Patents

Literature

32results about How to "Increase Conversion Ratio" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Ultrasound knife

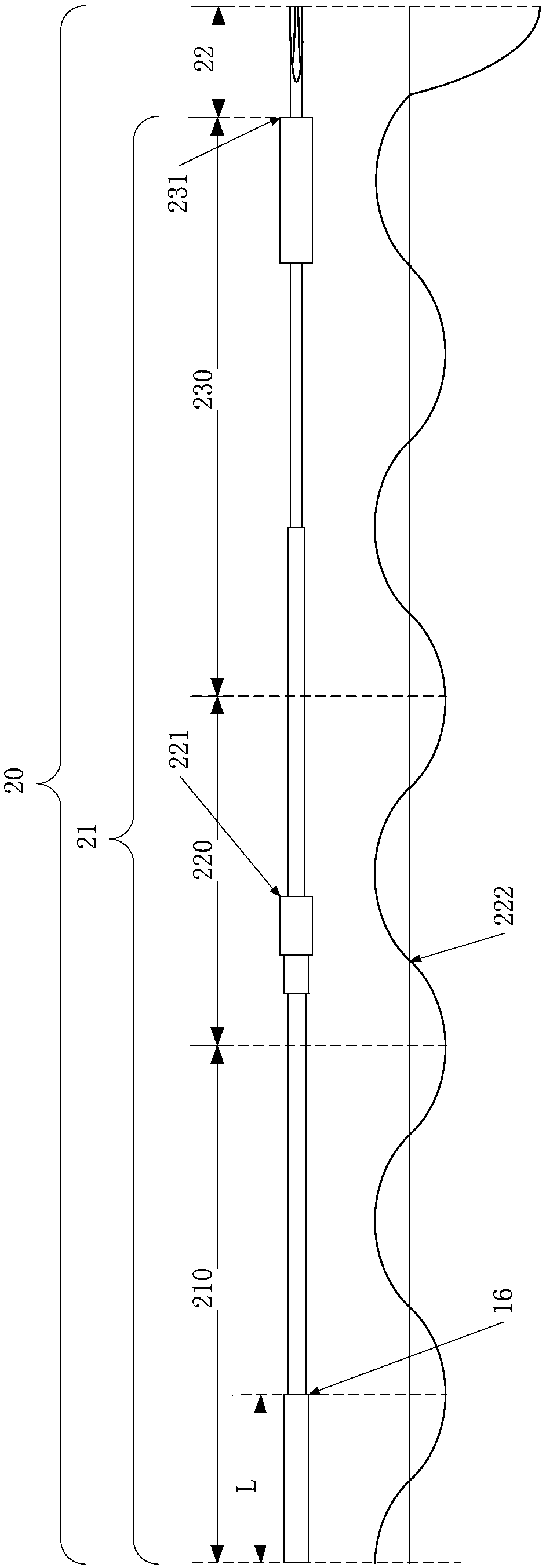

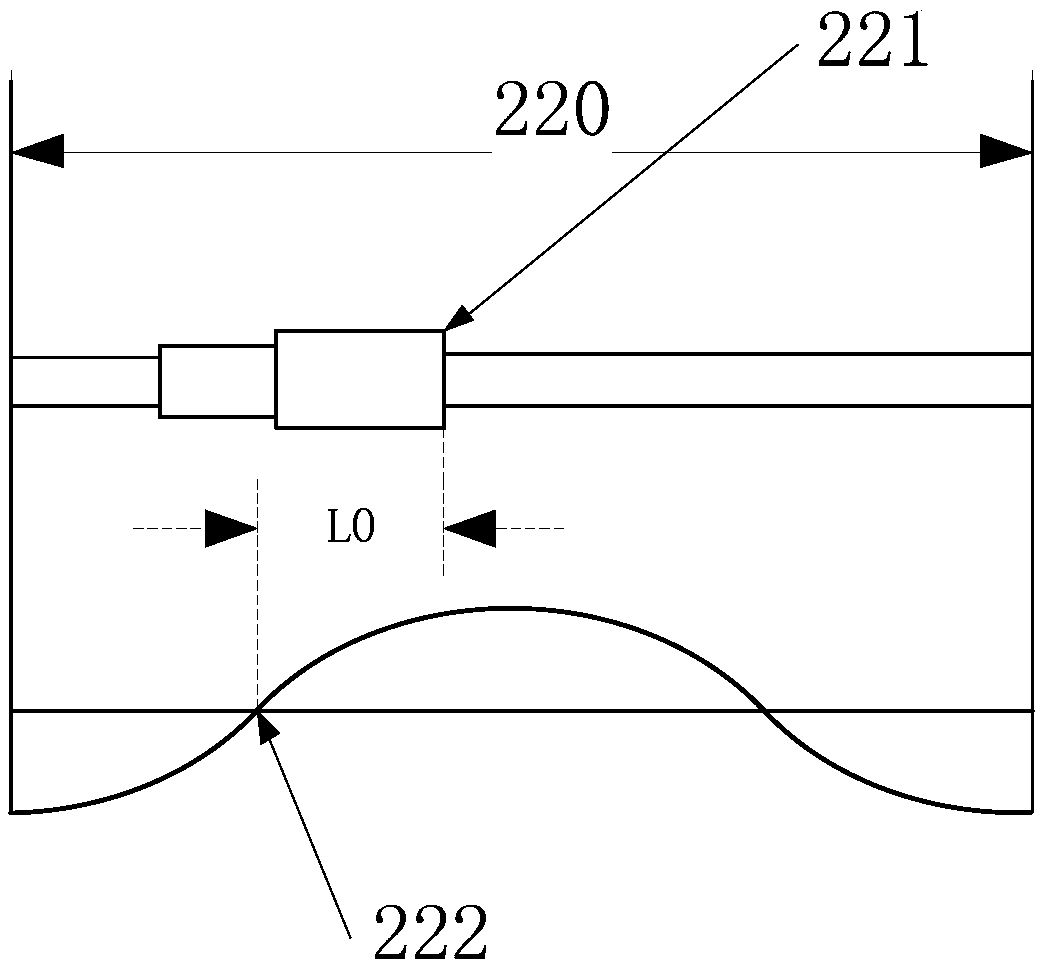

PendingCN108784786AImproved Phase ToleranceImprove frequency characteristicsSurgeryEngineeringLength wave

The invention provides an ultrasound knife for a surgical operation. The ultrasound knife in the embodiment comprises a knife bar and a knife head, wherein the knife bar comprises a knife-bar near endaway from the knife head, a knife-bar middle end and a knife-bar far end, and the knife-bar far end is connected with the knife head; a gain step is arranged at the knife-bar middle end and / or the knife-bar far end, and the distance from a first node of the knife-bar middle end to the middle-end gain step is 10% to 20% of half-wavelength; the knife head is an arc cutting knife point. The ultrasound knife has the wider frequency bandwidth, a working resonance point has lower impedance, and a knife tip has larger and more-even amplitude output.

Owner:苏州锐诺医疗技术有限公司

Double-bootstrap three-level Zeta converter

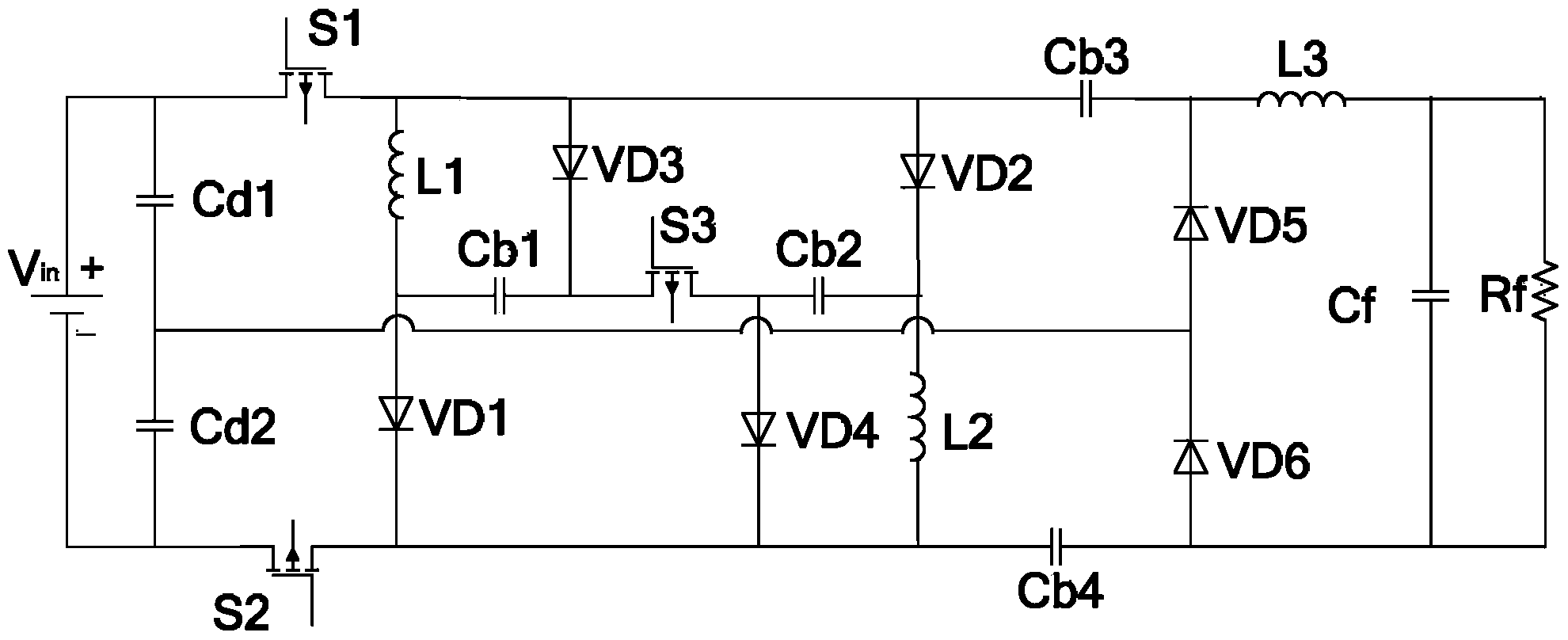

ActiveCN103986325AIncrease Conversion RatioReduce volumeDc-dc conversionElectric variable regulationThree levelCascade converter

The invention discloses a double-bootstrap three-level Zeta converter and belongs to the technical field of power electronic converters. The invention aims to solve the problems that loss in a conversion circuit and a cascade converter which do not need to be isolated is high, the equipment size is large and the cost is high when a topological structure of a direct current converter main circuit is changed by means of adding a transformer or utilizing cascade connection at present. According to the double-bootstrap three-level Zeta converter, a switching inductor circuit with an auxiliary switch is added on the basis of a topological structure of an original two-level Zeta converter circuit, so that a conversion ratio of the direct current converter is improved. The switching loss of the double-bootstrap three-level Zeta converter is 3 / 2n the switching loss under the condition that n circuits are in cascade connection with one another on the premise of the same effect with the traditional mode of increase of transformers and cascade connection of n circuits; and moreover the transformer equipment is reduced, so that the total equipment size is reduced, and the cost is saved. The invention is applied to modification of the topological structure of the direct current converter main circuit.

Owner:HARBIN INST OF TECH

Wireless energy transmission system and method

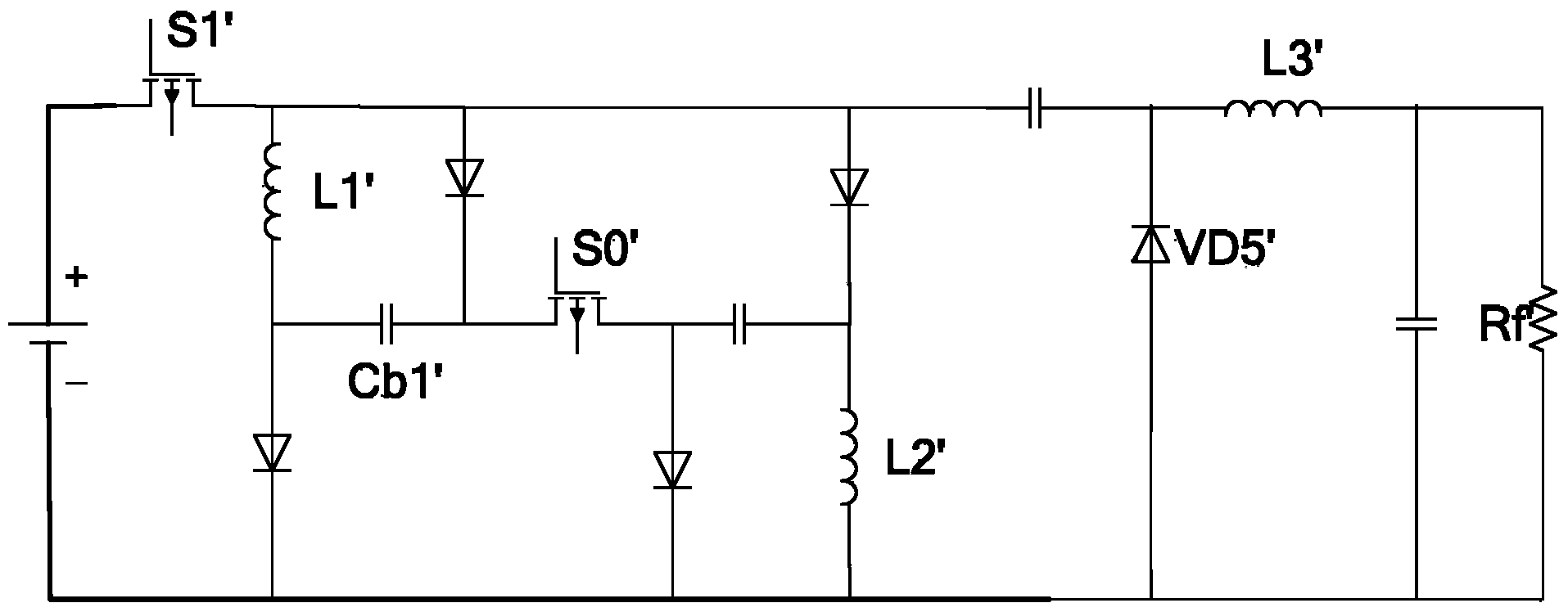

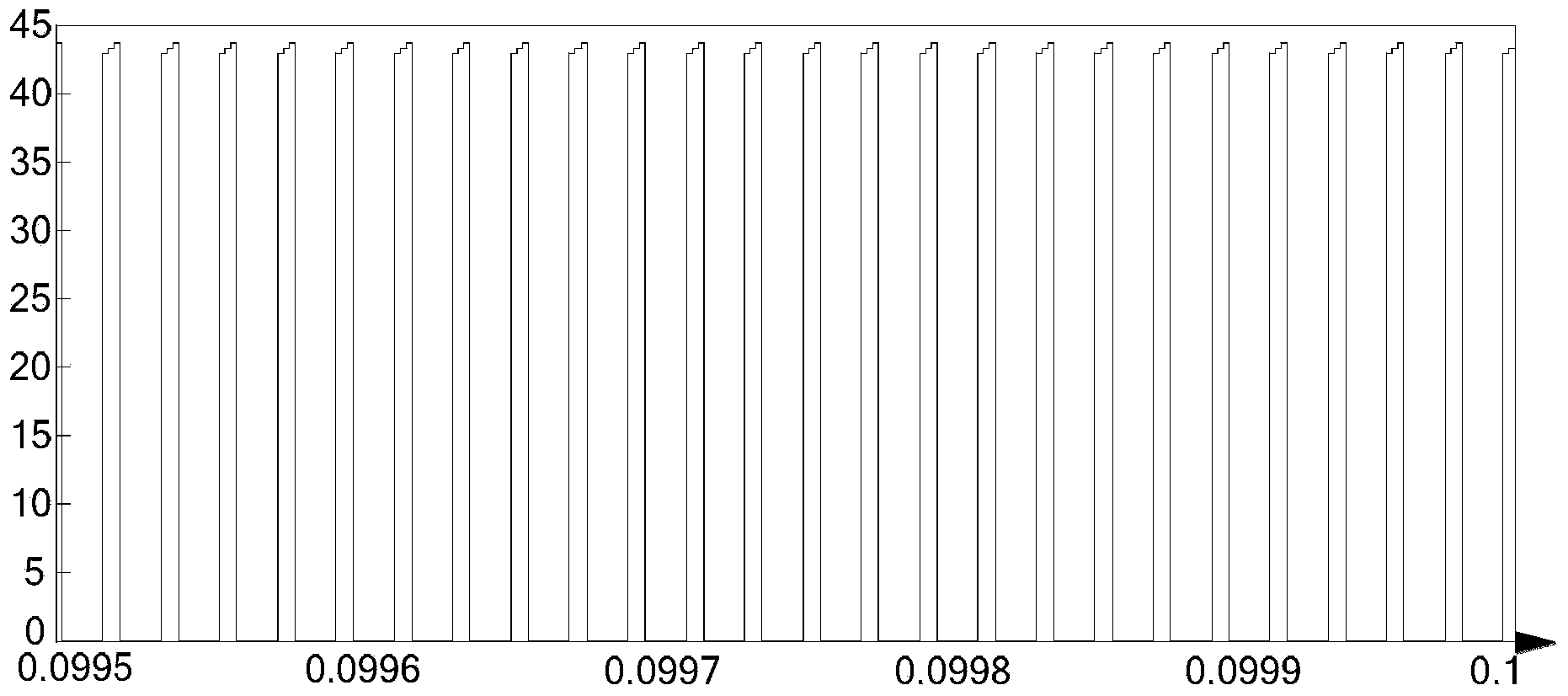

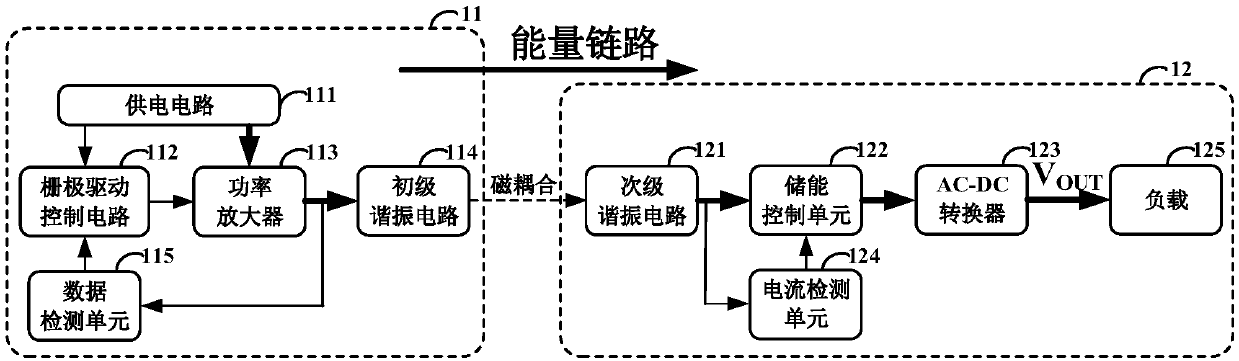

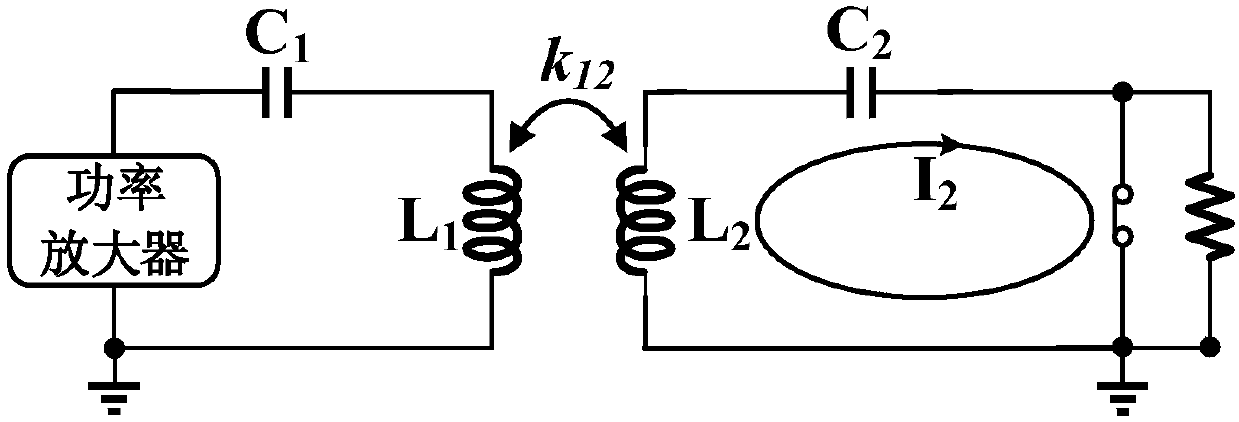

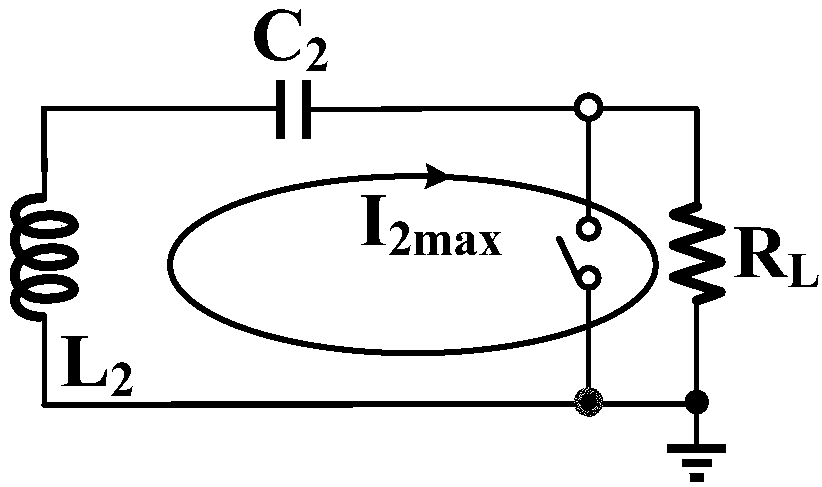

ActiveCN107666186AIncrease Conversion RatioIncrease the output voltageEfficient power electronics conversionCircuit arrangementsEngineeringProper time

The invention relates to a wireless energy transmission system and method; the method uses a switch to switch a receiving circuit between an energy storage mode and a discharge mode; when the switch is closed, a load is shorted, and a secondary resonance circuit is in the energy storage mode; when the switch is disconnected, the load is connected, the secondary resonance circuit is in the discharge mode, and the stored energy is released to the load; the method can use the secondary resonance circuit to serve as the current source input of an AC-DC converter of the receiving circuit, thus improving the voltage transition ratio, improving the output voltage, and satisfying the high output voltage application requirements without needing an extra off-chip capacitor; the method can close a power amplifier at a proper time, thus saving emission energy, and improving the system transmission efficiency; the method needs no complex feedback technology or wireless communication technology, andcan return a mode switch signal from the receiving circuit to an emission circuit, thus greatly reducing the system complexity.

Owner:SOUTH CHINA UNIV OF TECH

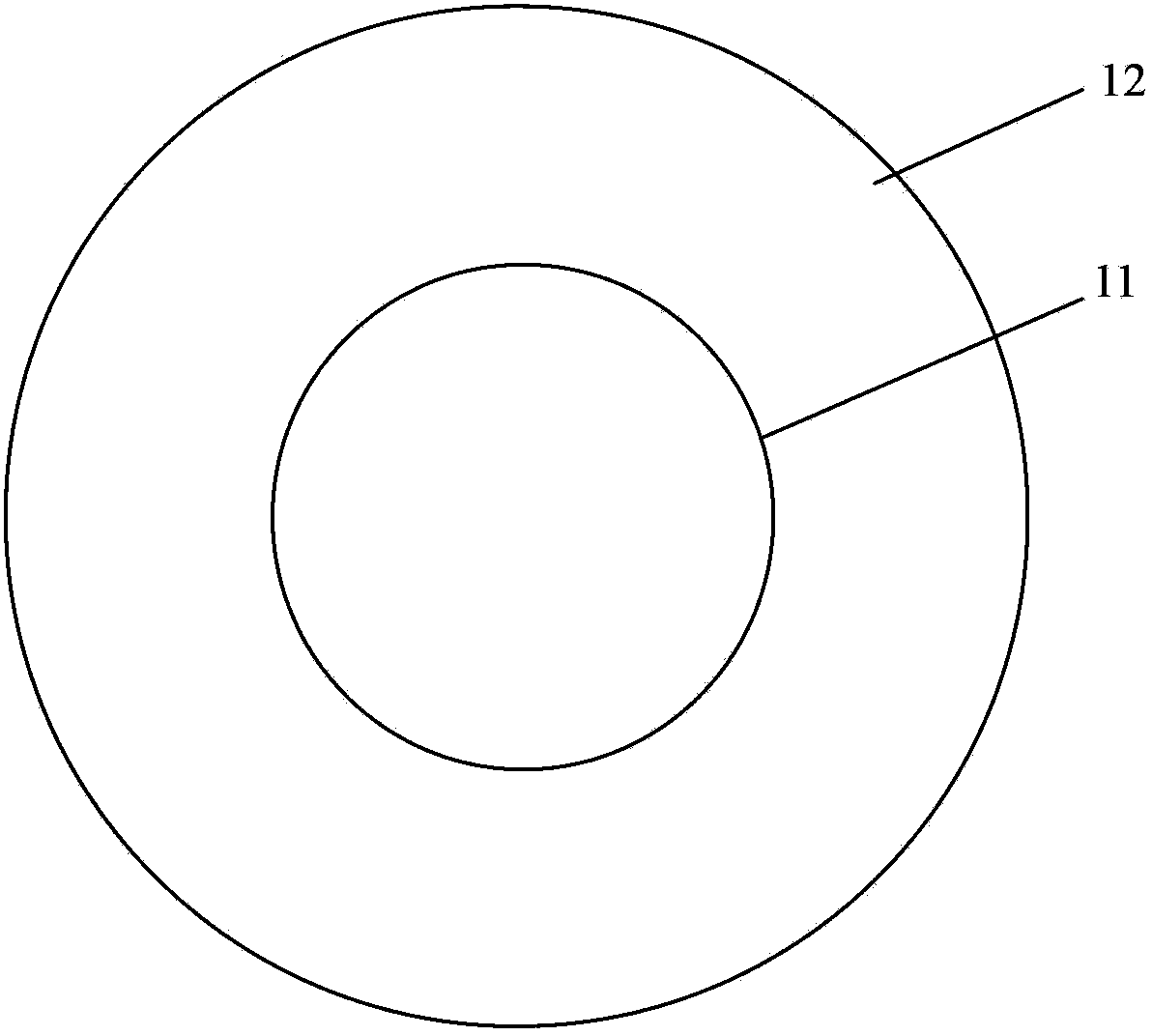

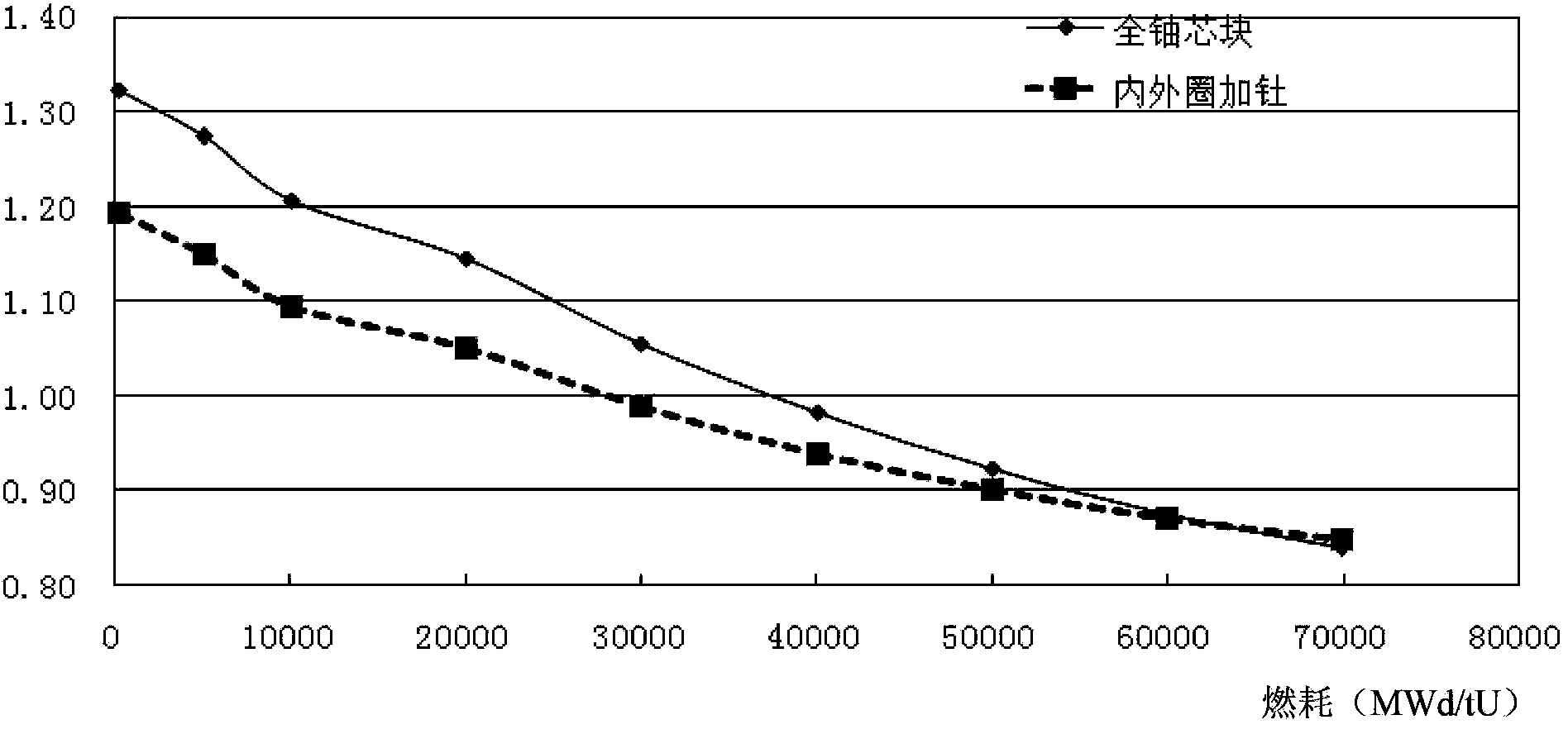

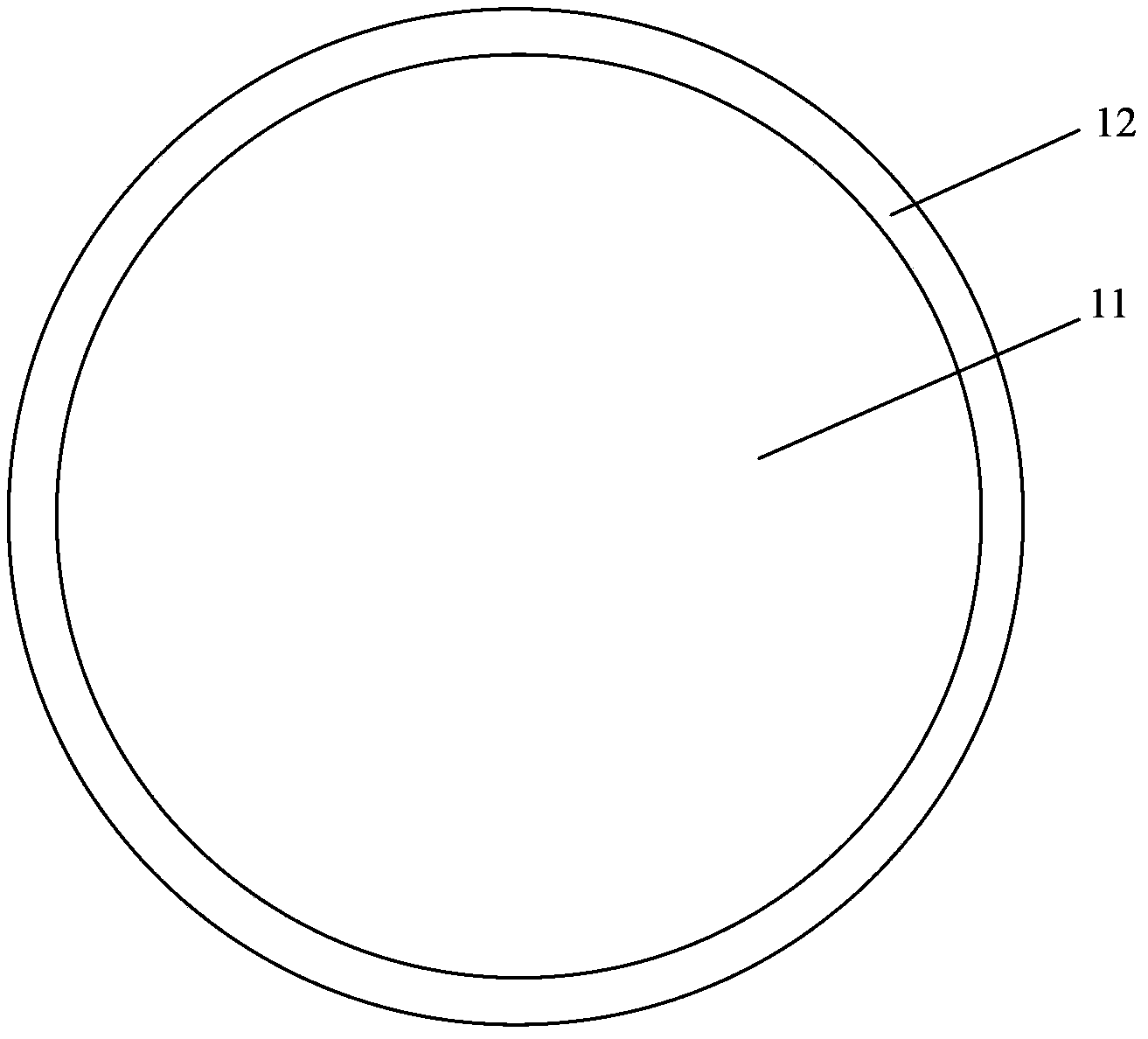

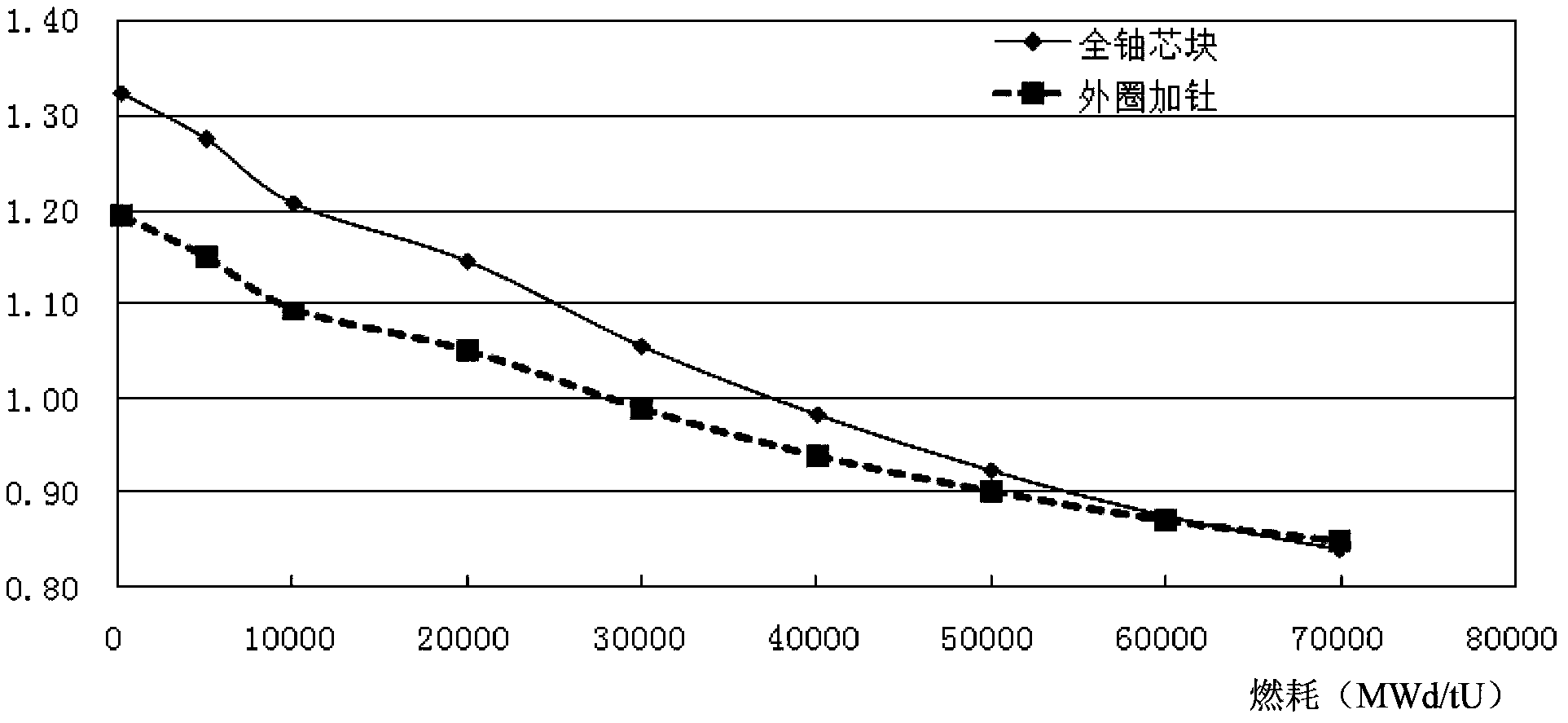

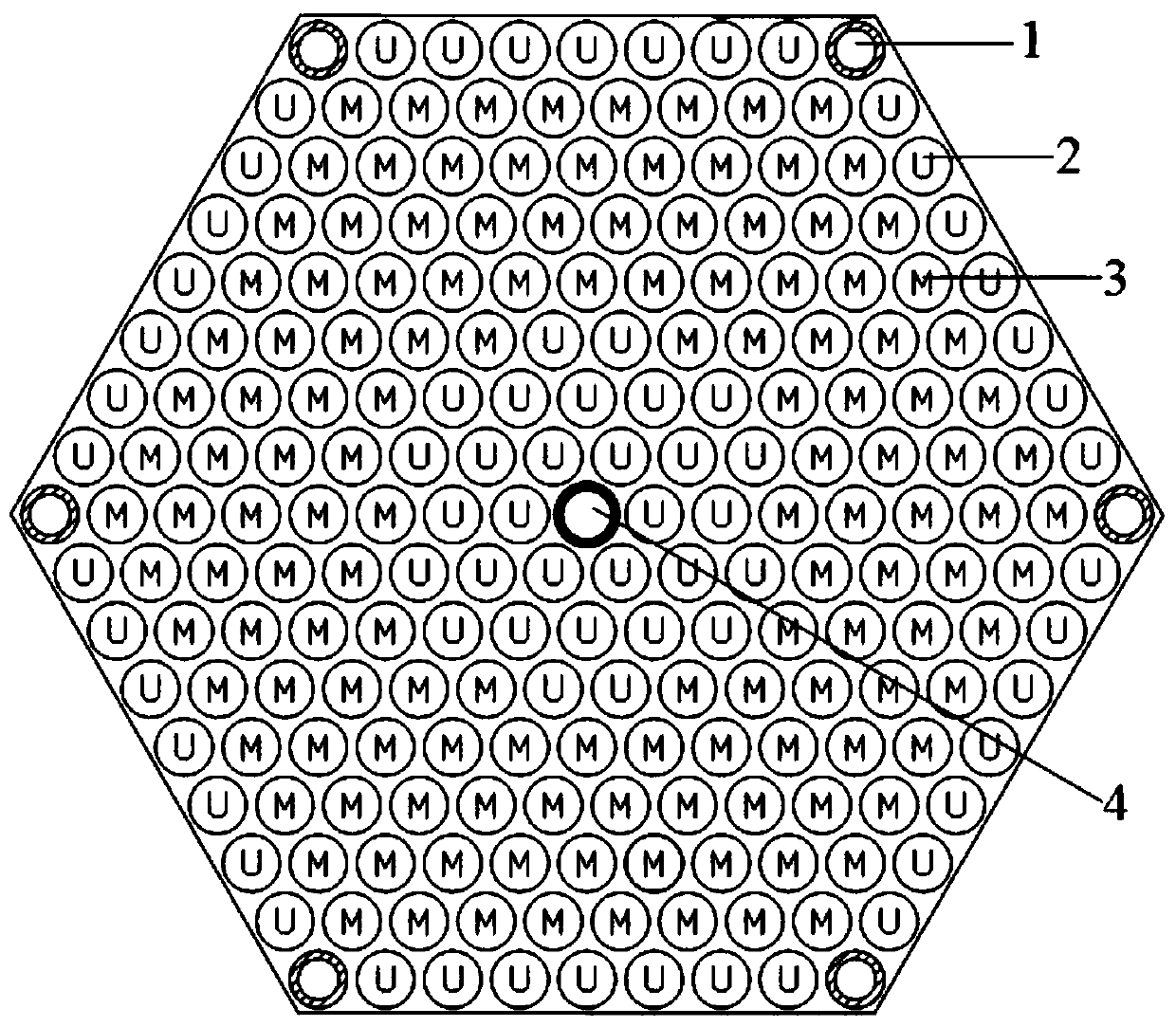

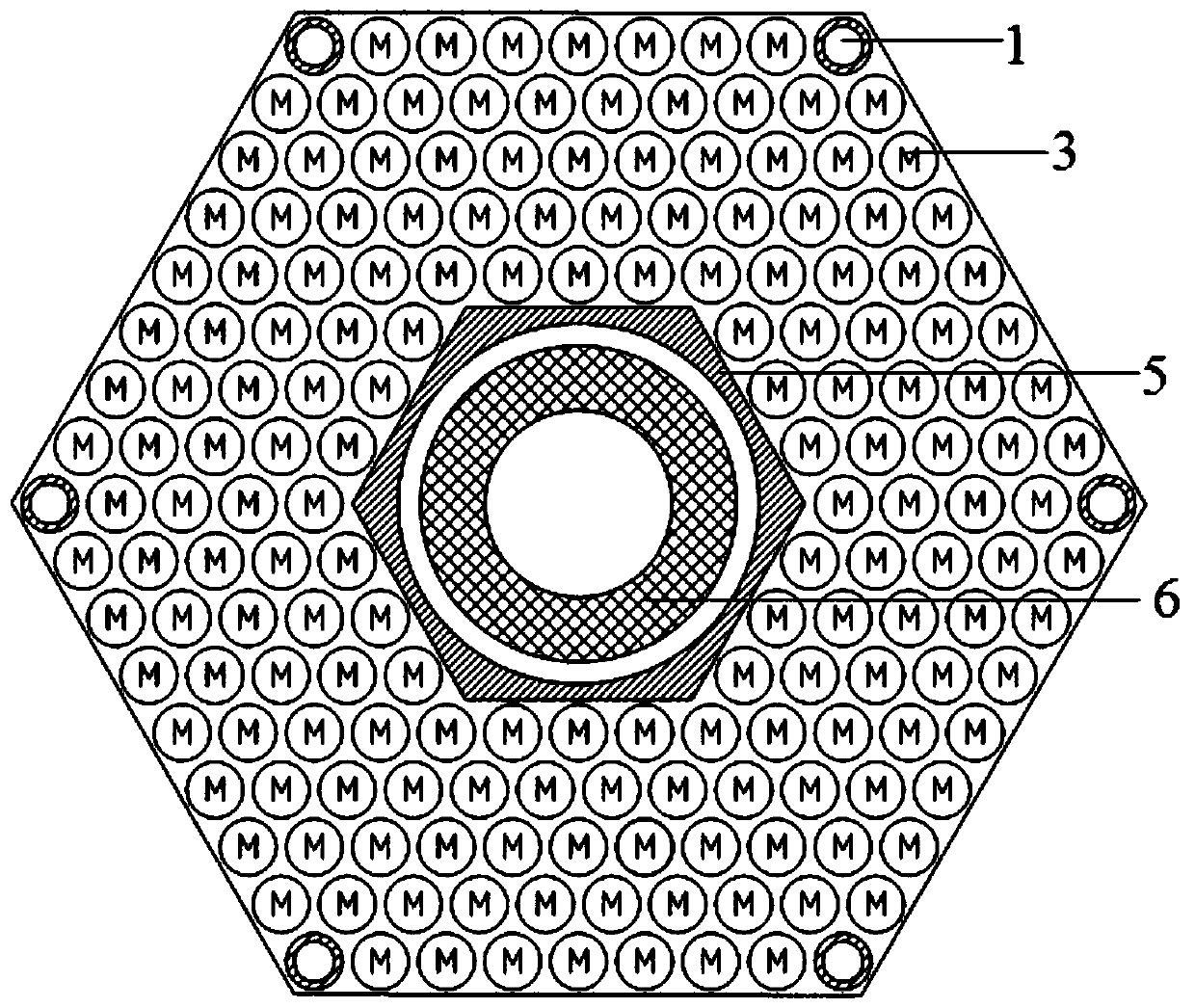

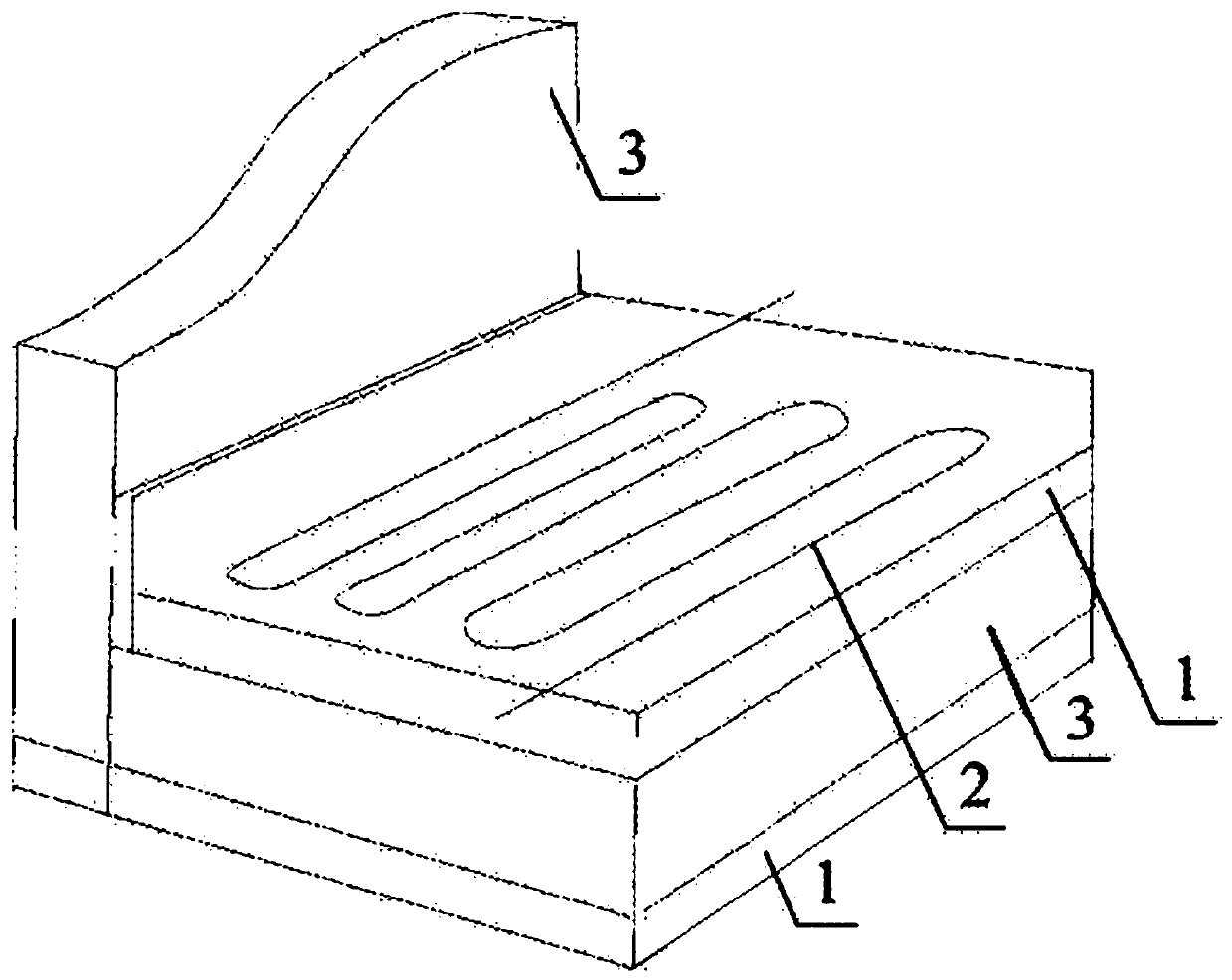

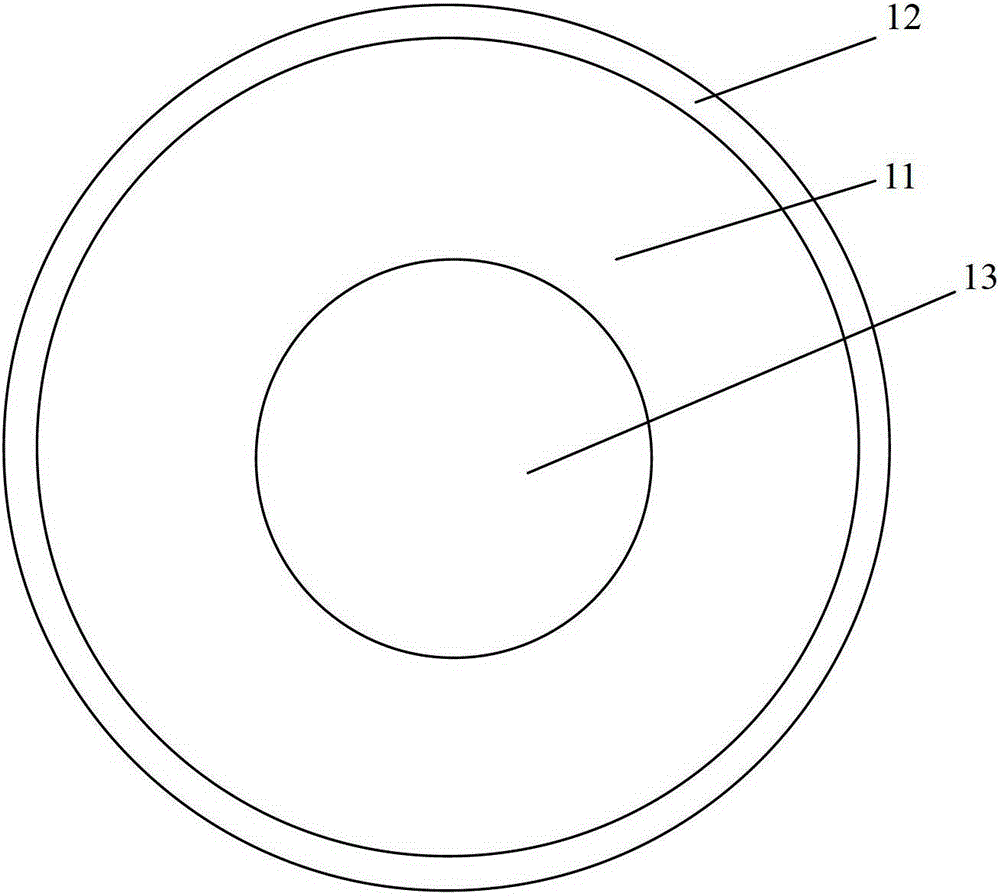

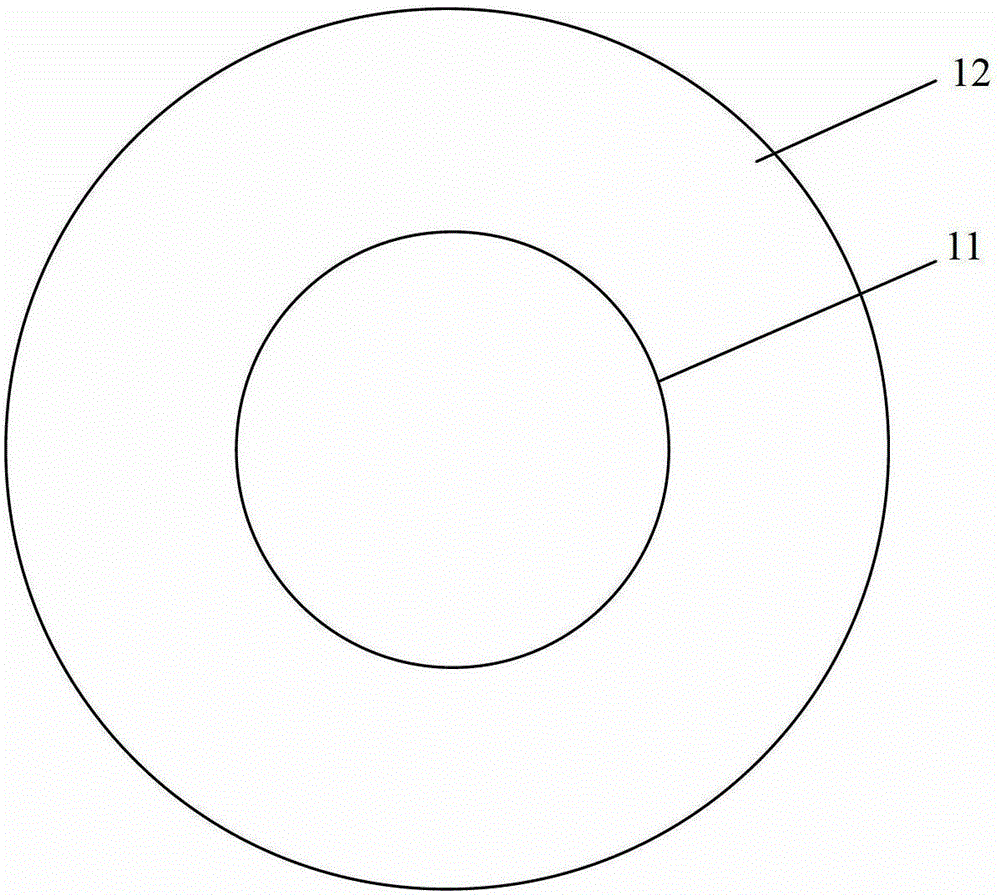

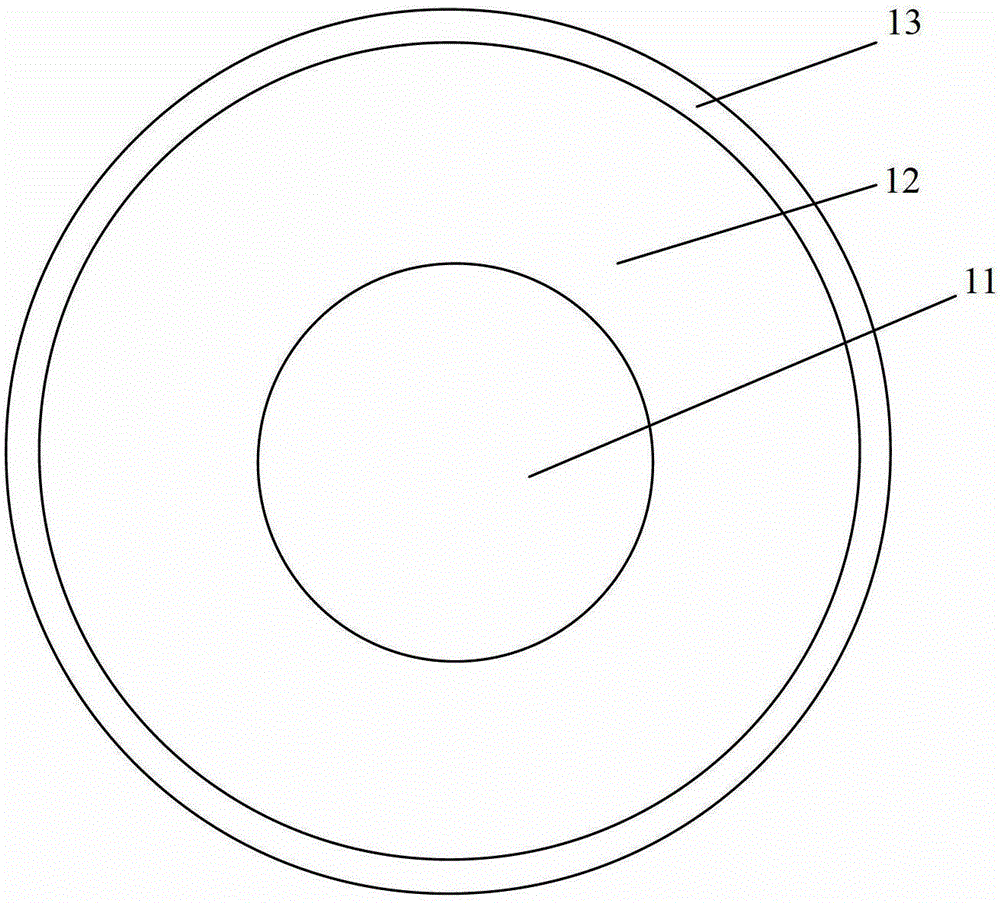

Nuclear fuel pellet and manufacturing method thereof, and nuclear reactor

ActiveCN103366835AImprove overall utilizationAvoid wastingFuel elementsNuclear energy generationNuclear reactor coreNuclear reactor

The invention relates to a nuclear fuel pellet which comprises nuclear fuel materials. The nuclear fuel pellet at least comprises a first fuel zone and a second fuel zone which are arranged from inside to outside, wherein the reactivity of the nuclear fuel material of the first fuel zone is lower than that of the nuclear fuel material of the second fuel zone. The nuclear fuel with lower reactivity is arranged at the center of the nuclear fuel pellet, thereby avoiding the problem of low nuclear fuel material utilization ratio in the central zone, having the action of reducing fissible material residues in the discharge fuel, and avoiding the waste of the nuclear fuel materials.

Owner:CHINA NUCLEAR POWER TECH RES INST CO LTD +1

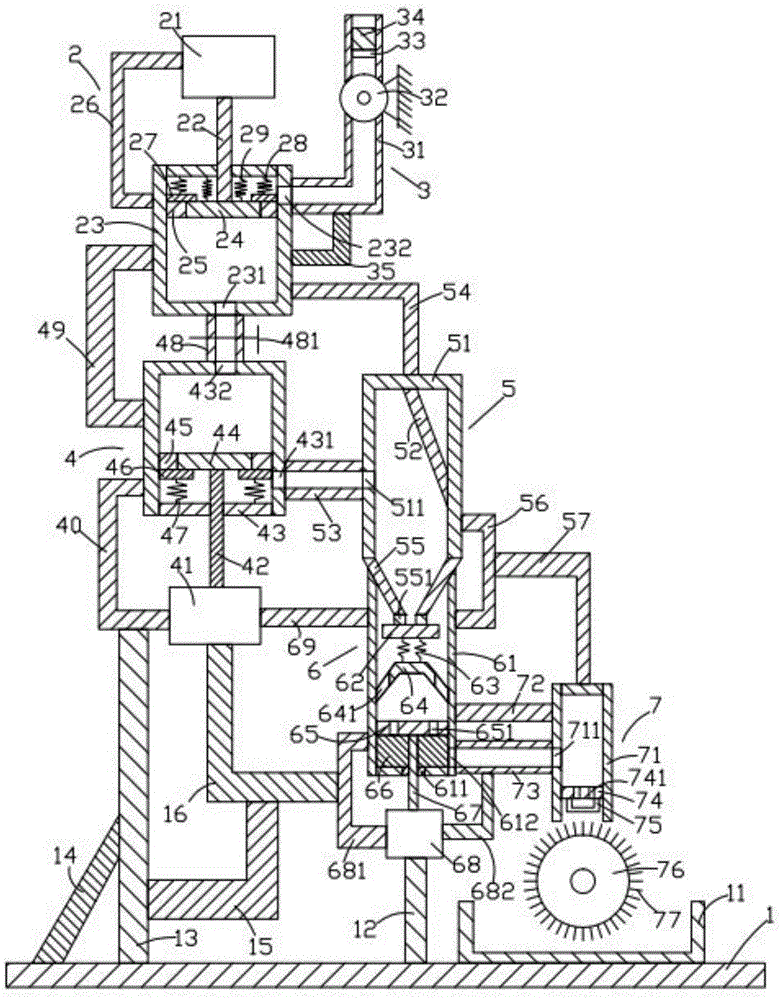

Air compressing water generator

The invention provides an air compressing water generator which comprises a bottom plate, a first compressing device, an air inlet device, a second compressing device, a condensing device, an air cylinder device and a filtering device. The bottom plate is provided with a collecting frame, a first supporting rod, a second supporting rod, a first sway rod, a first support and a second support. The first compressing device comprises a first air cylinder, a first pushing rod, a first compressing box, a first pushing plate, a first sealing ring, a first pushing ring, a first spring, a second spring and a first fixing rack. The air inlet device comprises an air inlet pipe, a fan, a first filter screen, a first sponge block and a third support. The second compressing device comprises a second air cylinder, a second pushing rod, a second compressing box, a second pushing plate and a second sealing ring. The second pushing plate is located on a third fixing rack below the second fixing rack. The condensing device comprises a condensing box, a condensing plate, a first pipeline and a fourth support. Vapor in air is converted into liquid water, efficiency is high, the conversion rate is large, and water resources in the air can be utilized fully.

Owner:张萍

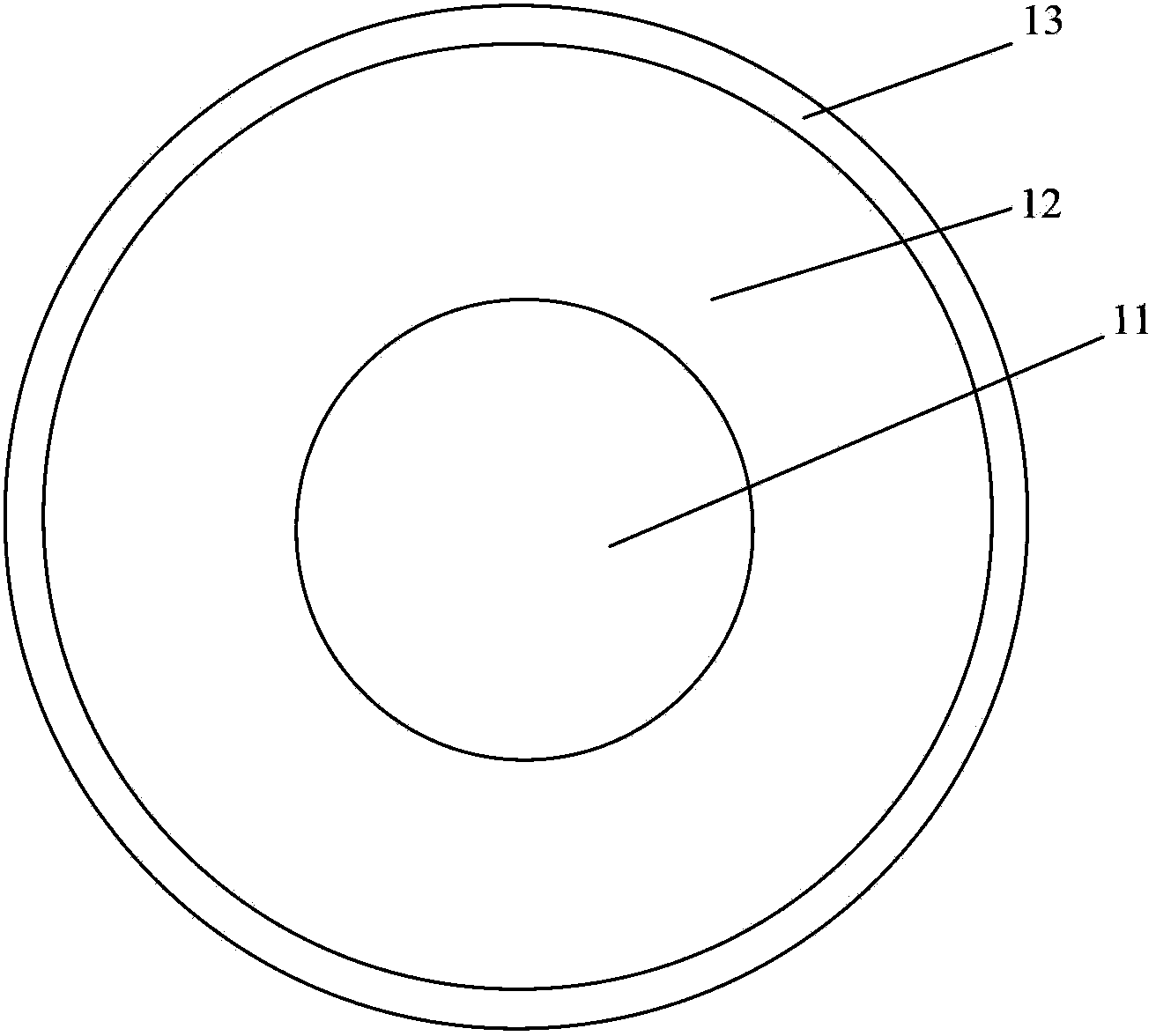

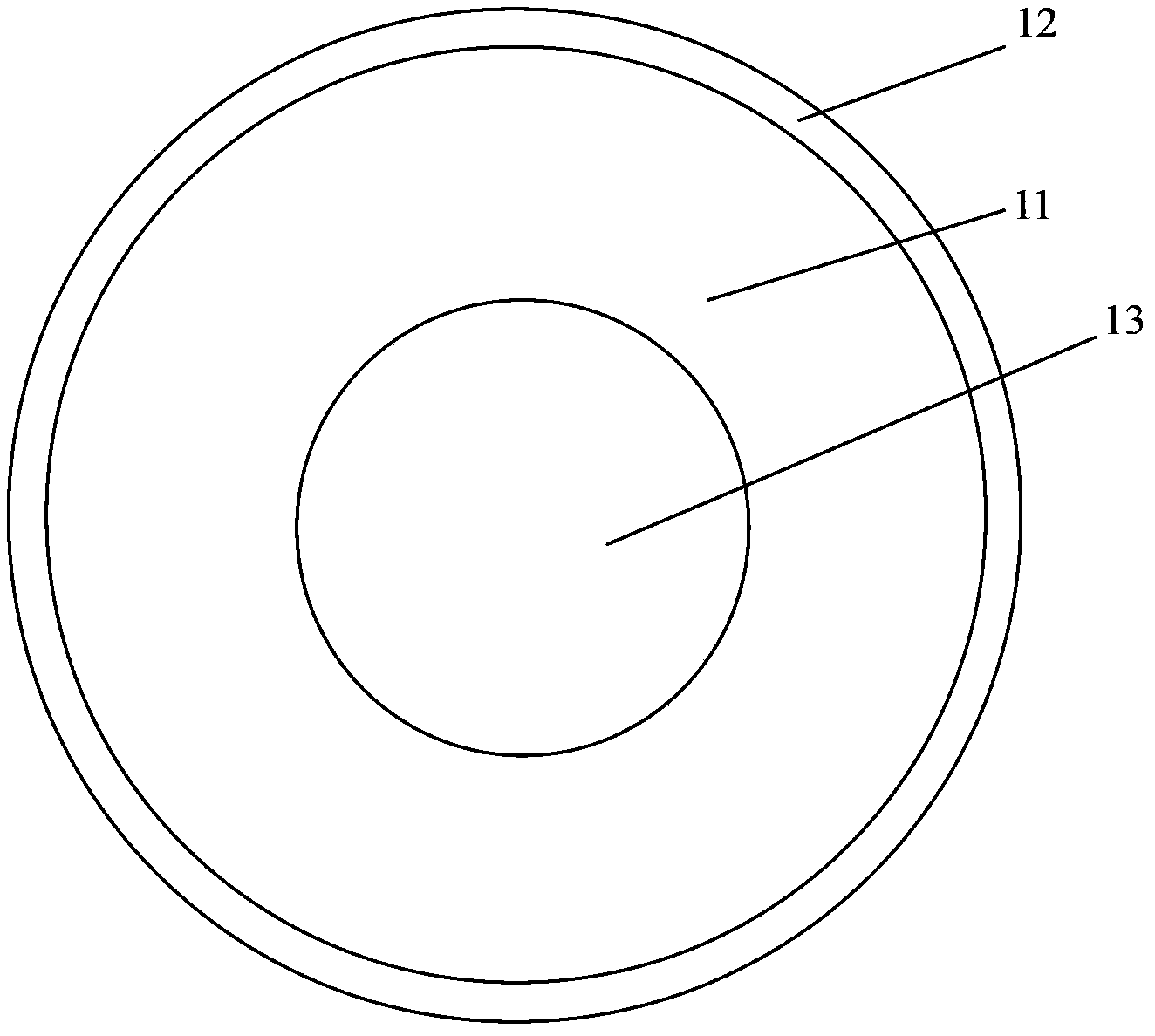

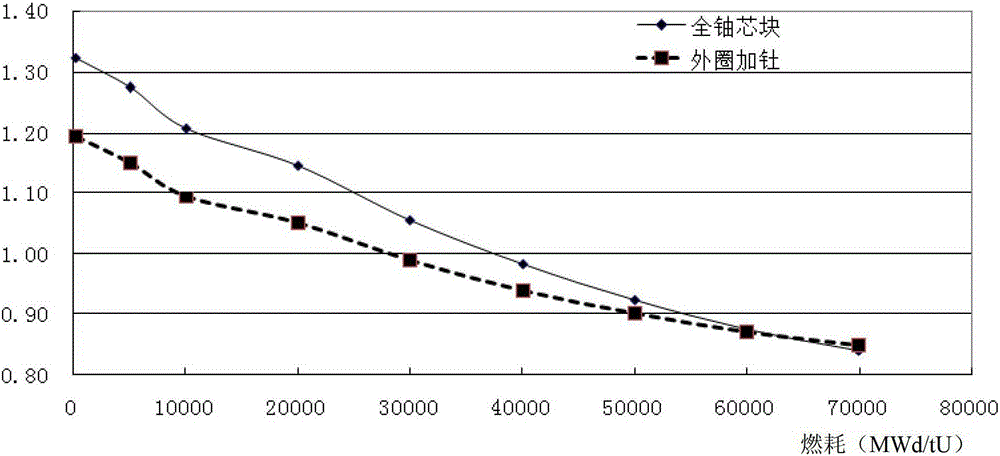

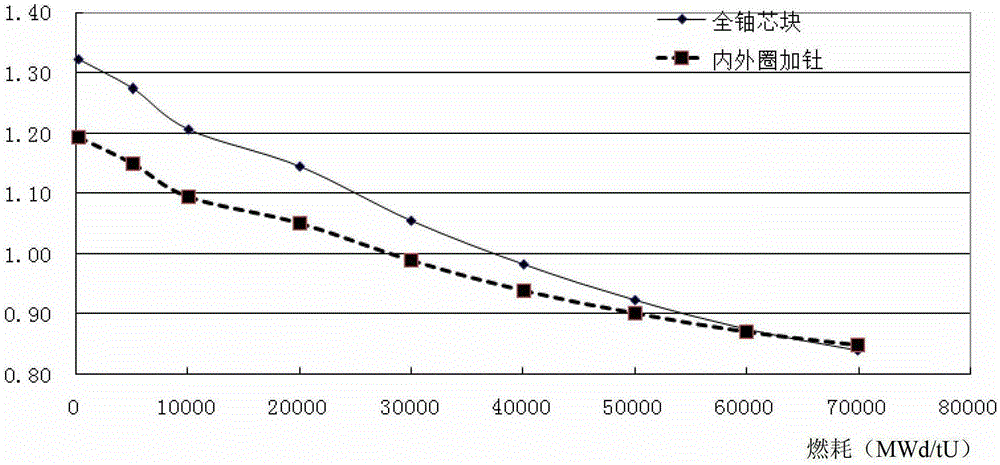

Nuclear fuel pellet and manufacturing method thereof, and nuclear reactor

ActiveCN103366836AIncrease profitSimple designFuel elementsNuclear energy generationNuclear reactor coreNuclear reactor

The invention relates to a nuclear fuel pellet and a manufacturing method thereof, and a nuclear reactor. The nuclear fuel pellet at least comprises a first fuel zone and a second fuel zone which are arranged from inside to outside, wherein the thickness of the second fuel zone is much smaller than that of the first fuel zone; and the reactivity of a nuclear fuel material of the first fuel zone is higher than that of a nuclear fuel material of the second fuel zone. The nuclear fuel material with lower reactivity is arranged on the periphery of the nuclear fuel pellet with higher reactivity to perform the function of lowering initial reactivity margin, so that burnable poisons and / or boric acid in the reactor core are correspondingly reduced, thereby being beneficial to reactor core nuclear design and reactivity control; or more fissionable materials can be loaded to implement longer fuel cycle. More neutrons can be effectively absorbed, thereby enhancing the conversion ratio of the fuel. Besides, the nuclear fuel material with lower reactivity is arranged at the innermost ring of the nuclear fuel pellet to have the function of reducing fissible material residues, thereby enhancing the utilization ratio of nuclear fuels.

Owner:CHINA NUCLEAR POWER TECH RES INST CO LTD +2

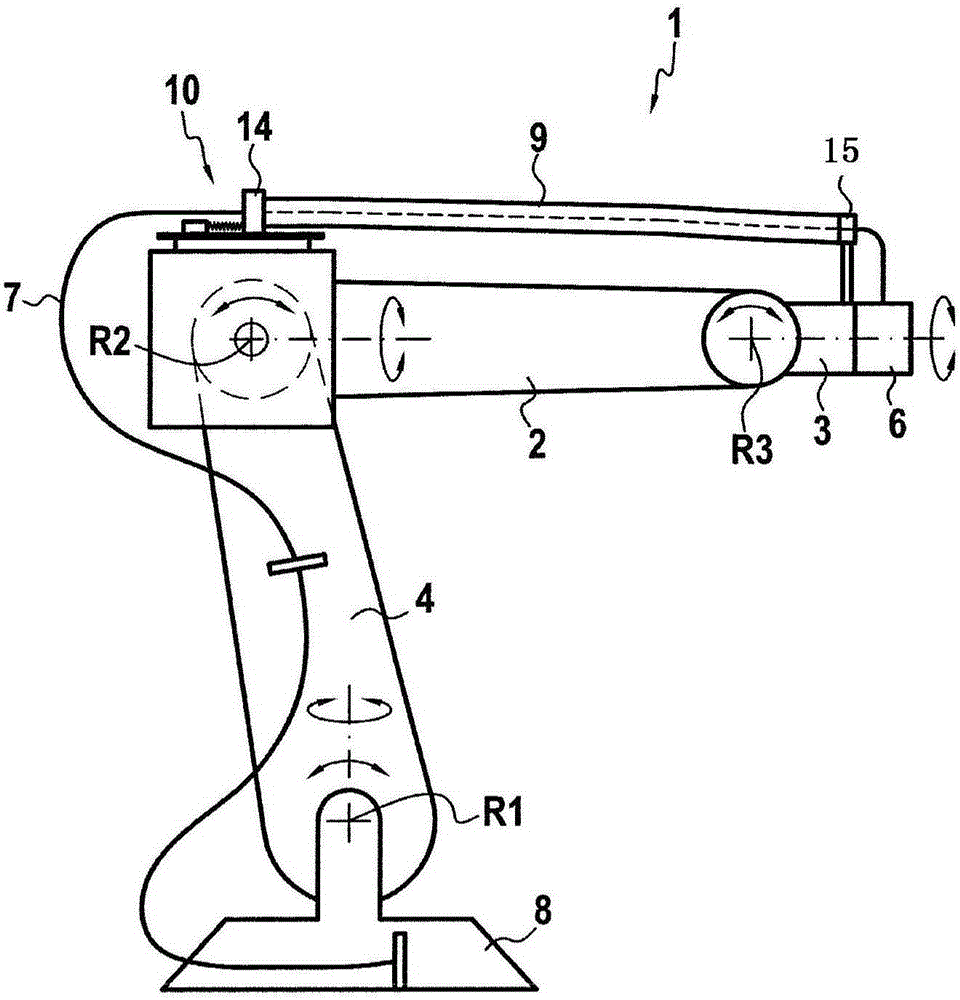

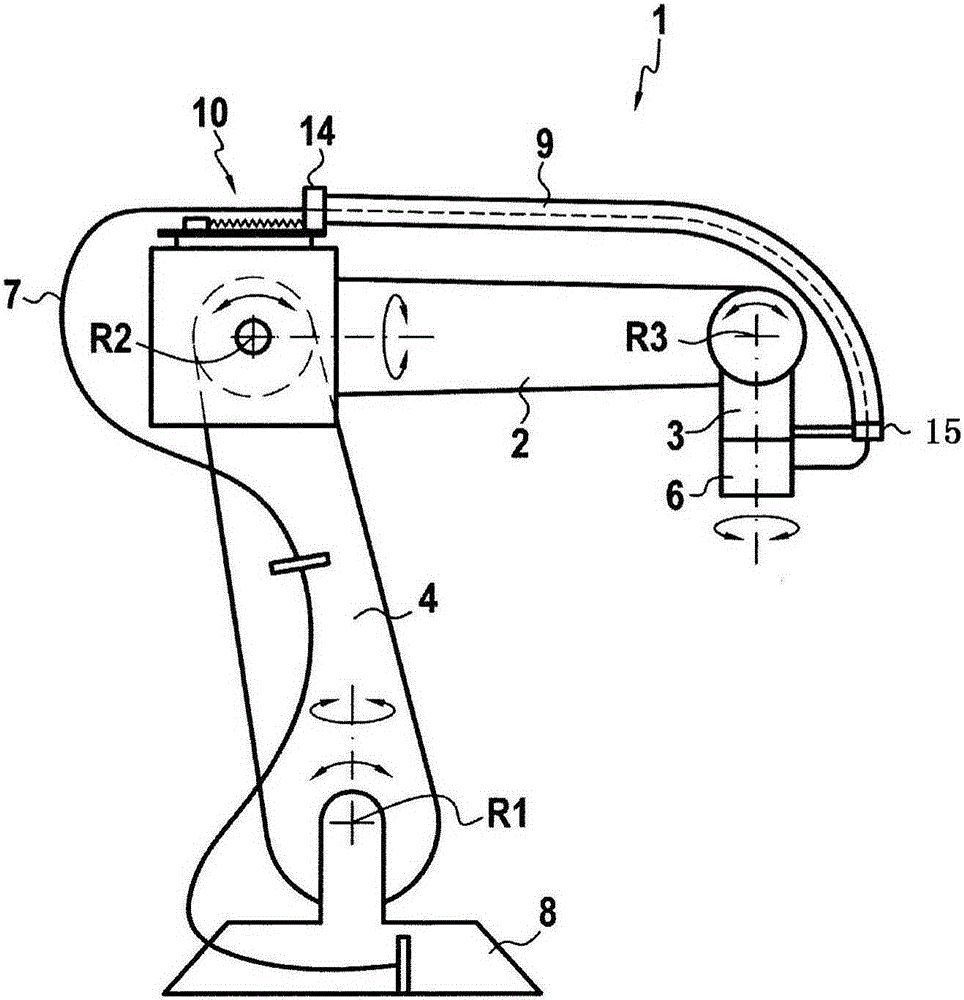

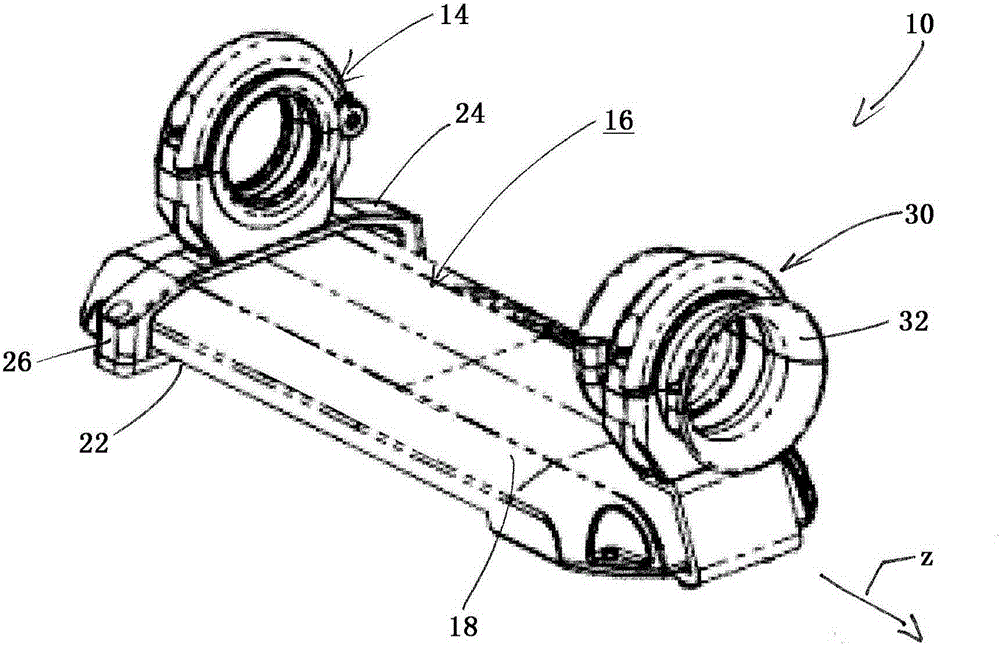

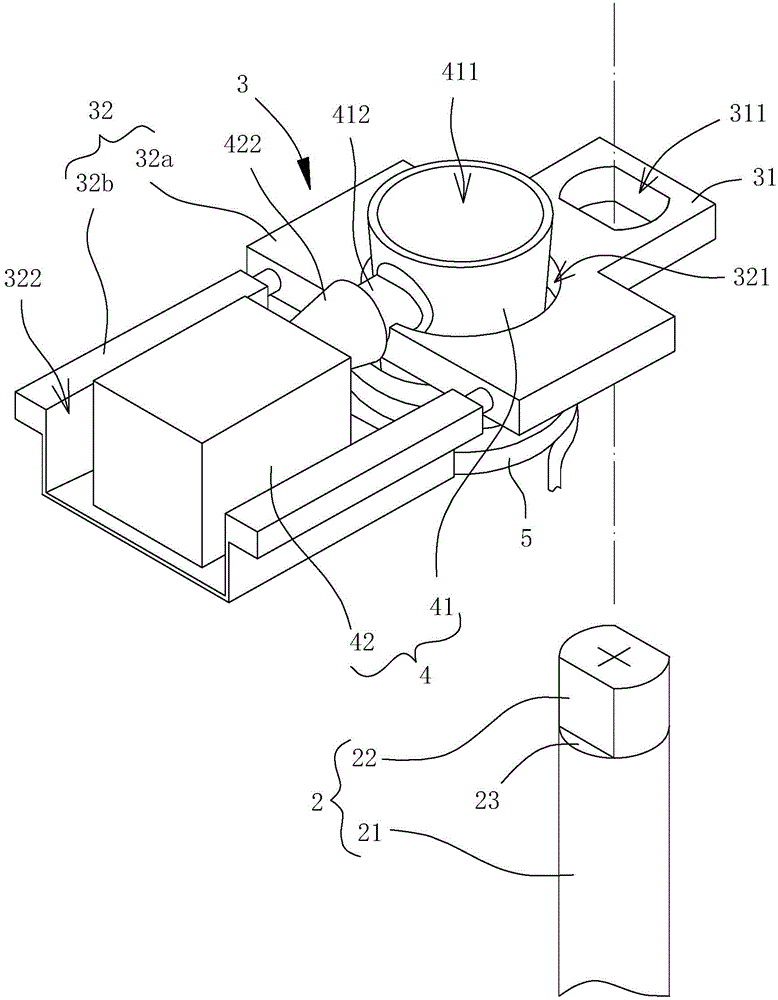

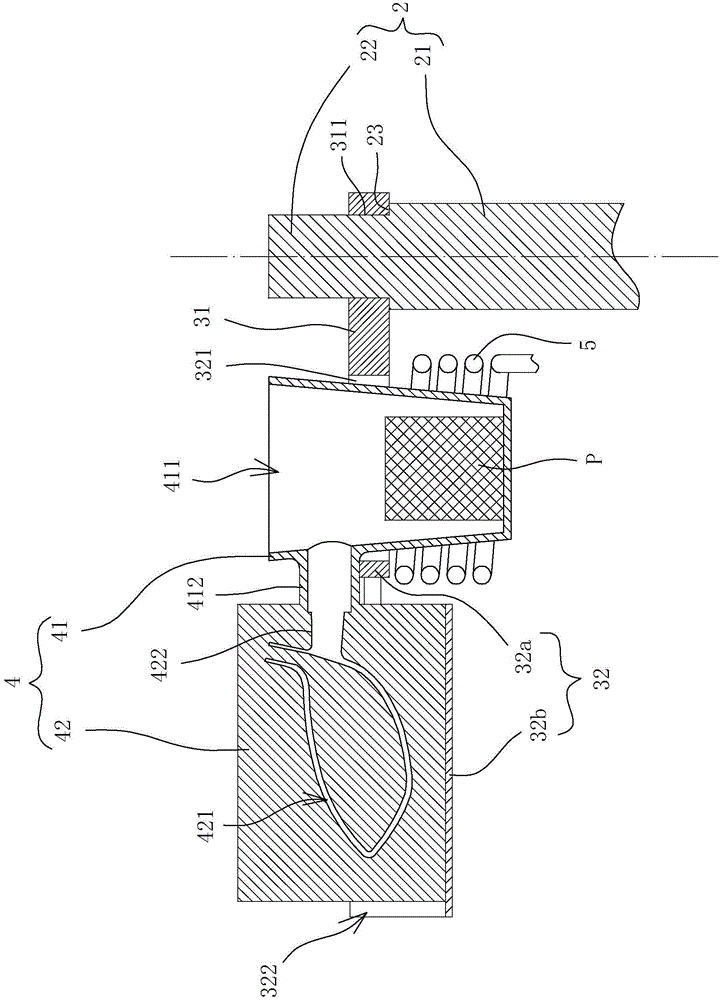

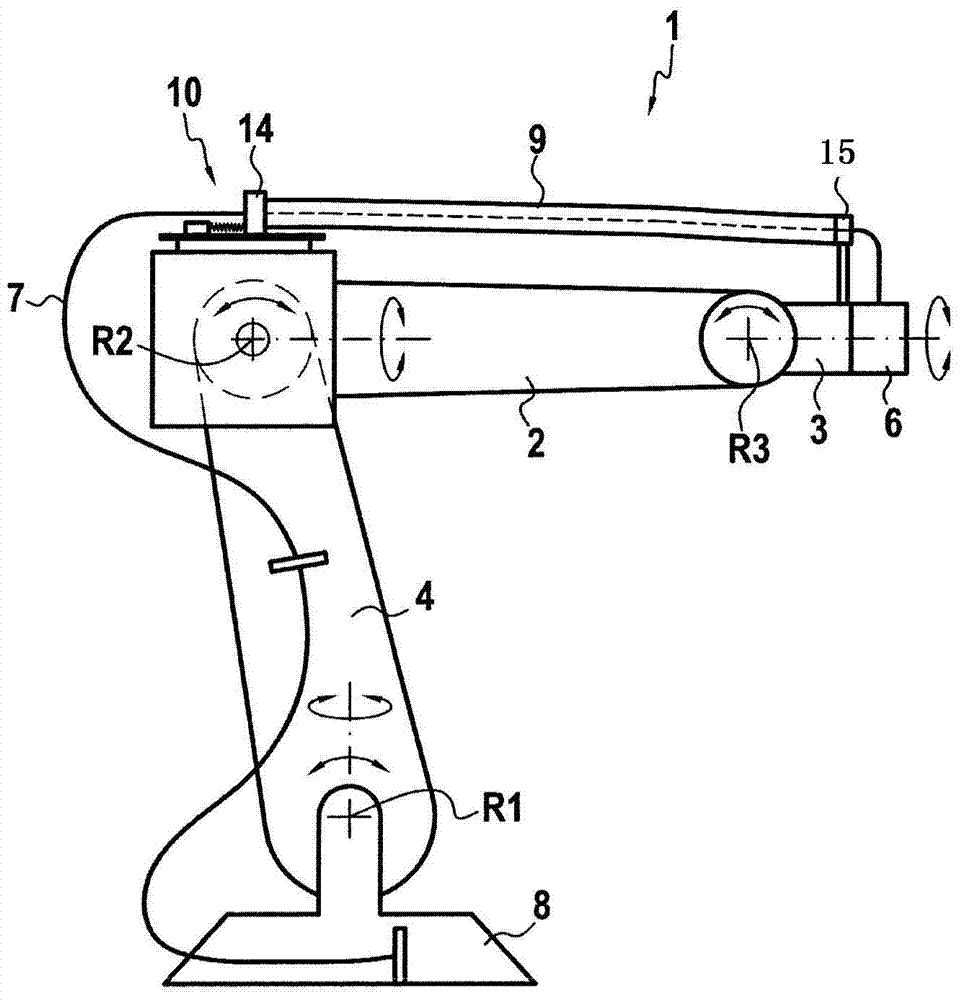

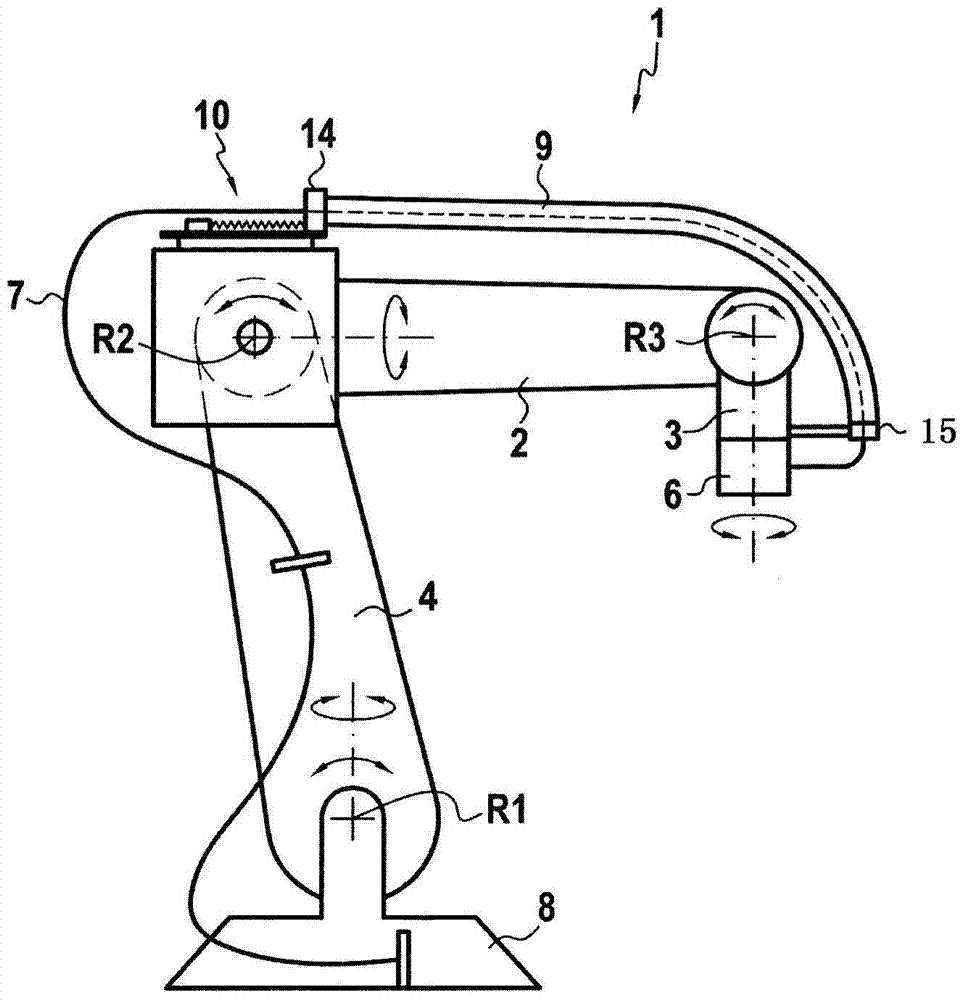

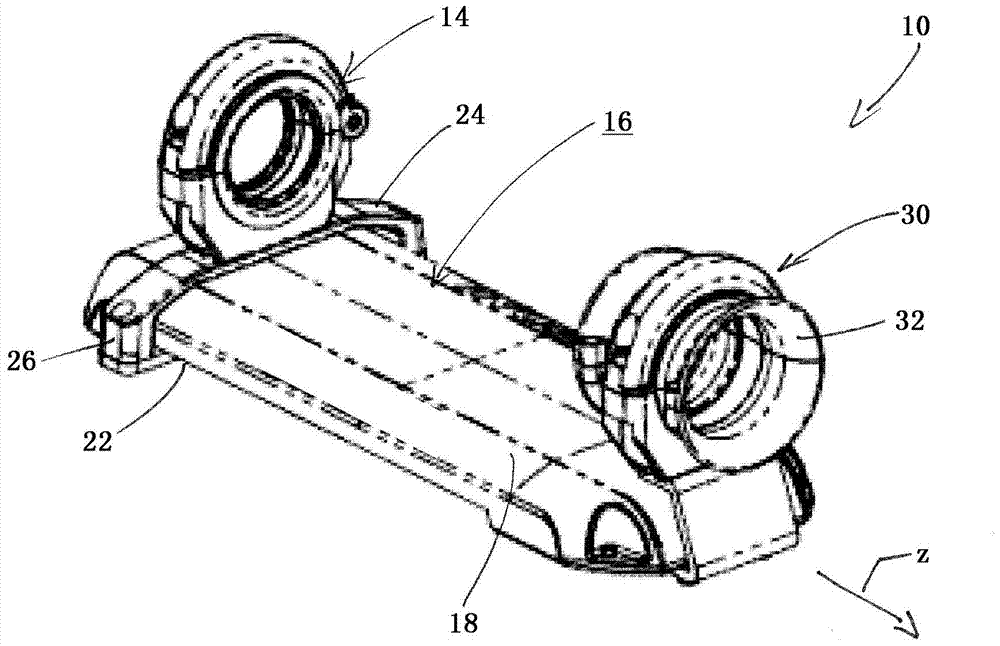

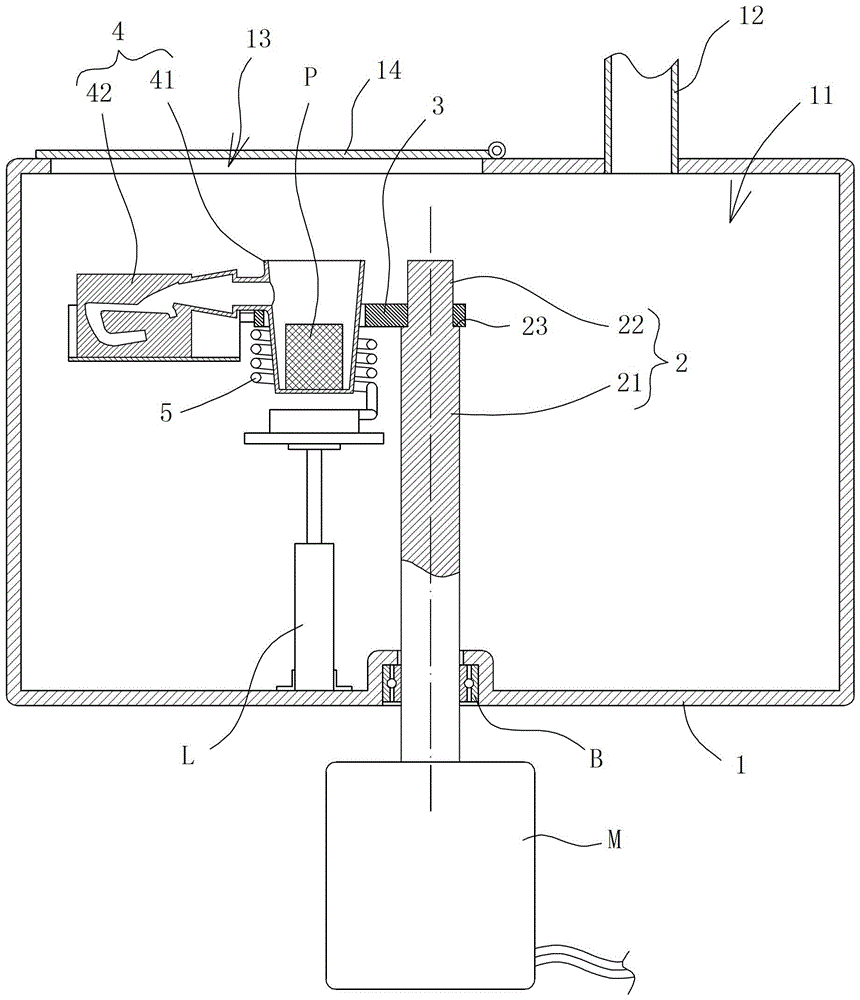

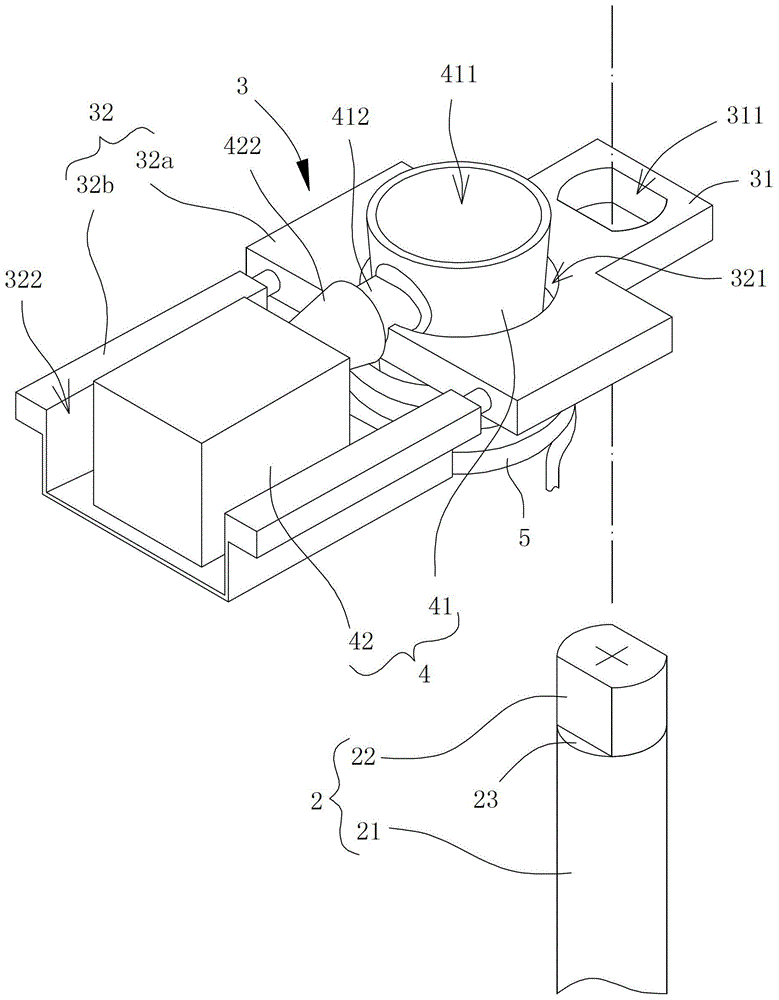

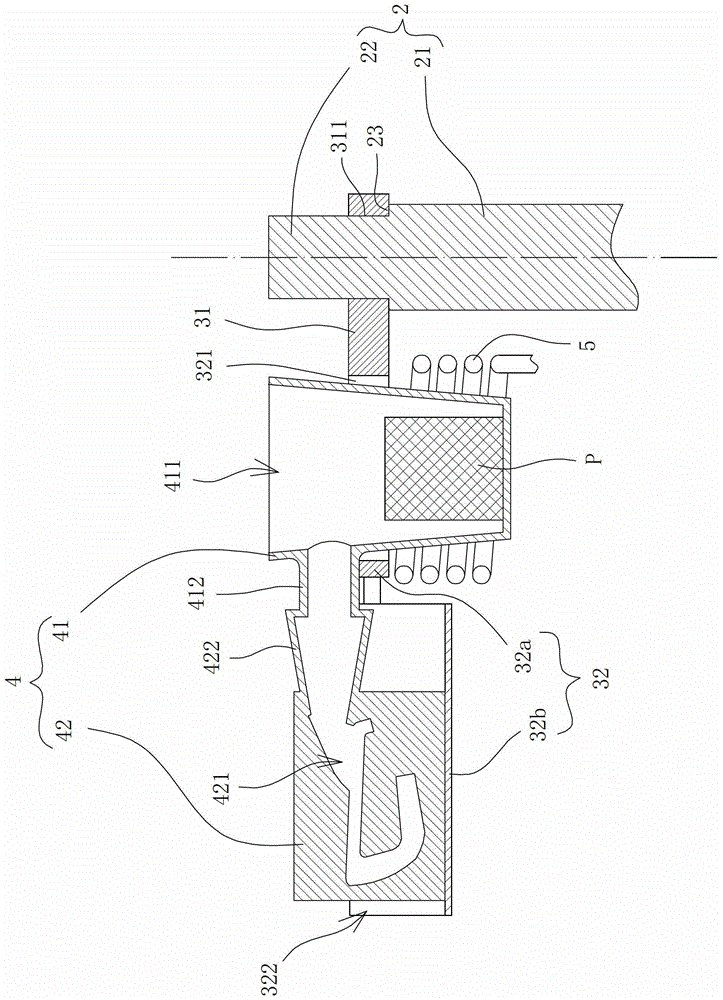

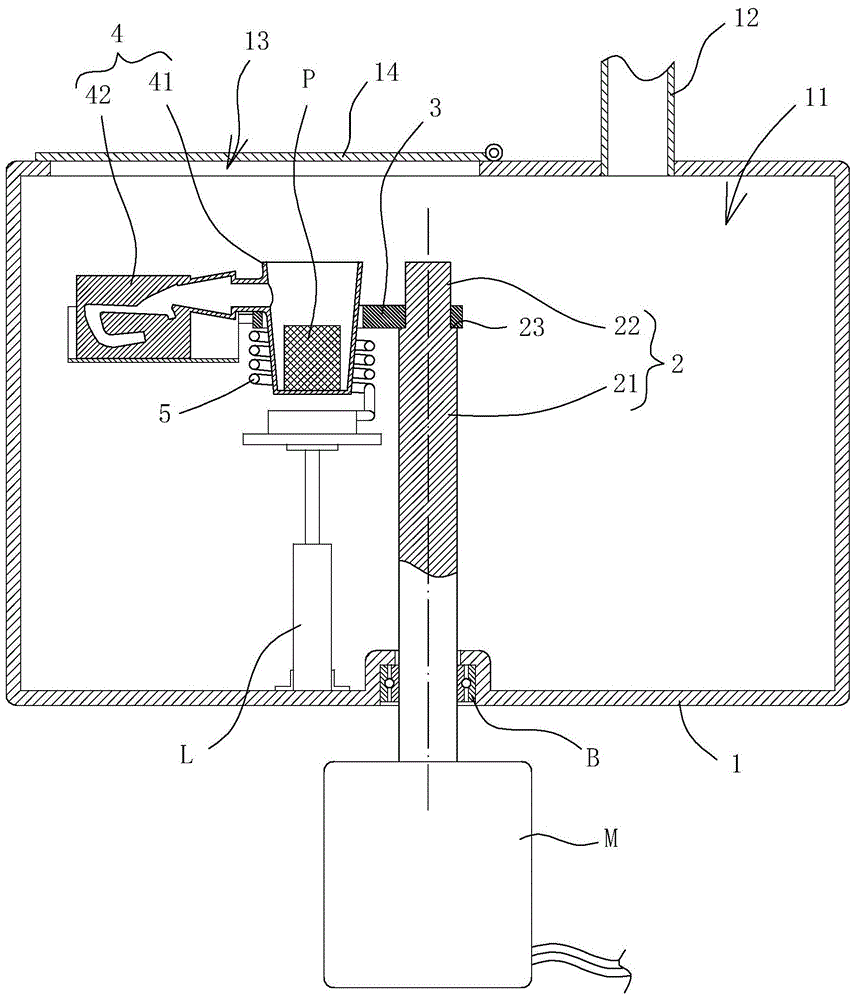

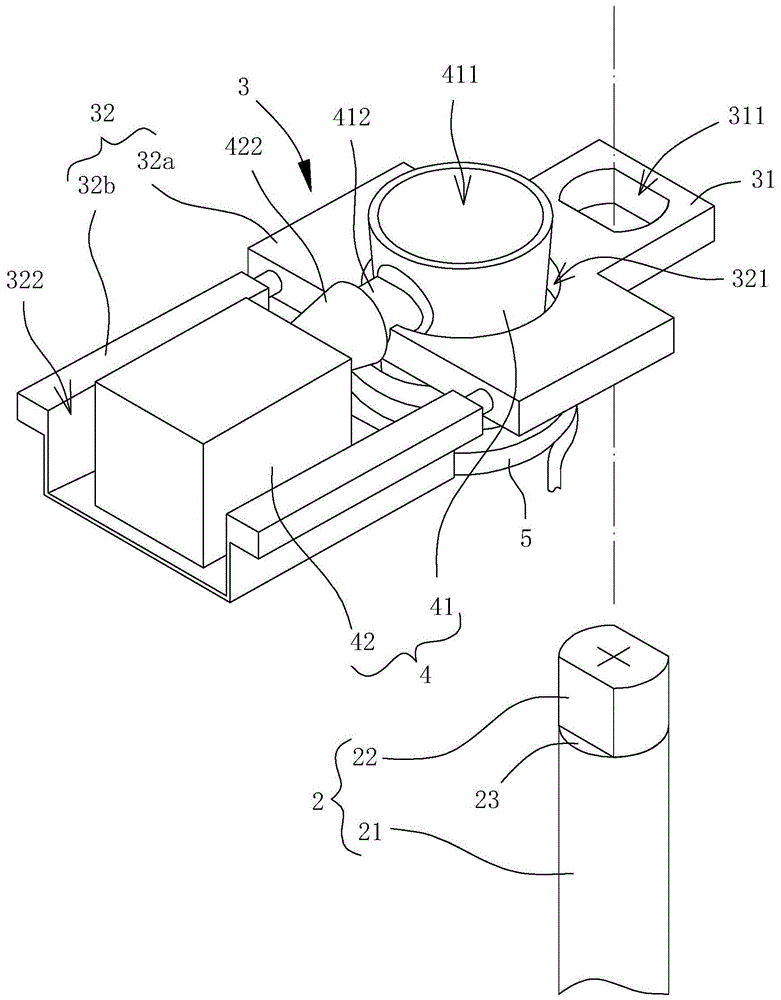

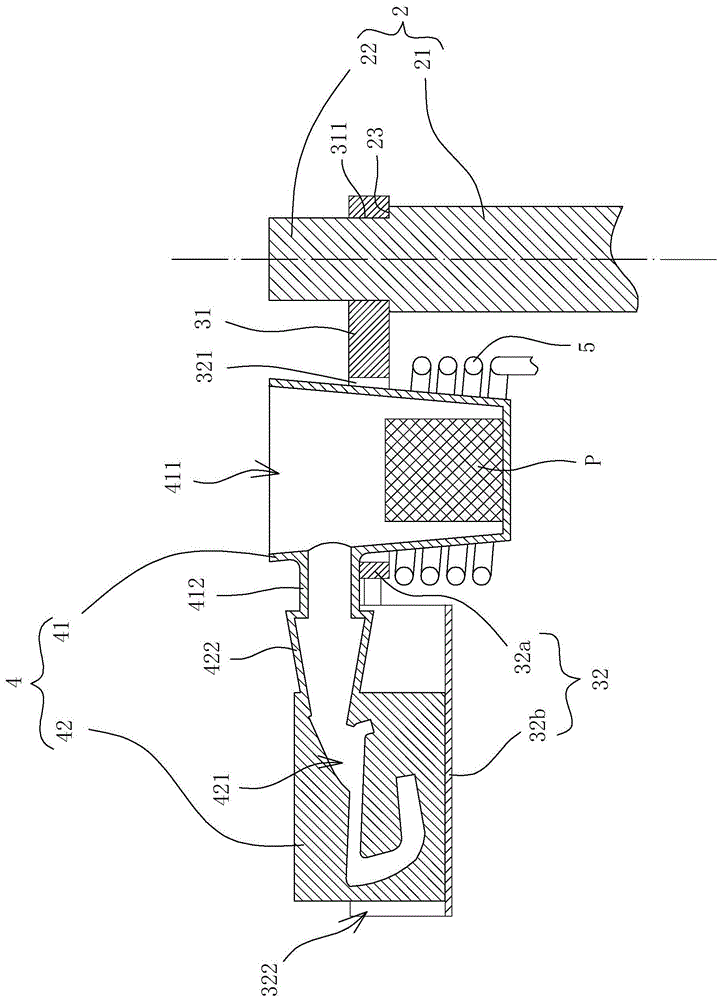

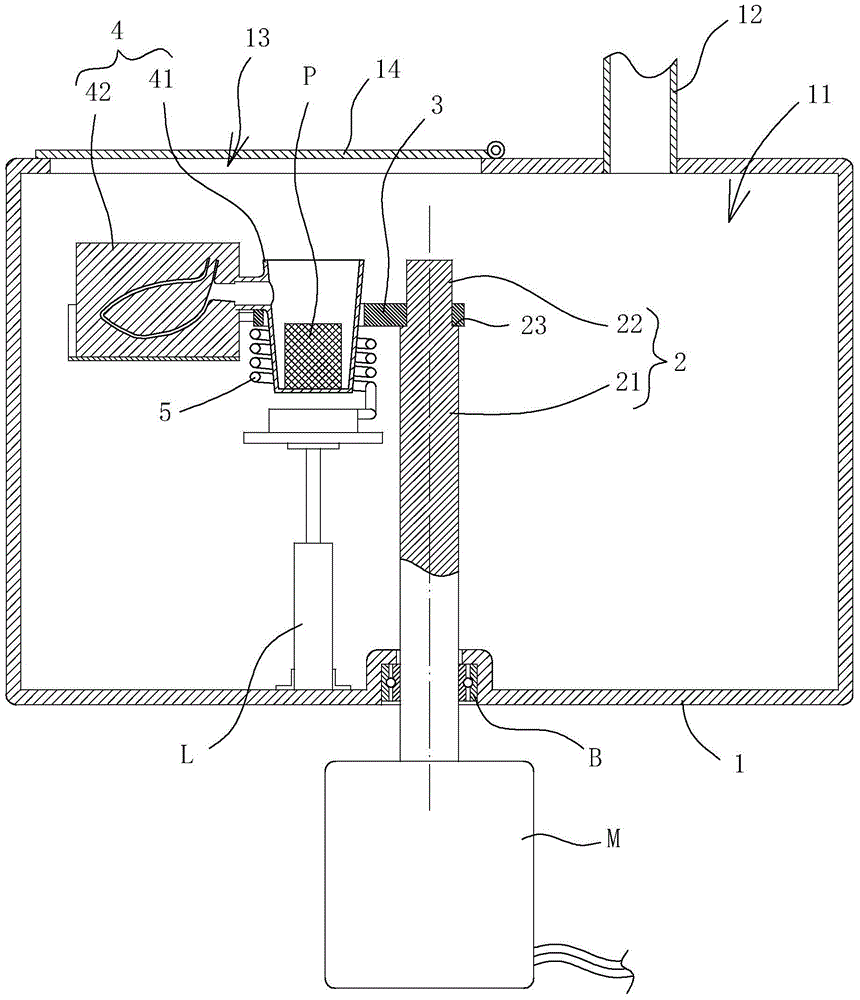

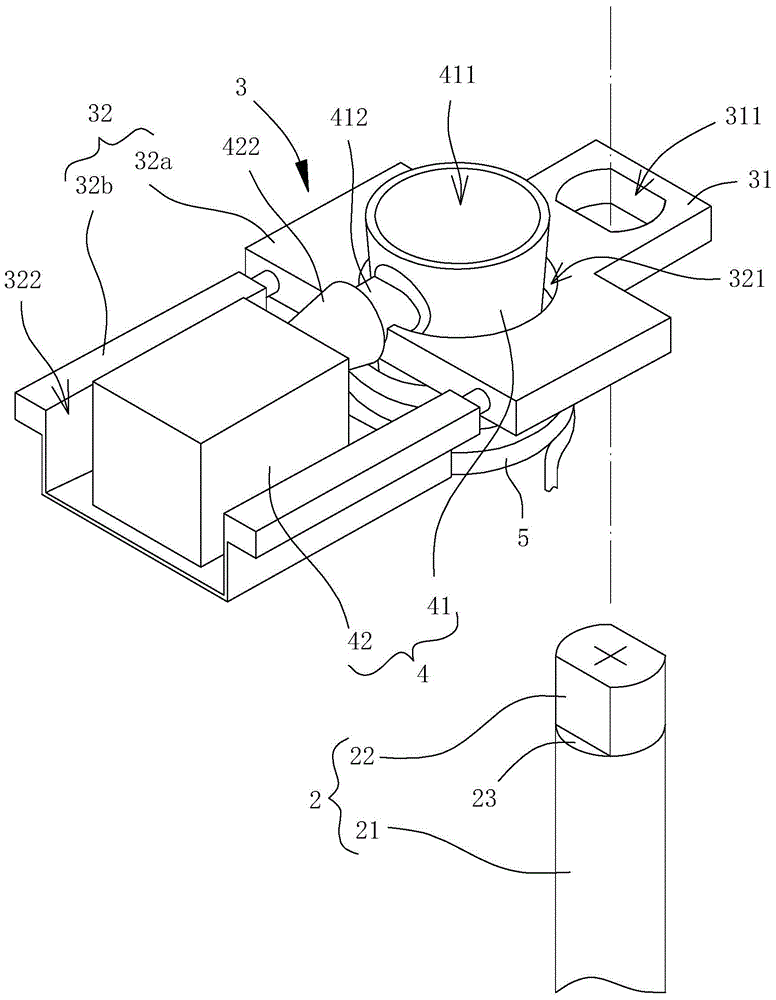

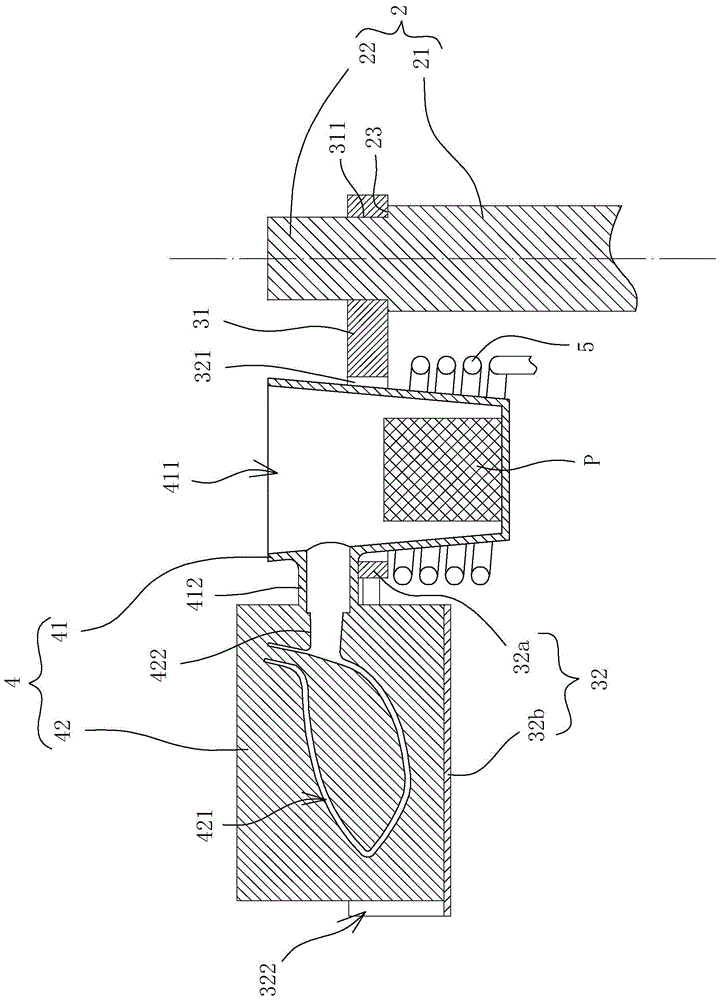

Device for guiding at least one line of a joint arm robot, and joint arm robot

ActiveCN105189054ALarge adjustment strokeReduce hardnessMechanical apparatusArrangements using spring-loaded loopEngineeringManipulator

In order to exert a suitable restoring force in a device (10) for guiding at least one line of a joint arm robot (1), a restoring mechanism (40) is designed to exert an elastic restoring force. The restoring mechanism comprises a guiding unit (42, 20) and a slider element (28) movably mounted on the guiding unit. An elastic restoring unit is arranged between the slider element (28) and the guiding unit (42, 20), said restoring unit having at least one deflecting element, which is preferably designed as a deflecting roller (44, 60), and a flexible strand-like connecting element (46, 66).

Owner:贸联机器人解决方案(德国)有限公司

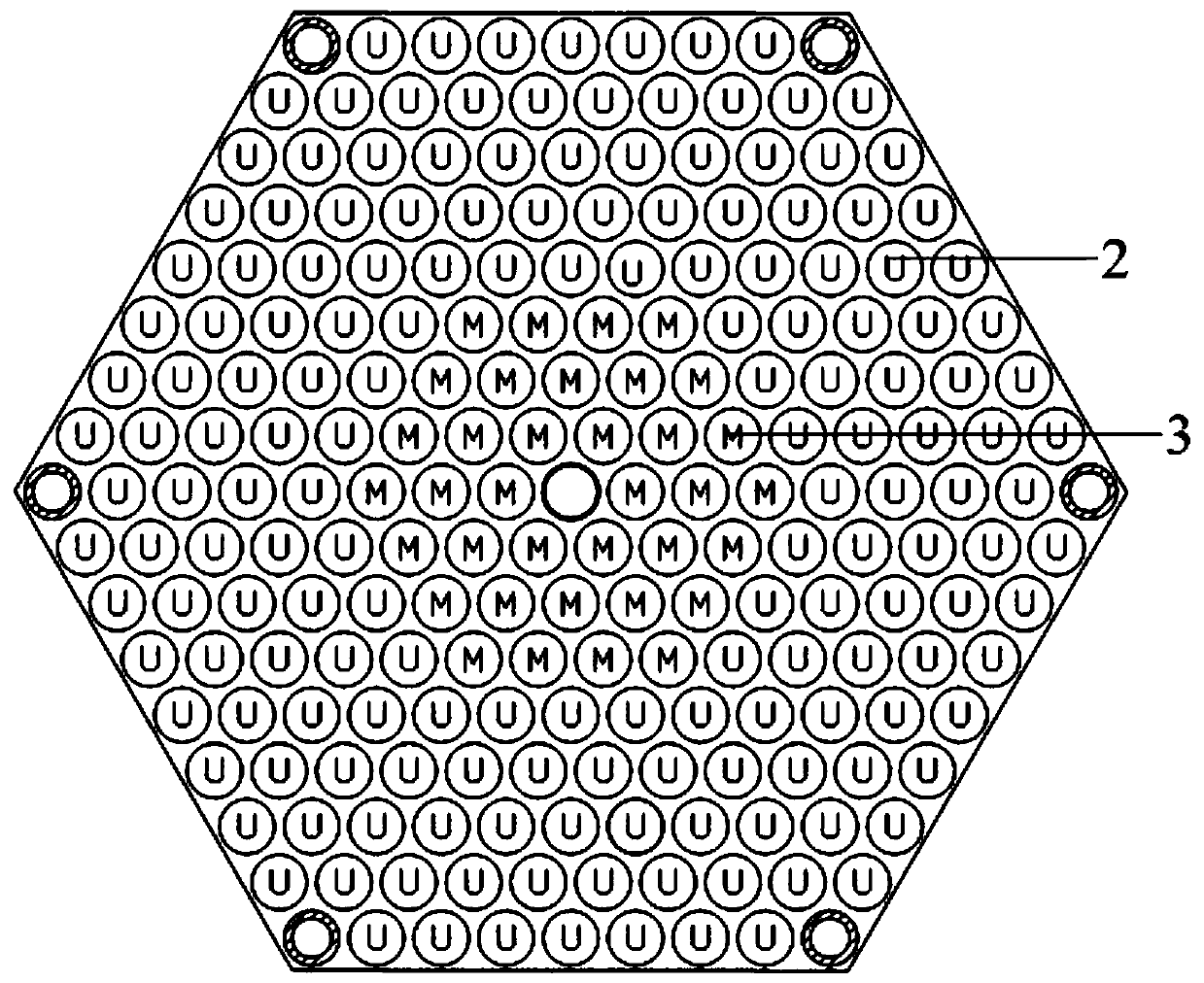

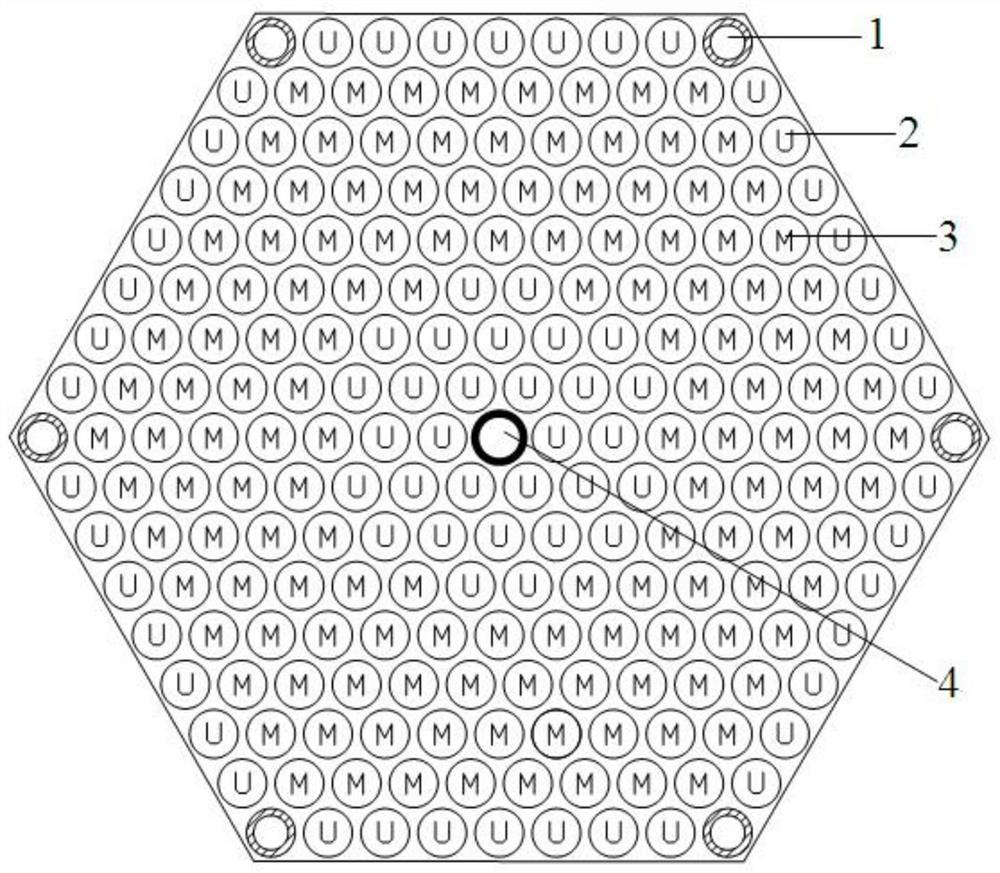

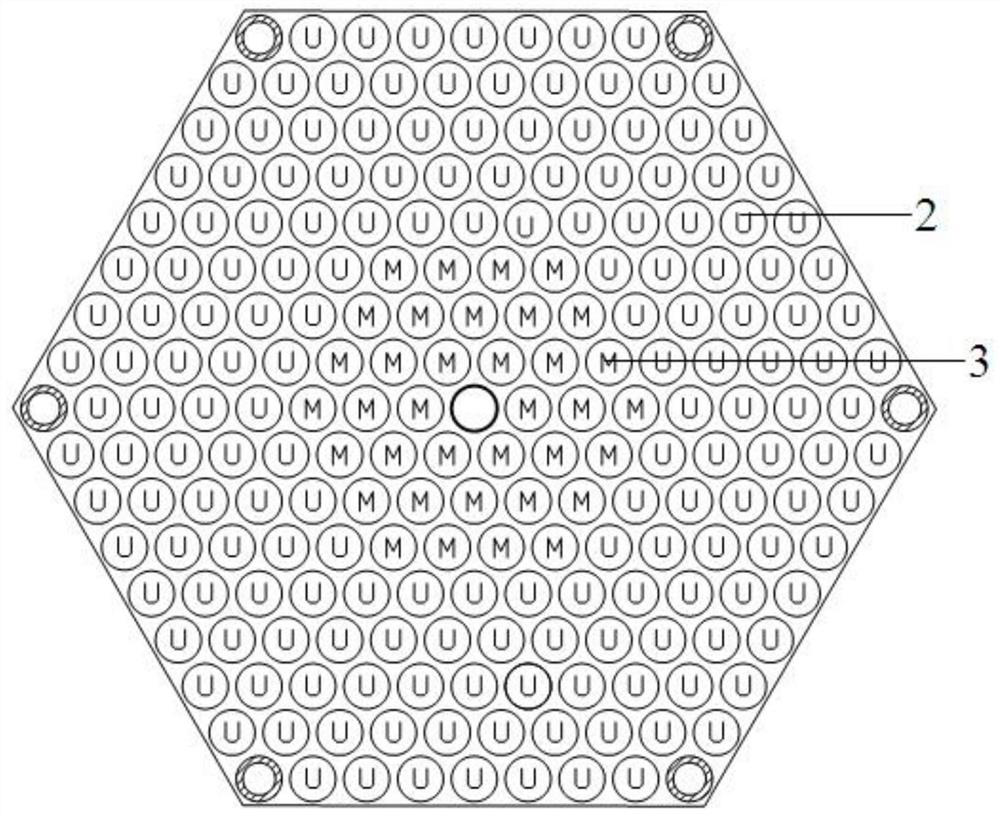

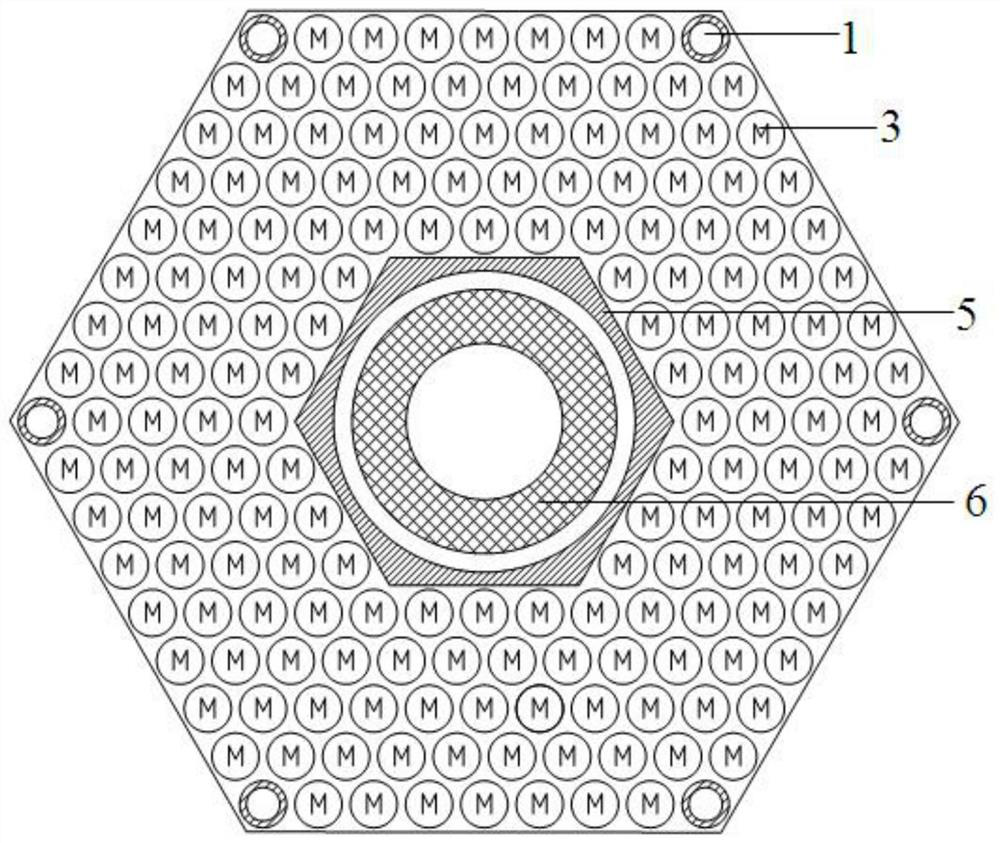

Liquid metal cooling reactor based on increase of fuel utilization rate and management method

ActiveCN110867262AReduce loadingImprove average unloaded fuel consumptionNuclear energy generationShieldingChemistryPlutonium

The invention discloses a liquid metal cooling reactor based on increase of a fuel utilization rate and a management method. A low-temperature intensive moderating component is arranged at the periphery of a reactor core of the reactor; a high-temperature intensive moderating component is arranged at a secondary periphery; and high-power control rod components and high-power intensive moderating components are alternatively arranged in an inner area of the reactor core. According to characteristics of inherent neutronic properties, power and burnup distribution of a liquid metal cooling fast reactor, components of different functions and purposes are constructed, namely a lower-power fuel component which is used at the outermost periphery of the reactor core and used for reducing neutron leakage, and a high-power fuel component and a control rod component which are used inside the reactor core, a unique liquid metal cooling fast reactor core loading scheme is formed, the average unloading burnup and the nuclear fuel conversion rate of the liquid metal cooling fast reactor are remarkably increased, and the engineering realizability of a closed uranium-plutonium fuel cycle system ofthe liquid metal cooling fast reactor is improved.

Owner:NUCLEAR POWER INSTITUTE OF CHINA

Manufacturing method of titanium-alloy golf club head

ActiveCN104550814AIncrease Conversion RatioImprove step rateFoundry mouldsFoundry coresTitanium alloyMaterials science

The invention provides a manufacturing method of a titanium-alloy golf club head. Problems of low transforming proportion between casting materials and casting objects and low yield rate of casting objects in the former casting methods are solved. The manufacturing method includes steps that a shell mold is positioned on a rotation platform and comprises a crucible part and a mold cavity part, wherein the crucible part is communicated with the mold cavity part; the rotation platform is connected to a rotation shaft; solid titanium-alloy casting materials are placed on the crucible part of the shell mold and are heated and fused into liquid titanium alloy in 35-45 seconds in a vacuum environment; the rotation shaft is driven to drive the rotation platform to rotate; the rotation speed of the rotation shaft is 500-800 rpm; the rotation speed of the rotation shaft is accelerated from 0-0.5s to 800-1400 rpm / sec, so the liquid titanium alloy is allowed to flow into the mold cavity part of the shell mold; the rotation speed of the rotation shaft is reduced until the rotation shaft stops, and then a casted shell mold is taken down; the shell mold is damaged, so a casting object comprising a casting piece part is obtained; and the casting piece part is separated from the casting object, so at least one titanium-alloy golf club head is obtained.

Owner:FUSHENG IND CO LTD

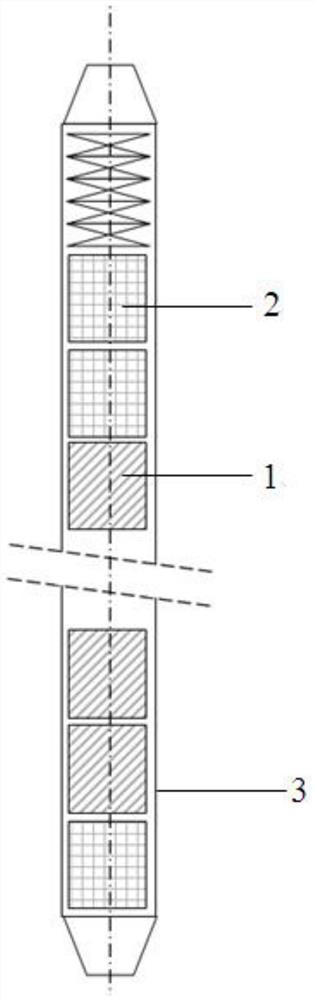

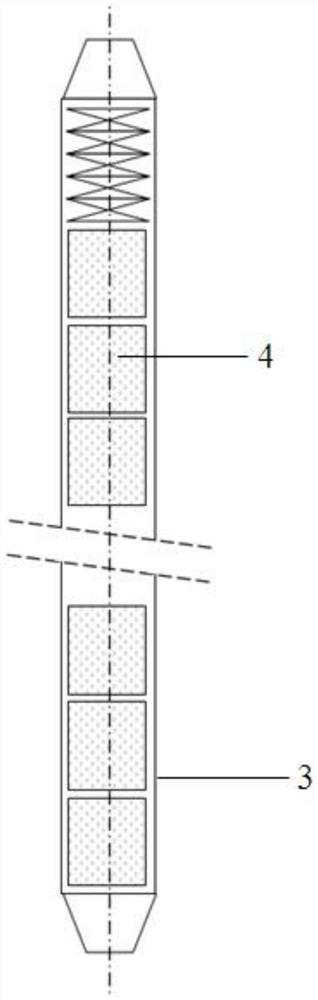

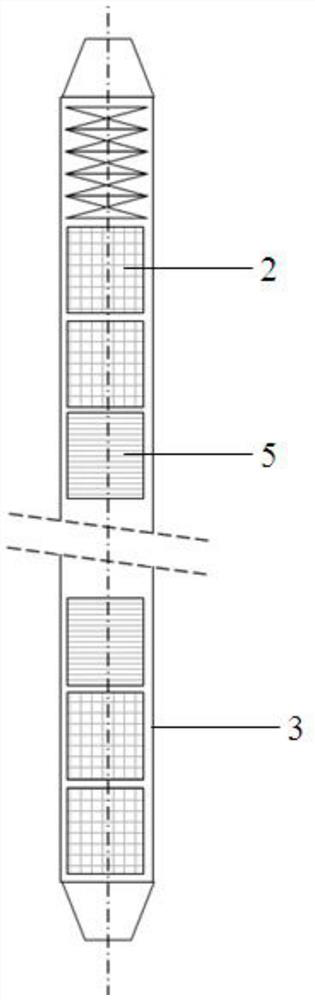

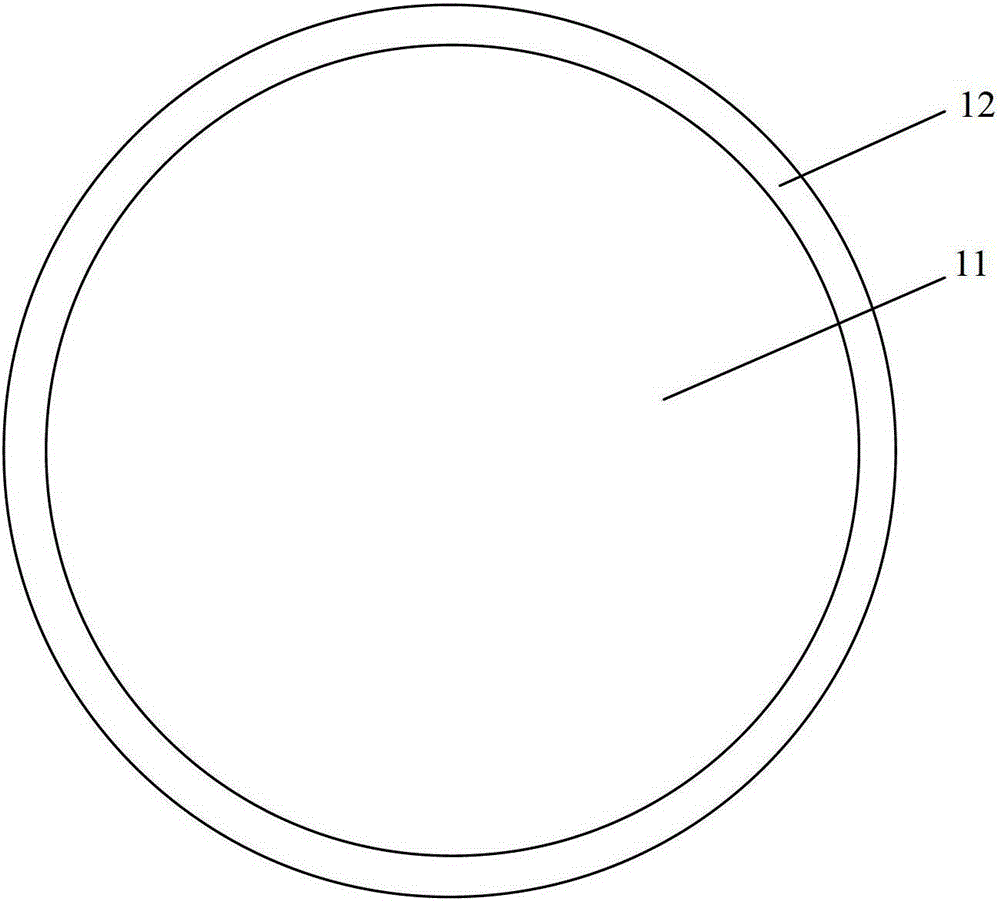

Multi-type core block mixed loading metal cooling reactor and management method

ActiveCN110867261AImprove average unloaded fuel consumptionImprove competitivenessNuclear energy generationReactor fuel susbtancesPhysicsChemistry

The invention discloses a multi-type core block mixed loading metal cooling reactor and a management method. Moderation type assemblies are arranged on the periphery of a reactor core of the reactor;proliferation type fuel assemblies are arranged on the sub-periphery of the reactor core of the reactor; power type fuel assemblies are arranged in the inner region of the reactor core of the reactor;each moderation type assembly consists of a plurality of moderation type elements; each moderation type element comprises a cladding shell; zirconium hydride metal blocks are arranged in the claddingshell; each proliferation type fuel assembly consists of a plurality of proliferation type fuel elements; each proliferation type fuel element comprises a cladding shell; beryllium oxide ceramic coreblocks are arranged at two ends in the cladding shell; natural uranium dioxide fuel core blocks are arranged in the middle of the cladding shell; and each power type fuel assembly consists of a plurality of power type fuel elements; each power type fuel element comprises a cladding shell; beryllium oxide ceramic core blocks are arranged at two ends in the cladding shell; and plutonium-uranium mixed oxide fuel core blocks are arranged in the middle of the cladding shell. The multi-type core block mixed loading metal cooling reactor and the management method provided by the invention solve theproblems of great fuel loading capacity, low utilization rate and the like of the existing metal cooling reactor.

Owner:NUCLEAR POWER INSTITUTE OF CHINA

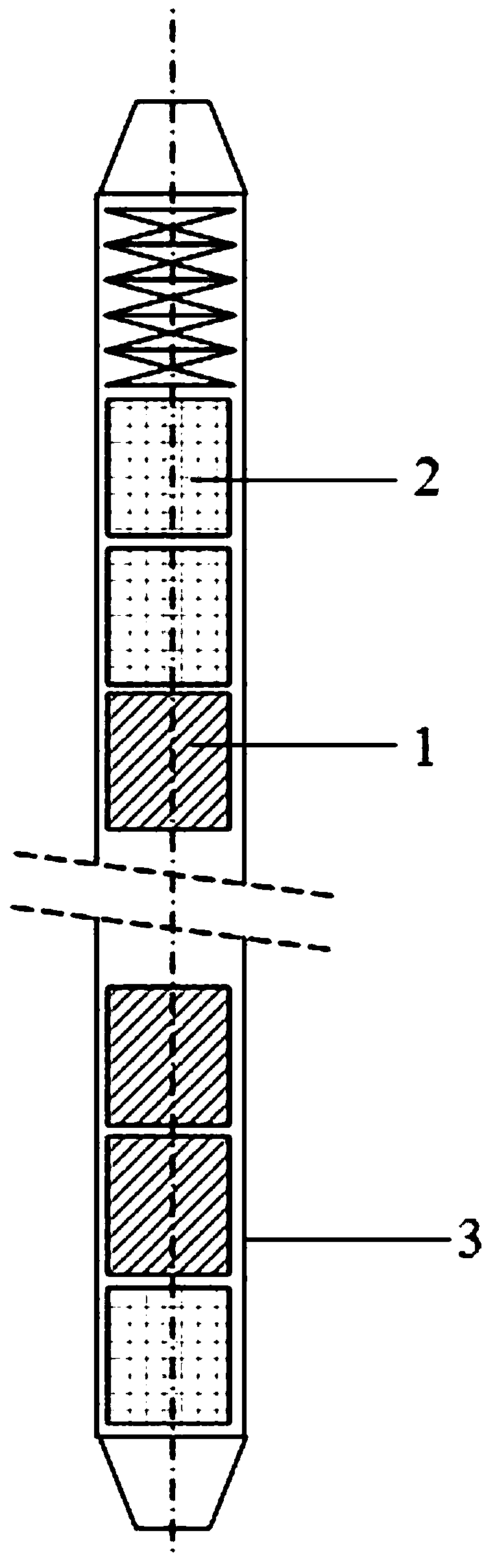

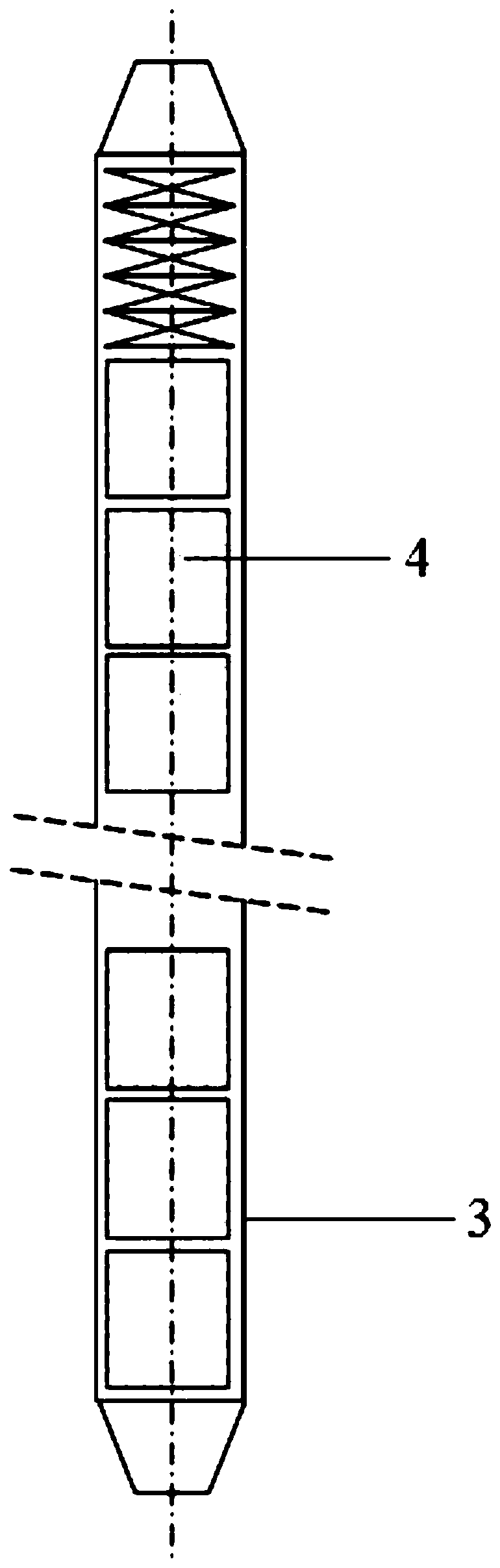

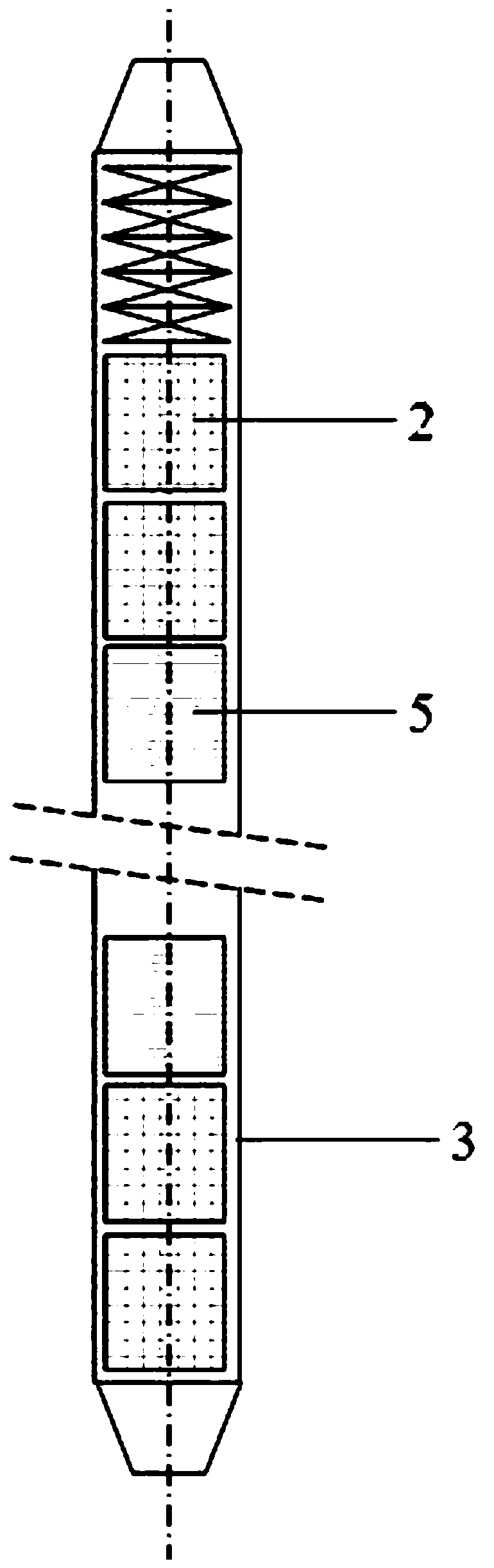

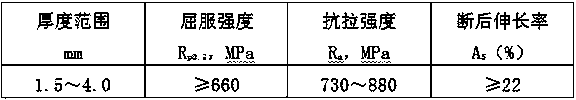

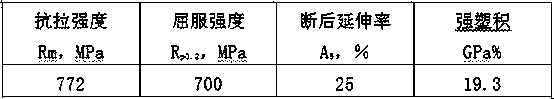

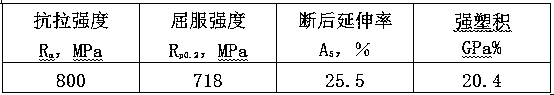

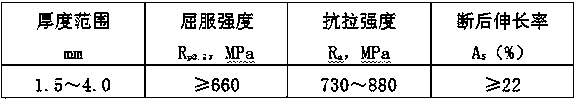

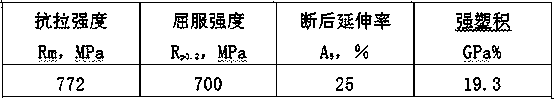

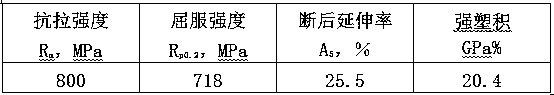

Production process of thin-gauge 700MPa-grade ultra-high strength hot rolled black leather steel strip

The invention discloses a production process of a thin-gauge 700MPa-grade ultra-high strength hot rolled black leather steel strip. The production process includes processes of rough rolling, finish rolling, cooling and coiling; in the process of finish rolling, the finish rolling entry temperature is 1030-1100 DEG C, and the finishing rolling temperature is 830-880 DEG C; in the cooling process,the steel strip is rapidly cooled to 750-790 DEG C through laminar flow cooling, cooled by intermediate air cooling, and then rapidly cooled to coiling temperature through the laminar flow cooling; and in the coiling process, the coiling temperature is 600-650 DEG C. The elongation of the hot rolled black leather steel strip obtained by the production process is not less than 22%; the product of strength and elongation is not less than 16 GMPa%; the steel strip has better cold forming performance and is suitable for producing cold roll forming hollow steel sections such as passenger car skeletons, truck side beams, and through beams; mechanical properties and coating surface quality requirements are met under the condition of omitting the processes of pickling chemical rust removal and mechanical rust removal; and the hot rolled black leather steel strip obtained by the production process is used to replace the Q345B, and can reduce the thickness of required steel plates, the weight ofa whole vehicle and the fuel consumption of the vehicle while the strength of a vehicle body is increased.

Owner:TANGSHAN STAINLESS STEEL +1

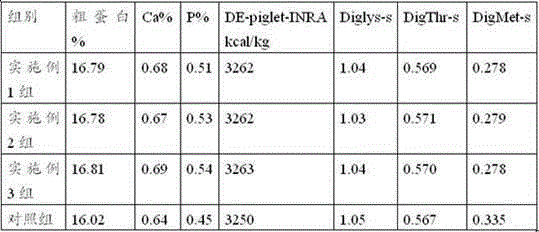

Sorghum medium pig feed and preparation method thereof

InactiveCN104982754AImprove digestion utilizationImprove digestionAnimal feeding stuffAbsorption capacityPhytase

The invention discloses sorghum medium pig feed and a preparation method thereof. The sorghum medium pig feed comprises corn, 46% bean pulp, corn DDGS, rice bran, sorghum, a premixing compound and a liquid enzymic preparation. The sorghum medium pig feed and the preparation method thereof have the advantages that the American sorghum low in tannin content is used for replacing the corn at a high price, an appropriate quantity of the liquid enzymic preparation containing phytase is added, in this way, the digestion and absorption capacity of pigs for all nutrients is remarkably improved, the digestive utilization ratio of the sorghum is improved, and therefore the consumption of the corn and the bean pulp in the formula is reduced; by adding some traditional Chinese additives, the sorghum medium pig feed has the auxiliary functions of harmonizing the stomach for descending adverse qi, warming the spleen and reinforcing the kidneys, in this way, the appetite and the absorbing performance of the pigs are improved, and the material-pork conversion ratio is higher; the feed utilization efficiency is improved, the pigs are promoted to grow, the feed cost is reduced, and the economic benefits are increased.

Owner:SHANDONG NEW HOPE LIUHE GROUP

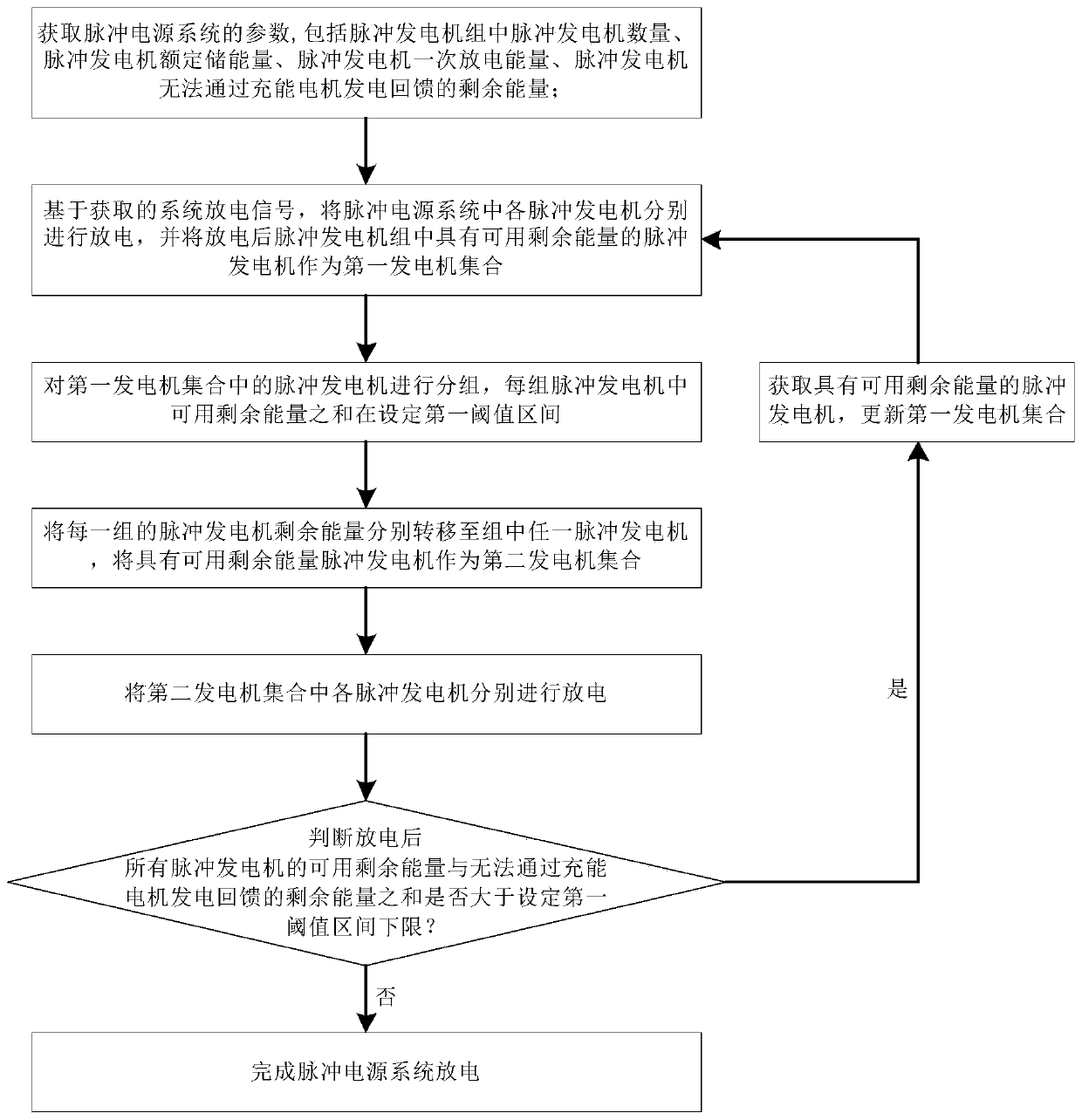

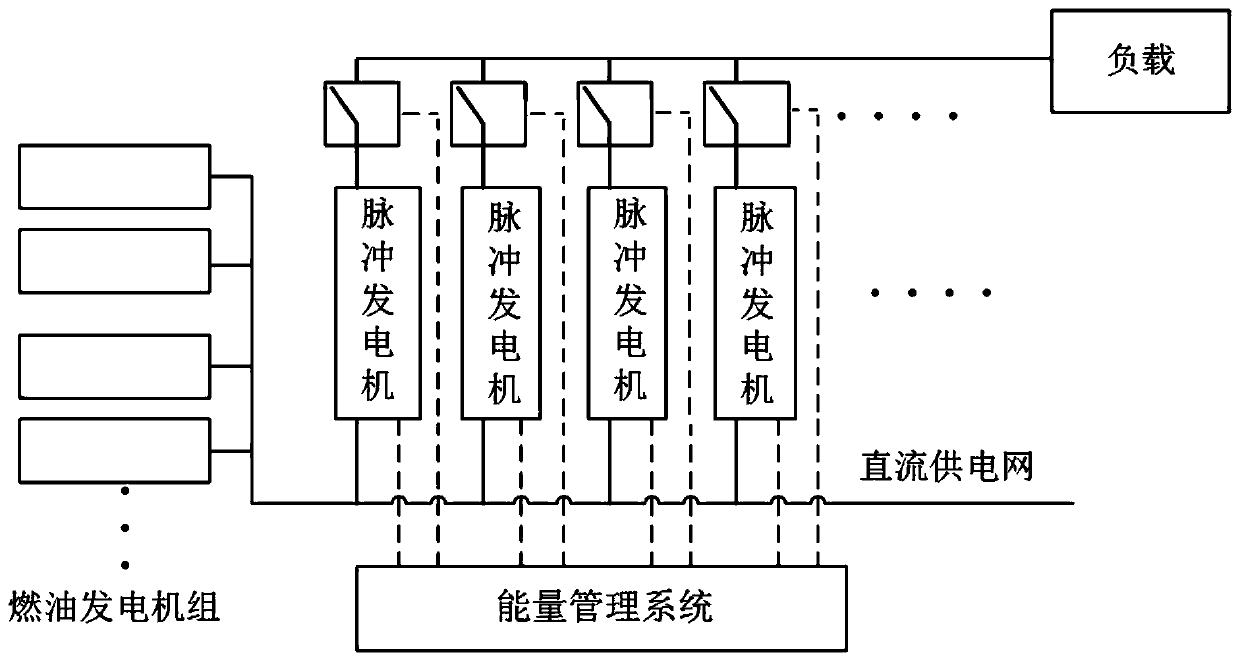

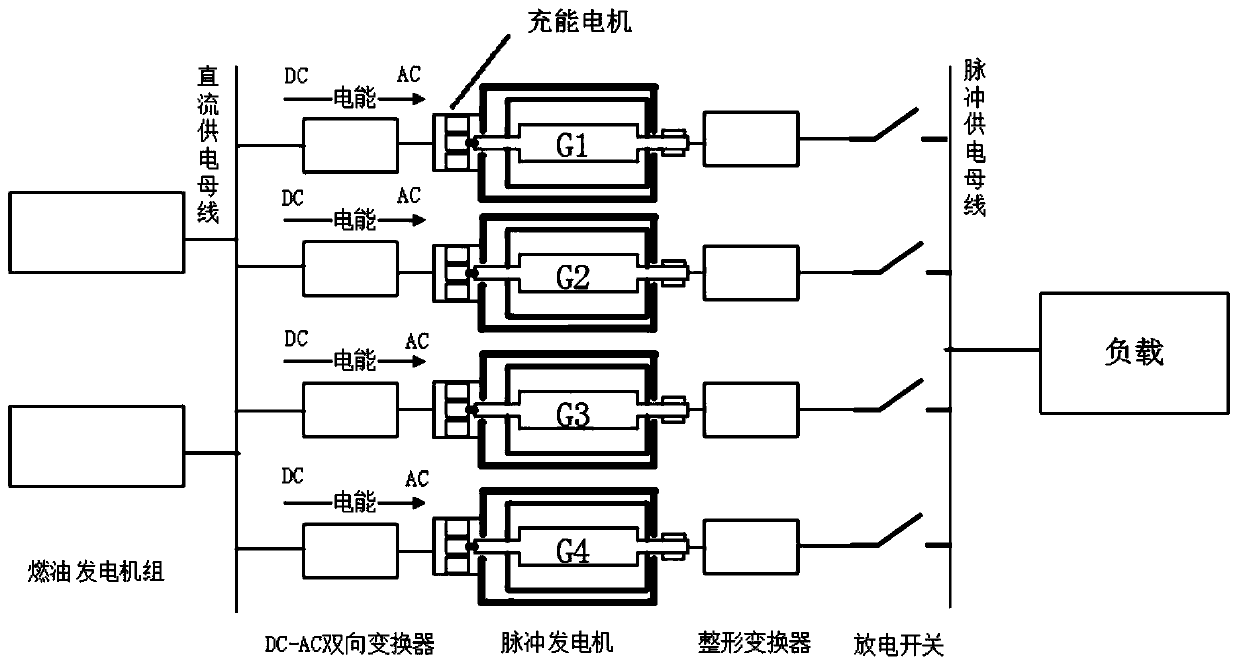

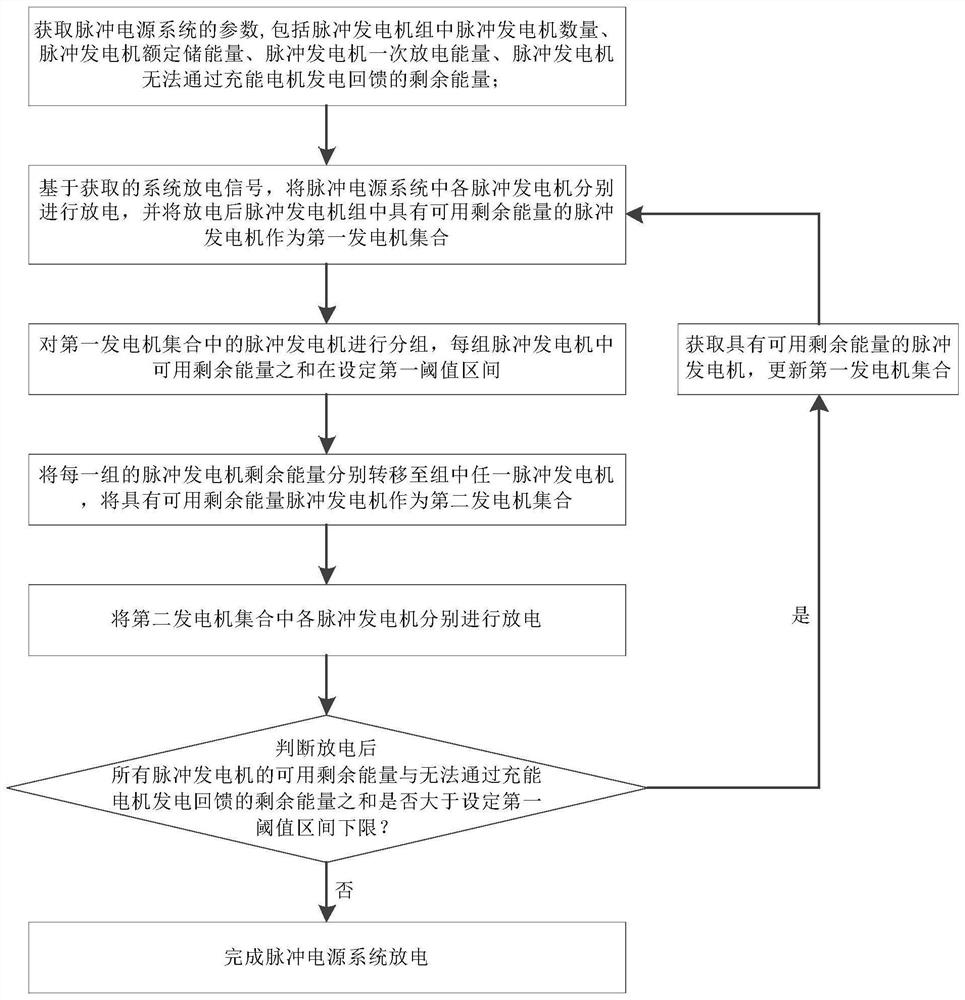

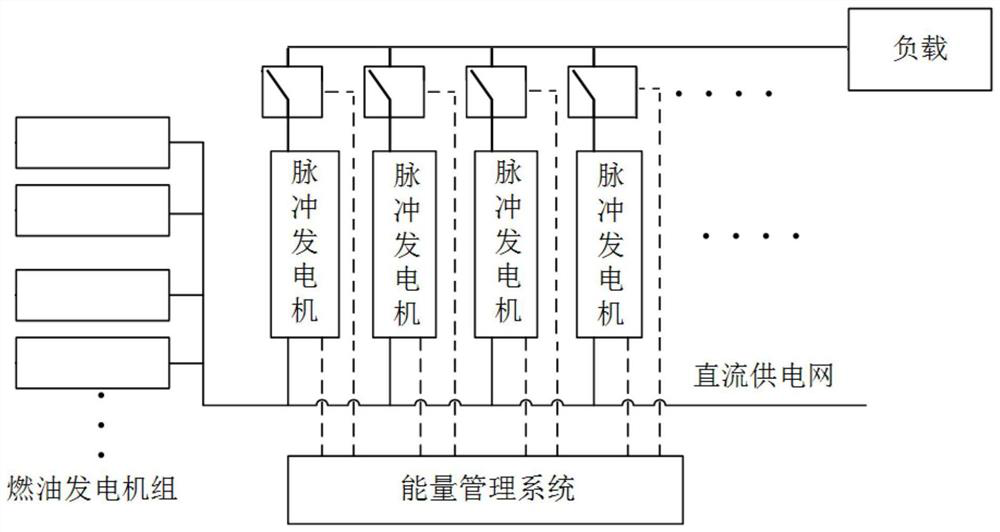

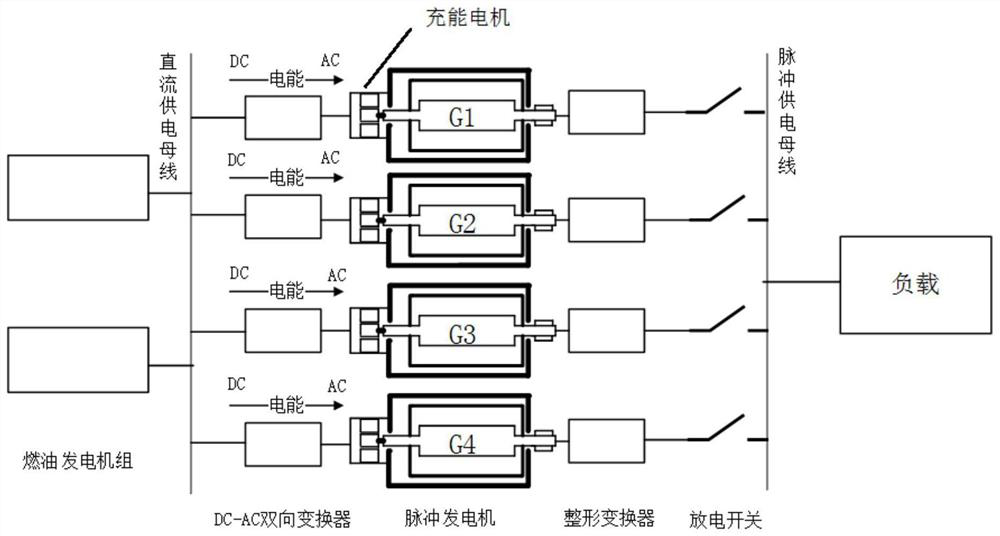

Pulse power supply system based on generator cluster and energy storage microgrid and discharging method

ActiveCN110867888AUnavailable solutionIncrease profitSingle network parallel feeding arrangementsAc network load balancingMicrogridPulse power supply

The invention belongs to the field of pulse power generation, particularly relates to a pulse power supply system based on a generator cluster and an energy storage microgrid and a discharging method,and aims to solve the problem that residual energy of a pulse generator cannot be fully utilized in the prior art. The method comprises the following steps: respectively discharging each pulse generator based on a system discharge signal and parameters; grouping the pulse generators, and transferring the residual energy of each group to any pulse generator in the group; discharging again, grouping the pulse generators with available residual energy, and performing energy transfer again; and iteratively discharging the pulse generator set until the rotating speed of the pulse generator is reduced to the condition that discharge and the power generation indexes do not meet the requirements. According to the invention, by utilizing the characteristic that through the controllable rectification of charging motor, constant-voltage power generation can be carried out in a wide rotating speed range, so residual energy can be transferred in the pulse generator cluster, the conversion ratio from inertia kinetic energy to pulse electric energy is improved from the system level, and the energy utilization rate is improved.

Owner:INST OF ELECTRICAL ENG CHINESE ACAD OF SCI

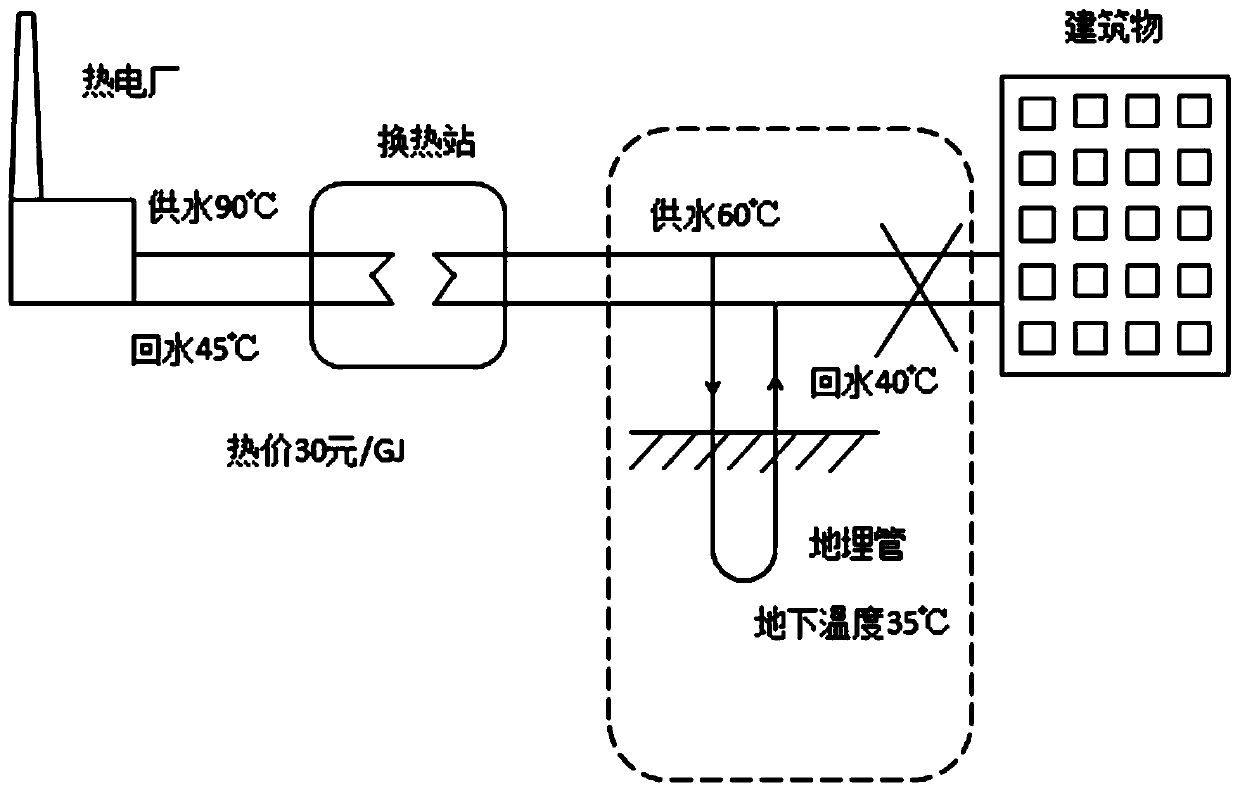

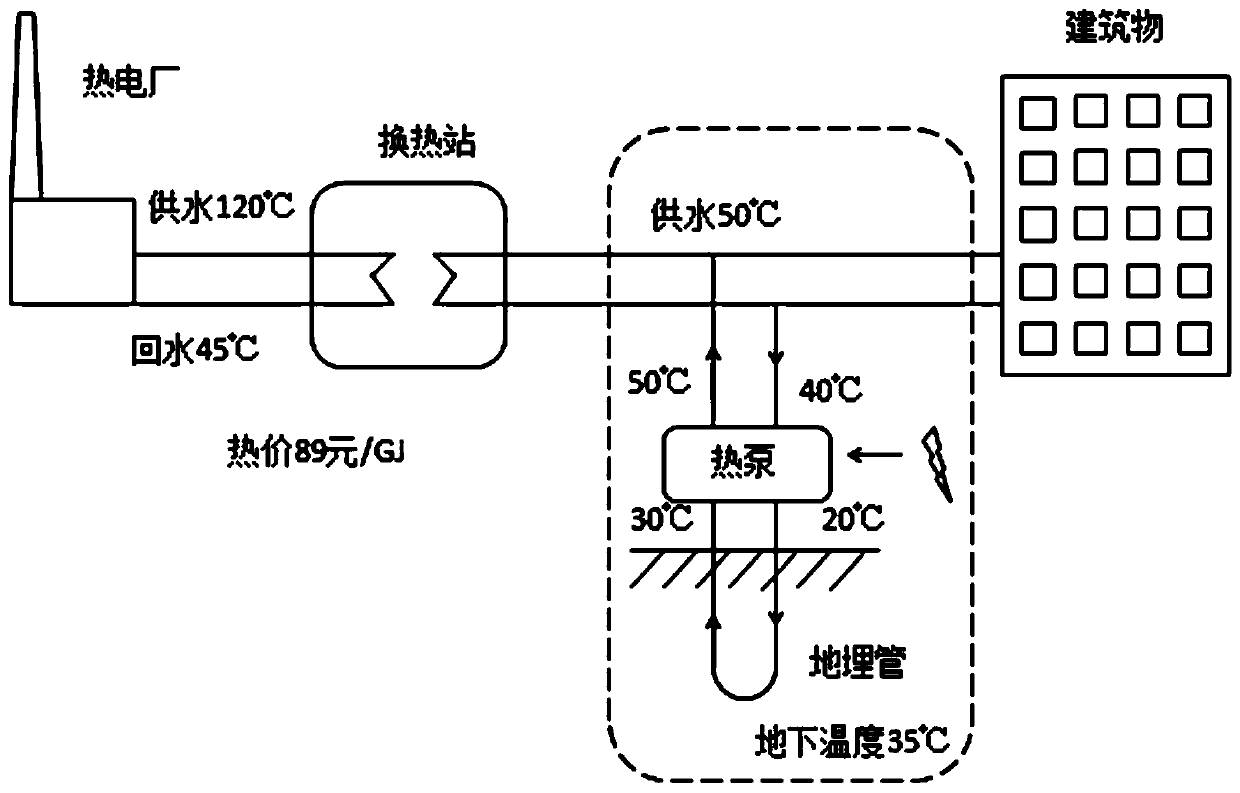

Terrestrial heat season-crossing heat storage and supply method and system through heat supply network

ActiveCN109764400AReduce consumptionImprove conversion ratioCentral heating with accumulated heatLighting and heating apparatusPublic open spaceProcess engineering

The invention discloses a terrestrial heat season-crossing heat storage and supply method and system through a heat supply network. A terrestrial heat storage unit is arranged through an existing heat-supply pipe network and the space, nearby a user building, in a heat supply plant, on the non-heat-supply season, an urban heating network system is used for enabling redundant low-cost waste heat tobe stored underground, on the heat supply season, a heat pump system is used for extracting the heat stored underground to be changed into a product, profits are achieved, meanwhile, the consumptionof fossil fuel in winter can be reduced, and the urban heat supply network burdens and atmospheric pollutions are relieved; the problem of season heat supply need imbalance is solved, and the method and system can be suitable for large-area popularization of the residential area and the public open space; the method and system are supplemented with the concentrated heat supply, the system reliability is improved, the large network load can be reduced, the heat supply load high-peak use is considered, and the design of redundancy of the heat supply system can be reduced.

Owner:北京市热力集团有限责任公司

Device for guiding at least one line of an articulated arm robot and articulated arm robot

ActiveCN105189054BLarge adjustment strokeSmall spring hardnessMechanical apparatusManipulatorEngineeringManipulator

In order to apply a suitable restoring force in the device (10) for guiding at least one path of the articulated arm manipulator (1), a restoring mechanism (40) for applying an elastic restoring force is formed. The reset mechanism comprises a guide unit (42, 20) and a slide element (28) movably supported on the guide unit. Between the sliding element (28) and the guide unit (42, 20) is arranged an elastic reset unit, which has at least one deflection element preferably configured as a deflection roller (44, 60) and a flexibly curved, strip-shaped Connecting elements (46, 66).

Owner:贸联机器人解决方案(德国)有限公司

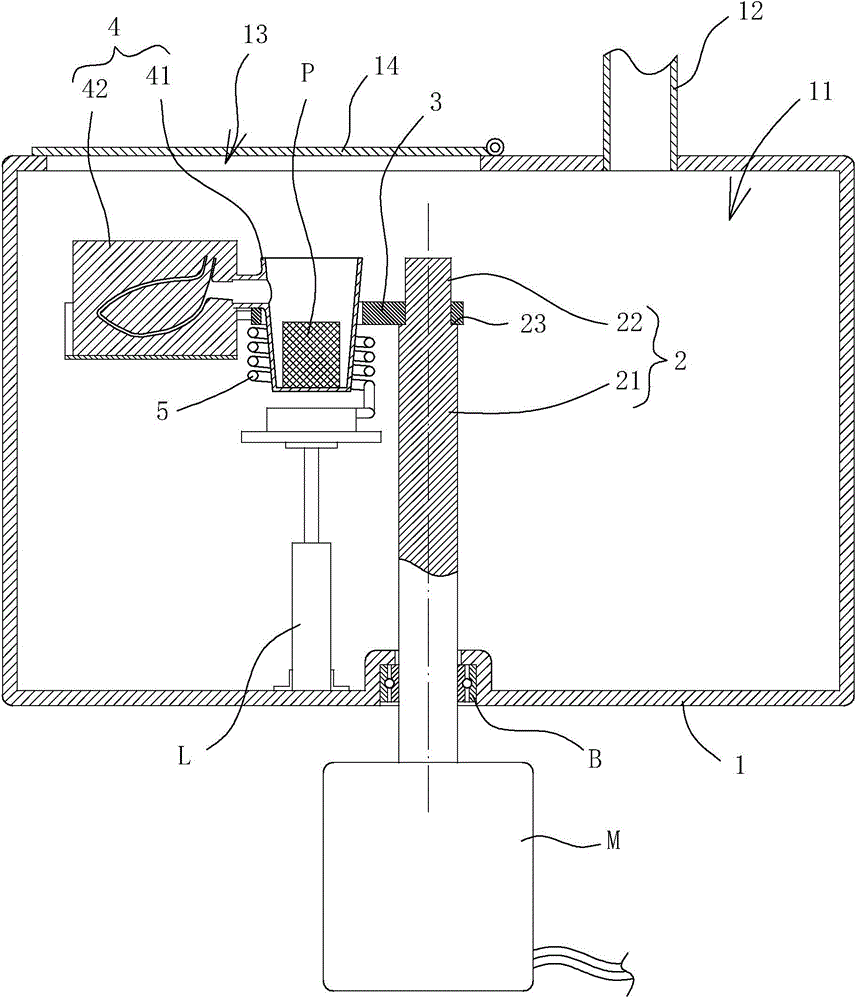

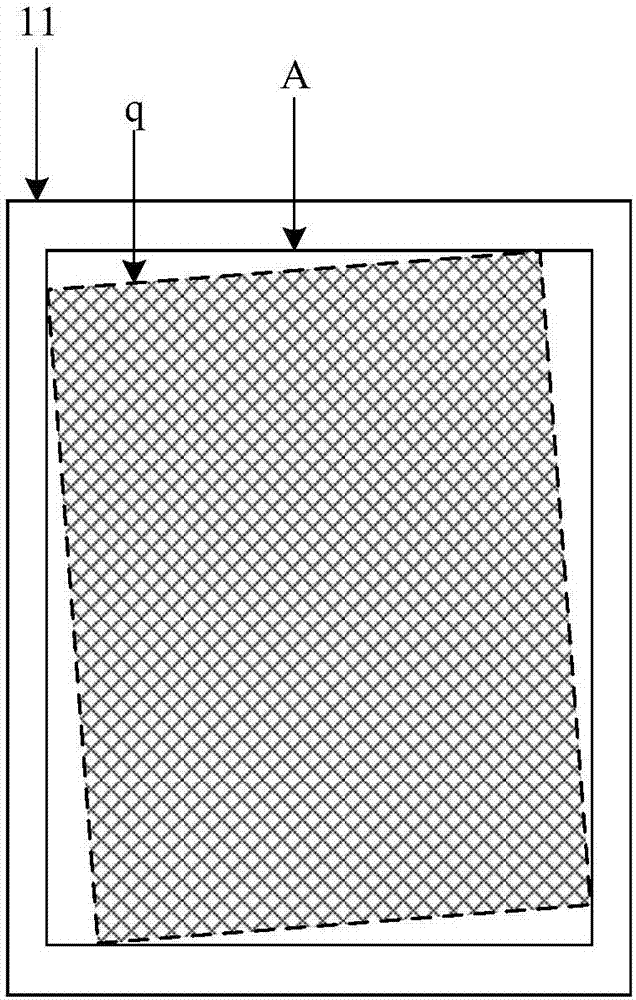

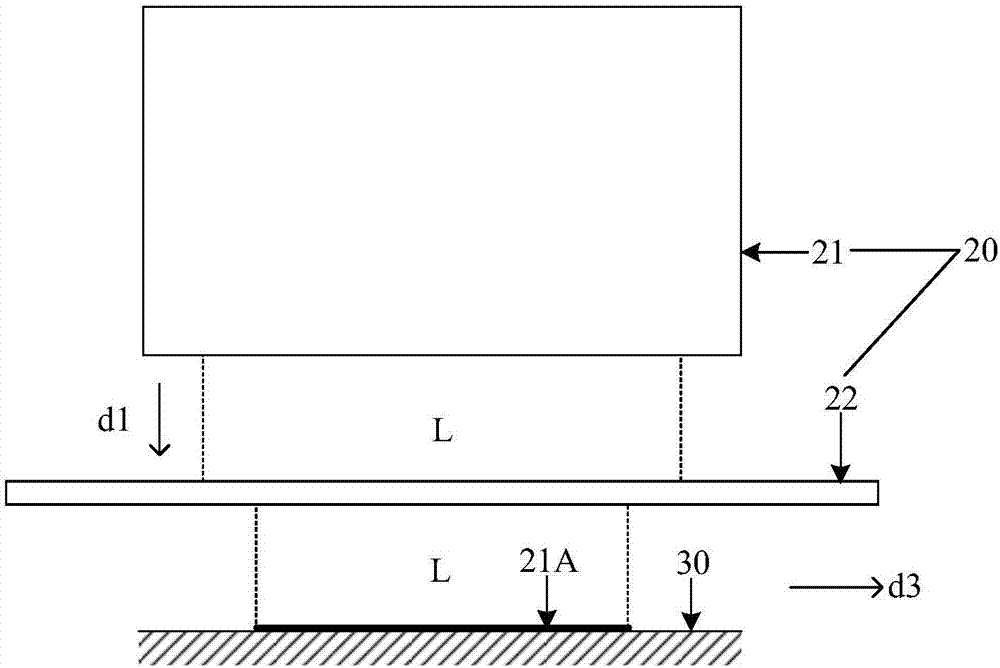

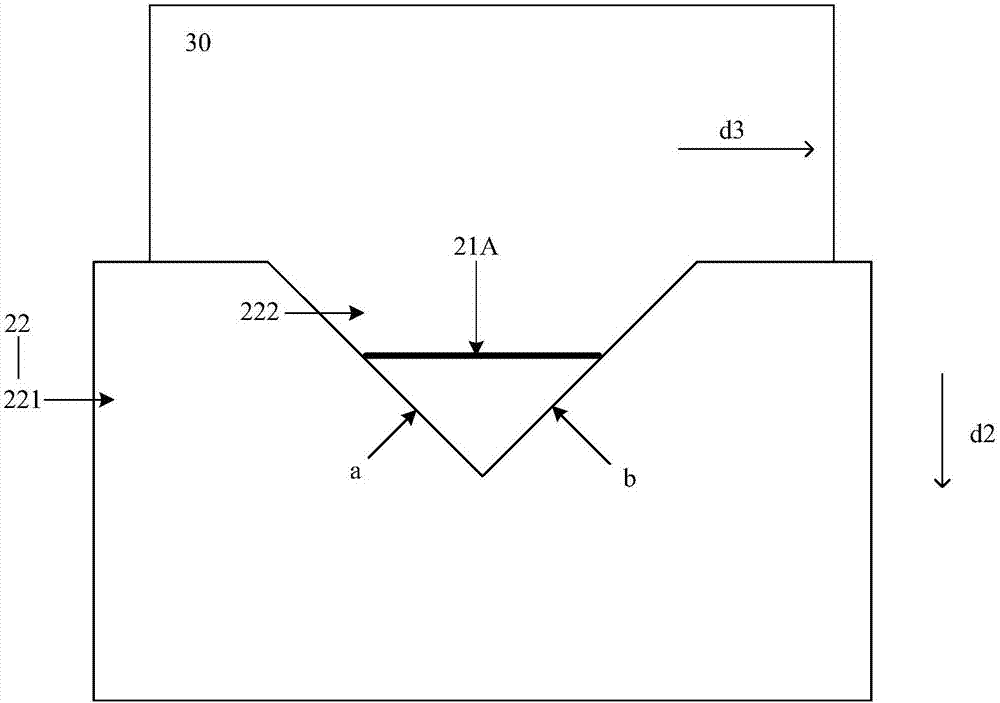

Laser annealing equipment and laser annealing method

InactiveCN107492515AIncrease Conversion RatioSemiconductor/solid-state device manufacturingLight spotAmorphous silicon

The invention discloses laser annealing equipment and a laser annealing method and belongs to the technical field of display. The laser annealing equipment comprises a linear laser and a light cutter arranged in a light outlet direction of the linear laser, wherein the light cutter comprises a plate-shaped body; the plate-shaped body is provided with a hollow area limited by at least two edges; two edges of the hollow area are gradually close to each other along a default direction; and the length direction of a linear light spot of the linear laser on a default irradiation surface is not parallel to the default direction. When the light cutter and the linear laser relatively move along the default direction, the length of the light spot of the linear laser can be adjusted; and when an amorphous silicon layer is irradiated, the whole amorphous silicon layer can be transformed into a polysilicon layer through adjusting the length of the light spot, so that the problem that the transformation ratio of the polysilicon layer is affected due to the fact that one part of amorphous silicon layer is not transformed into the polysilicon layer in related technologies is solved, thereby achieving the effect of improving the transformation ratio of the polysilicon layer.

Owner:BOE TECH GRP CO LTD +1

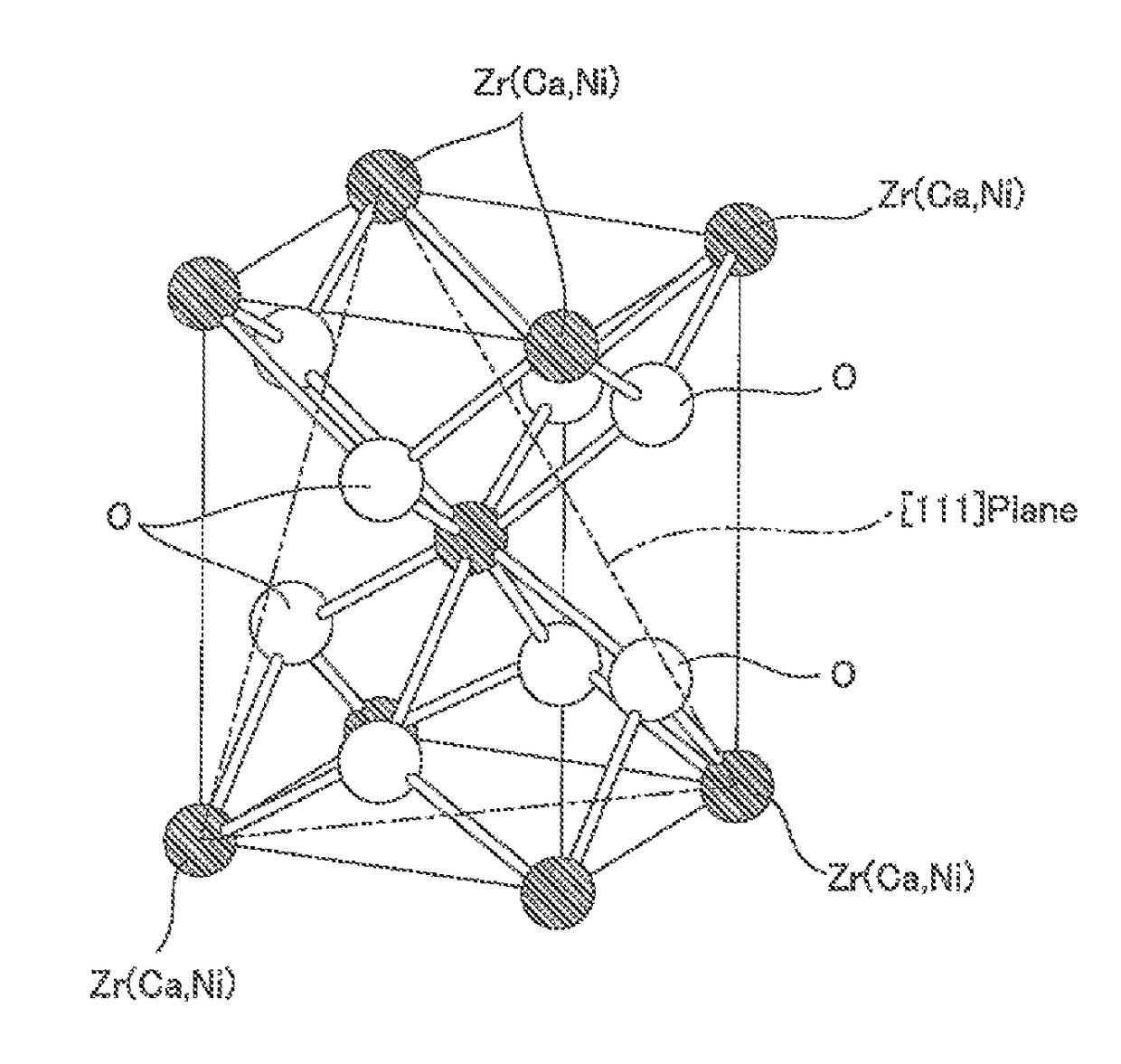

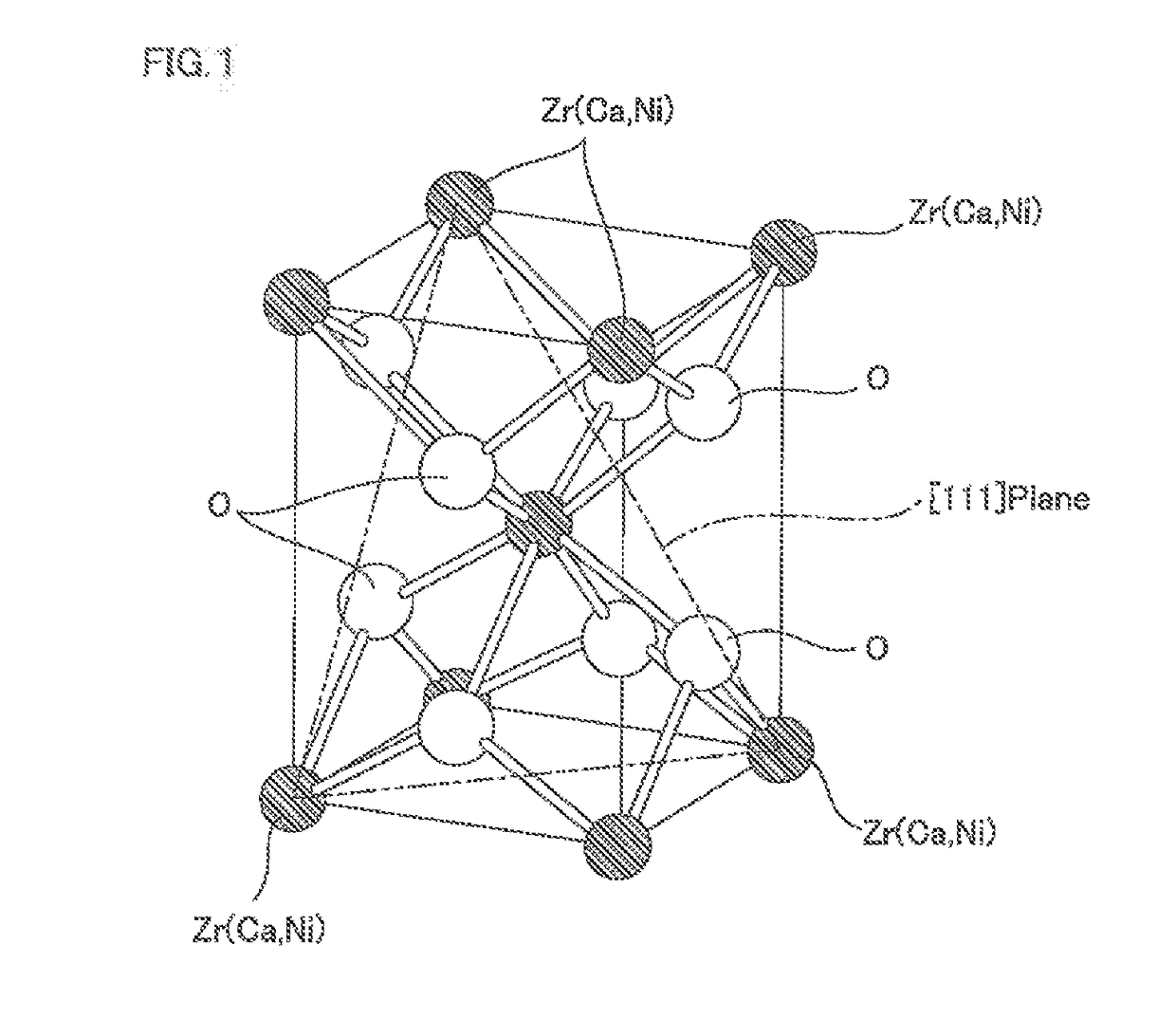

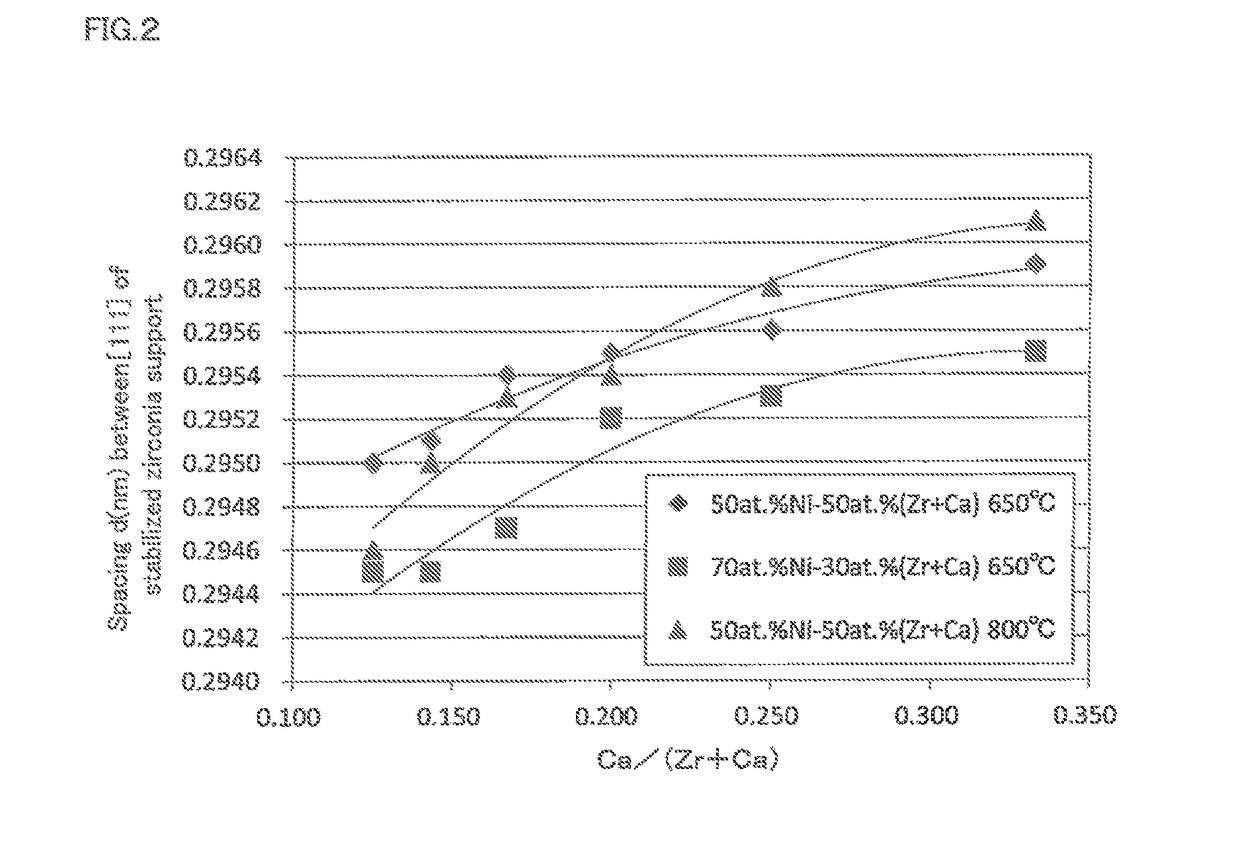

Methanation reaction catalyst, method for producing methanation reaction catalyst and method for producing methane

ActiveUS20170209851A1Carbon dioxide conversion ratio be improveCost reductionHydrocarbon from carbon oxidesOrganic chemistry methodsCarbon dioxideAtomic ratio

A methanation reaction catalyst for methanation by allowing carbon dioxide to react with hydrogen, wherein the methanation reaction catalyst includes a stabilized zirconia support having a tetragonal crystal structure and in which Ca and Ni are incorporated in the crystal structure, and Ni in the metal state supported on the stabilized zirconia support, includes the following in atomic % based on metals in the element state, A) Zr composing the stabilized zirconia support: 6 to 62 atomic %, B) Ca incorporated in the crystal structure: 1 to 20 atomic %, and C) a total of Ni incorporated in the crystal structure and Ni supported on the stabilized zirconia support: 30 to 90 atomic %, and the atomic ratio of Ca / (Zr+Ca) is 0.14 to 0.25.

Owner:HITACHI ZOSEN CORP

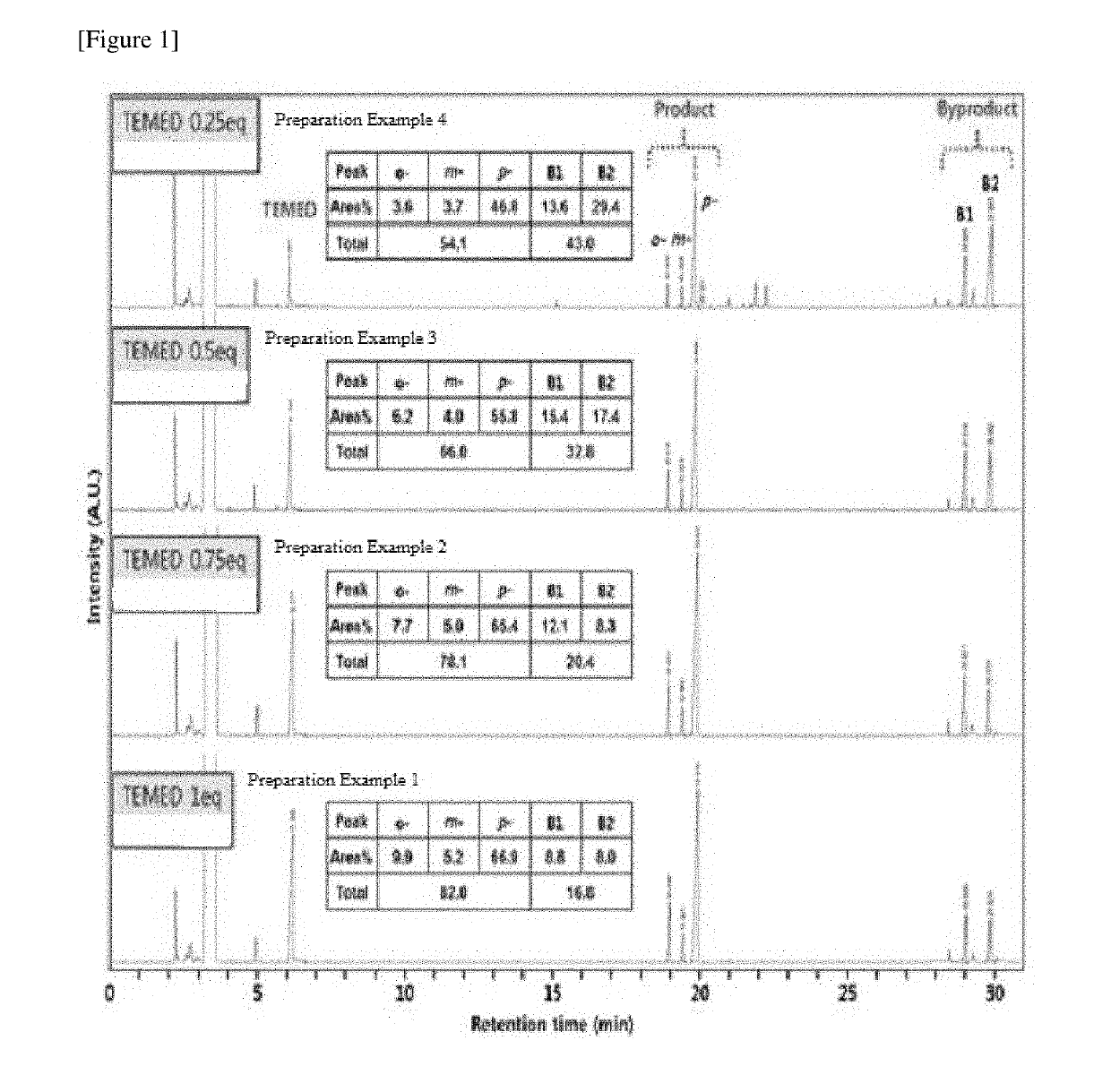

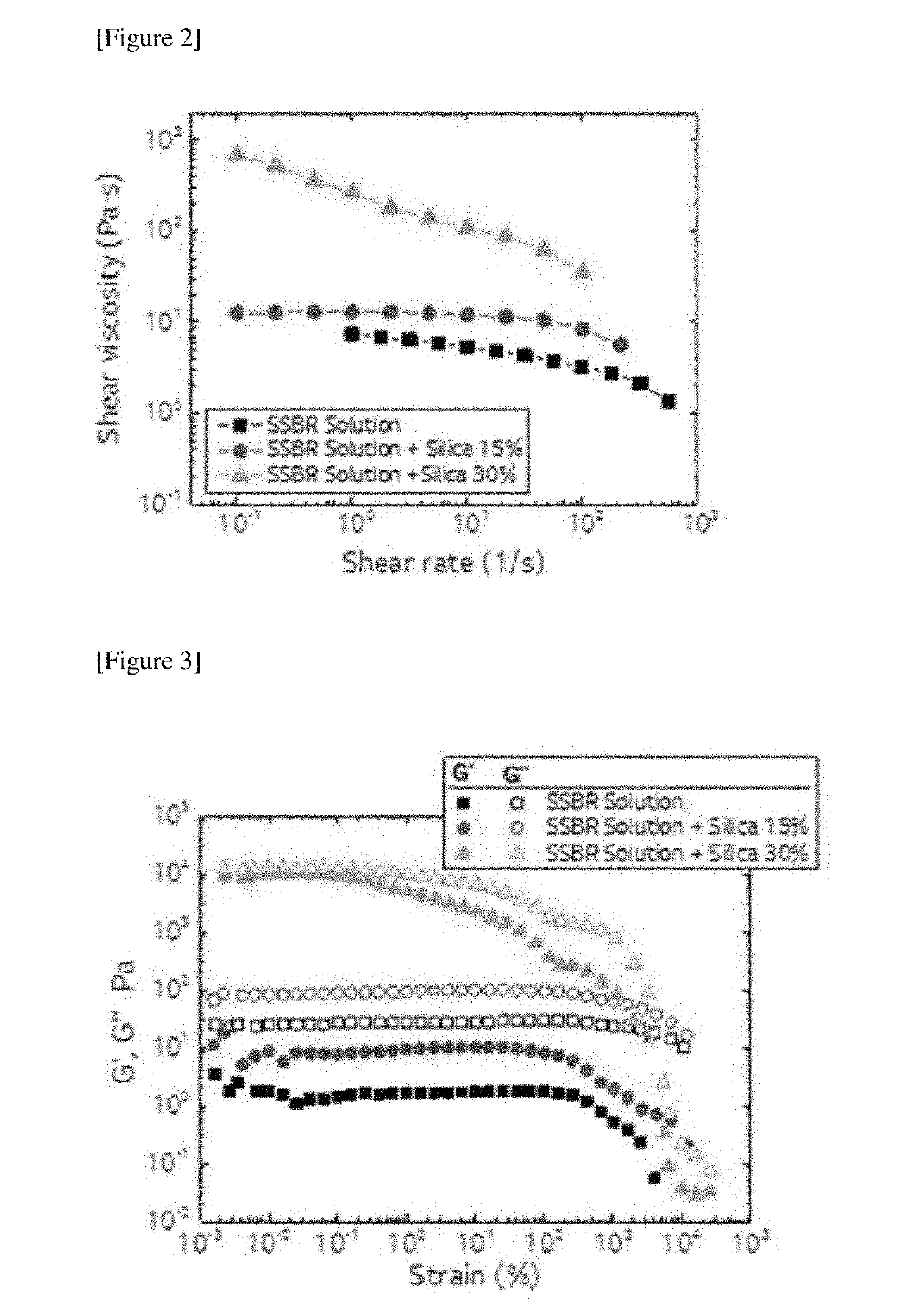

Polymerization Initiator Composition, Preparation Method Therefor, And Method For Preparing Polymer Using Same

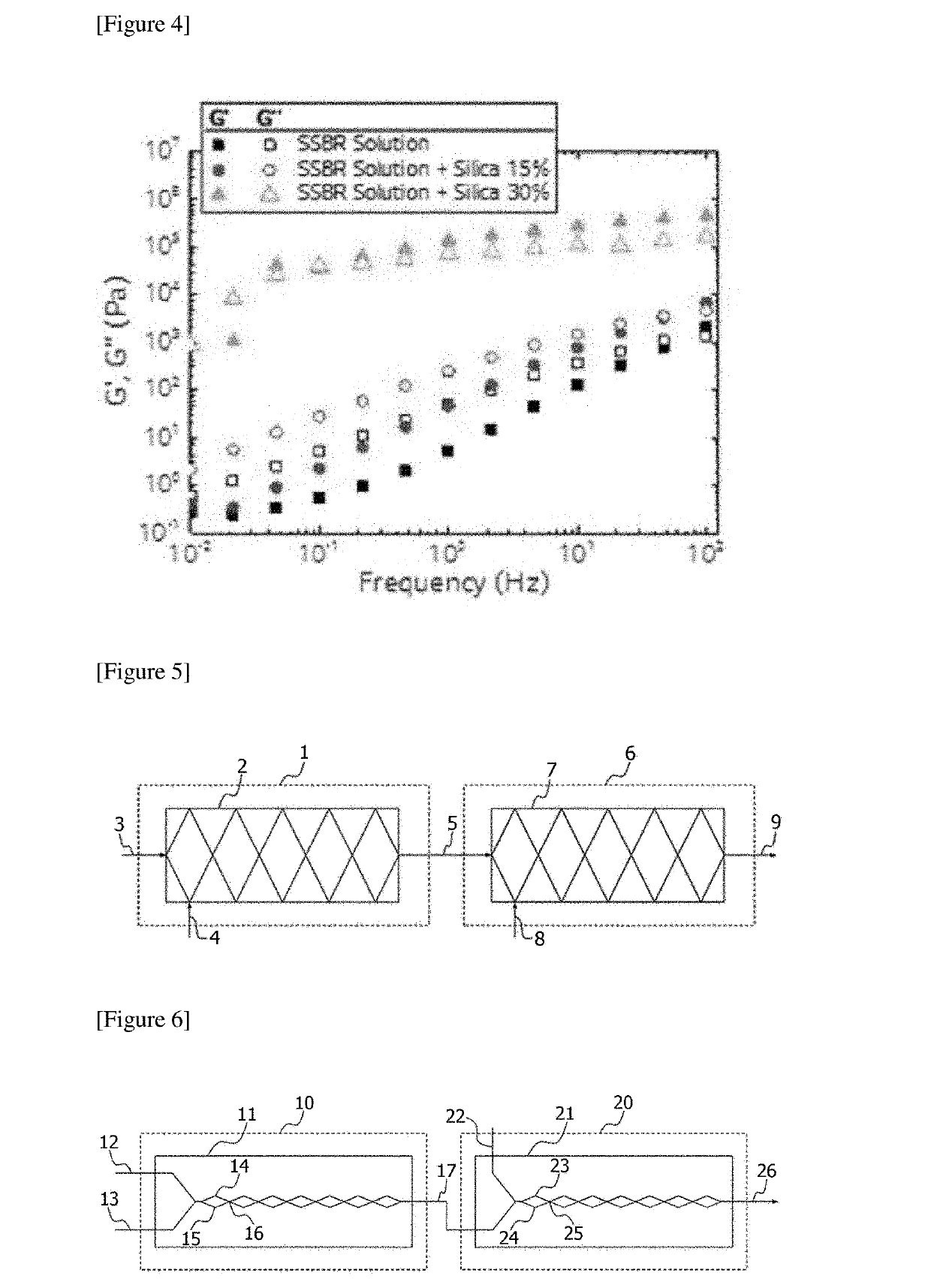

ActiveUS20190330447A1Avoid instabilityMaterial minimizationOrganic compound preparationAmino compound preparationPolymer sciencePhysical property

A polymerization initiator composition includes isomers of the polymerization initiator, thereby preventing instability and inertness of the polymerization initiator and physical property degradation of the SSBR, minimizing by-products and unreacted materials, and remarkably improving a conversion ratio. In addition, when the polymerization initiator composition according to the present invention is used, there is no need to add a polar additive separately upon polymer polymerization, since the polar additive is already added at the time of preparing the polymerization initiator. Further, the polymer initiator composition has high polarity so that the hydrophobic SSBR and the hydrophilic silica can be effectively dispersed.

Owner:LG CHEM LTD

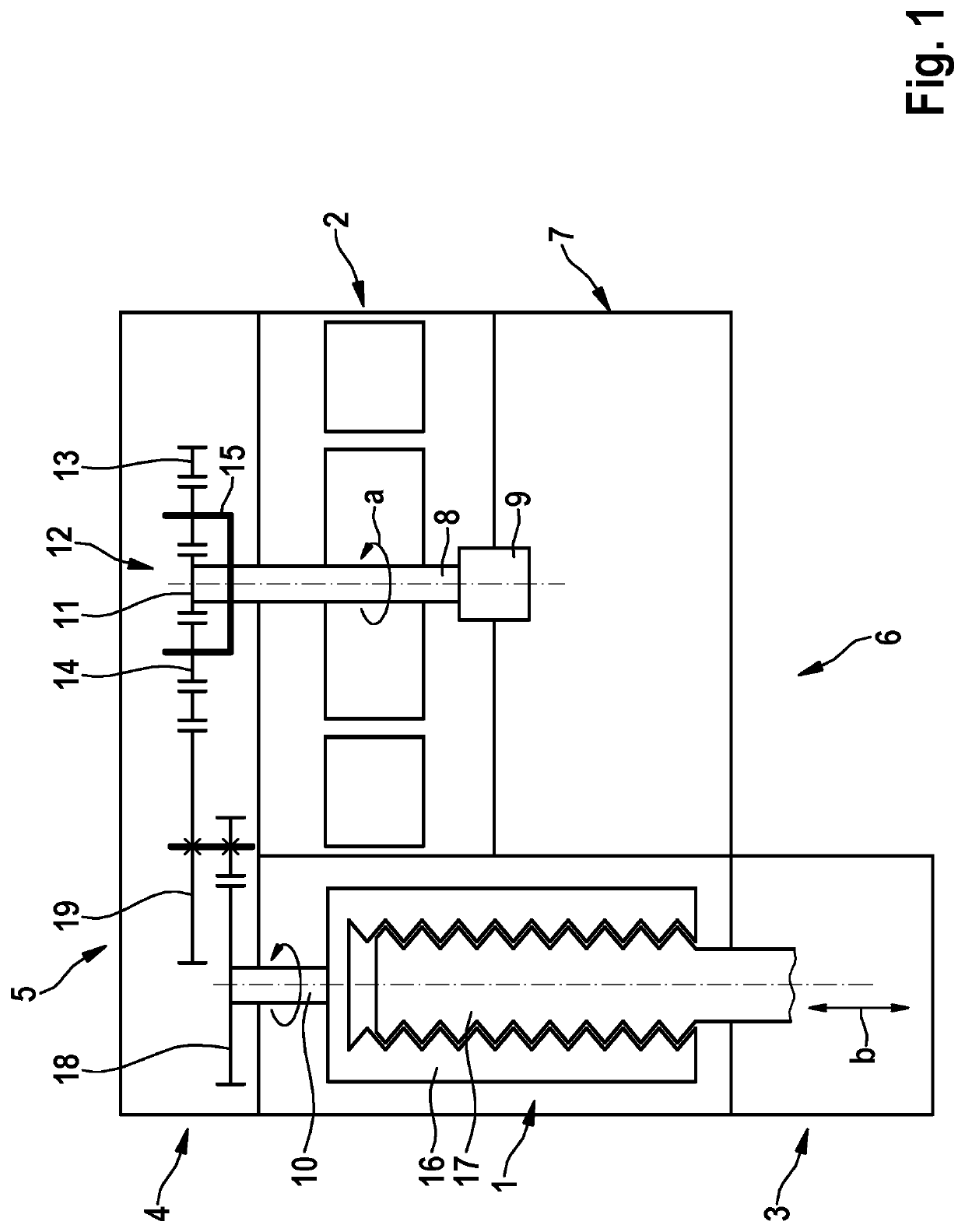

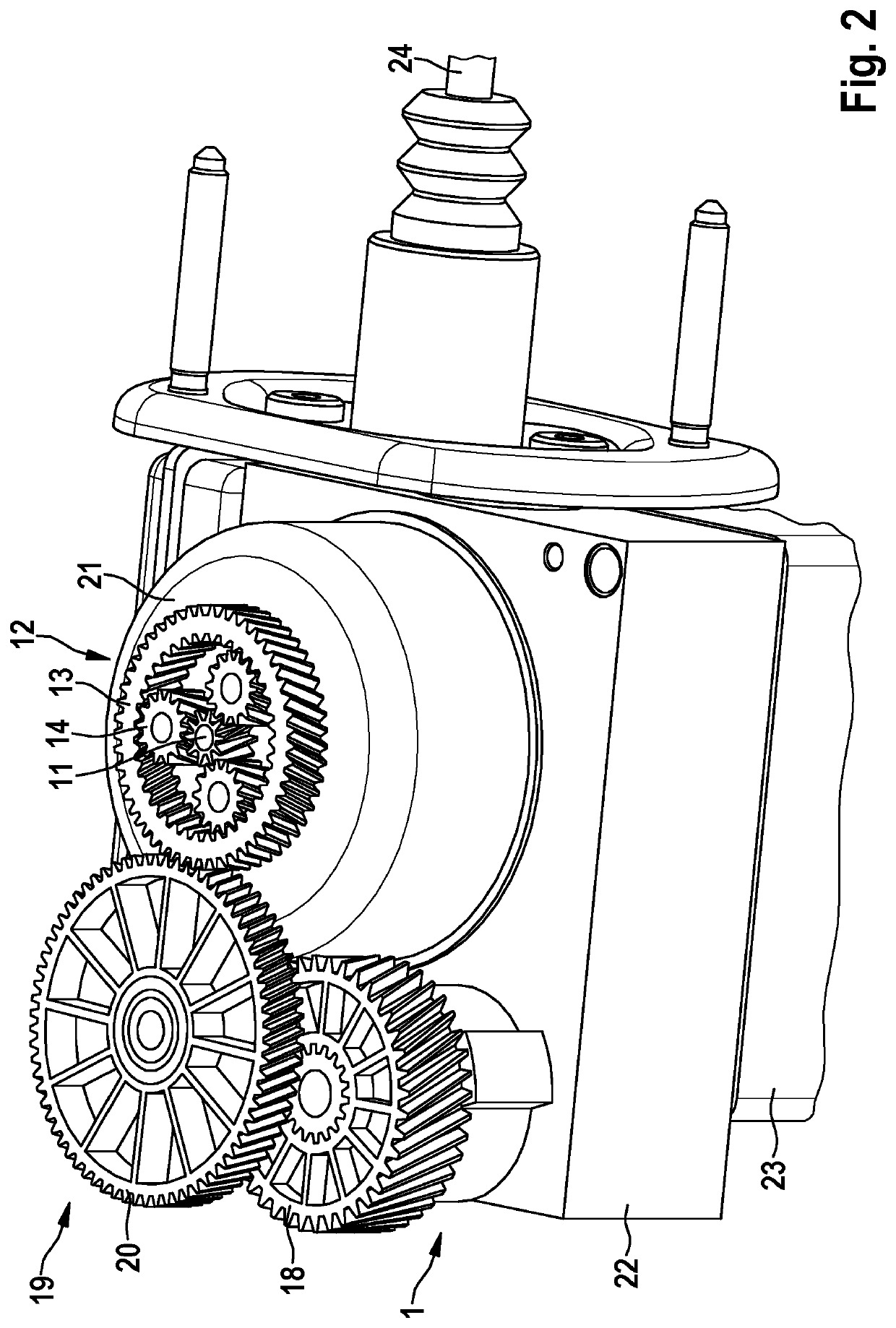

Electromechanical brake pressure generator for a hydraulic brake system of a vehicle

PendingUS20220126807A1Increase conversion ratioRaise the ratioBraking action transmissionVehicle sub-unit featuresElectric drivePiston

An electromechanical brake pressure generator for a hydraulic braking system of a vehicle. The brake pressure generator has a spindle drive unit for converting an input-drive-side rotational motion into a translational motion for piston actuation of a hydraulic piston / cylinder unit. A multi-stage gear linkage is disposed between the spindle drive unit and an electric drive motor. The gear linkage encompasses a planetary gearset unit driven by a motor pinion constituting a sun gear, the output-drive-side ring gear of which unit drives the spindle drive unit. A motor shaft of the electric drive motor extends in adjacently parallel fashion next to a spindle drive shaft of the spindle drive unit.

Owner:ROBERT BOSCH GMBH

Vacuum centrifugal casting method and its device

The invention relates to a vacuum centrifugal casting method. The method aims to improve poor conversion proportion between casting materials and castings in a traditional vacuum casting method. The vacuum centrifugal casting method includes the steps that a shell mold is positioned and placed on a rotating platform, the rotating platform is connected to a rotating shaft capable of rotating in the axial direction, and metal ingots are placed on a crucible portion of the shell mold and are heated and melted under the vacuum environment; the rotating shaft is driven to drive the rotating platform to rotate so as to enable molten metal to flow into a mold cavity portion of the shell mold; the cast shell mold is taken down from the rotating platform; the shell mold is destroyed, and a casting is obtained. The invention further discloses a vacuum centrifugal casting device matched with the vacuum centrifugal casting method. By means of the vacuum centrifugal casting method and device, the violent oxidizing reaction generated by the molten metal is avoided, the convention proportion between the casting materials and the castings can be improved, the waste of the casting materials is avoided, the casting yield can be improved effectively, and casting cost can be reduced effectively.

Owner:FS PRECISION TECH

Method for manufacturing steel-based golf club heads containing reactive metals

The present invention provides a method for manufacturing a steel golf club head containing reactive metal, which can solve the problem that the conversion ratio of casting material to casting products is poor by using the conventional vacuum casting method. The method includes: locating a shell mold on a rotating platform, wherein the shell mold includes a crucible part and a mold cavity part which are communicated with each other, and the rotating platform is connected with a rotating shaft which can rotate axially; putting a steel metal ingot containing reactive metal into the crucible part of the shell mold, and heating and melting the steel metal ingot into metal liquid in vacuum environment; driving the rotating shaft to rotate the rotating platform such that the melt metal liquid flows into the mold cavity part of the shell hold; stopping the rotating shaft slowly and taking down the shell mold after casting; and breaking the shell mold to obtain a golf club head casting product.

Owner:FUSHENG IND CO LTD

Manufacturing method of titanium alloy golf club head

ActiveCN104550814BIncrease Conversion RatioImprove step rateFoundry mouldsFoundry coresTitaniumTitanium alloy

Owner:FUSHENG IND CO LTD

Multi-type Pellet Mixed Loading Metal Cooling Reactor and Management Method

ActiveCN110867261BTake advantage of inherent neutronics propertiesImprove average unloaded fuel consumptionNuclear energy generationReactor fuel susbtancesZirconium hydrideUranium oxide

The invention discloses a multi-type pellet mixed-loaded metal-cooled reactor and a management method. The reactor core is surrounded by a moderation type component, the sub-periphery is a multiplication type fuel assembly, and the inner area of the core is arranged with a power type fuel assembly. The moderating component is composed of several moderating elements, the moderating element includes a cladding, and a zirconium hydride metal block is arranged in the cladding; the multiplication fuel assembly is composed of several multiplication fuel elements, and the multiplication fuel The element includes a cladding, and beryllium oxide ceramic pellets are arranged at both ends of the cladding, and natural uranium dioxide fuel pellets are arranged in the middle; the power type fuel assembly is composed of several power type fuel elements, and the power type fuel element includes a cladding , beryllium oxide ceramic pellets are arranged at both ends of the cladding, and plutonium-uranium mixed oxide fuel pellets are arranged in the middle. The invention solves the problems of large fuel loading and low utilization rate of the existing metal cooling reactor.

Owner:NUCLEAR POWER INSTITUTE OF CHINA

Nuclear fuel pellets, manufacturing method and nuclear reactor

ActiveCN103366836BIncrease profitSimple designFuel elementsNuclear energy generationNuclear reactorReactive control

The invention relates to a nuclear fuel pellet and a manufacturing method thereof, and a nuclear reactor. The nuclear fuel pellet at least comprises a first fuel zone and a second fuel zone which are arranged from inside to outside, wherein the thickness of the second fuel zone is much smaller than that of the first fuel zone; and the reactivity of a nuclear fuel material of the first fuel zone is higher than that of a nuclear fuel material of the second fuel zone. The nuclear fuel material with lower reactivity is arranged on the periphery of the nuclear fuel pellet with higher reactivity to perform the function of lowering initial reactivity margin, so that burnable poisons and / or boric acid in the reactor core are correspondingly reduced, thereby being beneficial to reactor core nuclear design and reactivity control; or more fissionable materials can be loaded to implement longer fuel cycle. More neutrons can be effectively absorbed, thereby enhancing the conversion ratio of the fuel. Besides, the nuclear fuel material with lower reactivity is arranged at the innermost ring of the nuclear fuel pellet to have the function of reducing fissible material residues, thereby enhancing the utilization ratio of nuclear fuels.

Owner:CHINA NUCLEAR POWER TECH RES INST CO LTD +2

Production process of thin gauge 700mpa grade ultra-high strength hot-rolled black steel strip

ActiveCN109355484BIncrease Conversion RatioIncreased strength and plasticityLaminar coolingRoll forming

Owner:TANGSHAN STAINLESS STEEL +1

Liquid Metal Cooling Reactor and Management Method Based on Improving Fuel Utilization

ActiveCN110867262BImprove average unloaded fuel consumptionIncrease Conversion RatioNuclear energy generationShieldingControl powerBurnup

The invention discloses a liquid metal cooling reactor and a management method based on improving the fuel utilization rate. The reactor core is surrounded by a low-temperature strong moderator component, and a high-temperature strong moderator component is arranged on the sub-periphery. Rod assemblies and high power moderated assemblies. According to the inherent neutronic characteristics, power and burnup distribution characteristics of the liquid metal cooled fast reactor, the present invention constructs components with different functions and uses: low-power fuel components for reducing neutron leakage at the outermost periphery of the reactor core, and for reactors The high-power fuel assembly and control rod assembly inside the core form a unique liquid metal-cooled fast reactor core loading scheme, which significantly improves the average unloading fuel consumption and nuclear fuel conversion ratio of the liquid metal-cooled fast reactor, and enhances liquid metal cooling. Engineering feasibility of a fast reactor closed uranium-plutonium fuel cycle system.

Owner:NUCLEAR POWER INSTITUTE OF CHINA

Pulse power supply system and discharge method based on generator cluster and energy storage microgrid

ActiveCN110867888BUnavailable solutionIncrease profitSingle network parallel feeding arrangementsAc network load balancingMicrogridPulse power supply

The invention belongs to the field of pulse power generation, particularly relates to a pulse power supply system based on a generator cluster and an energy storage microgrid and a discharging method,and aims to solve the problem that residual energy of a pulse generator cannot be fully utilized in the prior art. The method comprises the following steps: respectively discharging each pulse generator based on a system discharge signal and parameters; grouping the pulse generators, and transferring the residual energy of each group to any pulse generator in the group; discharging again, grouping the pulse generators with available residual energy, and performing energy transfer again; and iteratively discharging the pulse generator set until the rotating speed of the pulse generator is reduced to the condition that discharge and the power generation indexes do not meet the requirements. According to the invention, by utilizing the characteristic that through the controllable rectification of charging motor, constant-voltage power generation can be carried out in a wide rotating speed range, so residual energy can be transferred in the pulse generator cluster, the conversion ratio from inertia kinetic energy to pulse electric energy is improved from the system level, and the energy utilization rate is improved.

Owner:INST OF ELECTRICAL ENG CHINESE ACAD OF SCI

Nuclear fuel pellets, manufacturing method and nuclear reactor

ActiveCN103366835BImprove overall utilizationAvoid wastingFuel elementsNuclear energy generationNuclear reactor coreNuclear reactor

The invention relates to a nuclear fuel pellet which comprises nuclear fuel materials. The nuclear fuel pellet at least comprises a first fuel zone and a second fuel zone which are arranged from inside to outside, wherein the reactivity of the nuclear fuel material of the first fuel zone is lower than that of the nuclear fuel material of the second fuel zone. The nuclear fuel with lower reactivity is arranged at the center of the nuclear fuel pellet, thereby avoiding the problem of low nuclear fuel material utilization ratio in the central zone, having the action of reducing fissible material residues in the discharge fuel, and avoiding the waste of the nuclear fuel materials.

Owner:CHINA NUCLEAR POWER TECH RES INST CO LTD +1

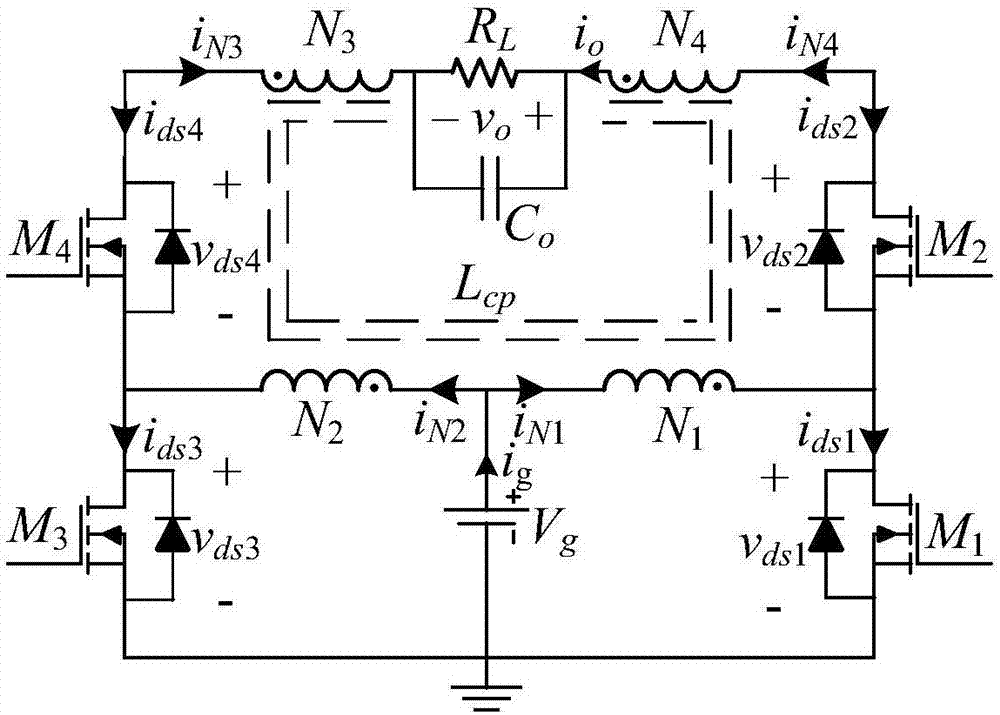

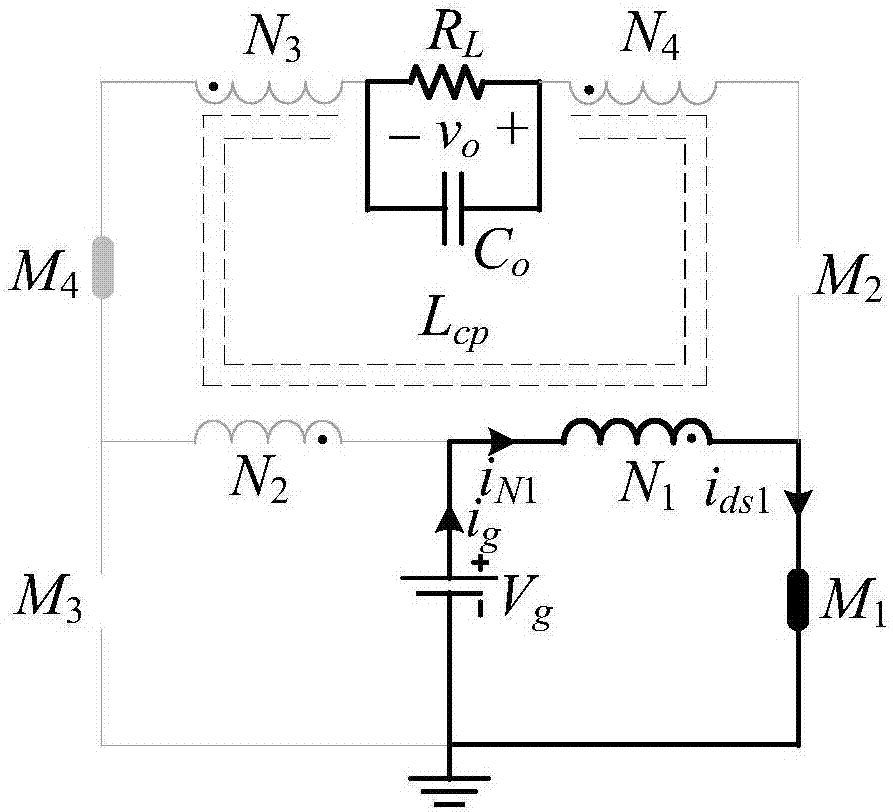

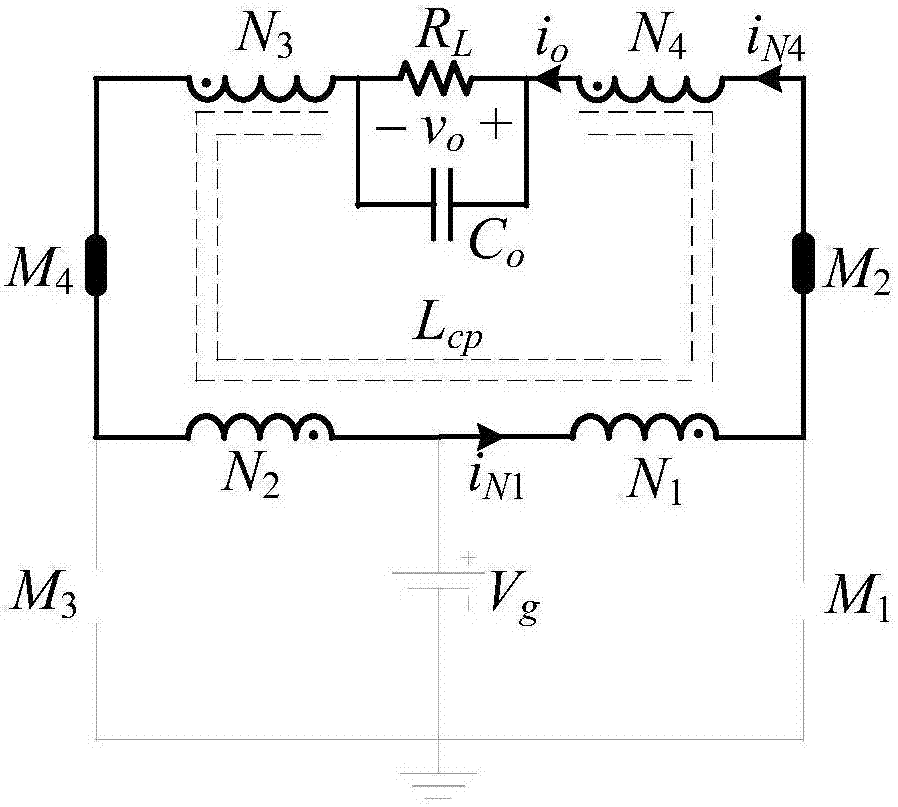

Single-stage type high-conversion-ratio Buck-Boost inverter

The invention relates to a single-stage type high-conversion-ratio Buck-Boost inverter. The single-stage type high-conversion-ratio Buck-Boost inverter comprises a full bridge circuit consisting of four switching tubes (M1-M4), a coupling inductor Lcp having four windings, an output filtering capacitor Co and an equivalent load Rl. The coupling inductor is designed as two pairs of symmetric windings. The primary-end winding of the coupling inductor has same windings N1=N2 and the auxiliary side of the coupling inductor has same windings N3=N4. The transformation ratio of the coupling inductor is n=N3 / N1=N4 / N2. Targeting a problem that most of topologies of the Buck-Boost type single-stage type inverter are limited by limited voltage transformation ratios and although few topologies can realize high transformation ratios, the quantity of devices is greatly increased, the invention provides a single-stage high-transformation ratio Buck-Boost inverter topology, which can realize a high transformation ratio under a condition that semiconductor devices are few.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

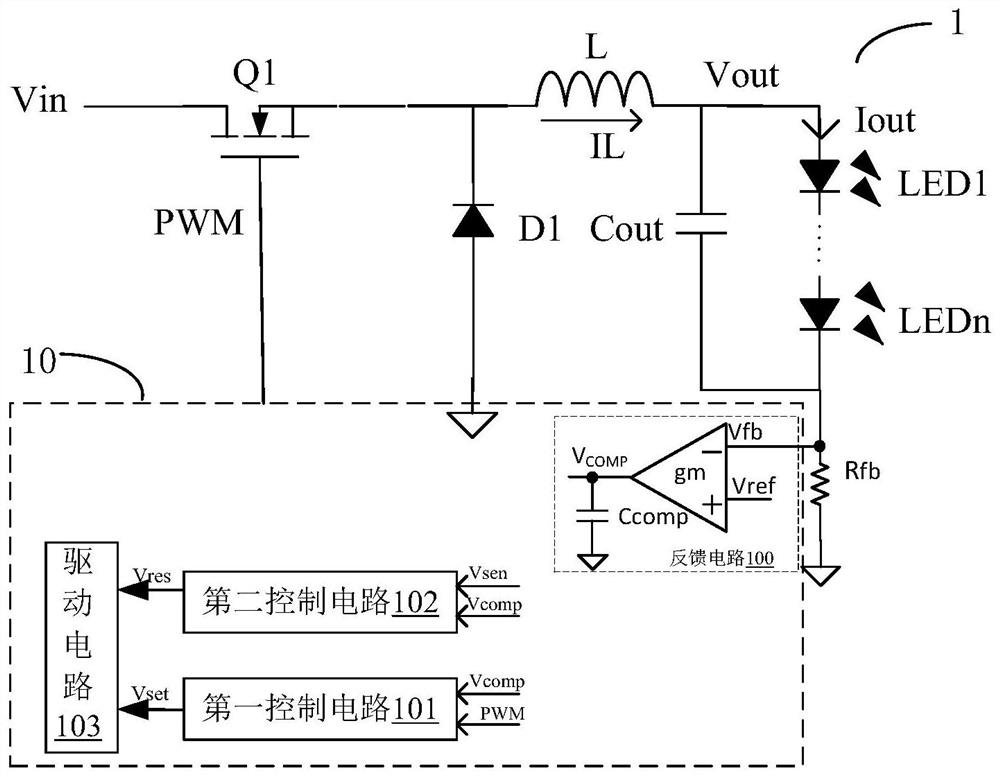

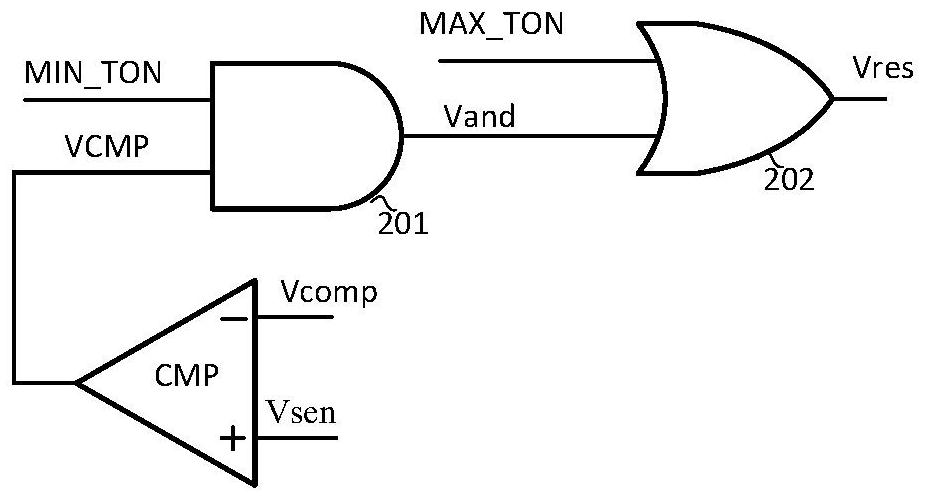

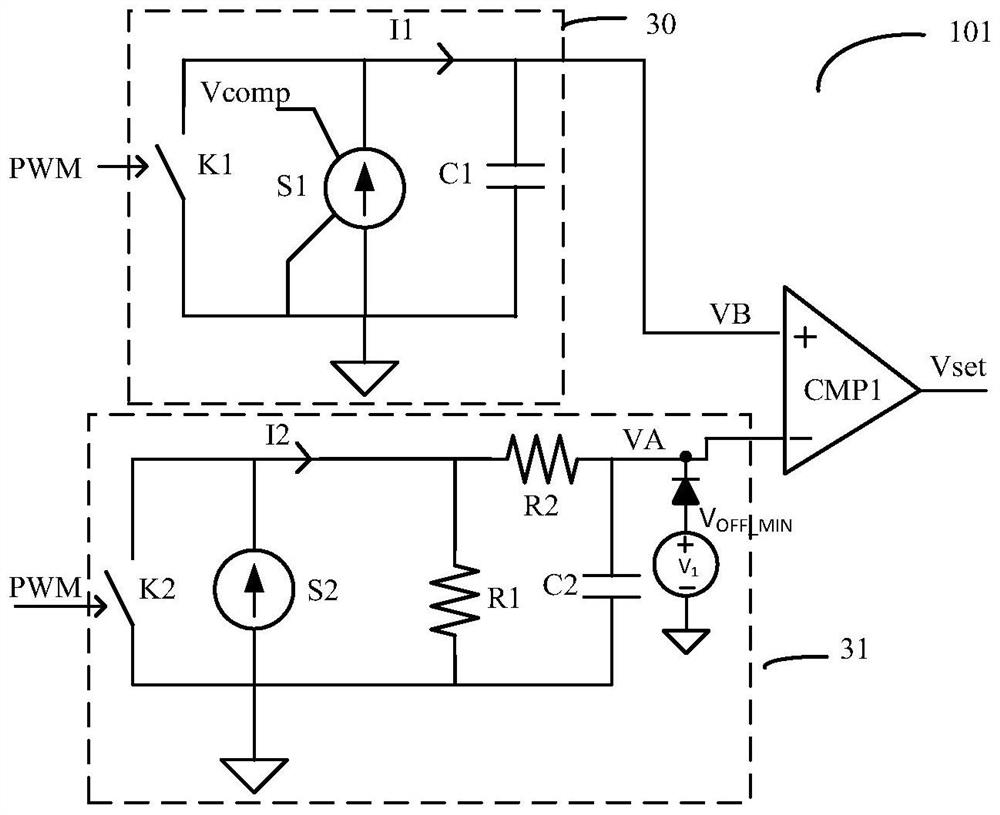

Control circuit and switching converter using it

ActiveCN112383220BReduce operating frequencyIncrease Conversion RatioDc-dc conversionElectric variable regulationConvertersSoftware engineering

Owner:SILERGY SEMICON TECH (HANGZHOU) CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com