Patents

Literature

133results about How to "Improve measurement error" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

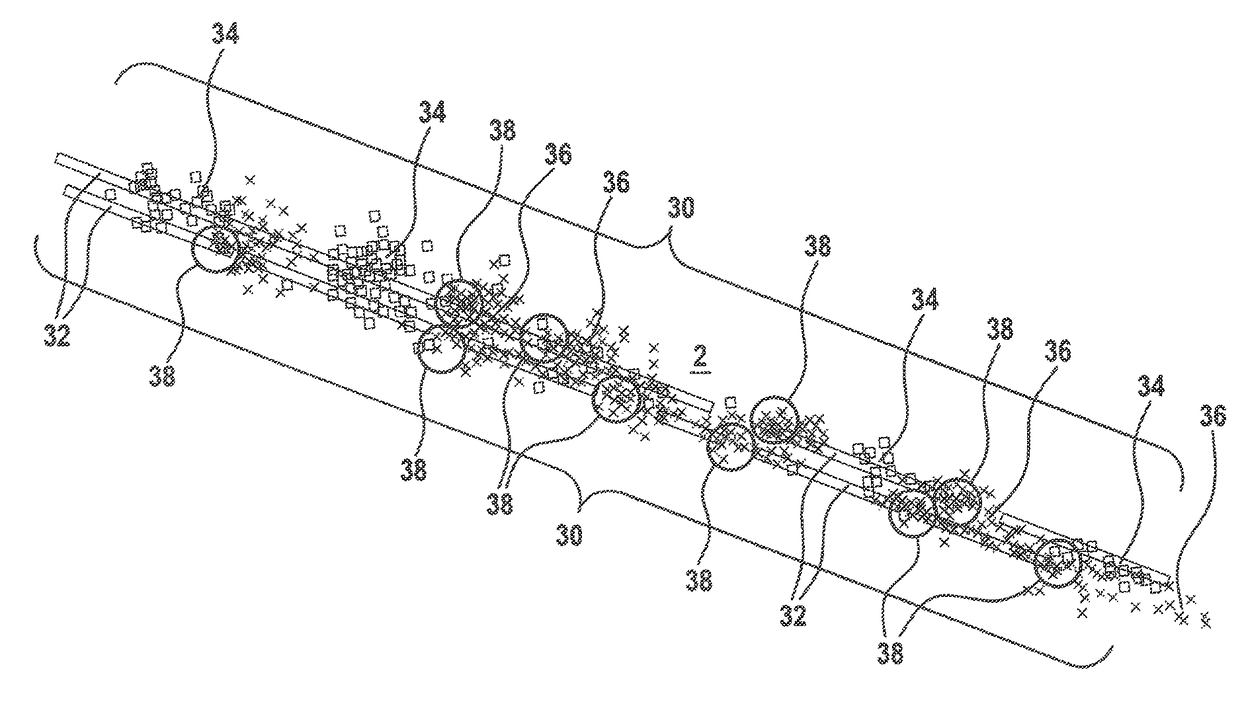

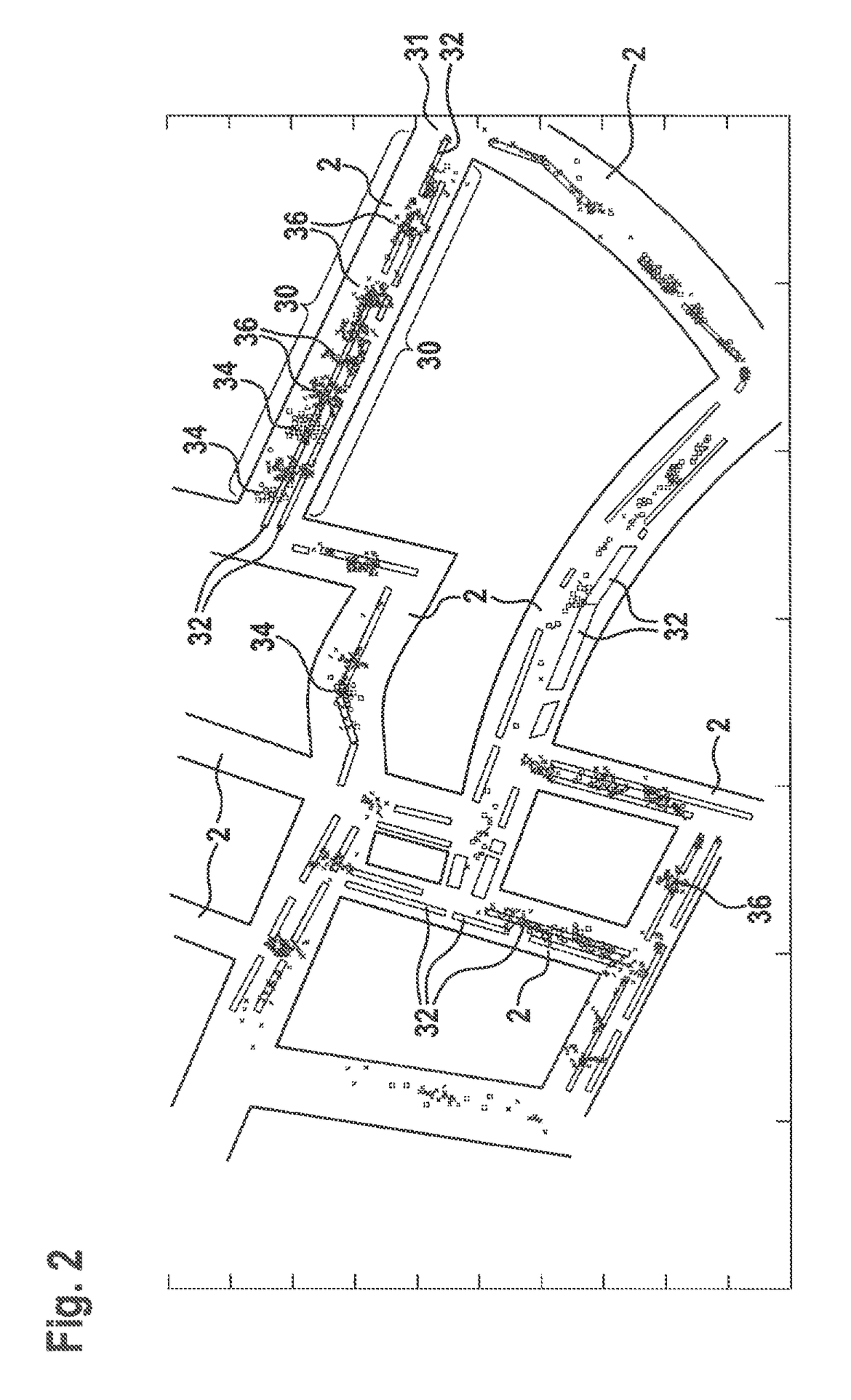

Method for identifying parking areas and/or free spaces--

ActiveUS20160321926A1Short timeQuick updateIndication of parksing free spacesAnti-collision systemsParking areaDriver/operator

A method for identifying free spaces (parking not permitted) and / or permitted parking areas, vehicles transmitting pieces of information about possible parking spaces (PPS) to a central computer facility (CCF). Positions of PPS are detected with vehicle surroundings sensors, and the detected PPS are evaluated based on the data collected, a categorization being performed for recording the PPS, with positions, in a CCF database and evaluating the data using a cluster analysis. When the analysis is performed, PPS are assigned to a street portion, a function is assigned to the street portion, which is given by the quotient of the frequency of PPS detections in a certain position along the street portion and the number of vehicle passages through the street portion and a weighting factor from the evaluation. A free space is inferred when the function value is greater than a predefined second limiting value and / or a parking area is inferred when the function value is within a predefined range. Also described is a device for assisting a driver, a central computer facility, and a related computer program.

Owner:ROBERT BOSCH GMBH

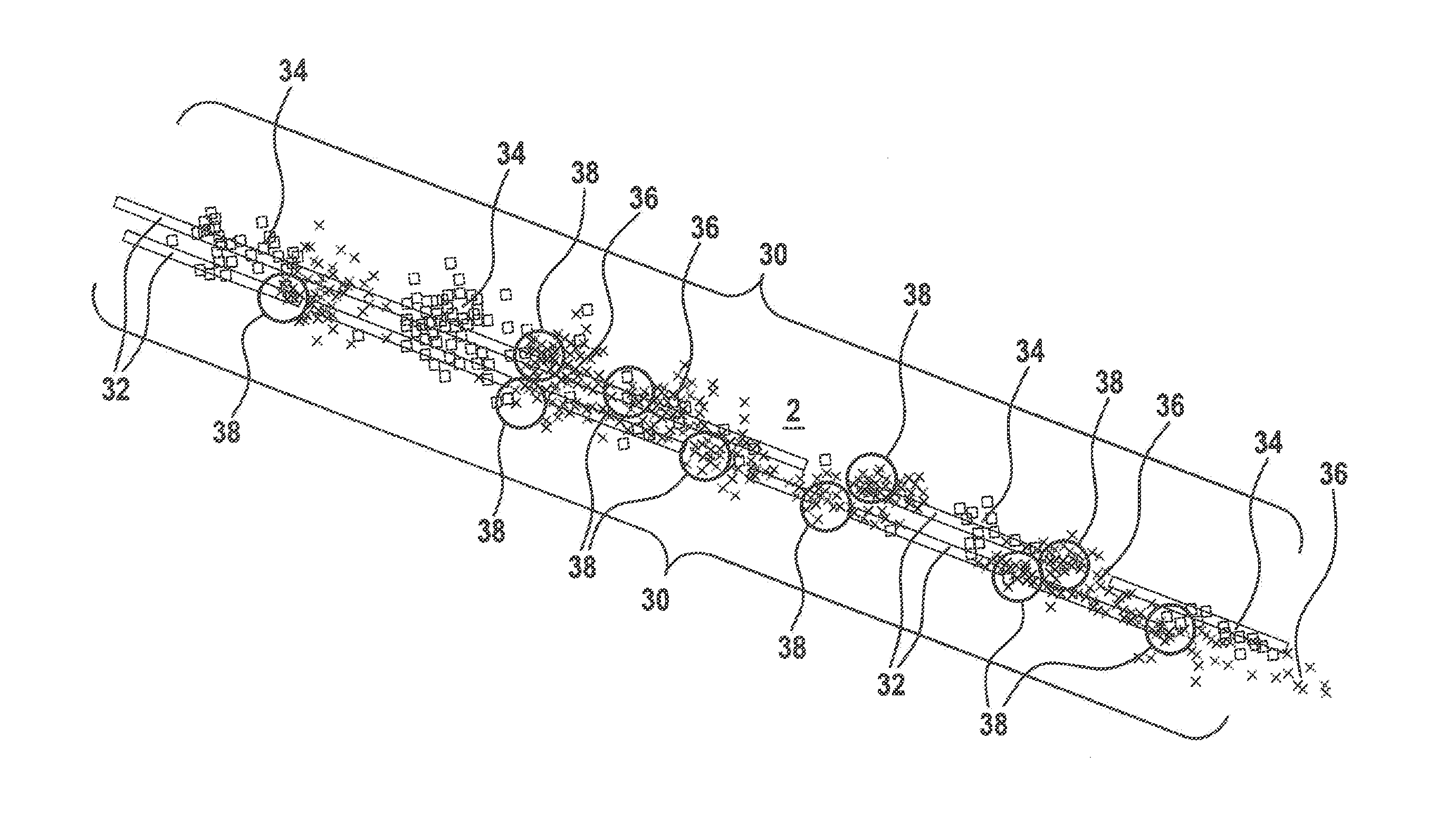

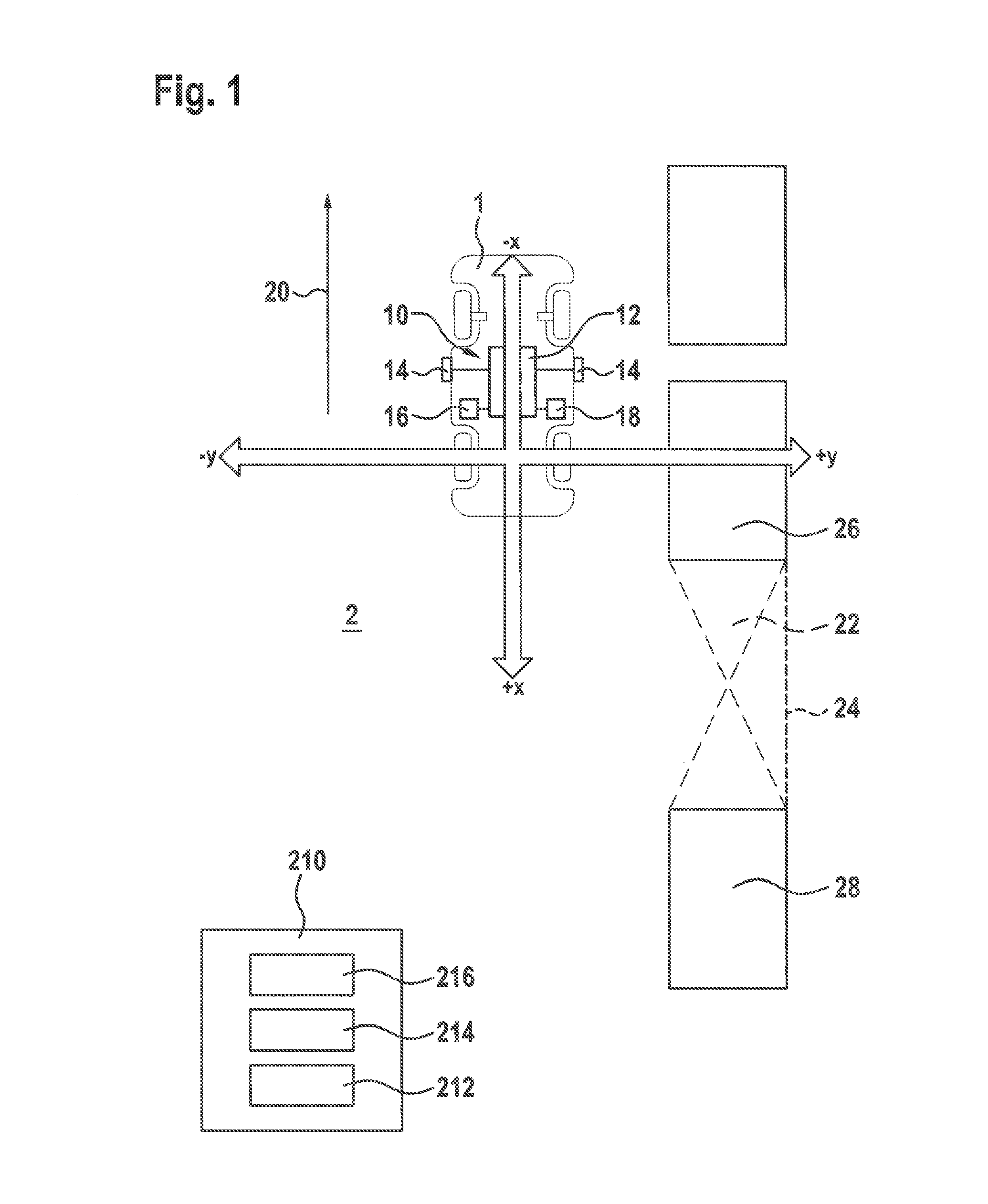

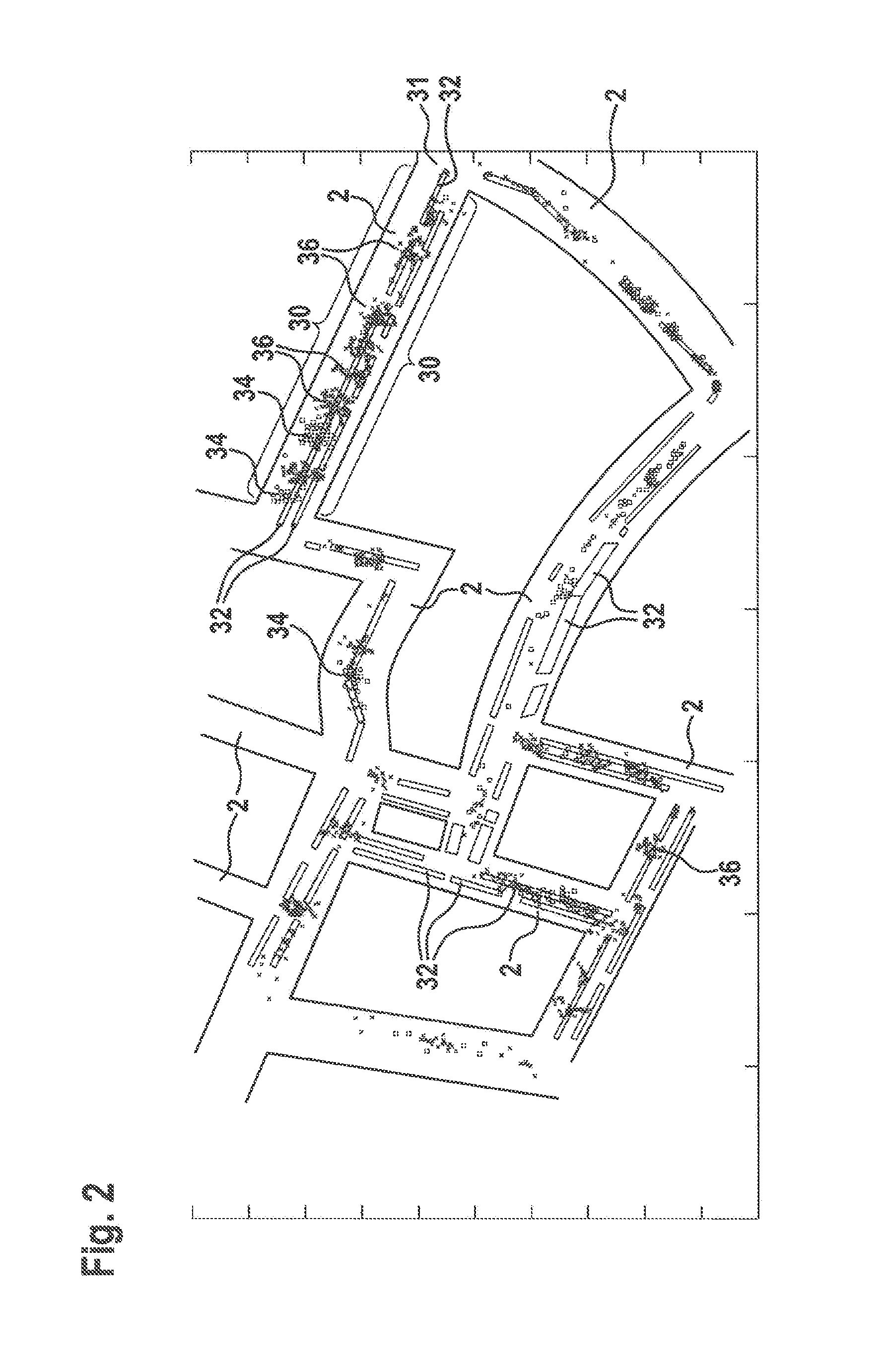

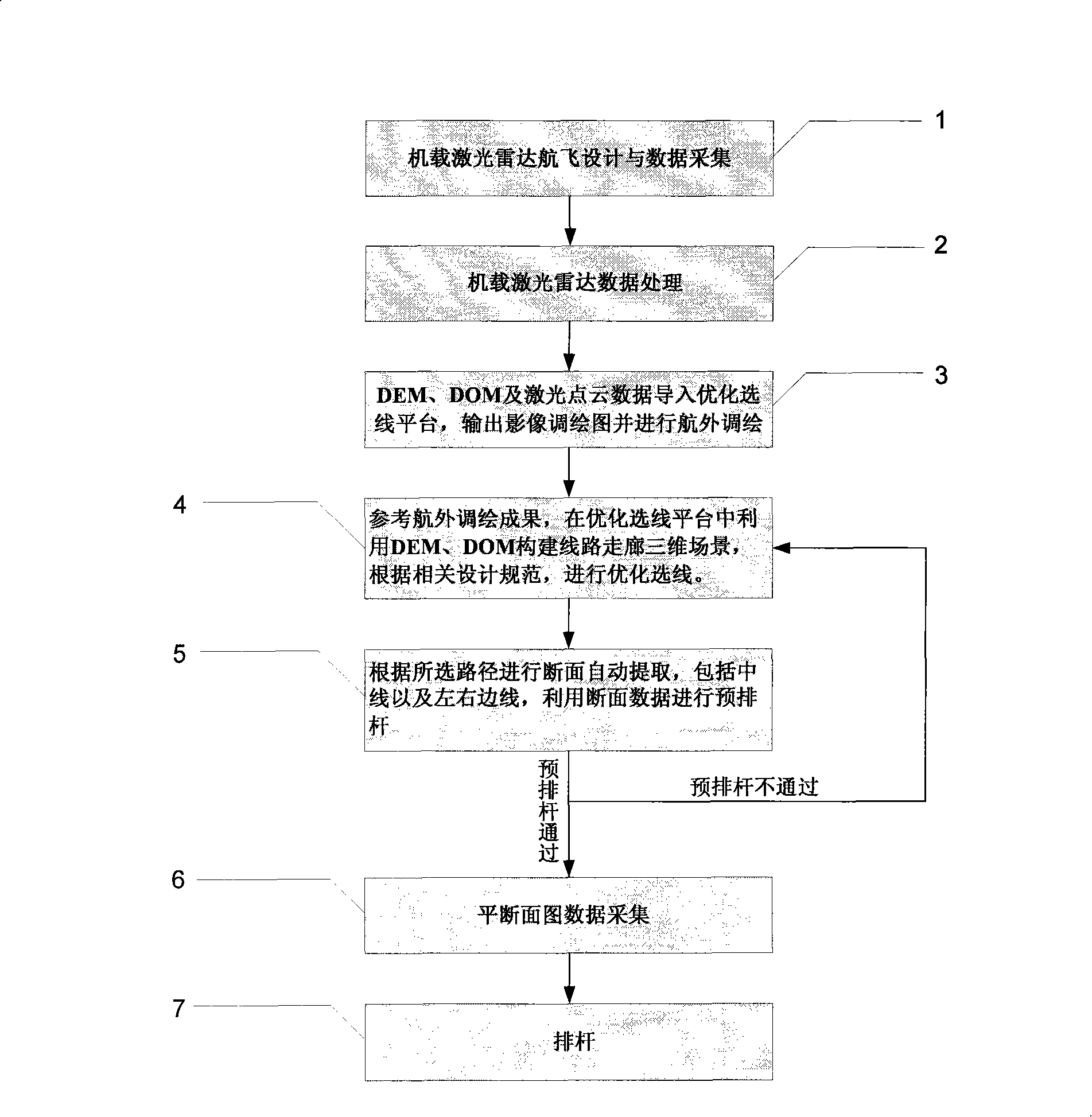

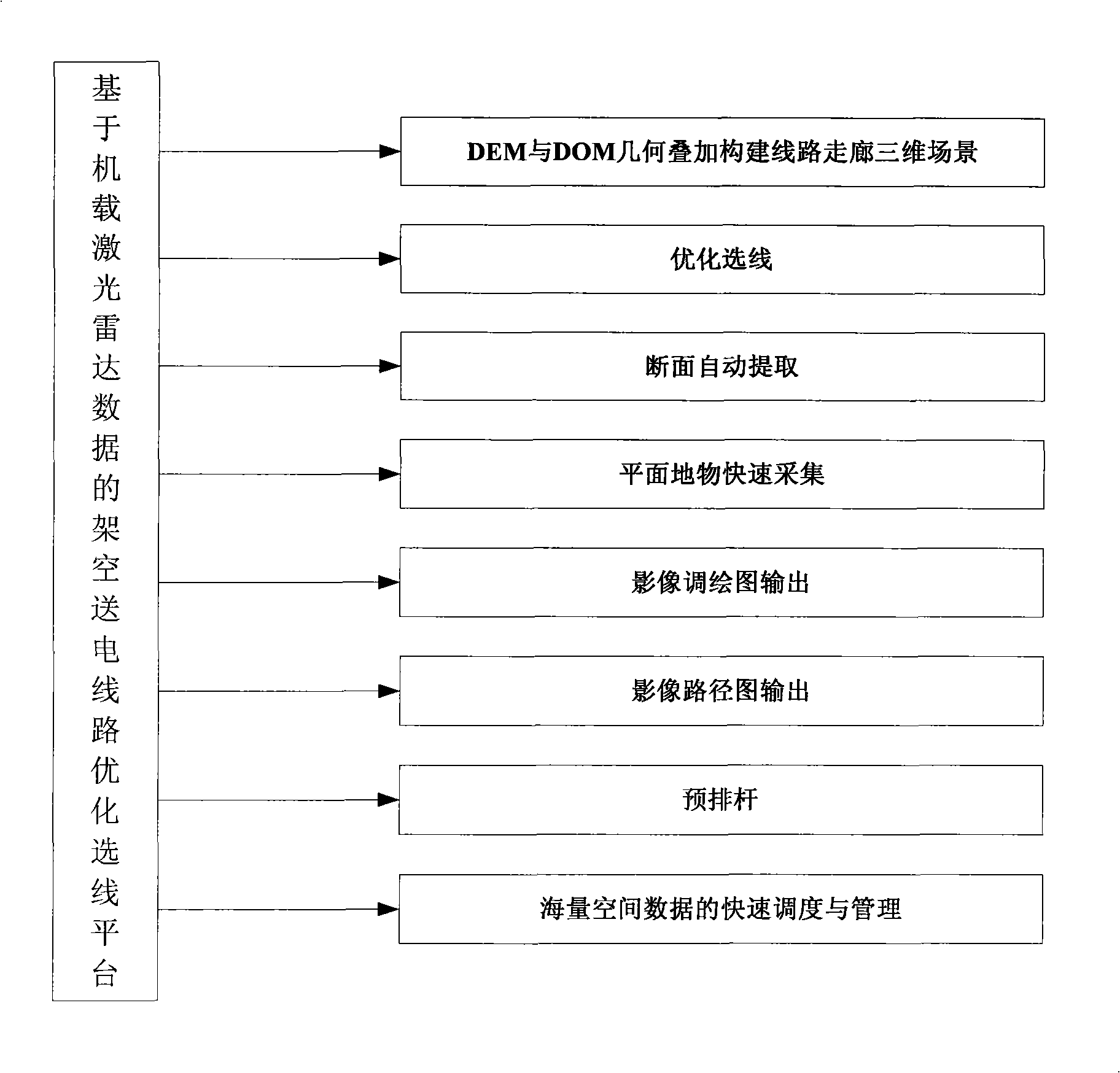

Overhead power transmission line optimized line selection method based on airborne laser radar data

InactiveCN101335431ARealistic 3D visualizationReduce configuration requirementsElectromagnetic wave reradiationApparatus for overhead lines/cablesAviationSimulation

The invention discloses an optimal route selection method for overhead transmission line route. Onboard lidar equipment is adopted to acquire laser point cloud data and aerial digital photo data of the transmission line route corridor range; the onboard lidar data is processed after the wave filtering and the sorting of the laser point cloud data, and the points of the ground surface are made into a digital elevation model with high precision; then data processing is carried out by utilizing the data of the digital elevation model with high precision and ortho-rectification is carried out to the aerial photo by utilizing the internal and external orientation elements of the aerial digital photo to generate digital orthophoto maps; through the overlying of the digital elevation model and the digital orthophoto maps, the tridimensional visualization of the transmission line route corridor can be realized to optimize the transmission line route selection; finally prearrangement of power pole and power pole arrangement are carried out according to the data of plane cross sections. The route selection platform of the invention has simple operation and lifelike tridimensional scene, thus being convenient for full roaming and multi-view observation and greatly improving the efficiency of the inner plane cross section survey operation. Compared with the optimal route selection technology based on the aerial photographing measuring method, the efficiency of the inner plane cross section survey operation can be improved by about 75 percent.

Owner:GUANGXI ELECTRIC POWER IND INVESTIGATION DESIGN & RES INST

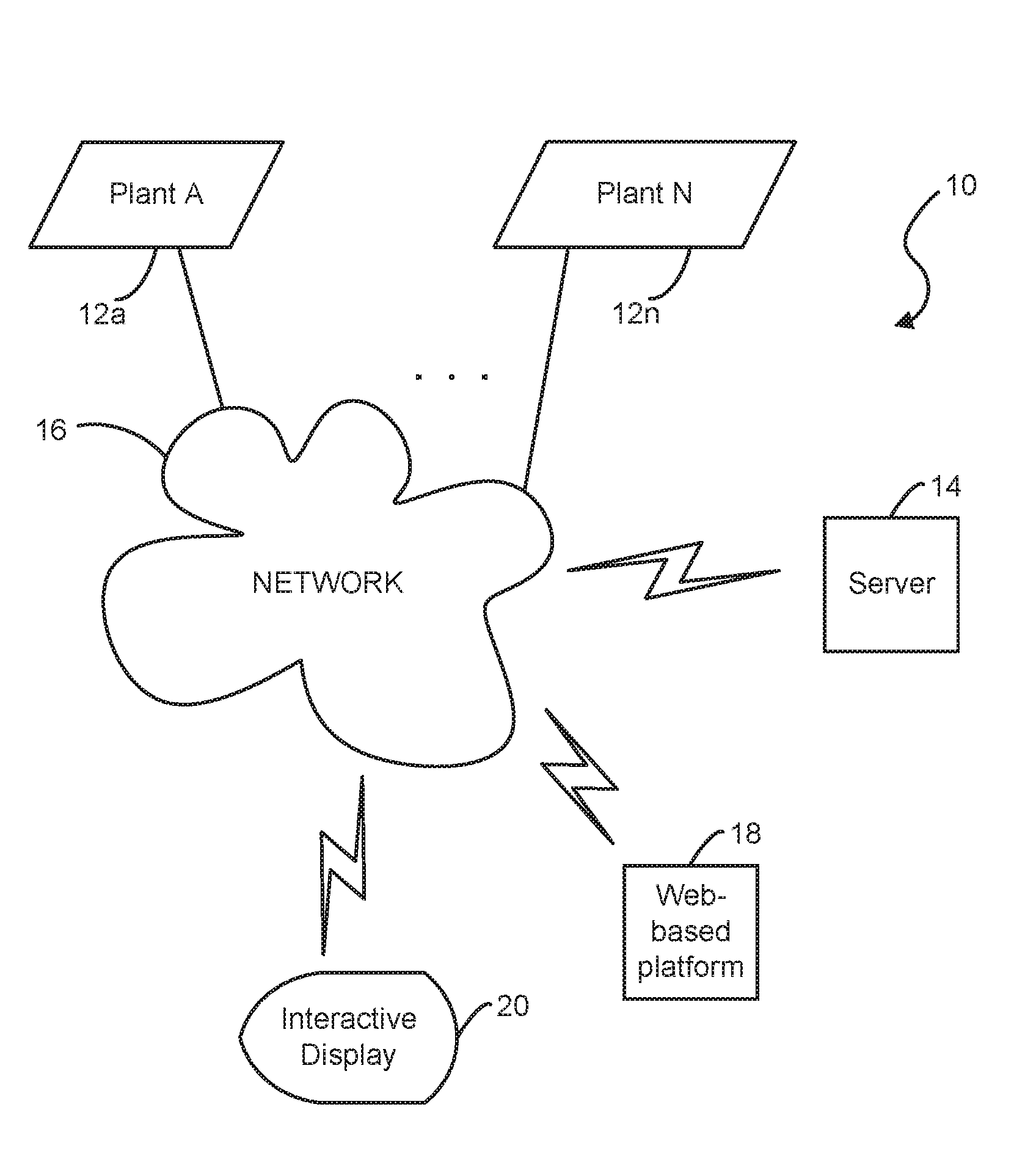

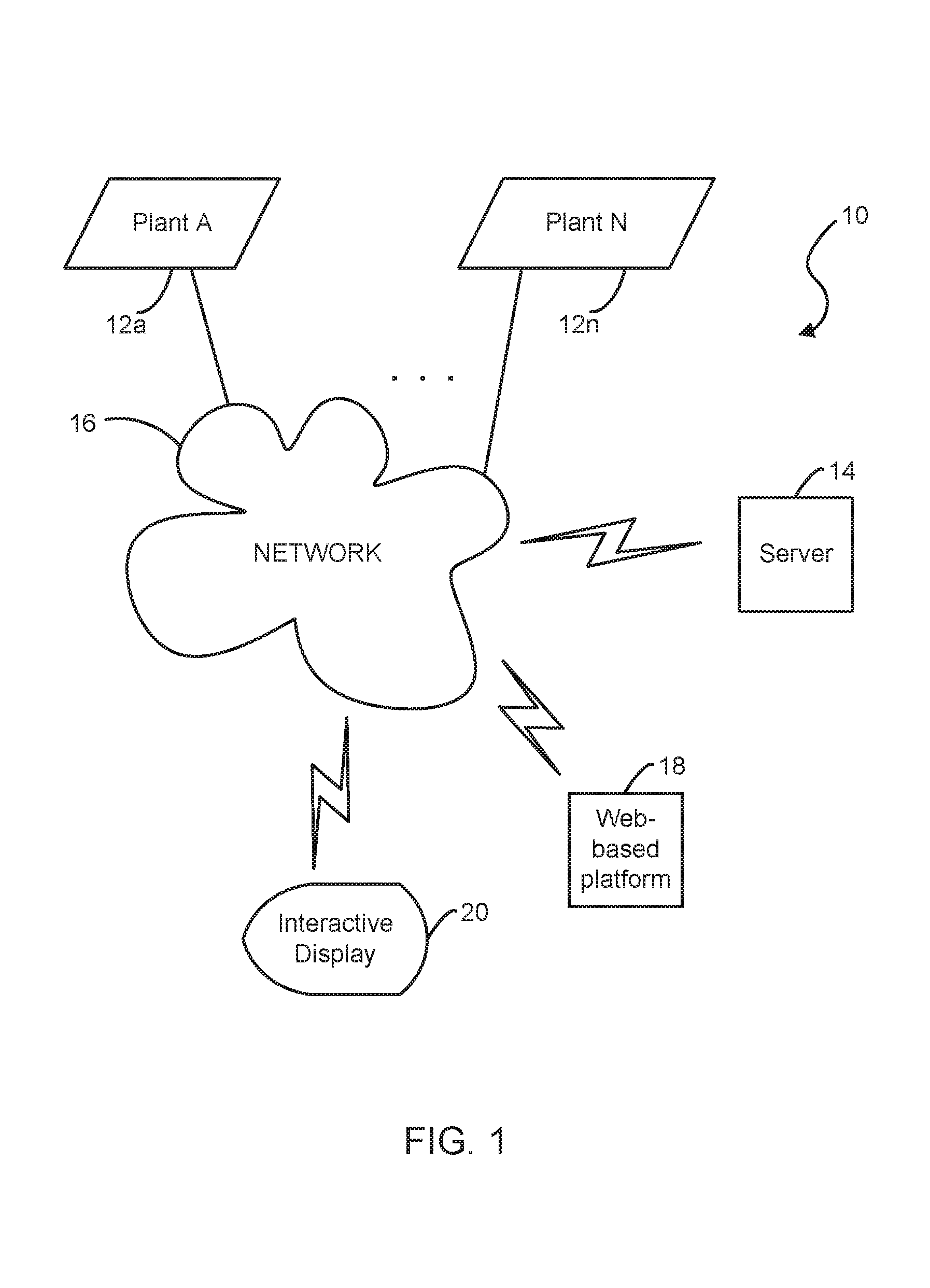

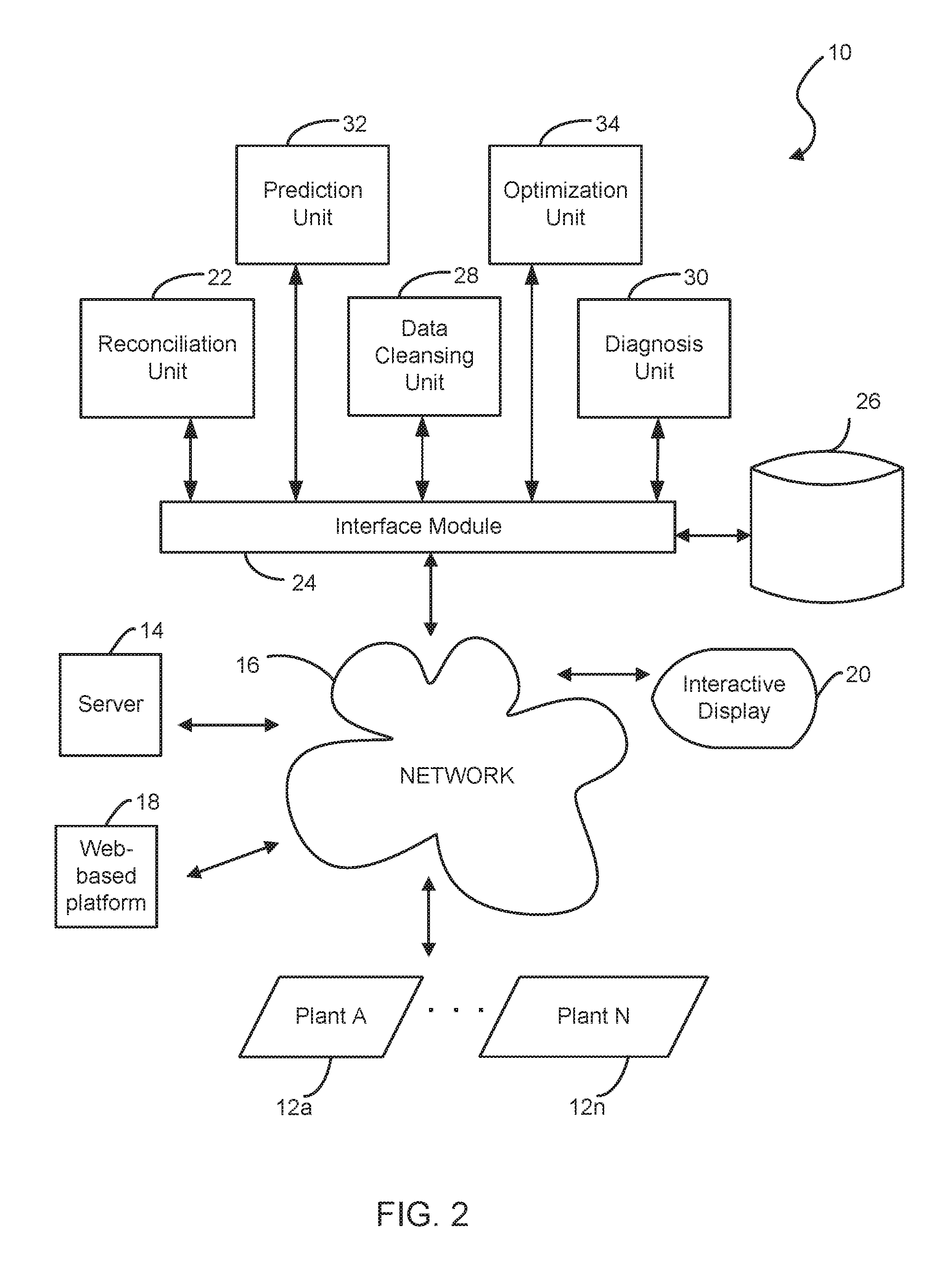

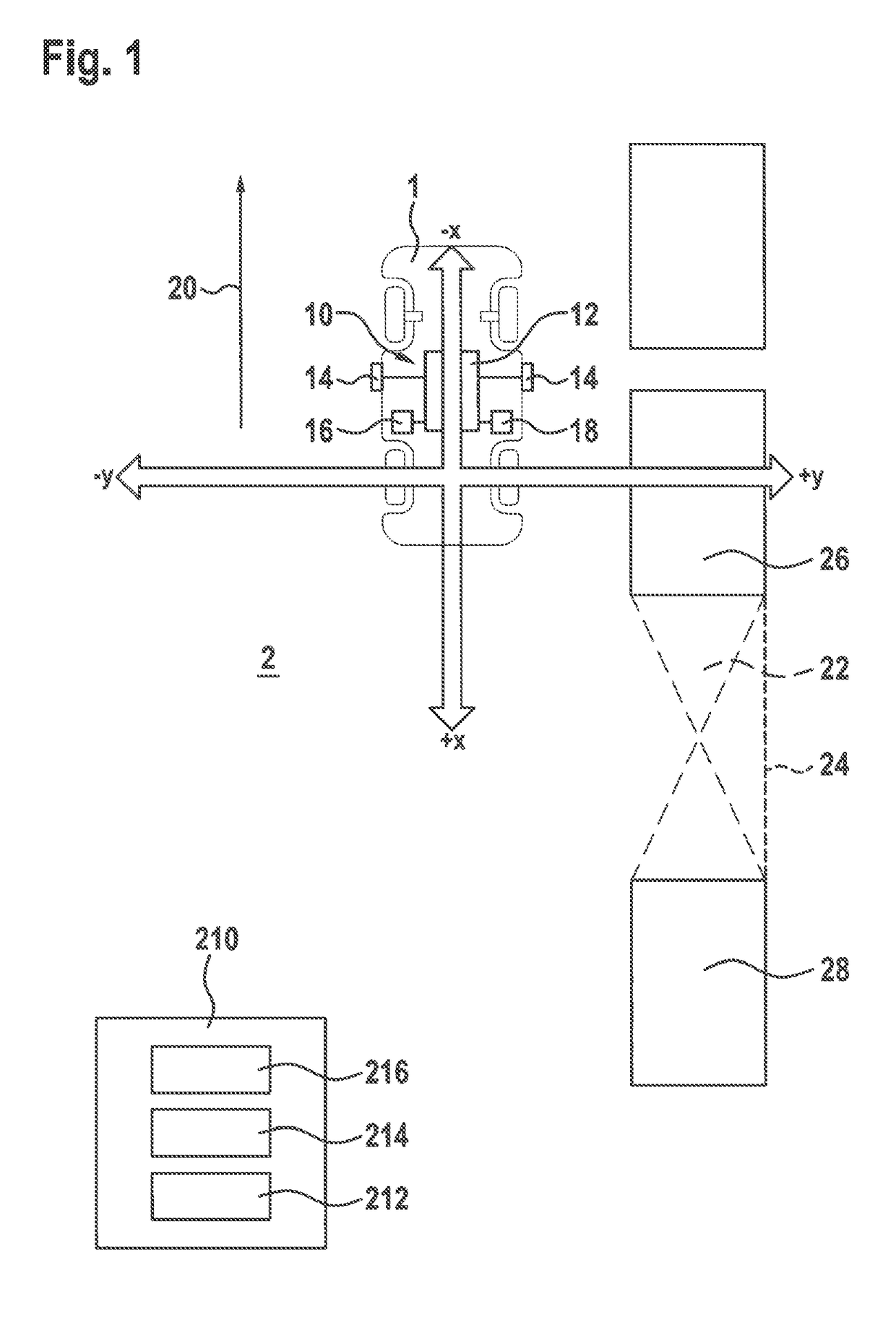

Advanced data cleansing system and method

InactiveUS20160292325A1Improving measurement error estimationEasy to detectTesting/monitoring control systemsVolume variation compensation/correction apparatusObservational errorComputerized system

A cleansing system for improving operation of a plant. A server is coupled to the cleansing system for communicating with the plant via a communication network. A computer system has a web-based platform for receiving and sending plant data related to the operation of the plant over the network. A display device interactively displays the plant data. A data cleansing unit is configured for performing an enhanced data cleansing process for allowing an early detection and diagnosis of the operation of the plant based on at least one environmental factor. The data cleansing unit calculates and evaluates an offset amount representing a difference between a measurement and a simulation for detecting an error of measurement during the operation of the plant based on the plant data.

Owner:UOP LLC

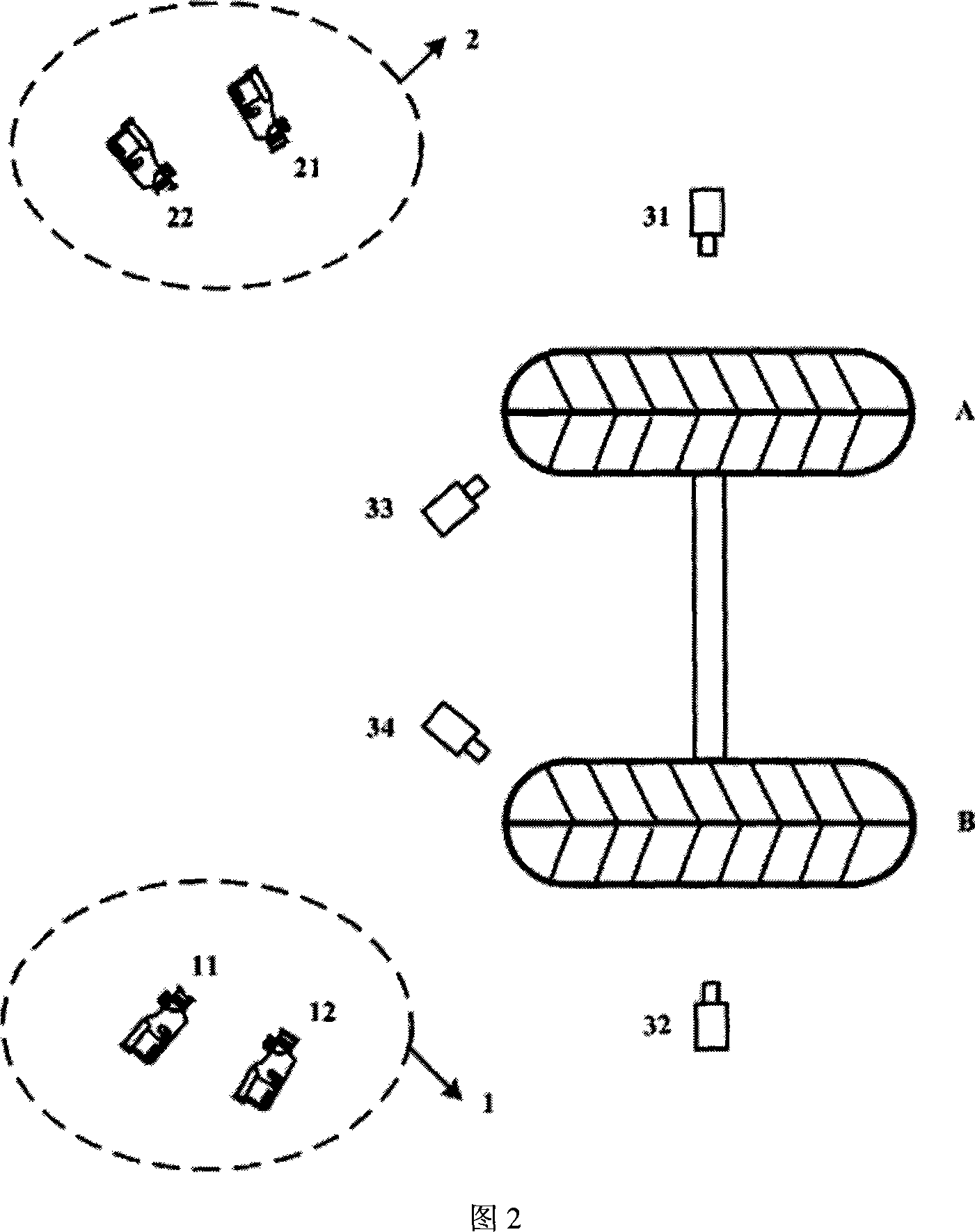

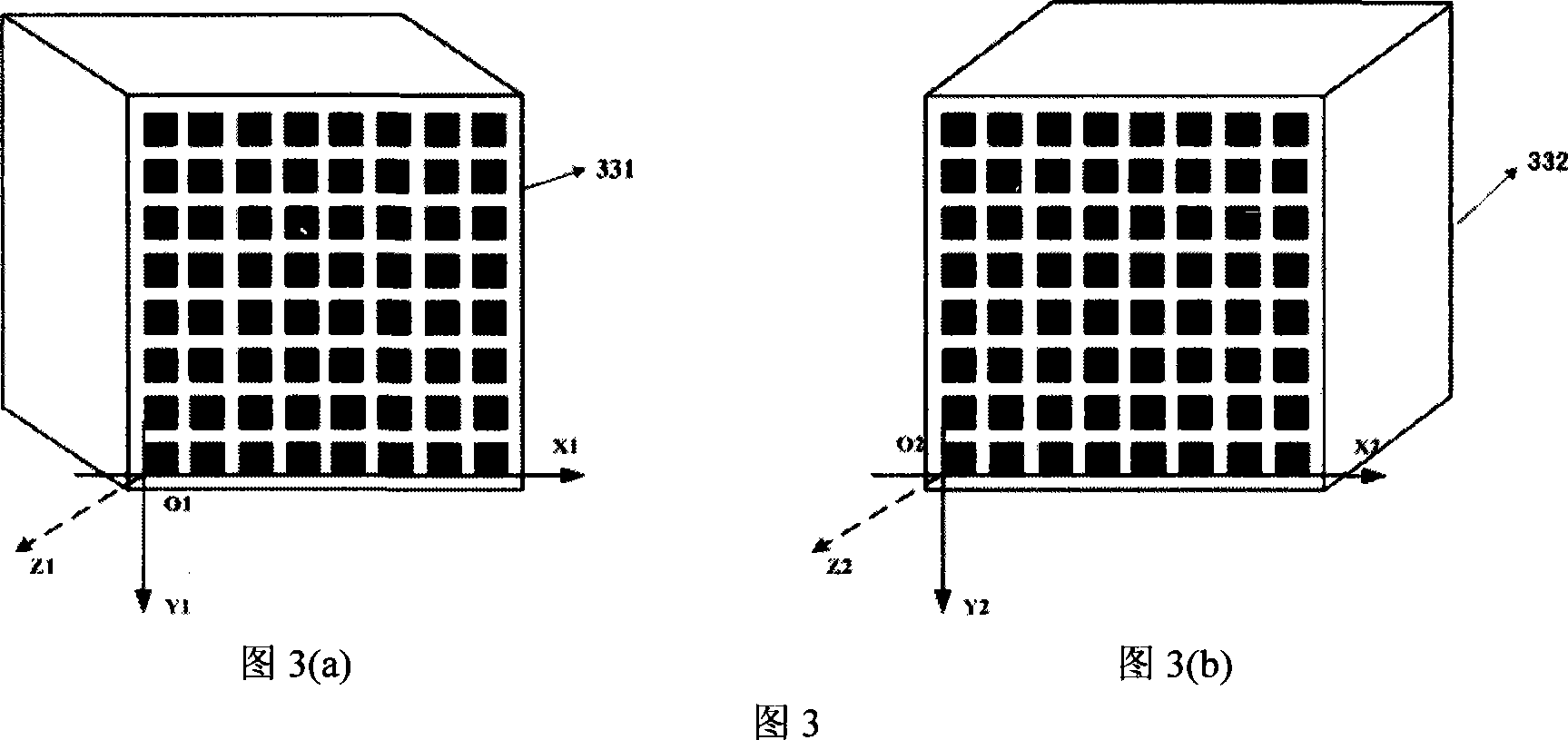

Vehicle tread measurement method based on stereo vision and laser

InactiveCN101059340AHigh precisionExpand field of viewUsing optical meansPicture interpretationVisual perceptionTangential point

The invention provides a wheel distance measuring method based on stereo vision and laser, which uses a stereo vision laser measuring system to obtain relative measuring parameters. The method uses a digit camera to shoot laser pattern projected on the tyre crown, uses image processing method to extract laser pattern target, uses stereo match algorism and three-dimension rebuild algorism to obtain laser pattern stereo point. And the invention projects the laser pattern stereo point on a simulated plane of the laser pattern, uses the projected point to generate a two-dimension curvature, to calculate out an extreme point of the two-dimension curvature, while the extreme point is relative to the tangential point of the tyre crown. And the invention uses one tangential point at inner tyre crown and at least three tangential points at outer tyre crown to simulate a tangential plane to calculate out the central plane of tyre. And the invention calculates out the distance between the cross lines of the central planes of left and right tyres on one shaft and the wheel support plane to obtain the vehicle wheel distance.

Owner:SOUTHEAST UNIV

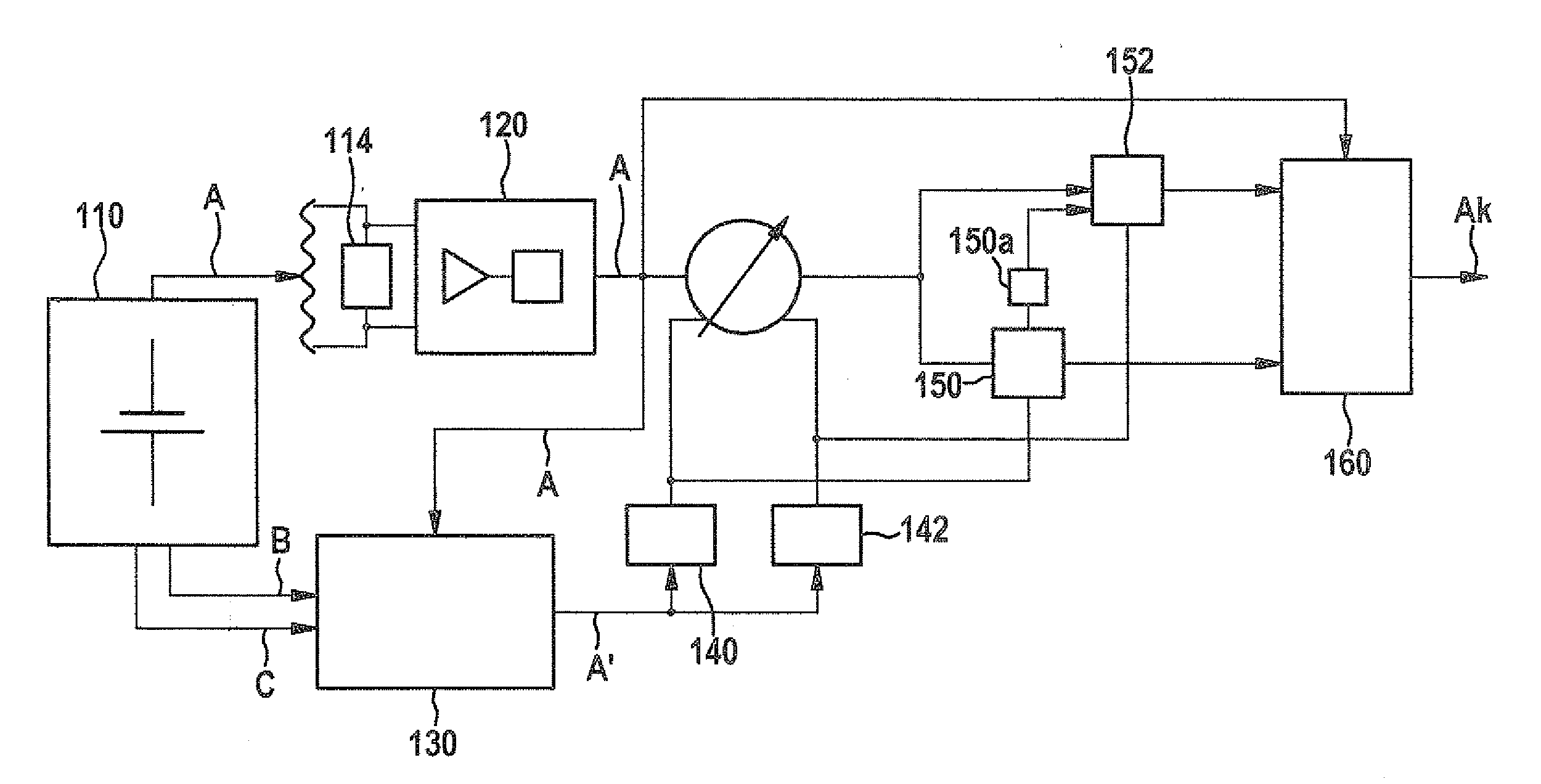

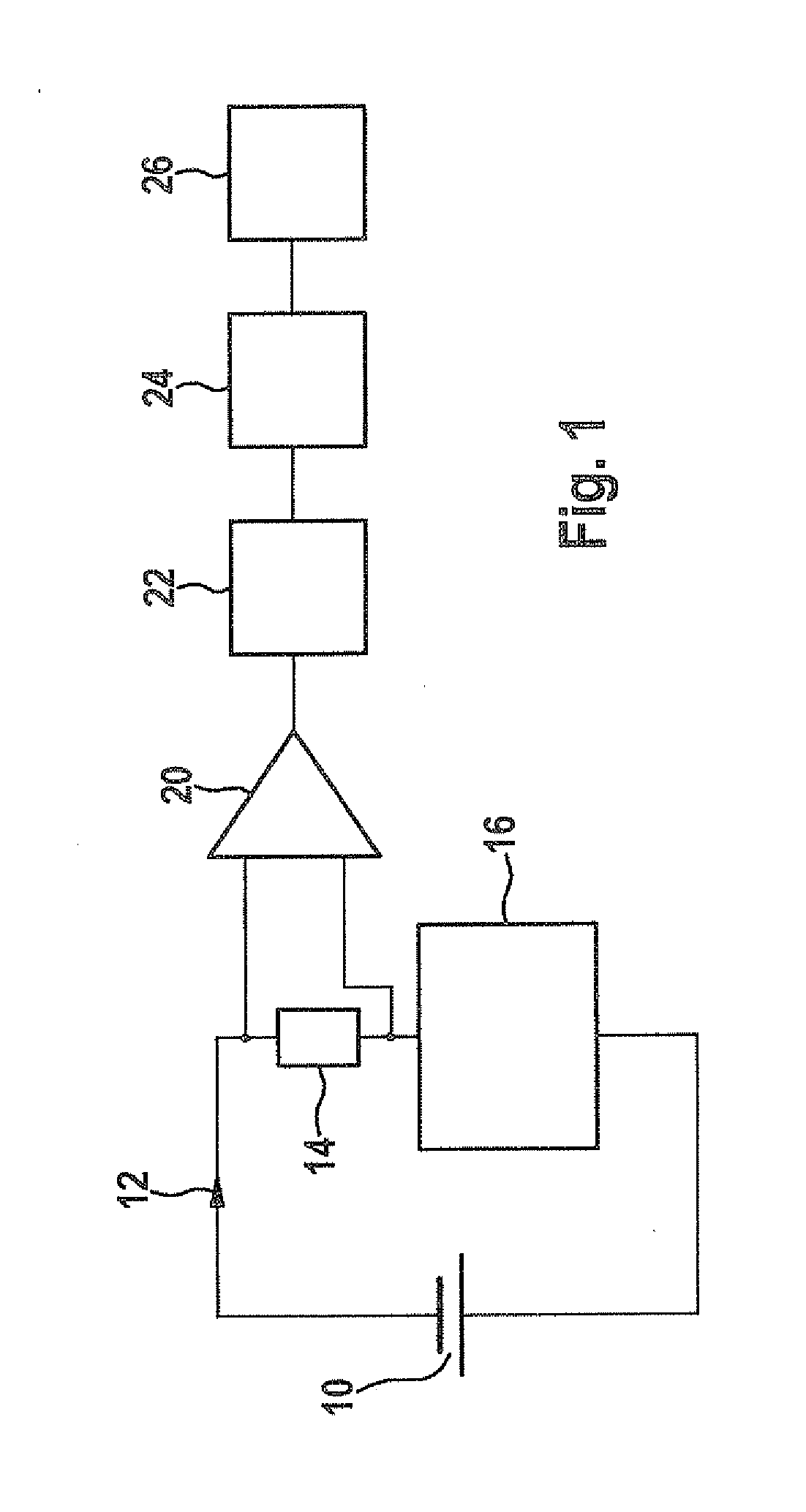

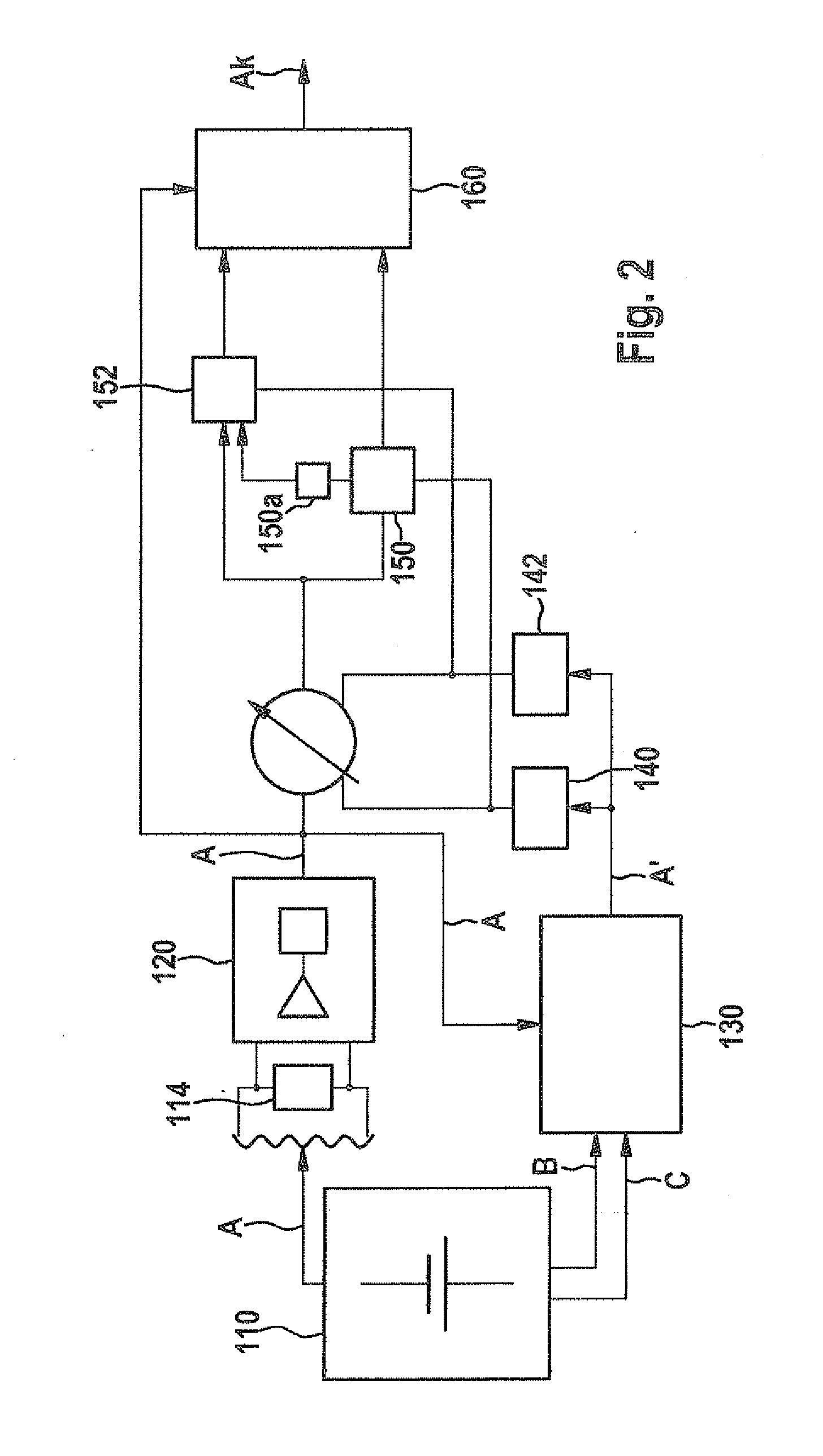

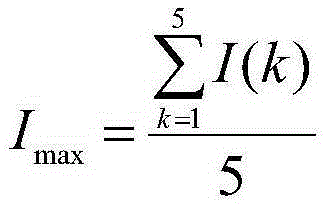

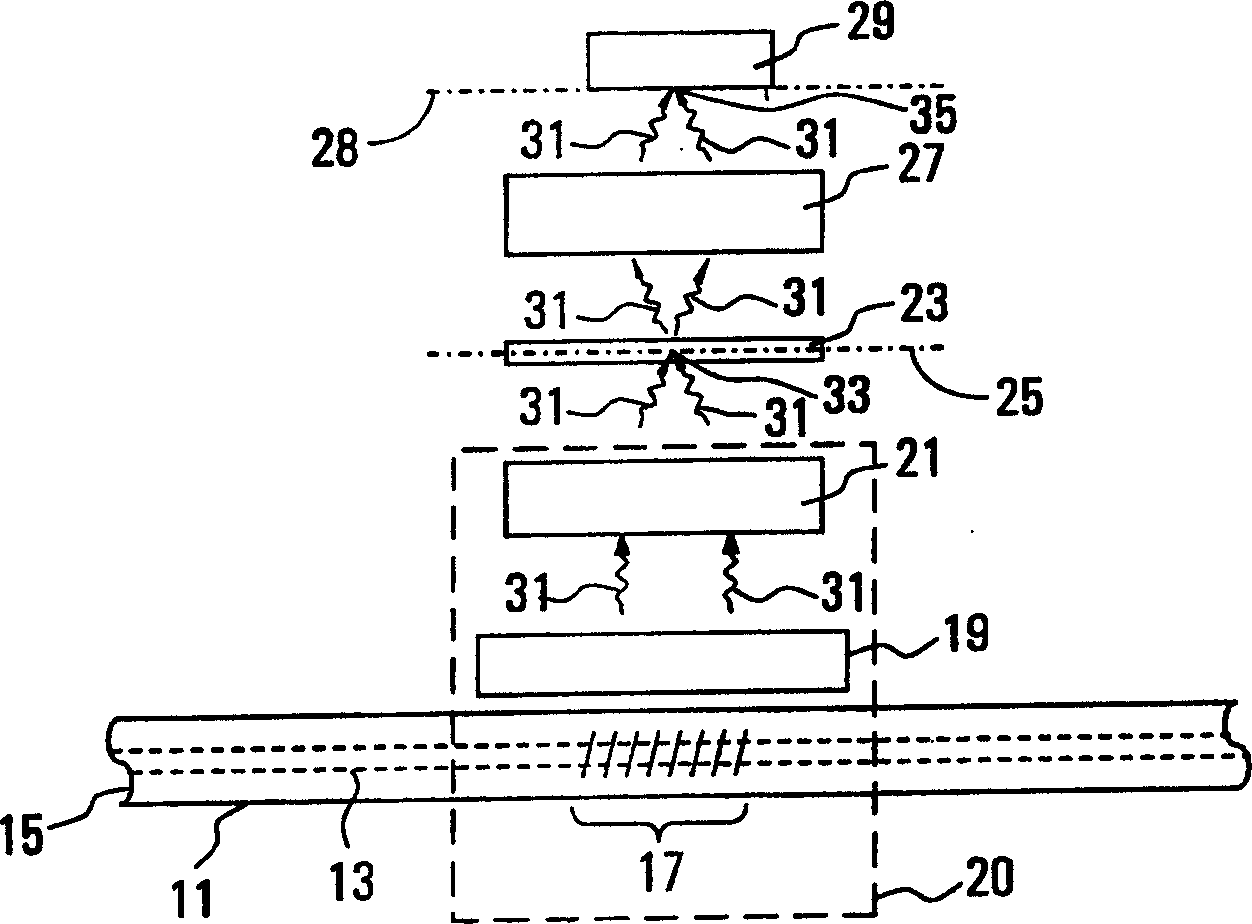

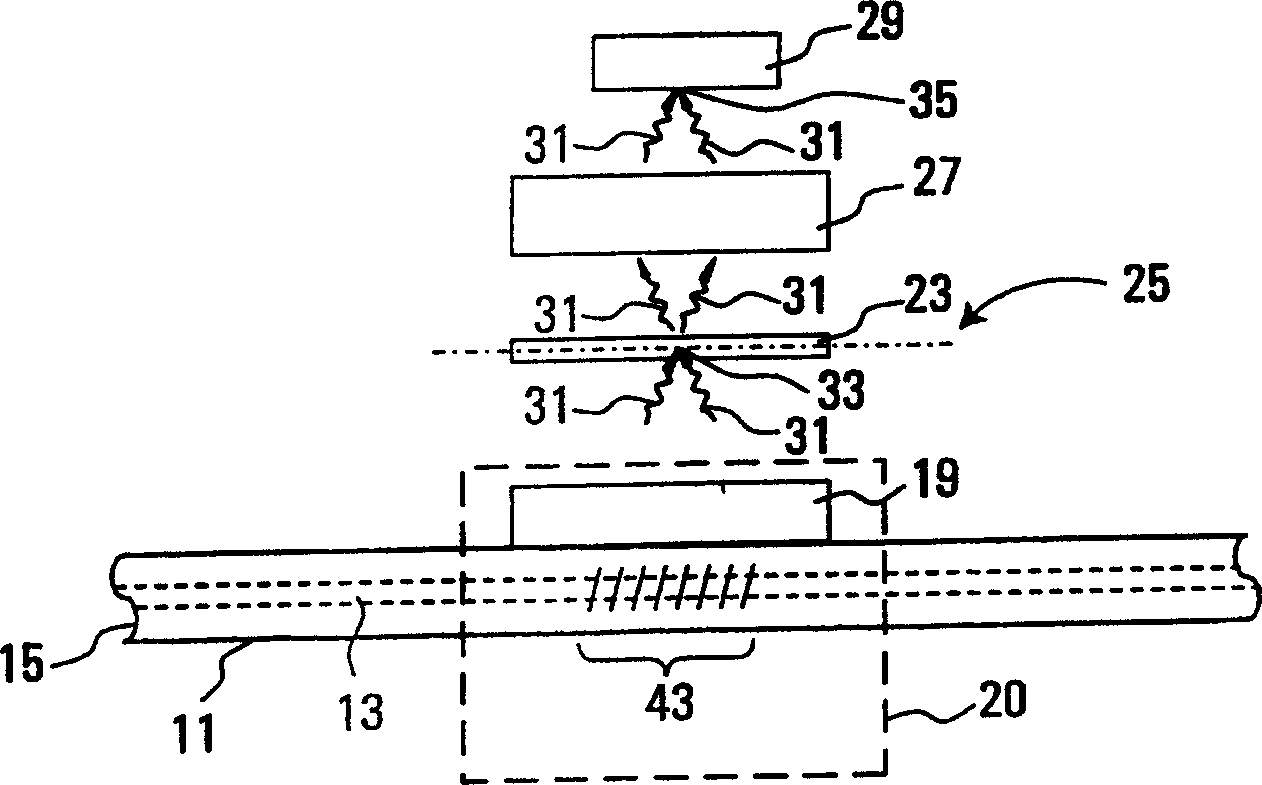

Method and device for error-compensated current measurement of an electrical accumulator

InactiveUS20120283970A1Improve Manufacturing TolerancesImprove accuracyElectrical testingCurrent measurements onlyEngineeringRelative maximum

A method for error-compensated current measurement of an electrical accumulator, including: providing a time window-related estimated charge ascertained by a model-based estimator from operating variables of the accumulator and reflecting the estimated charge that has been withdrawn from the accumulator and supplied to the accumulator within the time window; and detecting the accumulator current supplied to the accumulator and withdrawn from the accumulator during the time window, with a current detection sensor. A zero crossing point in time (estimated charge is essentially zero) and a maximum point in time (the absolute value of the estimated charge essentially has a relative maximum or has a value which is greater than a minimum charge difference) are detected. A current measurement offset error is ascertained at the zero crossing point in time by comparing the estimated charge to the detected accumulator current. The accumulator current is ascertained according to the current measurement offset error, and a current measurement scaling error is ascertained at the maximum point in time by comparing the estimated charge to the detected accumulator current. The ascertained current measurement offset error is subtracted from the comparison result thus obtained, and the accumulator current is compensated for based on the current measurement scaling error. A related device for error-compensated current measurement is also described.

Owner:ROBERT BOSCH GMBH

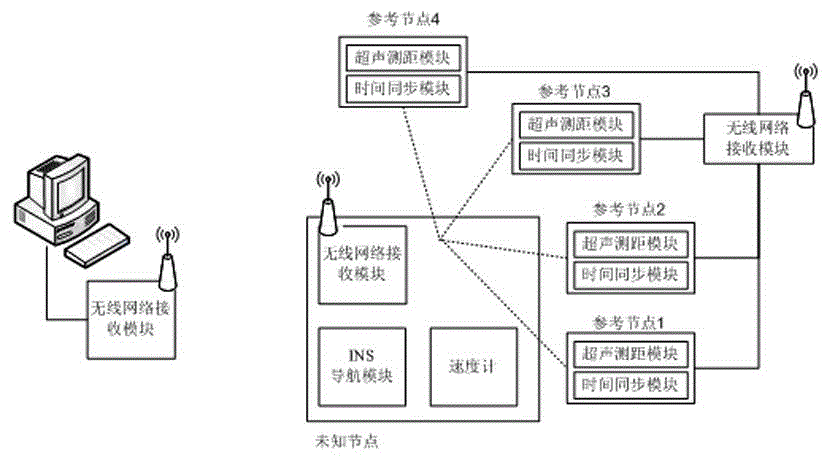

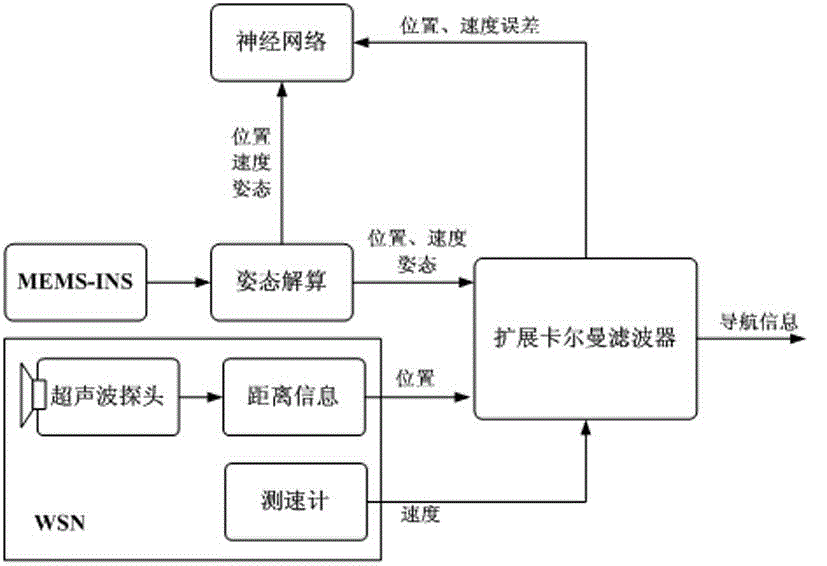

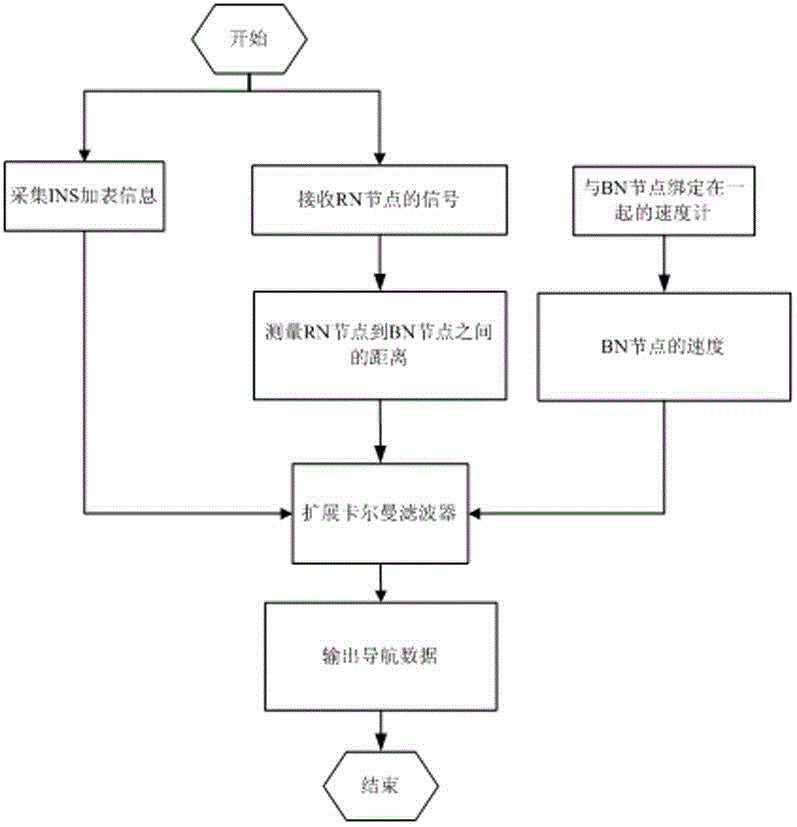

INS (inertial navigation system)-assisted wireless indoor mobile robot positioning method

ActiveCN103148855AImprove measurement errorSatisfy positioningNavigational calculation instrumentsPosition fixationWireless sensor networkingPositioning technology

The invention discloses an INS (inertial navigation system)-assisted wireless indoor mobile robot positioning method, belonging to the technical field of wireless positioning of a robot. The positioning method comprises a training stage and a pre-estimating stage. The training stage comprises the following steps of: integrating an INS and a WSN (web shell navigator) in a local relative coordinate system; and carrying out data fusion on obtained synchronized navigation data by expanding a Kalman filtering wave to obtain continuous and stable navigation information. The pre-estimating stage comprises the following steps of: inputting the position and speed information measured by the INS into the training stage, and carrying out error compensation by a neural-network-trained INS error model to obtain optimal navigation information. According to the method provided by the invention, the INS positioning precision can be improved, and the positioning range of the indoor robot can be expanded on the basis that the WSN network scale is reduced.

Owner:SOUTHEAST UNIV

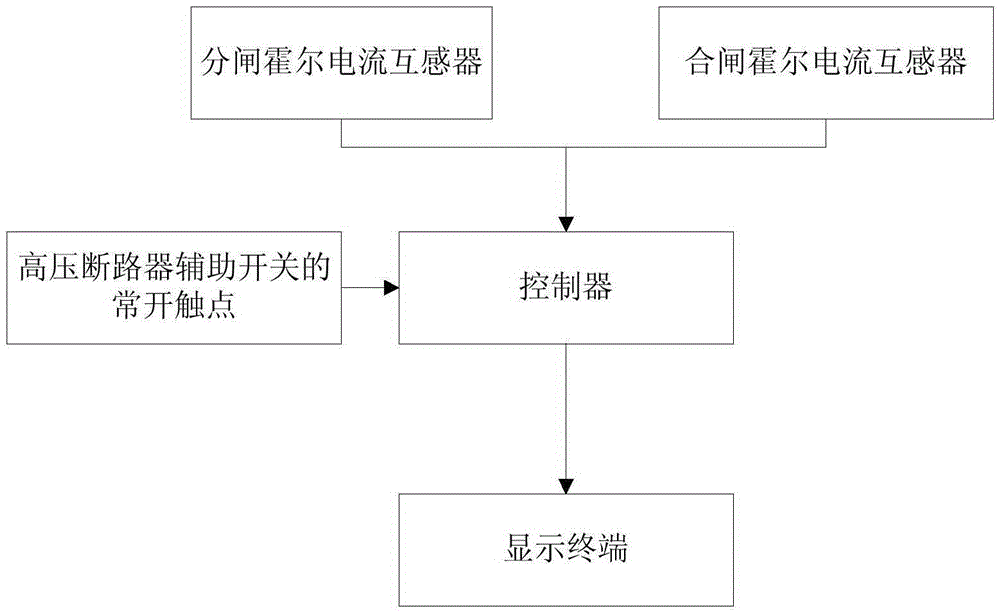

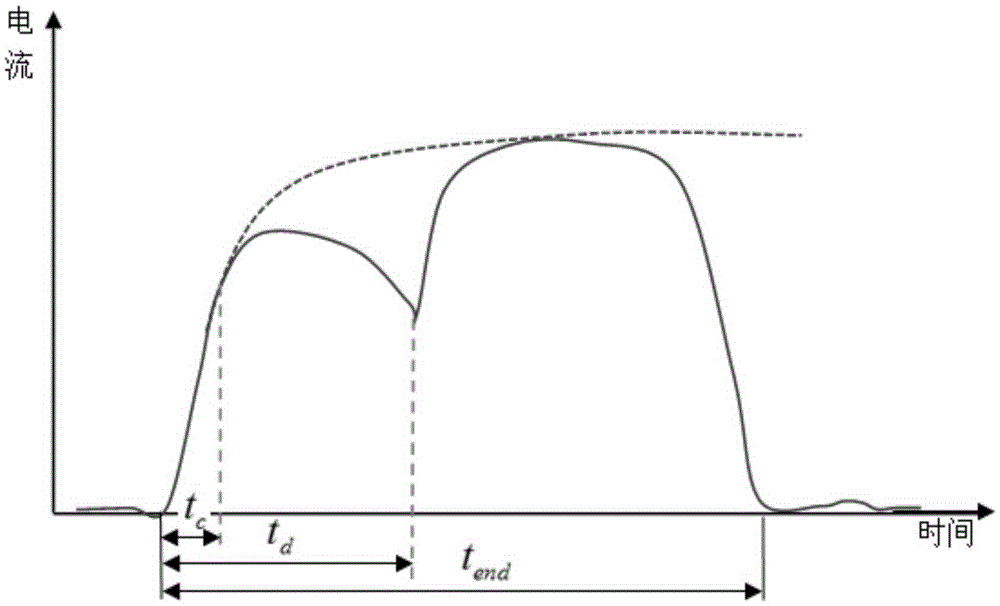

Fault on-line monitoring device of high-voltage breaker and monitoring method thereof

ActiveCN105403831AImprove measurement errorHigh measurement accuracyCircuit interrupters testingData acquisitionEngineering

The invention discloses a fault on-line monitoring device of a high-voltage breaker and a monitoring method thereof. An opening Hall current transformer, a closing Hall current transformer and the normally-opened contact of a high-voltage breaker auxiliary switch are connected with a controller via wires. The controller is connected with a display terminal. The monitoring method comprises steps of acquiring data; calculating basic data; judging direct-current grounding faults of a high-voltage breaker mechanism and turn-to-turn short circuit faults of electromagnetic coils; judging the 'opened-after-closed' fault of the circuit breaker caused by a failure to keep an opening tripper of the high-voltage breaker mechanism to be closed; judging the fault of a failure of restoration caused by deformation of a reset spring of the high-voltage breaker mechanism; judging the jam fault of the tripper of the high-voltage breaker mechanism; and judging the jam fault of an iron core of an electromagnet. The fault on-line monitoring device is simple in structure and high in measuring precision; data is precise; the calibration method is simple and easy; and technical problems in the prior art are overcome.

Owner:GUIZHOU POWER GRID CO LTD ZUNYI POWER SUPPLY BUREAU

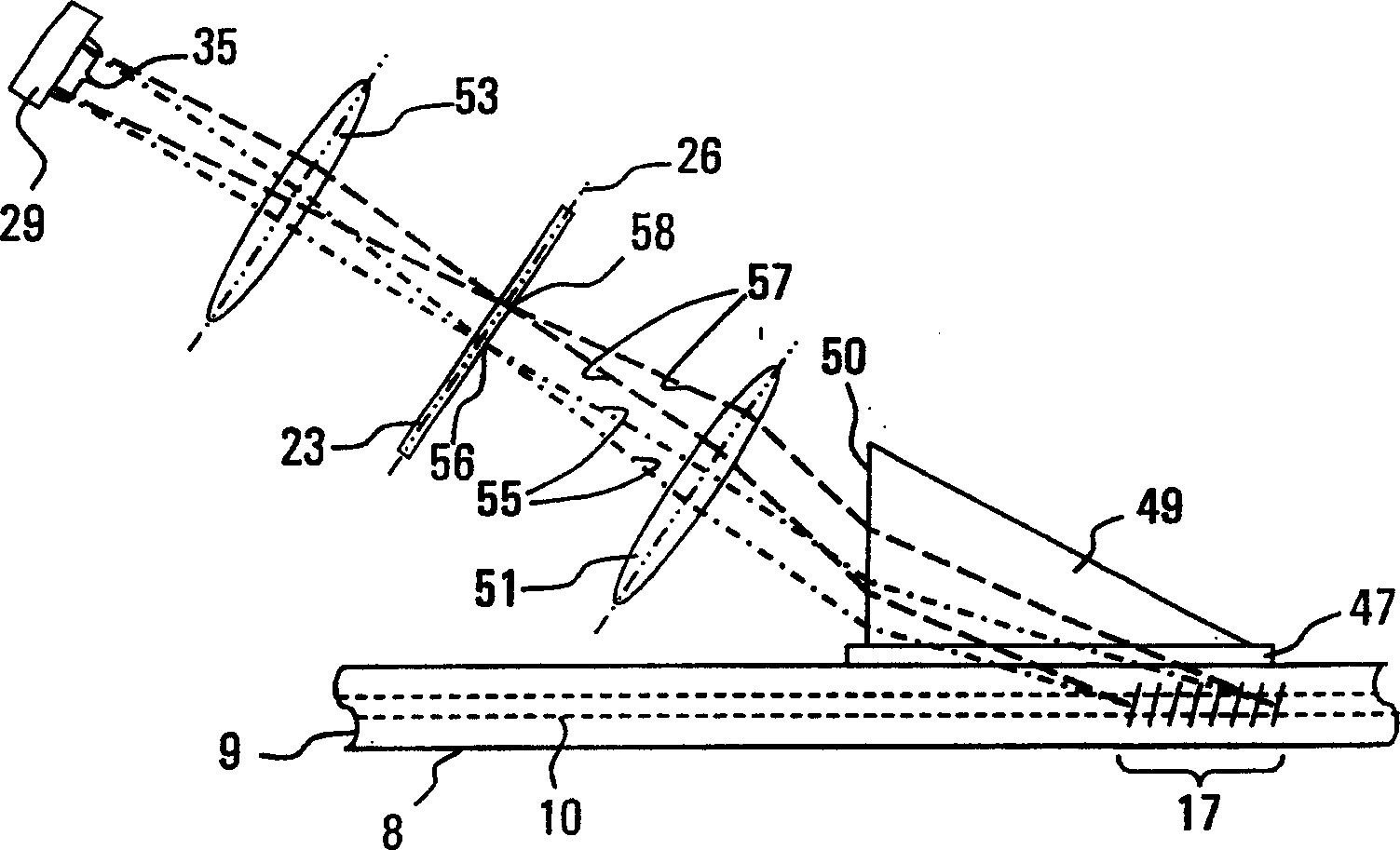

Processing method for position and light of built-in tilt Bragg raster containing optical waveguide

InactiveCN1869747AHigh sensitivityImprove measurement errorCoupling light guidesSpectrometry/spectrophotometry/monochromatorsGratingSpatial light modulator

The invention is commonly (widely or generally) characterized in being an optical device, where a light waveguide is in the optical device and an inclined grating is in the optical device to couple in one or plural irradiating beams through guide mode; light irradiated from the inclined grating is focused into intermediate image in the preset position on a middle image plane, and the position of the intermediate image depends on light wavelength and effective refractive index of the guide mode. And the invention can place a spatial light modulator to control phase and / or amplitude of light beam. More remarkably, the invention comprises a last-stage focusing device to focus light transmitted by the spatial light modulator into last stage image in local region, so as to improve light strength, i.e. improving detecting sensitivity, where the last- stage focusing device can be a lens. And the invention also comprises a light receiver, which can be a optical fiber detector, or a last-stage image detecting light detector array.

Owner:SOUTHEAST UNIV +1

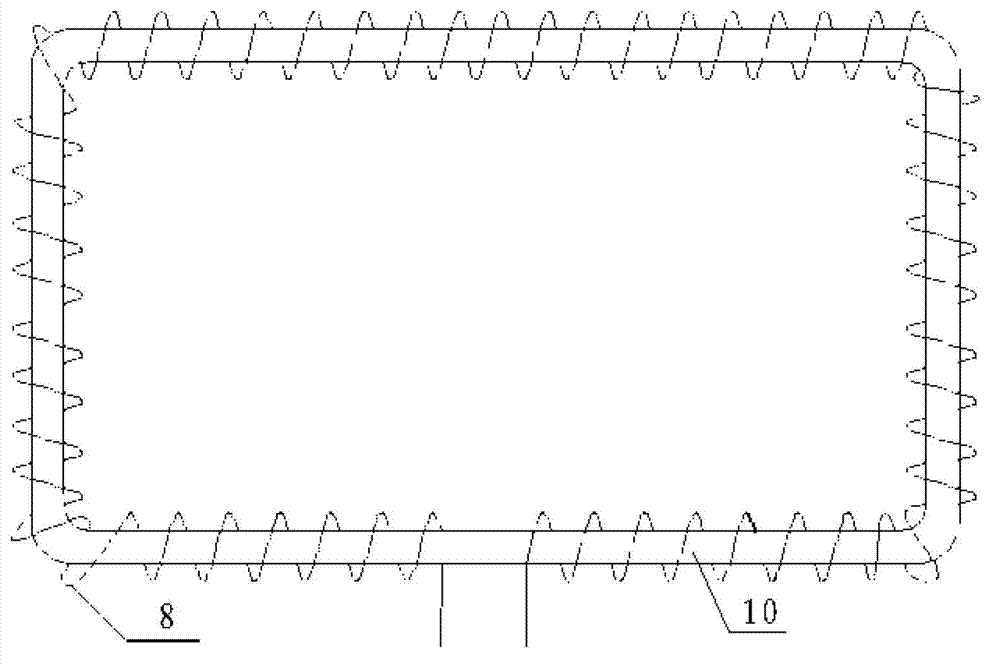

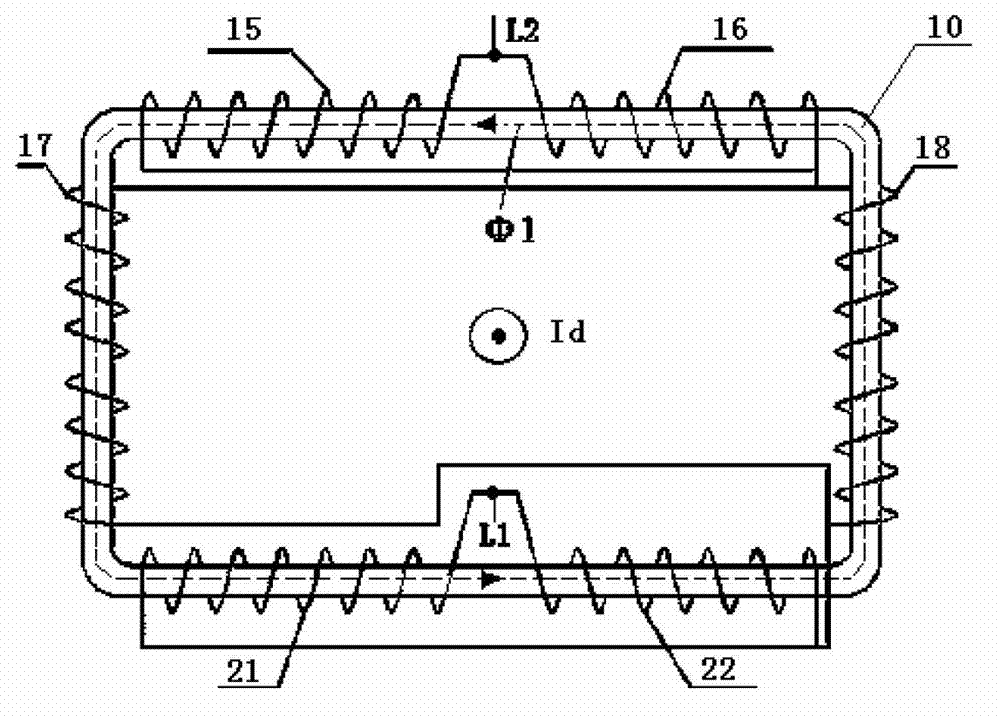

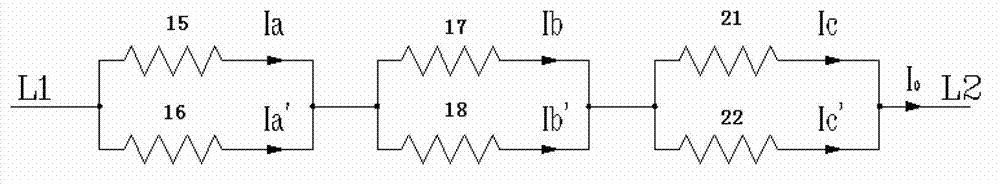

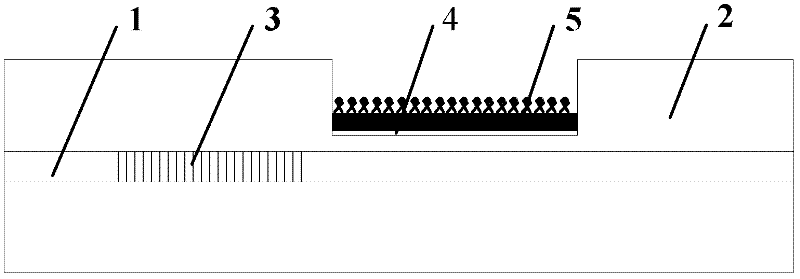

Residual current transformer

ActiveCN103050265AReduce external distractionsImprove measurement errorTransformersTransformers/inductances coils/windings/connectionsPhysicsMagnetic core

The invention discloses a residual current transformer which comprises a magnetic core component, a coil component and a shielding component. The coil component surrounds the outer surface of the rectangular magnetic core component and comprises a test coil and a measurement coil. The measurement coil is positioned outside the test coil, surrounds the outer surface of the magnetic core component and comprises a left winding coil, a right winding coil, two upper winding coils and two lower winding coils, wherein the left winding coil is wound along a first direction, the right winding coil is wound along a second direction, the two upper winding coils are wound along the first direction and the second direction respectively, and the two lower winding coils are wound along the first direction and the second direction respectively. The left winding coil and the right winding coil are in parallel connection and positioned between the two upper winding coils in parallel connection and the two lower winding coils in parallel connection. By the aid of the residual current transformer, saturation of the shielding component can be restrained, measurement errors are reduced, and reliability of a circuit breaker is improved.

Owner:CHANGSHU SWITCHGEAR MFG CO LTD (FORMER CHANGSHU SWITCHGEAR PLANT)

Fiber surface plasmon resonance glucose sensor with temperature self-compensation

InactiveCN102507503AEasy to manufactureSimple structureScattering properties measurementsObservational errorGrating

The invention relates to a fiber surface plasmon resonance glucose sensor with temperature self-compensation. The fiber surface plasmon resonance glucose sensor comprises a fiber core; a fiber cladding wraps the periphery of the fiber core; a fiber grating is written in a 10-30mm section of the fiber core; and a chromium layer, a gold film and a glucose molecule specific adsorption layer are arranged on the periphery of a 15-30mm section of the fiber cladding from inside to outside. Fiber is single mode fiber; the fiber grating is a long-period fiber grating or a tilted fiber grating; the thickness of the chromium layer is 3-5 nm; and the thickness of the gold film is 30-60 nm. The fiber surface plasmon resonance glucose sensor has the advantages of simple structure, small volume, anti-electromagnetic interference and corrosion resistance, can be easily combined with a tissue fluid transdermal extraction chip so as to manufacture a miniaturized instrument, and meanwhile, is suitable for implanted measurement. With the adoption of the fiber surface plasmon resonance glucose sensor with temperature self-compensation, the measurement errors arising from temperature and the interference on measurement caused by external environments can be reduced.

Owner:TIANJIN UNIV

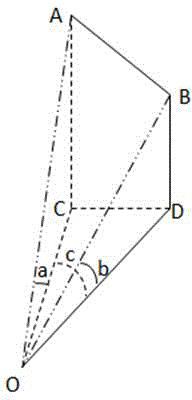

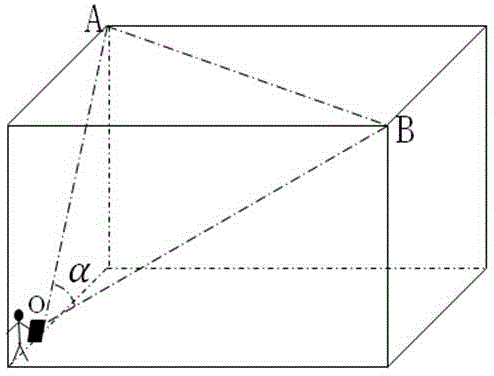

Space distance measurement method based on intelligent cell phone

InactiveCN103604413AAvoid the effects of displacementImprove errorOptical rangefindersLaser rangingData acquisition

The invention provides a space distance measurement method based on an intelligent cell phone. The space distance measurement method is realized by three steps of indirect distance data acquisition, data processing and mathematical calculation. The space distance measurement method has the advantages that (1) indirect measurement is carried out step by step by using a laser distance measurement module to obtain parameters needed by space distance measurement, so as to prevent the problem of like products that the cost of equipment is increased by adopting a plurality of laser distance measurement modules to measure distances; (2) a innovative single-arm fixed shoulder positioning method is used for realizing two-times distance measurement so as to avoid causing influences that a distance measurement starting point has displacement; meanwhile, complicated operation of similar methods in which a fixed bracke is rotated to obtain an angle change is avoided so that the space distance measurement is simple and convenient.

Owner:NANCHANG HANGKONG UNIVERSITY

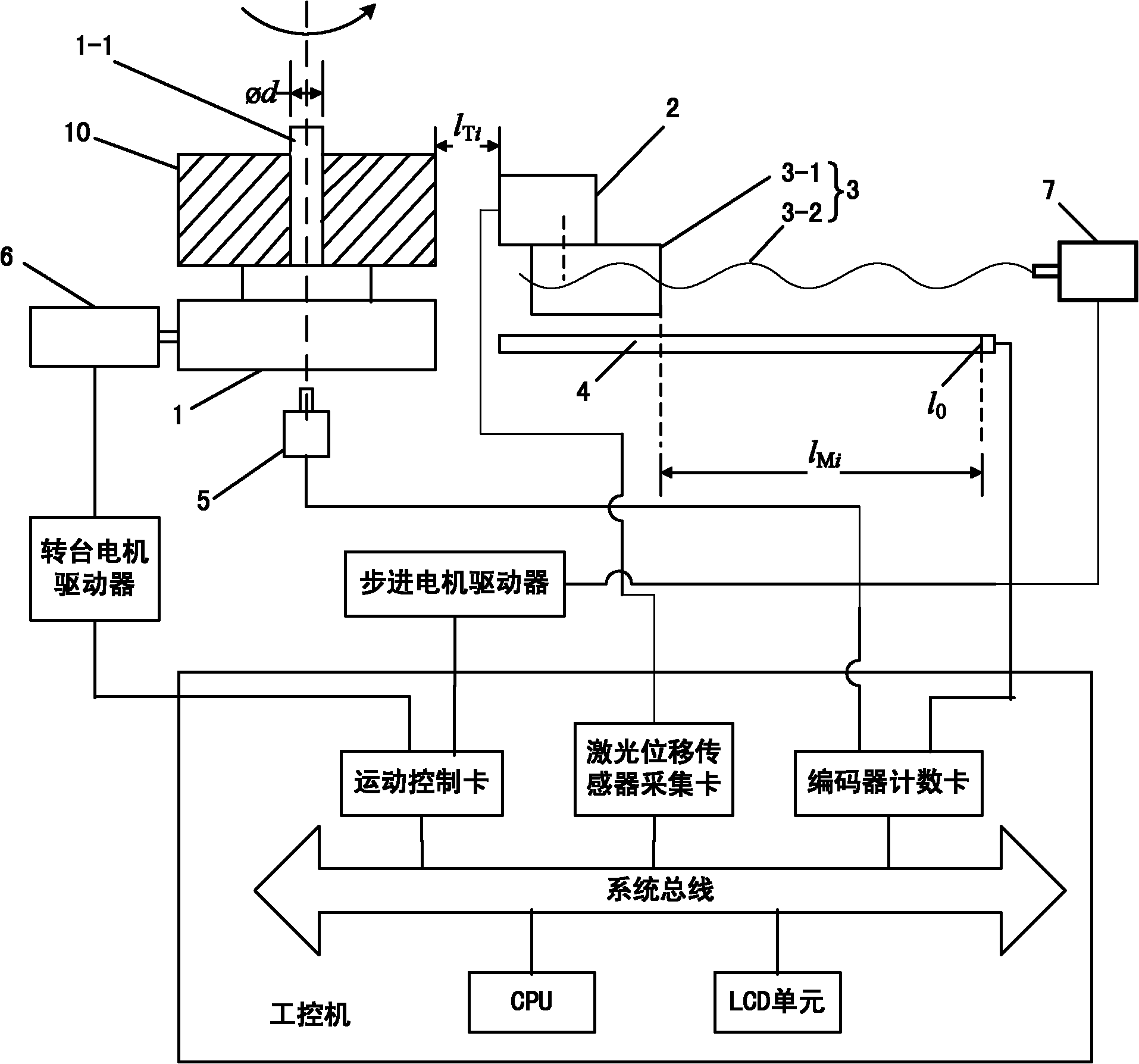

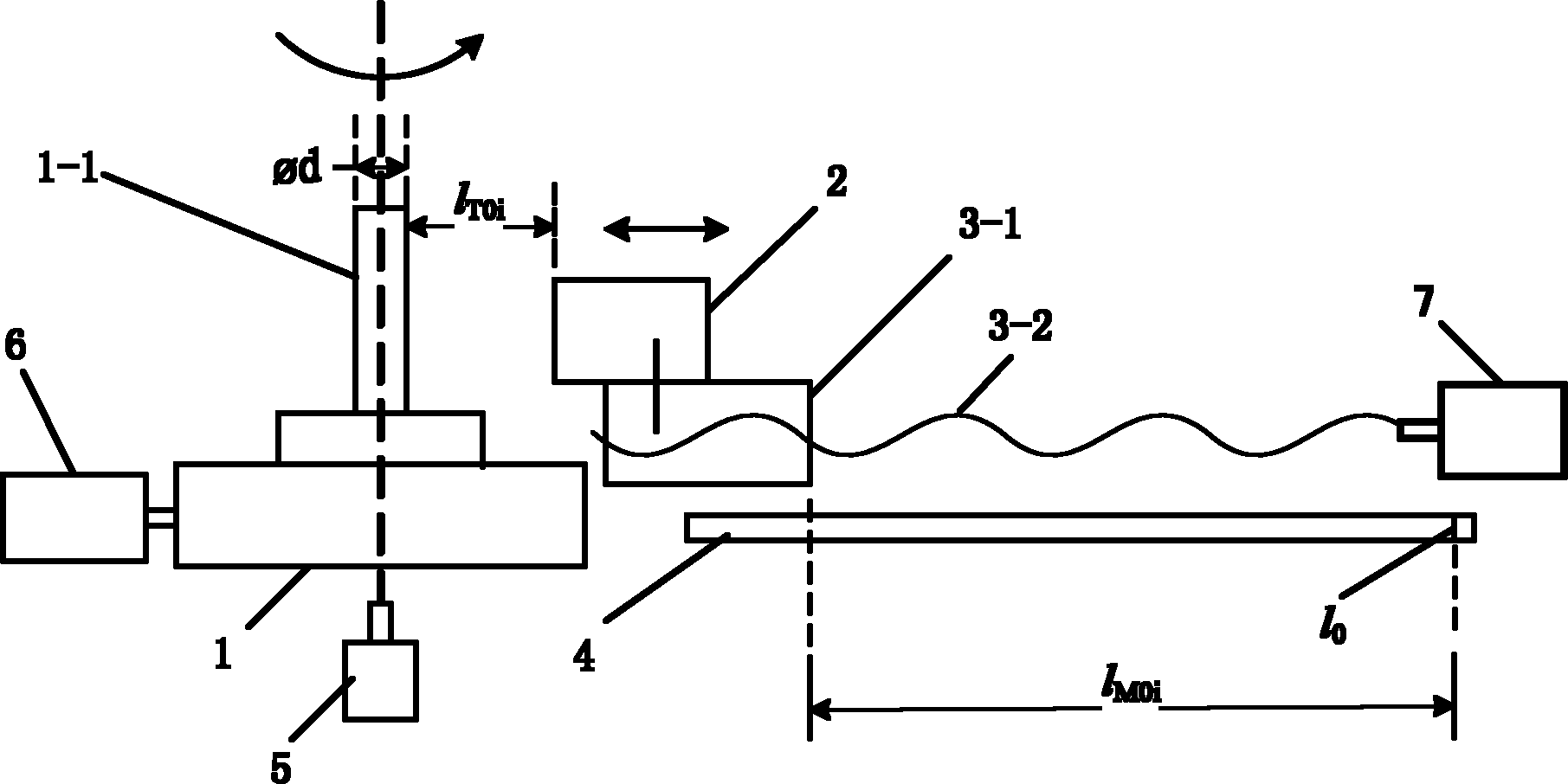

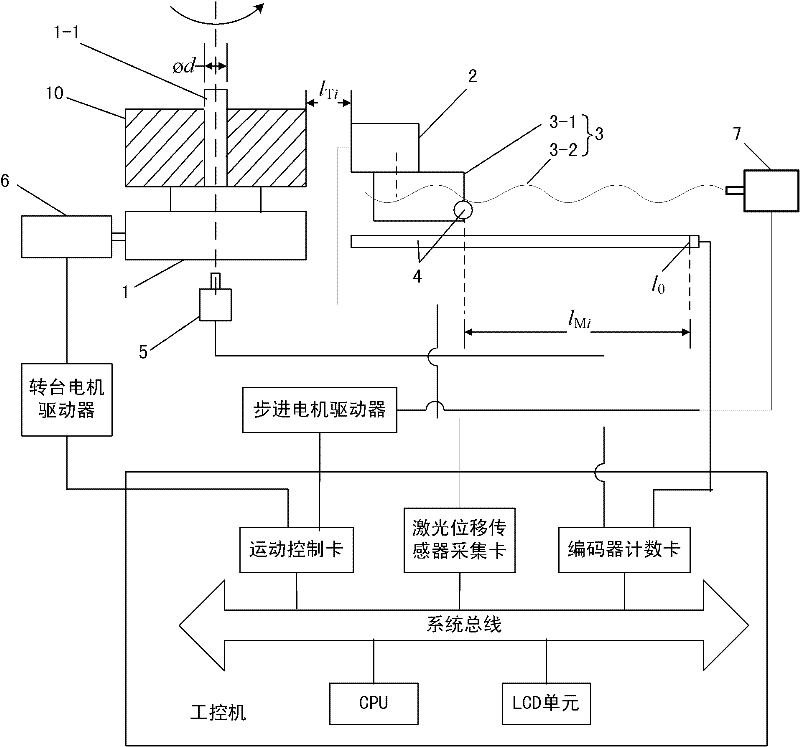

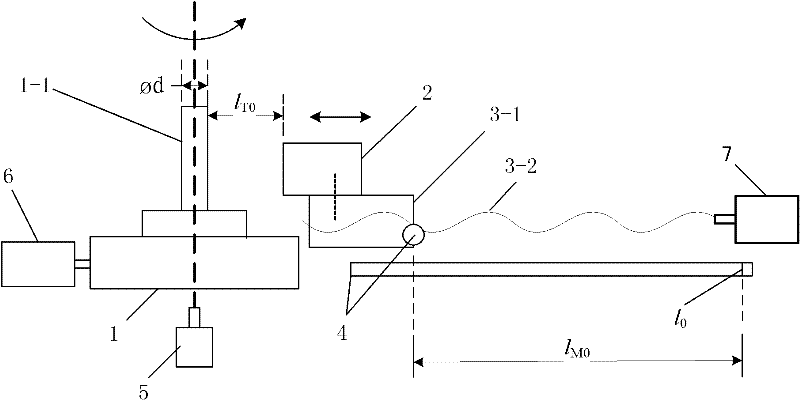

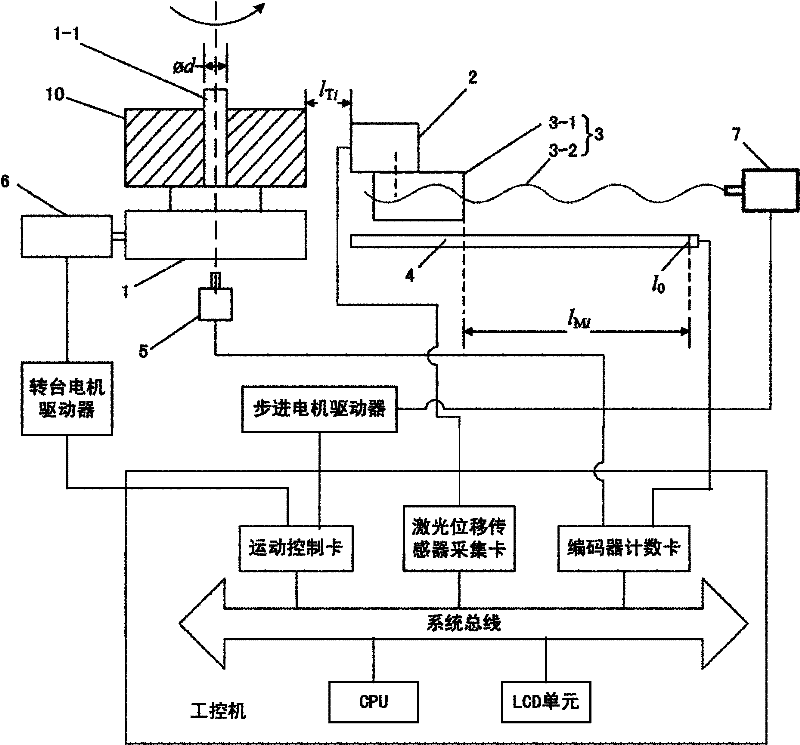

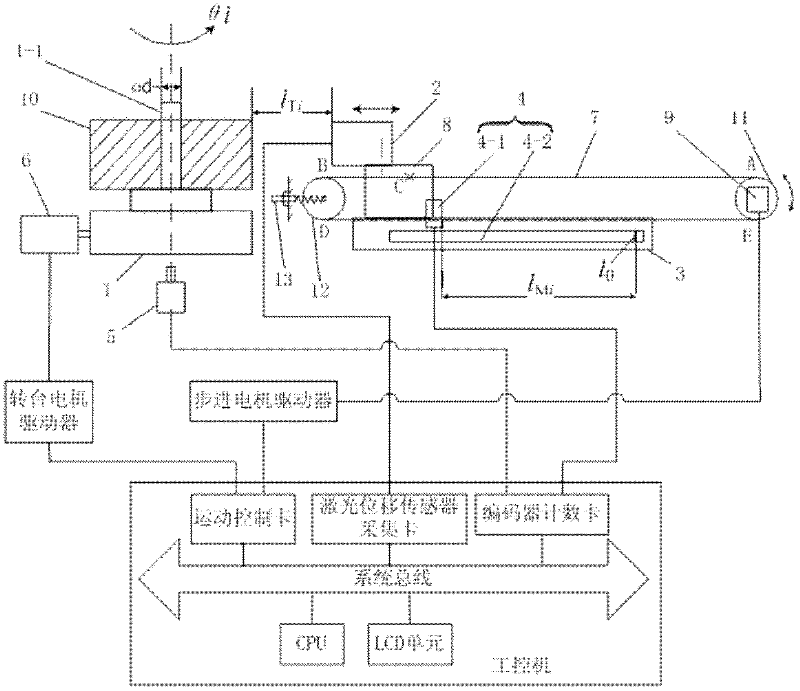

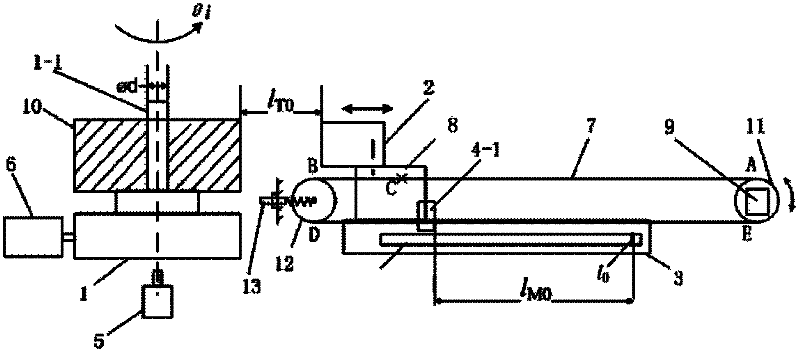

Detection method for cam outline detection system

The invention provides a detection method for a cam outline detection system which has a simple structure and high detection precision and efficiency. The adopted cam outline detection system comprises a numerically controlled rotary table, a screw rod and nut pair, a laser measurement head, a grating bar displacement sensor, an encoder and an industrial control computer; the numerically controlled rotary table is used for driving a cam to horizontally and coaxially rotate around a vertical mandrel; the screw rod and nut pair is horizontally arranged on one side of the numerically controlled rotary table; the laser measurement head is arranged on a movable nut of the screw rod and nut pair and positioned on one side of the cam; the grating bar displacement sensor is used for measuring the horizontal displacement value of the movable nut; the encoder is used for detecting a rotary angle of the cam; and the industrial control computer controls the operation of the numerically controlled rotary table and the screw rod and nut pair, and obtains data of the outer outline of the cam according to data measured by the laser measurement head, the grating bar displacement sensor and the encoder.

Owner:CHANGZHOU INST OF TECH

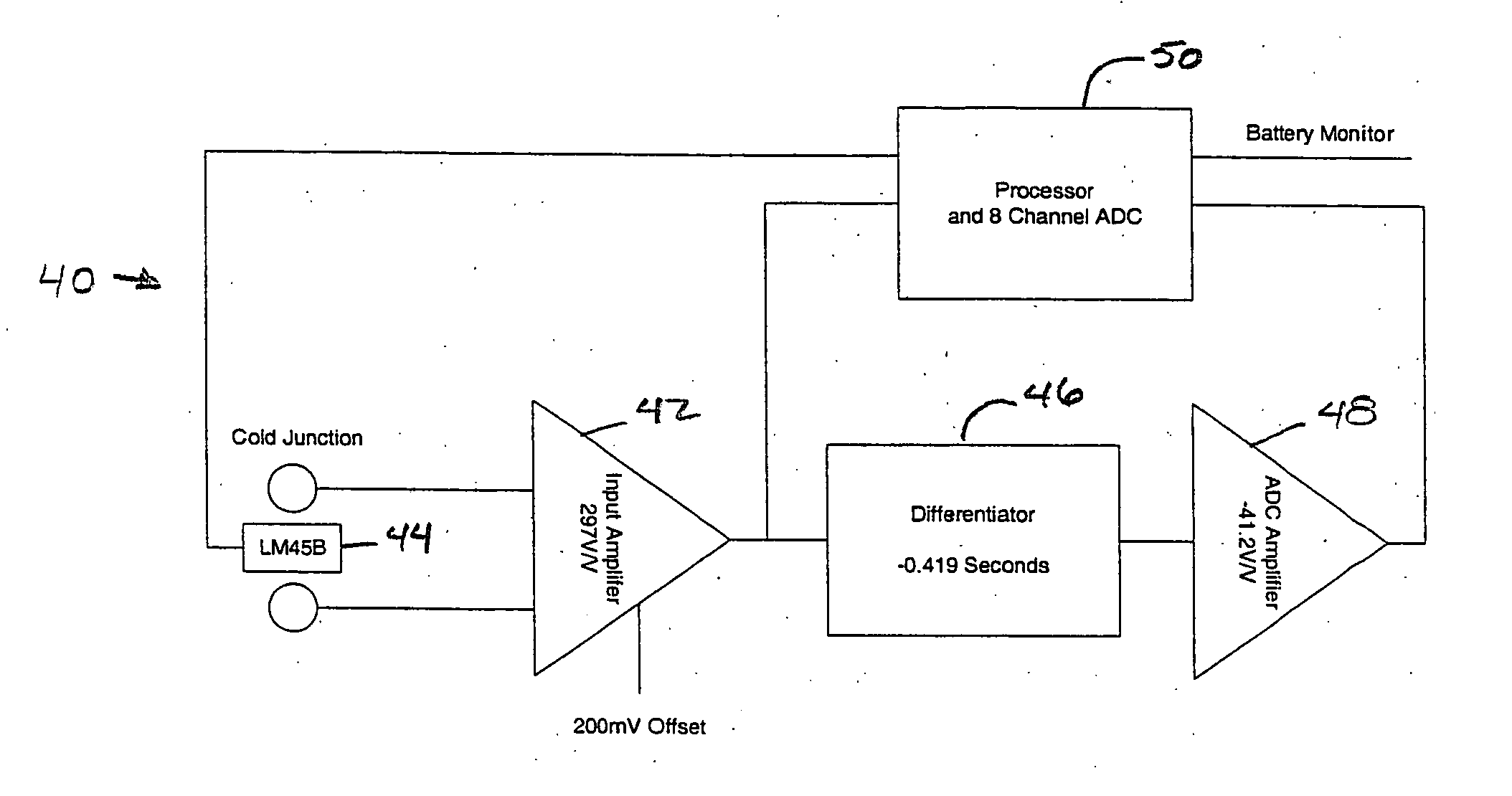

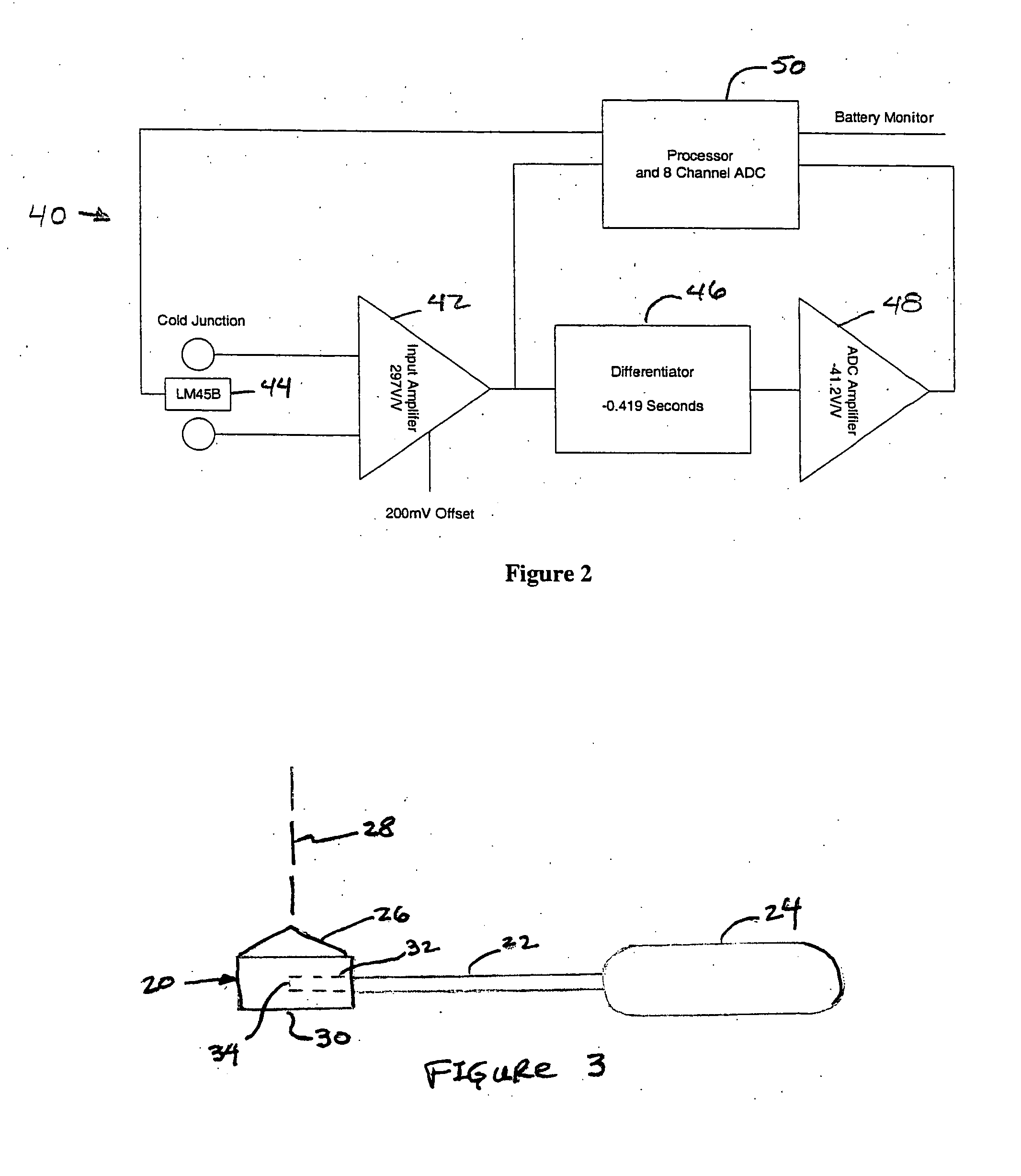

Laser power meter

ActiveUS20050018178A1Low costAccurate measurementMaterial thermal analysisPhotometry using electric radiation detectorsThermodynamicsDifferentiator

A laser power meter and associated method are disclosed. The laser power meter has an absorber that is placed in a path of a laser beam during a power measurement, a temperature sensor for measuring the temperature of the absorber, a differentiator for determining a rate of change of the temperature of the absorber, and a processor that computes an estimated power of the laser beam based on the temperature and its rate of change without considering power related loss effects and then computes the power of the laser beam based on the estimated power and the temperature and its rate of change.

Owner:COHERENT INC

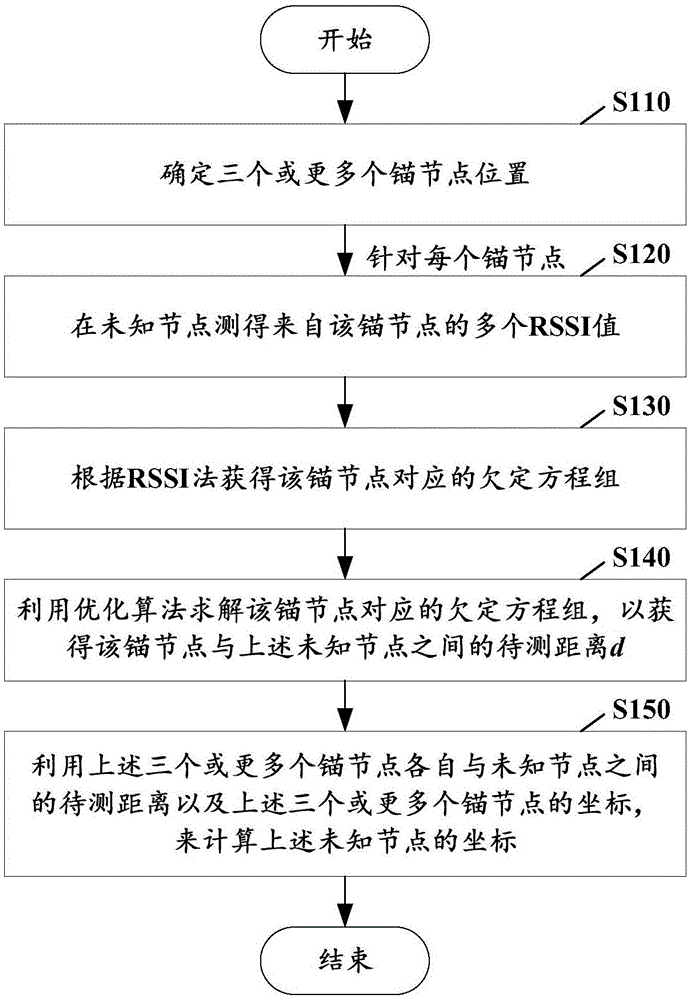

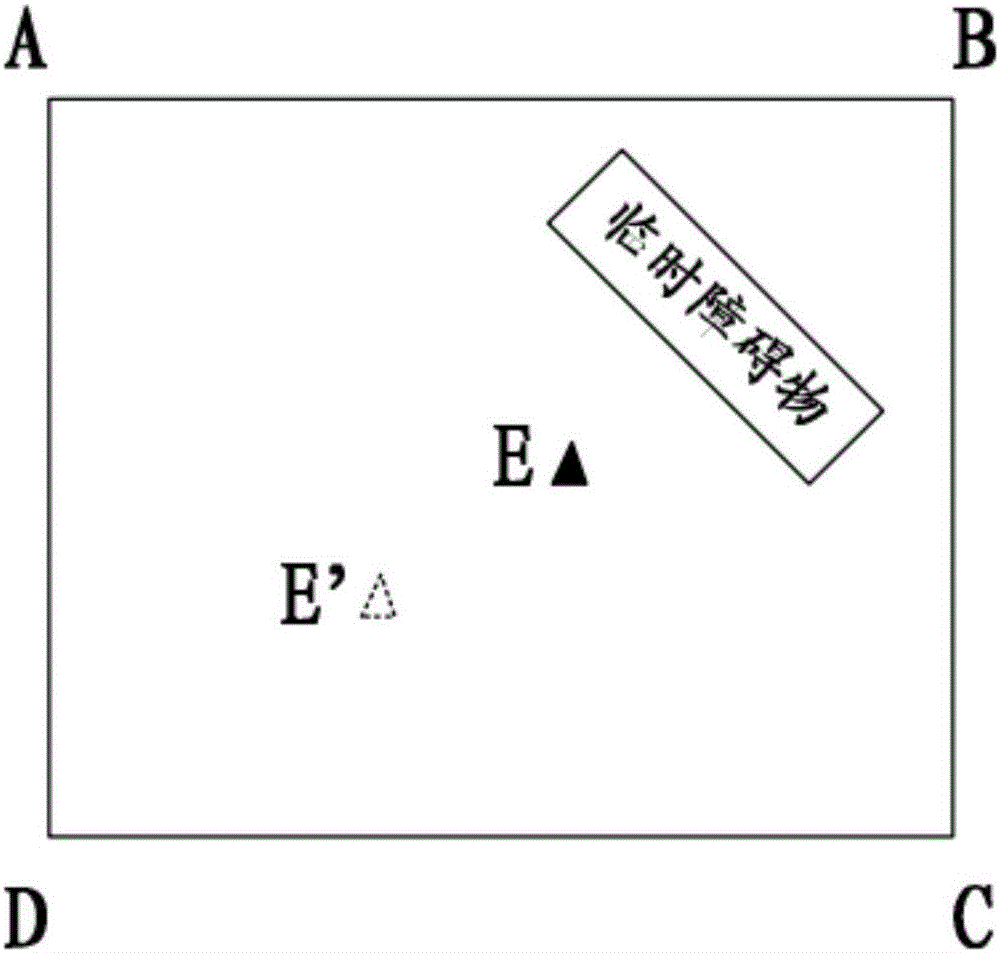

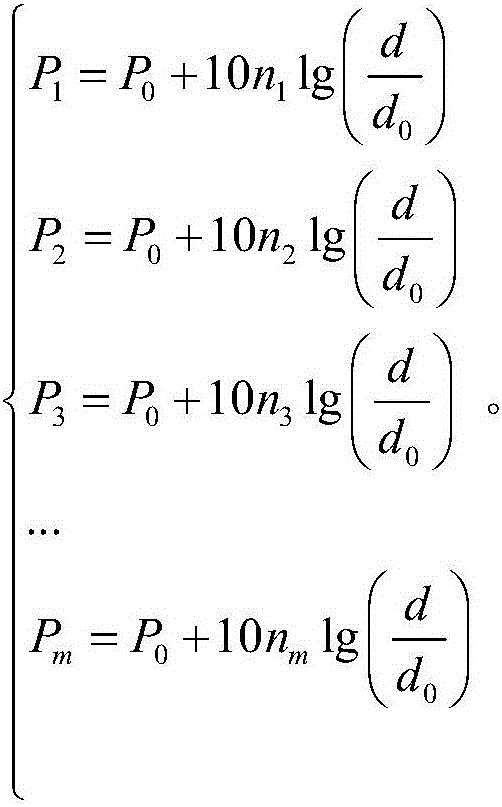

RSSI indoor multipath scattering positioning method based on optimization algorithm

ActiveCN106842120AImprove measurement errorHigh measurement accuracyPosition fixationMultipath scatteringUnderdetermined system

The invention provides an RSSI indoor multipath scattering positioning method based on an optimization algorithm. The method includes the steps that the positions of three or more anchor nodes are determined; aiming at each anchor node, an RSSI request instruction is transmitted to the anchor node from an unknown node multiple times, multiple received signal intensity values from the anchor node are measured on the unknown node, an underdetermined system of equations of the anchor node is obtained according to an RSSI method, unknown quantities in the underdetermined system of equations comprise the to-be-measured distance between the anchor node and the unknown node and m path loss coefficients, and the underdetermined system of equations corresponding to the anchor node is solved through the optimization algorithm to obtain the to-be-measured distance between the anchor node and the unknown node; coordinates of the unknown node are calculated according to the to-be-measured distances between the three or more anchor nodes and the unknown node and coordinates of the three or more anchor nodes.

Owner:山东博蓝建筑工程有限公司

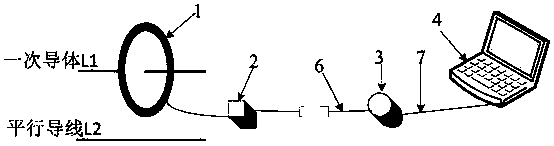

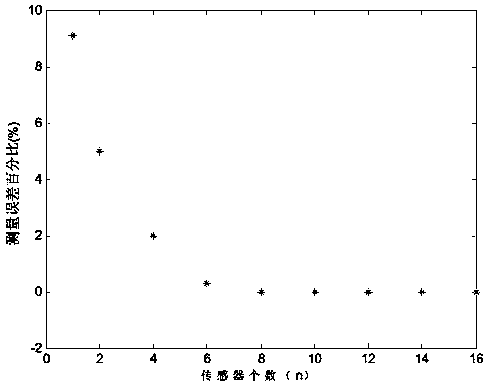

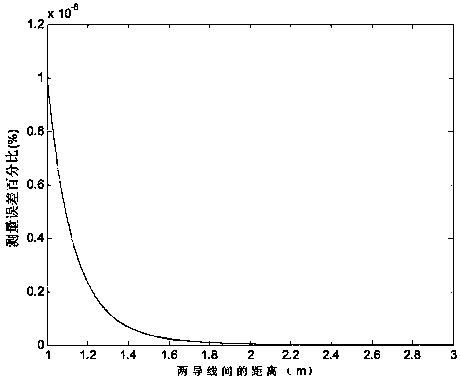

High-precision current measurement system based on toroidal magnetic field sensing array

ActiveCN108333406AImprove measurement errorImprove measurement accuracyNon-electrical signal transmission systemsVoltage/current isolationToroidal magnetic fieldsElectrical conductor

Disclosed is a high-precision current measurement system based on a toroidal magnetic field sensing array. Circuit current is measured by adopting the toroidal magnetic field sensing array, the toroidal magnetic field sensing array is composed of a plurality of sensors which are evenly distributed on bases of all vertices of an inscribed regular polygon of a ring, and each base can be driven by arotating motor to rotate by any angle on a plane where the sensing array is located. The high-precision current measurement system based on the toroidal magnetic field sensing array has high capability of resisting adjacent-phase current interference, and the measurement accuracy during primary conductor eccentricity is greatly improved. In the presence of adjacent-phase wire current interference,the number n of the sensors is greater than or equal to 8, when the ratio of a wire spacing to the sensing array is greater than 2.37, the measurement error is smaller than 0.1%, and the accuracy requirement is met; by adopting a novel sensor rotation measurement method, the measurement error during primary conductor eccentricity can be reduced to be smaller than 0.1% from 0.6%, the measurement error during eccentricity is greatly reduced, and therefore the accuracy requirement is met.

Owner:CHINA THREE GORGES UNIV

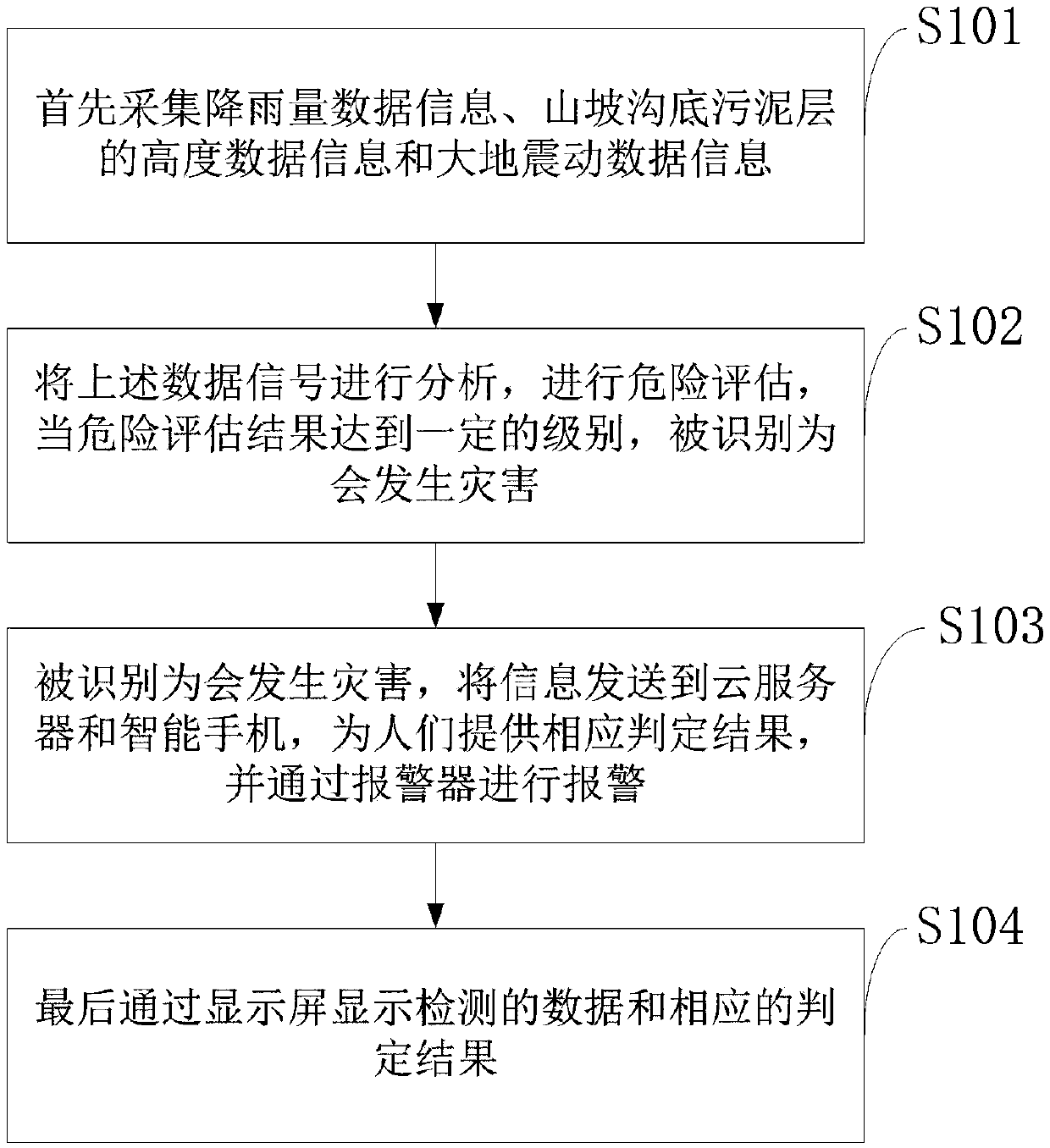

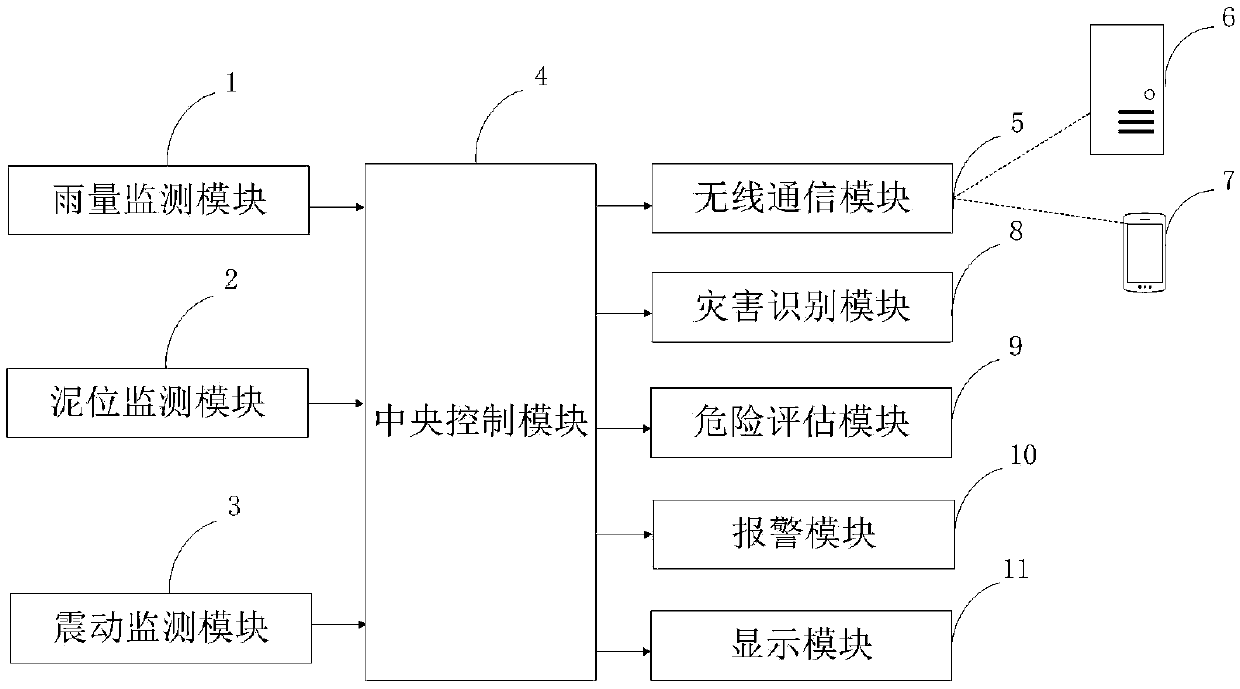

The invention discloses an iInformatization service integrated control system and method based on big data geological disaster prevention and control

InactiveCN109615118APlay a preventive role in advanceReduce lossesForecastingInformatizationControl system

The invention belongs to the technical field of geological disaster prevention and control. The invention discloses an informatization service integrated control system and method based on big data geological disaster prevention and control. The informatization service integrated control system based on big data geological disaster prevention comprises a rainfall monitoring module, a mud level monitoring module, a vibration monitoring module, a central control module, a wireless communication module, a cloud server, a smart phone, a disaster identification module, a danger assessment module, an alarm module and a display module. According to the invention, a geological disaster occurrence area is positioned and analyzed by combining a 3S technology, namely a GPS (Global Positioning System), an RS (Remote Sensor) and a GIS (Geographic Information System), through the disaster identification module, and finally, the scale and the damage degree of geological disasters are identified; andmeanwhile, the danger assessment module can play a role in preventing geological disasters in advance, so that loss caused by the geological disasters is reduced to the minimum, and the geological disaster danger assessment result has relatively high reliability.

Owner:QUANZHOU INST OF EQUIP MFG

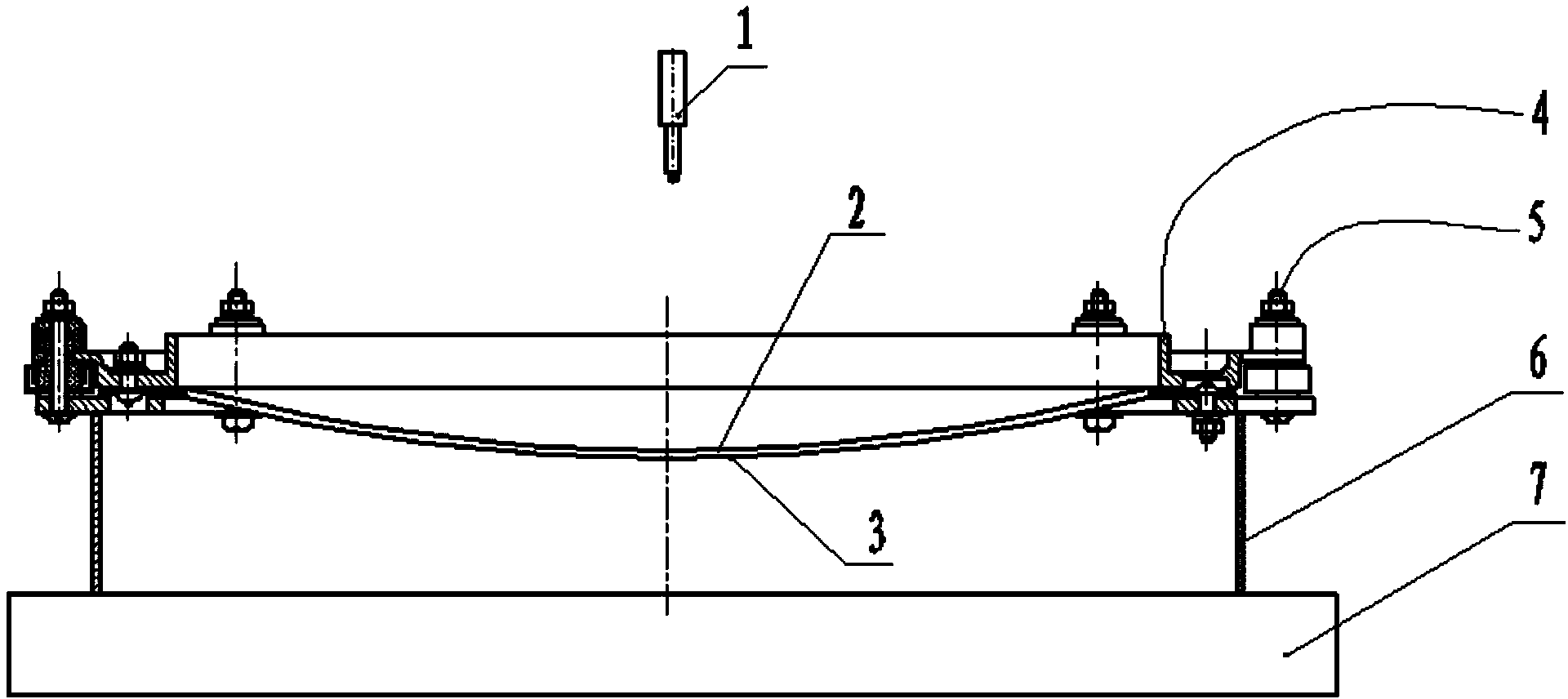

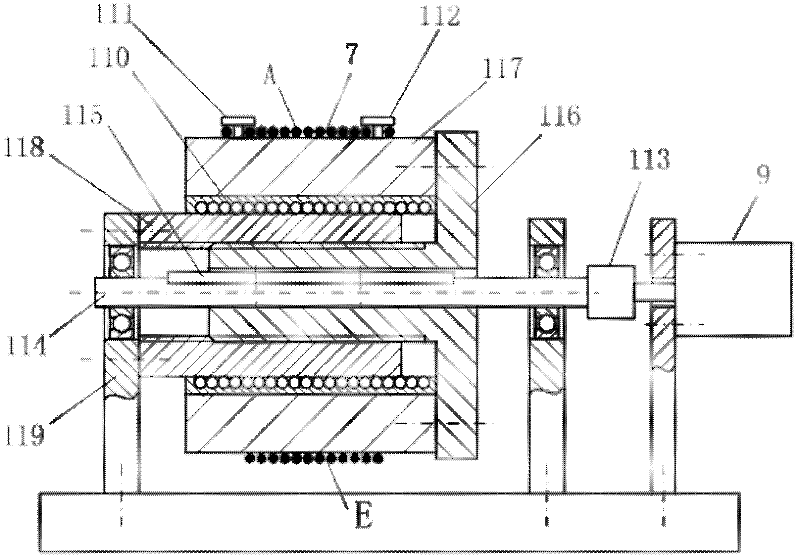

Numerical control system for detecting cam contours

InactiveCN102122144BReduce loadSmall precision retentionUsing optical meansNumerical controlEngineeringPersonal computer

The invention provides a numerical control system for detecting cam contours, which has a simple structure, high precision and high efficiency. The numerical control system comprises a numerical control turntable, a screw rod nut pair, a laser measuring head, a grating scale displacement sensor, an encoder and an industrial personal computer, wherein the numerical control turntable is used for driving a cam to horizontally and coaxially rotate around a vertical mandrel; the screw rod nut pair is horizontally arranged on one side of the numerical control turntable; the laser measuring head is arranged on a movable nut of the screw rod nut pair and is positioned on one side of the cam; the grating scale displacement sensor is used for measuring the horizontal displacement of the movable nut; the encoder is used for detecting the rotation angle of the cam; and the industrial personal computer is used for controlling the numerical control turntable and the screw rod nut pair to act and acquiring external contour data of the cam according to data acquired by the measurement of the laser measuring head, the grating scale displacement sensor and the encoder.

Owner:CHANGZHOU INST OF TECH

Method for identifying parking areas and/or free spaces

ActiveUS9747791B2High rateIncrease probabilityDetection of traffic movementIndication of parksing free spacesDriver/operatorParking brake

A method for identifying free spaces (parking not permitted) and / or permitted parking areas, vehicles transmitting pieces of information about possible parking spaces (PPS) to a central computer facility (CCF). Positions of PPS are detected with vehicle surroundings sensors, and the detected PPS are evaluated based on the data collected, a categorization being performed for recording the PPS, with positions, in a CCF database and evaluating the data using a cluster analysis. When the analysis is performed, PPS are assigned to a street portion, a function is assigned to the street portion, which is given by the quotient of the frequency of PPS detections in a certain position along the street portion and the number of vehicle passages through the street portion and a weighting factor from the evaluation. A free space is inferred when the function value is greater than a predefined second limiting value and / or a parking area is inferred when the function value is within a predefined range. Also described is a device for assisting a driver, a central computer facility, and a related computer program.

Owner:ROBERT BOSCH GMBH

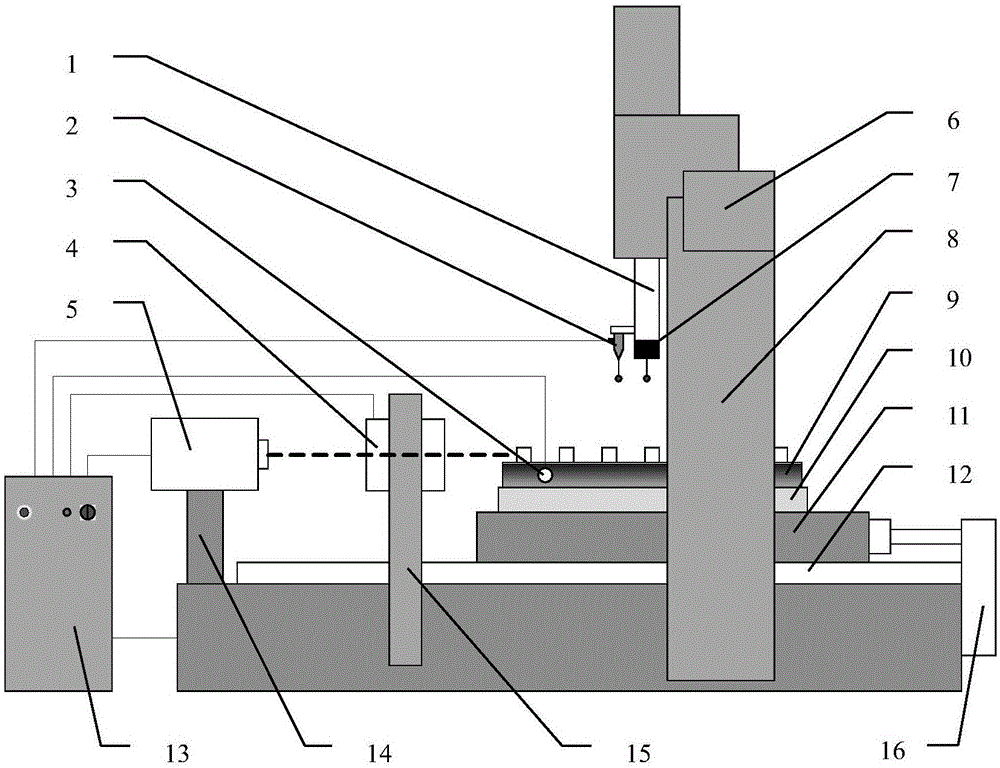

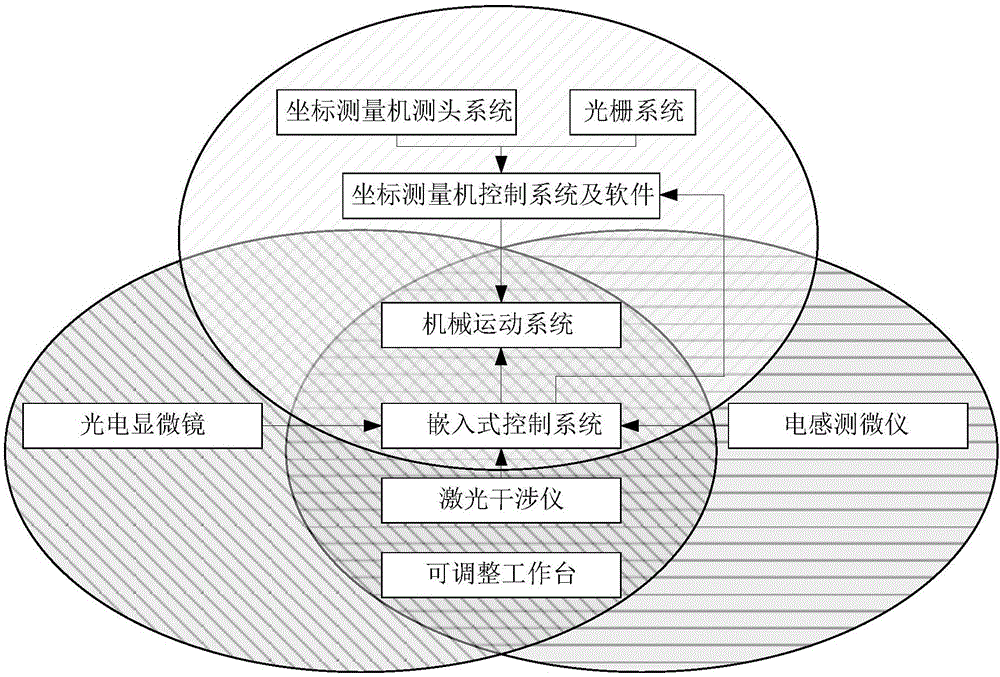

System for measuring composite coordinate based on multi-aiming device

ActiveCN106352823ARealize measurementRealize 1D high-precision contact measurement functionMeasurement devicesCoordinate-measuring machineData treatment

The invention relates to a system for measuring a composite coordinate based on a multi-aiming device and belongs to the field of measurement technology. The system provided in the invention comprises a coordinate measurer, a laser interferometer, an inductance micrometer, a photoelectric microscope, a mechanical kinematic system, an adjustable working table and an embedding control and data processing system. One-dimensional high-precision contacting coordinate measuring system composed of the embedding control system, mechanical kinematic system, laser interferometer, inductance micrometer and adjustable working table and conforming to the Abbe principle and one-dimensional non-contacting coordinate measuring system composed of the embedding control system, coordinate measuring machine, mechanical kinematic system, laser interferometer, photoelectric microscope and adjustable working table and conforming to Abbe principle can realize testing different testing pieces,such as realizing the needed measuring function of multiple length measurers of a club, a stepgage, a gauge block, a caliper gauge, a ring gauge, a screw, a linear scale, a dividing plate and the like. The machine has multi-purpose and wide social benefit and prospect.

Owner:BEIJING CHANGCHENG INST OF METROLOGY & MEASUREMENT AVIATION IND CORP OF CHINA

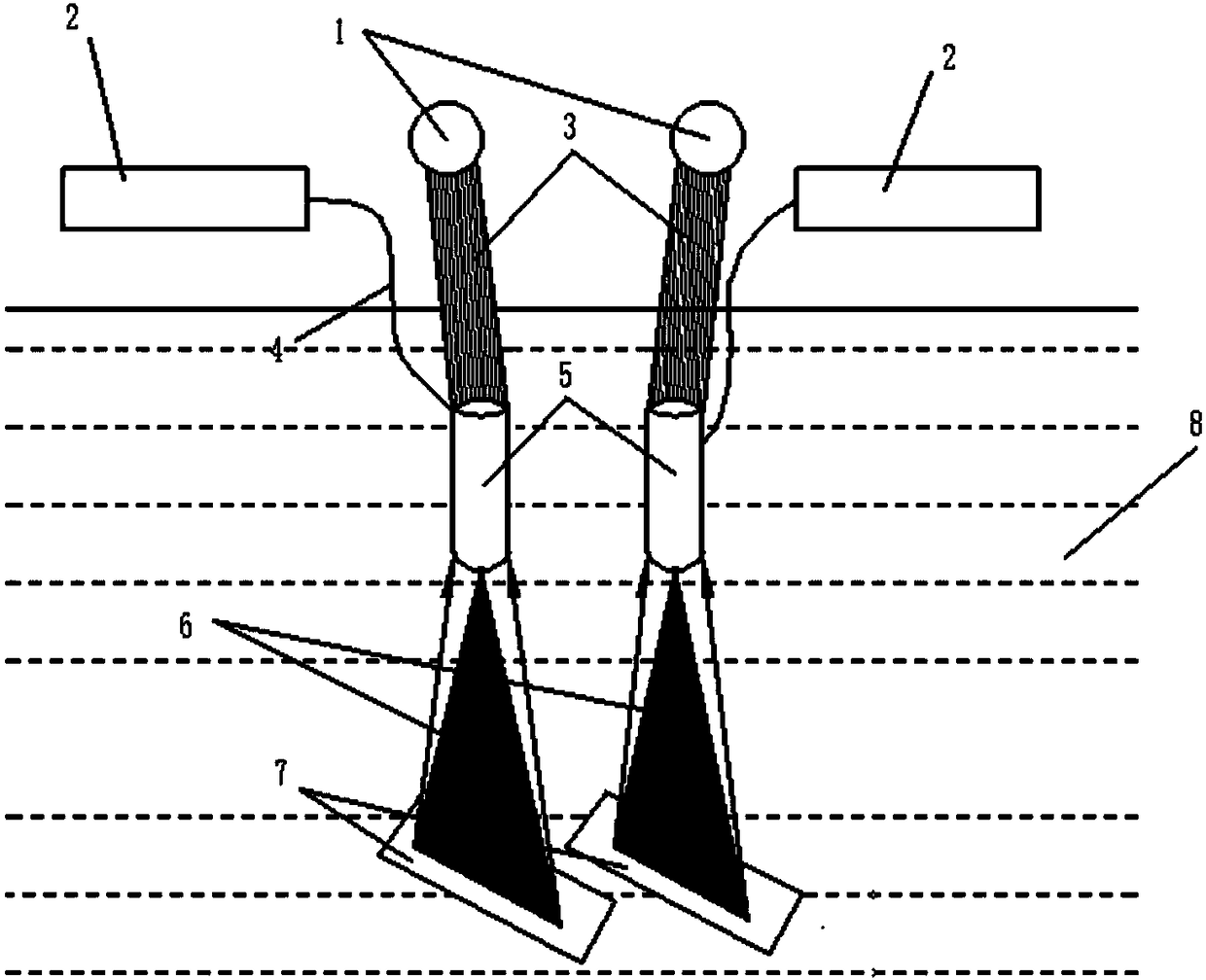

Device and method for speed test underwater by taking laser light curtain as core

ActiveCN108287252AStrong penetrating powerImprove the problem of serious attenuationDevices using time traversedElectromagnetic wave reradiationPhotovoltaic detectorsUnderwater

The present invention discloses a device and a method for speed test underwater by taking a laser light curtain as a core which solves the important problems of underwater speed test seal and watertightness and effective recycle of light. The speed test device is formed by two sets of laser light curtains and photoelectric detection devices, and each set of the laser light curtain and the photoelectric detection device comprises one photoelectric detector, one laser, one optical fiber array, one optical fiber, one collimator, one laser light curtain and one retro-reflection screen. The lasersare connected with the collimators through the optical fibers, and the collimators are connected with the photoelectric detectors through the optical fiber arrays; the retro-reflection screens are arranged below the collimators; and the whole device is vertically arranged in the water. Electrical signals of the speed test device are amplified through an amplification circuit, and are subjected todata collection and processing to obtain speed parameters of corresponding target objects. The device and the method for speed test underwater by taking a laser light curtain as a core can be used forunderwater and non-contact speed test with fast response speed and accurate measurement.

Owner:ZHONGBEI UNIV

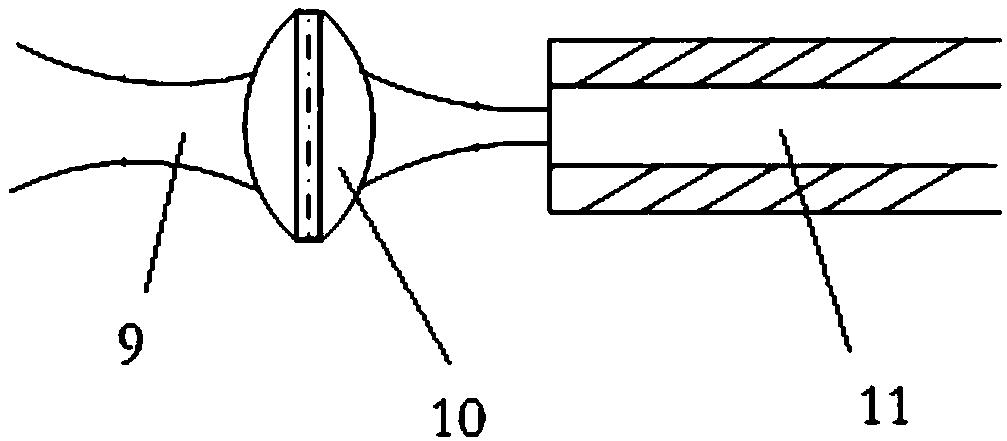

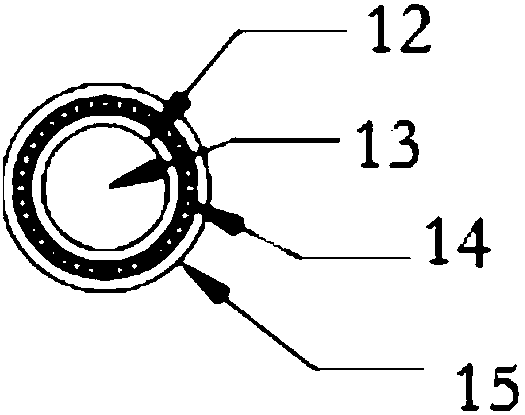

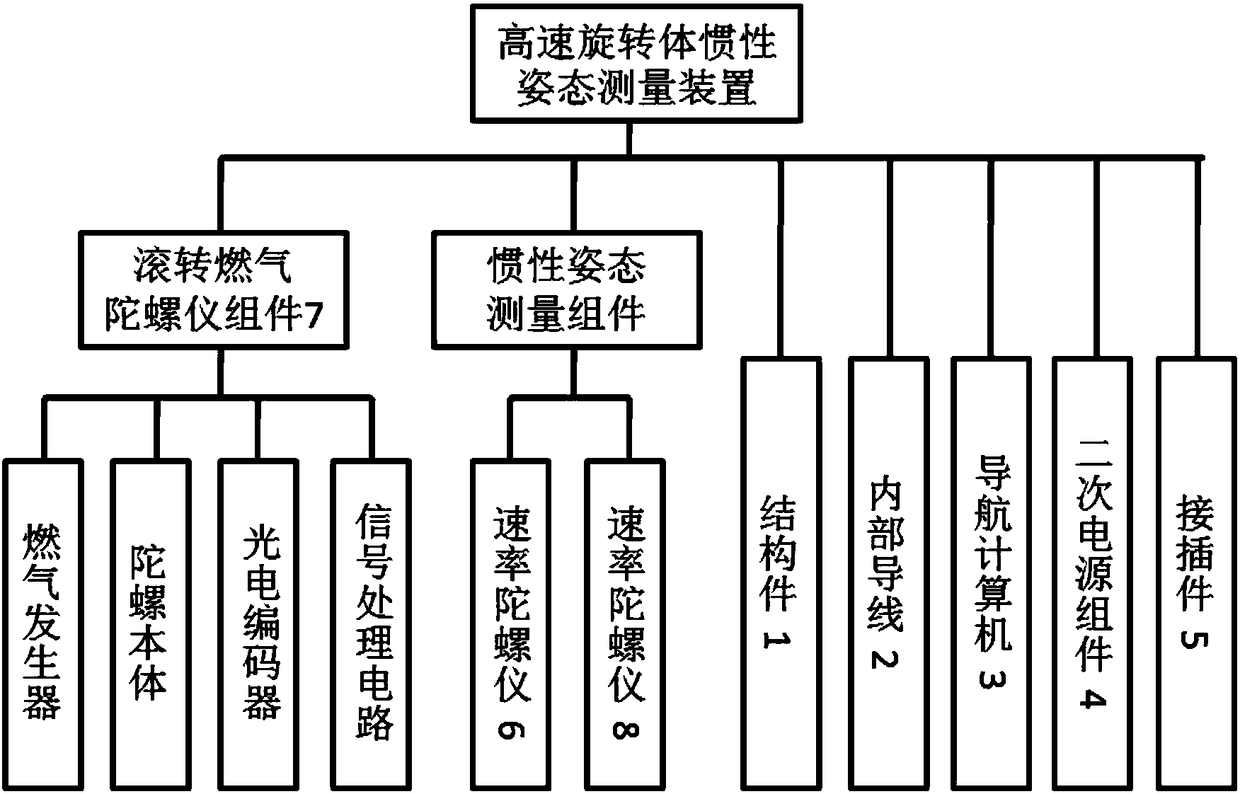

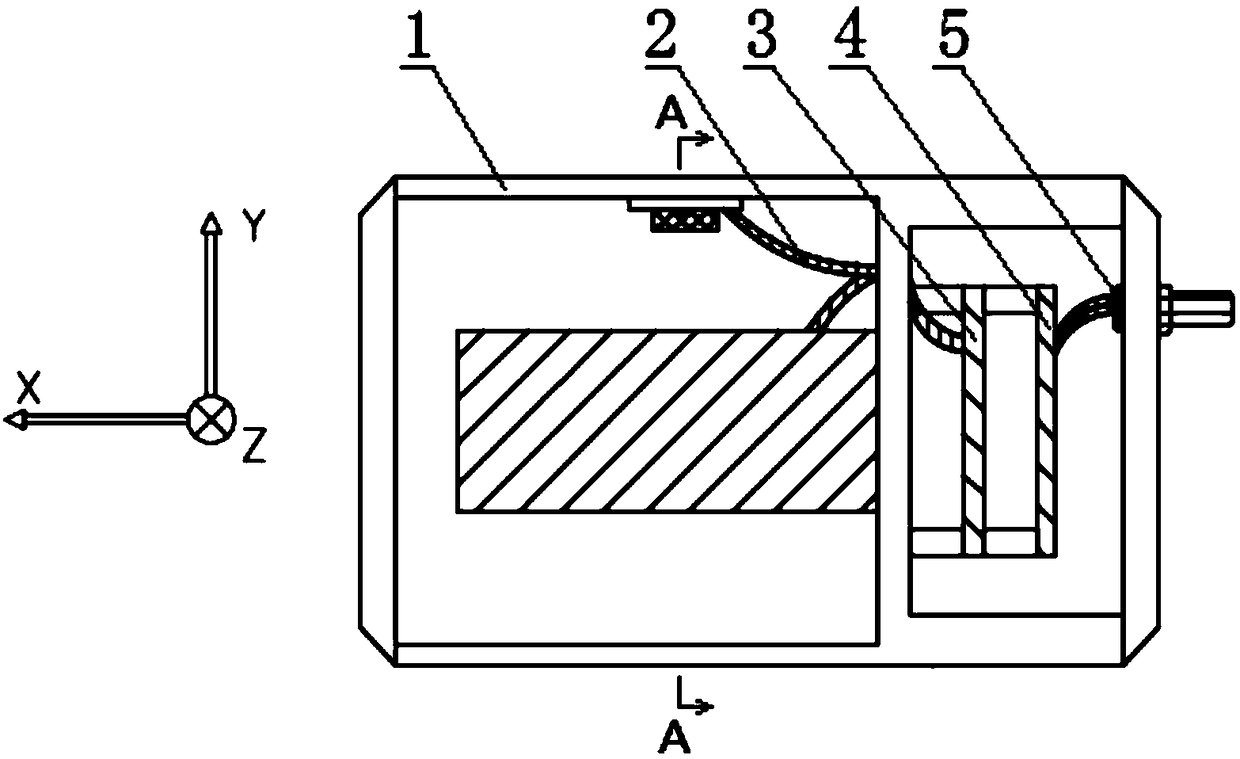

Inertial attitude measurement apparatus for high-speed rotating carrier

ActiveCN108168550AImprove measurement errorHigh measurement accuracyNavigation by speed/acceleration measurementsMeasurement deviceAngular velocity

The invention discloses an inertial attitude measurement apparatus for a high-speed rotating carrier, and belongs to the technical field of an inertial attitude measurement apparatus. The apparatus includes a gas gyroscope used for measuring the angular rate in a rolling axis direction and two rate gyroscopes used for measurement in yawing and pitching directions. The apparatus can measure the roll angle, yaw angle and pitch angle and triaxial angular velocity of a high-speed rotating carrier in real time. The roll angle measurement error of the apparatus only depends on the drift rate of theroll gas gyroscope and isn't fast diverged with time. The attitude is accurately measured when the carrier rotates at a high speed. The apparatus is simple in structure and manufacture process, low incost, small in size, and good in crypticity and reliability. The apparatus works, depending on the devices of itself and can work without limitation by meteorological conditions.

Owner:西安现代控制技术研究所

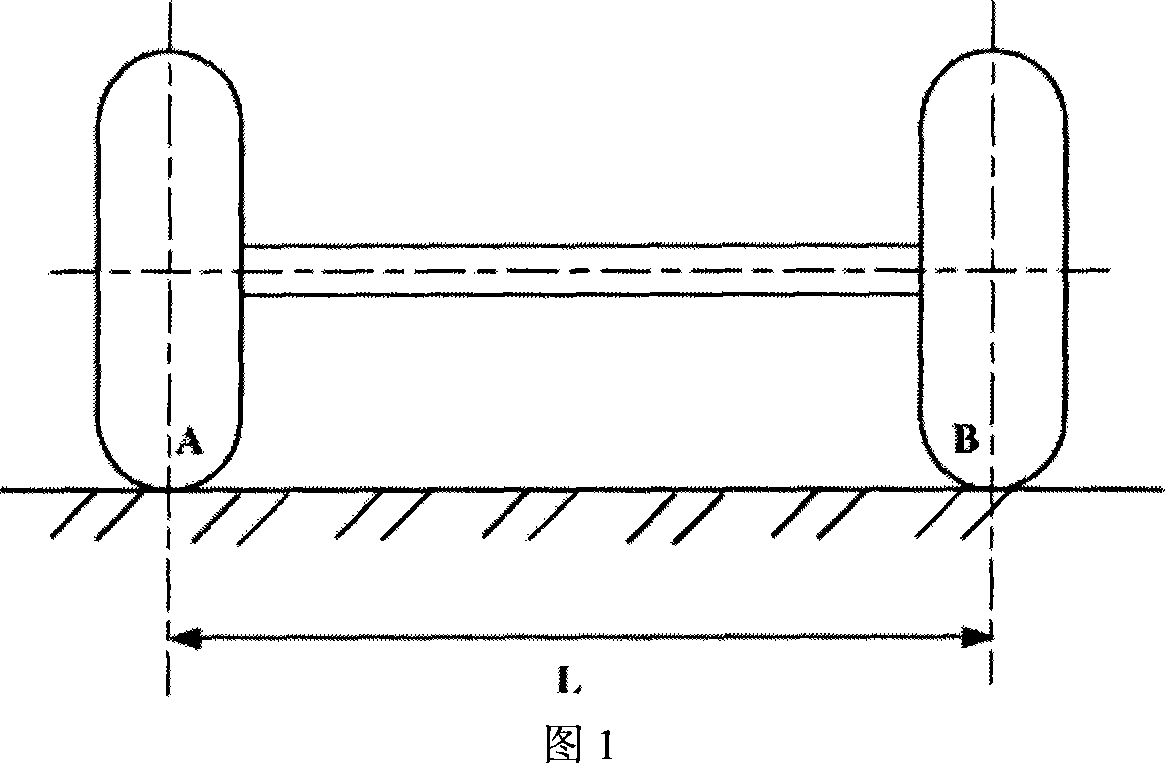

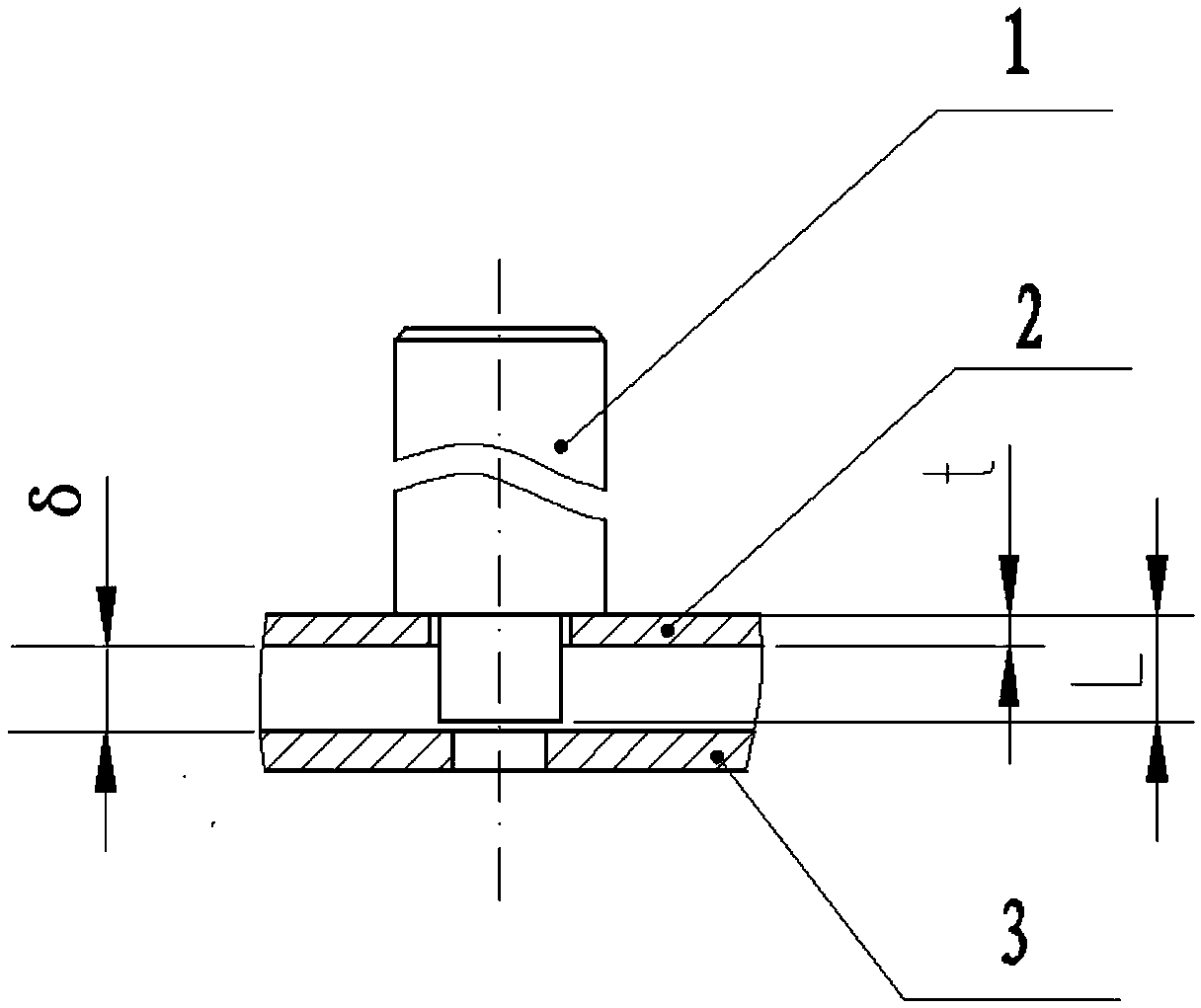

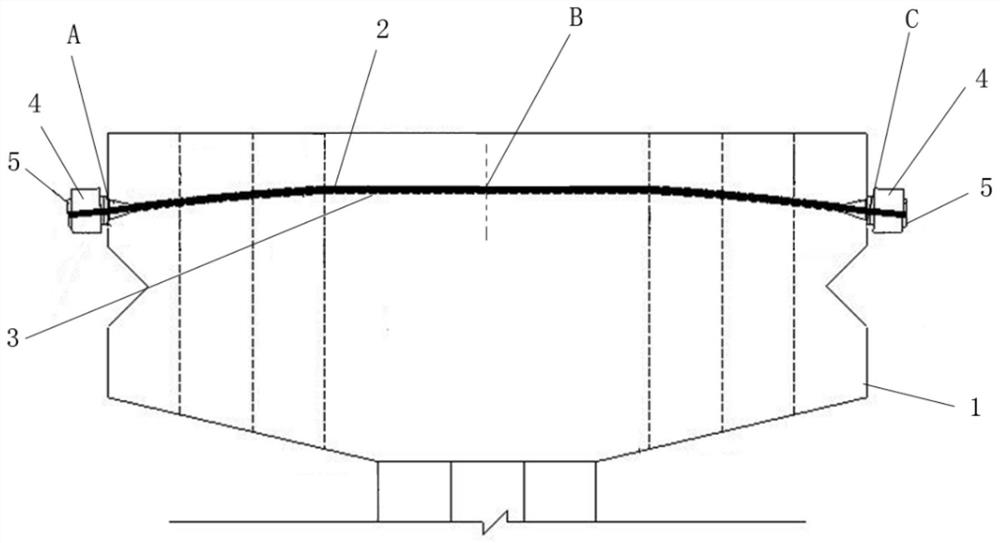

Grid interval measurement method and measurement tool for ion thruster grid electrode assembly

ActiveCN104236426ASolve detection technical problemsSimple structureMechanical clearance measurementsEngineeringMultimeter

The invention discloses a grid interval measurement tool for an ion thruster grid electrode assembly. The measurement tool is composed of a stepped shaft type plug gauge with different detection segment lengths, wherein the stepped shaft type plug gauge is made of conductive metal material, the stepped shaft type plug gauge is divided into a handle segment and detection segments by the steps in the stepped shaft type plug gauge, the diameter of each detection segment is larger than the hole diameter of an accelerating grid electrode and smaller than the hole diameter of a screen grid electrode, and the diameter of the handle segment is larger than the hole diameter of the screen grid electrode. The invention further provides a measurement method. The special plug gauge is inserted in a screen grid electrode hole, and the grid electrode interval of the detected grid electrode assembly is judged according to whether the front end face of the special plug gauge makes contact with the accelerating grid electrode or not; in the detecting process, a multimeter is adopted for detecting whether the screen grid electrode and the accelerating grid electrode are electrically connected or not so that whether the front end of the special plug gauge makes contact with the accelerating grid electrode or not can be judged. The grid interval measurement method and the measurement tool for the ion thruster grid electrode assembly effectively solve the technical problem about detection of the interval between grid electrodes in the spherical surface area of the grid electrode assembly on the basis of the characteristic of the ion thruster grid electrode assembly.

Owner:LANZHOU INST OF PHYSICS CHINESE ACADEMY OF SPACE TECH

Cam Profile Detection System Driven by Wire Rope

The invention provides a cam contour detection system which is driven by a wire rope and has simple structure, high detection precision and high efficiency. The system comprises the following parts: a numerical control rotary table used for driving a cam to carry out horizontal coaxial rotation around a vertical mandrel, a guide rail which is provided at one side of the numerical control rotary table horizontally, a slide block provided on the guide rail, a laser range finding head which is provided on the slide block and at one side of the cam, a raster ruler displacement sensor used for measuring horizontal displacement amount of the laser range finding head, an encoder used for detecting a rotation angle of the cam, a wire storage cylinder assembly and a directive wheel which are provided at two sides of the slide block respectively, a wire rope which is elastically sleeved on the wire storage cylinder assembly and the directive wheel, and is fixedly connected to slide block, and an industrial control computer. The wire storage cylinder assembly is in transmission connection with a stepping motor. The industrial control computer controls movement of the numerical control rotarytable and the stepping motor, and calculates outer contour data of the cam according to data measured by the laser range finding head, the raster ruler displacement sensor and the encoder.

Owner:CHANGZHOU INST OF TECH

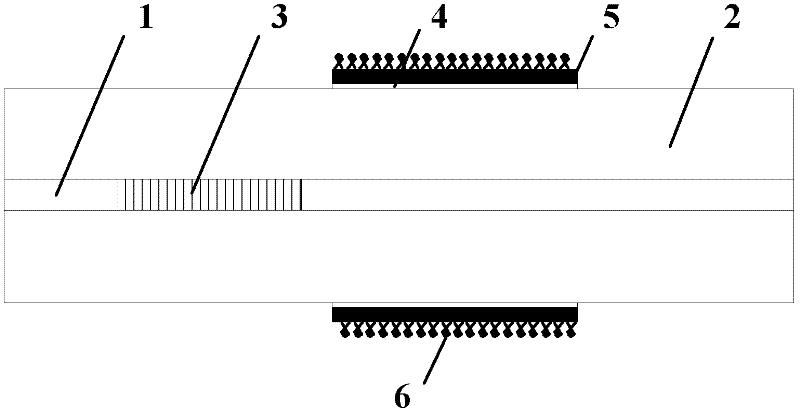

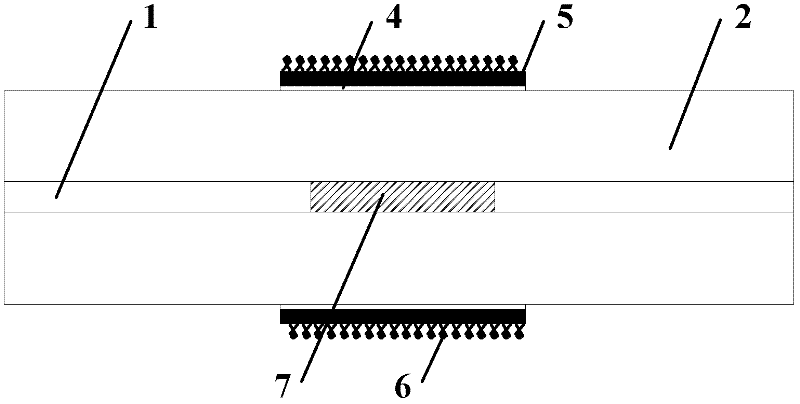

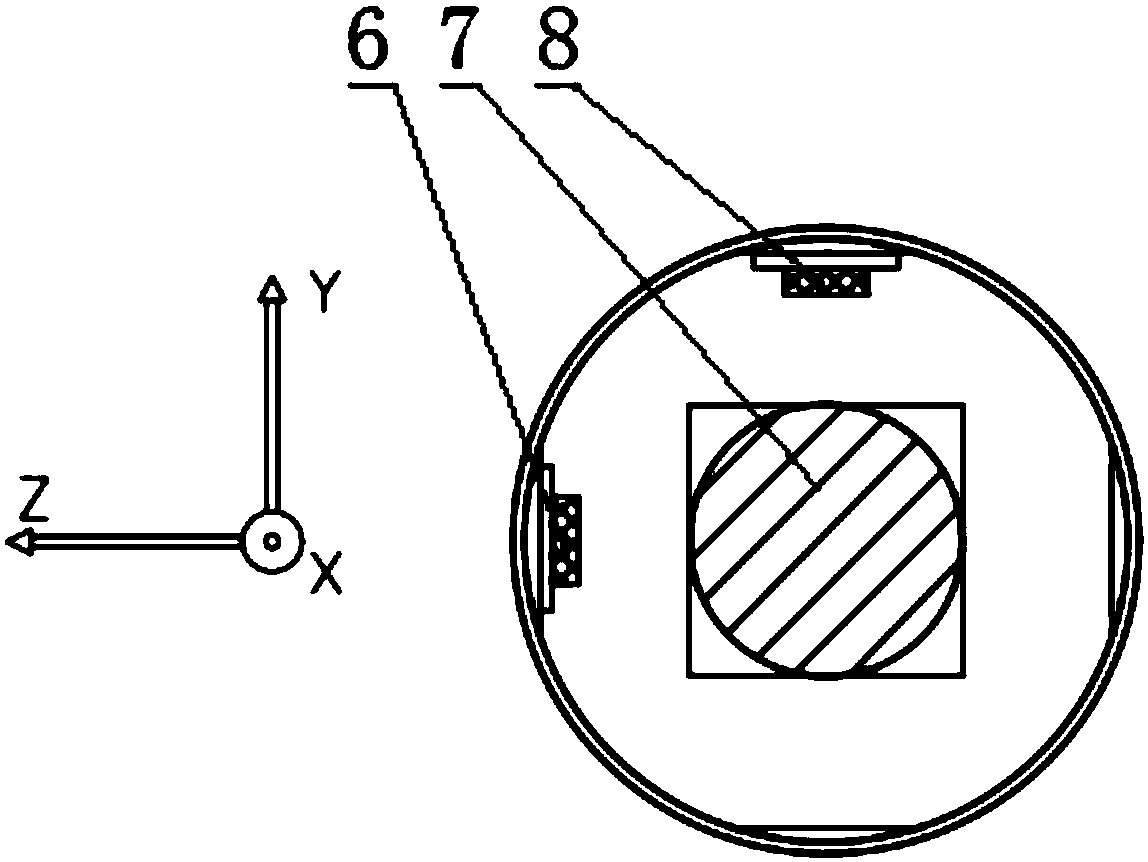

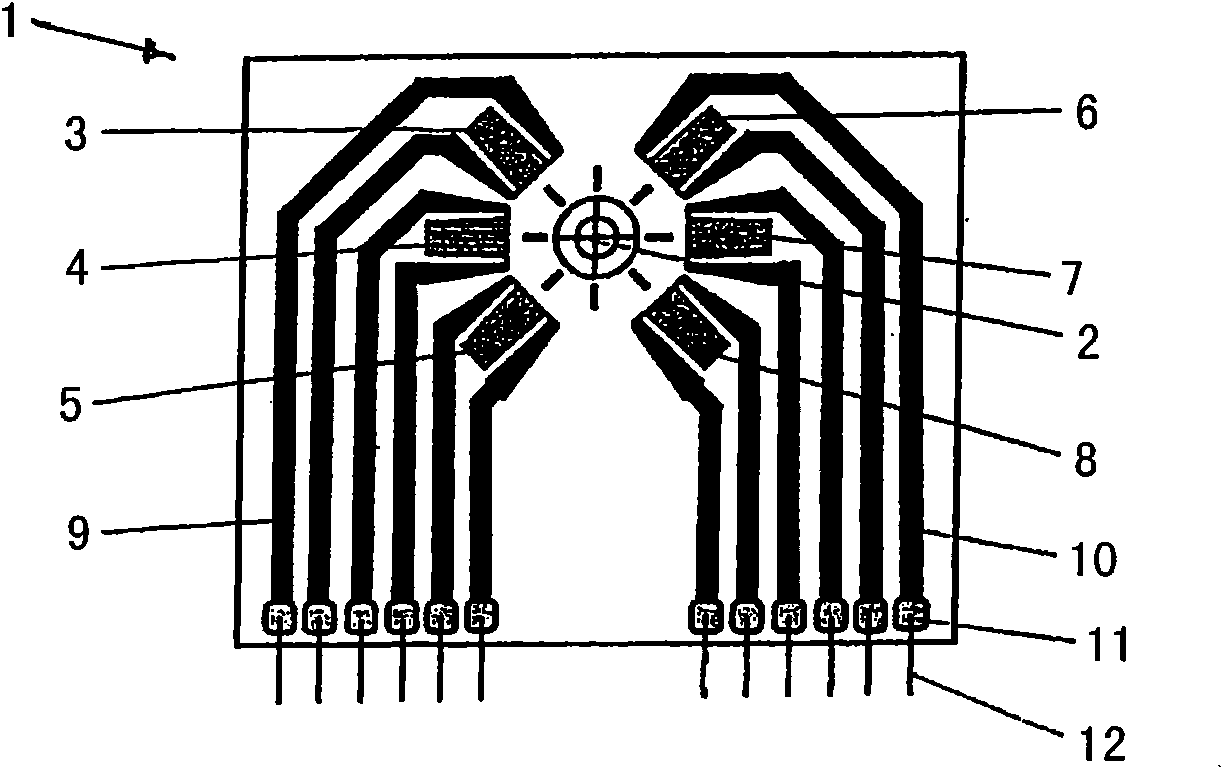

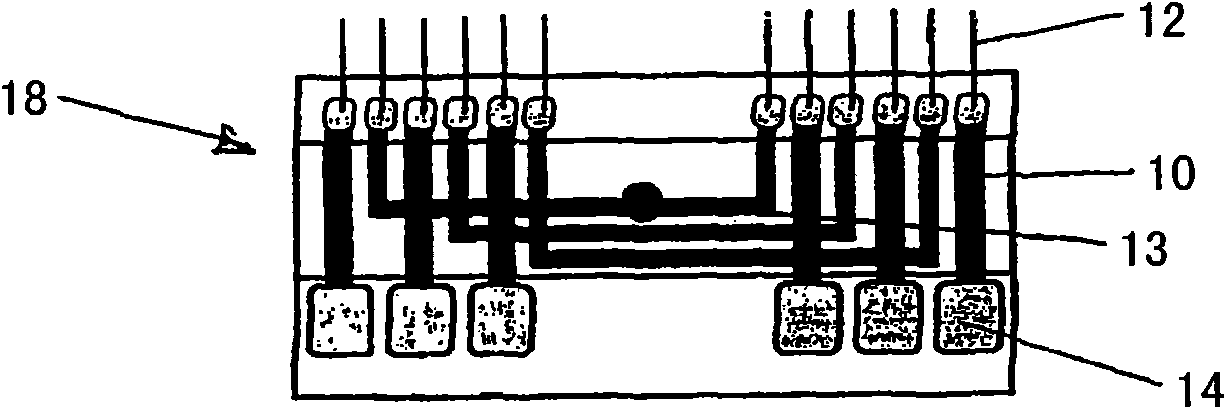

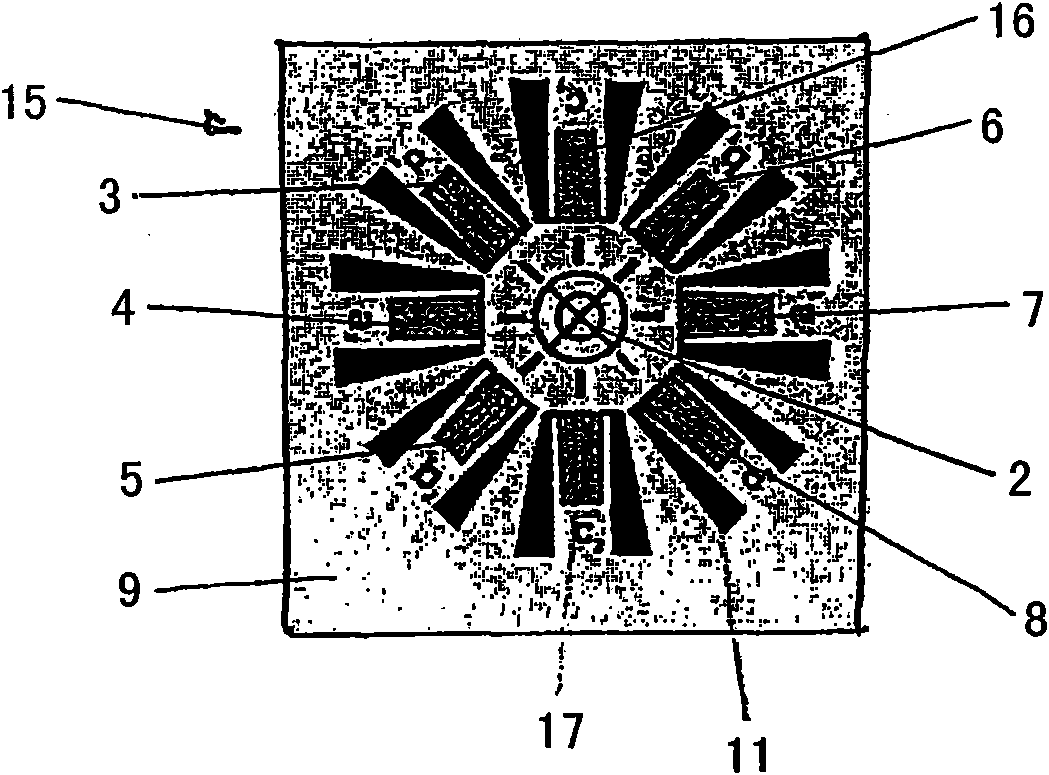

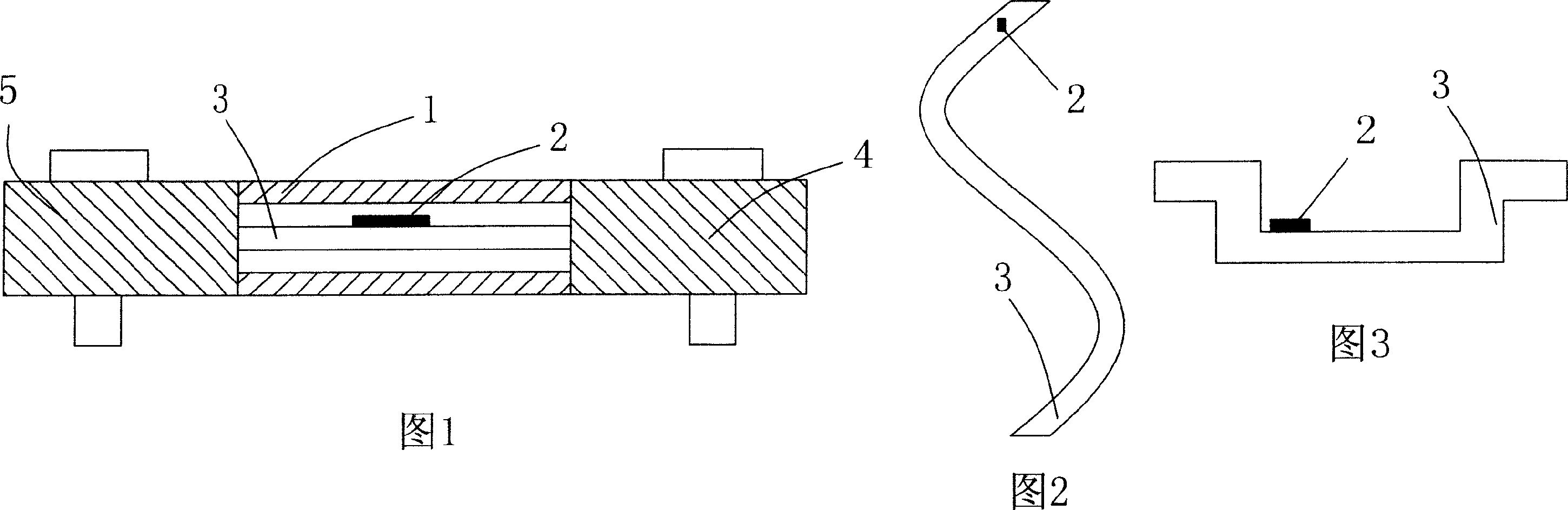

Strain gauge rosette for internal stress measurement

InactiveCN101965506AImprove measurement errorSimple series connectionForce measurementApparatus for force/torque/work measurementEngineeringStrain gauge

The invention relates to a strain gauge rosette for internal stress measurement on workpieces according to the bore hole method, comprising within an angular region of 0 - < 180 DEG at least three measurement grids 3, 4, 5 at equal distances and in different directions radially about a centering mark 2. The invention is characterized in that each of the at least three measurement grids 3, 4, 5 is associated with an equivalent measurement grid 6, 7, 8 that is disposed opposite and aligned in the same direction. To this end, all measurement grids 3, 4, 5, 6, 7, 8, 16, 17 have the same radial distance to the central marking 2. The opposing measurement grid pairs 3, 8,4, 7,5, 6,16, 17 of a tensile direction are connected or coupled to each other such that the measuring signals thereof are averaged.

Owner:HOTTINGER BALDWIN MESSTECHNIK GMBH

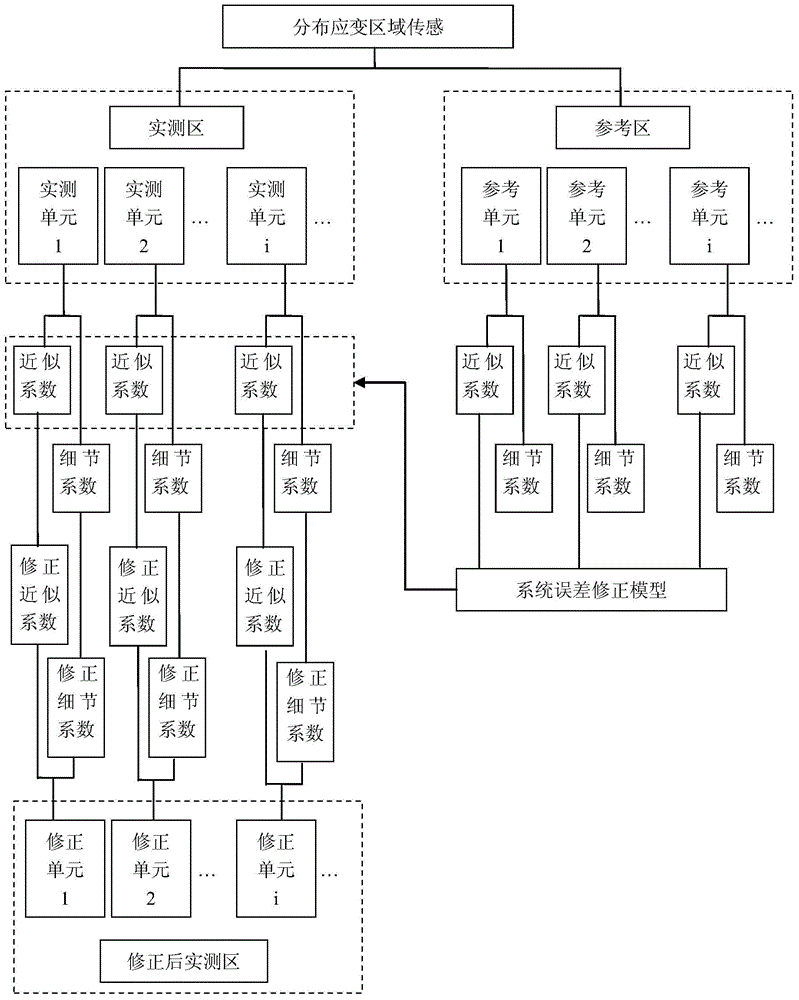

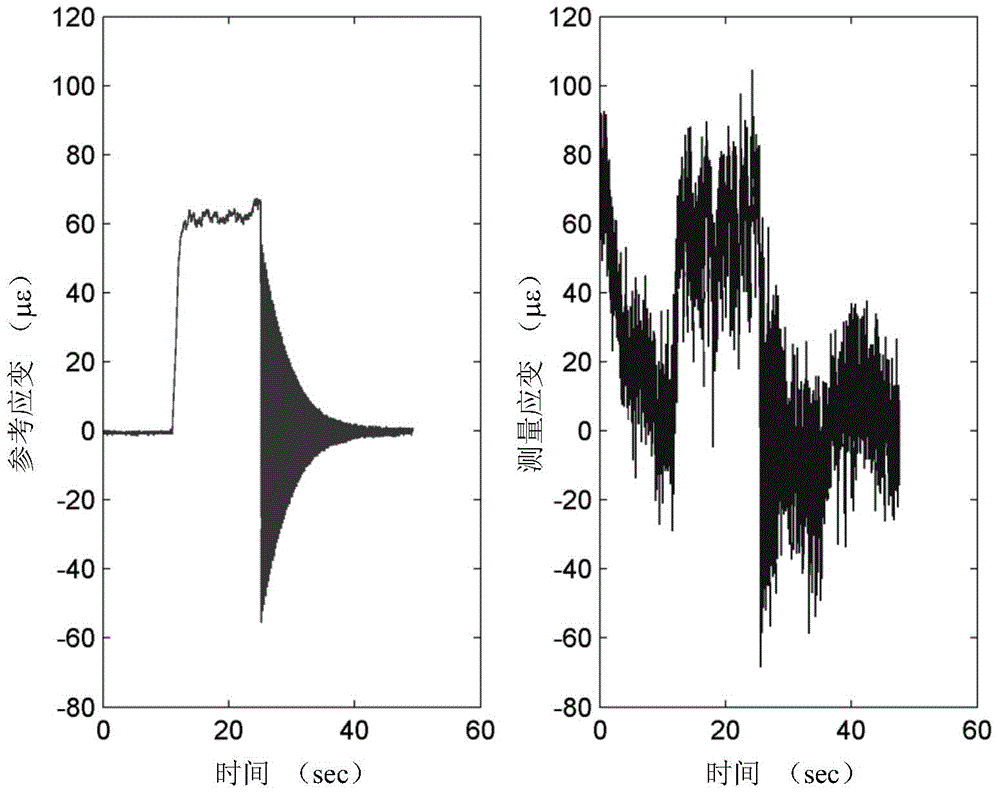

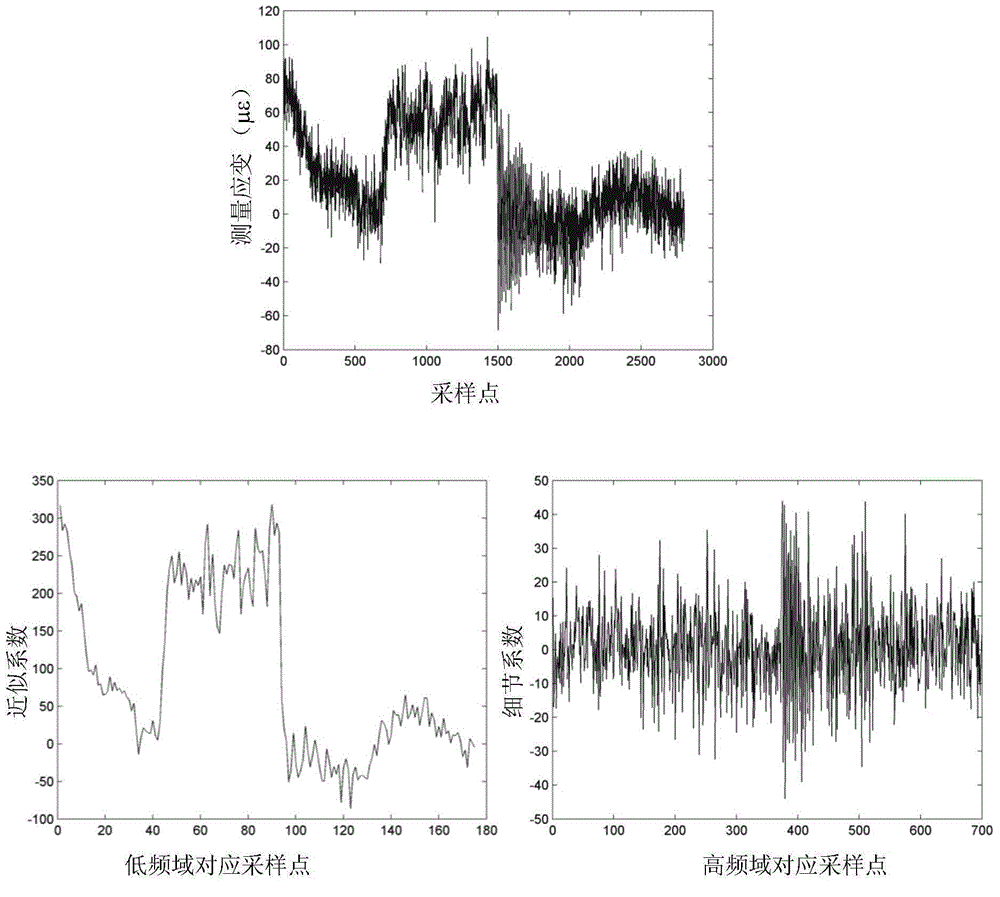

Real-time base line and denoising processing method based on distributed sensing and wavelet analyzing technologies

ActiveCN105004278AImprove measurement errorImprove measurement performanceUsing optical meansComplex mathematical operationsDecompositionSystematic error

The invention relates to a real-time base line and denoising processing method based on distributed sensing and wavelet analyzing technologies. Based on distributed area sensing characteristics of optical fiber or carbon fiber strain sensing, measurement signals are divided into an actual measurement zone related to structural strain parameters and a reference zone related to measurement errors. According to wavelet multilayer decomposition calculation, a plurality of measurement points contained in the actual measurement zone and the reference zone are respectively decomposed into approximation coefficients and detail coefficients. By means of the approximation coefficients of the plurality of measurement points of the reference zone, an error correction module related to system errors in the measurement process is established. By means of the error correction module, the approximation coefficients of the plurality of measurement points of the actual measurement zone are respectively corrected. In addition, reconstruction calculation is carried out with the detail coefficients capable of realizing adaptive filtering, and strain signals of the actual measurement zone after the correction are obtained. According to the invention, measurement errors in the distributed strain measurement process of optical fiber or carbon fiber or the like are substantially improved, the measurement performance of sensors is enhanced, and the purpose of high-accuracy high-precision structural dynamic-static strain measurement is achieved.

Owner:SOUTHEAST UNIV

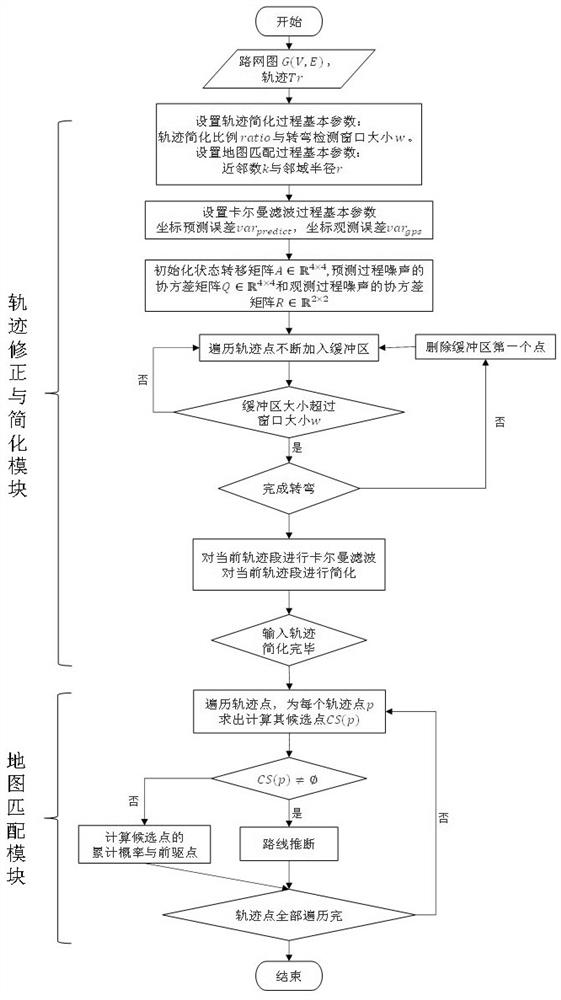

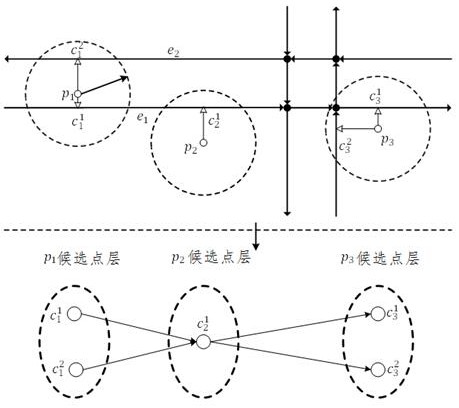

Electric bicycle track map matching method based on track correction and simplification

ActiveCN112989223AImprove efficiency and accuracyHigh densityGeographical information databasesComplex mathematical operationsComputer visionMap matching

The invention provides an electric bicycle track map matching method based on track correction and simplification. Aiming at the problem that the map matching efficiency and accuracy are reduced due to the characteristics that the sampling frequency of track points of the track data of the electric bicycle is too high, the density of the track points is relatively large and invalid track fragments exist, a track correction and simplification process is added in the map matching method, so that the density of the track points can be effectively reduced; meanwhile, a segmentation mechanism is introduced in the map matching process, invalid track fragments can be effectively recognized, and efficiency and accuracy in the map matching process of the track data of the electric bicycle are both considered.

Owner:HANGZHOU DIANZI UNIV

Strain measuring device for ocean platform

InactiveCN1971212AAvoid corrosionImprove measurement errorElectrical/magnetic solid deformation measurementSurface oceanEngineering

A strain measuring apparatus used for ocean platform is disclosed that includes: first and second mounting bases, seal cavity, and strain bridge. The first and second mounting bases are mounted symmetrically on the both sides of seal cavity; the seal cavity is mounted on the measuring location of ocean platform, said strain bridge is mounted in seal cavity, the two ends connect with first and second mounting bases, strain gages are mounted on the strain bridge. The measurement results are got by strain gages via the measuring location of ocean platform and the variation of location measured by the strain bridge. So it can improve the measurement tolerance greatly, be used in deep ocean to prevent the strain gages form corrosion.

Owner:INST OF MECHANICS - CHINESE ACAD OF SCI

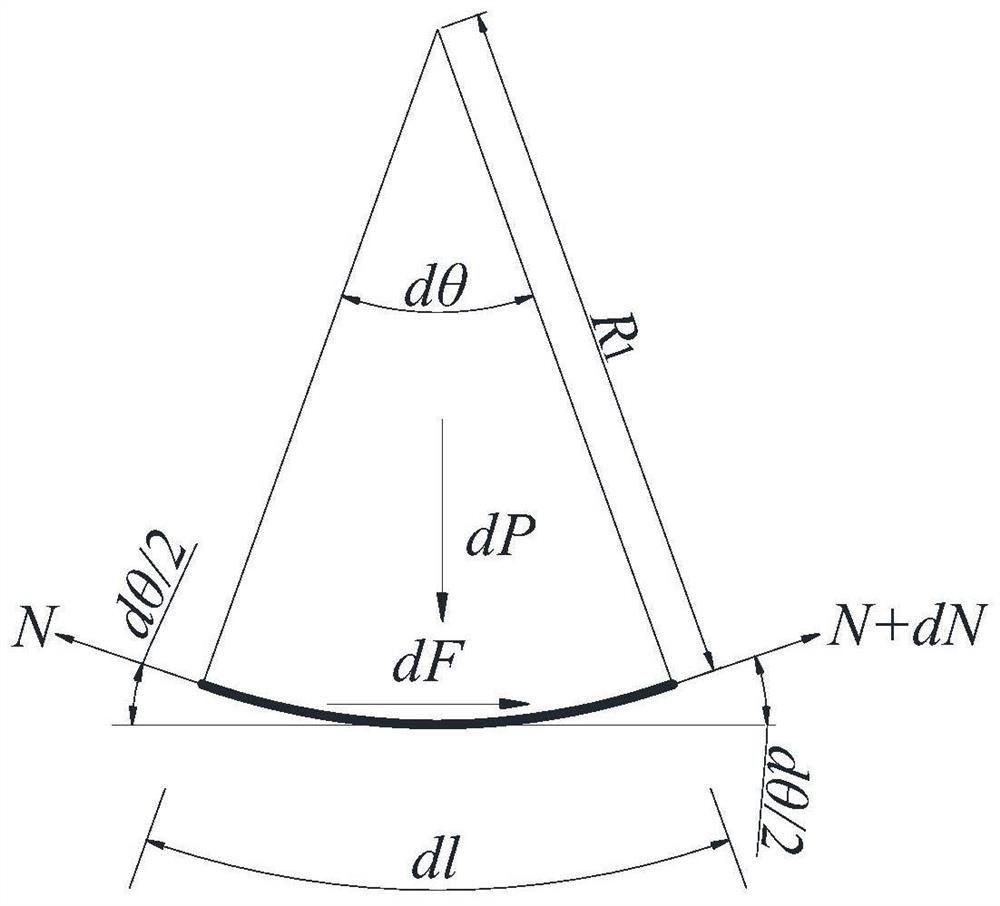

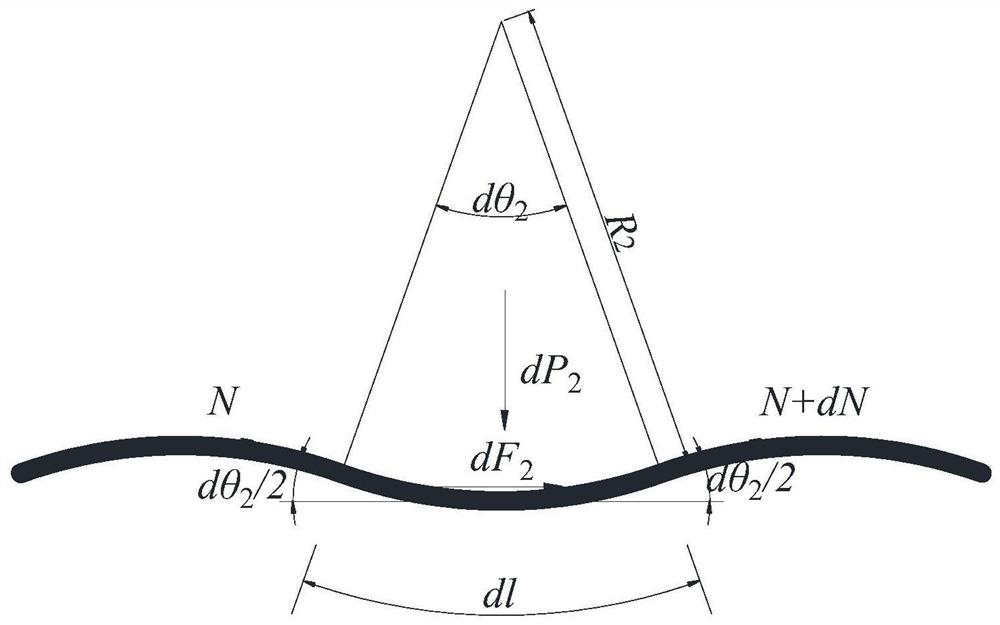

Prestressed pipeline friction loss test and calculation method

InactiveCN112014310AEasy to testImprove efficiencyUsing mechanical meansMaterial analysisPre stressFriction loss

The invention provides a prestressed pipeline friction loss test and calculation method. The test and calculation method comprises the following steps: (1) carrying out multiple times of asymmetric tensioning and symmetric tensioning operations on a prestressed steel bundle, and recording related data; (2) deducing a calculation formula of a friction influence coefficient of the prestressed pipeline based on a stress uniform distribution principle in a Hertz contact theory; and (3) according to the deduced calculation formula, calculating a friction influence coefficient of the prestressed pipeline by utilizing the elongation difference of the prestressed steel beams which are tensioned twice, and evaluating the prestressed friction loss. The method is based on the stress uniform distribution principle of the Hertz contact theory and skillfully utilizes the Hooke law; the test method is convenient and economical, can effectively and reasonably calculate the friction influence coefficient and the prestress friction loss value of the prestress pipeline, and is suitable for prestress concrete bridges with symmetrically arranged prestress steel beams; and the prestressed pipeline friction loss test and calculation method is convenient and fast in test, high in efficiency, low in cost, good in economy and high in accuracy.

Owner:GUANGXI UNIV

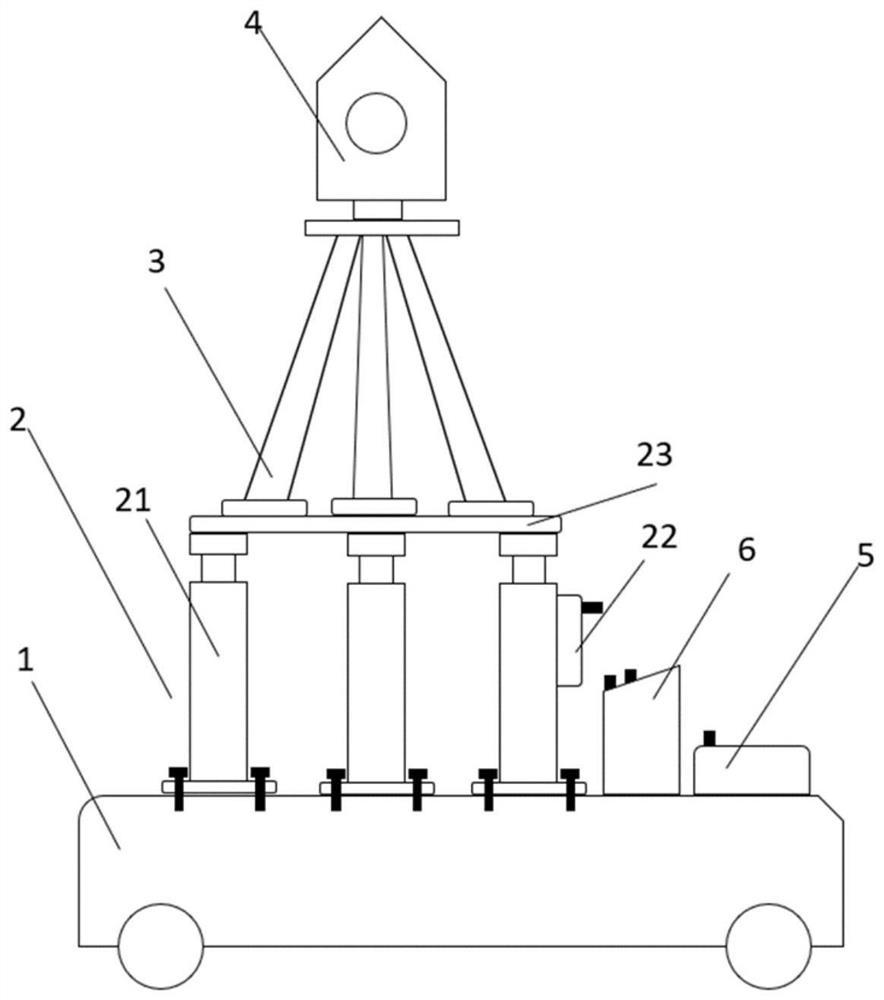

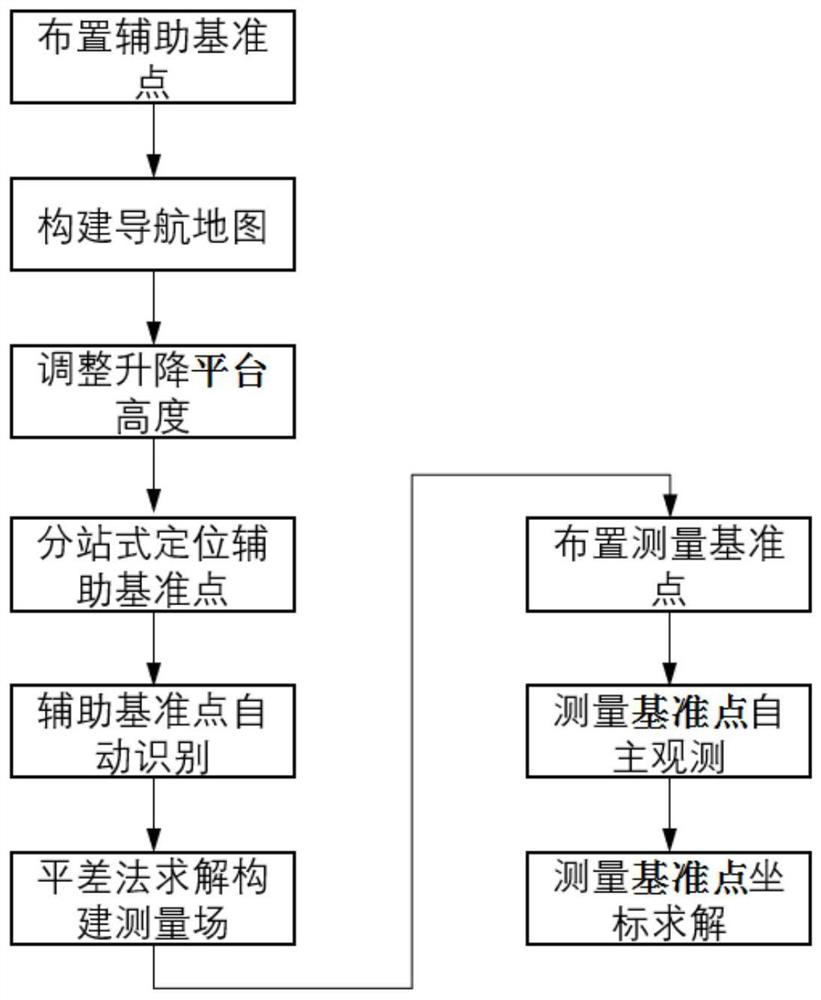

Integrated positioning device and method based on AGV and laser tracker

ActiveCN111811400AImprove measurement errorFully automatic transferUsing optical meansMeasurement deviceThree dimensional measurement

The invention relates to an integrated positioning device and method based on AGV and a laser tracker. The device and the method employ an AGV platform which can achieve the autonomous navigation andpositioning as a mobile platform to carry various types of three-dimensional measurement equipment, so the full-automatic transfer of a measurement position in a large-scale measurement process is achieved, and the overall measurement efficiency is improved. Fusion processing is carried out on measurement data of the laser tracker and positioning data of the AGV, recognition and numbering of auxiliary datum points are achieved through a datum point matching algorithm, measurement errors of the auxiliary datum points are optimized through an adjustment method, and a high-precision measurement field is automatically constructed, so the overall precision of the measurement field is guaranteed, and frequent data export and data arrangement are avoided. The AGV is combined with a binocular photogrammetry device to automatically measure the reference point, and the measurement coordinates of the measurement reference point are projected to the global coordinate system of the measurement field by means of an auxiliary reference point matching method, so that the problem of measurement error accumulation caused by measurement position transfer is avoided, and high-precision positioning ofparts can be realized.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

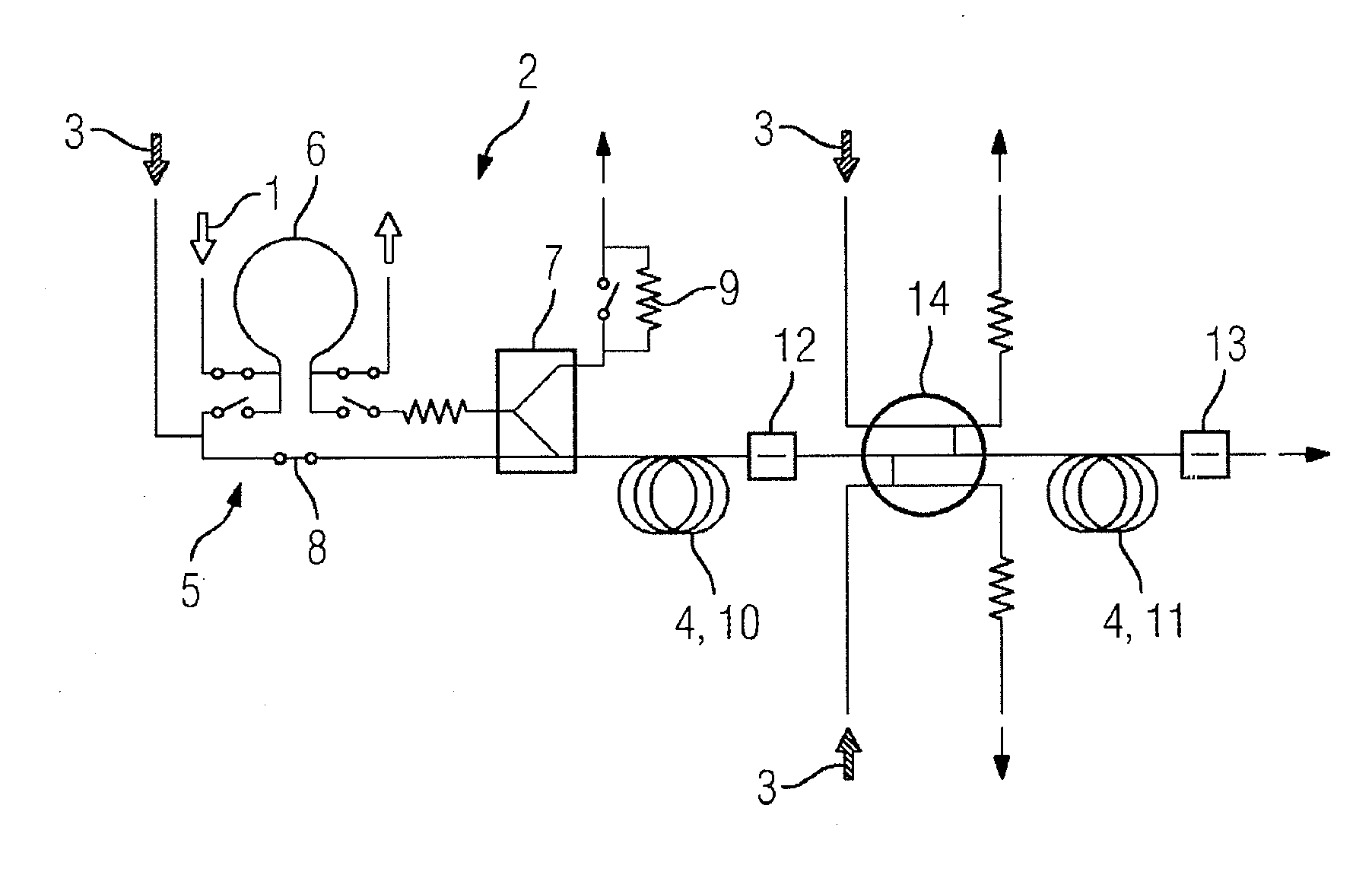

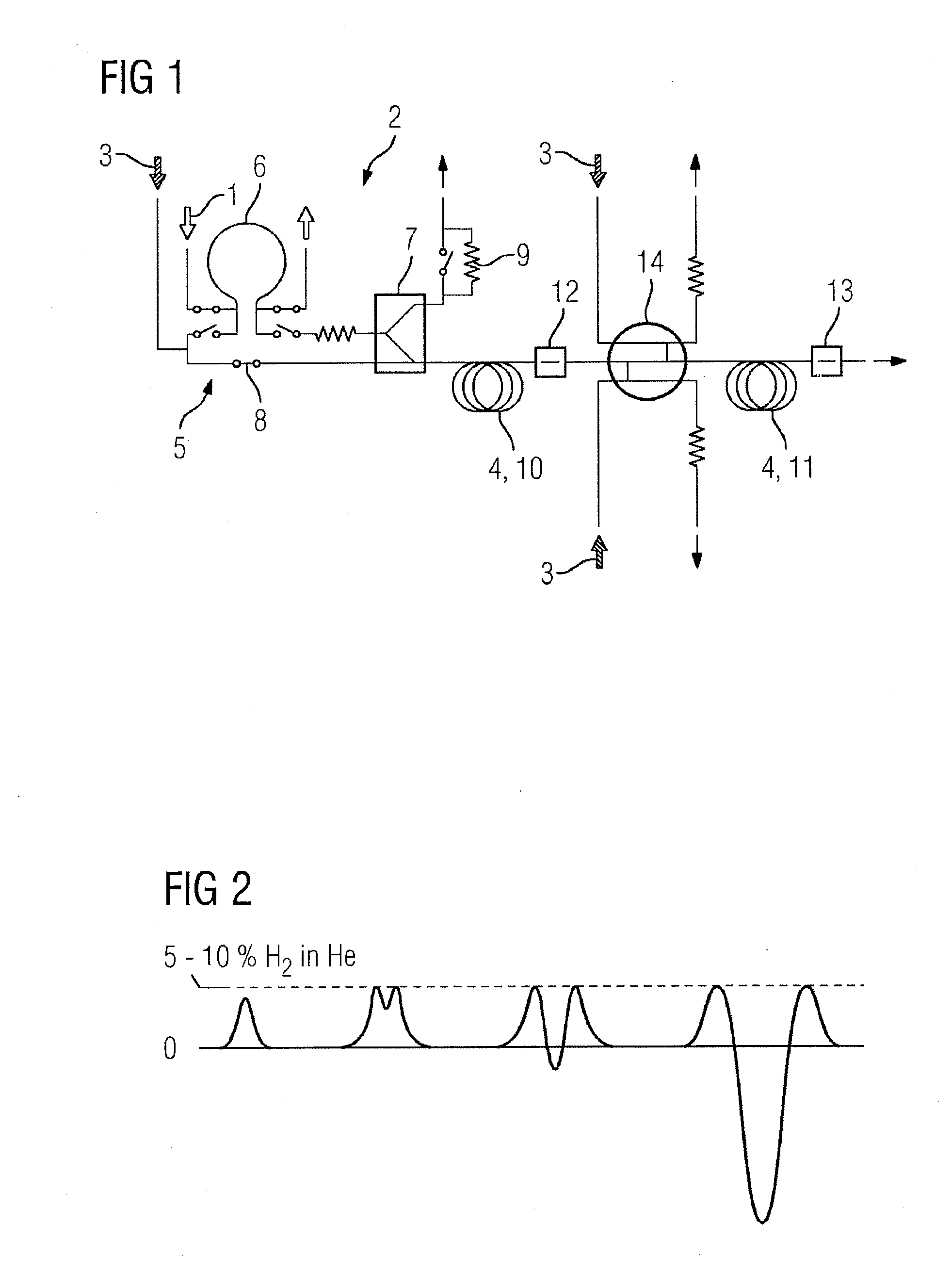

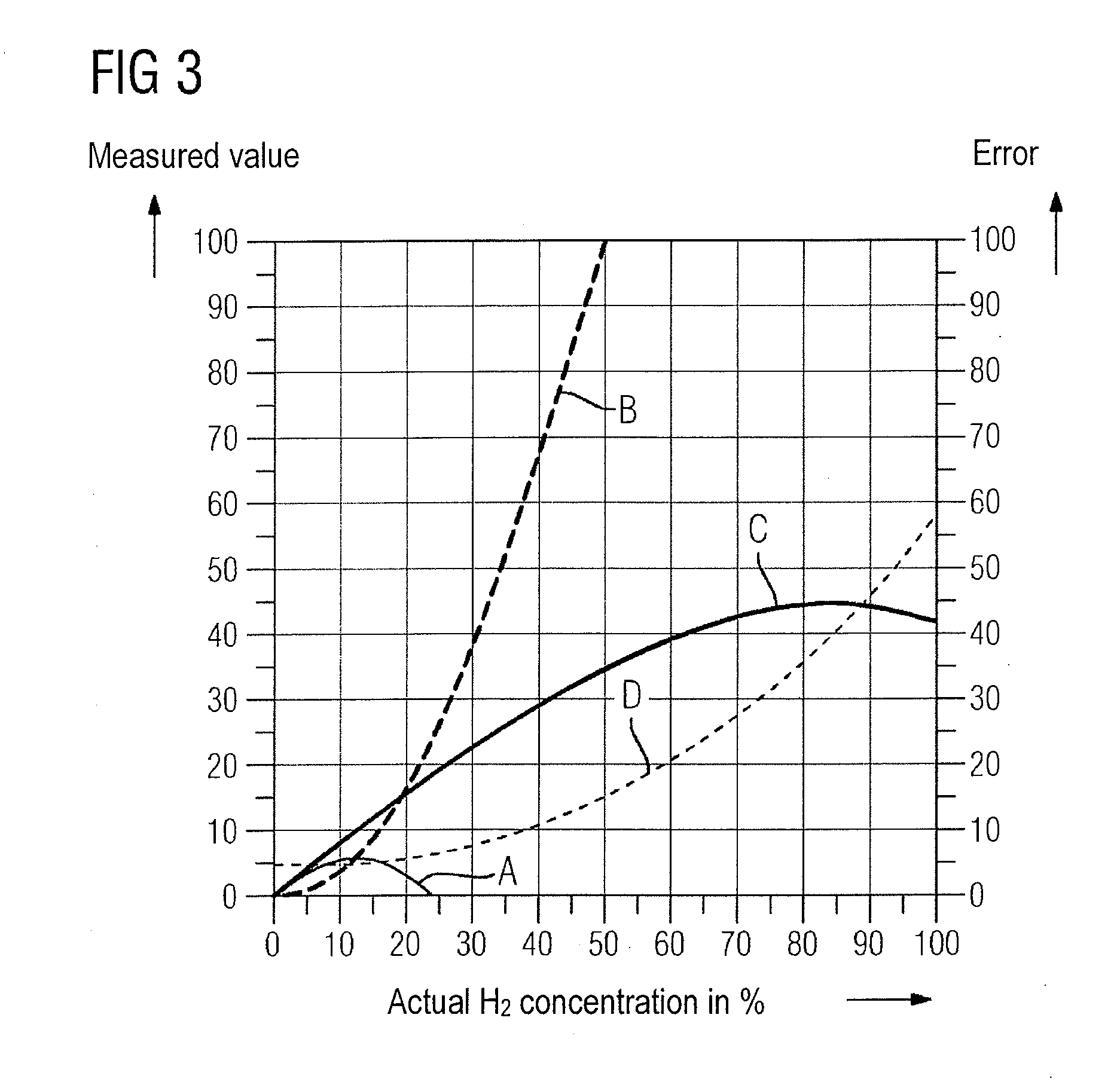

Method for Chromatographic Analysis of a Hydrogen-Containing Gas Mixture

InactiveUS20140060152A1Improve measurement errorSamplingComponent separationHydrogen concentrationPhysical chemistry

Method for chromatographic analysis of a hydrogen-containing gas mixture, wherein a first dose of the gas mixture is guided through a separation device using helium as a carrier gas during a first measurement pass and concentrations of separated components are measured, the concentration of the hydrogen in the gas mixture is measured and the measurement value is obtained up to an upper limit value in the range from 5% to 6%, and a second dose of the same gas mixture is guided through the separation device using the same carrier gas during a second measurement pass, wherein as compared to the first measurement pass the dose is reduced, the gas mixture is volumetrically diluted and / or the carrier-gas speed is reduced, and the hydrogen concentration is re-measured, and the measurement value obtained during the first measurement pass is verified against the measurement value obtained in the second measurement pass.

Owner:SIEMENS AG

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com