Surface modification method of special nano calcium carbonate for silicone sealants

A nano-calcium carbonate and surface modification technology, which is applied in the direction of fibrous fillers, dyed low-molecular organic compound treatment, adhesive additives, etc. Poor rubber extrudability, complex preparation process and other problems, to achieve the effect of small investment, good dispersion and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

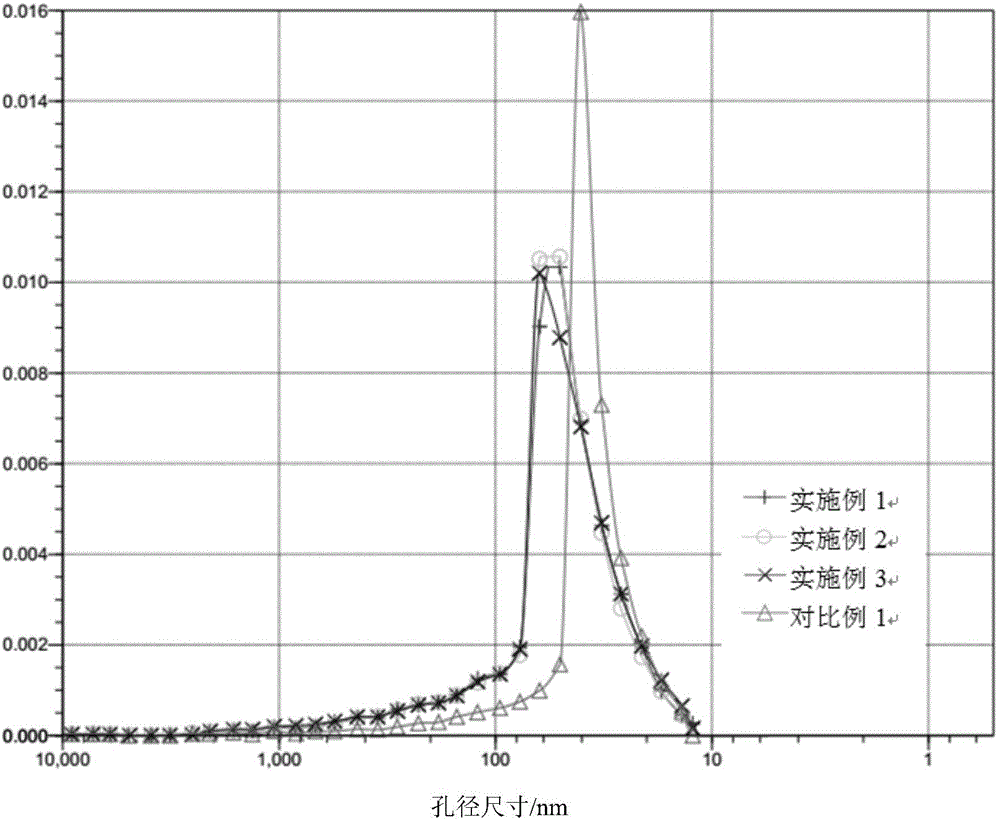

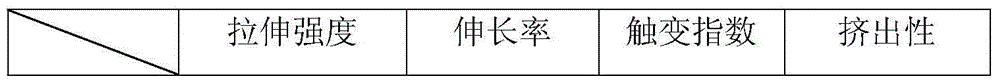

Embodiment 1

[0034] (1) The specific surface area is 26.9m 2 / g of calcium carbonate slurry was heated to 85°C and kept at a constant temperature.

[0035] (2) Preparation of surface treatment agent: add 1.0m 3 After heating up to 90°C and maintaining a constant temperature, add 1.0% (calcium carbonate dry basis mass) sulfated sodium oleate, stir for 15 minutes, then add 2.5% (calcium carbonate dry basis mass) stearic acid and palmitate A mixture of acids (stearic acid: palmitic acid = 8:2) was emulsified and stirred for 40 min.

[0036] (3) Add the surface treatment agent prepared in step (2) to the slurry obtained in step (1), and stir for 60 minutes to complete the surface modification.

[0037] (4) The calcium carbonate slurry obtained in step (3) is press-filtered and dehydrated, and a chain-belt drier is adopted at a drying temperature of 100 to 150° C., pulverized, classified and packaged to obtain the special nano-calcium carbonate product for silicone sealant of the present inve...

Embodiment 2

[0039] (1) The specific surface area is 23.3m 2 / g, the calcium carbonate slurry that concentration is 13.0% is heated to 85 ℃ and keeps constant temperature.

[0040] (2) Preparation of surface treatment agent: add 1.0m 3 After heating up to 90°C, keep the constant temperature, add 0.8% (calcium carbonate dry basis mass) sulfated sodium oleate, stir for 15min, then add 2.0% (calcium carbonate dry basis mass) stearic acid and palm A mixture of acids (stearic acid:palmitic acid=8:2) was emulsified and stirred for 40min.

[0041] (3) Add the surface treatment agent prepared in step (2) to the slurry obtained in step (1), and stir for 60 minutes to complete the surface modification.

[0042] (4) The calcium carbonate slurry obtained in step (3) is press-filtered and dehydrated, and a chain-belt drier is adopted at a drying temperature of 100 to 150° C., pulverized, classified and packaged to obtain the special nano-calcium carbonate product for silicone sealant of the present i...

Embodiment 3

[0044] (1) The specific surface area is 23.3m 2 / g, the calcium carbonate slurry that concentration is 13.0% is heated to 85 ℃ and keeps constant temperature.

[0045] (2) Preparation of surface treatment agent: add 1.0m 3After heating up to 90°C and maintaining a constant temperature, add 1.5% (calculated on a dry basis of calcium carbonate) sulfated sodium oleate, stir for 15 minutes, and then add 1.3% (calculated on a dry basis of calcium carbonate) stearic acid and palmitate A mixture of acids (stearic acid:palmitic acid=8:2) was emulsified and stirred for 40min.

[0046] (3) Add the surface treatment agent prepared in step (2) to the slurry obtained in step (1), and stir for 60 minutes to complete the surface modification.

[0047] (4) The calcium carbonate slurry obtained in step (3) is press-filtered and dehydrated, and a chain-belt drier is adopted at a drying temperature of 100 to 150° C., pulverized, classified and packaged to obtain the special nano-calcium carbon...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com