Waste automobile battery disassembling machine

A technology for automobile batteries and machines is applied in the field of dismantling machines for used automobile batteries, which can solve the problems of low disassembly efficiency and high labor intensity for disassembling used batteries, and achieve the effect of improving efficiency and reducing labor intensity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

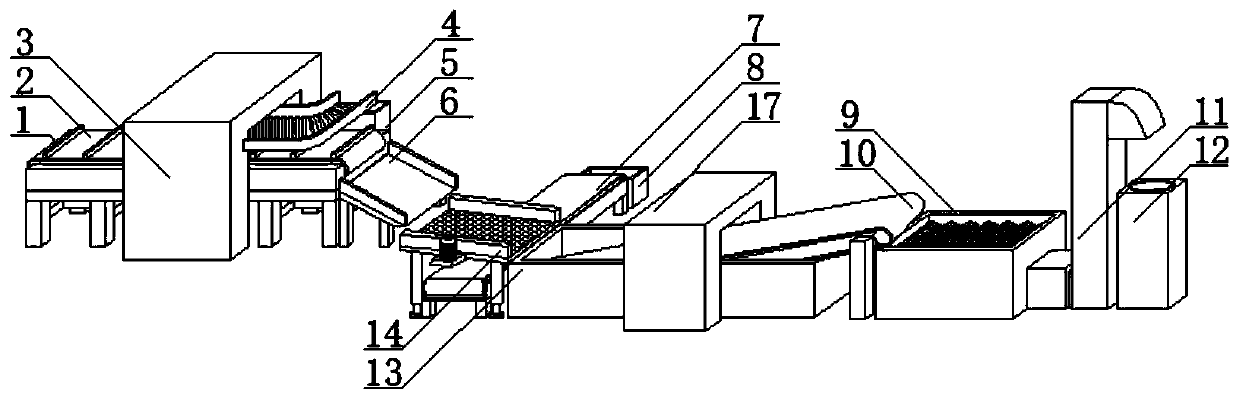

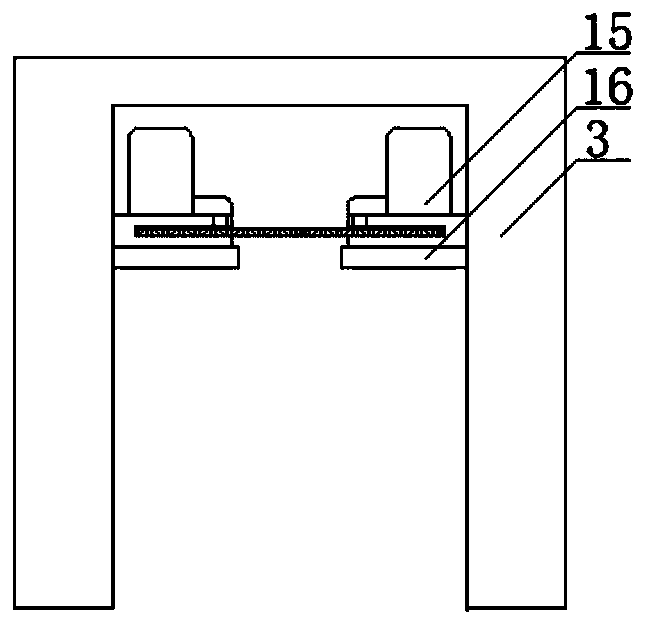

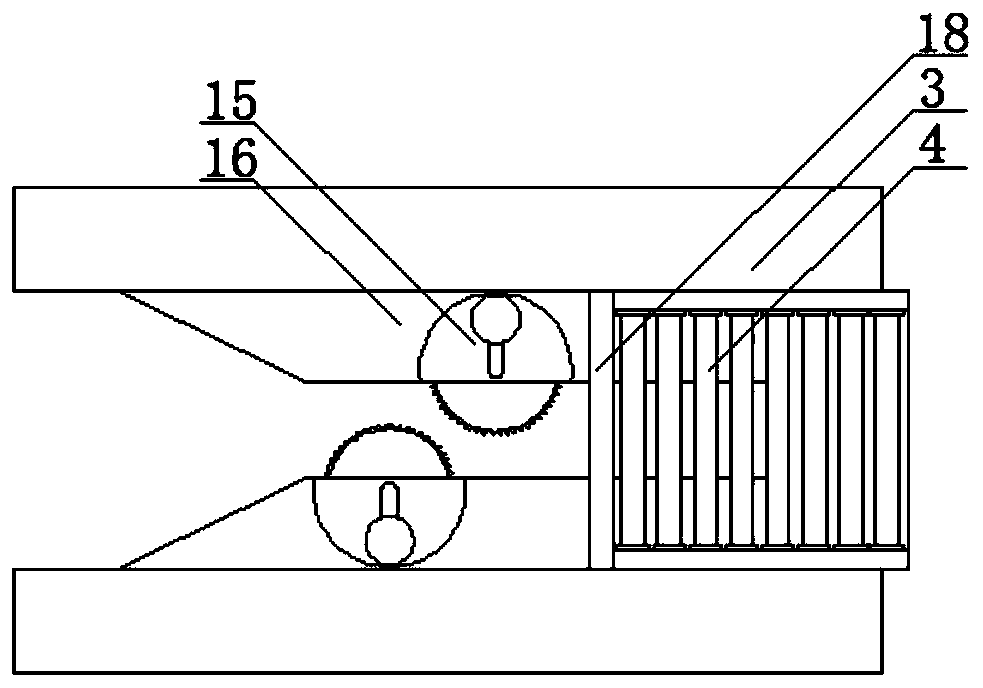

[0022] In order to enable those skilled in the art to better understand the technical solutions in the present application, the technical solutions in the embodiments of the present application will be clearly and completely described below in conjunction with the accompanying drawings.

[0023] see Figure 1-4 A waste car battery dismantling machine, including a feeding conveyor belt 2, used to complete the feeding of waste batteries, one side of the feeding conveyor belt 2 is sequentially provided with a conveying plate 6, a support frame 3, a vibrating separation screen 14, and a cleaning machine 17. Cleaning liquid collection pool 13, cleaning conveyor belt 10, pulverizer 9, bucket elevator 11 and drying machine 12, multiple baffles 1 are fixed at equal intervals on the feeding conveyor belt 2, and the baffles are driven when the feeding conveyor belt 2 moves 1 moves, and the baffle plate 1 pushes the waste lead-acid battery to move when cutting, which is beneficial to the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com