Chemical co-production equipment and method for phosphorus and coal

A technology for coal chemical industry and equipment, applied in the field of equipment for co-production of phosphorus coal chemical industry, can solve the problems of inability to utilize the heat of crude synthesis gas, incapable utilization of heat energy in high temperature section, incapable of fully utilizing heat energy, etc., so as to solve the problem of heat source sources and reduce energy consumption. The effect of uniform consumption and preheating

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0053] Exemplary embodiments of the present invention will be described in detail below with reference to the accompanying drawings.

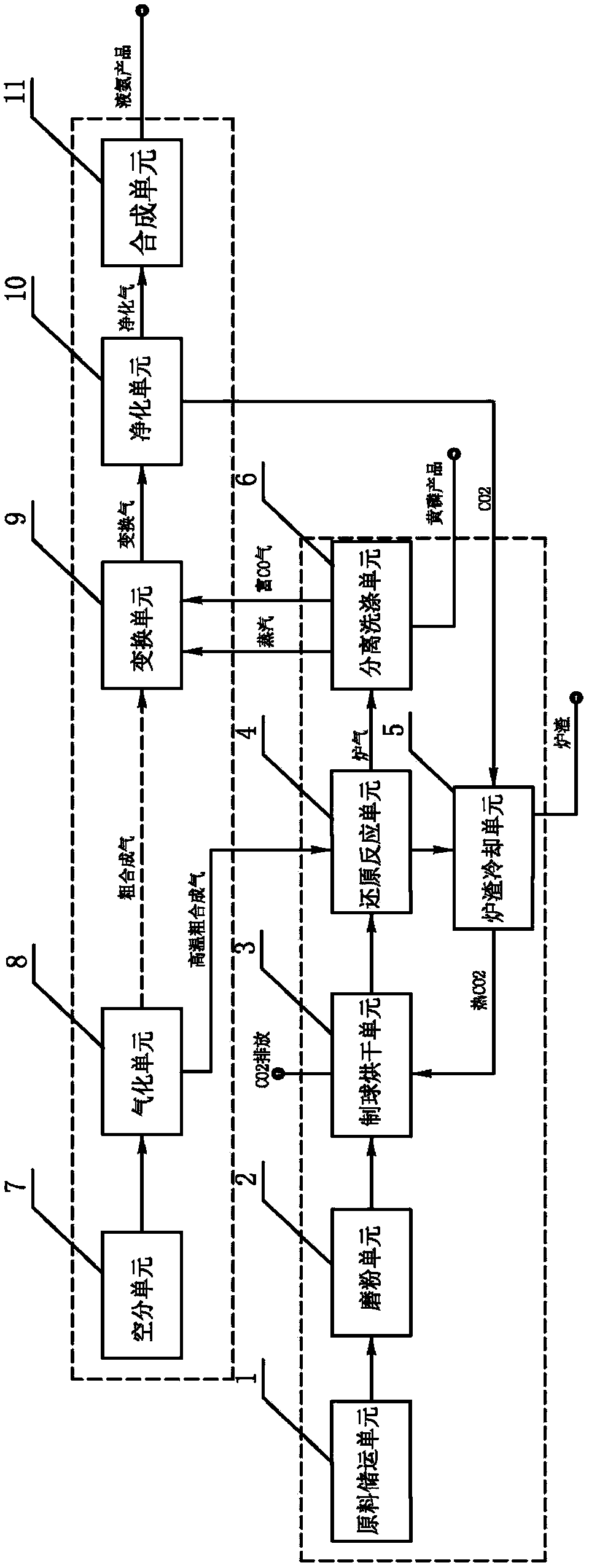

[0054] combine figure 1 As shown, a kind of phosphorus coal chemical co-production equipment provided in the present invention includes: raw material storage and transportation unit 1, milling unit 2, pellet drying unit 3, reduction reaction unit 4, slag cooling unit 5, separation and washing Unit 6, air separation unit 7, gasification unit 8, conversion unit 9, purification unit 10 and synthesis unit 11.

[0055] The raw material storage and transportation unit 1 is configured to store raw materials including phosphate rock, silica, coal powder (or coke), and initially crush the raw materials, and send the crushed three kinds of raw materials to the grinding unit 2.

[0056] The milling unit 2 is configured as follows: respectively store the raw materials from the raw material storage and transportation unit in each raw material self-storage...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com