Autoclaved lime-sand brick containing steel slag tailings and preparation method thereof

A technology of autoclaved lime-sand bricks and steel slag tailings, which is applied in the direction of sustainable waste treatment, solid waste management, climate sustainability, etc., can solve the problems of difficult utilization of construction and production waste, reduce aging links, reduce Cost, Effect of Enhanced Strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

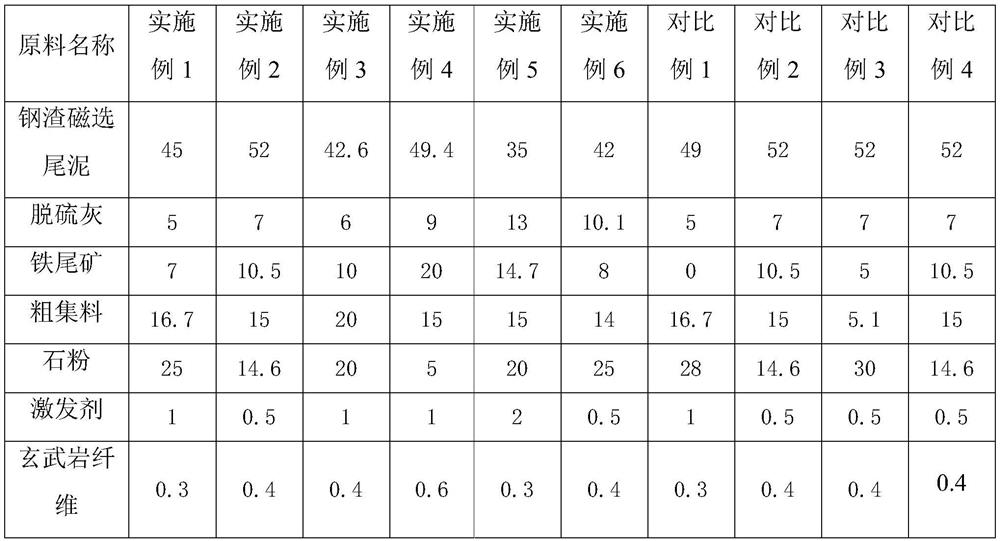

Embodiment 1

[0047] The raw material composition of an autoclaved lime-sand brick containing steel slag tailings of this embodiment is shown in Example 1 in Table 1. The desulfurized ash is semi-dry desulfurized ash, the coarse aggregate is river sand, and the activator is desulfurized gypsum. The fineness or particle size of each component is as follows: the fineness of the tailings of the magnetic separation of steel slag is 0.08mm and the remainder is 23.9%; the SiO of the iron tailings is 23.9%. 2 The content is 68.9%, and the fineness modulus is 0.7; the coarse aggregate is river sand, and the fineness modulus is 2.5;

[0048] A kind of preparation method of the autoclaved lime-sand bricks containing steel slag tailings of the present embodiment, comprises the following steps:

[0049] S1. Dehydration process: use the dehydration equipment plate and frame filter press to dehydrate the steel slag magnetic separation tailings to a moisture content of 24.7%;

[0050] S2, mixing process...

Embodiment 2

[0055] The raw material composition ratio of an autoclaved lime-sand brick containing steel slag tailings of this embodiment is shown in Example 2 in Table 1. The desulfurization ash is semi-dry desulfurization ash, the coarse aggregate is gravel, and the activator is water glass. The fineness or particle size of each component is as follows: the fineness of the tailings of the magnetic separation of steel slag is 0.08mm and the remainder is 19.7%; the SiO of the iron tailings is 19.7%. 2 The content is 63.7%, and the fineness modulus is 0.86; the coarse aggregate is crushed stone, and the fineness modulus is 2.9;

[0056] A kind of preparation method of the autoclaved lime-sand bricks containing steel slag tailings of the present embodiment, comprises the following steps:

[0057] S1. Dehydration process: use a belt filter press of dehydration equipment to dehydrate the steel slag magnetic separation tailings to a moisture content of 23.5%;

[0058] S2, mixing process: the ...

Embodiment 3

[0063] The raw material composition ratio of an autoclaved lime-sand brick containing steel slag tailings of this embodiment is shown in Example 3 in Table 1. Among them, the desulfurized ash is semi-dry desulfurized ash, the coarse aggregate is crushed stone prepared by crushing old concrete, and the activator is desulfurized gypsum and sodium sulfate mixed in a mass ratio of 1:1. The fineness or particle size of each component is as follows: the fineness of the tailings of steel slag magnetic separation is 0.08mm and the remainder is 16.9%; the SiO of iron tailings is 16.9%. 2 The content is 62.5%, and the fineness modulus is 0.95; the coarse aggregate is crushed stone prepared by crushing old concrete, and the fineness modulus is 2.9;

[0064] A kind of preparation method of the autoclaved lime-sand bricks containing steel slag tailings of the present embodiment, comprises the following steps:

[0065] S1, dehydration process: use dehydration equipment centrifugal dehydrat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com