Method for red mud reduction by adopting gas-based shaft furnace

A red mud and air-based technology, applied in the field of metallurgy, can solve problems such as red mud research is only in the laboratory stage, adverse effects on the ecological environment, limited red mud chemical composition, etc., achieve good results, reduce energy consumption, save Effect of the coking step

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

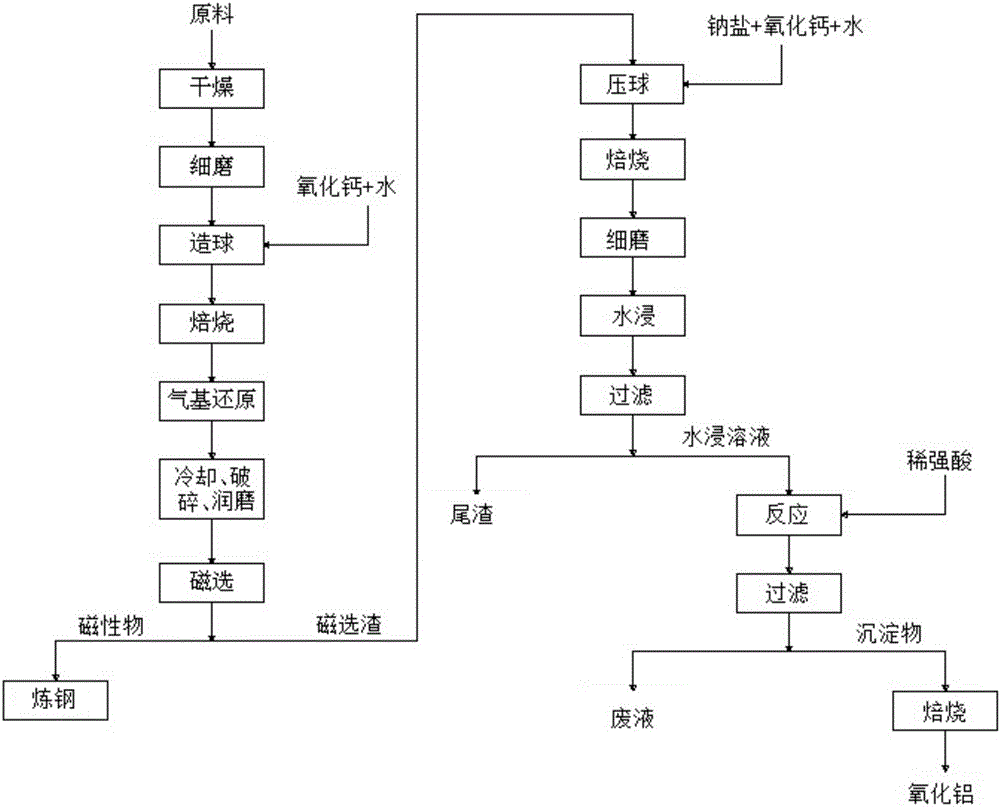

[0064] This embodiment adopts figure 1 The process flow shown for Bayer process red mud is as follows:

[0065] Prepare red mud raw materials;

[0066] The red mud raw material is dried to a moisture content below 5%, and finely ground. Select 1000g of red mud powder with particle size ≤0.15mm.

[0067] Put the above-mentioned red mud powder, 50g CaO and 80g water into a mixer, and mix together for 20 minutes; then put the mixture into a disc pelletizer to form the first pellet with a diameter of 8mm.

[0068] The first pellets were dried in a drying oven at 105°C for 24 hours, then sent to a roasting furnace, and fired for 15 minutes in an oxidizing atmosphere at 1200°C to obtain oxidized pellets.

[0069] Send the metallized pellets into the air-based shaft furnace, pass in reducing gas with a temperature of about 950°C, and reduce for 4 hours to obtain the metallized pellets.

[0070] The metallized pellets are cooled and crushed, then rubbed to ≤75 μm (passing through ...

Embodiment 2

[0079] This embodiment adopts figure 1 The process flow shown to treat red mud is as follows:

[0080] Prepare red mud raw materials;

[0081] The red mud raw material is dried to a moisture content below 5%, and finely ground. Select 1000g of red mud powder with particle size ≤ 1mm.

[0082] Put the above-mentioned red mud powder, 20g CaO and 50g water into a mixer, and mix together for 15 minutes; then put the mixture into a disc pelletizer to form the first pellet with a diameter of 16mm.

[0083] Put the first pellet into a drying oven at 105°C for 24 hours, then put it into a roasting furnace, and bake it in an oxidizing atmosphere at 1050°C for 5 minutes to obtain oxidized pellets.

[0084] Send the metallized pellets into the air-based shaft furnace, pass in reducing gas with a temperature of about 800°C, and reduce for 7 hours to obtain the metallized pellets.

[0085] The metallized pellets are cooled and crushed, then rubbed to ≤75 μm (passing through a 200-mesh ...

Embodiment 3

[0094] This embodiment adopts figure 1 The process flow shown for Bayer process red mud is as follows:

[0095] Prepare red mud raw materials;

[0096] The red mud raw material is dried to a moisture content below 5%, and finely ground. Select 1000g of red mud powder with particle size ≤ 1mm.

[0097] Put the above-mentioned red mud powder, 35g CaO and 60g water into the mixer, and mix together for 20 minutes; then put the mixture into the disc pelletizer to form the first pellet with a diameter of 12mm.

[0098] The first pellets were dried in a drying oven at 105°C for 24 hours, then sent to a roasting furnace, and fired for 15 minutes in an oxidizing atmosphere at 900°C to obtain oxidized pellets.

[0099] Send the metallized pellets into the air-based shaft furnace, pass in reducing gas with a temperature of about 1000°C, and reduce for 6 hours to obtain the metallized pellets.

[0100] The metallized pellets are cooled and crushed, then rubbed to ≤75 μm (passing throu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com