Copolyester suitable for serving as 3D printing material and preparation method thereof

A 3D printing and copolyester technology, which is applied in the field of copolyester as a 3D printing material and its preparation, can solve problems such as poor compatibility, uneven dispersion of inorganic substances, complicated methods, etc., and meet the environmental protection performance Requirements, avoid compatibility problems, excellent mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

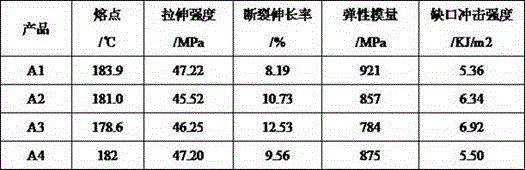

Examples

Embodiment 1

[0022] 232g (1.4mol) of terephthalic acid, 99.6g (0.6mol) of isophthalic acid, 4.04g (0.02mol) of sebacic acid, 230.28g (3.03mol) of 1,3-propanediol, and 0.166 of tetrabutyl titanate g, add it into the 1L reactor. The reactor is equipped with a stirring, temperature measurement system, rectification column and reflux condenser. The temperature is gradually increased to 100°C and then the stirring is turned on. When the temperature is close to 170°C, water begins to distill out, and the distillation temperature is 98-100°C, continue The temperature is raised to about 215°C, and the esterification reaction ends when the water output reaches 95% of the theoretical value. Then add 0.332g antioxidant, 33.2g additive (nano calcium carbonate) and 1.1869g auxiliary agent (oleic acid), carry out reduced compression polymerization reaction, gradually increase the temperature to 260℃, keep warm; the pressure in the reactor is gradually reduced to 50Pa, and maintain for 3 hours, the polyc...

Embodiment 2

[0024] 232g (1.4mol) of terephthalic acid, 99.6g (0.6mol) of isophthalic acid, 10.1g (0.05mol) of sebacic acid, 233.7g (3.075mol) of 1,3-propanediol, and 0.1711 of tetrabutyl titanate g, add it into the 1L reactor. The reactor is equipped with a stirring, temperature measurement system, rectification column and reflux condenser. The temperature is gradually increased to 100°C and then the stirring is turned on. When the temperature is close to 170°C, water begins to distill out, and the distillation temperature is 98-100°C, continue The temperature is raised to about 215°C, and the esterification reaction ends when the water output reaches 95% of the theoretical value. Then add 0.3421g antioxidant, 51.315g additive (nano silica) and 2.0410g auxiliary (polyethylene wax) to carry out reduced compression polymerization reaction, gradually increase the temperature to 255°C and keep it warm; the pressure in the reactor is gradually reduced It is as small as 50 Pa and maintained for...

Embodiment 3

[0026] Combine terephthalic acid 232g (1mol), isophthalic acid 99.6g (0.6mol), sebacic acid 16.16g (0.08mol), 1,4-butanediol 252.93g (3.328mol), tetrabutyl titanate 0.1741g, added to the 1L reactor. The reactor is equipped with a stirring, temperature measurement system, rectification column and reflux condenser. The temperature is gradually increased to 100°C and then the stirring is turned on. When the temperature is close to 175°C, water begins to distill out, and the distillation temperature is 98-100°C. Continue The temperature is raised to about 215°C, and the esterification reaction ends when the water output reaches 95% of the theoretical value. Then add 0.3482g antioxidant, 34.816g additive (powdered glass fiber) and 1.1062g auxiliary (sodium polyamide), carry out reduced compression polymerization reaction, gradually increase the temperature to 255℃, keep warm; the pressure in the reactor Gradually reduce to 50Pa and maintain for 3 hours to complete the polycondensat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| impact strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com