Flame-retardant and sound-proof insulation wall brick synthesized by waste

A technology of sound insulation, heat preservation and waste, which is applied in the direction of building materials, etc., and can solve the problem of unusable waste of aerated bricks

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

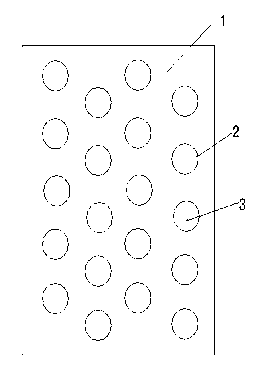

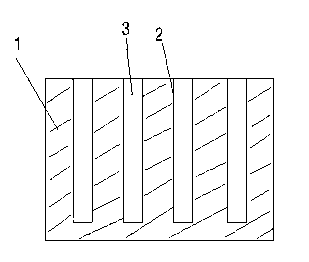

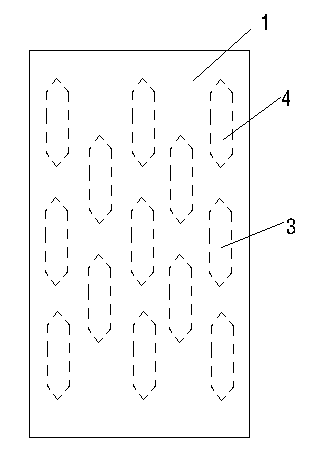

[0007] The figure includes a cold-pressed fly ash brick body 1, which is characterized in that several counterbores 2 are opened on the cold-pressed fly ash brick body, and aerated brick waste powder 3 is filled in the counterbores. image 3 Among them, the counterbore opened above the cold-pressed fly ash brick body is a blind hole 4 closed at the top, and the aerated brick waste powder 3 is filled in the blind hole. It is characterized in that: the counterbore is circular, polygonal or elliptical.

[0008] During production, the ingredients of the cold-pressed fly ash brick body, such as 40% fly ash, 40% calcium carbide mud, 10% perlite powder, and 10% adhesive, can be mixed and pressed before pressing. The selected pressure is 5000-7000 kg, and then placed for use. The waste of aerated bricks is recovered and crushed for later use.

[0009] After the cold-pressed fly ash brick body is dry, a small amount of adhesive can be mixed with aerated brick waste powder and filled ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com