High-precision current measurement system based on toroidal magnetic field sensing array

A sensor array and annular magnetic field technology, applied in signal transmission systems, non-electrical signal transmission systems, measurement devices, etc., can solve the problems of single measurement method, low measurement accuracy, and inability to measure DC current, and achieve accurate measurement. The effect of improving the degree of measurement, improving the measurement accuracy, and strong anti-interference ability of the adjacent conductor current

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

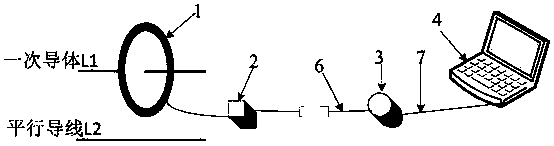

[0063] Such as figure 1 As shown, a high-precision current measurement system based on an annular magnetic field sensing array includes a current sensing unit 1 , a signal conversion unit 2 , a signal transmission unit 3 , and a display platform 4 . The current sensing unit 1 is used to obtain the current signal of the primary conductor L1 , the current sensing unit 1 is connected to the signal conversion unit 2 , the signal conversion unit 2 is connected to the signal transmission unit 3 , and the signal transmission unit 3 is connected to the display platform 4 .

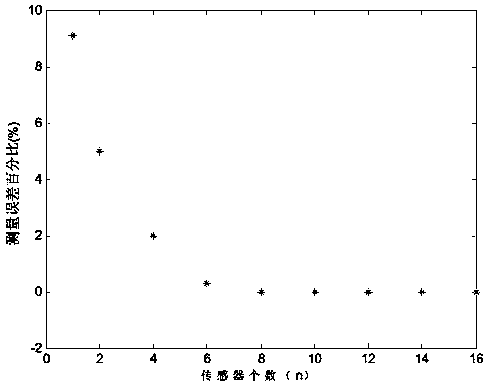

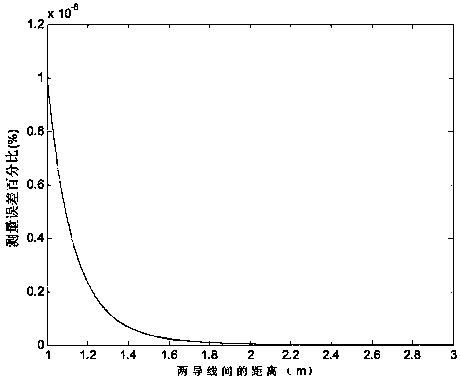

[0064] Such as figure 2 As shown, the current sensing unit 1 includes a ring-shaped magnetic field sensing array 5, and the ring-shaped magnetic field sensing array 5 contains a plurality of sensors 8, and the plurality of sensors 8 are evenly distributed on the vertices of the regular polygon inscribed in the ring. On the base 9, the base 9 is connected to a rotating motor, and driven by the rotating motor, the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com