Narrow decorative solid wood floor and production method for its combination

A production method and technology for solid wood flooring, which can be applied to wood processing appliances, buildings, floors, etc., can solve the problems of unsuitable use of end waste, waste of solid wood materials, lack of suitable processing equipment and processing methods, etc., to increase added value. , avoid wasteful effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

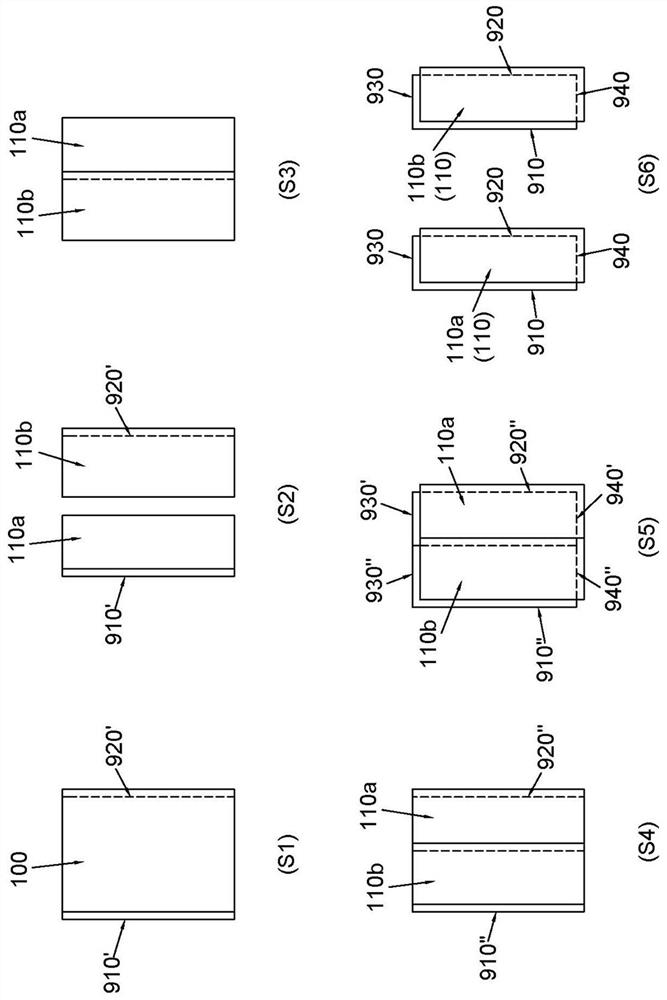

[0051] Example 1: Reference figure 1 The production method of a narrow decorative solid wood floor, including the following steps:

[0052] S1. Repairing the blank 100, the blank 100 is a disk bean end waste having a specification of 80 mm (length) × 80 mm (width) × 18 mm (thick), and the first long side is formed on the long side of the two sides. Mutter 910 ', the first long sideline 920', the first long bitch 910 ', the first long side female 920' is a mutually mutually mating lock structure;

[0053] S2. Put the blank 100 after the long side is divided into the longitudinal direction, the cross section can be machined from the sawing machine or circular saw, forming a first piece of material 110a having a first long bonus 910 ', with first The second sub-material 110b of the long side figurine 920 ', and the first sub-material 110a is the same as the width of the second sub-material 110b, and the present embodiment is used as an example reference, and the sawing loss is not co...

Embodiment 2

[0058] Example 2: Reference figure 2 The production method of a narrow decorative solid wood floor, including the following steps:

[0059] S1. Repairing the blank 100, the blank 100 is a red oak tip waste having a specification of 60 mm (length) × 75 mm (width) × 18 mm (thick), and the first long side mutter is formed on both sides of the long side. 910 ' , The first long sideline 920 ', the first long bitch 910', the first long side female 920 'is a mutually mutually mounted lock structure;

[0060] S2. The longitudinally formed blank 100 is divided into the longitudinal direction, forming a first sub-material 110a having a first long-sided male 910 ', a second sub-material 110b having a first long side female 920', wherein The width of the azimetic 110a is 25 mm, and the width of the second sub-material 110b is 50 mm, and the embodiment is used as an example, and the sawing loss is not considered.

[0061] S3. The first sub-material 110a and the second sub-material 110b are ass...

Embodiment 3

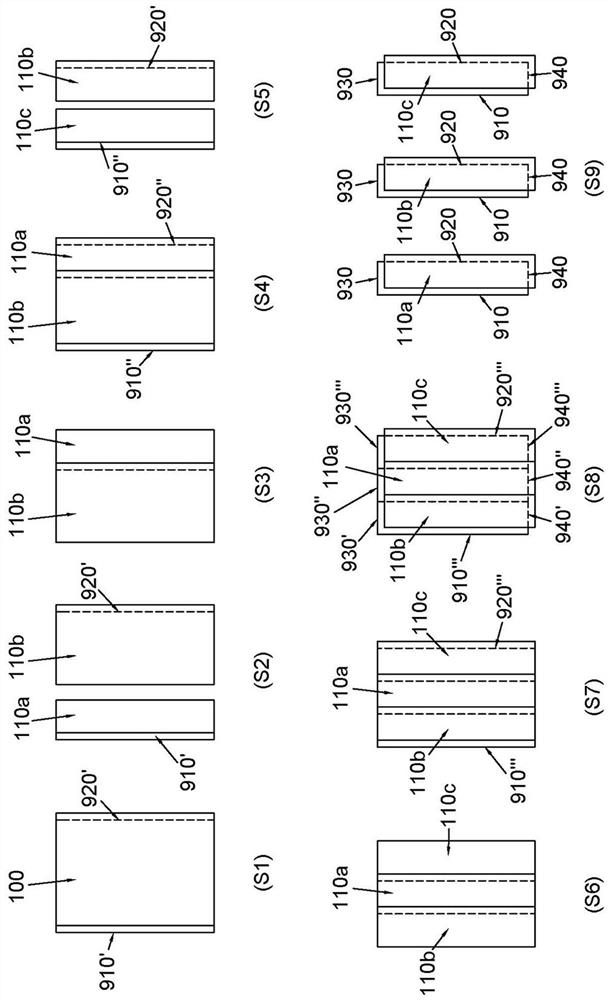

[0070] Example 3: Example 3 provides a production method of a floor combination of a narrow-type decorative solid wood floor prepared using Example 1, Example 2, including the following steps:

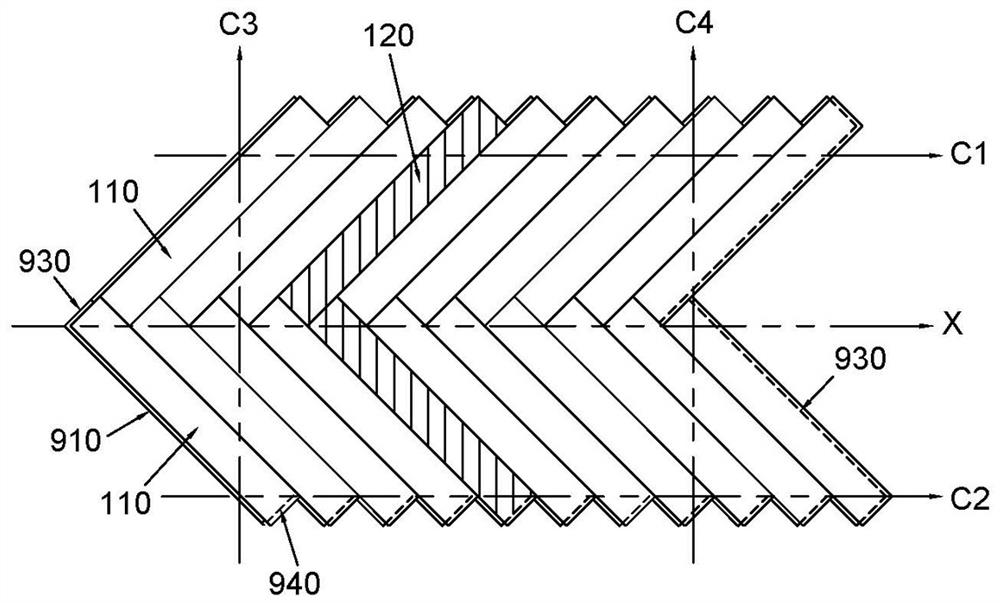

[0071] S1. Reference image 3 As shown, the above subprominal 110, the sub-material 110, which is the same as the multi-block, including the mutomosis 910, 930, and the pendant 920, 940 set the sequential material 120 ', sub-material 2 110' '; sub-material 110 is 60 mm ( Length) × 25mm (width) × 18mm (thick), the surrounding side of the sub-material one 110 'sequentially has a small material long side mutomy 910, the short edge mutter 930, the seed length female 920, small material short On the side of the mother, 940, both of which are buckled structures, and the surrounding side of the submits 2 110 '' is sequentially having a small material long side mutomy 910, the short side of the small edge 940, the seed length of the female side 920, small material short Side male 930;

[0072] S2. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com