A method for preparing manganese-containing powder pressed pellets with self-reducing properties

A powder and pellet technology is applied in the field of manganese-containing powder pressed pellet preparation, which can solve the problems of a large amount of ash content of the binder, large ash content, and low high-temperature strength of the pellet, so as to reduce the demand, improve the high-temperature strength and the price. low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

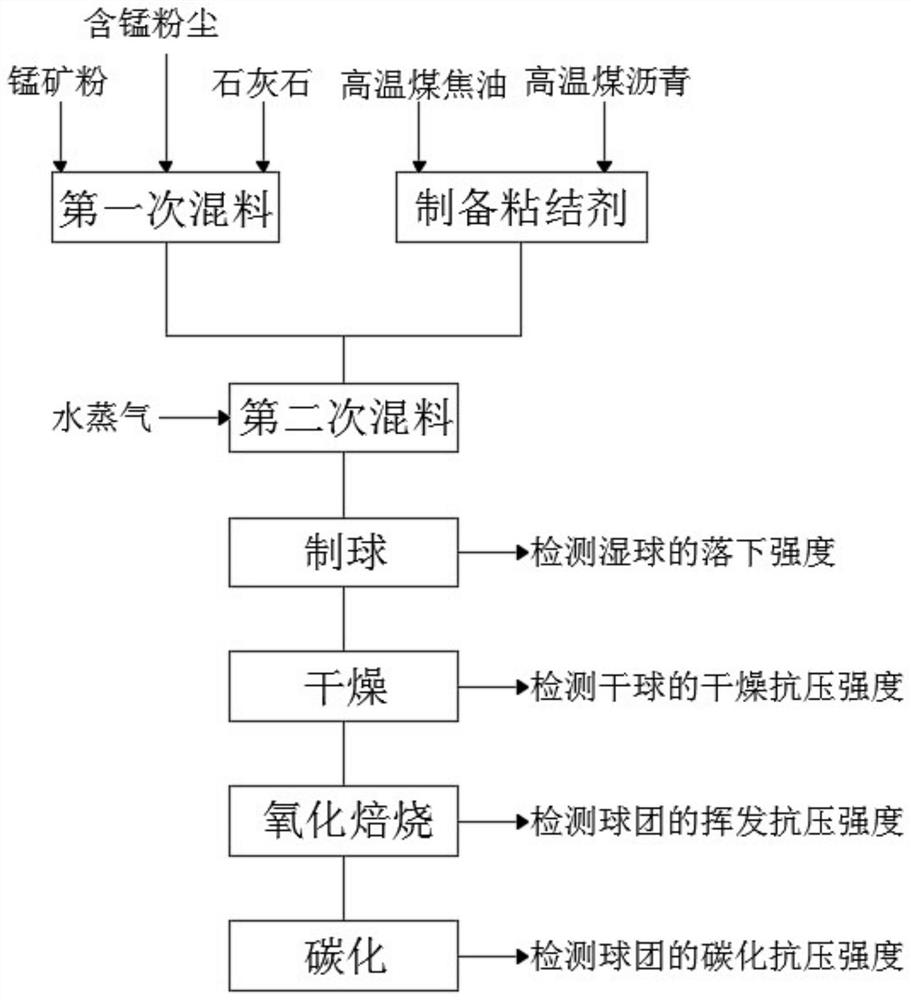

[0038] In this example, the reducing manganese-containing powder pressed pellets were prepared according to the following steps:

[0039] S1, mixing and stirring the manganese-containing powder and limestone to obtain a primary mixed raw material, wherein the quality of the limestone is 3-5% of the total mass of the manganese-containing powder;

[0040] S2, heating the coal tar, and adding coal tar pitch to the coal tar and stirring until the coal tar and the coal tar pitch are completely dissolved and mixed to obtain a binder;

[0041] S3. First feed water vapor into the mixer, and then add the primary mixed raw material in S1 and the binder in S2 to the mixer, so that the primary mixed raw material and binder are uniformly mixed to obtain the secondary mixed raw material , the mass of the added binder is 8-10% of the total mass of the manganese powder in S1;

[0042] S4, pressing the secondary mixed raw material in S3 into pellets;

[0043] S5, drying the pellets pressed a...

Embodiment 2

[0067] Such as figure 1 As shown, in this example, manganese-containing powder pressed pellets with reducibility are prepared according to the following steps, and the strength index of manganese-containing powder pressed pellets at each stage is detected during the preparation process. The specific steps are as follows:

[0068] S1, mixing for the first time, mixing the manganese powder and limestone and adding it to the mixer to stir to obtain a mixed raw material; the manganese powder includes manganese ore powder and manganese dust, the quality of the manganese ore powder and manganese dust The ratio is 7:3, manganese-containing dust includes blast furnace ashes and electric furnace ashes, and the particle size of manganese ore powder is below 5mm. Among them, the mass of manganese ore powder with a particle size between 3-5mm accounts for 31% of the total mass of manganese ore powder, and the particle size is 0.5 The mass of manganese ore powder between -3mm accounts for ...

Embodiment 3

[0077] The difference between the preparation process of the manganese-containing powder pressed pellets in this example and Example 2 is that in S2, the total mass of the binder is 10% of the total mass of the manganese-containing powder.

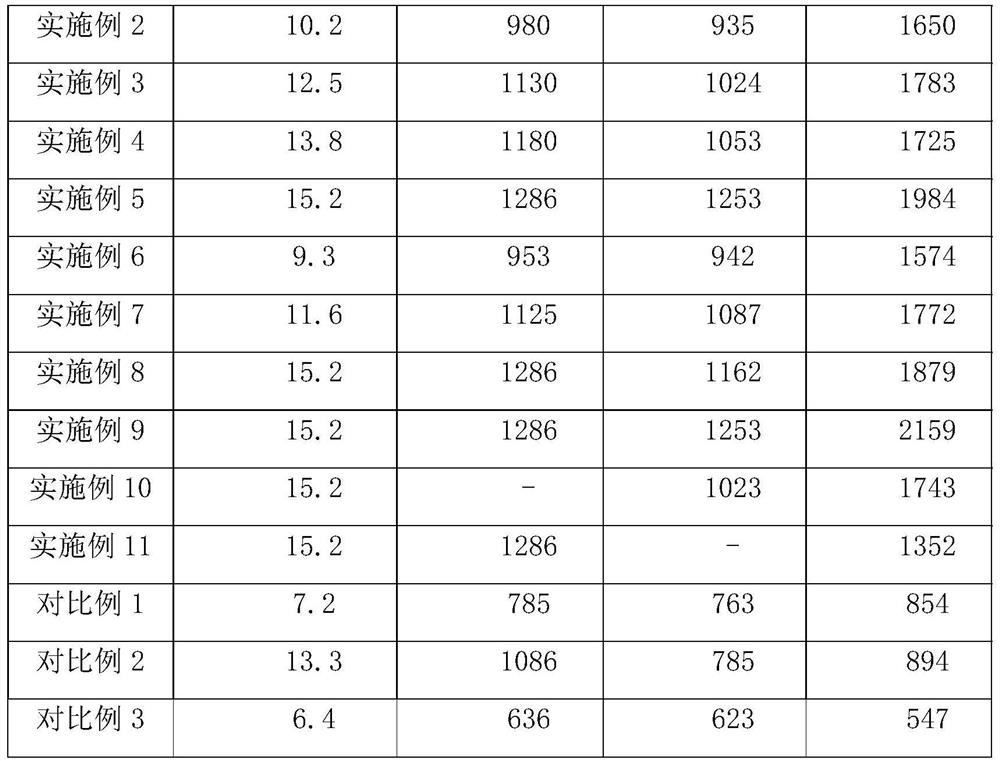

[0078] The strength indexes of the manganese-containing powder pressed pellets prepared in this example at each stage are respectively: the wet ball drop strength is 12.5 times (1m) -1 , The dry compressive strength is 1130N, the volatile compressive strength of pellets is 1024N, and the carbonized compressive strength of pellets is 1783N.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com