Single-stage type high-conversion-ratio Buck-Boost inverter

A high conversion and inverter technology, applied in the direction of output power conversion device, AC power input conversion to DC power output, electrical components, etc., can solve the problem of weakening flyback topology, simple structure, reduced decoupling capacitor, efficiency Lowering and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] Now in conjunction with embodiment, accompanying drawing, the present invention will be further described:

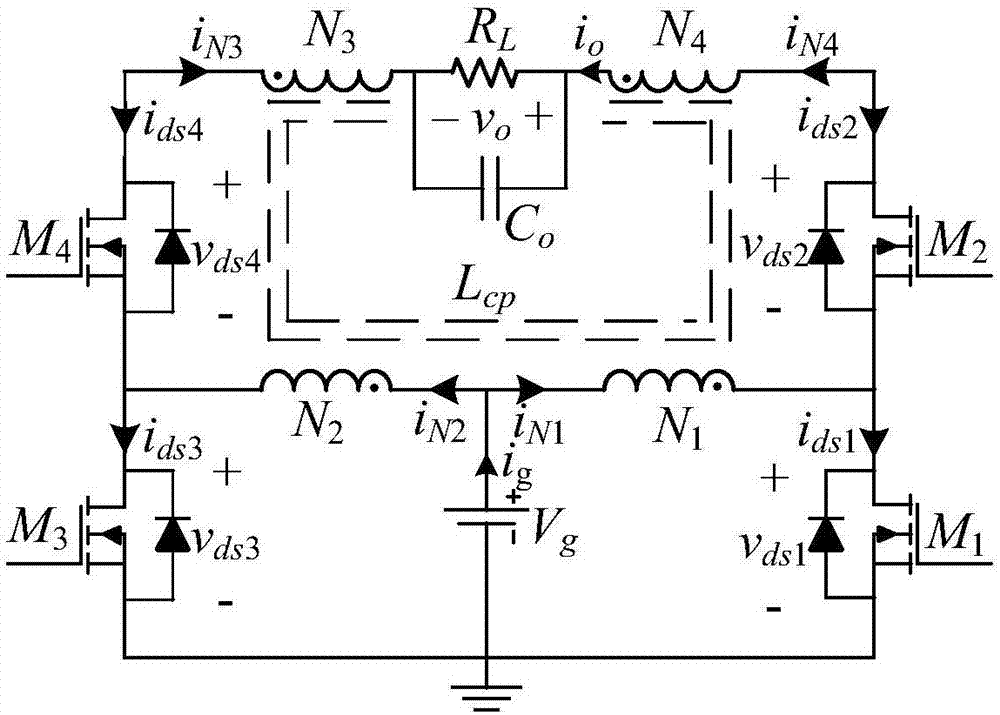

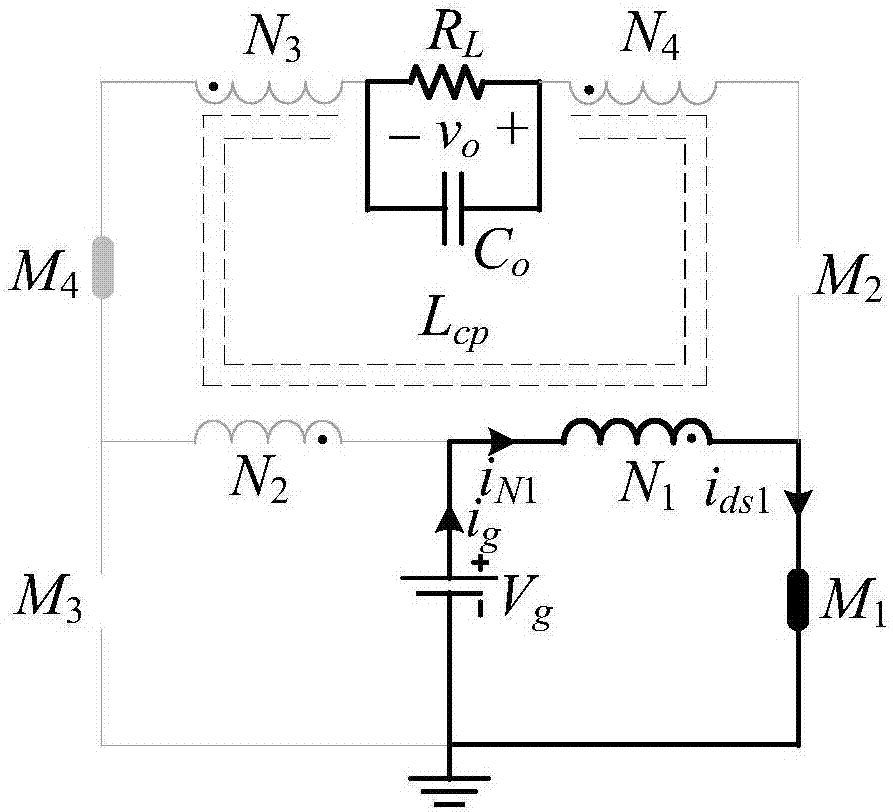

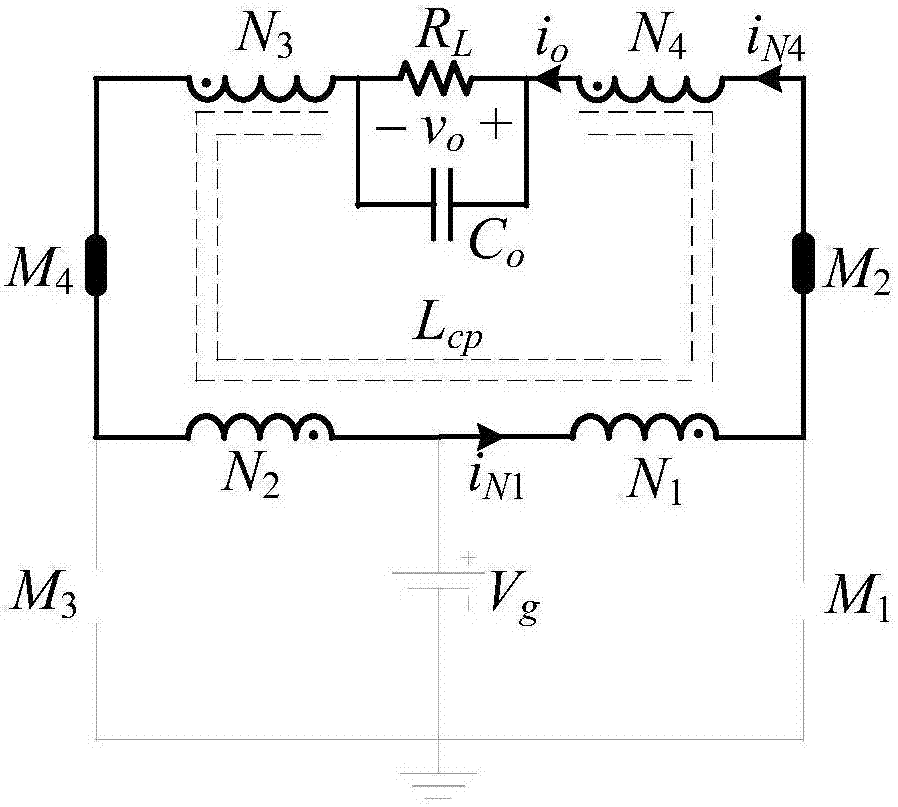

[0027] Such as figure 1 As shown, the topology basic structure of the present invention is a common full-bridge circuit, and the switching tubes are respectively M 1 ~ M 4 . Coupled inductor N 1 :N 2 :N 3 :N 4 Used as an energy storage device to achieve a high conversion ratio boost, the secondary to primary turns ratio is defined as n=N 4 / N 1 =N 3 / N 2 . Due to the symmetry of the positive and negative half cycles of the output, the primary winding N 1 with N 2 have the same number of turns, therefore, the secondary winding N 3 with N 4 also have the same number of turns. The output capacitor is C o , the load is the equivalent resistance R L .

[0028] Among them, the switching tube M 1 , M 3 The source and the negative pole of the input power supply are connected and grounded, and the switching tube M 1 The drain, M 2 source of the coupl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com