Polymer electrolyte for polymer battery and preparation method of polymer electrolyte

A polymer and electrolyte technology, applied in the field of electrolytes, can solve the problems that polymers cannot be shaped and are not easy to reprocess, and achieve good mechanical properties, improve mechanical strength, and meet the effects of mechanical properties.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

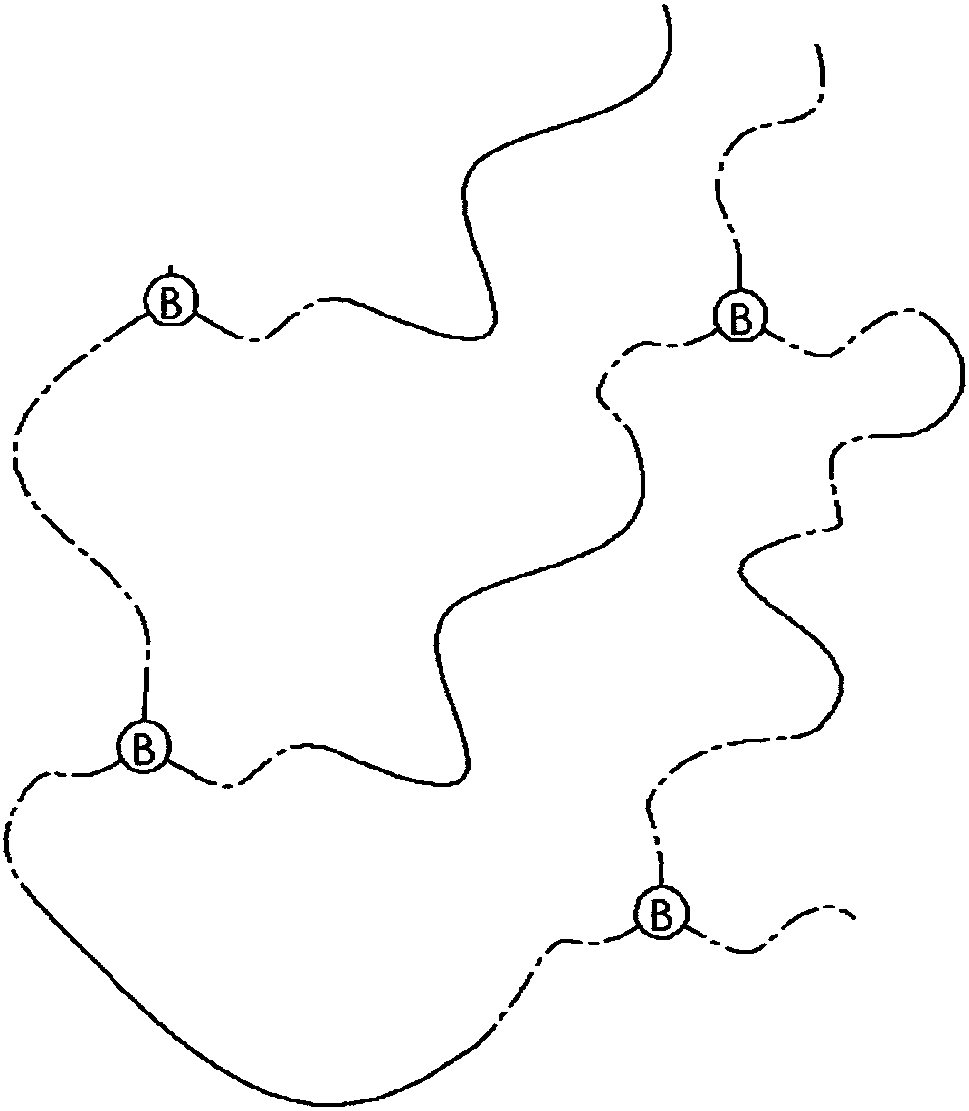

Image

Examples

Embodiment 1

[0039] (1) Under an ice-water bath, mix dichlorodimethylsilane, dichloromethylphenylsilane, dichloromonomethylsilane, ether, polyethylene glycol (molecular weight 400), boric acid and water, and the mass of the mixture is The number of parts is: dichlorodimethylsilane: dichloromethylphenylsilane: dichloromonomethylsilane: ether: polyethylene glycol: boric acid: water = 1:0.5:0.25:2.5:0.8:0.15:0.2 , to obtain the first solution;

[0040] (2) The temperature of the first mixed solution was raised to 40° C., and reacted for 6 hours under a vacuum of 0.1 bar to obtain the second mixed solution;

[0041] (3) The temperature of the second mixed solution was raised to 60° C., and the volatile components were distilled for 2 hours under a vacuum of 0.5 bar to obtain the first mixture;

[0042] (4) Xylene, lithium perchlorate and lithium borate are added in the first mixture, the mass fraction of mixing is: first mixture: xylene: lithium perchlorate: lithium borate=1:0.8:0.1:0.1, mix...

Embodiment 2

[0045] (1) At room temperature, mix dichlorodimethylsilane, dichlorodiphenylsilane, toluene, polypropylene glycol (molecular weight 600), tributyl borate and water, and the mixed mass parts are: dichlorodimethylsilane Base silane: dichlorodiphenylsilane: toluene: polypropylene glycol: tributyl borate: water=1:0.15:4:2.5:0.5:0.5, obtain the first solution;

[0046] (2) The temperature of the first mixed solution was raised to 60° C., and reacted for 2 hours under a vacuum of 0.4 bar to obtain the second mixed solution;

[0047] (3) The temperature of the second mixed solution was raised to 100° C., and the volatile components were distilled for 0.5 hours under a vacuum of 0.9 bar to obtain the first mixture;

[0048] (4) Add toluene and lithium perchlorate in the first mixture, the mass parts of mixing are: the first mixture: toluene: lithium perchlorate=1:1.8:0.26, mix 4 hours at 90 ℃, obtain the second mixture;

[0049] (5) The temperature of the second mixture was raised t...

Embodiment 3

[0051] (1) Under ice-water bath, dichlorodimethylsilane, tetrahydrofuran, polytetrahydrofuran (molecular weight 800), trimethyl borate and water are mixed, and the mass parts of mixing are: dichlorodimethylsilane: tetrahydrofuran: poly THF: trimethyl borate: water=1:0.6:2:0.28:0.06, to obtain the first solution;

[0052] (2) The temperature of the first mixed solution was raised to 50° C., and reacted for 3 hours under a vacuum of 0.2 bar to obtain the second mixed solution;

[0053] (3) The temperature of the second mixed solution was raised to 70° C., and the volatile components were distilled for 2 hours under a vacuum of 0.5 bar to obtain the first mixture;

[0054] (4) Add ethyl acetate and lithium perchlorate to the first mixture, the mass parts of mixing are: first mixture: ethyl acetate: lithium perchlorate=1:1.1:0.3, mix at 70°C for 6 hours , to obtain the second mixture;

[0055] (5) The temperature of the second mixture was raised to 70° C., and the volatile compo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com