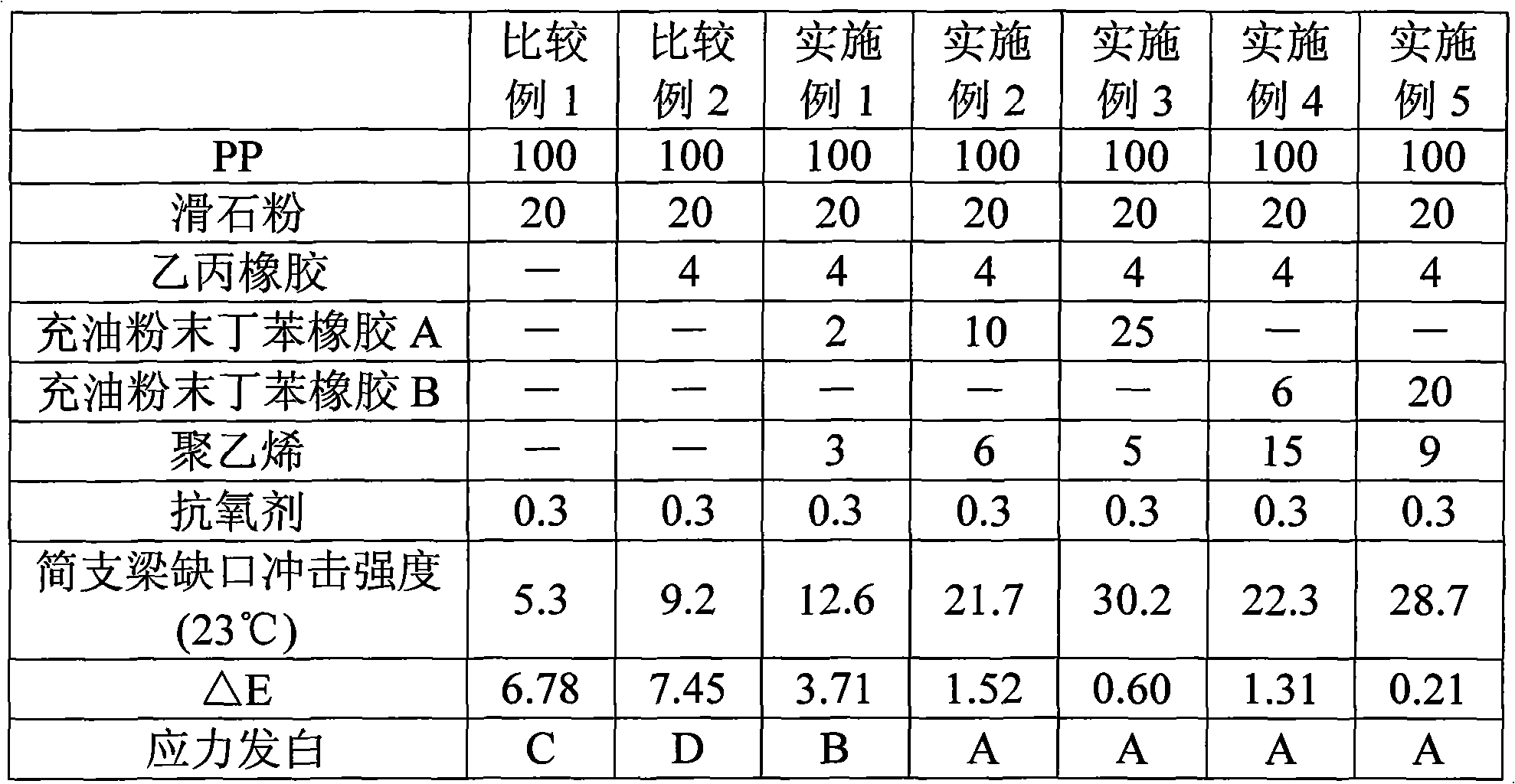

Stress whitening resistant and scratch resistant polypropylene composition, and preparation method thereof

The present invention provides a stress whitening resistant and scratch resistant polypropylene composition, and a preparation method thereof. The polypropylene composition comprises the following components, wherein the components are blended, and comprise, by weight, 100 parts of a polypropylene resin, 0-50 parts of a mineral filler, 0.05-40 parts of oil-filled fully-vulcanized powdered rubber,0.01-30 parts of polyethylene and 0-30 parts of a toughening agent. The oil-filled fully-vulcanized powdered rubber is the fully-vulcanized powdered rubber filled with a polysiloxane lubricant and / orhydrocarbon lubricating oil, and the average particle size of the full-vulcanized powdered rubber is 20-2000 nm. The polypropylene composition of the present invention has characteristics of good mechanical property, scratch resistance and stress whitening resistance.

Owner:CHINA PETROLEUM & CHEM CORP +1

Method for preparing bionic laminar articular cartilage/bone compound implant

InactiveCN1961975AMeet the mechanicsSatisfy physiological functionJoint implantsPolyvinyl alcoholBiomechanics

The invention relates to a method for preparing bionic laminated cartilage / bone element, wherein it comprises preparing porous same heterogenous bone or different bone elements; preparing artificial cartilage and laminated cartilage / bone composite. The invention processes the bone into needed size and shape, to be washed and immunity treatment, to be put at the bottom of mould; then at positive and passive pressures, pouring the polyvinyl alcohol / biological active component preformed element and polyvinyl alcohol / lubricant molecule preformed element into mould; flattening the surface and compressing; freezing and fusing, shaping. The inventive product has surface layer as abrasion-resistant lubricant layer, middle layer as force layer, and bottom layer as biological active cartilage / bone combine layer, to meet biological physica property and physiological function.

Owner:UNIV OF SCI & TECH BEIJING

Heat insulation composite material with high temperature mechanical property and preparation method thereof

The invention discloses a heat insulation composite material with high temperature mechanical property and a preparation method thereof. The material comprises 33-39% of barium-phenolic resins, 5-7% of ethanol and 56-60% of high strength glass fiber cloth by mass. The method is characterized by firstly clipping the high strength glass fiber cloth, then mixing the barium-phenolic resins and the ethanol to form barium-phenolic resin adhesive solution, proportionally immersing the barium-phenolic resin adhesive solution into the high strength glass fiber cloth to form S-glass / phenolic aldehyde composite material prepreg and finally drying the aired S-glass / phenolic aldehyde composite material prepreg with an electrothermal blowing dry box. The invention solves the problem that the materials with heat insulation requirement in the aerospace products have poor mechanical properties at high temperature and simultaneously has the characteristics of low material price, simple production and low possibility of debris falling after the product is produced.

Owner:中国航天科工集团第二研究院二八三厂

Foaming silicone master batch as well as preparation method and application thereof

The invention relates to the field of high-molecular materials. The usage amount of silicone powder as an additive is generally lower than 5 parts by weight; in order to solve the problem that the silicone powder is unequally dispersed after being directly added and blended with a granular material base body, the invention provides a foaming silicone master batch. The foaming silicone master batch is prepared by blending the following components in parts by weight: 100 parts of thermoplastic high-molecular resin, 70-150 parts of the silicone powder, 0.5-1 part of foaming agents and 2-8 parts of an antioxidant. The foaming silicone master batch has the advantages of light weight and low density, and is easy to blend and disperse together with the granular thermoplastic high-molecular resin.

Owner:HUBEI HUIFU NANOMATERIAL CO LTD

Light aging resisting and high-strength anti-flaming enhancement polybutylene terephthalate composition and preparation method thereof

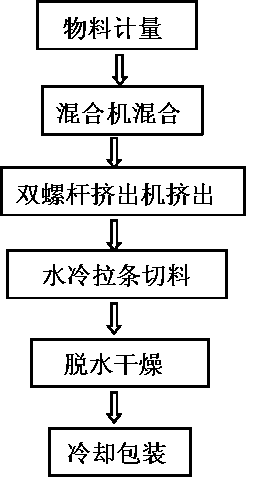

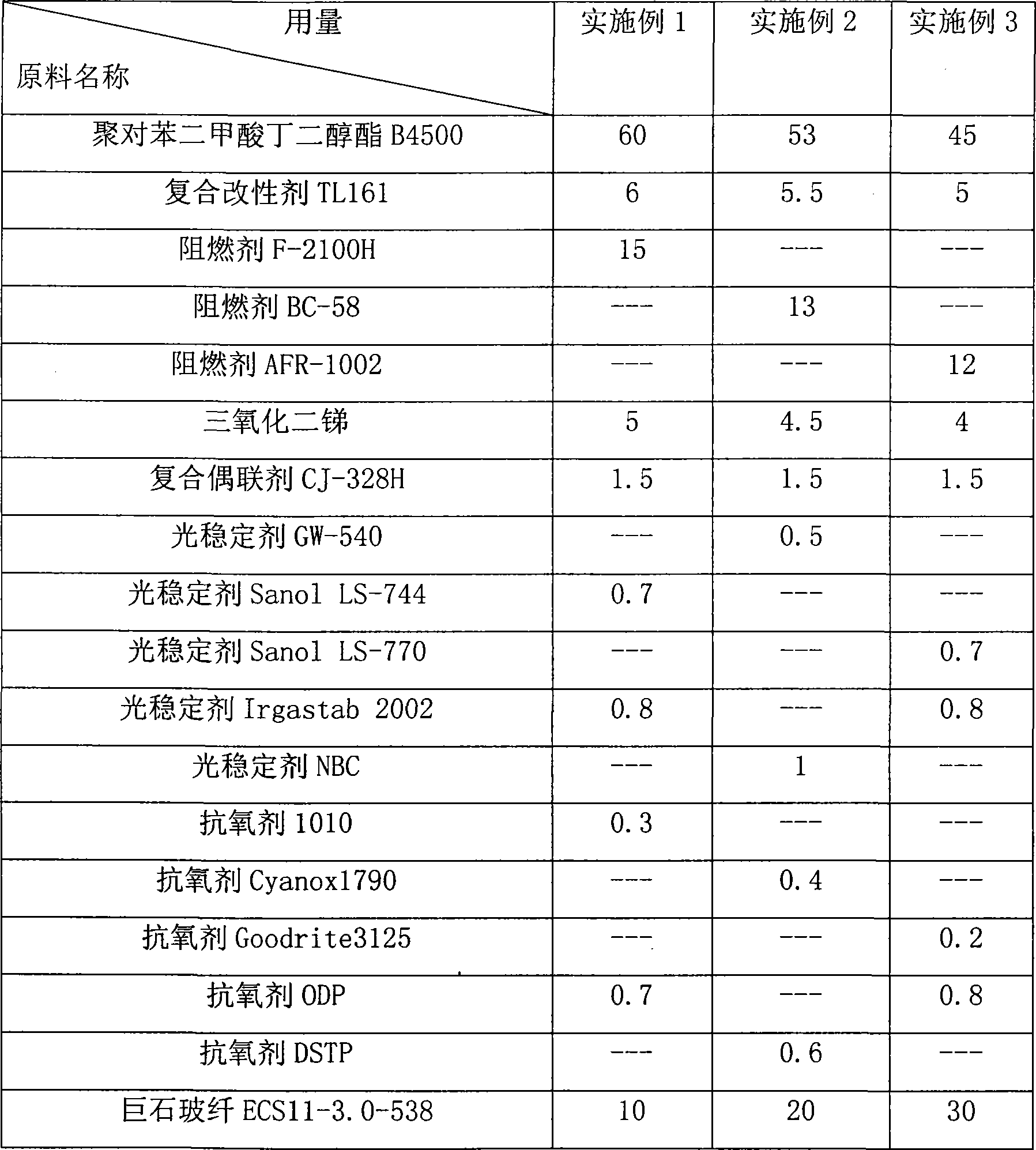

The invention relates to light weathering and high strength flame retardant reinforced polybutylece terephthalate compound. The invention is characterized in that the compound consists of polybutylece terephthalate, compound modifier, main fire retardant, auxiliary fire retardant, fiber glass, special compound accessory ingredient and compound coupling agent. The invention has a preparation method that the compound modifier, the special compound accessory ingredient and the compound coupling agent are put in a high-speed blender to be dryly mixed for two to three minutes, the pre-mixing matter obtained in the step one, the polybutylece terephthalate, the main fire retardant, the auxiliary fire retardant and the fiber glass are added into an extruding machine through respective exact metering feeders, and are mixed and dispersed in a threaded tube through a combined threaded rod, and the product is obtained through melting extrusion and granulation. The invention has the advantages of outstanding light weathering performance as well as outstanding comprehensive mechanical performance.

Owner:SHANGHAI KINGFA SCI & TECH +1

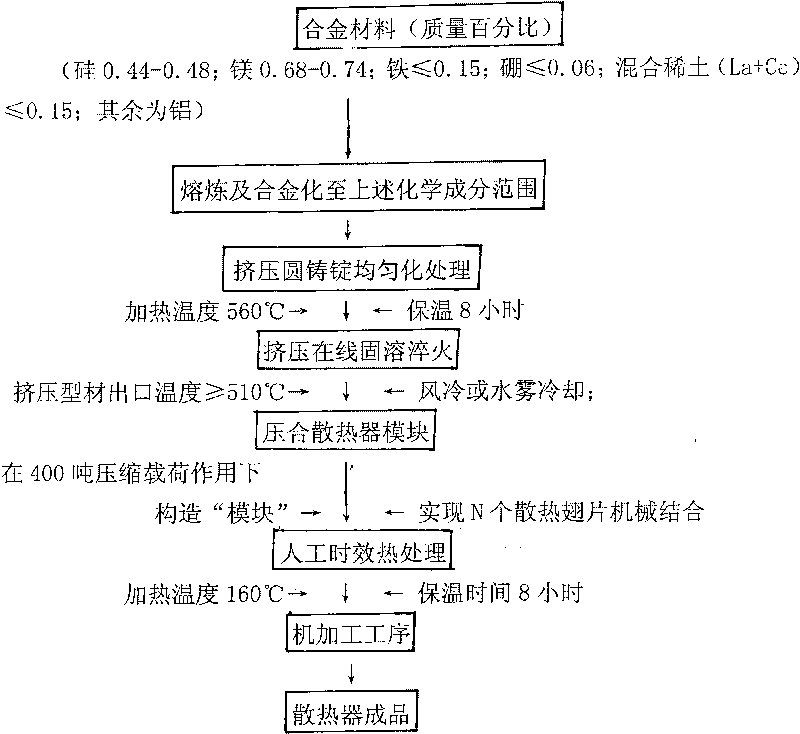

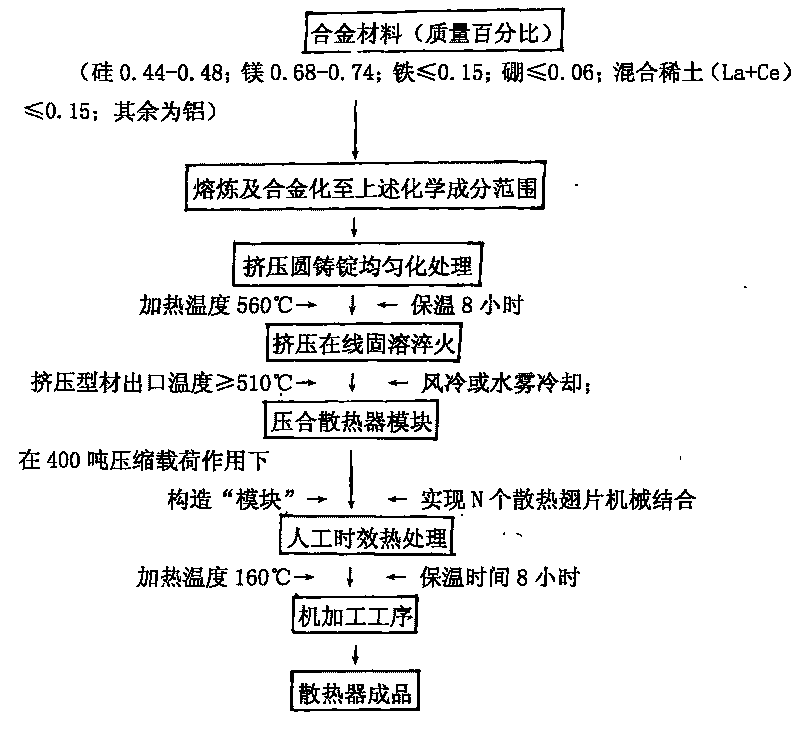

Al-Mg-Si aluminium alloy material for pressed module heat radiator and machining process thereof

InactiveCN101724771AImprove thermal conductivityMeet the intensityCooling/ventilation/heating modificationsRare earthMechanical property

The invention relates to an Al-Mg-Si aluminium alloy material for a pressed module radiator and a machining process thereof, wherein the alloy material comprises the following chemical ingredients in percentage by weight of: 0.44-0.48 of Si, 0.68-0.74 of Mg, less than or equal to 0.15 of Fe, less than or equal to 0.06 of B, less than or equal to 0.15 of mischmetal (La+Ce), and the balance of Al. The machining process of the pressed module radiator which adopts the Al-Mg-Si aluminium alloy material comprises the following steps of: firstly, smelting and alloying to reach the ranges of the chemical ingredients; secondly, extruding a round cast ingot and carrying out homogenization treatment; heating to 560 DEG C and preserving the temperature for 8 hours; thirdly, extruding and carrying out online solution hardening with the outlet temperature of an extruded section more than 510 DEG C, and air-cooling or mist-cooling; and finally, carrying out artificial ageing heat treatment on a radiator module subjected to the pressing working procedure, heating to 160 DEG C, and preserving the temperature for 8 hours. The invention has the advantages of simple method, convenient operation, improved thermal conductivity and ensured mechanical properties, such as the strength and the hardness, and the like of the product.

Owner:天津锐新昌科技股份有限公司

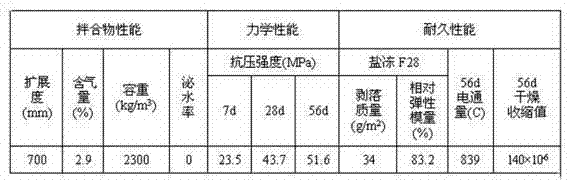

Self-compacting concrete for high-speed railway turnout area slab ballastless track filling layer

The invention relates to concrete, in particular to self-compacting concrete for a high-speed railway turnout area slab ballastless track filling layer, and solves the problem that the conventional self-compacting concrete in the high-speed railway turnout area slab ballastless track filling layer cannot meet the design requirement. The self-compacting concrete for the high-speed railway turnout area slab ballastless track filling layer is prepared from the following raw materials in part by weight: 330 to 335 parts of cement, 195 to 200 parts of class I fly ash, 70 to 75 parts of expanding agent, 805 to 808 parts of medium sand, 355 to 360 parts of continuously graded broken stone with the particle size of 5 to 10mm, 355 to 360 parts of continuously graded broken stone with the particle size of 5 to 16mm, 180 to 185 parts of water, 7.5 to 8.0 parts of polycarboxylic acid water reducing agent and 6.0 to 6.5 parts of anti-cracking agent. The self-compacting concrete has a good filling effect and can be widely suitable for filling the high-speed railway turnout area slab ballastless track filling layer.

Owner:CHINA RAILWAY 12TH BUREAU GRP

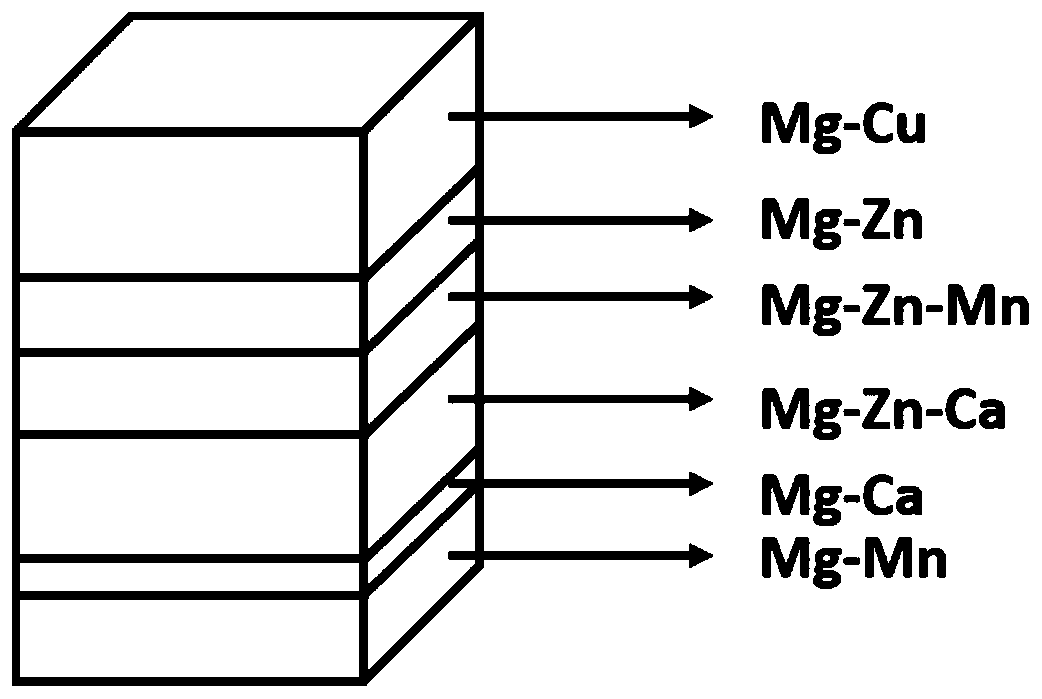

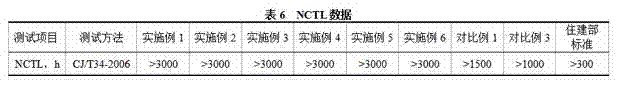

Degradable stephanoporate magnesium basis complex tissue project bracket stuff within biosome

ActiveCN101156960AGood biocompatibilityImprove mechanical propertiesProsthesisMagnesium matrix compositeChemical reaction

The invention relates to porous magnesium matrix composite tissue engineering scaffold biomaterial which can degrade in the bio-body. The components and the volume percent contents are 70 percent to 20 percent of high purity magnesium and magnesium alloy powder, 10 percent to 20 percent of HA powder and 20 percent to 70 percent of pore forming agent, the high purity magnesium and the magnesium alloy powder are HA alloys, high purity magnesium alloys, high purity Mg-Zn alloys, high purity Mg-Zn-Ca alloys, high purity Mg-Zn-Ca-Fe alloys, high purity Mg-Mn alloys and high purity Mg-Zn-Mn alloys, and the purity rate of the alloy is higher than or equal to 99.99 percent. The bone tissue engineering scaffold biomaterial prepared by the invention which adopts the powder metallurgy technology utilizes the chemical reaction of the magnesium in aqueous medium to be converted into magnesium ions, and the magnesium ions adjust the balance through the in vivo absorption and the kidney metabolism, thereby leading the scaffold to be gradually degraded and absorbed in vivo.

Owner:CHANGSHU MICROTUBE TECH

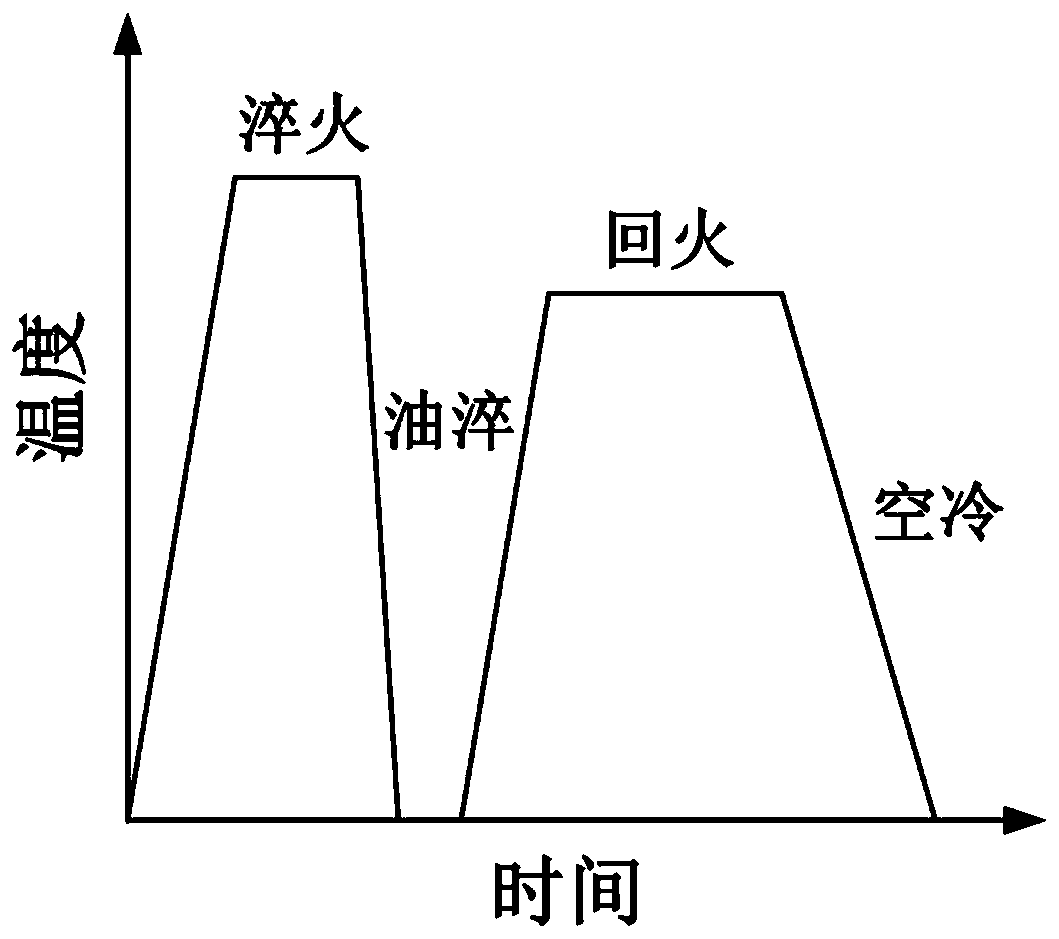

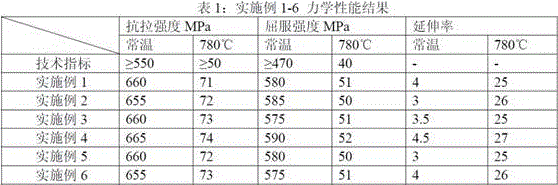

High-toughness cold-hot-fatigue-resistant cast steel for high-speed train brake disc and preparation method thereof

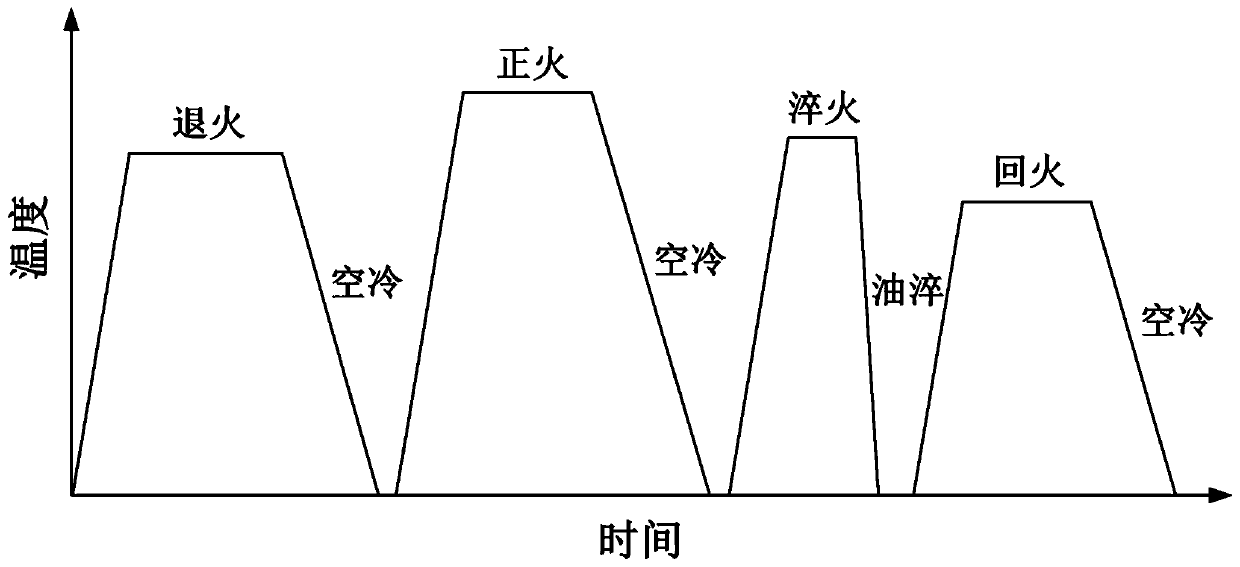

ActiveCN111360198AMatch mechanicsMatching cold and heat fatigue resistanceFoundry mouldsFurnace typesBrakeMetallic materials

The invention relates to high-toughness cold-hot-fatigue-resistant cast steel for a high-speed train brake disc and a preparation method thereof, belongs to the field of metal materials and preparation thereof, and solves the problem of matching of room-temperature toughness, high-temperature mechanical properties and cold and hot fatigue failure resistance of the cast steel for the high-speed train brake disc in the prior art. The high-toughness cold-hot-fatigue-resistant cast steel for the high-speed train brake disc comprises the following chemical components, in percentage by mass, of 0.20%-0.40% of C, 0.30%-0.70% of Si, 0.50%-2.00% of Mn, 0.50%-2.00% of Cr, 0.50%-2.00% of Ni, 0.40%-1.80% of Mo, 0.01%-0.30% of V, smaller than or equal to 0.015% of P, smaller than or equal to 0.010% ofS, smaller than or equal to 0.010% of O, smaller than or equal to 0.015% of N, and the balance Fe and inevitable impurities, wherein the total content of the Mn, the Cr and the Ni is 2.00%-6.00%, andthe total content of the Mo and the V is 0.41%-2.00%. Through reasonable composition, organization structure and preparation process regulation and control, excellent room-temperature toughness, high-temperature mechanical property and cold and hot fatigue failure resistance of the cast steel are matched, the requirements for comprehensive mechanical property and long service life of the cast steel brake disc of a high-speed train are met, and the cast steel is suitable for being used as a material for the cast steel brake disc of the high-speed train.

Owner:ADVANCED MFG TECH CENT CHINA ACAD OF MASCH SCI & TECH +1

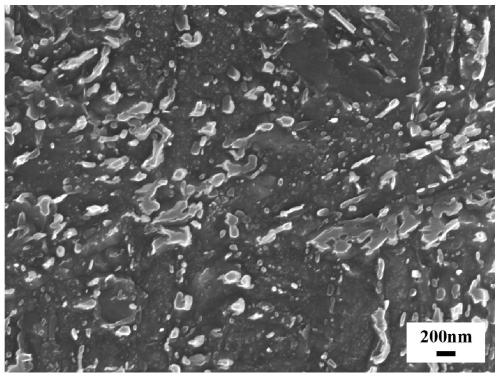

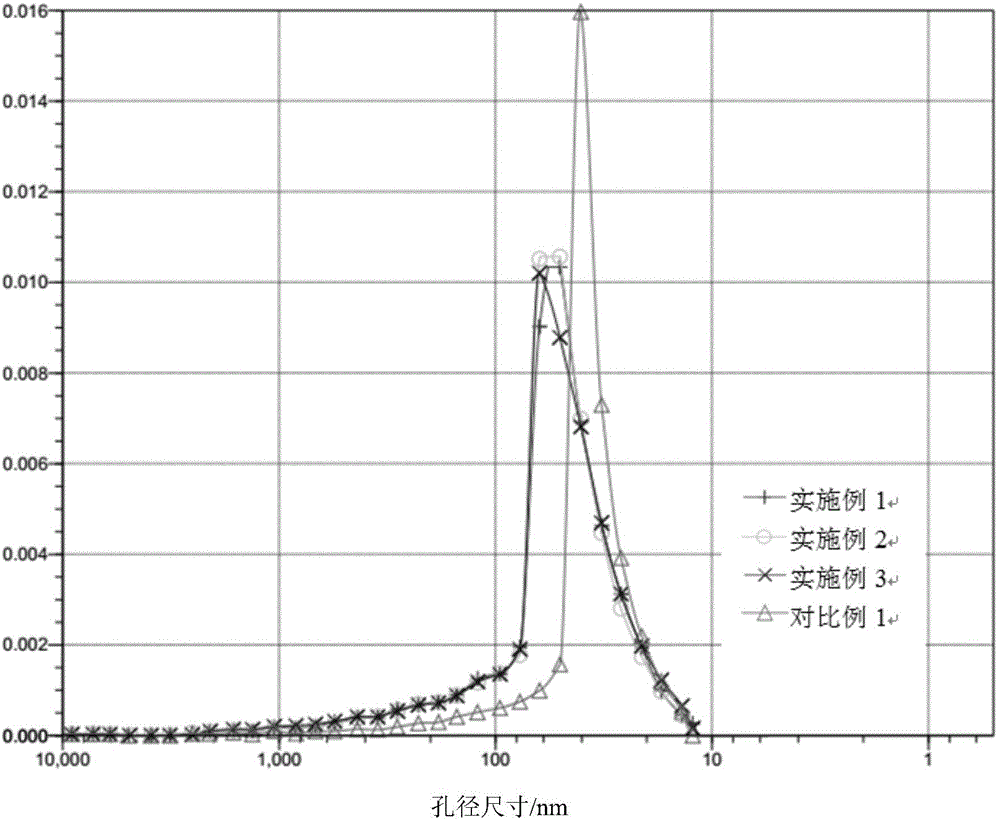

Surface modification method of special nano calcium carbonate for silicone sealants

ActiveCN104479411AMeet the mechanicsFulfil requirementsNon-macromolecular adhesive additivesPigment treatment with non-polymer organic compoundsDispersitySlurry

The invention discloses a surface modification method of special nano calcium carbonate for silicone sealants, which comprises the following steps: adding 0.8-1.5m<3> of tap water into a dosage tank, heating to 70-95 DEG C, keeping the temperature constant, adding sulfated sodium oleate, stirring for 10-20 minutes, and adding C12-C32 fatty acids for emulsification to obtain a surface treating agent; and heating a calcium carbonate slurry, adding the prepared surface treating agent which accounts for 2.5-4.5 wt% of the calcium carbonate on dry basis, stirring for 60-120 minutes to complete surface modification, dehydrating, drying at 100-150 DEG C, pulverizing, and packaging to obtain the product. The product can satisfy the requirements of mechanical properties and bonding properties for the filling silicone sealants, and has the advantages of favorable thixotropy, favorable extrudability, favorable dispersity and low aggregation tendency. The method has the advantages of simple technique and small investment, is suitable for industrial production, and has favorable economic benefits.

Owner:GUANGXI HUANA NEW MATERIALS TECH CO LTD

Preparation method of high-density polyethylene IBC inner container blow molding material

The invention discloses a preparation method of a high-density polyethylene IBC inner container blow molding material. The method comprises the following steps that 1, in the single-loop slurry process polythene production technology, on the condition that diluents are always in a circulating state, ethylene and hexene-1 are placed in a reaction container, a polymerization reaction is performed on the condition that a catalyst exists to generate ethylene-hexene-copolymerization polyethylene resin with the melt flow rate of 5.60-7.0 g / 10 min, the density of 0.943-0.947 kg / m<3>, the weight-average molecular weight of 250-290 thousands, the molecular weight distribution of 13-18 and the hexene-1content of 0.3%-0.6%, and the reaction temperature in the reaction container is set at 92.0+ / -2.0 DEG C; 2, the ethylene-hexene-copolymerization polyethylene resin, antioxidants, antioxidant aids and light stabilizers are taken to be mixed evenly, and then extruding and pelleting are performed to obtain the granular high-density polyethylene IBC inner container blow molding material. According to the IBC inner container blow molding material prepared through the method, molecular weight distribution is wide, the comonomer hexene content is high, the processing property and the moldability are good, and a blow-molded IBC inner container product has the outstanding rigid-tough balance capacity, antioxidant capacity and anti-corrosion and environmental stress cracking resistance properties and the good rebound resilience.

Owner:CHINA PETROLEUM & CHEM CORP

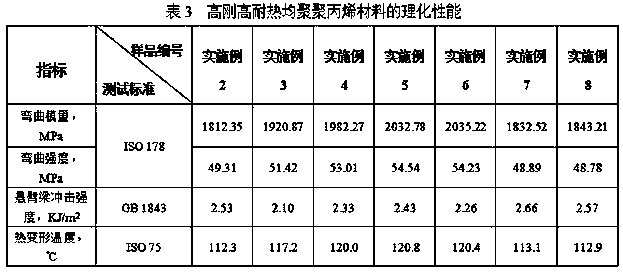

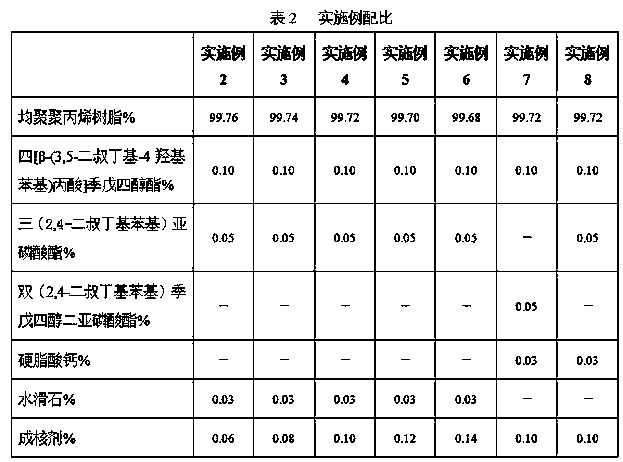

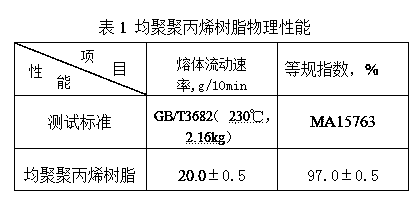

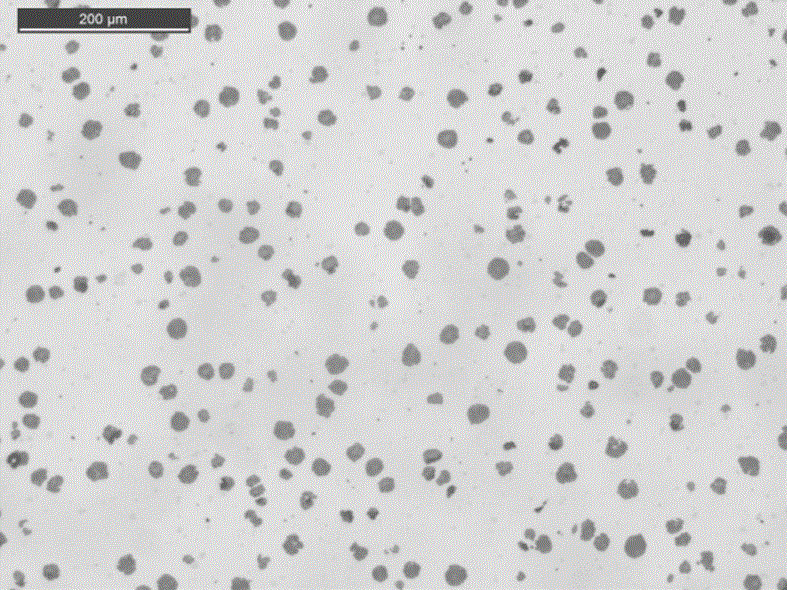

High-rigidity high-heat-resistance homo-polypropylene material and preparation method thereof

ActiveCN103554660AImprove adjustabilityImprove melt fluidityHeat deflection temperaturePtru catalyst

The invention discloses a high-rigidity high-heat-resistance homo-polypropylene material which is prepared from the following raw materials: a homo-polypropylene resin, an antioxidant, a halogen absorbent and a nucleating agent. The homo-polypropylene resin is prepared by the following steps: adding the raw material propylene into a loop reactor, adding the catalyst, cocatalyst, electron donor and antistatic agent, and uniformly stirring, wherein the reaction temperature in the loop reactor is controlled at 70+ / -1 DEG C, the reaction pressure is controlled at 3.4-3.8 MPa, and the hydrogen concentration is controlled at 3500-4500 ppm. The invention also discloses a preparation method of the high-rigidity high-heat-resistance homo-polypropylene material. The high-rigidity high-heat-resistance homo-polypropylene material has higher melt index, bending modulus and heat-deformation temperature, and can satisfy the raw material requirements of injection molding manufacturers of small home appliances, automobiles and the like.

Owner:CHINA PETROLEUM & CHEM CORP

Similar material for simulating expansive soil tunnel surrounding rock in model test and preparation method thereof

InactiveCN103242029AMeet the mechanicsMeet the characteristicsClaywaresSodium BentoniteResource utilization

The invention relates to a similar material for simulating expansive soil tunnel surrounding rock in a model test and a preparation method thereof. According to the similar material, clay and bentonite, which pass through a 4.75mm sieve, serve as main raw materials, the materials are proportioned by a weight part ratio according to different expansion levels, weak expansive soil is prepared from 100 parts of clay and not less than 2 and less than 10 parts of bentonite, medium expansive soil is prepared from 100 parts of clay and not less than 10 and less than 22 parts of bentonite, strong expansive soil is prepared from 100 parts of clay and not less than 22 and less than 30 parts of bentonite, water is added to the mixed materials, and compaction molding is carried out so as to prepare the similar material. According to the similar material and the preparation method, expansive soil with different free expansion ratios can be prepared so as to carry out the model test, so that the mechanical and deformation characteristics of the expansive soil surrounding rock can be met, the raw materials can be obtained locally, the operation is simple and convenient, and the resource utilization ratio is increased.

Owner:SHANDONG UNIV

Medium silicon molybdenum niobium spheroidal graphite cast iron material and preparation method thereof

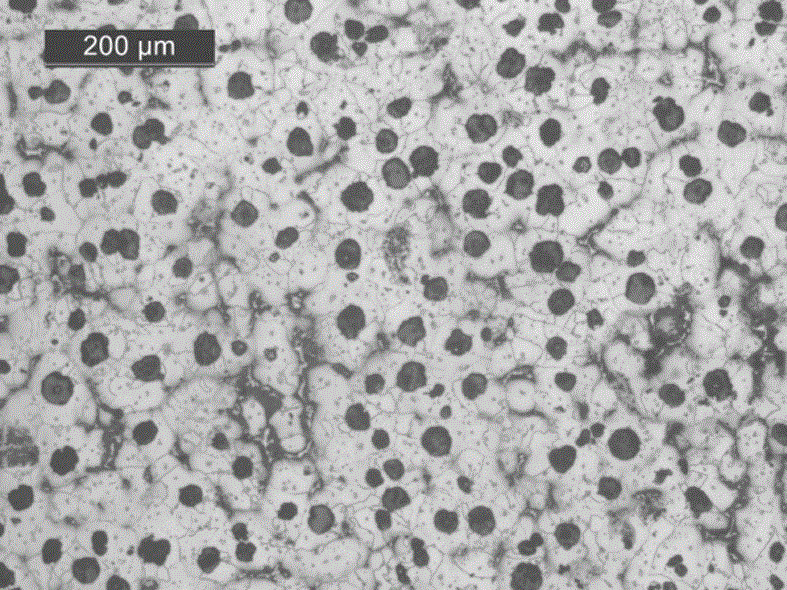

The invention discloses a medium silicon molybdenum niobium spheroidal graphite cast iron material and a preparation method thereof. The medium silicon molybdenum niobium spheroidal graphite cast iron material is prepared from the following chemical components in percentage by mass: 2.8-3.2% of C, 4.2-4.5% of Si, less than or equal to 0.4% of Mn, less than or equal to 0.04% of P, less than or equal to 0.015% of S, 0.8-0.9% of Mo, 0.6-0.9% of Ni, 0.4-0.7% of Nb, 0.03-0.06% of Mg, 0.15-0.25% of V and the balance of Fe and inevitable other elements. Since C04 high-purity pig iron and waste steel are taken as raw materials, a medium-frequency induction furnace is adopted for smelting, and a carburant, silicon carbide, ferrocolumbium, nickel plates, ferrosilicon and ferrovanadium are added in different time phases of smelting, raw iron chemical components and smelting temperature expected by design can be achieved, and the product disclosed by the invention can be prepared through nodulization and two times of inoculation. By adopting the edium silicon molybdenum niobium spheroidal graphite cast iron material disclosed by the invention, an exhaust manifold of an engine can work under a working condition of about 800 DEG C, the high-temperature use property of the exhaust manifold can be improved, and the service life of the exhaust manifold can be prolonged.

Owner:西峡县内燃机进排气管有限责任公司

Antibacterial aluminum alloy for food container

The invention relates to antibacterial aluminum alloy for a food container. The antibacterial aluminum alloy comprises the chemical components in percentage by weight as follows: 0.3-1.5% of Mn, 0.5-1.5% of Mg, 0.1-3.0% of Ag, 0.1-1.0% of Zn, 0.1-1.0% of RE, 0.1-0.2% of Ti, less than 0.3% of Si, less than 0.6% of Fe, less than 0.3% of Cu, less than or equal to 0.20% of other impurities and the balance of Al. The antibacterial aluminum alloy not only has excellent antibacterial performance with the antibacterial property greater than 99.0%, but also maintains good plasticity and corrosion resistance of aluminum alloy, so that the manufacturing demand and the demand on antibacterial performance of container products in industries such as food and kitchen and bath can be satisfied.

Owner:SHANDONG JIANZHU UNIV

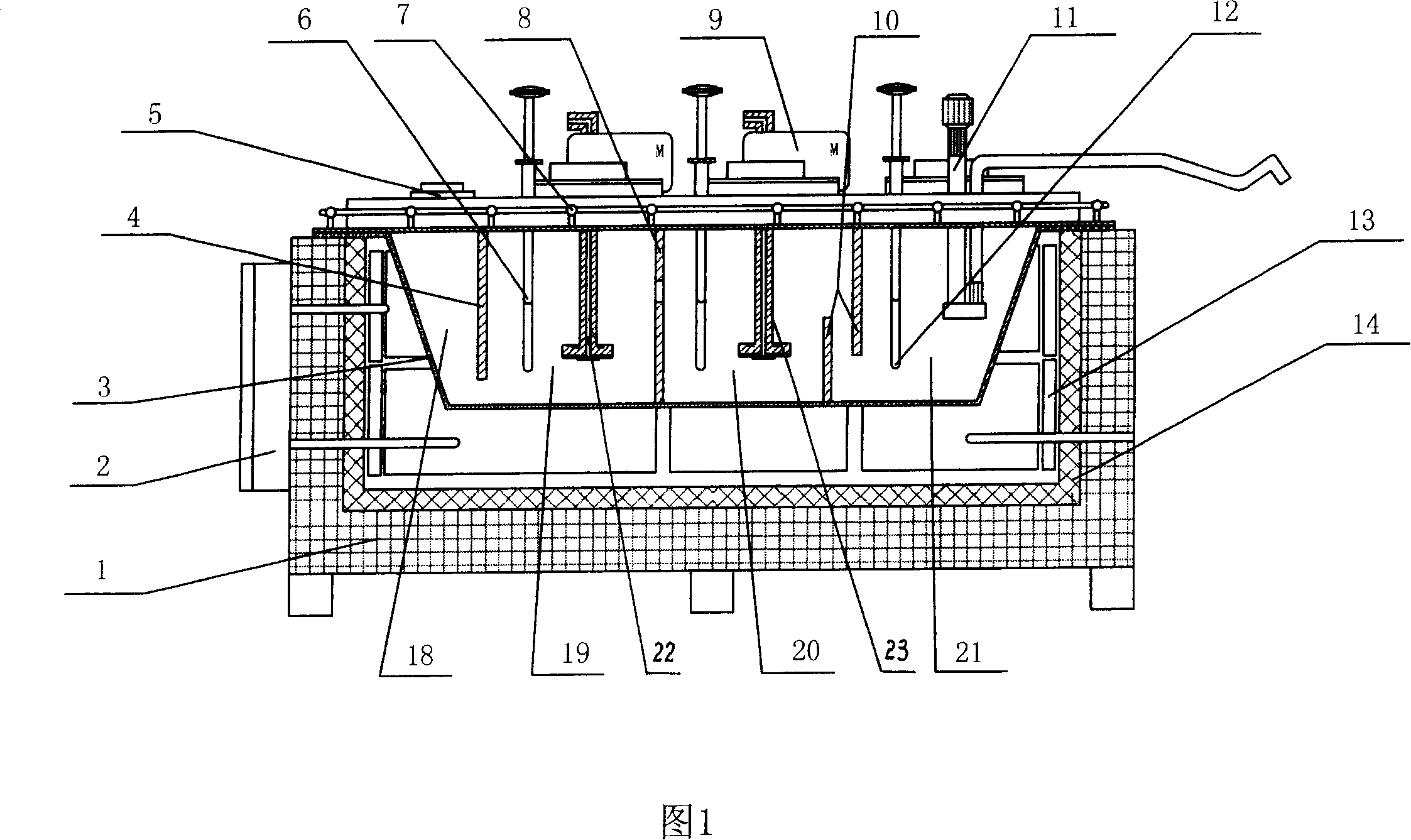

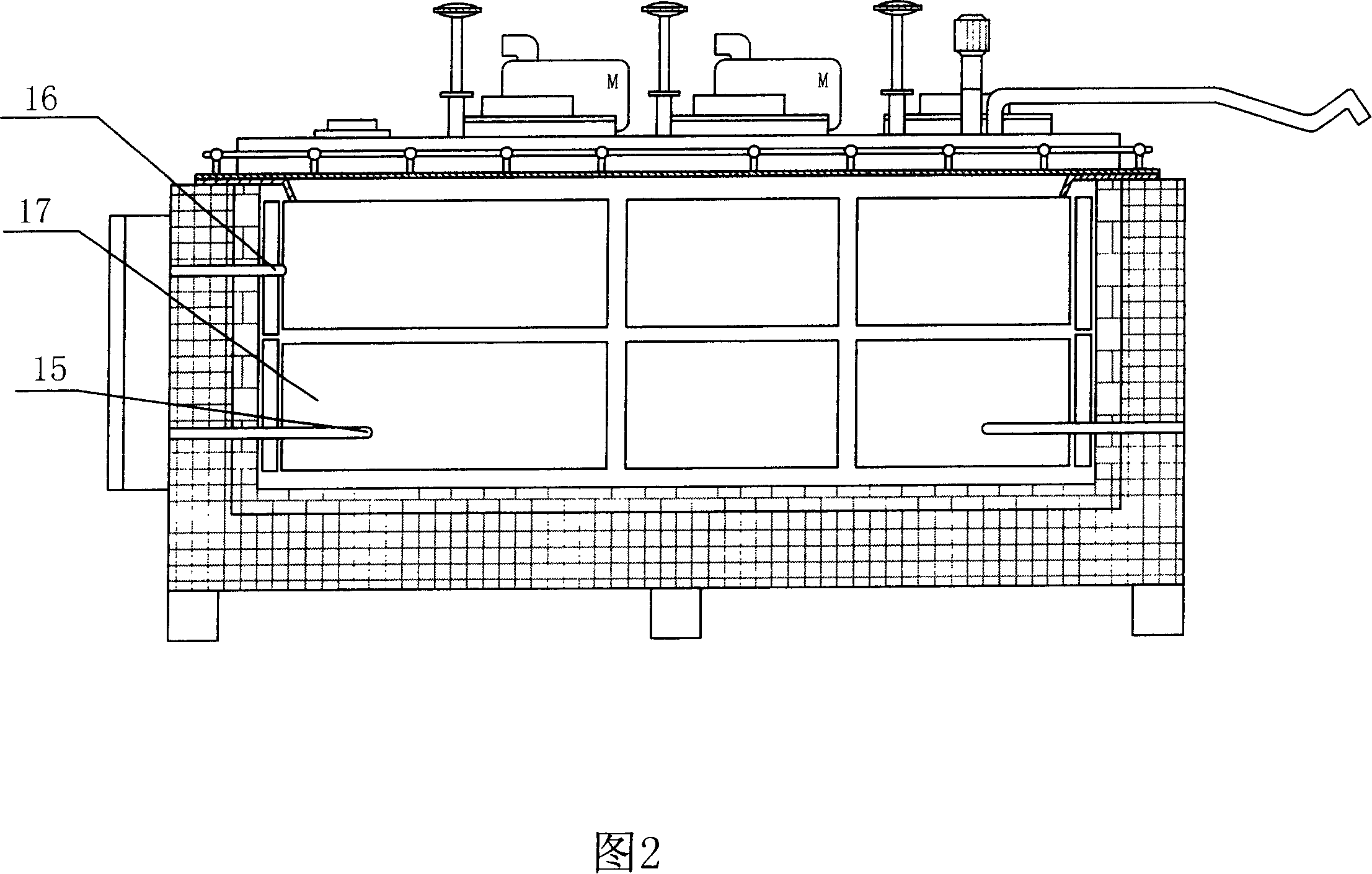

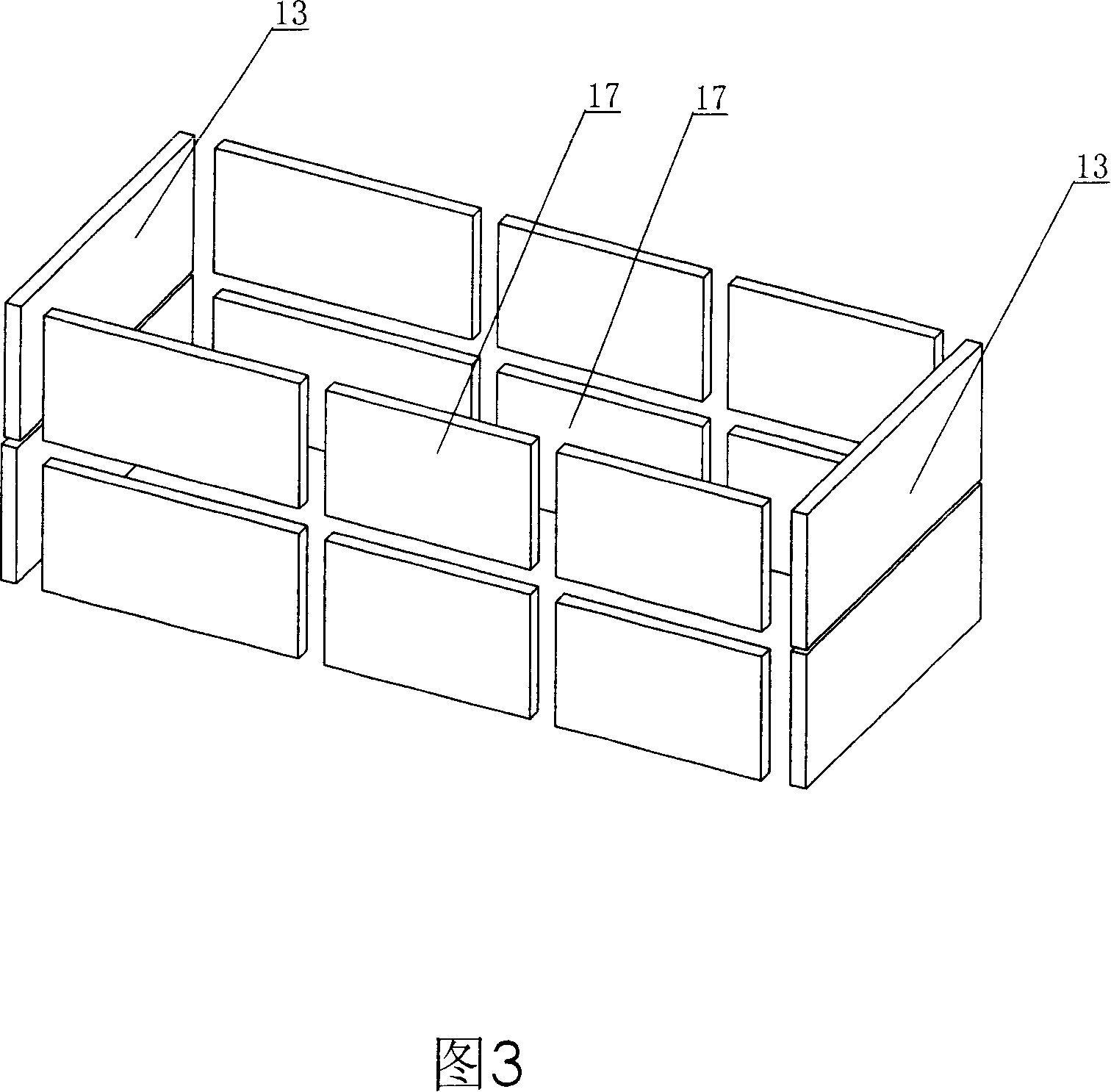

Magnesium alloy melting pool type crucible electrical resistance furnace

The utility model relates to a molten-pool pot resistance furnace of magnesium alloy, comprising heating modules of which two heating modules which are positioned up and down respectively on the inner wall of the furnace body are formed into a group; wherein, a group of two lateral face heating modules are positioned up and down on the left and the right inner wall of the furnace body which are corresponding to the front end and the back end of the pool-type pot; and two or more groups of frontal heating modules which are corresponding to the position of two or more chambers in the pool-type pot are positioned respectively on the front and the back inner wall of the furnace body which are corresponding to two side ends of the pool-type pot. The pool-type pot is divided into three temperature regions of temperature region I, temperature region II, and temperature region III when the pool-type pot is seen from the front; wherein, an up temperature region and a down temperature region form a subarea, thus forming synchronous heating regions which are mutually independent to maintain the flow of continuous and high-quality melts and satisfy the refined thermodynamic and dynamic conditions of the melts via precisely regulating the crafting parameters.

Owner:石家庄镁淇科技发展有限公司

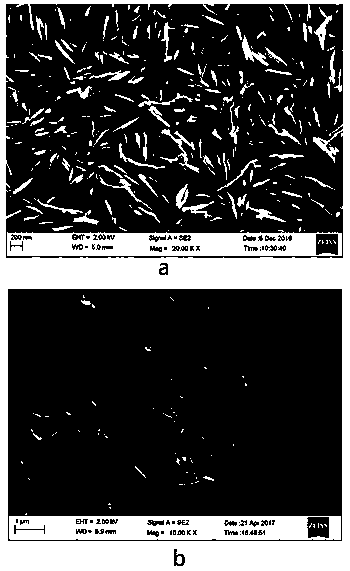

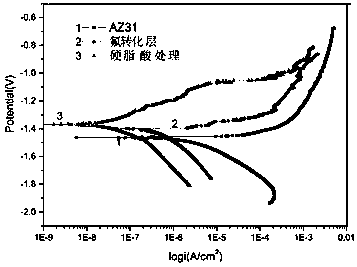

Preparation method of magnesium alloy surface super-hydrophobic fluorine conversion coating

InactiveCN107740083AReduce corrosionLessen the tendency to corrodeMetallic material coating processesNano structuringSimulated body fluid

The invention discloses a preparation method of a magnesium alloy surface super-hydrophobic fluorine conversion coating. The super-hydrophobic fluorine conversion coating of a micro / nano structure isprepared on the surface of a magnesium alloy by the adoption of a liquid-phase growth and hydro-thermal treatment combined method. Through cleaning, polishing, preparation of a fluorine conversion layer and hydrophobization treatment, a porous hydrophobic coating of a micro / nano structure is formed on the film layer. The contact angle of the coating in simulated body fluid reaches 150 degrees, thecontact area between a magnesium alloy sample and the liquid can be reduced, the corrosion current density of the magnesium alloy can be lowered by 3 grades, and the impedance magnitude is increasedfrom 12000 omega.cm<2> to 1400000 Omega.cm<2> and is increased by 100 times. The preparation method of the hydrophobic coating of the nano-structure is simple, equipment is simple and easy to control,cost is low, and the controllability is good.

Owner:CHONGQING UNIV OF TECH

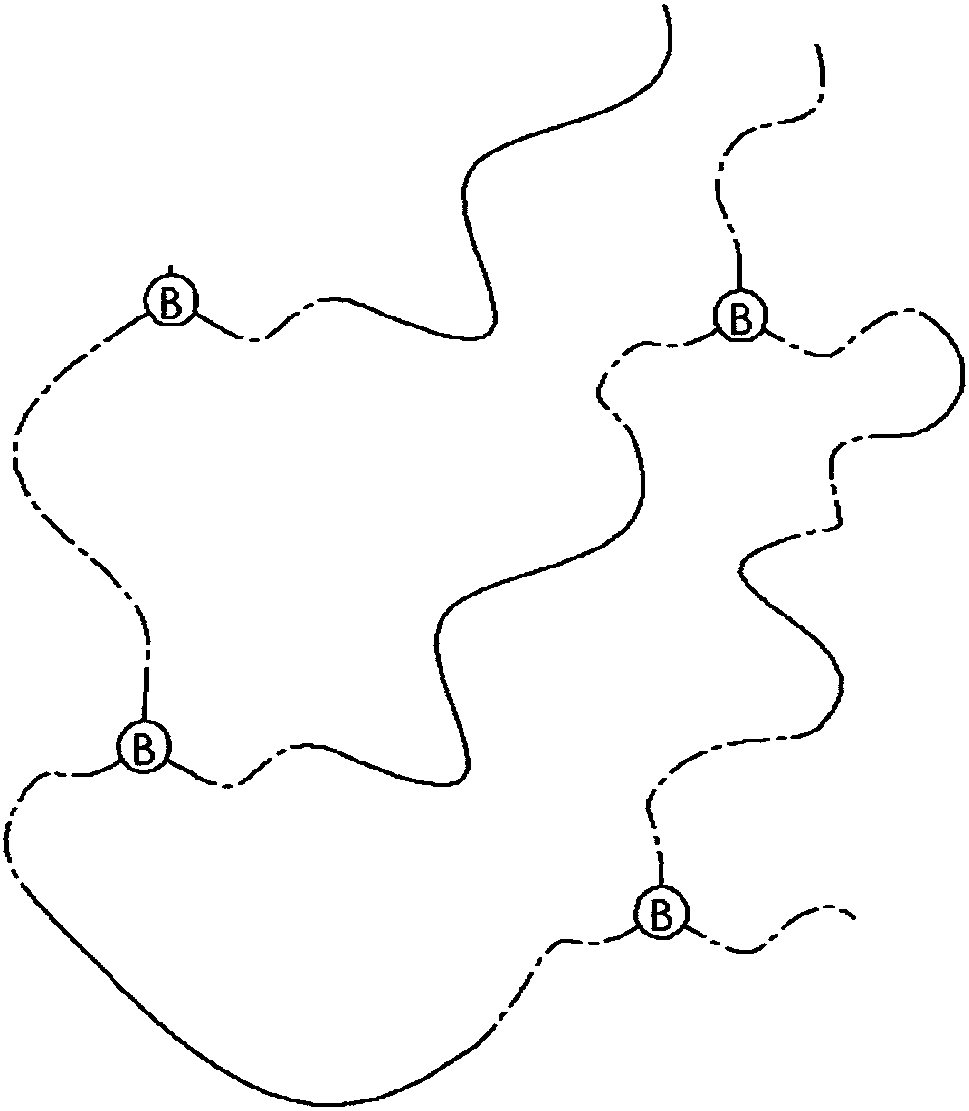

Polymer electrolyte for polymer battery and preparation method of polymer electrolyte

ActiveCN107634261AReduce crystallinityHigh mechanical strengthHybrid capacitor electrolytesSecondary cellsPolyesterPolymer science

The invention relates to a polymer electrolyte for a polymer battery and a preparation method of the polymer electrolyte, and belongs to the technical field of an electrolyte. The polymer electrode prepared by the method comprises four constituents of polyether, polysiloxane, a boron crosslinking (the former is a chemical constituent) and a conductive salt, and a part of polysiloxane chain segments are connected by Si-O-B bonds. The Si-O-B bonds of a polymer form crosslinking points of a system, the mechanical strength of the polymer can be improved, and the thermoplasticity of the polymer also can be maintained. According to the preparation method of the polymer electrode for the polymer battery, a polycondensation principle is mainly employed, the situation that the dependence on a feeding ratio is smaller than that of a traditional polycondensation method is determined by a special molecule structure, such as polyester; and by dynamic crosslinking, the polymer shows a solid state, the crystallinity of the polymer is reduced, thermal processing under a high temperature also can be performed, thus, by the preparation method, the molecular weight of the polymer is increased at a low cost, and the polymer has better dynamic performance.

Owner:TSINGHUA UNIV

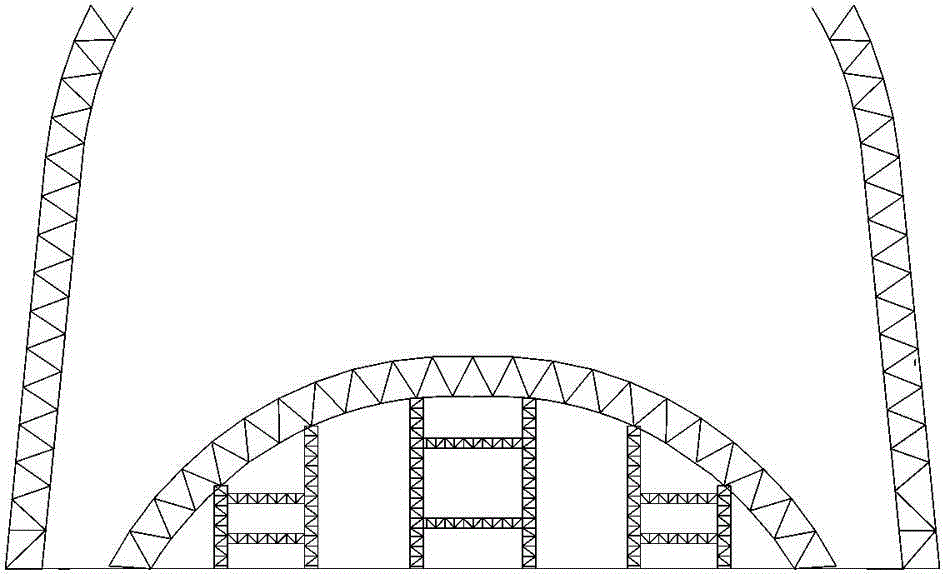

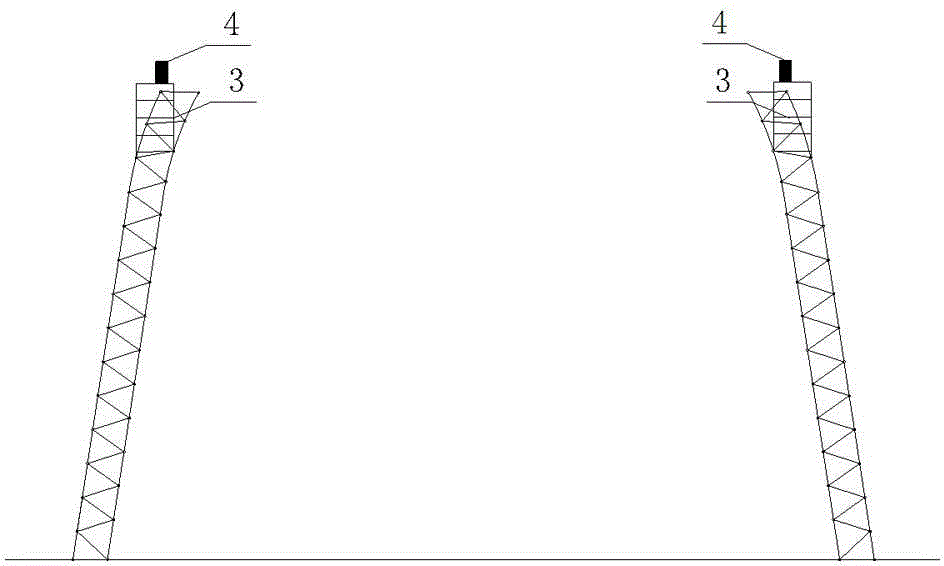

Lifting and installation method of high curved-surface net racks

ActiveCN104060836AMeet the mechanicsFulfil requirementsBuilding material handlingMechanical equipmentEngineering

The invention relates to high curved-surface net racks, particularly to a lifting and installation method of high curved-surface net racks, which can be applied in building steel structures. The lifting and installation method proceeds according to the processes of a lifting preparation stage and a lifting stage. According to the lifting and installation method of high curved-surface net racks, the structure is compact, the requirements for mechanical equipment is low, the construction efficiency is improved, the construction cost is reduced, and the construction safety is improved.

Owner:浙江东南网架股份有限公司

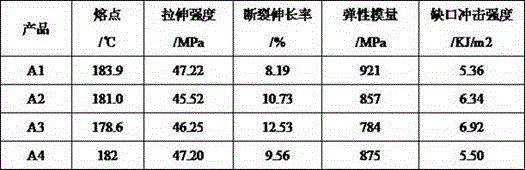

Copolyester suitable for serving as 3D printing material and preparation method thereof

ActiveCN105801819AImprove thermal stabilityGood mechanical propertiesAdditive manufacturing apparatusPolymer scienceCopolyester

The invention discloses copolyester suitable for serving as a 3D printing material and a preparation method thereof.The preparation method includes: reasonably selecting raw materials, reasonably designing a proportion, and adopting an esterification polymerization method to obtain the copolyester suitable for serving as the 3D printing material, high in thermostability and excellent in mechanical performance.Tensile strength of a copolyester material prepared by the method is greater than 45 MPa, notch impact strength is greater than 5.0 KJ / m2, elastic modulus is greater than 700 MPa, requirements, on performance of the raw materials, of 3D printing technology are met effectively, and the copolyester can be used for 3D making of functional mechanical parts; no gas is released in the printing process, so that requirements, on environment-friendly performance of the raw materials, of the 3D printing technology are met; the copolyester material is prepared through a direct copolymerization method, so that the preparation method is simple, cost is lowered, and the problem of compatibility caused by blending can be avoided effectively.

Owner:KUNSHAN TIANYANG HOT MELT ADHESIVE CO LTD +2

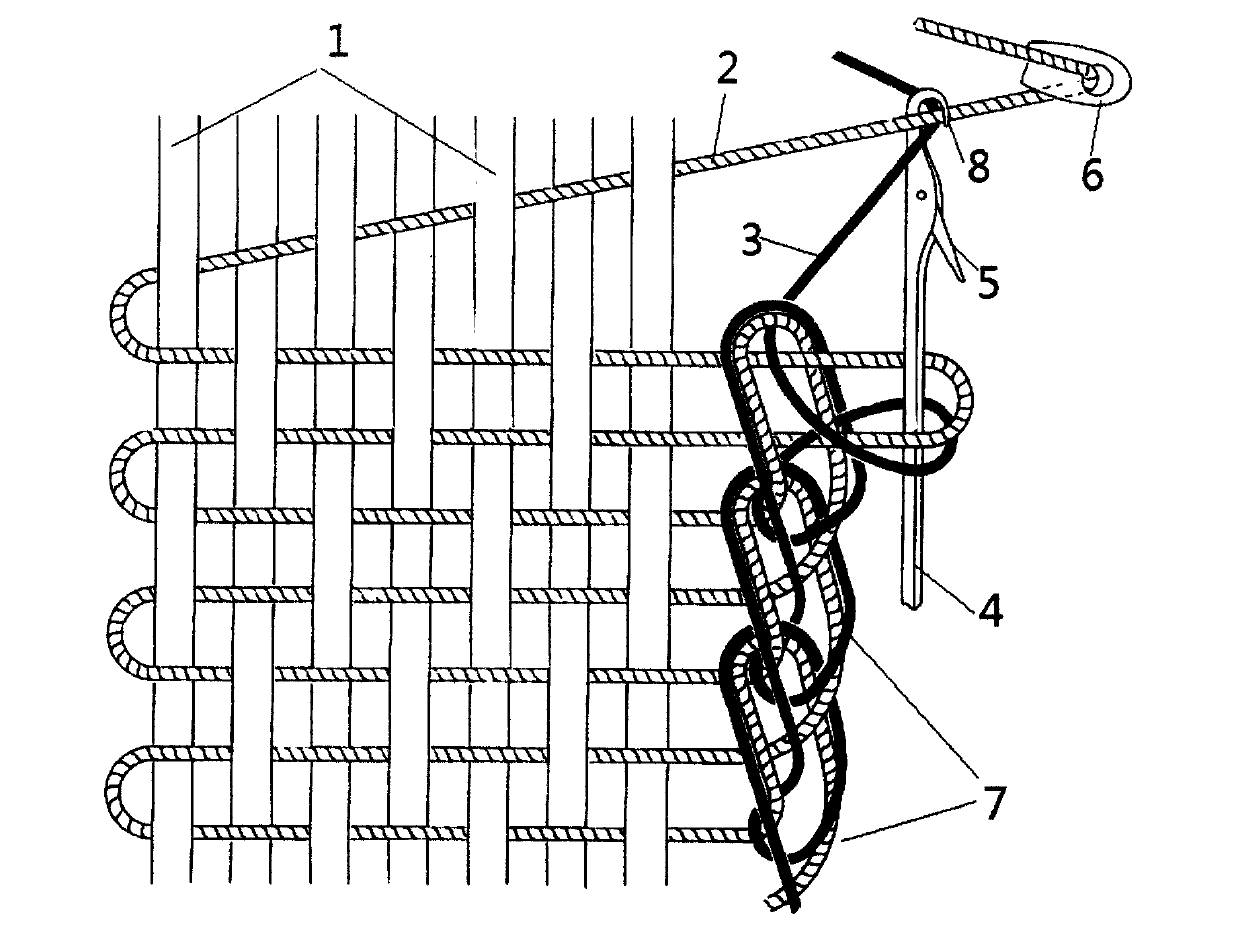

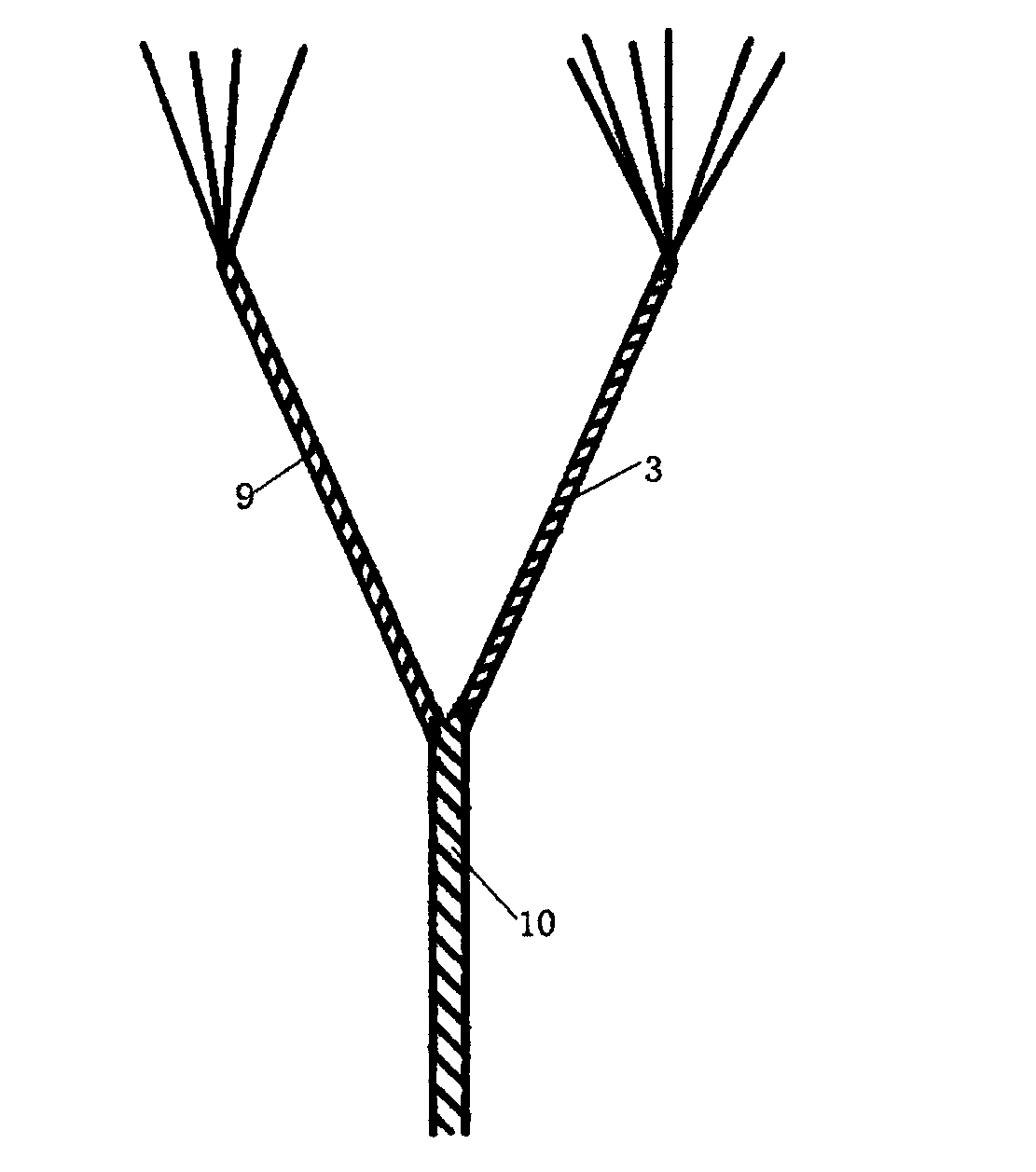

Method for serging shuttleless sleeve band for heavy parachute rope

InactiveCN103014987AGuaranteed mechanical propertiesStable structureLoomsHeating/cooling textile fabricsEngineeringHot melt

The invention discloses a method for serging a shuttleless sleeve band for a heavy parachute rope. The method comprises the steps as follows: selecting low-melting-point synthetic fiber multifilaments with the same characteristics as serging lines based on the original weft yarns and the serging lines; combining and twisting the low melting point synthetic fiber multifilaments with the original serging lines to serve as the serging lines; leading serging twisted yarns with hot melt fibers into the edge of a tubular sleeve band fabric by cooperation of a weft insertion needle and a serging bearded needle of a shuttleless ribbon loom to form knitted serging; and after finishing the serging operation, hotly shaping low-melting-point thermal links, controlling the shaping temperature for bonding the fibers with one part of the warp yarns, the weft yarns and the serging lines at selvedges, and cooling and shaping at a normal temperature for enabling the other part of the warp yarns, the weft yarns and the serging lines outside the selvedges to form bonding points under the action of the thermal links. According to the method, the low-melting-point thermal links with the similar characteristics are combined into a serging structure of a weaving system, so that the wear resistance and the stability of the knitted selvedges are improved and the problem of continuous weft sloughing caused by breakage of local serging lines due to larger load on the fabric or selvedge hooking is solved.

Owner:CHENGDU HAIRONG TECHNICAL TEXTILES CO LTD

Method for preparing high-strength self-compacting concrete through recycled fine aggregate

InactiveCN109534735AReduce construction costsReinforcement and stabilityCement mixing apparatusShotcreteMechanical property

The invention discloses a method for preparing high-strength self-compacting concrete through recycled fine aggregate, and relates to the technical field of concrete preparation. The method comprisesthe steps that 1, the recycled fine aggregate and required saturated water are mixed and stirred evenly; the recycled fine aggregate is recycled fine aggregate particles obtained in the mode that waste concrete is crushed, shaped and sieved, and the grain size of the recycled fine aggregate particles is not greater than 10 mm; and the required saturated water is calculated according to the water demand ratio of recycled mortar prepared from the recycled fine aggregate. According to the method for preparing the high-strength self-compacting concrete through the recycled fine aggregate, the final setting time can be controlled by adjusting the using amount of an accelerator, the construction time is convenient to control, concrete construction is convenient, the construction cost of engineering can be effectively lowered, through engineering practice, the sprayed concrete does not fall off after being poured, can be firmly combined with a constructed foundation pit slope, and can effectively reinforce the foundation pit slope, and the situation of secondary rework pouring is effectively avoided; and physical properties and mechanical properties of the concrete are met.

Owner:江苏宇辉新材料集团有限公司

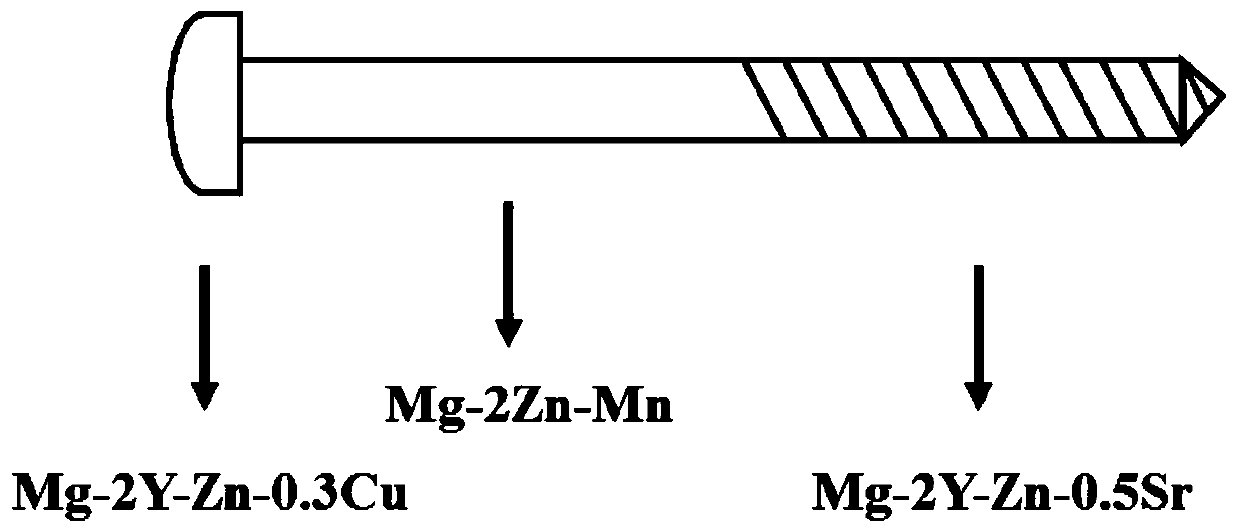

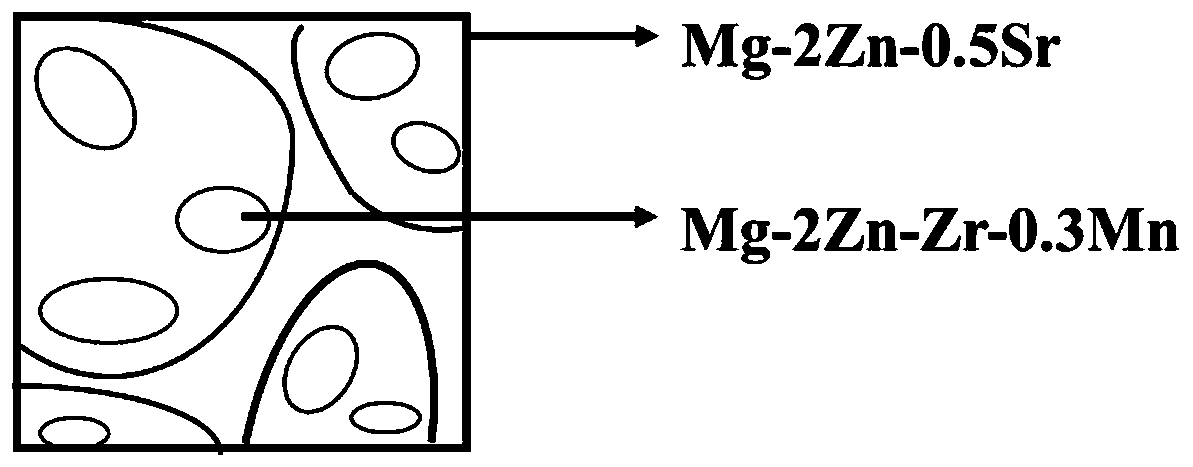

Degradable magnesium alloy material composed of multiple components as well as preparation method and application thereof

ActiveCN110976860ASolve the degradation rateSolve the mechanical propertiesAdditive manufacturing apparatusSurgeryComputer printingMetal powder

The invention discloses a degradable magnesium alloy material composed of multiple components as well as a preparation method and application thereof. The magnesium alloy material is formed by stacking a plurality of magnesium alloy layers with different component differences, wherein the component difference is that the adding elements in the magnesium alloy are different or the adding elements are the same, but the adding concentration is different. The preparation method comprises the following steps of (1) determining the type of required components, and placing the pure metal powder in different powder bins of a laser melting printer; (2) controlling the powder feeding amount of the pure metal powder of each element, and fully and mechanically mixing and then feeding the powder into apowder supply groove; and (3) carrying out melting and layered printing on the powder supplying laser in the powder supply groove to obtain the degradable magnesium alloy material with the corresponding shape and size and multiple components. The material is used as a medical implantable material to prepare bone repair or support materials. According to the degradable magnesium alloy material, mutual matching among the mechanical property, the degradation rate and the functionalization of the material is realized, and the requirements of the service environment of the biological material on the mechanical property, the degradation rate and the functionalization of the magnesium alloy are met.

Owner:SOUTHEAST UNIV

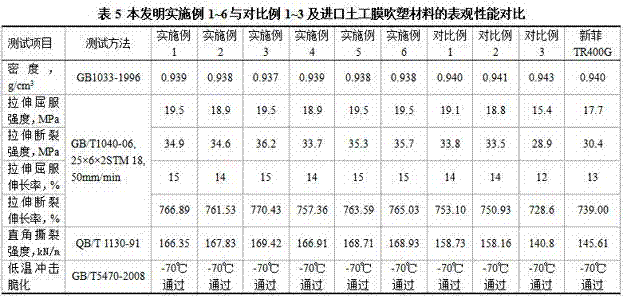

Preparation method of high-hexene grafted high-density polyethylene geomembrane blow molding material

ActiveCN104744795AImprove conversion efficiencyIncrease the amount of graftingBulk chemical productionBlow moldingPtru catalyst

The invention discloses a preparation method of a high-hexene grafted high-density polyethylene geomembrane blow molding material. The method comprises the following steps: (1) when a diluting agent is always under a circulation state, placing monomer ethylene and 1-hexene in a reaction vessel; adding an antistatic agent and an catalyst subjected to an activation treatment; adjusting the reaction temperature in the reaction vessel to 92-98 DEG C until the melt flow rate of a reaction product is 10.0-13.0g / 10min and the density of the reaction product is 0.937-0.939kg / m<3>, thereby obtaining ethylene-hexene polyethylene copolymer base resin with weight average molecular weight of 200,000 to 300,000, 1-hexene content of not less than 1.20% and crystallinity of 46.5-49.5%; (2) uniformly mixing 99.5-99.8 parts of the ethylene-hexene polyethylene copolymer base resin and 0.20-0.50 part of an antioxidant; and adding the mixture to a mixer for extrusion granulation, so as to obtain the geomembrane blow molding material. According to the method, a high-activity novel chromium catalyst is adopted, the equipment limitation of a loop slurry process is overcome, and high-hexene grafted high-density polyethylene is produced. With the method, reaction scale is effectively ameliorated, a reactor wall attachment phenomenon is reduced, production is smooth, and the productivity of the special material is high.

Owner:CHINA PETROLEUM & CHEM CORP

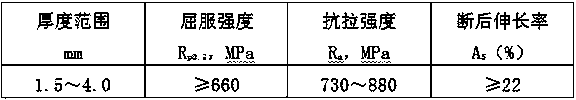

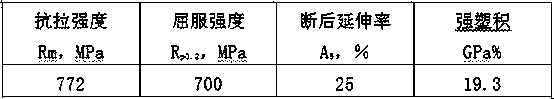

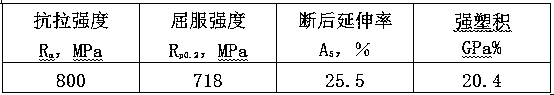

Production process of thin-gauge 700MPa-grade ultra-high strength hot rolled black leather steel strip

The invention discloses a production process of a thin-gauge 700MPa-grade ultra-high strength hot rolled black leather steel strip. The production process includes processes of rough rolling, finish rolling, cooling and coiling; in the process of finish rolling, the finish rolling entry temperature is 1030-1100 DEG C, and the finishing rolling temperature is 830-880 DEG C; in the cooling process,the steel strip is rapidly cooled to 750-790 DEG C through laminar flow cooling, cooled by intermediate air cooling, and then rapidly cooled to coiling temperature through the laminar flow cooling; and in the coiling process, the coiling temperature is 600-650 DEG C. The elongation of the hot rolled black leather steel strip obtained by the production process is not less than 22%; the product of strength and elongation is not less than 16 GMPa%; the steel strip has better cold forming performance and is suitable for producing cold roll forming hollow steel sections such as passenger car skeletons, truck side beams, and through beams; mechanical properties and coating surface quality requirements are met under the condition of omitting the processes of pickling chemical rust removal and mechanical rust removal; and the hot rolled black leather steel strip obtained by the production process is used to replace the Q345B, and can reduce the thickness of required steel plates, the weight ofa whole vehicle and the fuel consumption of the vehicle while the strength of a vehicle body is increased.

Owner:TANGSHAN STAINLESS STEEL +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com