Patents

Literature

34results about How to "Unavailable solution" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

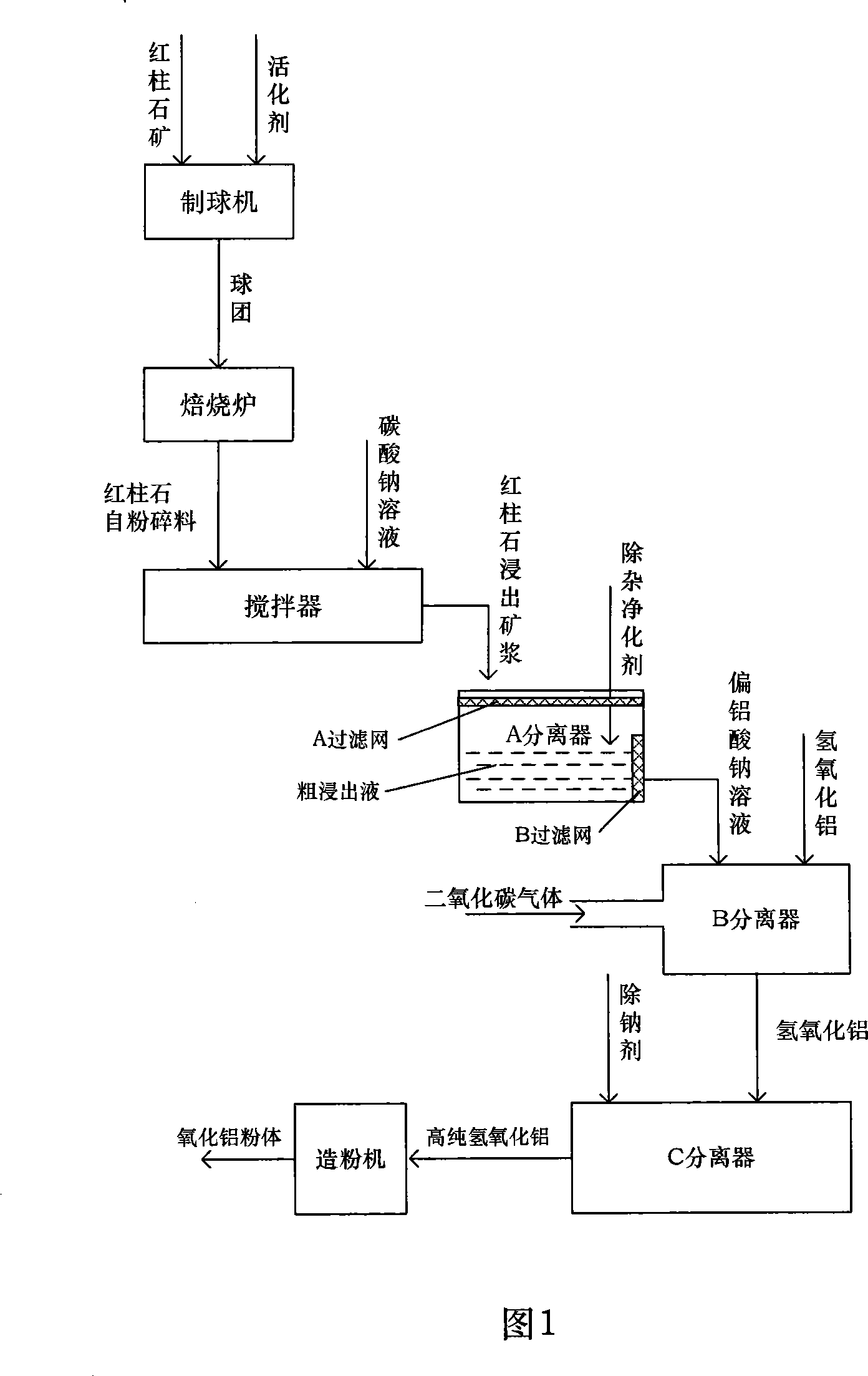

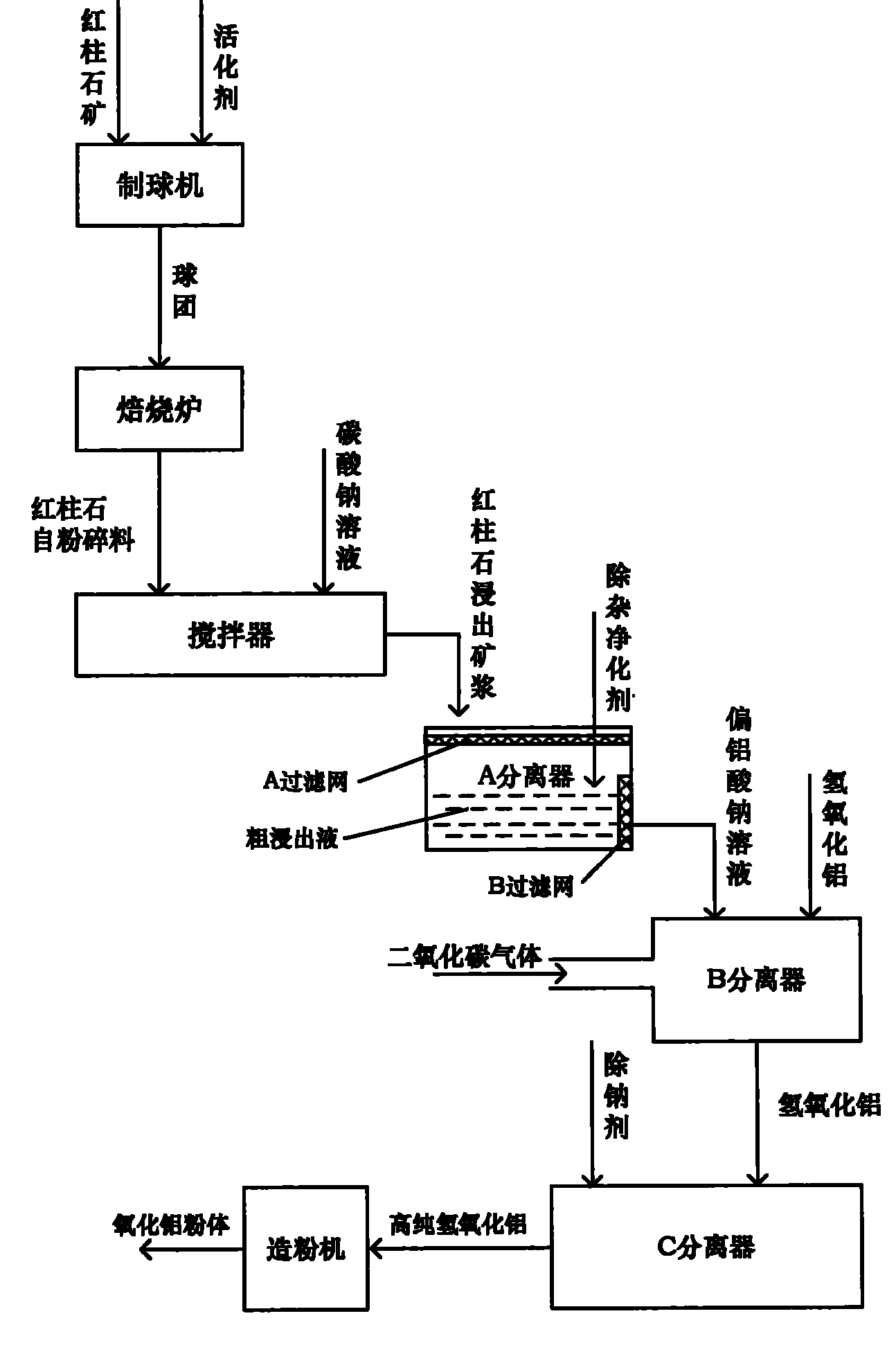

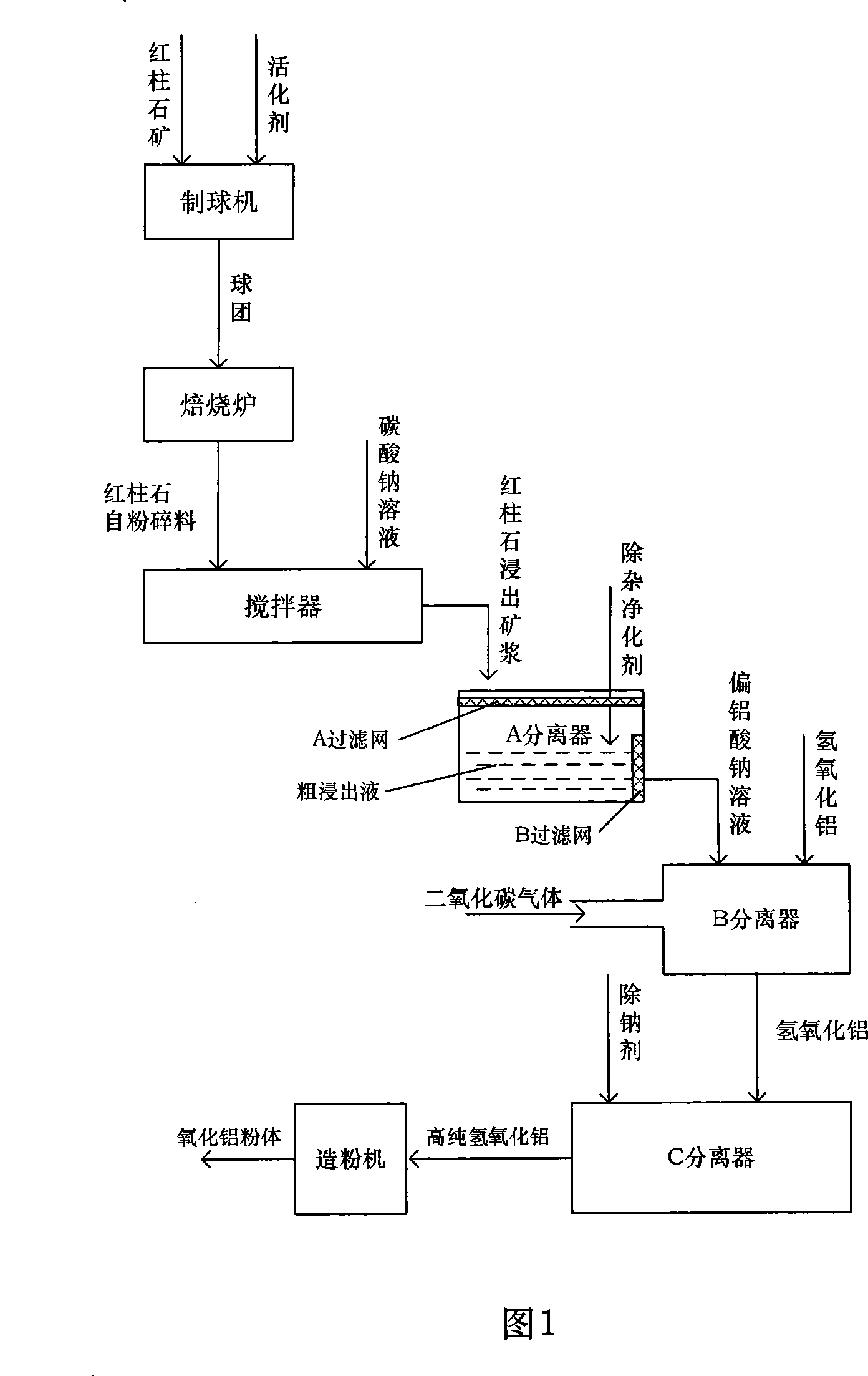

Method for preparing chemical aluminum oxide by using andalusite as raw material

InactiveCN101182025ALow costSimple processAluminium oxide/hydroxide preparationBeneficiationAluminium oxide

The invention discloses a method for preparing chemical alumina by using andalusite as a raw material. The preparation of chemical alumina is from the tailings of andalusite ore dressing through ball making, roasting, multi-stage separation, adding additives and granulation. The chemical alumina with a purity of 99.5-99.999% is extracted from the ore as a raw material, so that the andalusite resource can be comprehensively utilized, which not only saves resources, but also protects the environment.

Owner:蹬口县欧凯红柱石矿业有限公司 +1

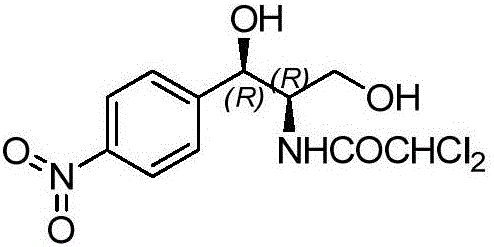

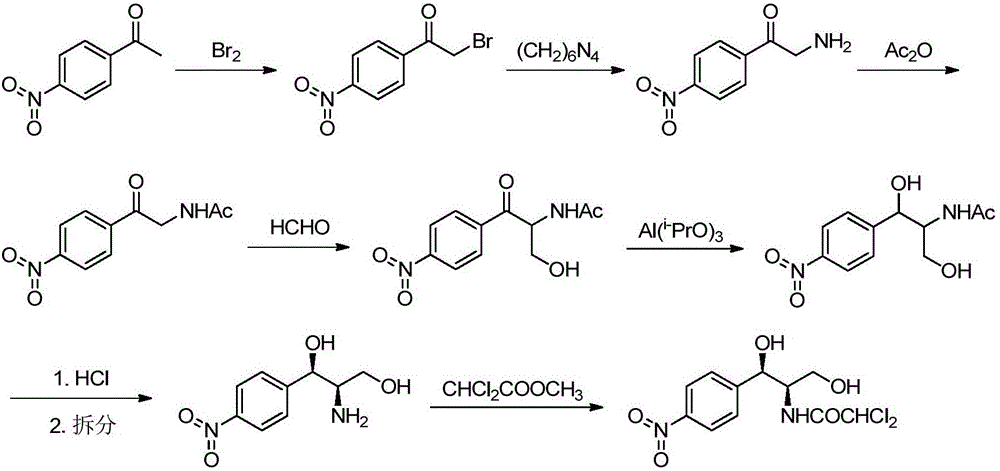

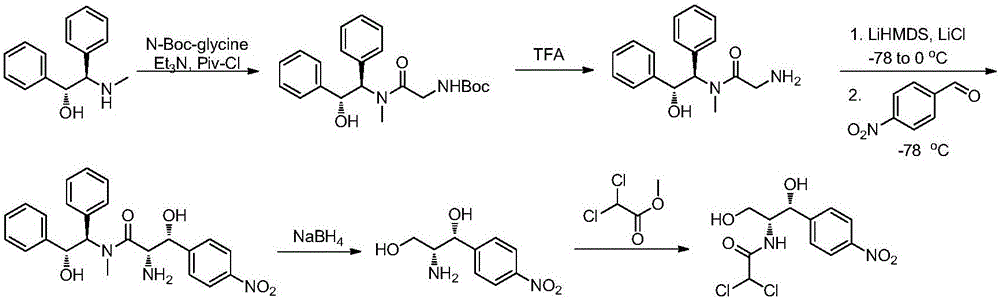

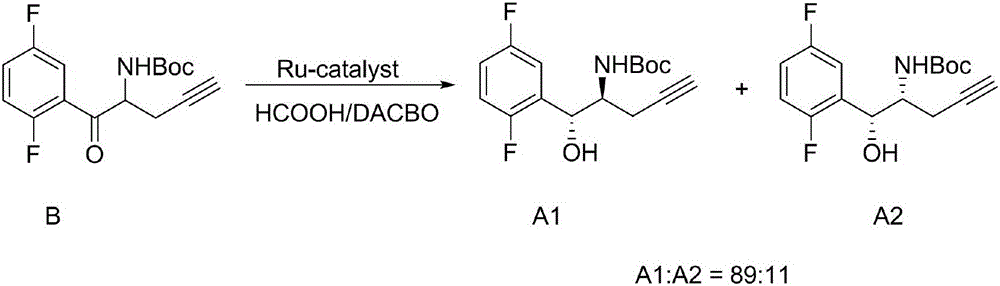

Preparation method of chloramphenicol compounds

The invention provides a preparation method of chloramphenicol compounds. The preparation method comprises the following steps: adding a chloramphenicol intermediate product to a buffer solution; then, adding ketoreductase to the solution so as to obtain a mixed solution; and conducting a reaction on the mixed solution at 25-35 DEG C, so that the chloramphenicol compounds are obtained. The preparation method of the chloramphenicol compounds provided by the invention not only reduces raw material cost but also improves economy of raw materials and improves yield; and the problems of the prior art that isomer by-products, obtained from the preparation of chloramphenicol, cannot be used, raw material cost is high and yield is low are solved.

Owner:SUZHOU LEAD BIOTECH CO LTD

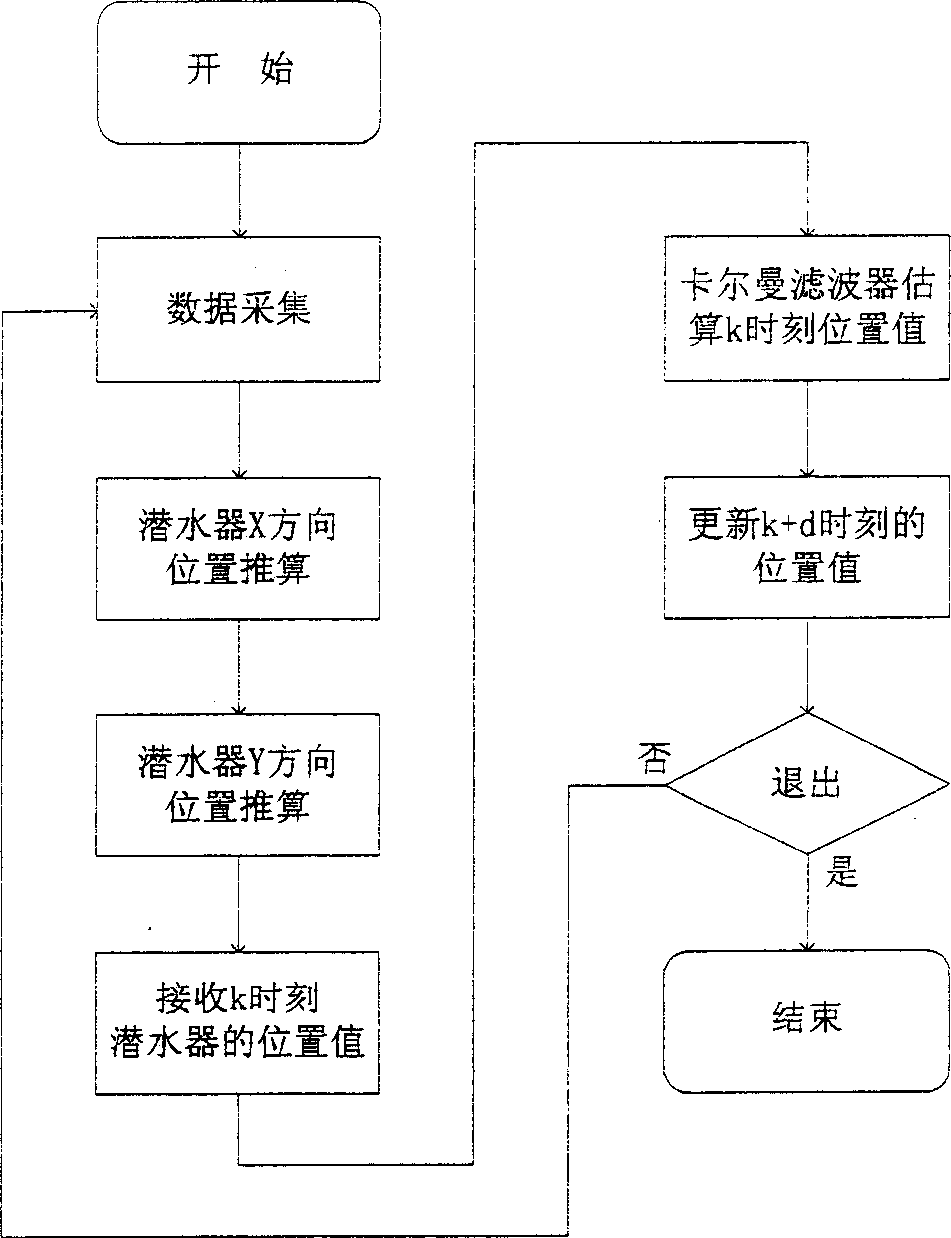

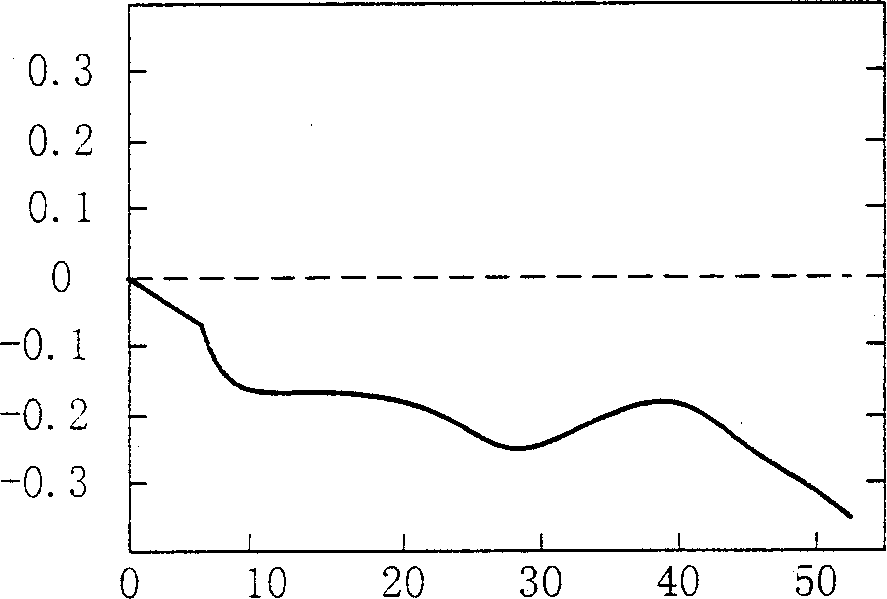

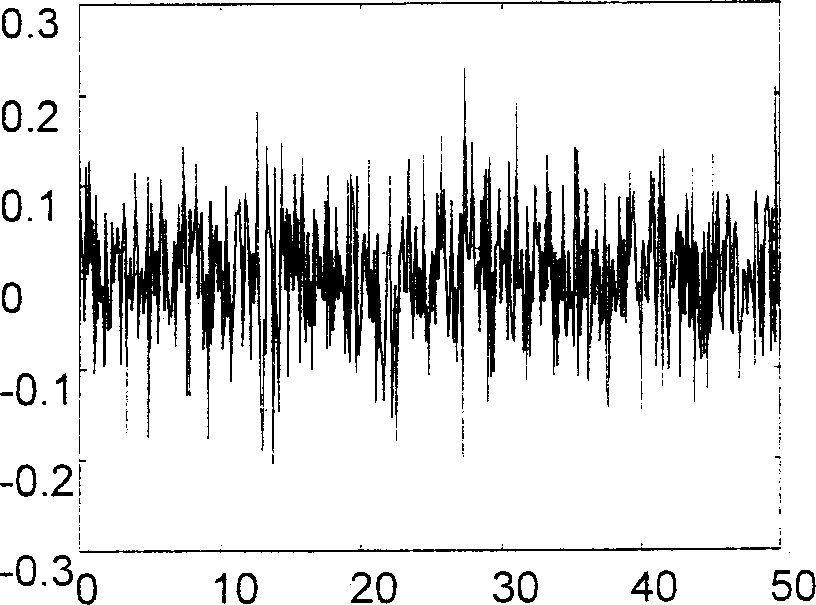

Time delay treatment method of manned diving apparatus position measurement

InactiveCN1719198AImprove measurement errorThe existence of measurement error, the position estimation error increasesNavigation instrumentsFilter algorithmEngineering

The present invention relates to a manned diving instrument position measurement time-delaying processing method. It is characterized by that it makes the currently-obtained over-time ultrashort baseline position measured value be compromised into manned diving instrument position culculation by means of Kallman filtering algorithm so as to implement optimum treatment of current manned diving instrument position information.

Owner:SHENYANG INST OF AUTOMATION - CHINESE ACAD OF SCI

Method for industrially preparing aluminum hydroxide, alumina and aluminum fluoride from andalusite sericite phyllite as raw material

InactiveCN101717104AEliminate the grinding processEnergy savingAluminium oxide/hydroxide preparationAluminium fluoridesHydrogen fluorideNational standard

The invention discloses a method for industrially preparing aluminum hydroxide, alumina and aluminum fluoride from andalusite sericite phyllite as a raw material, which comprises the steps of: extracting aluminum hydroxide with the purity of 96-98.5 percent from the andalusite sericite phyllite as the raw material in a mode of ball production, calcinations, multistage separation and auxiliary agent addition; then calcinating the raw material to obtain the alumina; and reacting fluorine hydride gas with wet hydrogen alumina and dehydrating and drying to obtain the aluminum fluoride. The method solves the problem that pseudo andalusite-sericite phyllite ore in Qingliu County, Sanming City, Fujian Province cannot be utilized; and the prepared aluminum hydroxide, alumina and aluminum fluoride accord with national standard.

Owner:福建天筑新型材料有限公司

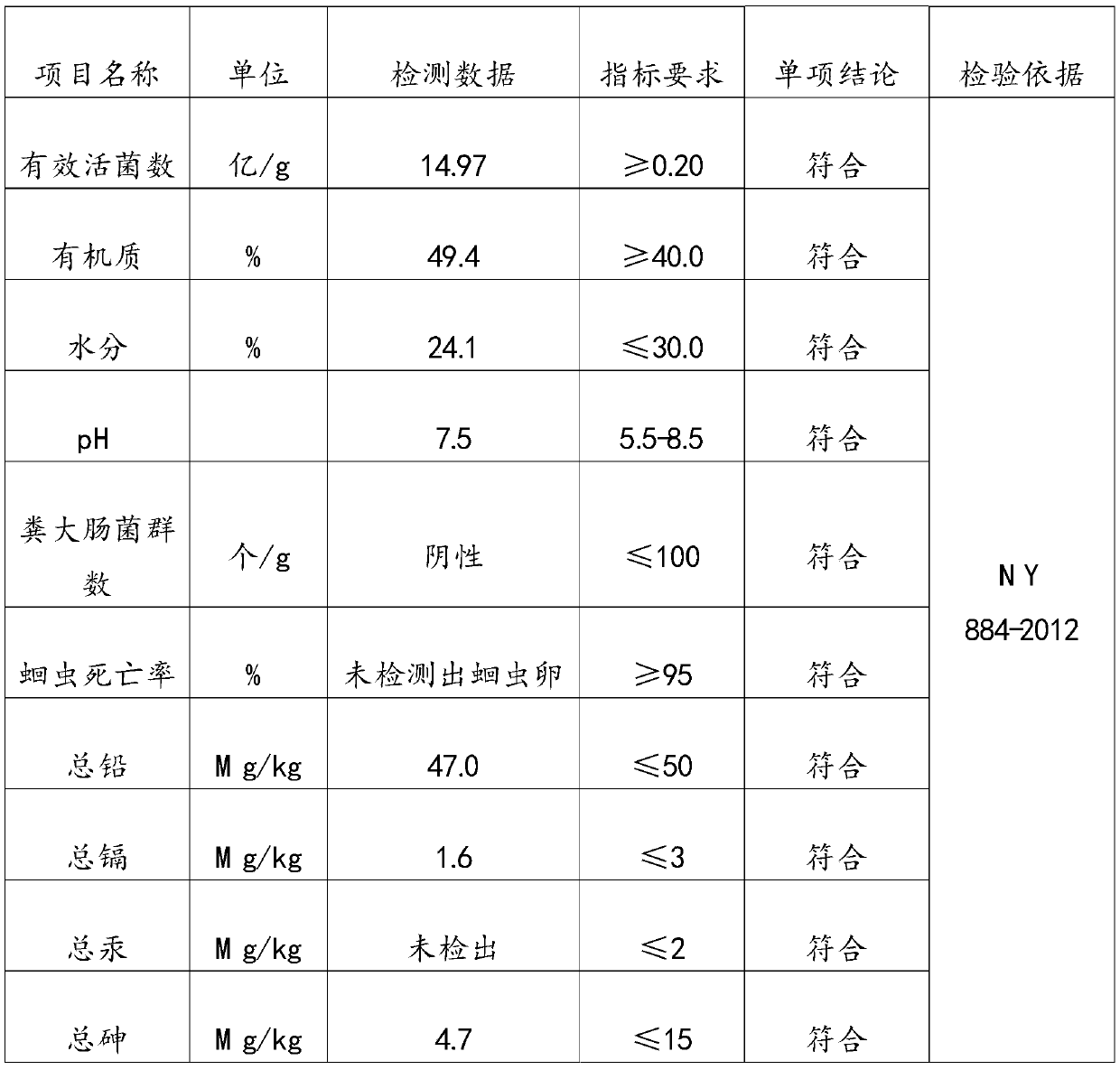

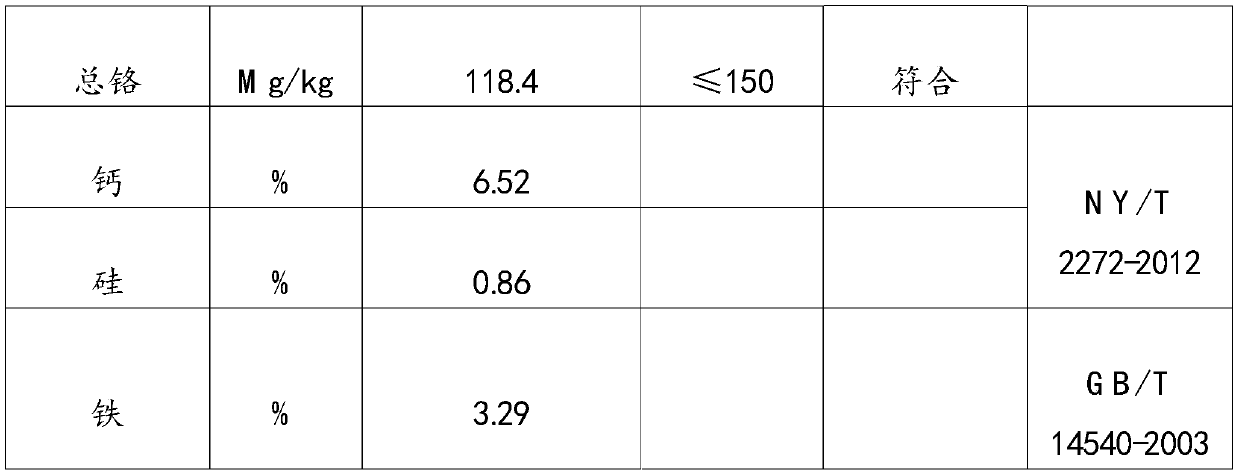

Organic fertilizer prepared from red mud and production process of organic fertilizer

InactiveCN109942339AUnavailable solutionSolve the pollution of the environmentFertilizer mixturesAluminum IonMicrobial agent

The invention discloses an organic fertilizer prepared from red mud and a production process of the organic fertilizer. The organic fertilizer includes animal excrements, straw, distillers' grains, saw dust, red mud, humic acid, low-molecular-weight organic acid, edible mushroom waste, bone meal, an antiviral agent and a microbial agent. The organic fertilizer has the advantages that the animal excrements, red mud, saw dust and straw are adopted as the raw materials, waste utilization is realized, environmental pollution is reduced, and the problem that the red mud cannot be utilized and pollutes the environment is solved. The low-molecular-weight organic acid and aluminum ions in the organic fertilizer cannot be absorbed by plants and fail after being exchanged and complexed, and nutrients in the red mud and other raw materials interact and can provide calcium, silicone and corresponding trace elements for crops; iron, silicone, calcium, magnesium and other nutrient elements are addedon the basis of an original organic fertilizer, the growth of the crops is promoted, diseases and insect pests can be reduced, an iron fertilizer is replaced, and a certain improvement effect on soilis realized.

Owner:刘凯平

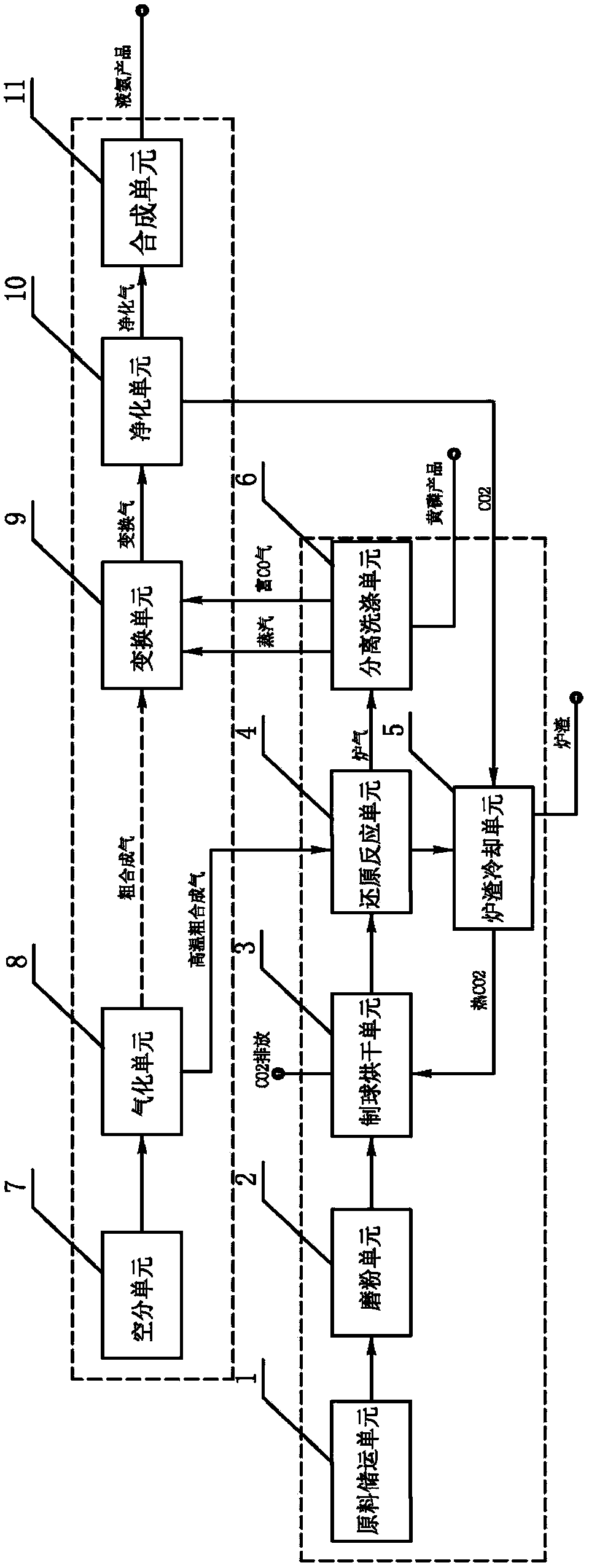

Chemical co-production equipment and method for phosphorus and coal

PendingCN107739025AUnavailable solutionImprove utilization efficiencyGasification processes detailsPhosphorus compoundsSyngasSlag

The invention discloses chemical co-production equipment and a method for phosphorus and coal. The equipment is characterized in that high-temperature crude synthesis gas produced in a coal gasifyingreaction is taken as a heat source for producing yellow phosphorus, so that the problem that heat at a high-temperature segment of the crude synthesis gas produced in the coal gasifying reaction cannot be used is solved; moreover, heat can be supplied to yellow phosphorus production, and the energy utilization rate is high; meanwhile, a reaction product CO produced during yellow phosphorus production and the crude synthesis gas are taken as raw materials of synthesis ammonia, so that the yield of liquid ammonia is increased, and a production process is efficient and contributes to energy saving and environment protection. The chemical co-production equipment for the phosphorus and coal comprises a raw material storing-transporting unit, a grinding unit, a pelletizing-drying unit, a reducing reaction unit, a slag cooling unit, a separating-washing unit, an air separating unit, a gasifying unit, a converting unit, a purifying unit and a synthesizing unit. The chemical co-production equipment and method have the advantages of simplified process flow, technically mature in units, energy saving, environmental friendliness and low application risk, and a beneficial technical option is provided for phosphorus and coal chemical complementation in various fields.

Owner:BEIJING AEROSPACE MWAY TECH CO LTD

Method of simultaneously producing crystallized sorbitol and daily chemical sorbitol

The invention discloses a method of simultaneously producing crystallized sorbitol and daily chemical sorbitol. According to the method disclosed by the invention, the crystallized sorbitol and the daily chemical sorbitol are simultaneously obtained by taking starch as a raw material and through size mixing of the starch, liquefying, saccharifying, impurity removal, deacidification and desalination, evaporation and concentration, hydrogenation, sedimentation and decoloration, desalination, as well as washing, filtering and purifying. The method disclosed by the invention has the advantages of high efficiency, high raw material utilization rate, high additional value of products, short process flow, low production cost, low energy consumption, energy saving and water saving, and a prepared crystallized sorbitol product is high in purity and capable of meeting the requirements of applying to the field of industries, such as medicines, food and Vc; in the meantime, the obtained daily chemical sorbitol as a side product has good physical and chemical properties and can meet the requirements of preparing the daily chemical products, such as toothpaste, cosmetics and cigarettes.

Owner:CHENGDU LIANJIE MEMBRANE TECH

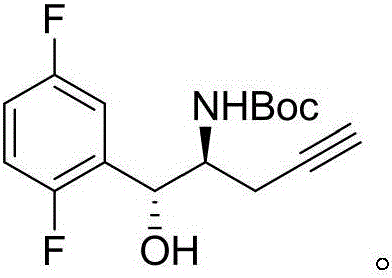

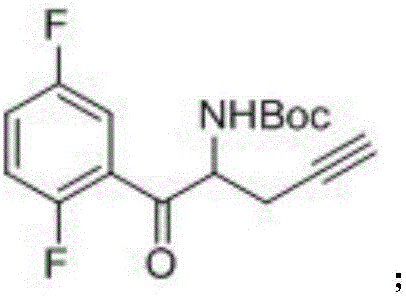

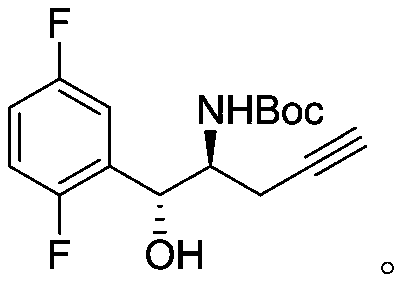

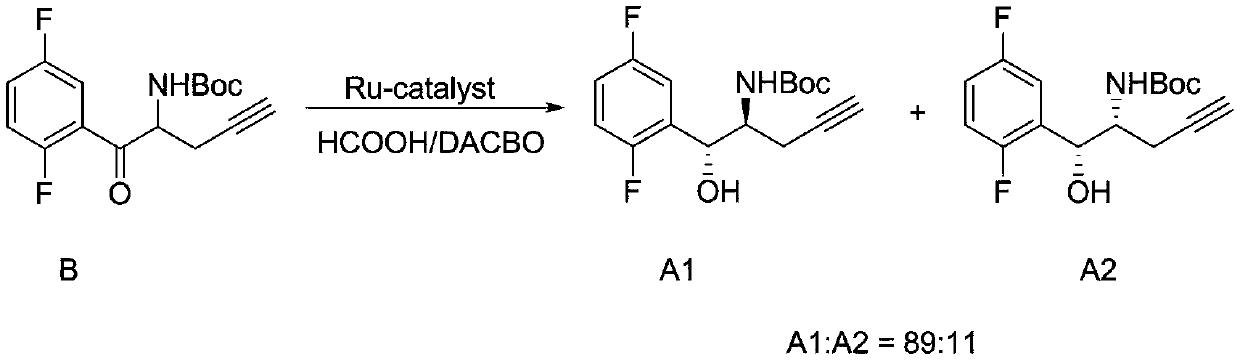

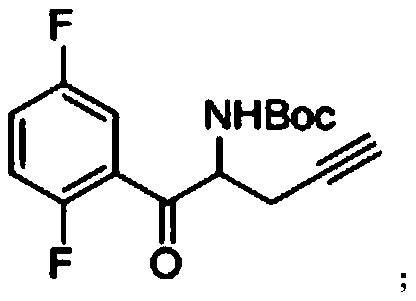

Omarigliptin intermediate preparation method

The invention provides an omarigliptin intermediate preparation method. The omarigliptin intermediate preparation method comprises the step of mixing a compound I with a catalyzing enzyme, and reacting to obtain an omarigliptin intermediate. The omarigliptin intermediate preparation method has the beneficial effects that the cost of raw materials is reduced; the problem in the prior art that isomer byproducts are generated during preparation of the omarigliptin intermediate and cannot be utilized is effectively solved; the yield and atom economy are increased; and the omarigliptin intermediate preparation method is simple in operation, mild in conditions, environment-friendly and suitable for industrial production.

Owner:SUZHOU LEAD BIOTECH CO LTD

Acne and freckle removing essence mask and preparation method

InactiveCN110236962AImprove skin care effectImprove comfortCosmetic preparationsToilet preparationsIrritationMedicine

The invention belongs to the field of masks, and particularly relates to an acne and freckle removing essence mask and a preparation method. Components of a mask essence, a preparation method of a spray mask and a cosmetic bottle for the spray mask are involved. The components of the mask essence have the good effects of cleaning and moisturizing the skin, resisting oil and whitening the skin, removing freckles and acne, and nursing the skin mildly without irritation. By adopting the preparation method, the active ingredients in the spray mask are ensured to the maximum, and the skin is better nursed; the spray mask needs to be used in cooperation with the cosmetic bottle for the spray mask, the function of assisting in spraying the mask can be achieved, and the effect of making the essence fully absorbed is achieved.

Owner:郭芮

Normal pressure method coking coal and ore powder molding binder and molding method

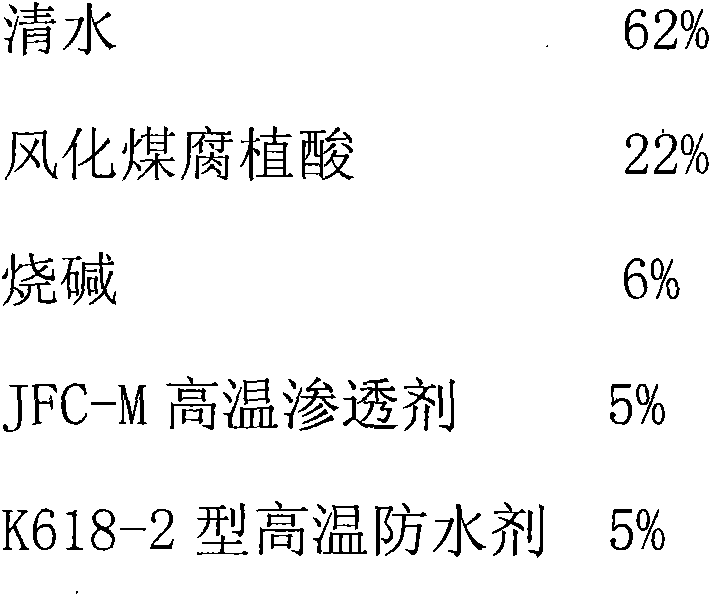

InactiveCN103992768AImprove adhesionUnavailable solutionNon-macromolecular adhesive additivesThermal insulationMixed materials

The present invention provides a normal pressure method coking coal and ore powder molding binder and a molding method, wherein the binder comprises 62% of clear water, 22% of weathered coal humic acid, 6% of caustic soda, 5% of a high temperature penetrant, and 5% of a high temperature waterproof agent. The production method comprises: 1, placing clear water into a reaction kettle to heat to a temperature of 60 DEG C; 2, placing weathered coal humic acid and caustic soda into the reaction kettle, stirring, and heating to a temperature of 85 DEG C; 3, adding a high temperature penetrant and a high temperature waterproof agent to the material obtained in the step 2, carrying out thermal insulation for 20 min, cooling to 50-60 DEG C, and taking the solution so as to obtain the finished product; and 4, placing the mixed material into a storage tank, and maintaining the 40-50 DEG C state for use. The molding method comprises: 1, processing coking coal powder into 50-100 mesh powder, and processing ore powder into 60-120 mesh powder; 2, taking a binder according to the coking coal powder content of 18-20% and the ore powder content of 15-18%; 3, conveying into a disc granulator to carry out mixing granulation; and 4, carrying out air-drying or drying to obtain the molded material. The obtained molded material can not burst at a high temperature of more than 1350-1600 DEG C, the cold material can not be subjected to moisture regain, and the material can be used for yellow phosphorus, metal smelting, calcium carbide production and other industries.

Owner:张长杰

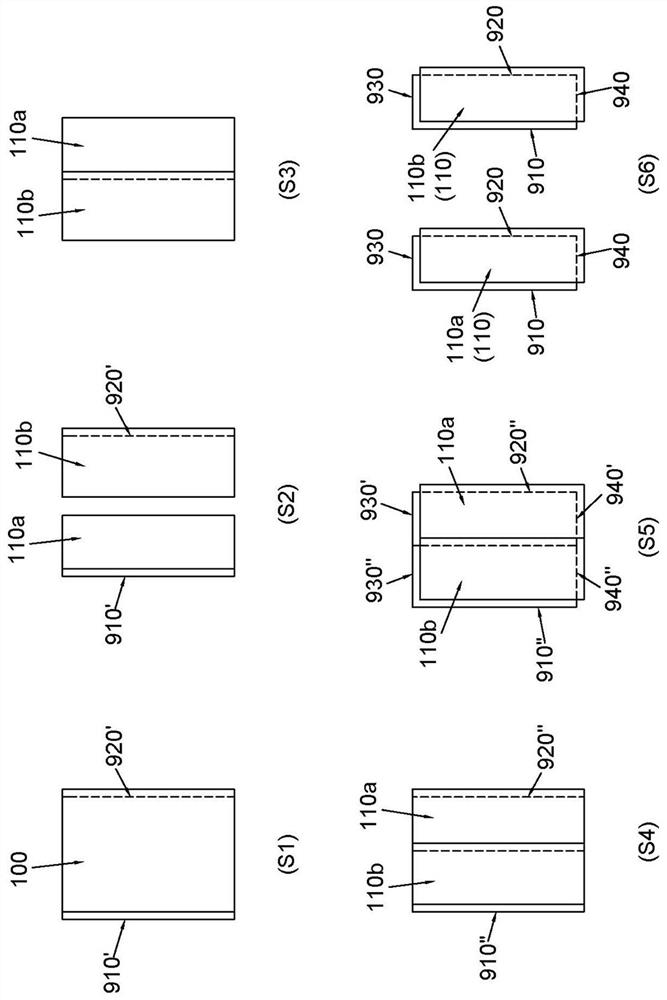

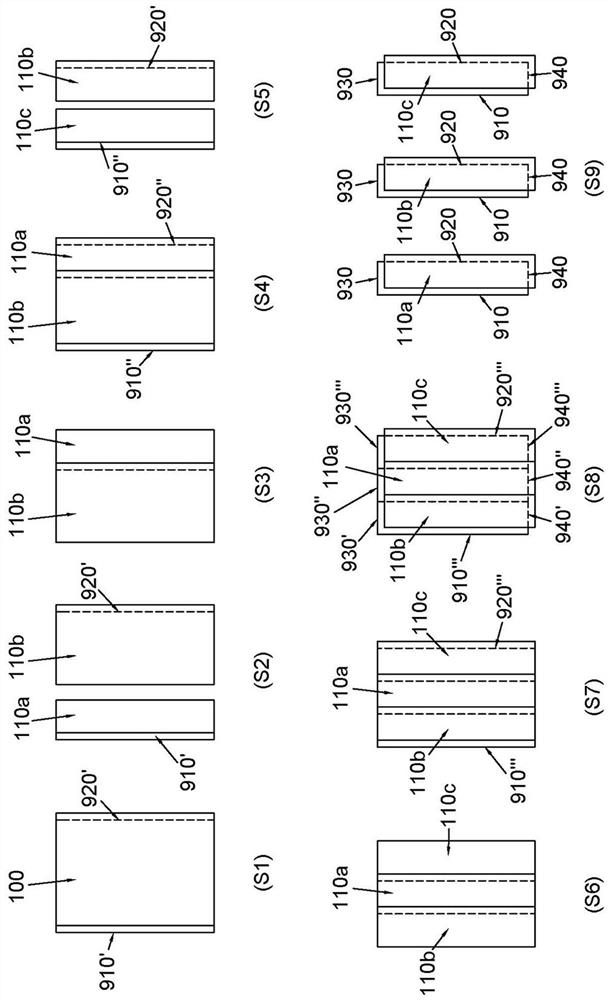

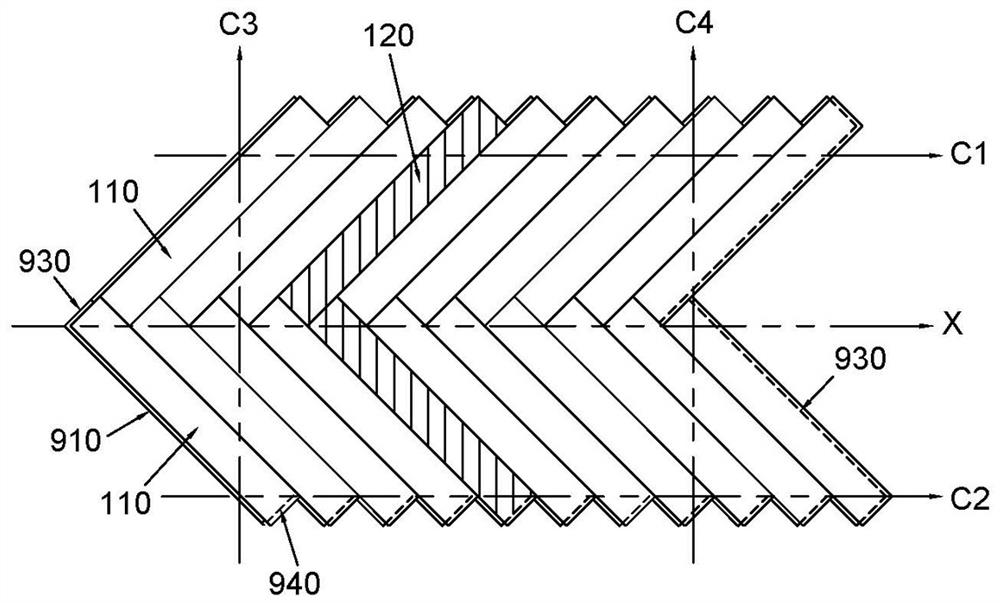

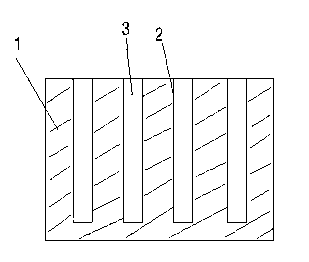

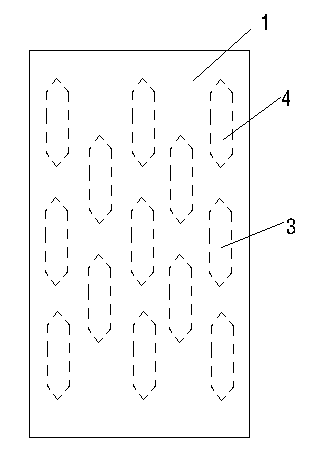

Narrow decorative solid wood floor and production method for its combination

ActiveCN110861182BUnavailable solutionSolve the problem of missing applicationsWood working apparatusFlooringSolid woodStructural engineering

The application discloses a production method of a narrow decorative solid wood floor, which includes the following steps: S1. Take a blank and process it on the long sides on both sides to form a first long-side male tenon and a first long-side female tenon; S2. Splitting the blank formed on the long side longitudinally to form a first sub-material and a second sub-material; S3. passing the first sub-material and the second sub-material through the first long-side male tenon Cooperate with the first long-side tenon to form a first intermediate material; S4. Process and form a second long-side male tenon and a second long-side tenon on the long sides of the first intermediate material , so as to form the second intermediate material; S5. process the short sides of the two ends of the second intermediate material to form the short-side male tenon and the short-side female tenon of the sub-material; S6. separating from the second sub-material to form the first sub-material and the second sub-material. Thereby end waste can be made into solid wood flooring, avoiding the waste of solid wood materials.

Owner:江苏天格地板有限公司

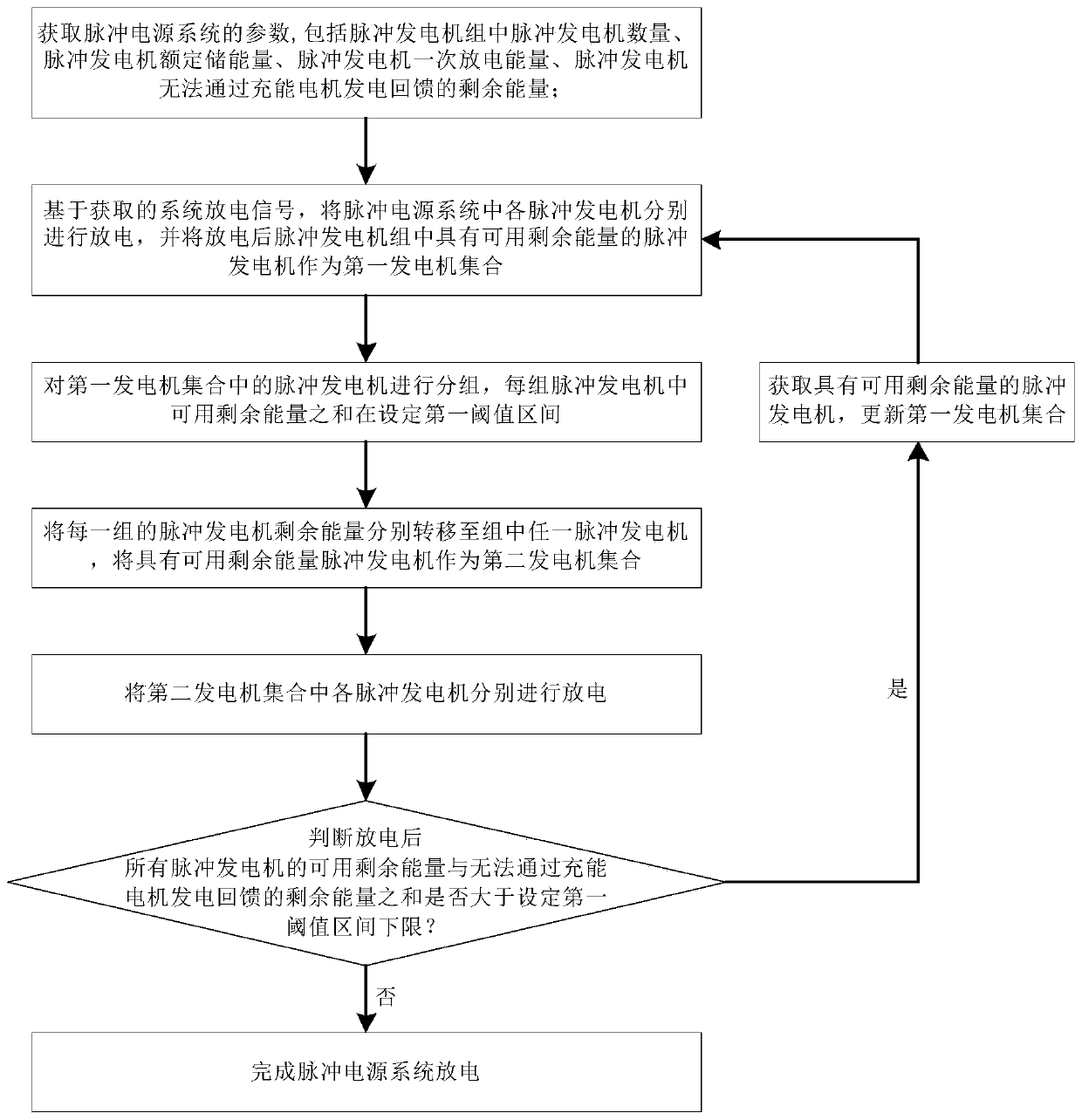

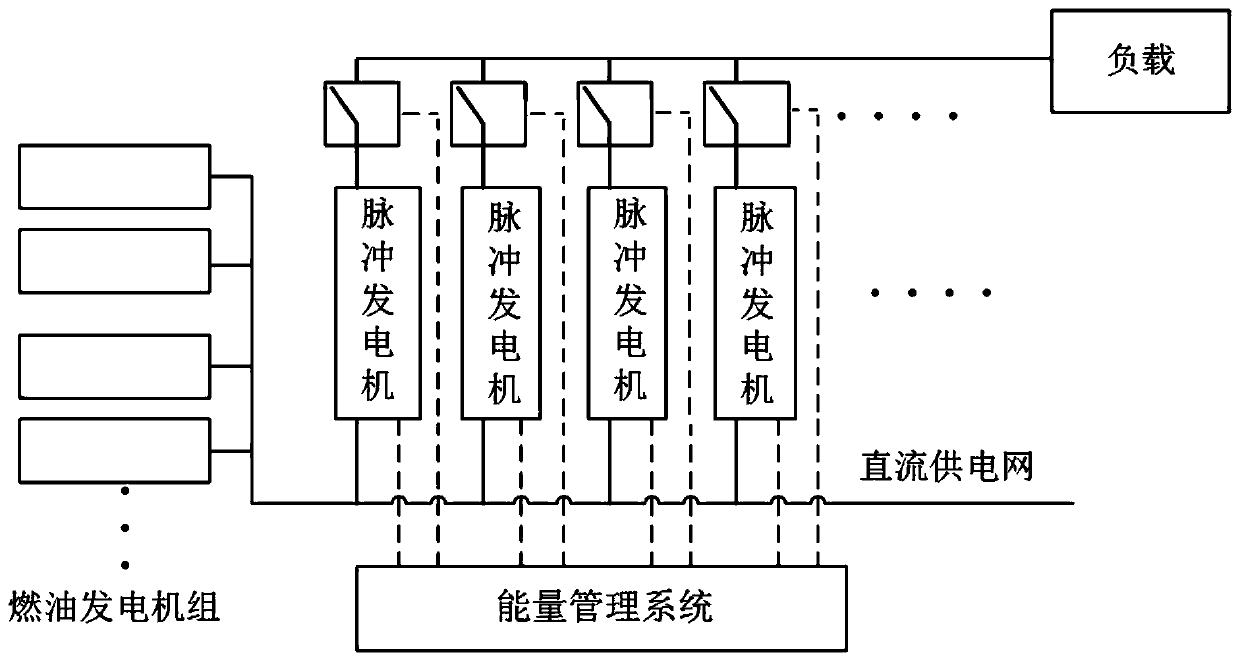

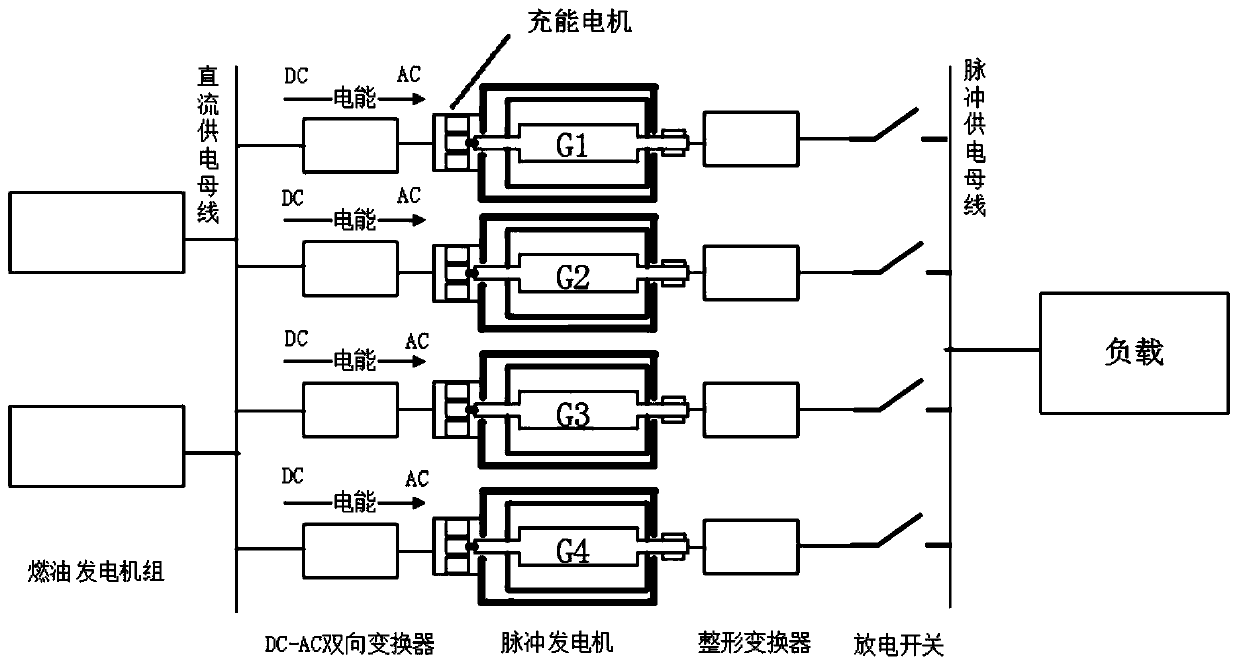

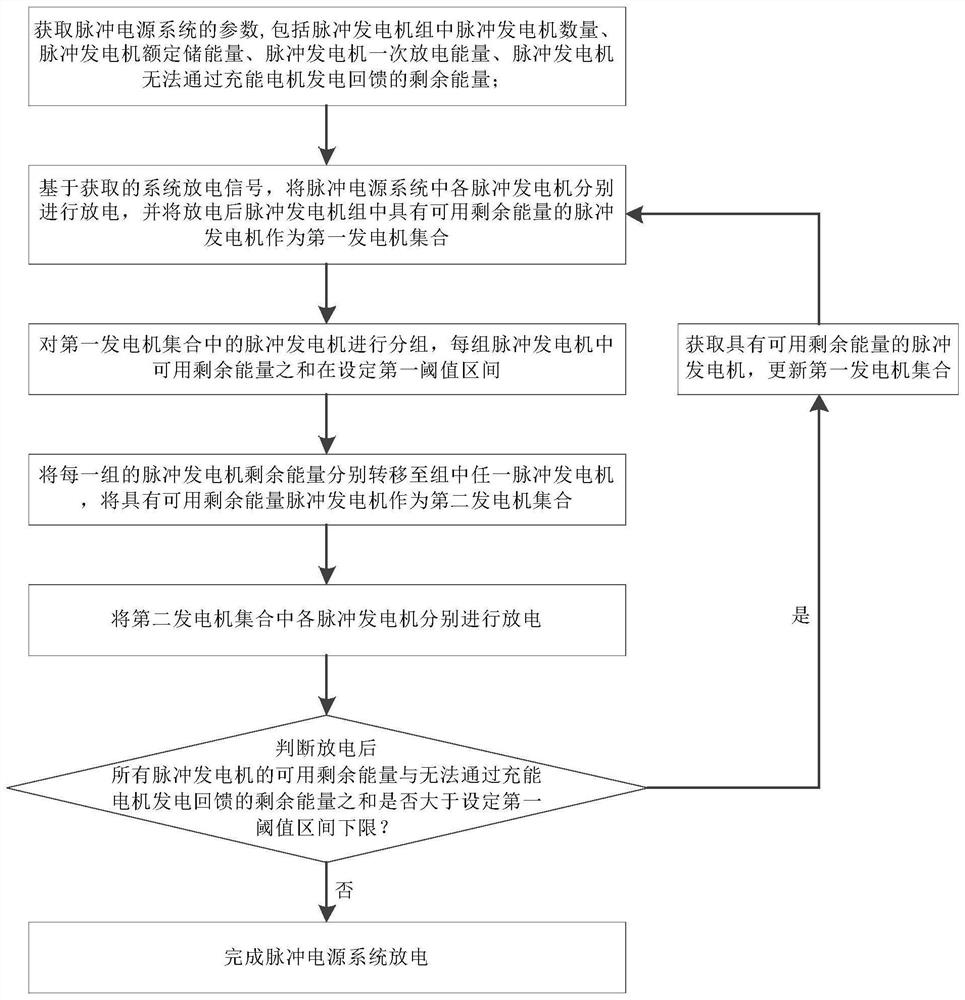

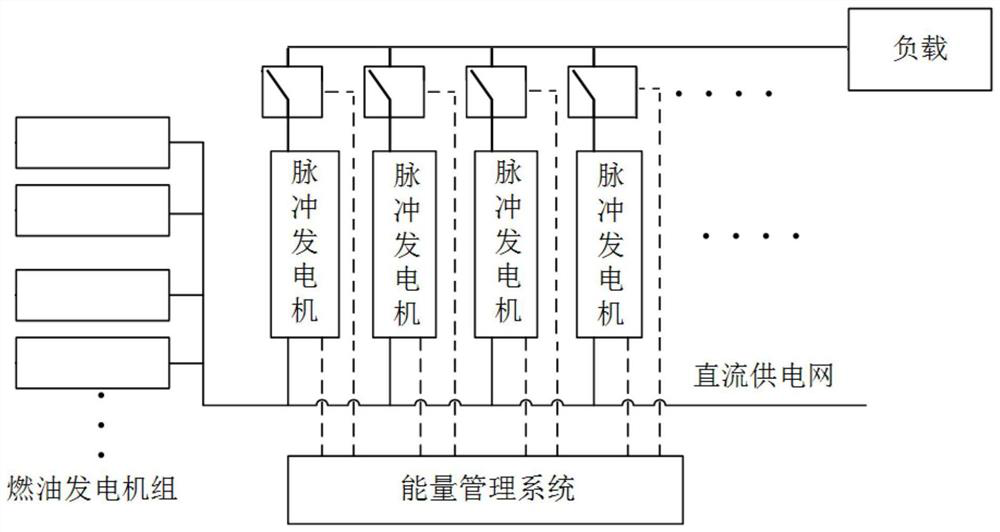

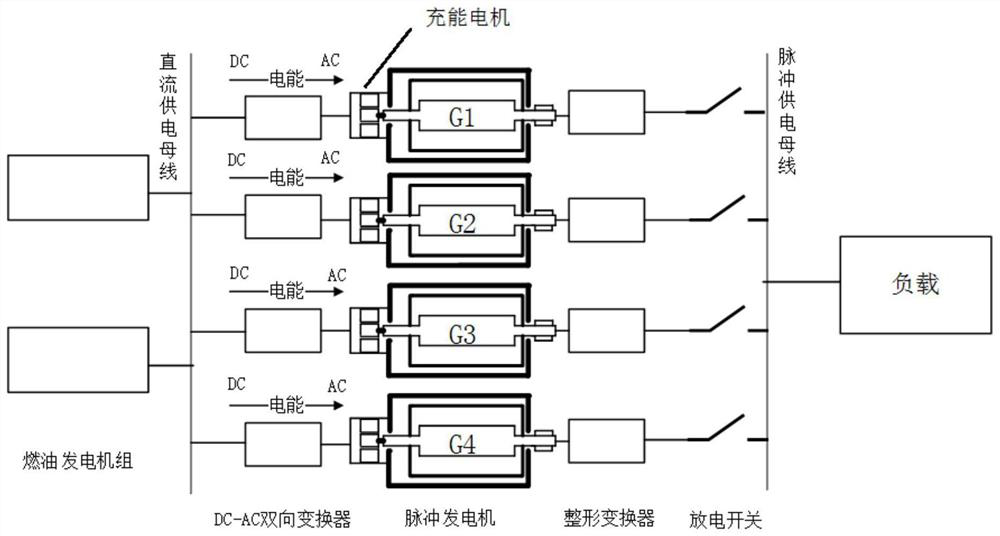

Pulse power supply system based on generator cluster and energy storage microgrid and discharging method

ActiveCN110867888AUnavailable solutionIncrease profitSingle network parallel feeding arrangementsAc network load balancingMicrogridPulse power supply

The invention belongs to the field of pulse power generation, particularly relates to a pulse power supply system based on a generator cluster and an energy storage microgrid and a discharging method,and aims to solve the problem that residual energy of a pulse generator cannot be fully utilized in the prior art. The method comprises the following steps: respectively discharging each pulse generator based on a system discharge signal and parameters; grouping the pulse generators, and transferring the residual energy of each group to any pulse generator in the group; discharging again, grouping the pulse generators with available residual energy, and performing energy transfer again; and iteratively discharging the pulse generator set until the rotating speed of the pulse generator is reduced to the condition that discharge and the power generation indexes do not meet the requirements. According to the invention, by utilizing the characteristic that through the controllable rectification of charging motor, constant-voltage power generation can be carried out in a wide rotating speed range, so residual energy can be transferred in the pulse generator cluster, the conversion ratio from inertia kinetic energy to pulse electric energy is improved from the system level, and the energy utilization rate is improved.

Owner:INST OF ELECTRICAL ENG CHINESE ACAD OF SCI

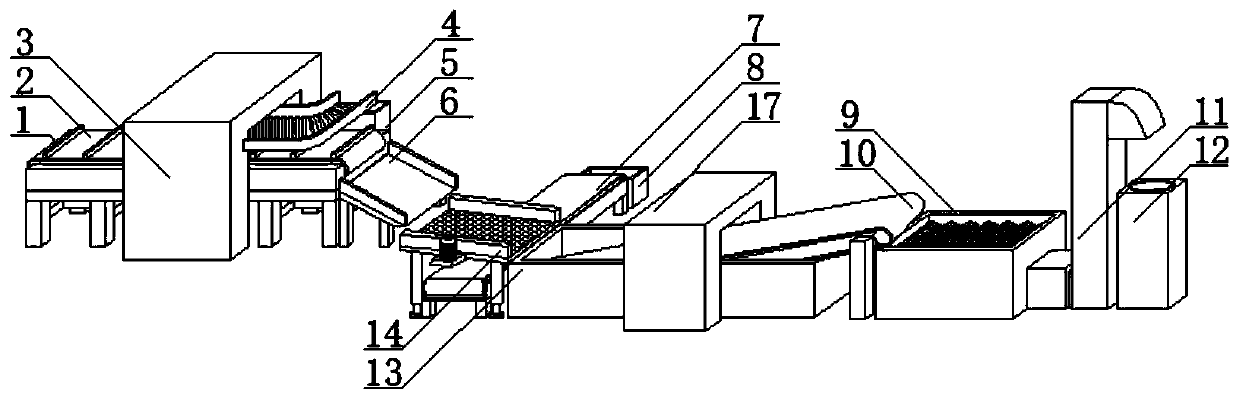

Waste automobile battery disassembling machine

PendingCN109830771AReduce labor intensityTime-consuming and laborious to solveWaste accumulators reclaimingBattery recyclingAutomotive batteryEngineering

The application discloses a waste automobile battery disassembling machine which comprises a loading conveyor belt, wherein a conveying plate, a support frame, a vibrating separation screen, a washingmachine, a cleaning liquid collection pool, a cleaning conveyor belt, and a pulverizer, a bucket elevator and a dryer are successively disposed at a side of the loading conveyor belt; a plurality ofbaffles are fixed to the loading conveyor belt at equal intervals; the support frame spans the loading conveyor belt; a cutting device is disposed in the support frame; the conveying plate and the vibrating separation screen are both inclined; and the lower end of the vibrating separation screen is provided with an electrode plate conveyor belt. The waste automobile battery disassembling machine reduces the labor intensity of an operator, has high disassembly efficiency, achieves automatic transport after loading materials, automatically separates battery cases from battery covers, can separate the battery cases from battery plates, and transports the battery plates to a collection area. The battery cases are cleaned, automatically pulverized and dried, and the waste battery cases are madeinto plastic granules to be recycled. The battery plates are used as raw materials for producing lead.

Owner:灵武市恒业有色金属冶化有限公司

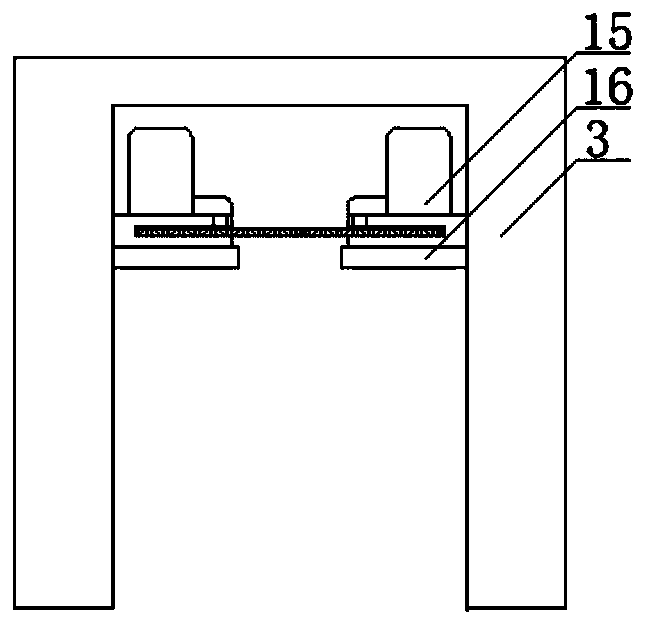

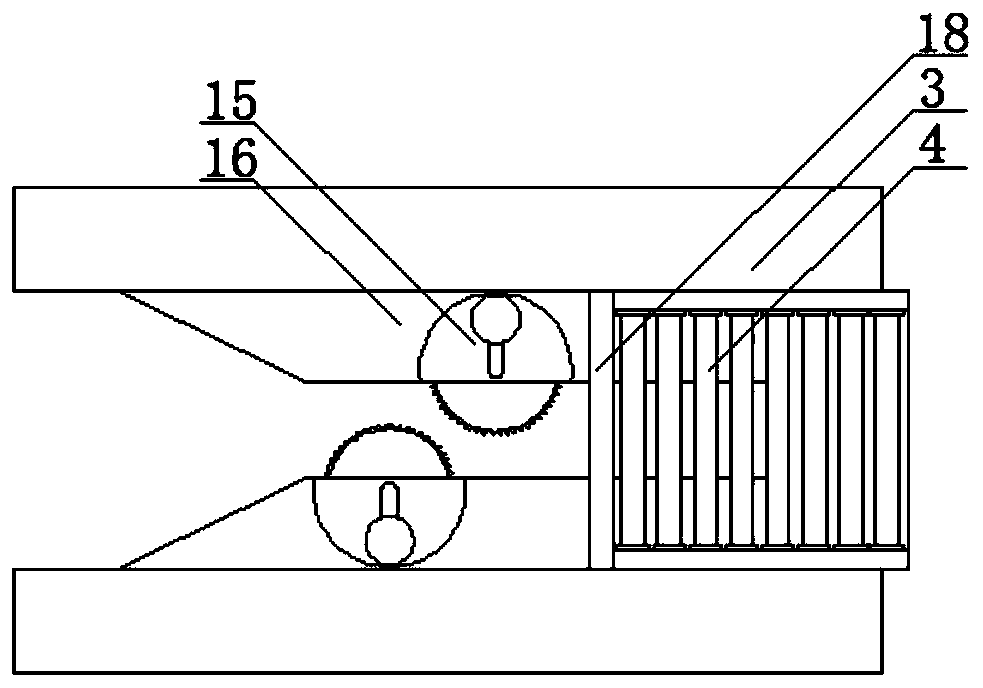

Cement caking waste grinding device and using method thereof

ActiveCN113117793AHigh environmental protection creates meaningIncrease profitSolid waste managementCement productionGrindingBuilding material

The invention discloses a cement caking waste grinding device. The cement caking waste grinding device comprises a double-gate type circulating screening and feeding device, a stepped continuous layered grinding device and an independent detachable material collecting device, the stepped continuous layered grinding device is arranged on the double-gate type circulating screening and feeding device, and the independent detachable material collecting device is arranged on the double-gate type circulating screening and feeding device. The invention belongs to the technical field of building material waste recovery, and particularly relates to the cement caking waste grinding device and a using method thereof. Blanking, screening and secondary grinding of large particles which are not completely ground are orderly controlled through the double-gate type circulating screening and feeding device, a grinding part is designed to be the stepped continuous layered grinding device, the effect of continuous grinding in a relatively closed space is achieved, during grinding, a grinding base and cement powder on the base are heated through an electric heating plate, and the problems that in the prior art, cement recycling treatment is difficult, and in the prior art, moisture is not easy to control, and grinding efficiency is low are effectively solved.

Owner:邢台金隅冀东水泥有限公司

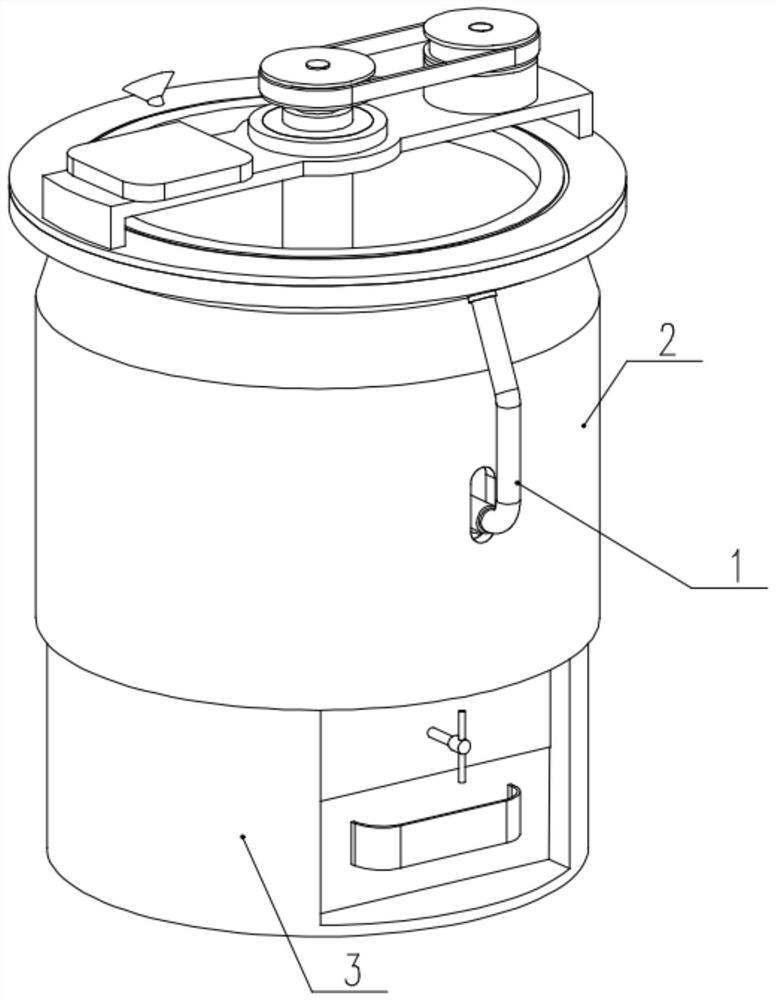

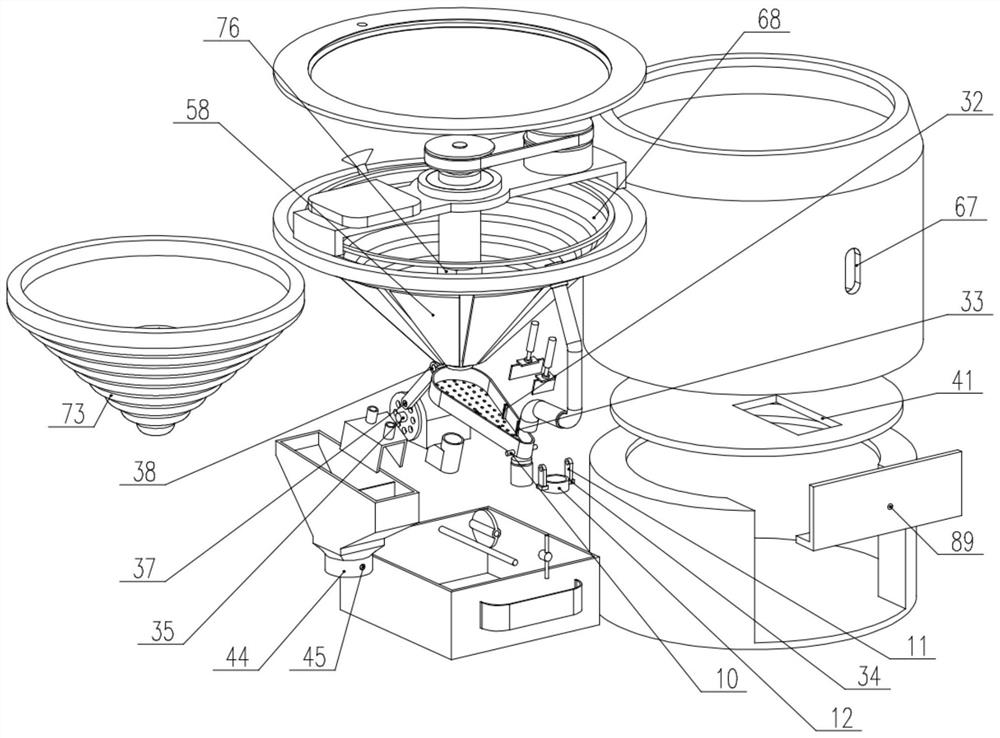

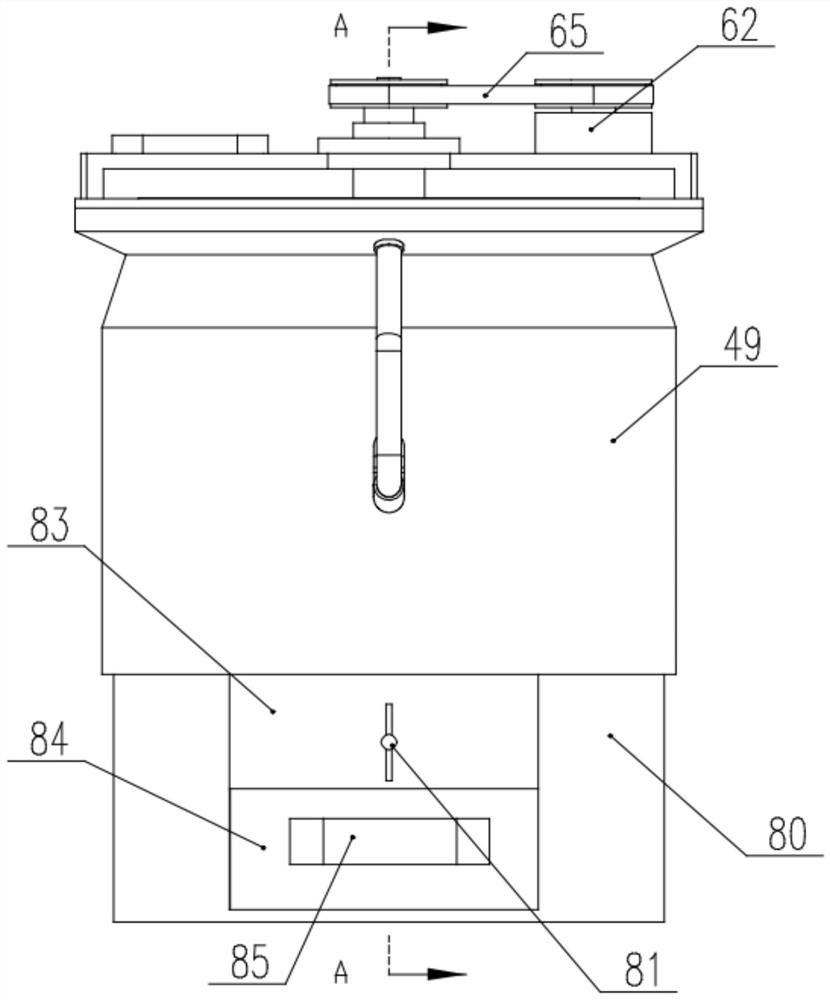

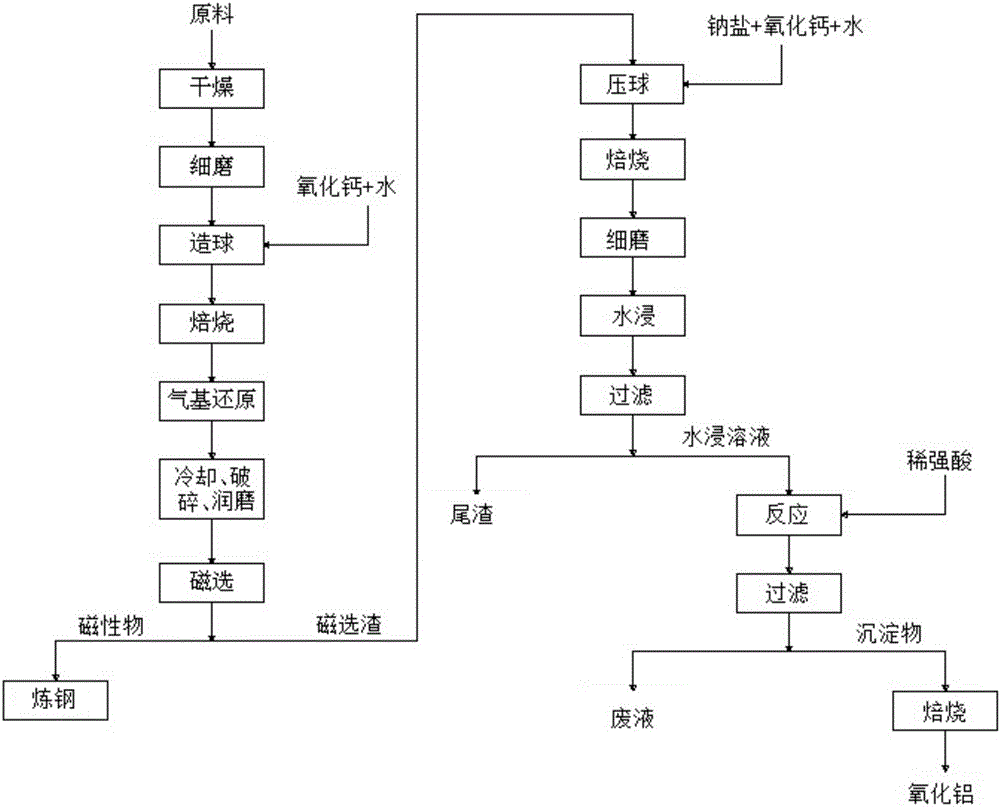

Method for red mud reduction by adopting gas-based shaft furnace

PendingCN106755966AShort processEliminate coking stepProcess efficiency improvementPollutantMetallurgical coke

The invention discloses a method for red mud reduction by adopting a gas-based shaft furnace. The method comprises the following steps: preparing red mud powder; mixing the red mud powder, CaO and water to prepare a first pellet; drying the first pellet, and roasting the dried first pellet into an oxidization pellet; feeding the oxidization pellet in the gas-based shaft furnace for reduction to obtain a metallized pellet; cooling, crushing and wet-grinding the metallized pellet, and then magnetic separation is carried out to obtain a magnetic substance and magnetic separation slag; and adopting the magnetic substance for steelmaking. According to the invention, the gas-based shaft furnace is adopted for red mud reduction without metallurgical coke, coking coal is not consumed, the technological processes are few, the coking step is eliminated, energy consumption of a system is reduced, and emission of pollutant is also reduced. The technology is simple and suitable for large-scale industrial production.

Owner:JIANGSU PROVINCE METALLURGICAL DESIGN INST

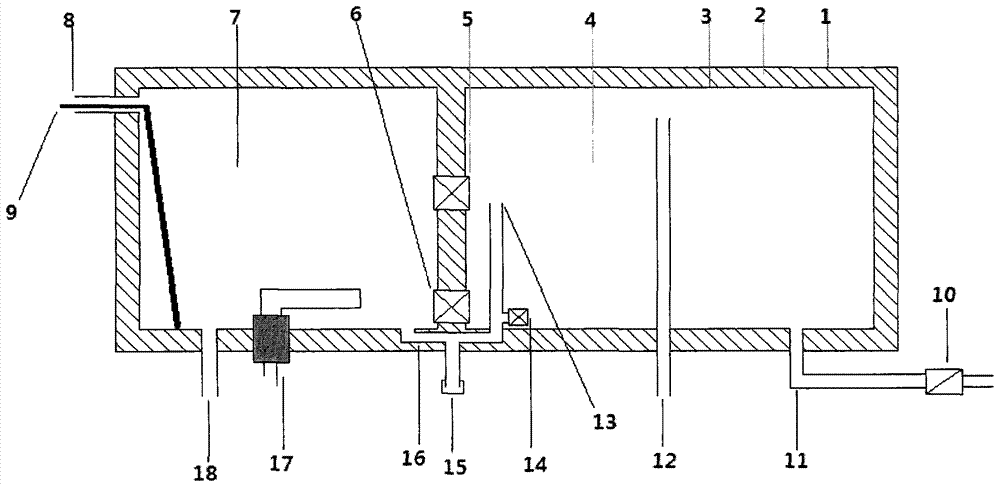

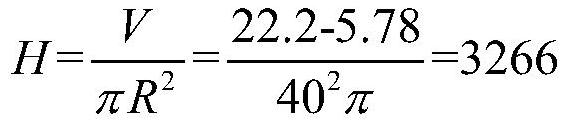

Heat preservation water tank capable of efficiently storing and utilizing solar energy heat through automatic separation and combination manners

InactiveCN103968585AEasy to useAvoid taking awaySolar heat devicesSolar thermal energy generationTemperature controlElectricity

The invention discloses a heat preservation water tank capable of efficiently storing and utilizing solar energy heat through automatic separation and combination manners. The heat preservation water tank is composed of an outer tank, a heat preservation layer, a first level water storing tank, a second water storing tank, a cold water inlet, an overflow hole which is utilized as an exhaust hole, an auxiliary electrical heating device, a hot water outlet, the exhaust hole, a U-shaped pipe sewage draining hole, a temperature controlled switch, a U-shaped pipe and an extending pipe, wherein two convection holes are formed between the two water tanks and are respectively provided with a convection temperature controlled switch, so that heat use ratio of solar energy is improved when the sunlight is not good, and heat storage volume of solar energy is improved when the sunlight intensity is high; one end of the U-shaped pipe is provided with a small temperature controlled switch and the extending pipe, a condition that water in the two water tanks is not mixed when the water tanks are electrically heated in rainy days is guaranteed, when the hot water is used, cold water can not enter the water tank, and the water in the two water tanks is used up in sunny day, so that the problem that abundant time and electricity are consumed during electric heating by the one-tank solar water heater is solved, and the problems that when a common two-tank solar water heater is used, cold water enters while hot water is used, so that the hot water can not be completely utilized, and the energy utilization rate is low are also solved.

Owner:周才强

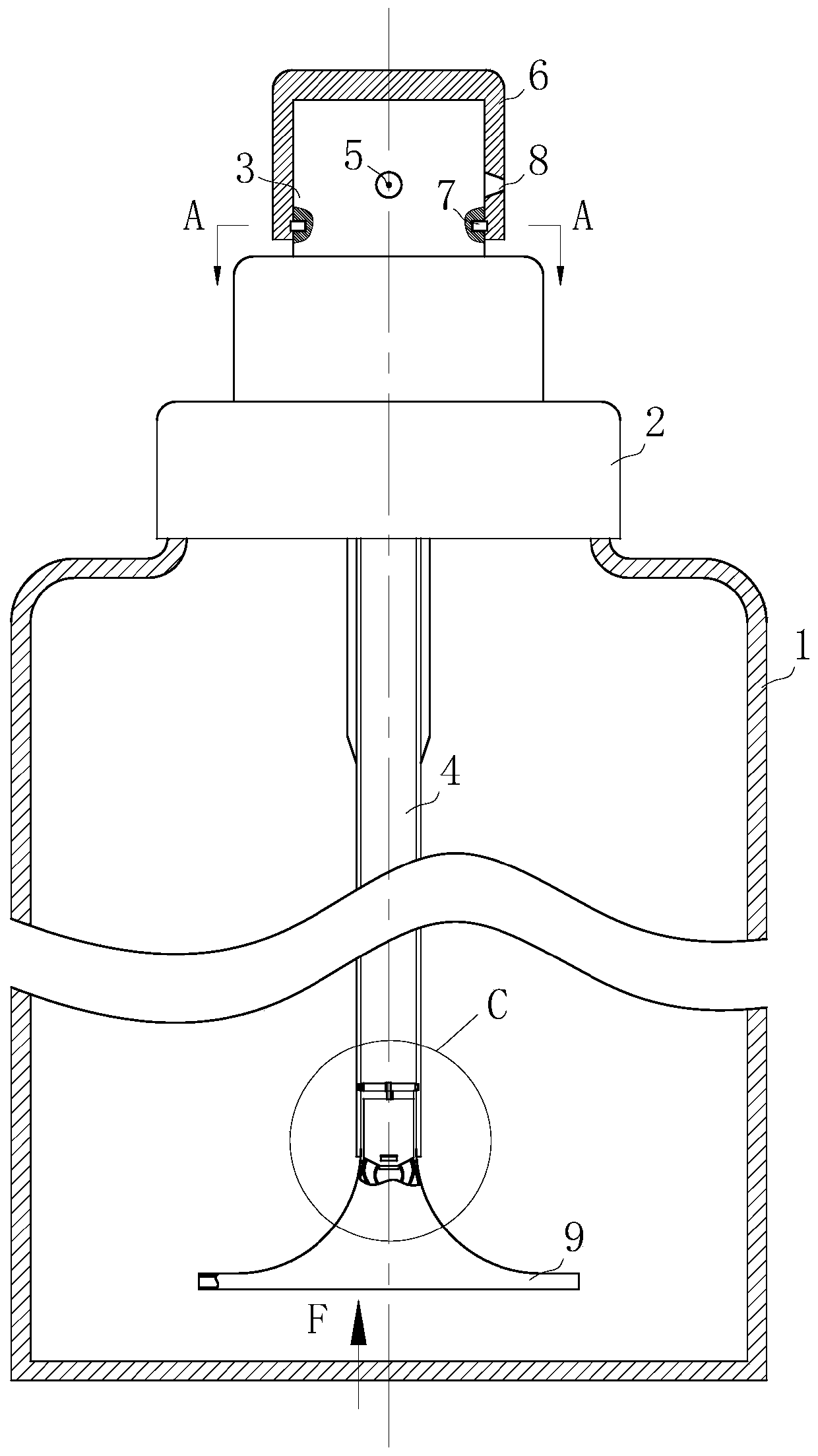

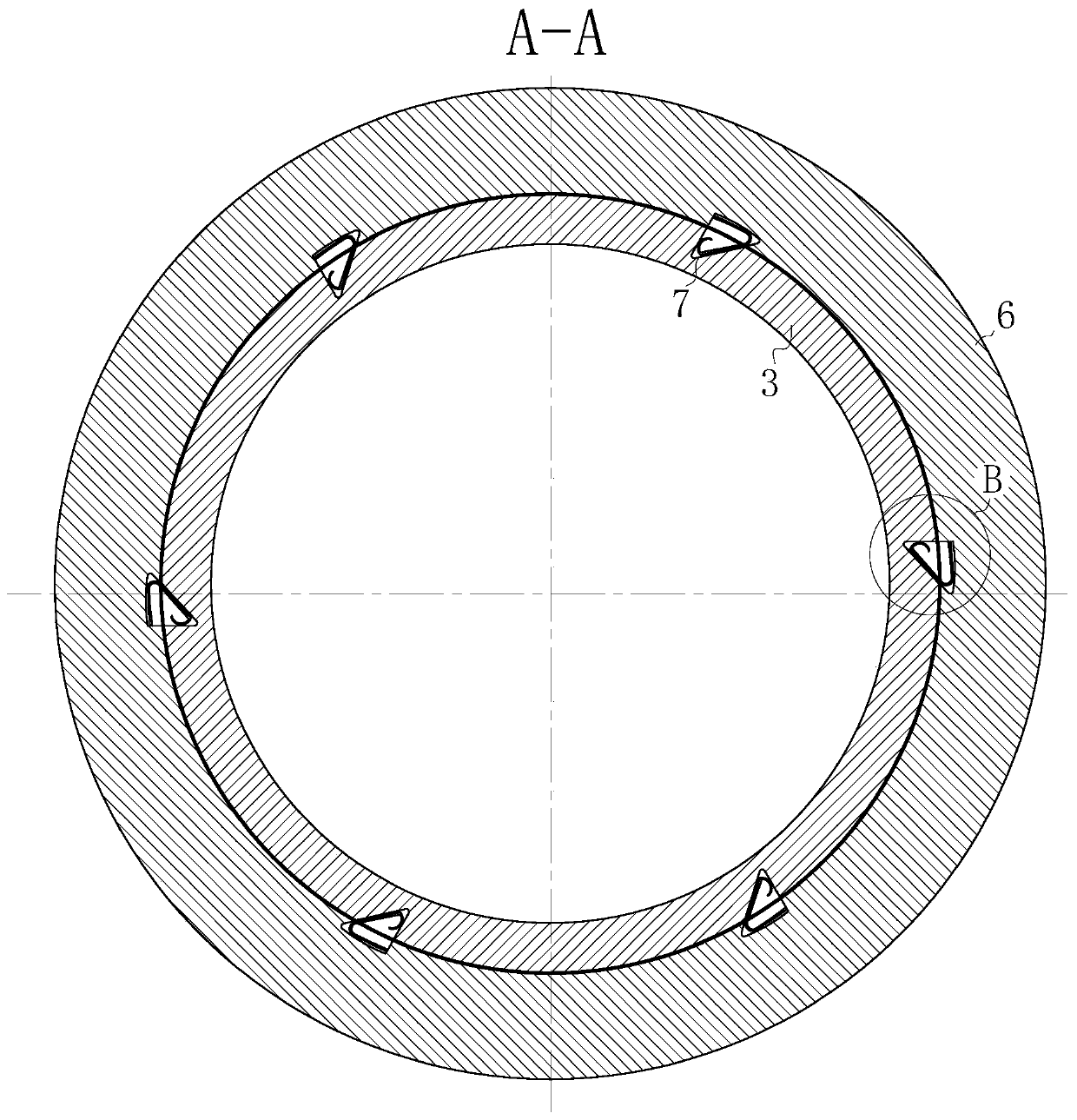

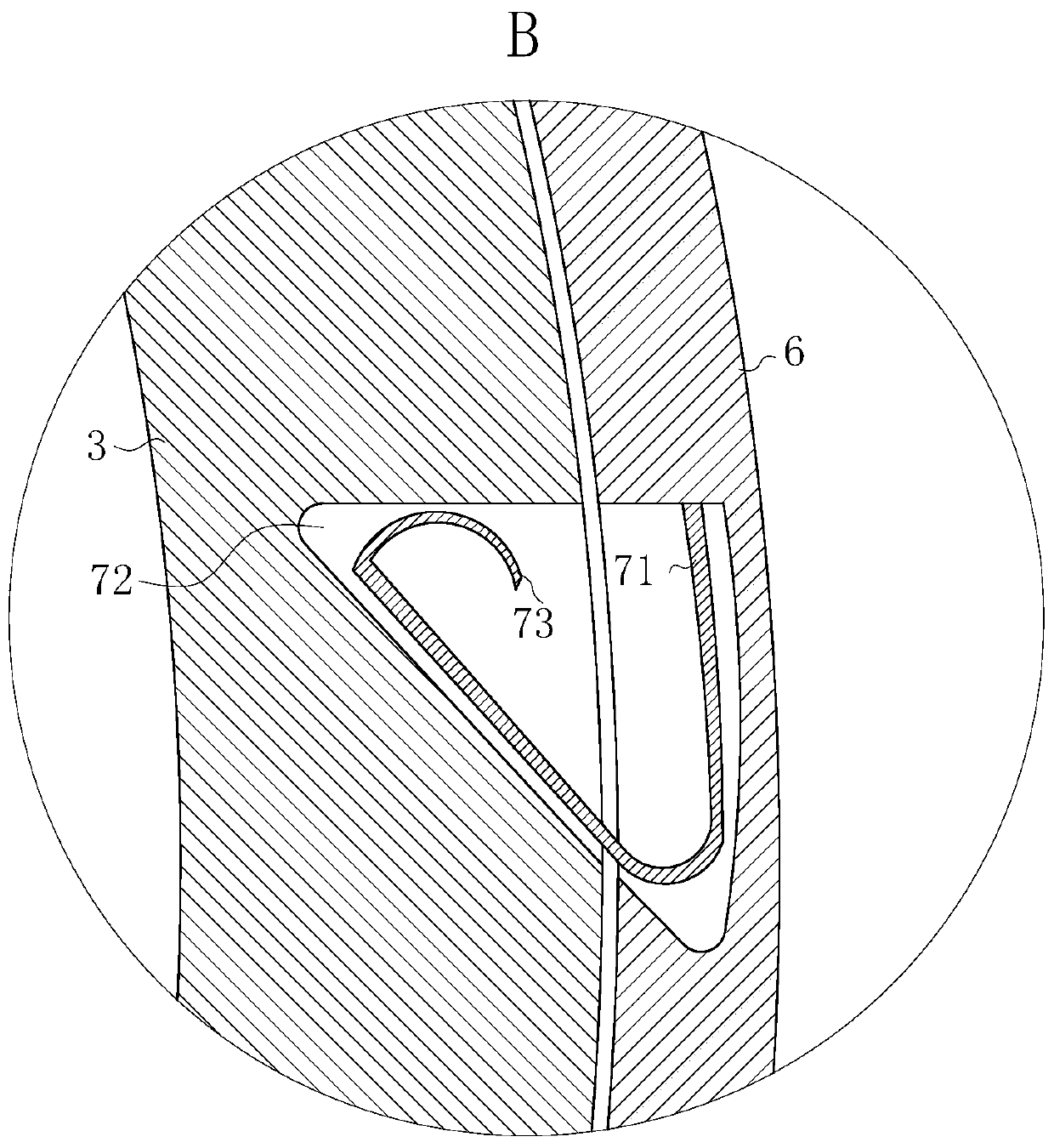

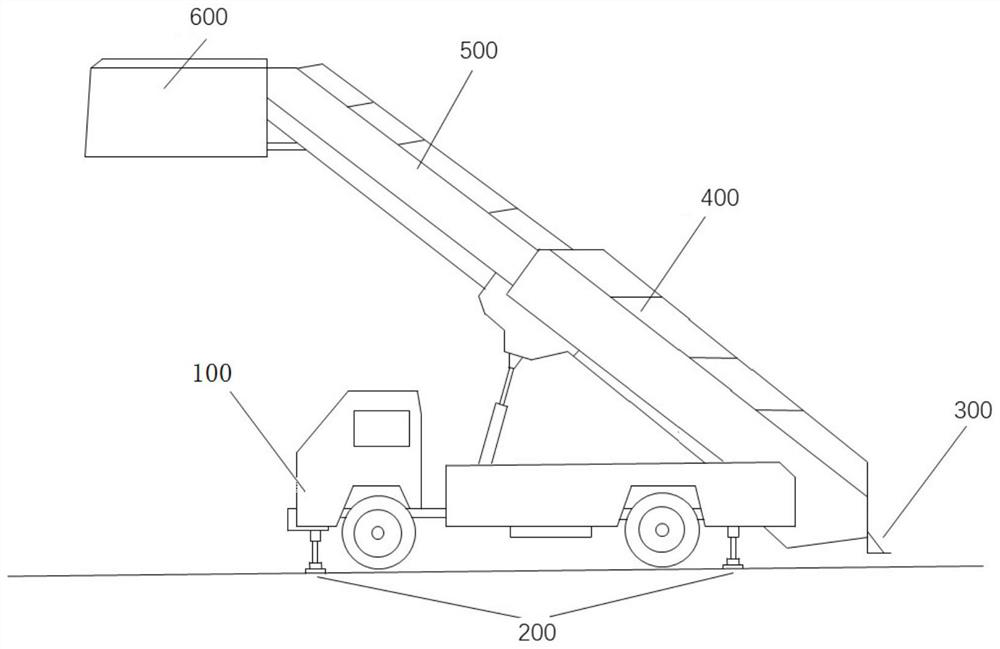

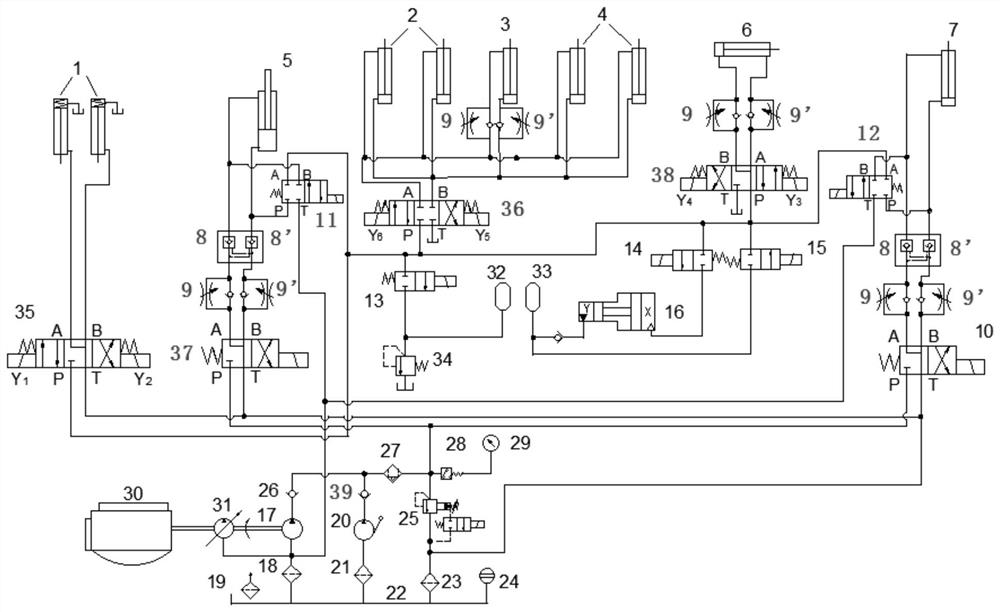

A hydraulic control system and method for passenger boarding ladders based on energy recovery

ActiveCN111946676BUnavailable solutionReduce in quantityServomotor componentsAccumulator installationsPartial gravityFixed ladder

The invention discloses a hydraulic control system and method for passenger boarding ladders based on energy recovery, which utilizes two main oil cylinders, an elevating oil cylinder and a hoisting oil cylinder, to recover potential energy for driving the support, tail ladder and platform extension and retraction, and solves the problem of current boarding ladders. The problem that most of the gravitational potential energy released during the descending process cannot be used and is consumed in vain reduces the economic cost. The excess energy can also be stored in the accumulator, which is controlled by the electromagnetic reversing valve to realize the controllability of the energy release of the accumulator. The hydraulic system retains the separate working process of each oil cylinder when the existing passenger boarding ladder is docked with the aircraft, which changes the working process that the passenger boarding ladder does not need to move back 15 meters and then recover the fixed ladder and sliding ladder when evacuating the aircraft. It not only saves the time for the vehicle to evacuate the aircraft, but also improves the economic efficiency.

Owner:威海军之翼智能科技有限公司

Preparation method of low-temperature ceramic combined SiC grinding material

PendingCN113913155AHigh strengthImprove grinding performanceOther chemical processesAbrasion apparatusCarbide siliconNanocomposite

The invention provides a preparation method of a low-temperature ceramic combined SiC grinding material, and belongs to the field of grinding material preparation and nano composite materials. The preparation method comprises the following specific preparation steps: adding silicon carbide micro powder into an ethanol water solution, ultrasonically stirring for 1-2 hours, adding a prepared low-temperature ceramic bond, and ultrasonically stirring for 1-2 hours; adding PVA into the silicon carbide mixed powder, performing mechanical stirring for 1-2 h, and performing sealed standing for 5-10 h; and granulating and drying the mixed powder, and carrying out heat treatment at 600-800 DEG C for 2-5 hours to obtain the low-temperature ceramic bonded SiC grinding material with reconstructed granularity. The silicon carbide is stable in property and excellent in use performance, but is relatively high in production cost, and more silicon carbide powder cannot be used due to too small particles in the production process, so that resource waste is caused. By introducing the low-temperature ceramic bond, the heat treatment temperature during particle size reconstruction of the silicon carbide is remarkably reduced, and the low-temperature ceramic bonded silicon carbide abrasive material after particle size reconstruction still has sharp edges and corners, higher strength and excellent grinding performance.

Owner:HENAN UNIVERSITY OF TECHNOLOGY

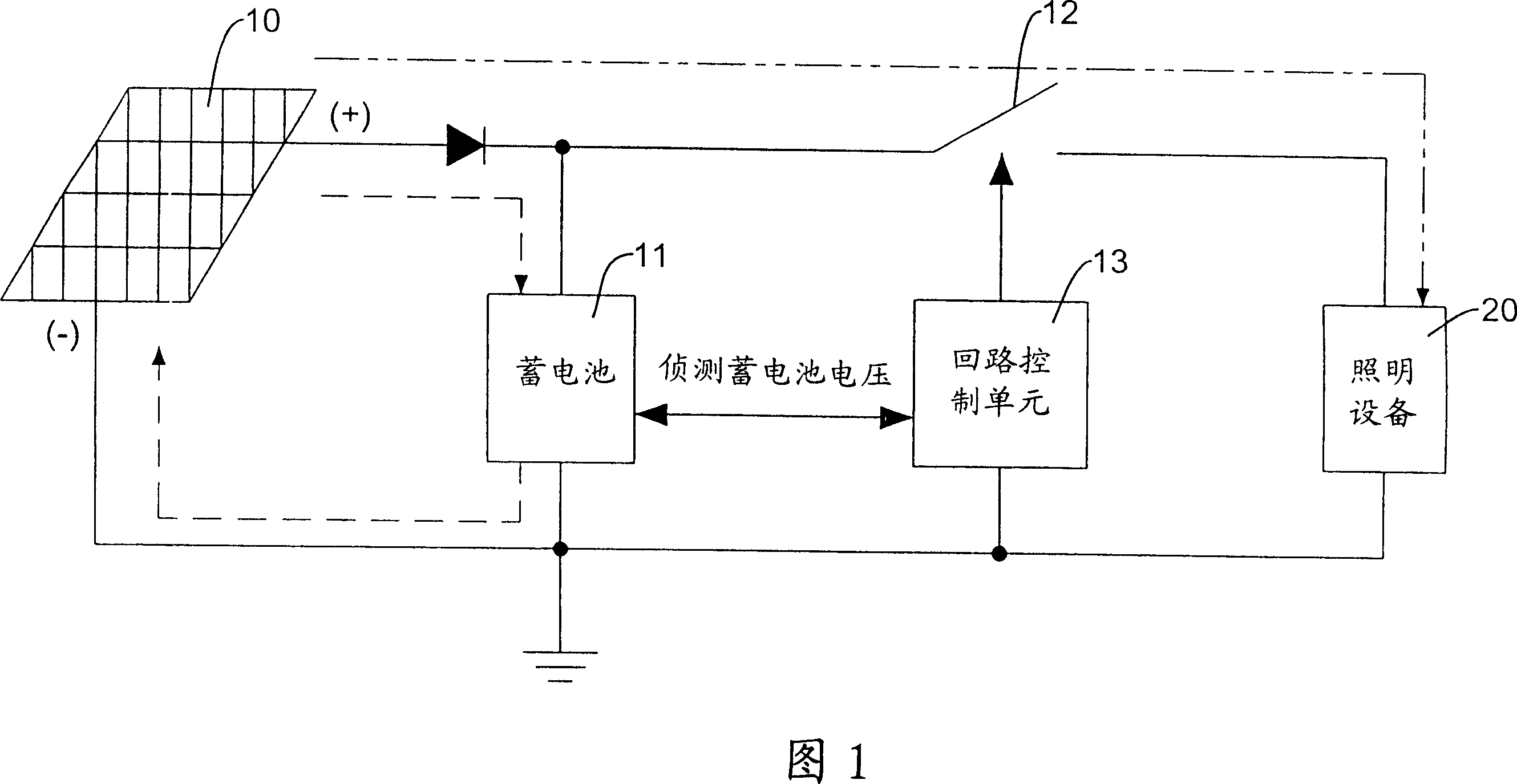

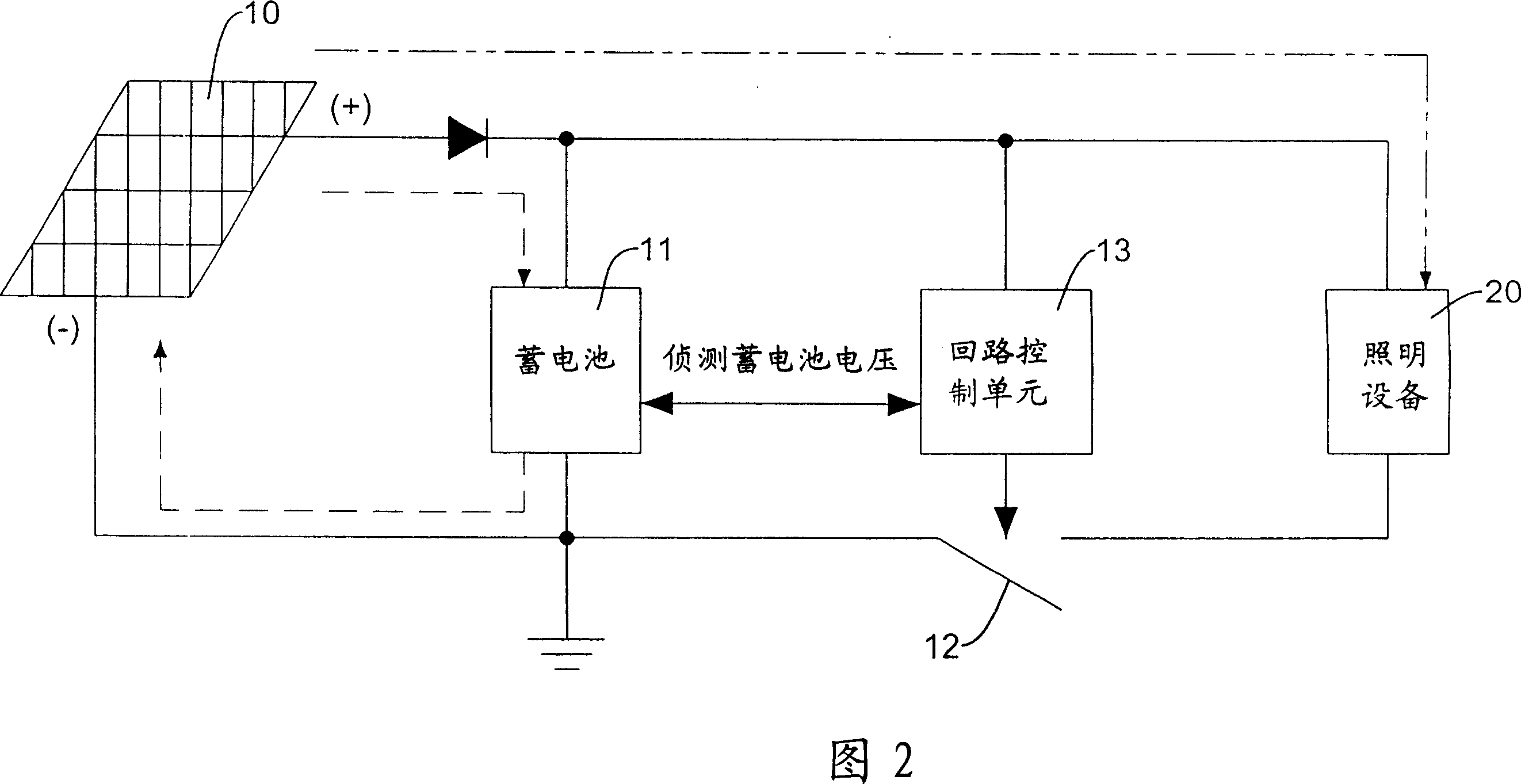

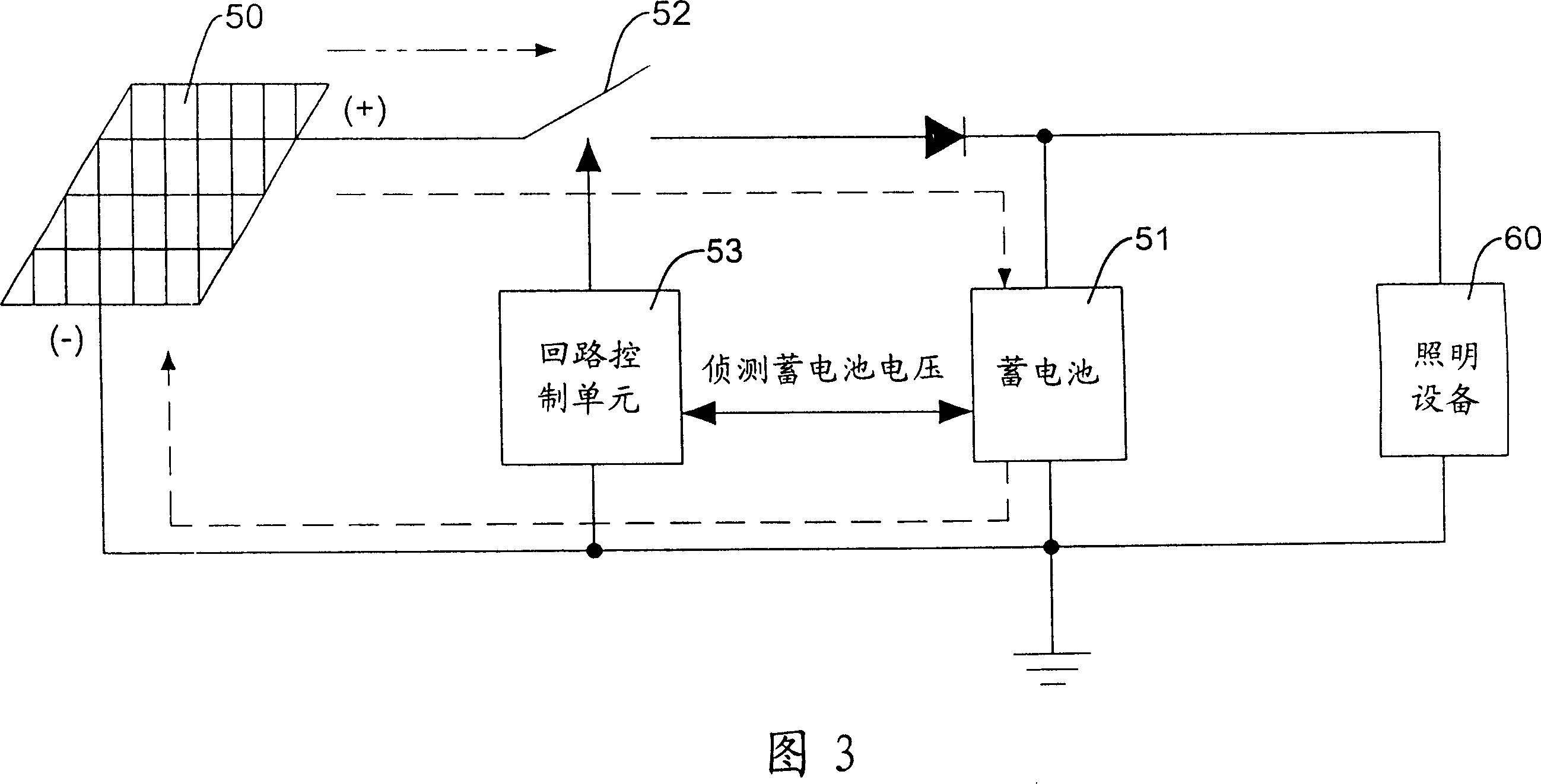

Charge-discharge controller for solar lighting equipment

InactiveCN101001025AUnavailable solutionBatteries circuit arrangementsElectric light circuit arrangementLight equipmentEffect light

The invention relates to a charging and discharging control device for solar lighting equipments, which is mainly composed of solar panels, a storage battery and lighting equipment. The described parts are paralleled together. A loop switch is installed on the power-loop between the storage battery and the lighting equipment. A controlling unit controls the loop switch to open or close which connects to the storage battery to detect the power level of the battery and takes it as the basis for the loop switch. When the battery is sufficient, the loop switch of the controlling unit is open, so batteries and solar panels provide lighting equipments.

Owner:ADDA

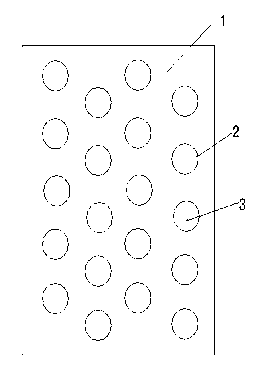

Flame-retardant and sound-proof insulation wall brick synthesized by waste

InactiveCN102888941AUnavailable solutionTake advantage of thermal insulationConstruction materialBrickCoal

The invention relates to a sound-proof insulation wall brick synthesized by waste. The sound-proof insulation wall brick synthesized by the waste comprises a cold-pressed coal ash brick body and is characterized in that a plurality of round counter bores are arranged in the cold-pressed coal ash brick body, and the round counter bores are filled with air-added brick waste powder. The sound-proof insulation wall brick synthesized by the waste is characterized in that the round counter bores formed in the cold-pressed coal ash brick body are blind holes of which the upper parts are sealed, and the blind holes are filled with the air-added brick waste powder. The sound-proof insulation wall brick synthesized by the waste has the advantage of turning the waste of the air-added brick into wealth, the insulation and heat-shielding performance of the waste of the air-added brick is fully made use, and the insulation performance of the outer wall brick is improved.

Owner:上海冬日环保科技有限公司

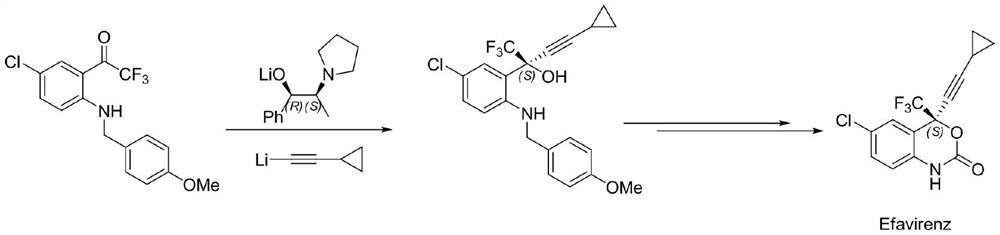

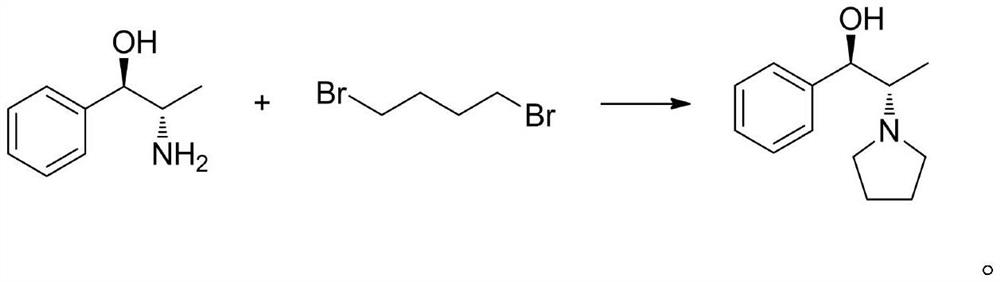

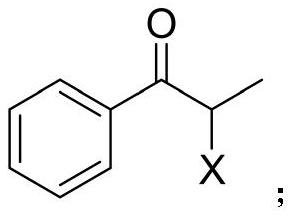

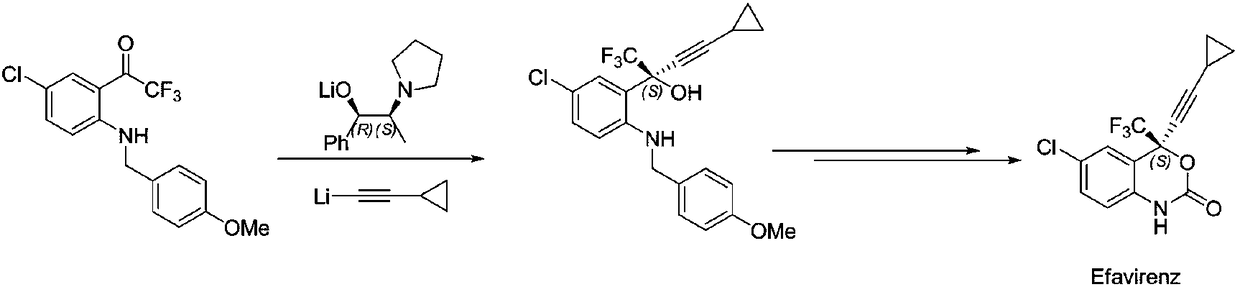

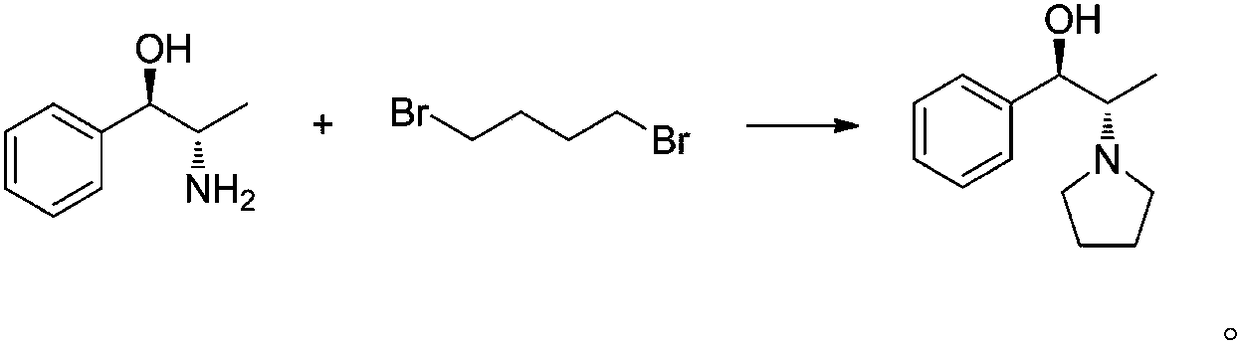

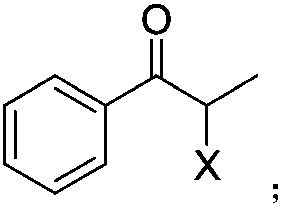

A method for preparing chiral (1r, 2s)-1-phenyl-2-(1-pyrrolidinyl)propan-1-ol

ActiveCN109134335BLow costAvoid norephedrineOrganic chemistry methodsFermentationAlcoholCombinatorial chemistry

The present invention provides a simple and easy enzyme-catalyzed new method for synthesizing (1R, 2S)-1-phenyl-2-(1-pyrrolidinyl)propane-1-alcohol. The body does not need to be separated, which greatly reduces the production cost and is suitable for large-scale industrial production. The synthesis method of the present invention is that, using compound I as a raw material, using ketoreductase (KRED) to carry out asymmetric reduction reaction on compound I, the obtained α-halohydrin is directly subjected to α-halohydrin under alkaline conditions without separation. Alcohol ring closure gives (1R,2R)-1-phenyl propylene oxide (compound Ⅱ), compound Ⅱ is subjected to ring-opening reaction with tetrahydropyrrole to obtain (1R,2S)-1-phenyl-2-(1-pyrrole Alkyl) propane-1-alcohol.

Owner:SUZHOU LEAD BIOTECH CO LTD

All-weather wind power generation system

InactiveCN103122831AUnavailable solutionIncrease profitWind motor combinationsMachines/enginesPrevailing windsWind power system

The invention discloses an all-weather wind power generation system comprising a wind power collector in a trumpet shape, a settling chamber used for settling sands and dusts, a transmission pipe, a one-way valve, a pressure storage chamber, turbo generator units and diversion pipes used for distributing air flow into a plurality of turbo generator units. The wind power collector in the trumpet shape is arranged on a prevailing wind flue and a big mouth of the wind power collector in the trumpet shape faces towards the wind. The settling chamber is placed at the rear end of the wind power collector in the trumpet shape. The transmission pipe is arranged in front of the settling chamber and is communicated with a pipe at the tail portion of the wind power collector. The one-way valve is installed in the transmission pipe. One side of the pressure storage chamber is connected with the transmission pipe, and the other side of the pressure storage chamber is connected with the turbo generator units through a plurality of diversion pipes. The all-weather wind power generation system has a spot energy effect. Due to the adoption of a turbo generator unit power generation device which is mature in technique and high in efficiency, the utilization rate of wind power is high. The wind power can directly become energy which can be transmitted remotely.

Owner:HANGZHOU NORMAL UNIVERSITY

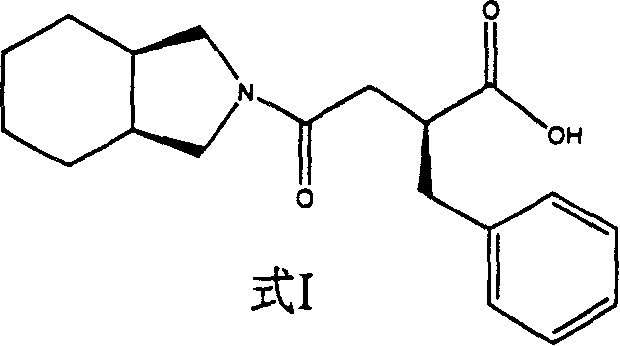

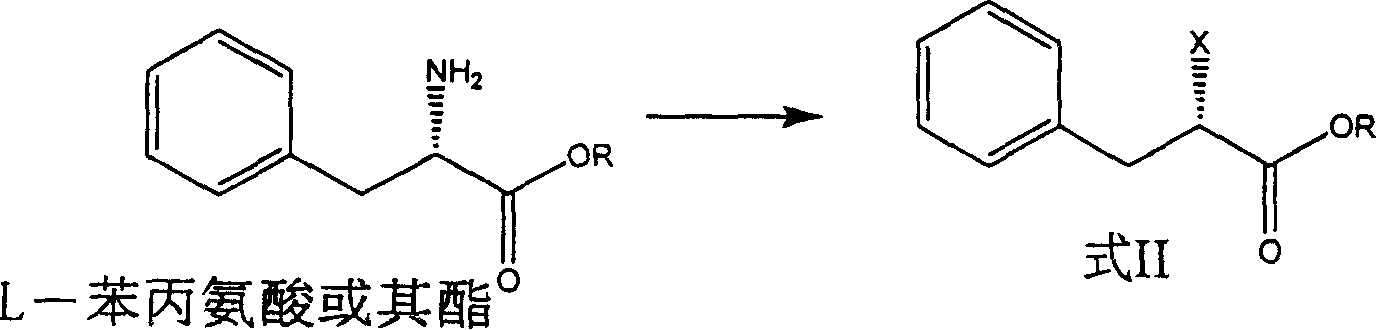

Preparation of miglitol

InactiveCN1324010CUnavailable solutionMild process conditionsOrganic chemistryMiglitolAsymmetric hydrogenation

Production of miglina is carried out by providing chiral center by L-phenylalanine. It achieves high efficiency and good optical purity, and to avoid chemical resolution and asymmetric hydrogenation.

Owner:江苏省药物研究所有限公司

A kind of method for preparing alogliptin intermediate

The invention provides an omarigliptin intermediate preparation method. The omarigliptin intermediate preparation method comprises the step of mixing a compound I with a catalyzing enzyme, and reacting to obtain an omarigliptin intermediate. The omarigliptin intermediate preparation method has the beneficial effects that the cost of raw materials is reduced; the problem in the prior art that isomer byproducts are generated during preparation of the omarigliptin intermediate and cannot be utilized is effectively solved; the yield and atom economy are increased; and the omarigliptin intermediate preparation method is simple in operation, mild in conditions, environment-friendly and suitable for industrial production.

Owner:SUZHOU LEAD BIOTECH CO LTD

Method for preparing chiral (1R,2S)-1-phenyl-2-(1-pyrrolidyl)propane-1-alcohol

ActiveCN109134335ALow costAvoid norephedrineOrganic chemistry methodsFermentationSynthesis methodsHalohydrin

The invention provides a new method for simply and feasibly synthesizing (1R,2S)-1-phenyl-2-(1-pyrrolidyl)propane-1-alcohol through enzymatic catalysis. The method is easy to operate and mild in condition, an intermediate does not need to be separated, the production cost is greatly reduced, and the method is suitable for large-scale industrial production. According to the synthesis method, a first compound serves as a raw material, ketoreductase (KRD) is utilized for conducting an asymmetric reduction reaction on the first compound to obtain alpha-halohydrin, alpha-halohydrin is directly subjected to ring closing under the alkaline condition without separation to obtain a second compound (1R,2S)-1-phenyl epoxypropane, and tetrahydropyrrole is utilized for conducting a ring-opening reaction on the second compound to obtain (1R,2S)-1-phenyl-2-(1-pyrrolidyl)propane-1-alcohol.

Owner:SUZHOU LEAD BIOTECH CO LTD

Pulse power supply system and discharge method based on generator cluster and energy storage microgrid

ActiveCN110867888BUnavailable solutionIncrease profitSingle network parallel feeding arrangementsAc network load balancingMicrogridPulse power supply

The invention belongs to the field of pulse power generation, particularly relates to a pulse power supply system based on a generator cluster and an energy storage microgrid and a discharging method,and aims to solve the problem that residual energy of a pulse generator cannot be fully utilized in the prior art. The method comprises the following steps: respectively discharging each pulse generator based on a system discharge signal and parameters; grouping the pulse generators, and transferring the residual energy of each group to any pulse generator in the group; discharging again, grouping the pulse generators with available residual energy, and performing energy transfer again; and iteratively discharging the pulse generator set until the rotating speed of the pulse generator is reduced to the condition that discharge and the power generation indexes do not meet the requirements. According to the invention, by utilizing the characteristic that through the controllable rectification of charging motor, constant-voltage power generation can be carried out in a wide rotating speed range, so residual energy can be transferred in the pulse generator cluster, the conversion ratio from inertia kinetic energy to pulse electric energy is improved from the system level, and the energy utilization rate is improved.

Owner:INST OF ELECTRICAL ENG CHINESE ACAD OF SCI

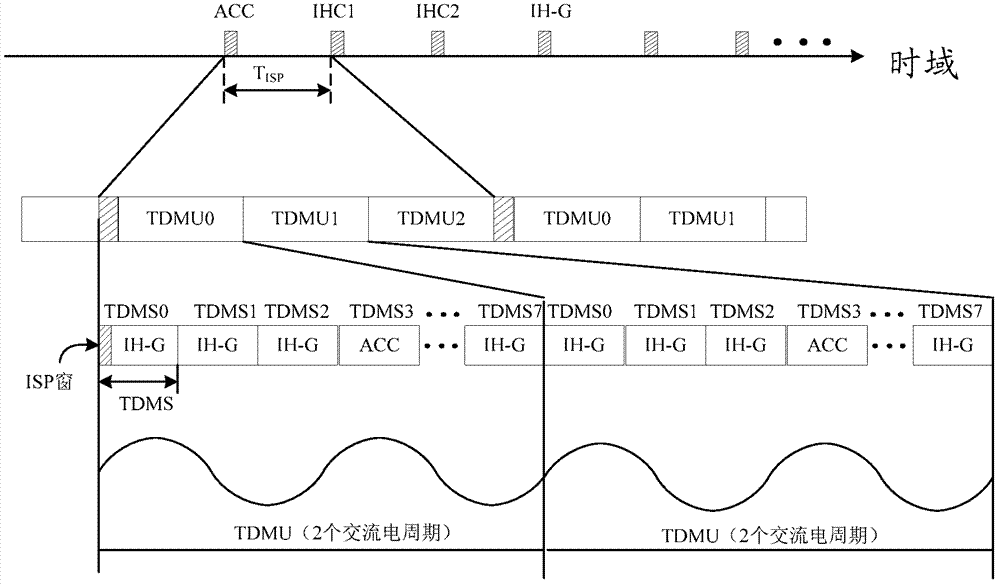

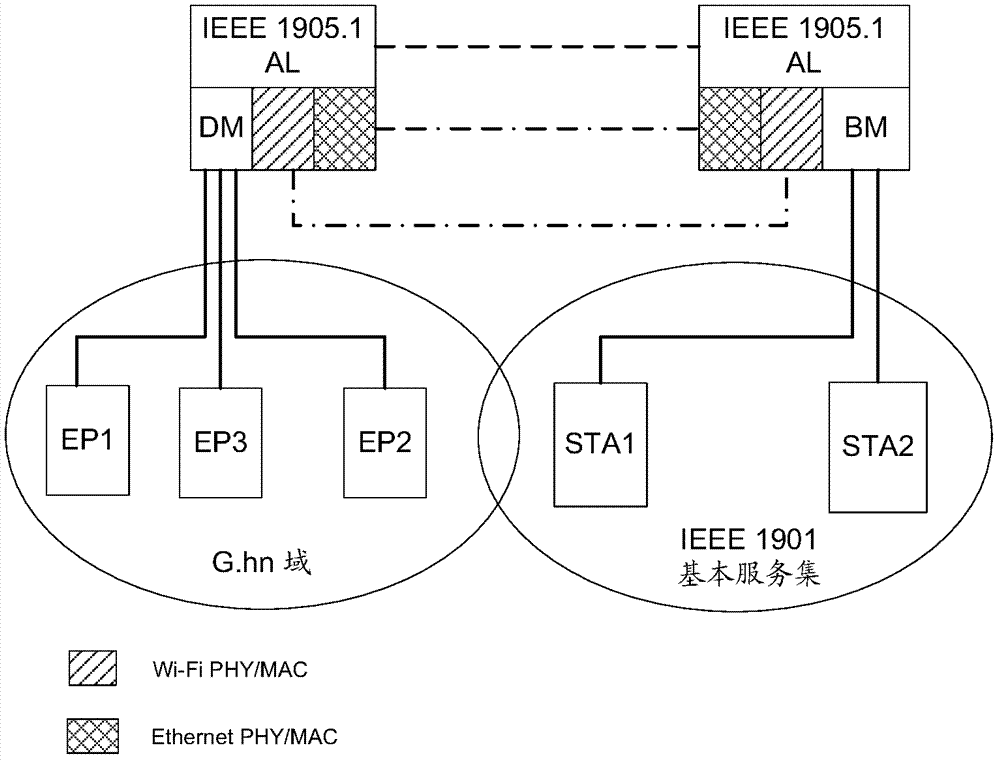

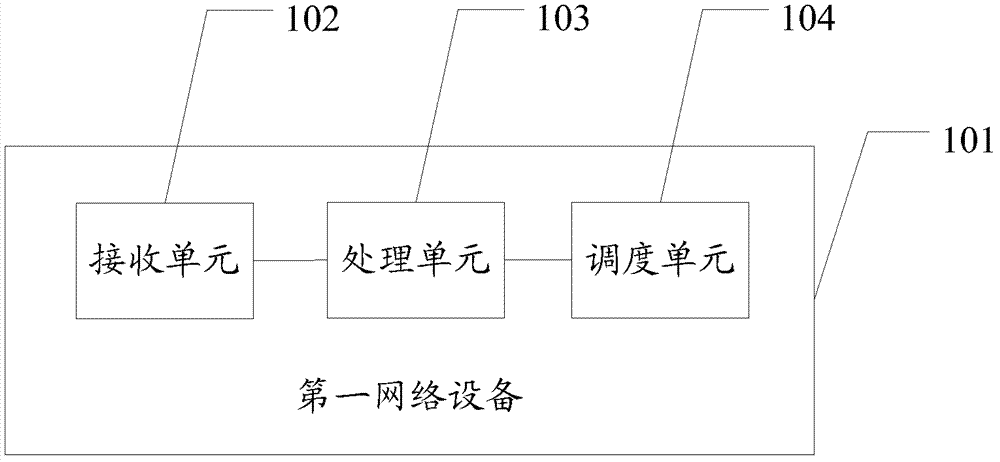

Network equipment and resource allocation method

InactiveCN105556863BSolve the idle problemUnavailable solutionPower distribution line transmissionTime informationResource allocation

Disclosed are a network device and a resource allocation method. In the present invention, after a node device in a first PLC network receives common dormancy time information sent by a node device in a second PLC network, information is transmitted by using a timeslot that is corresponding to the common dormancy time and is scheduled by the second PLC network, so that the problem is solved that a time resource corresponding to the second PLC network is idle and cannot be used when the node device in the second PLC network enters dormancy, thereby improving the utilization rate of the time resource.

Owner:HUAWEI TECH CO LTD

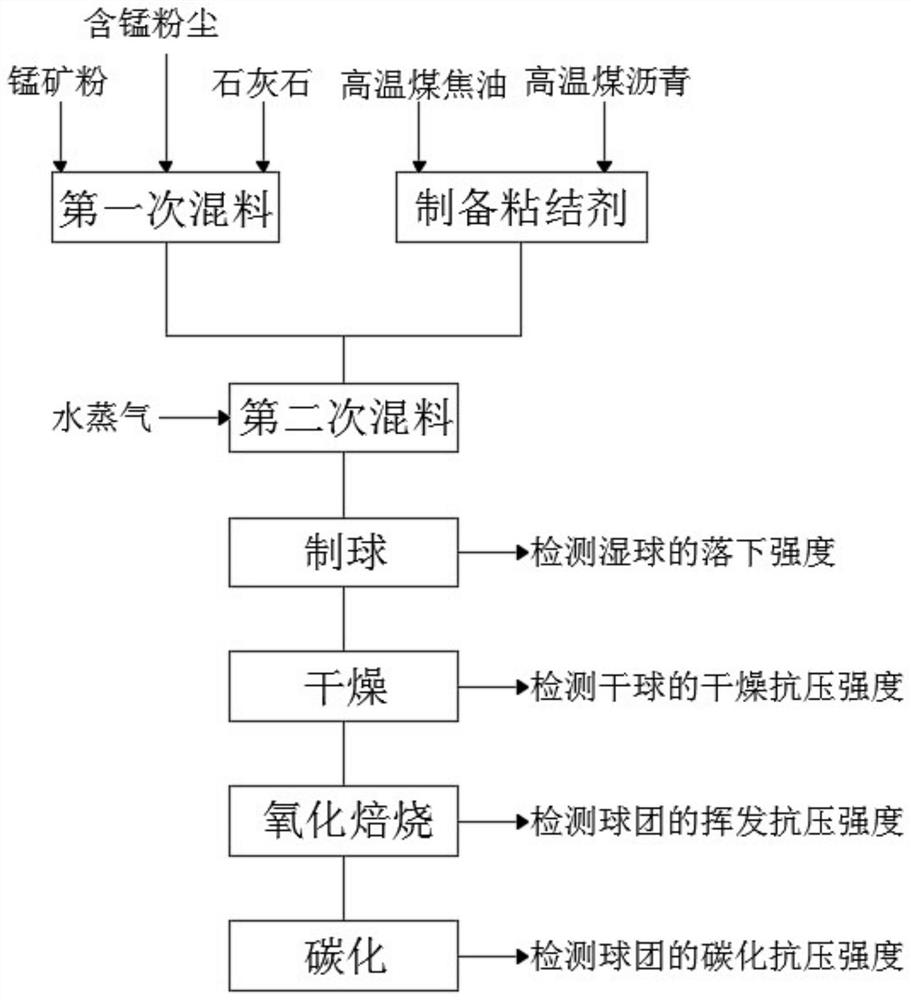

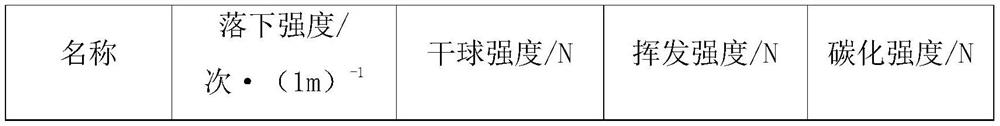

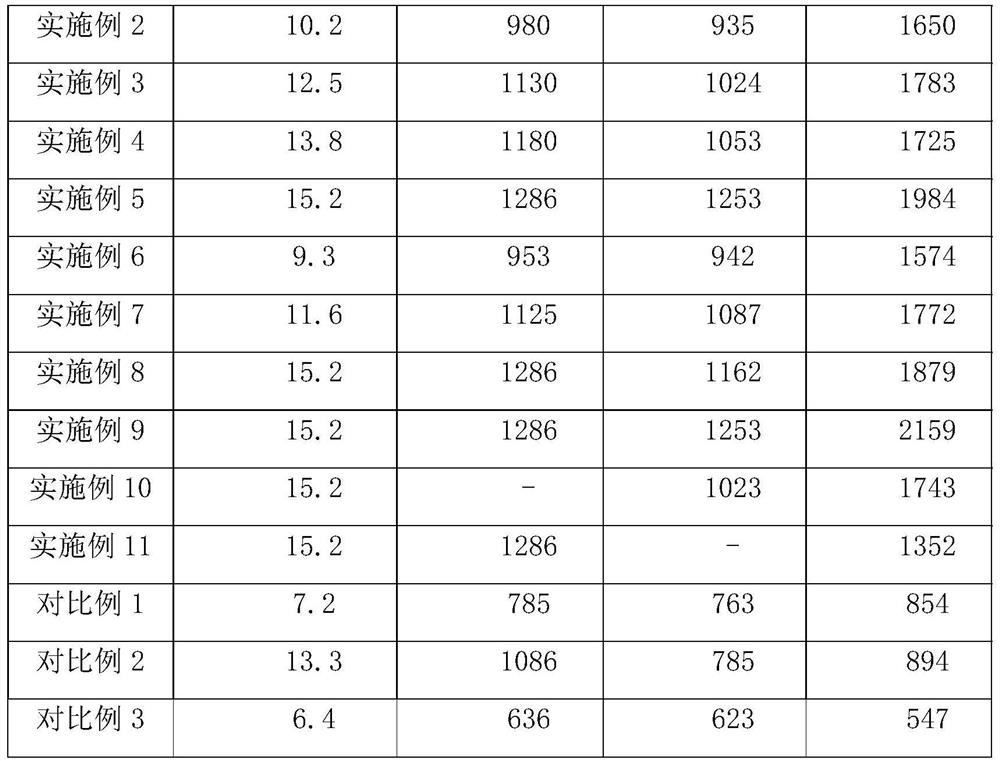

A method for preparing manganese-containing powder pressed pellets with self-reducing properties

The invention discloses a preparation method of manganese-containing powder pressed pellets with self-reducing performance, which includes: mixing and stirring the manganese-containing powder and limestone to obtain a primary mixed raw material; heating coal tar, and adding coal tar pitch to the coal tar and stirring , until the coal tar and coal tar pitch are completely dissolved and mixed to obtain a binder; first pass water steam into the mixer, and then add the primary mixed raw materials and binder to the mixer respectively, so that the primary mixed raw materials and the bonded Mix the raw materials evenly with the agent to obtain the secondary mixed raw materials; press the secondary mixed raw materials into pellets; dry the pressed pellets to remove free water in the pellets to obtain dry balls; roast the dry balls to remove coal tar pitch and Volatile matter and crystal water in coal tar; carbonize the roasted pellets to carbonize coal tar and coal tar pitch into coke, and obtain the final pressed pellets containing manganese powder. The manganese powder pellets prepared by the invention have no added ash and reduce external coke in subsequent smelting.

Owner:HUNAN UNIV

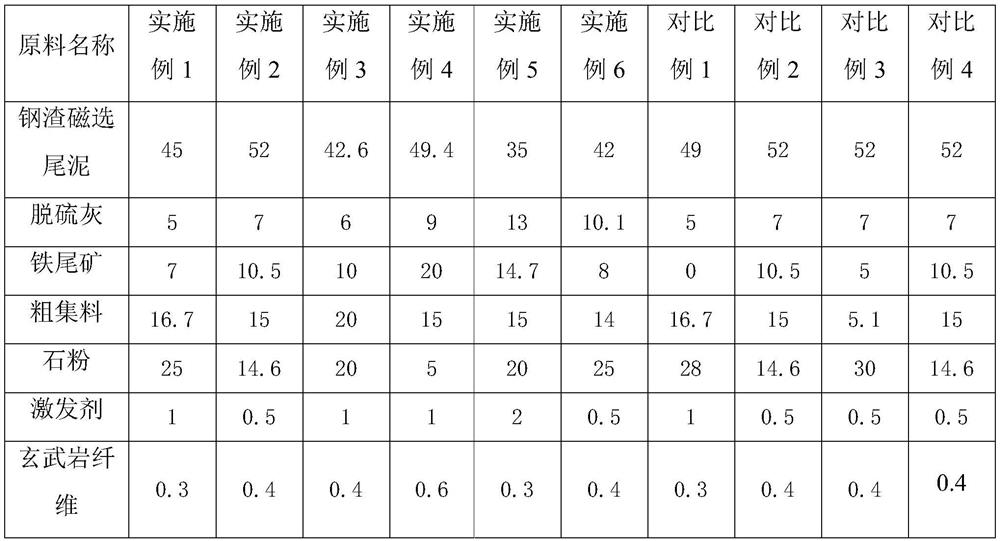

Autoclaved lime-sand brick containing steel slag tailings and preparation method thereof

The invention discloses an autoclaved lime-sand brick containing steel slag tailings and a preparation method thereof, belonging to the field of comprehensive utilization of solid waste. It is mainly composed of the following raw materials in proportion by weight: steel slag magnetic separation tailings: 35‑52 parts; desulfurization ash: 5‑13 parts; iron tailings: 7‑20 parts; coarse aggregate: 14‑20 parts ; Stone powder: 5-25 parts; Basalt fiber: 0.3-0.6 parts; Stimulator: 0.5-2 parts. Autoclaved lime-sand bricks are molded by vibration and pressure, and the bricks made are dense and high-strength, but strict proportioning of components is required to prepare high-quality autoclaved lime-sand bricks. Realize the waste utilization of various construction and production wastes, and can effectively solve the pollution problems of steel slag magnetic separation tailings and desulfurization ash.

Owner:ANHUI UNIVERSITY OF TECHNOLOGY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com