Light aging resisting and high-strength anti-flaming enhancement polybutylene terephthalate composition and preparation method thereof

A polybutylene terephthalate, anti-photoaging technology, applied in the field of polymer materials, can solve many problems such as preventing photodegradation, prolonging service life, maintaining strength and rigidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1- example 3

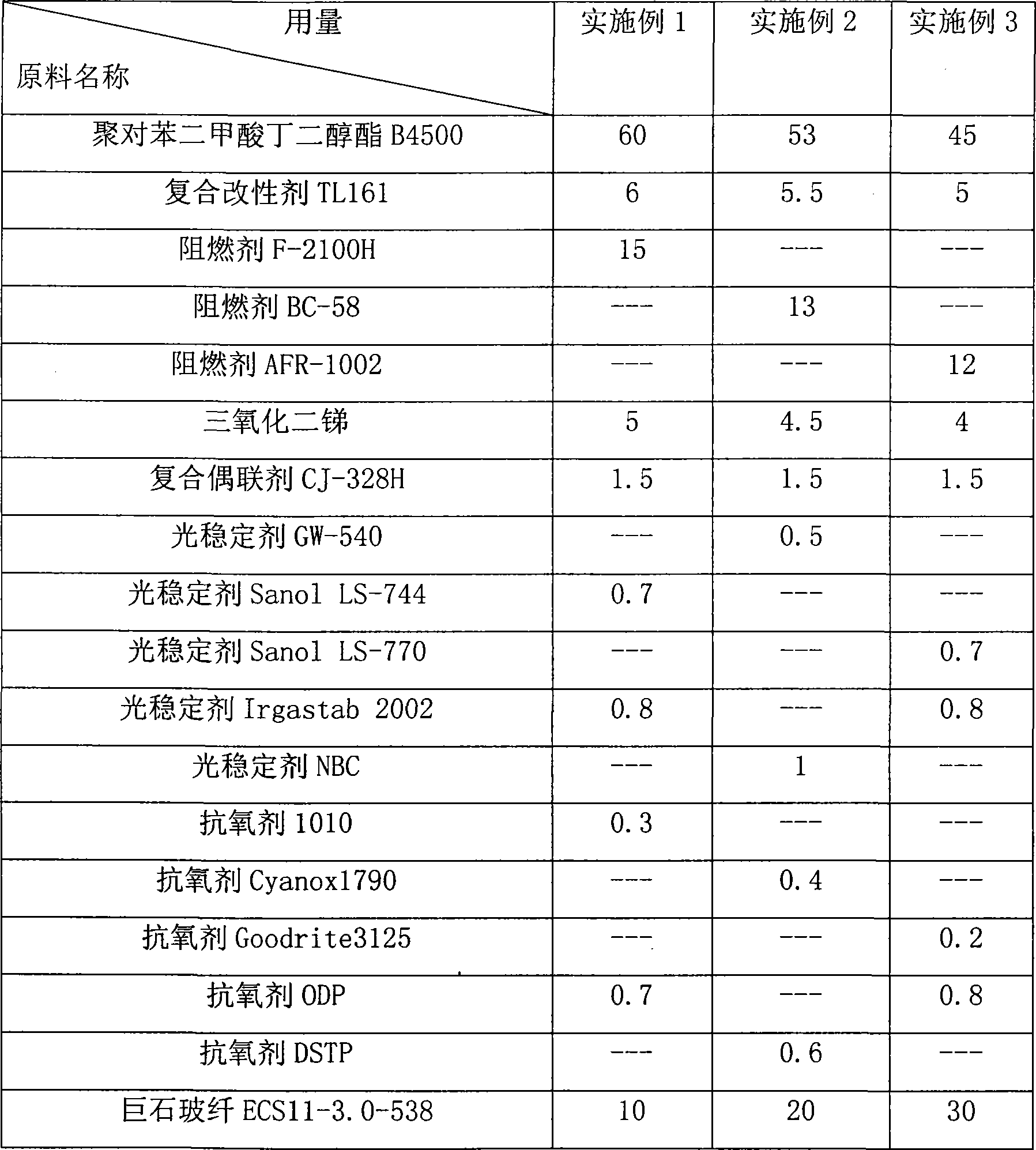

[0022] Embodiment 1-Example 3 The formula of each raw material is as follows (parts by weight):

[0023]

[0024] Its preparation method is:

[0025] The first step. take each raw material by weight;

[0026] Step 2. Put the composite modifier, special composite additive and composite coupling agent into the high-speed mixer for 2-3 minutes and dry mix at a speed of 800 rpm;

[0027] The third step. Five kinds of the premix obtained in step 1, polybutylene terephthalate, main flame retardant, synergistic flame retardant, and glass fiber are added to the extruder through their respective precision metered feeders. Exit the machine, mix and disperse in the screw barrel through the combined screw, and melt extrude and granulate to obtain the product. Wherein the screw speed is 350rpm, and the aspect ratio of the twin-screw extruder is 40:1;

[0028] The temperature of each zone of the extruder barrel from the feeding port to the machine head is: the temperature of the first...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com