Patents

Literature

89 results about "Toroidal magnetic fields" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

A toroid has a magnetic field inside of itself that forms a series of concentric circles. Outside of it, the field is zero. The strength of this magnetic field depends on the number of coils the toroid has on its body.

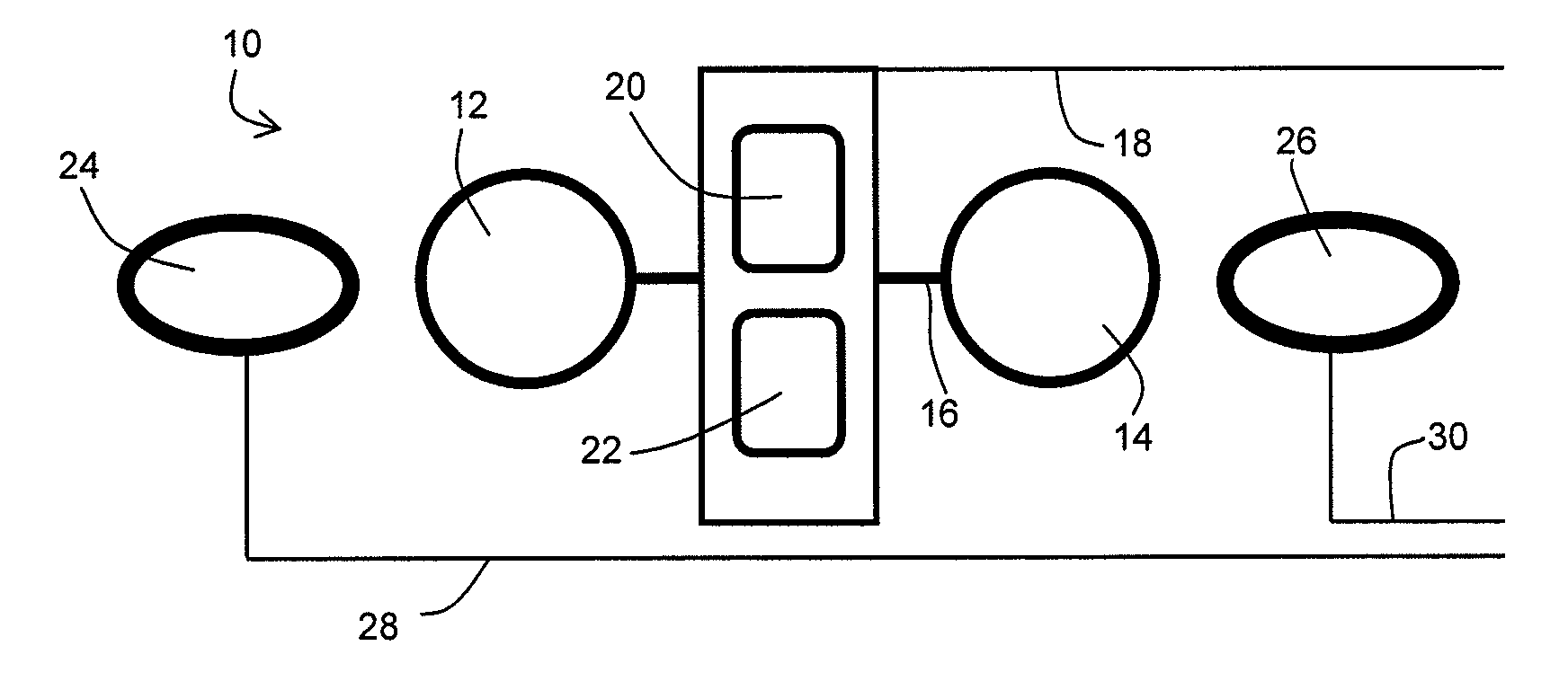

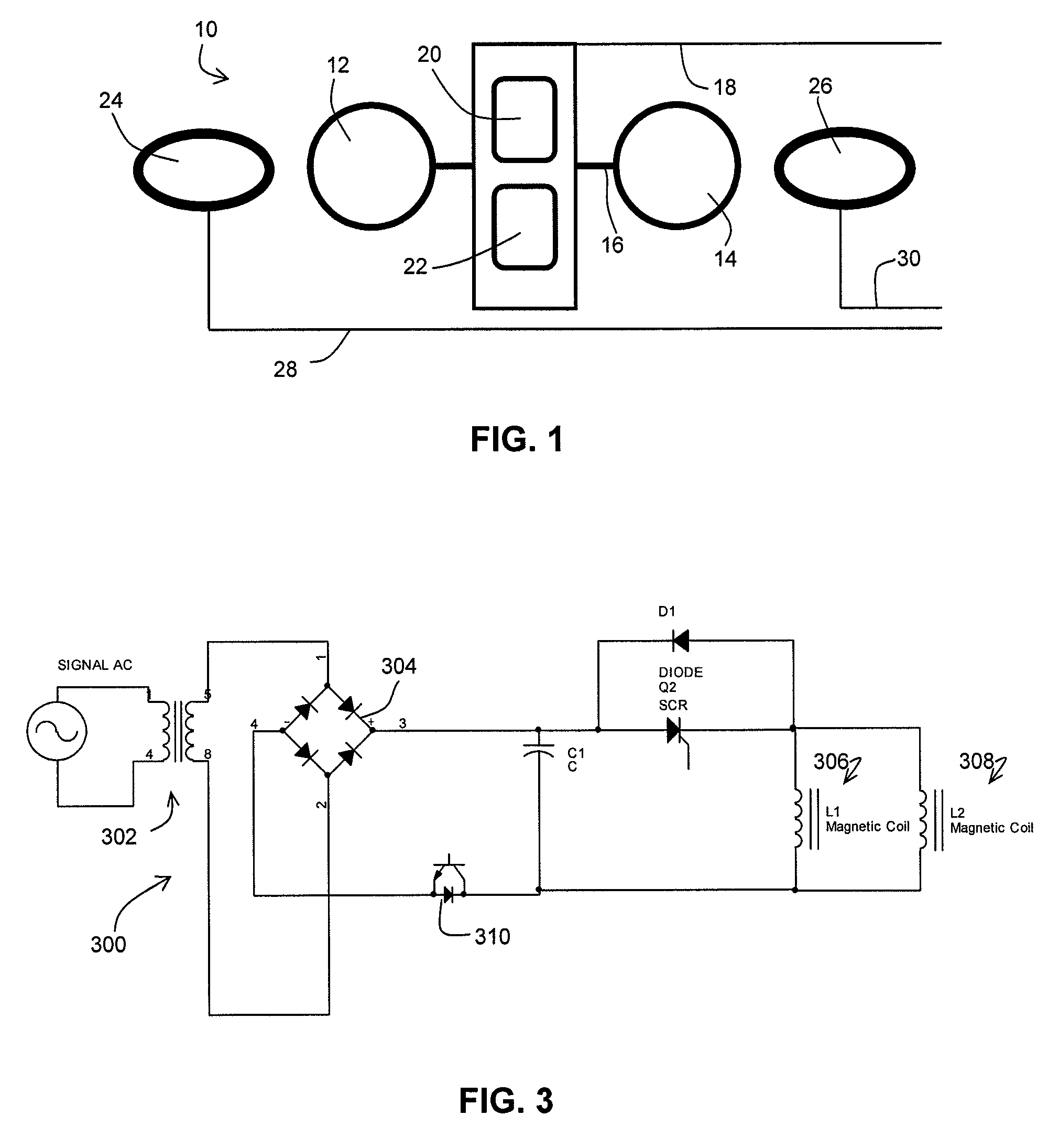

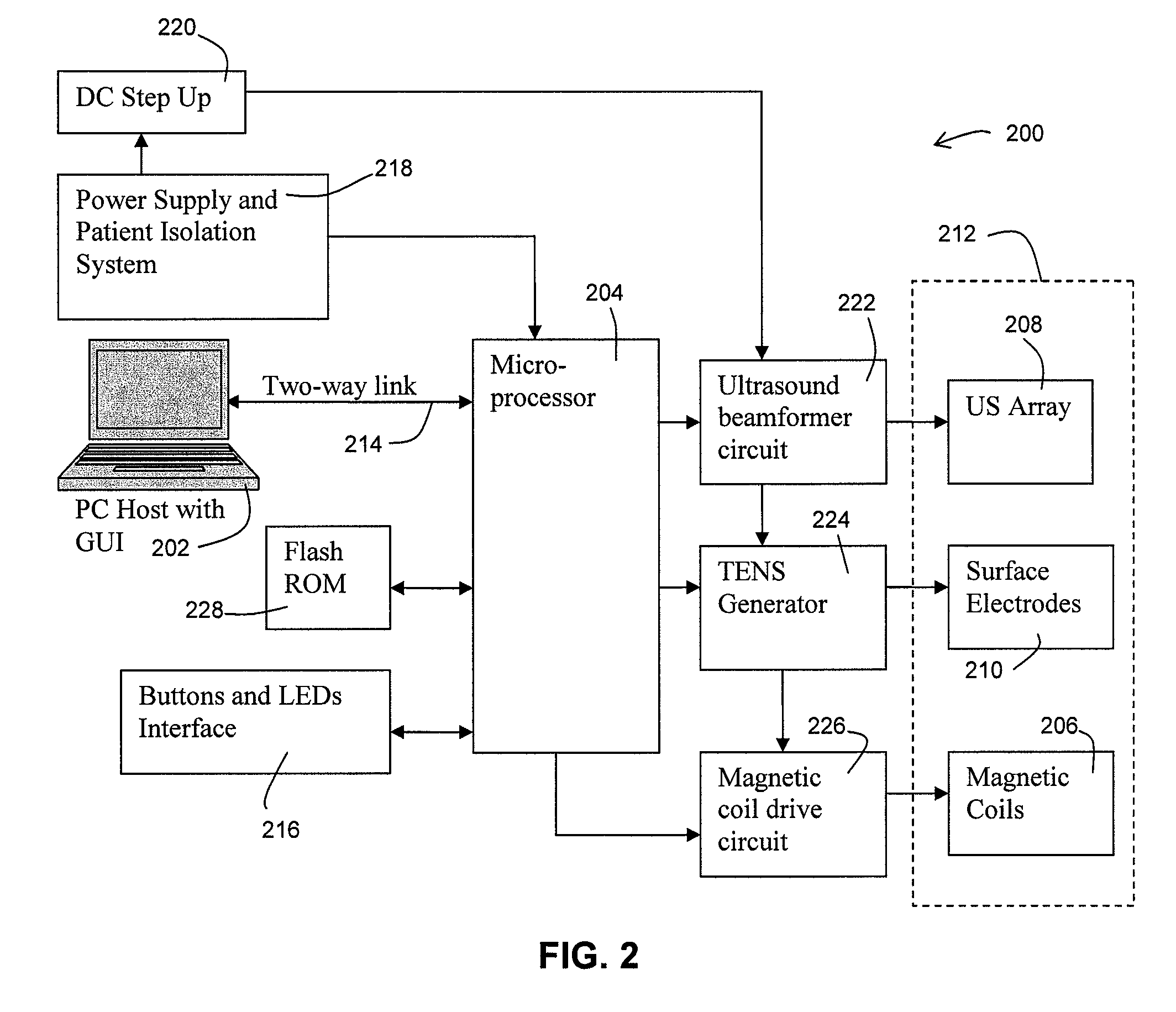

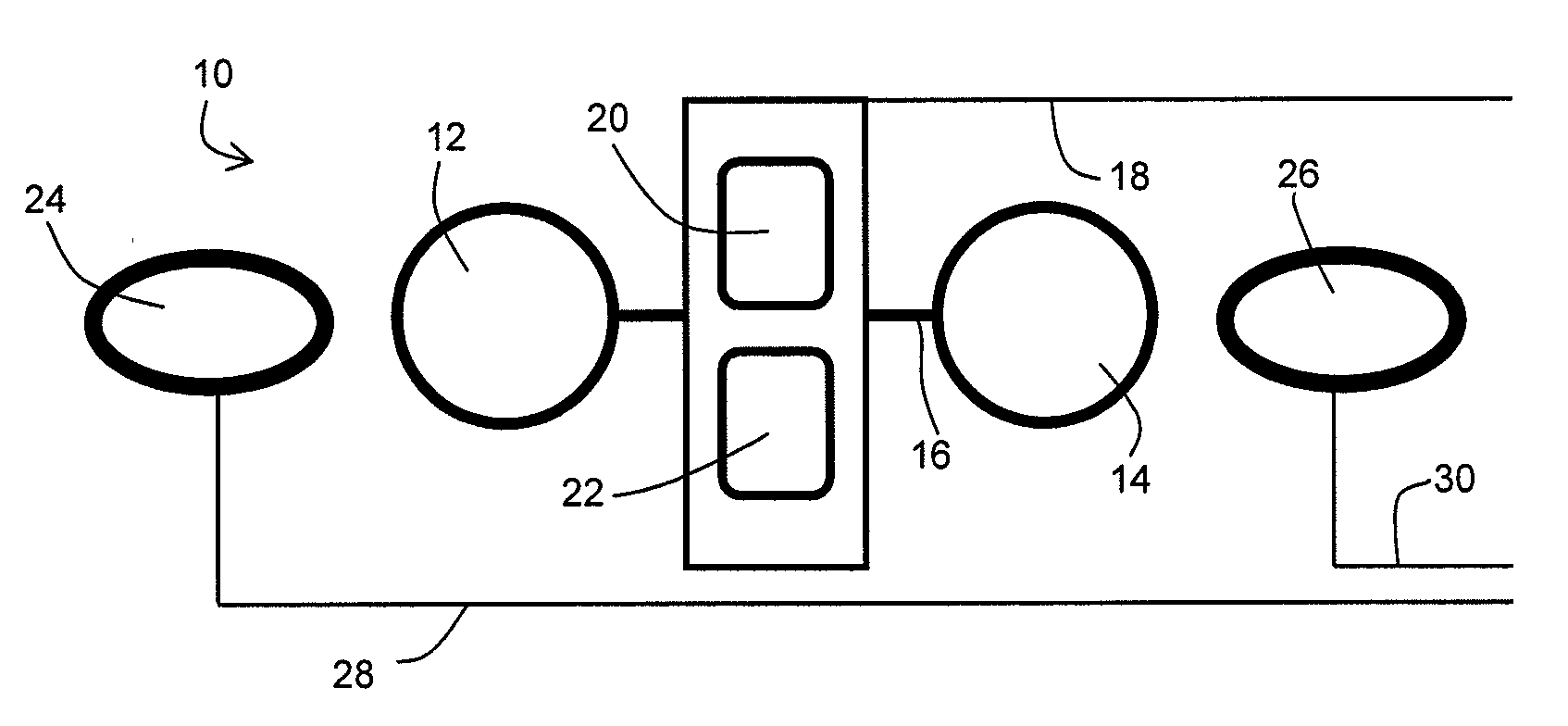

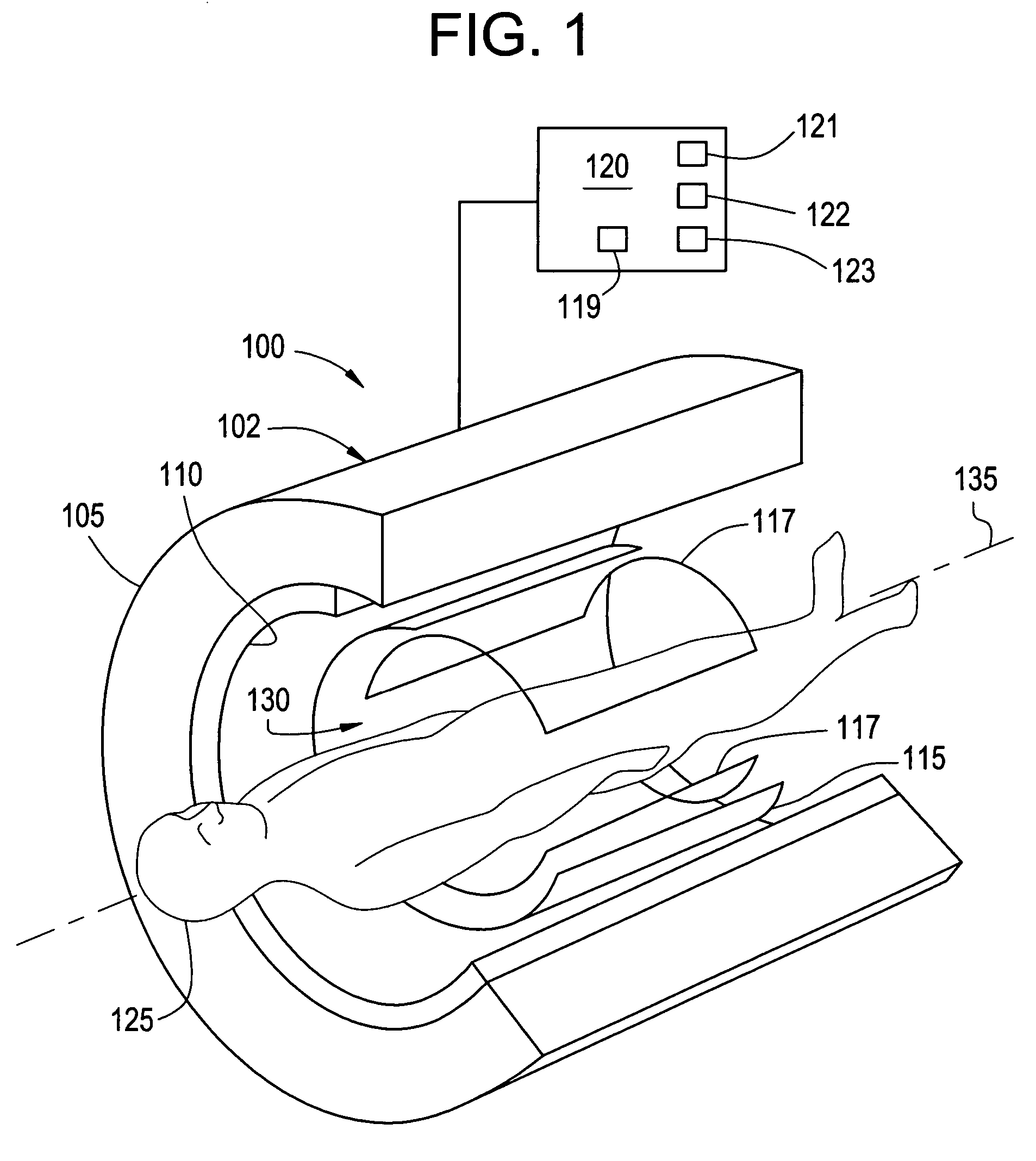

Device and method for non-invasive, localized neural stimulation utilizing hall effect phenomenon

InactiveUS7699768B2Reduce dosageReduce or eliminate intraoperative brain mappingUltrasound therapyElectrotherapyMedicineRadiology

Owner:KISHAWI EYAD +1

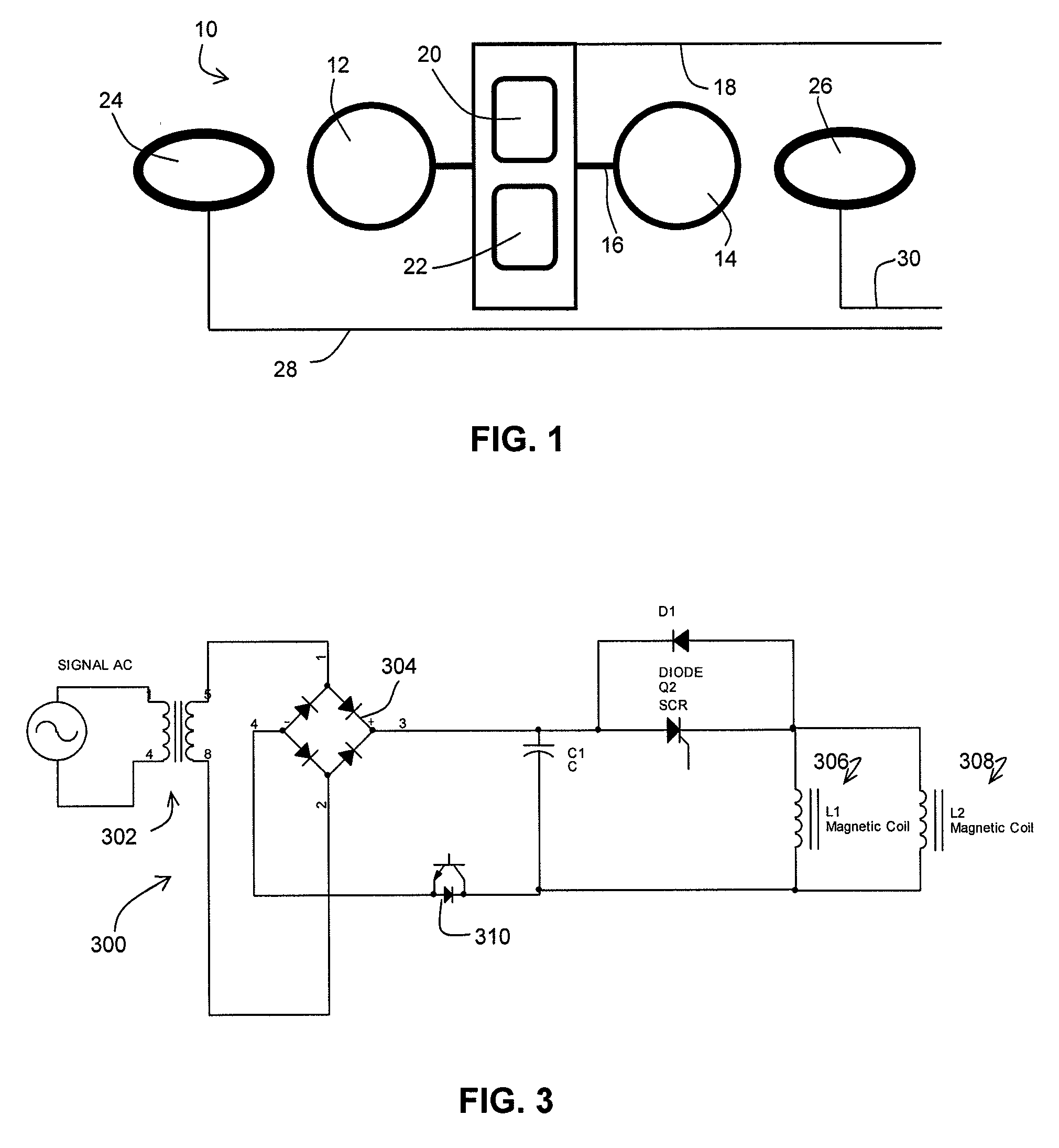

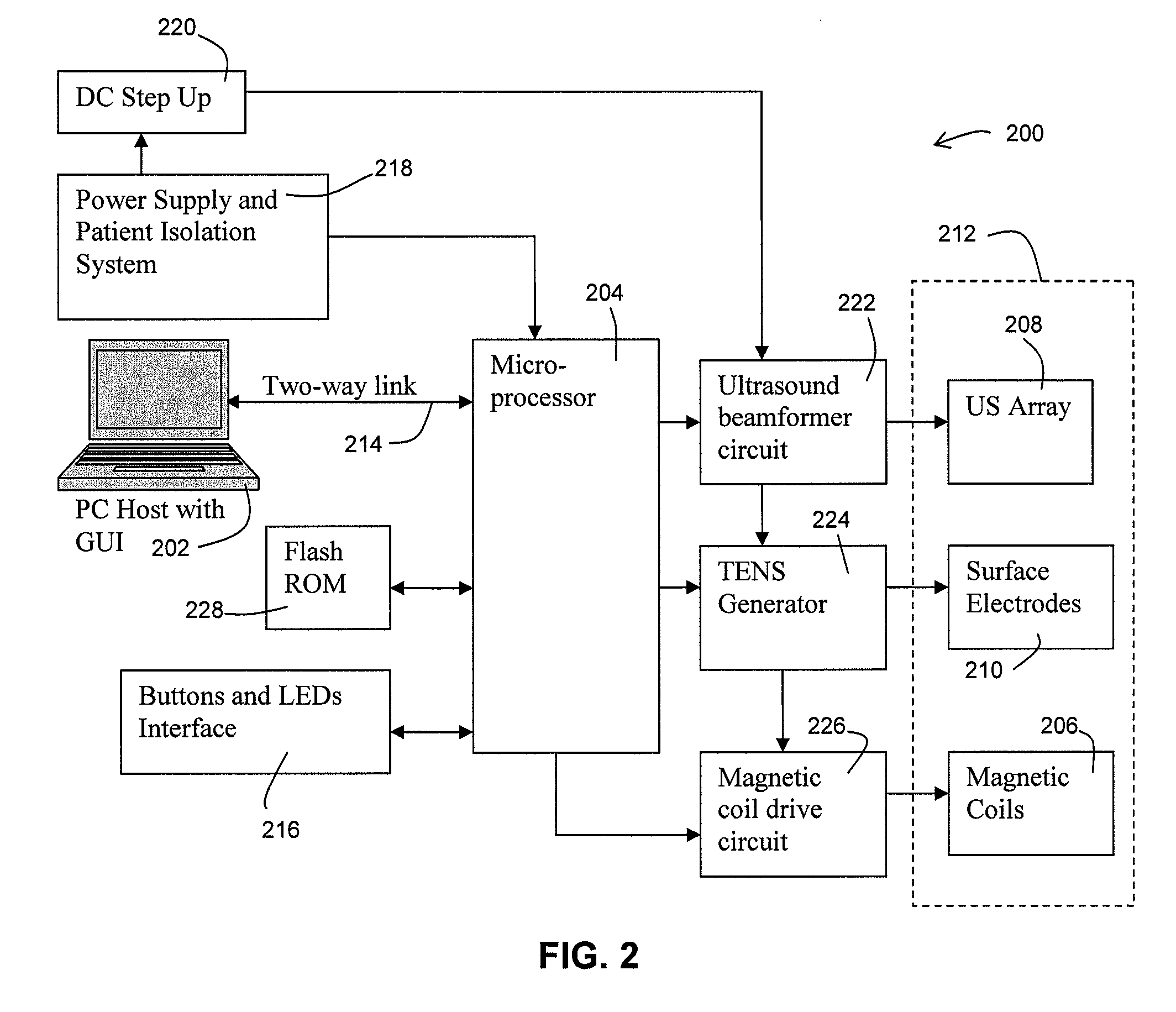

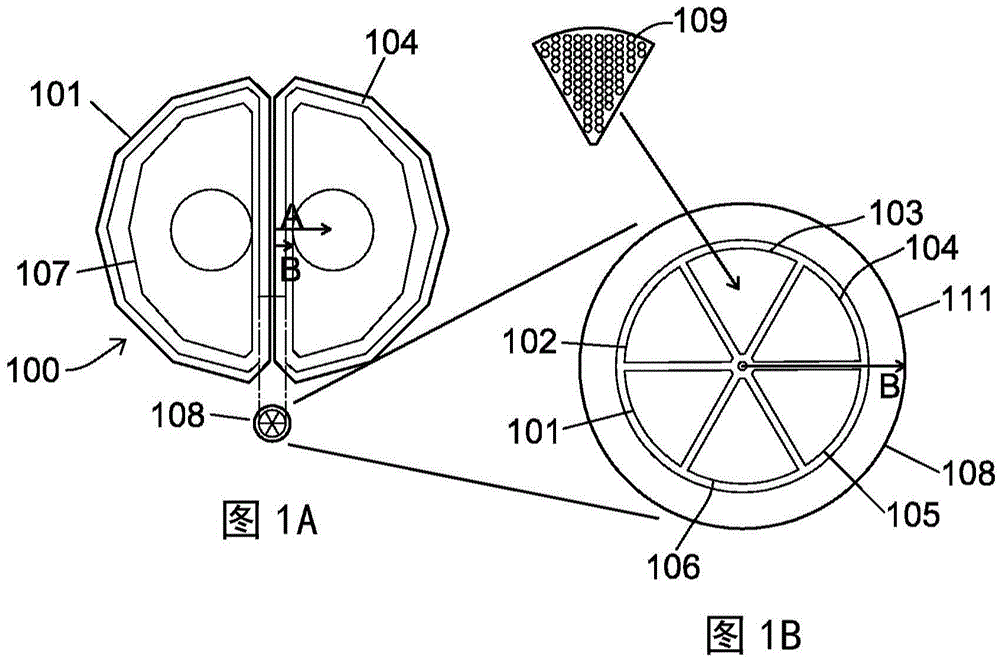

Device and Method for Non-Invasive, Localized Neural Stimulation Utilizing Hall Effect Phenomenon

InactiveUS20070255085A1Increase stimulationReduce dosageUltrasound therapyElectrotherapyMedicineElectrical polarity

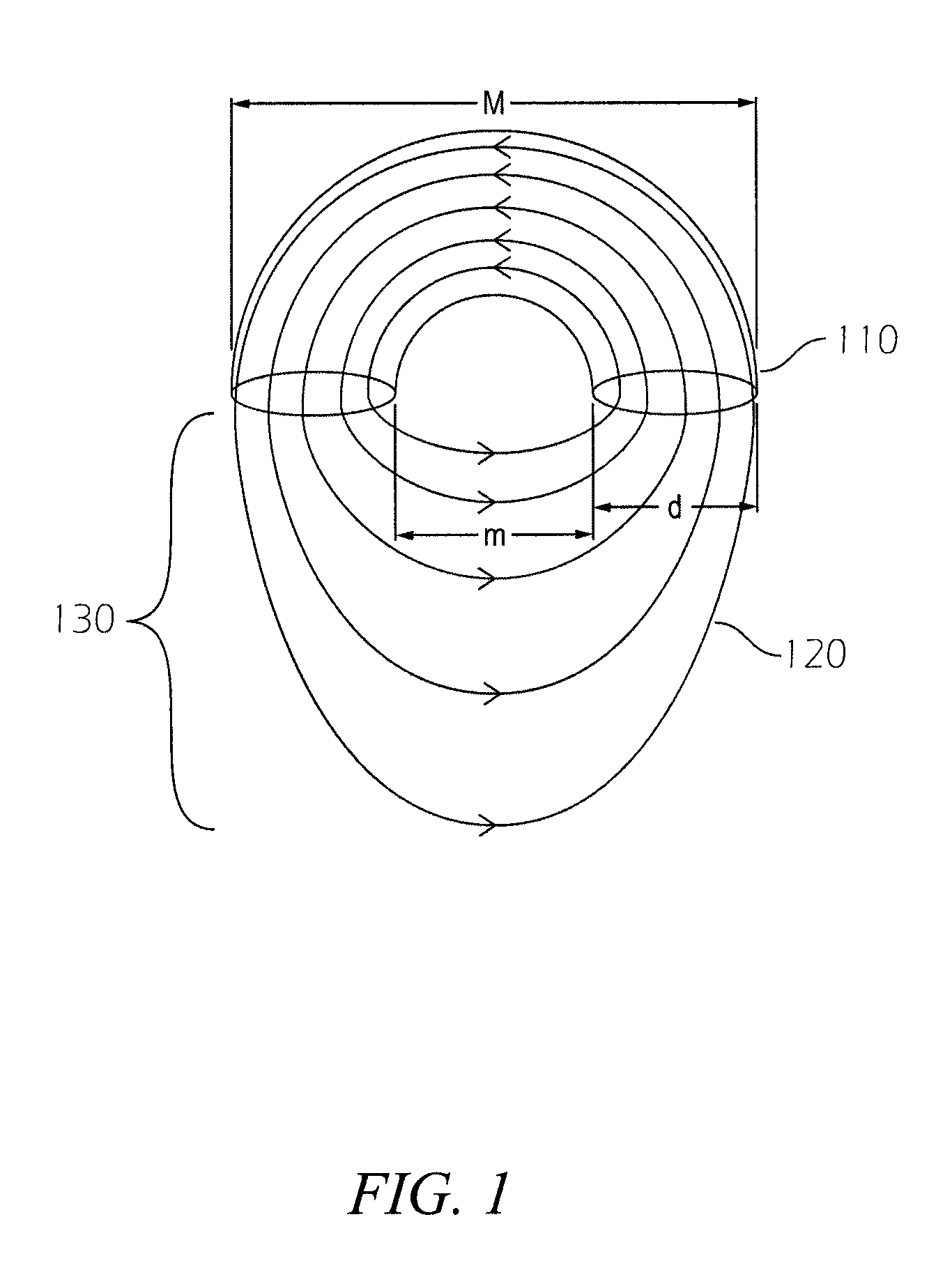

One aspect of the invention provides a method of stimulating a nerve in tissue of a patient. The method includes the following steps: applying a focused ultrasound beam to the tissue; applying a first magnetic field to the tissue; and applying a second magnetic field to the tissue, the ultrasound beam and the first and second magnetic fields combining to stimulate the nerve. Another aspect of the invention provides a nerve stimulation device having two magnetic coils of opposite polarity each adapted to generate a magnetic field in a patient's tissue, the coils being positioned to generate a substantially toroidal magnetic field within the patient's tissue; and an ultrasound source adapted to transmit a focused ultrasound beam into the patient's tissue.

Owner:KISHAWI EYAD +1

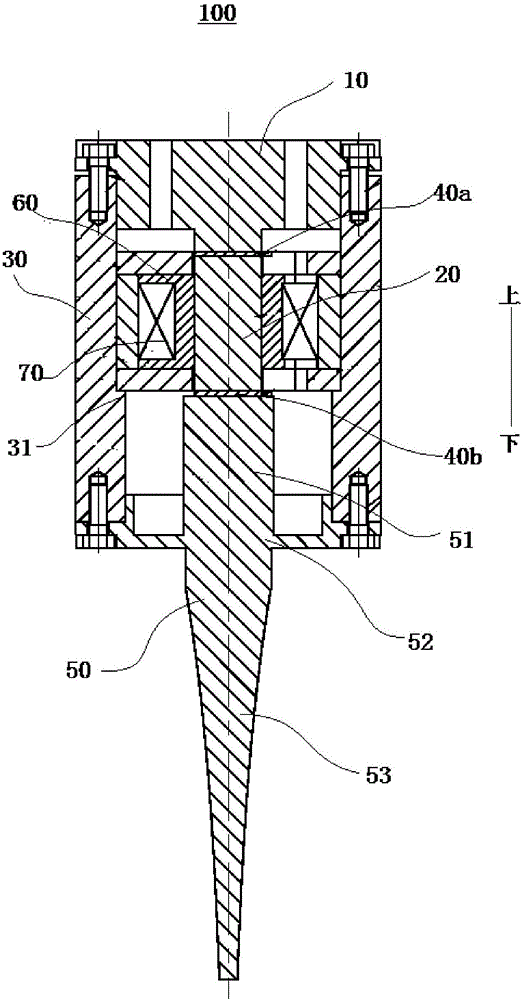

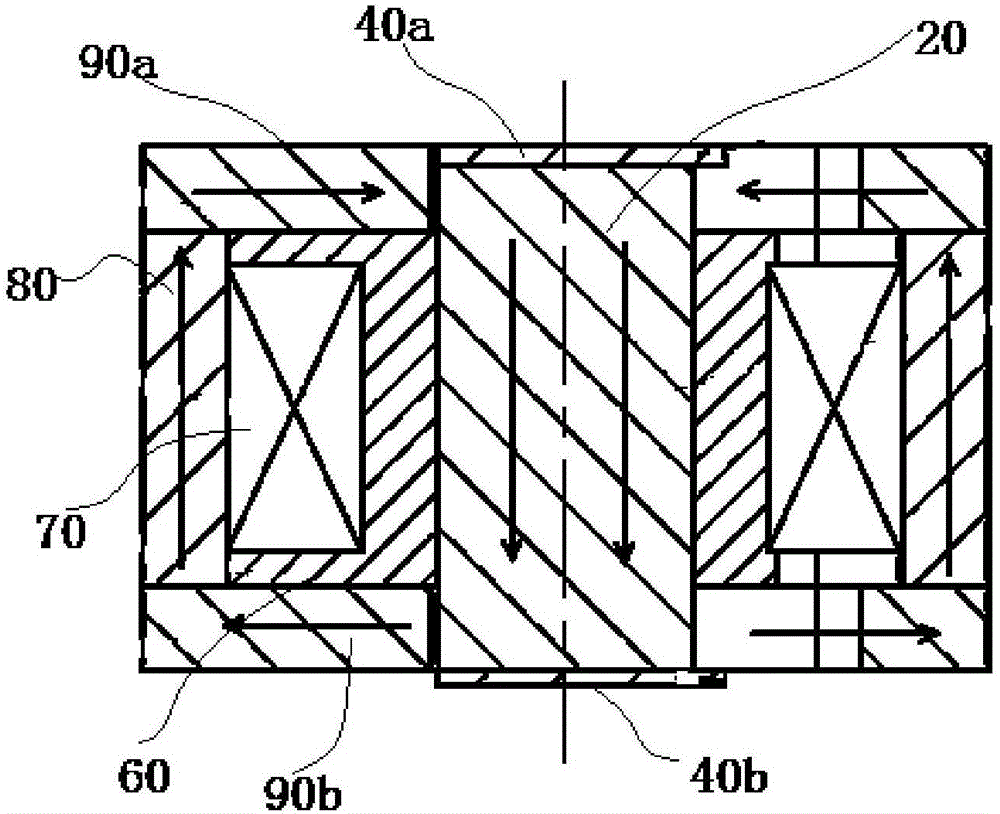

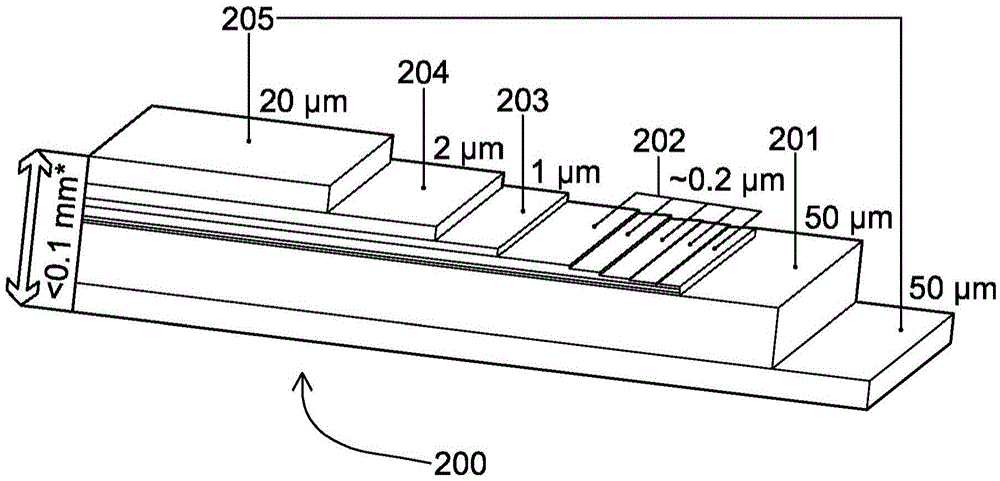

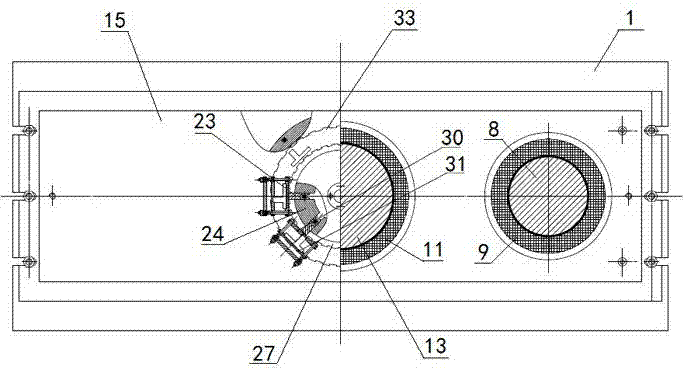

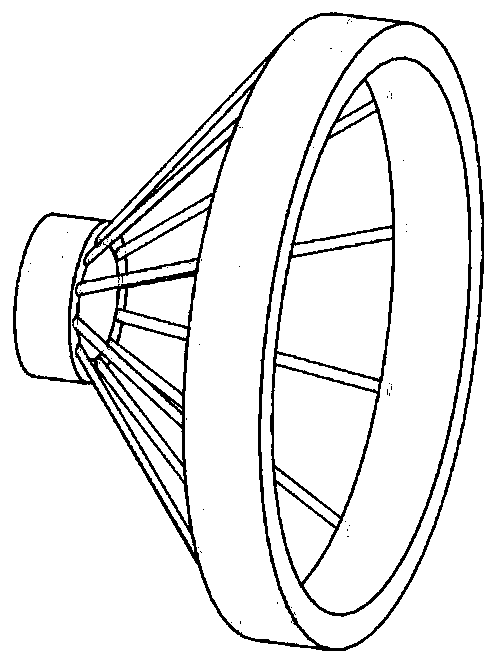

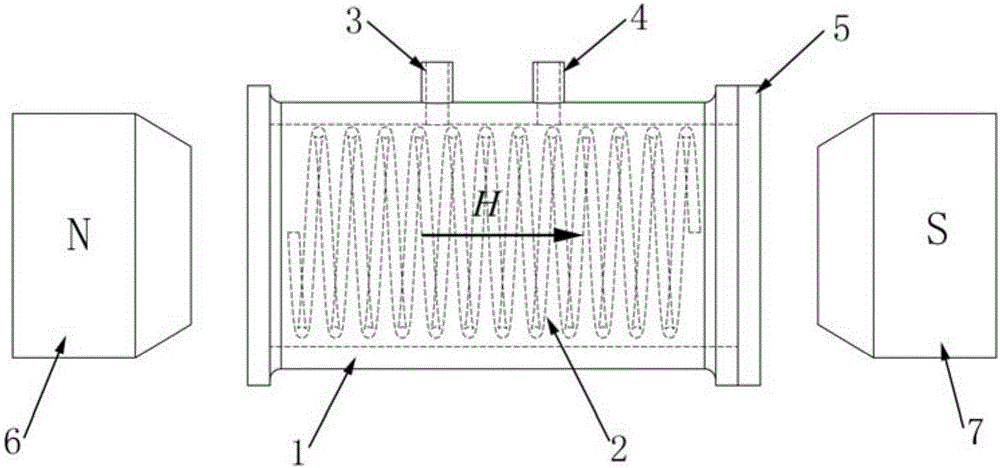

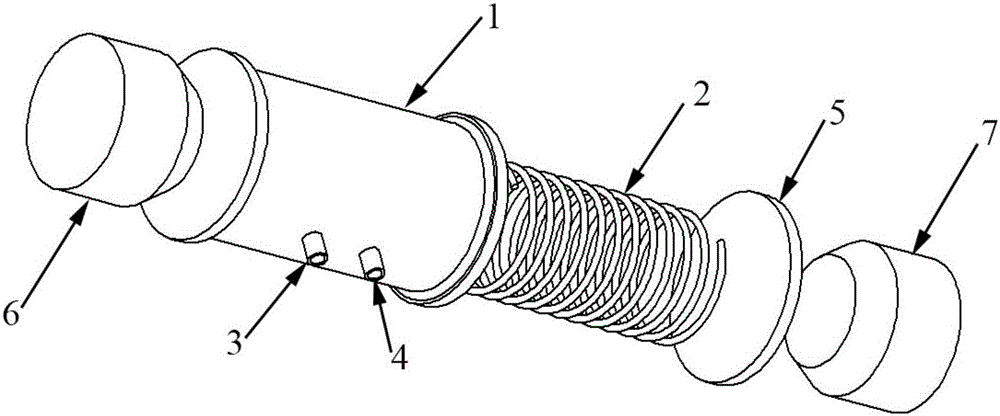

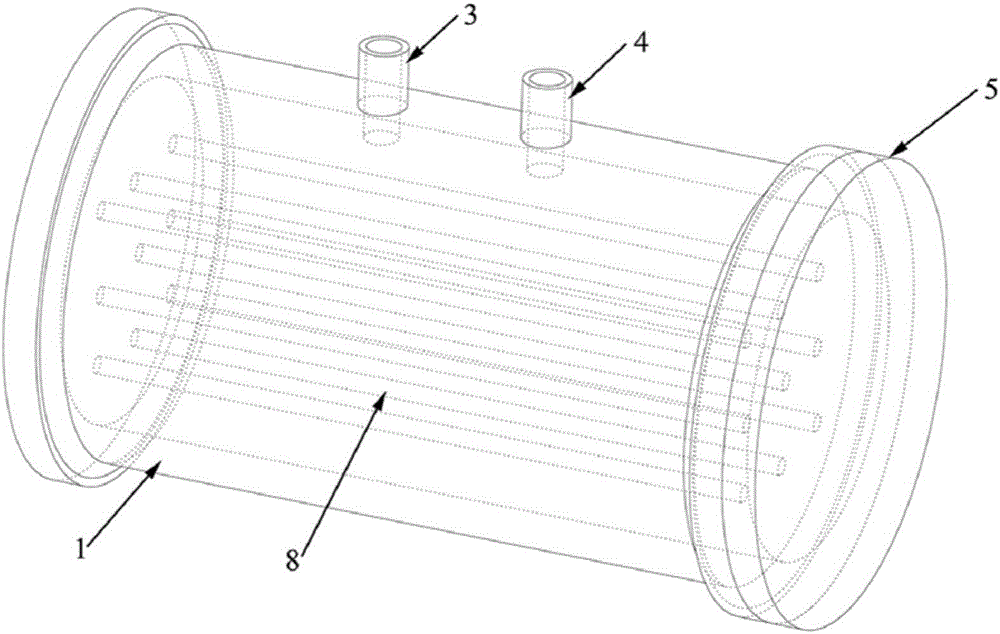

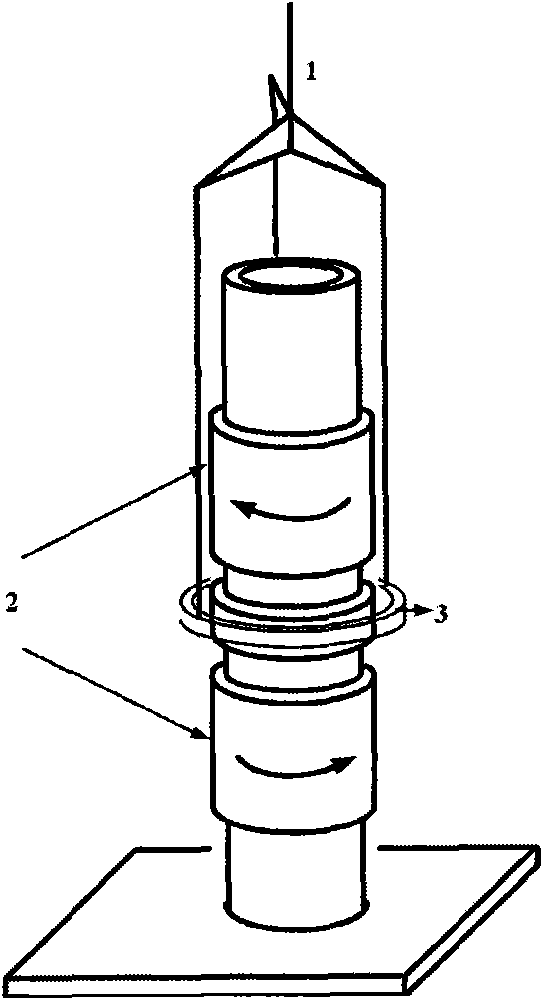

Magnetostriction longitudinal-tersional compound ultrasonic vibration transducer

ActiveCN106807615AReduce energy lossIncrease output powerMechanical vibrations separationElectricityResonance

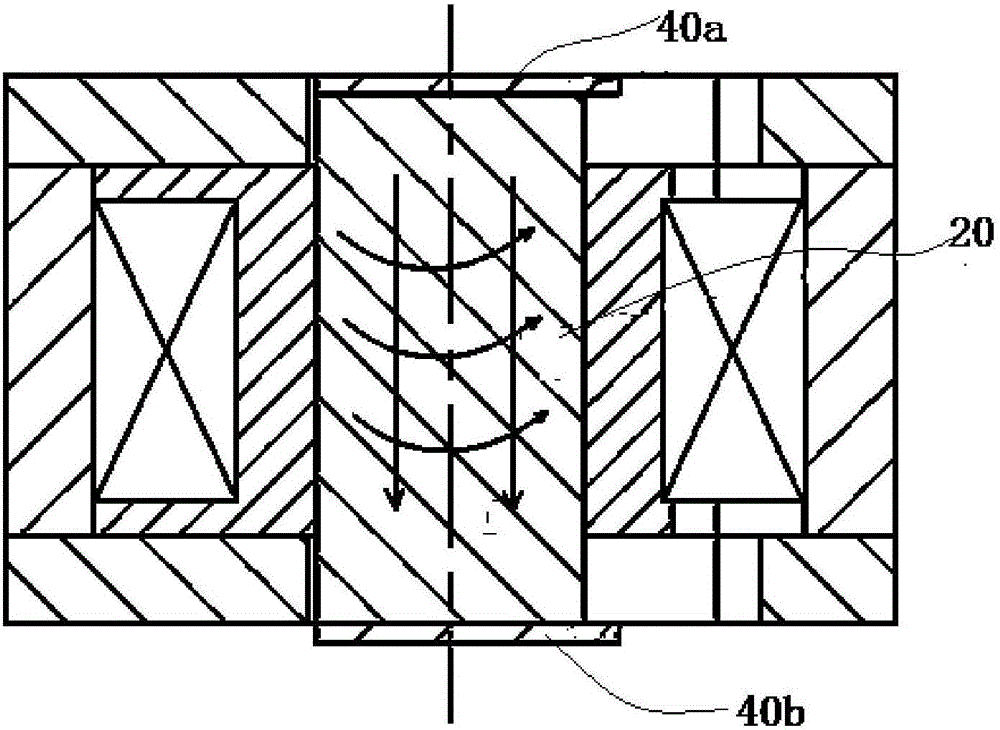

The invention discloses a magnetostriction longitudinal-tersional compound ultrasonic vibration transducer, which comprises a magnetostriction material piece, an amplitude-change pole, a first electrode slice, a second electrode slice, a coil framework and a coil. The first electrode slice and the second electrode slice are arranged on two ends of the magnetostriction material piece; the second electrode slice is arranged between the amplitude-change pole and the magnetostriction material piece and presses against the amplitude-change pole and the magnetostriction material piece; the first electrode slice and the second electrode slice are electrically connected with the outside, so that an alternating toroidal magnetic field is produced in the magnetostriction material piece; the coil framework sleeves on the periphery of the magnetostriction material piece; the coil winds on the coil framework; the coil is electrically connected with the outside, so that an alternating axial magnetic field is formed in the magnetostriction material piece; and the two magnetic fields are coupled to excite the magnetostriction material piece so as to realize longitudinal-tersional resonance. The magnetostriction longitudinal-tersional compound ultrasonic vibration transducer is simple and compact in structure, and beneficial to realizing a miniature design, the output power and the output amplitude can be increased, and the processing quality and the processing efficiency are improved.

Owner:TSINGHUA UNIV

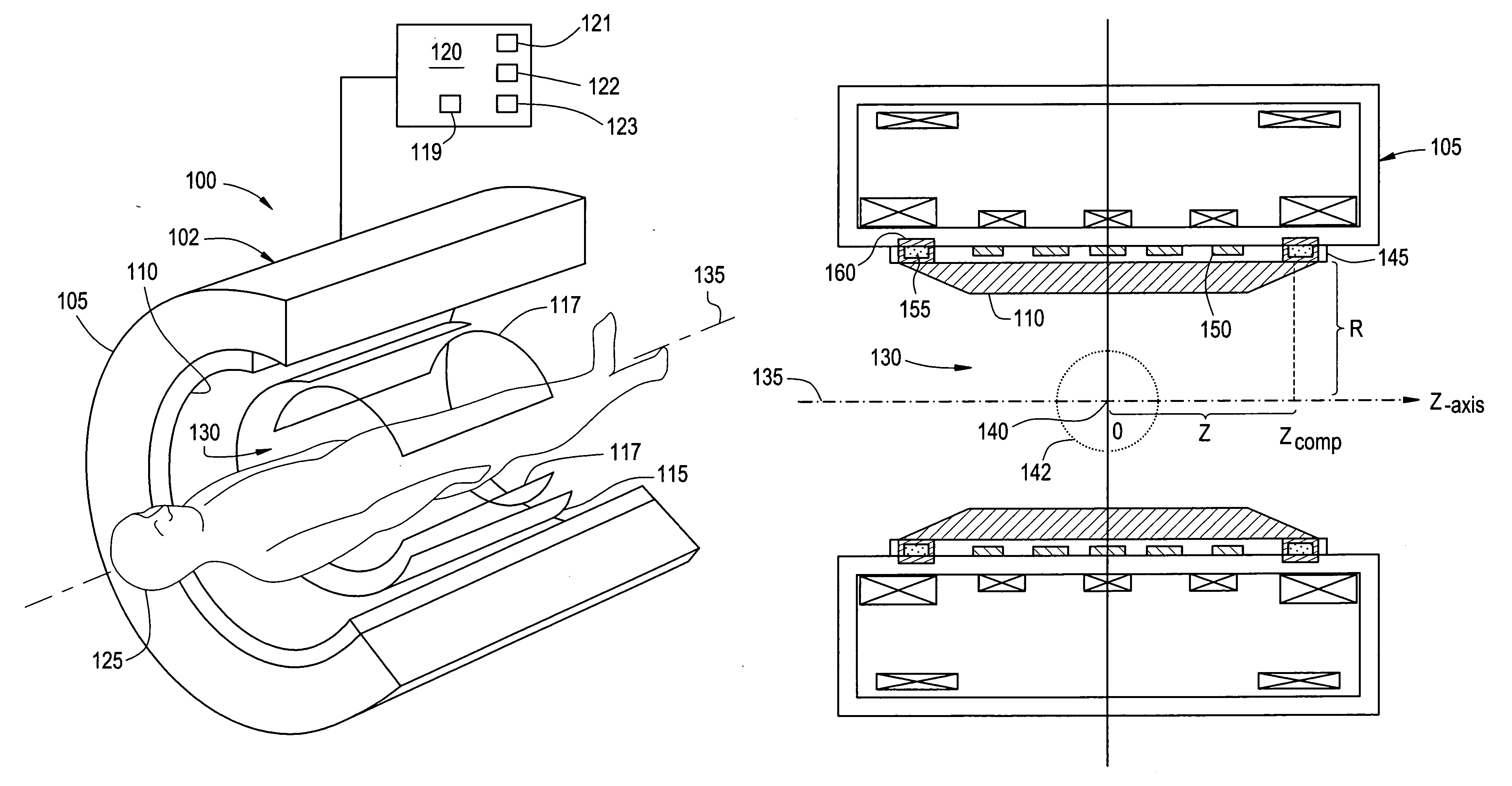

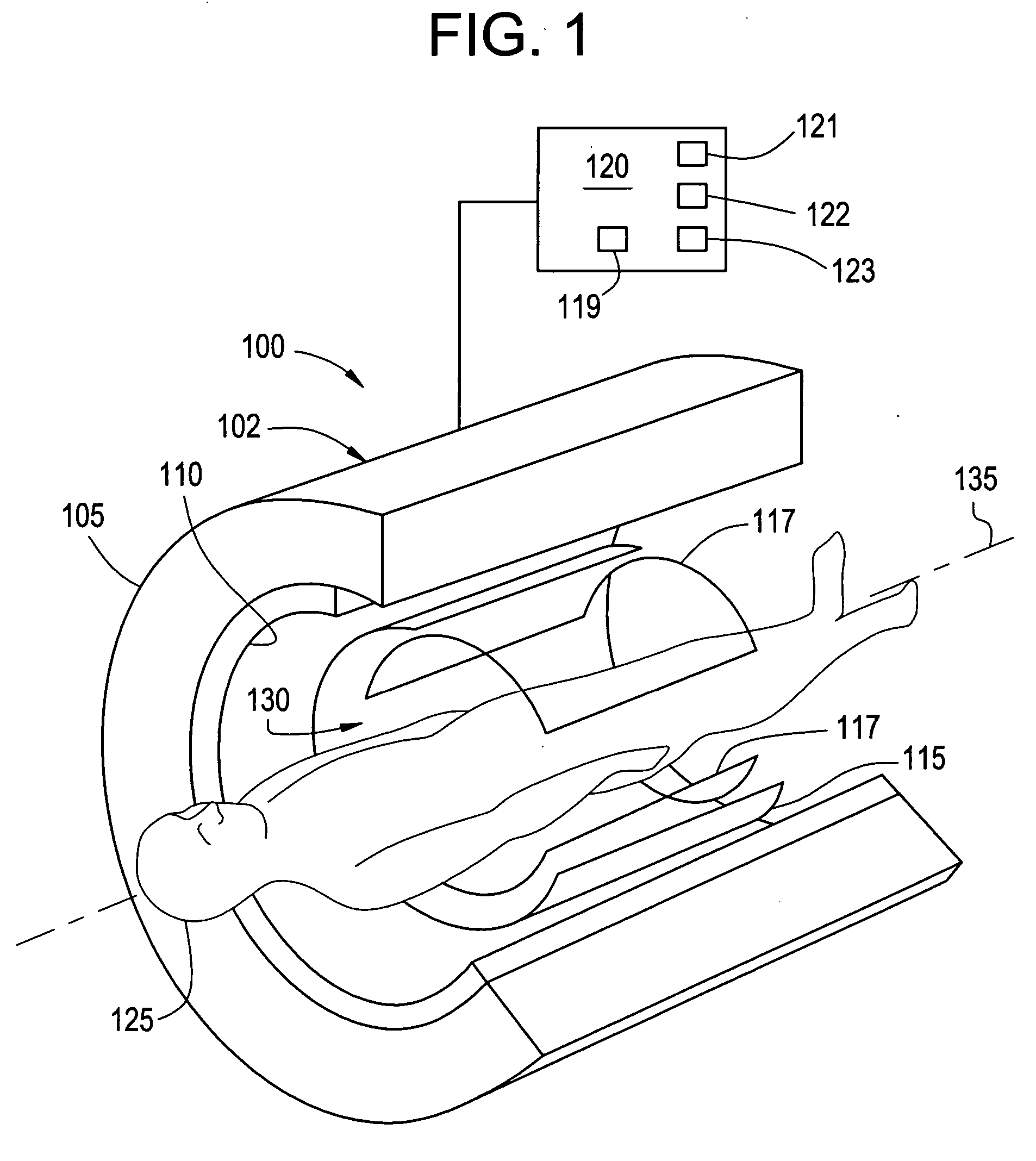

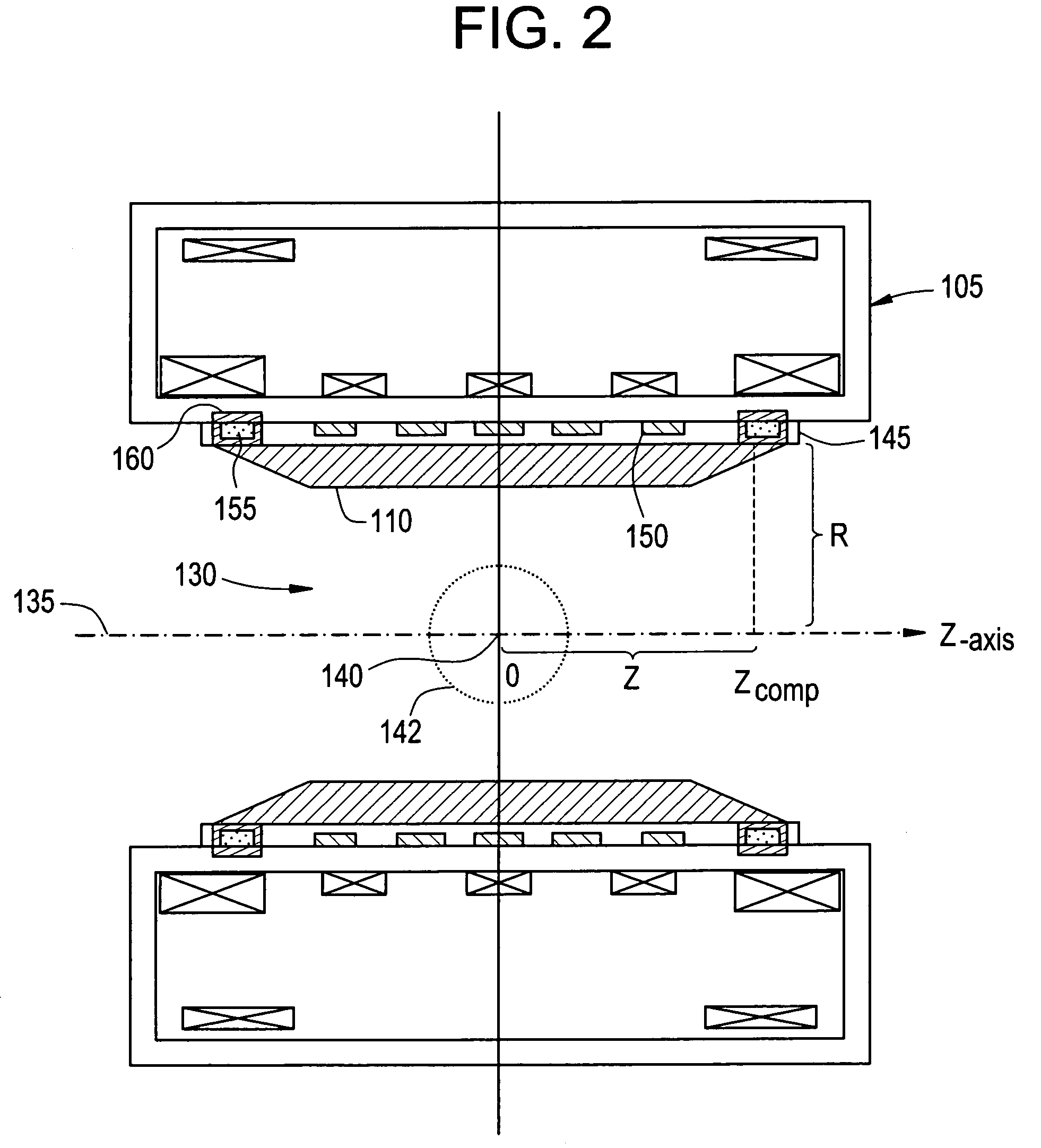

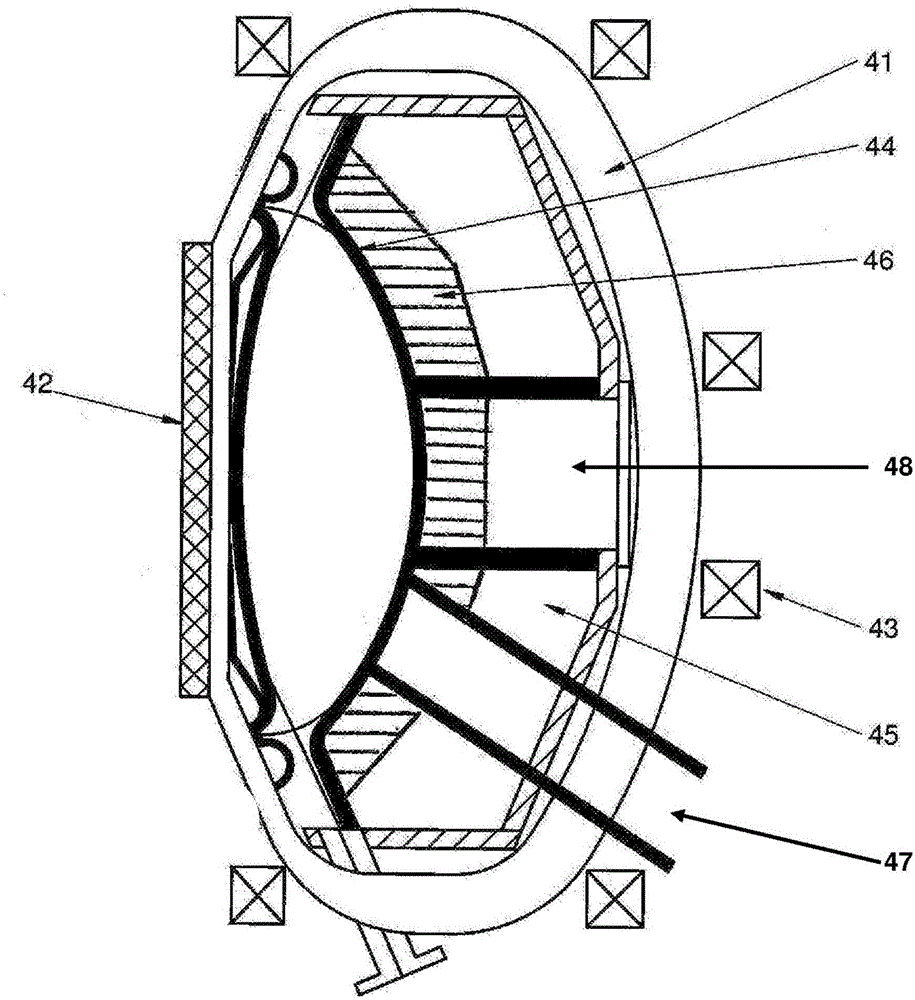

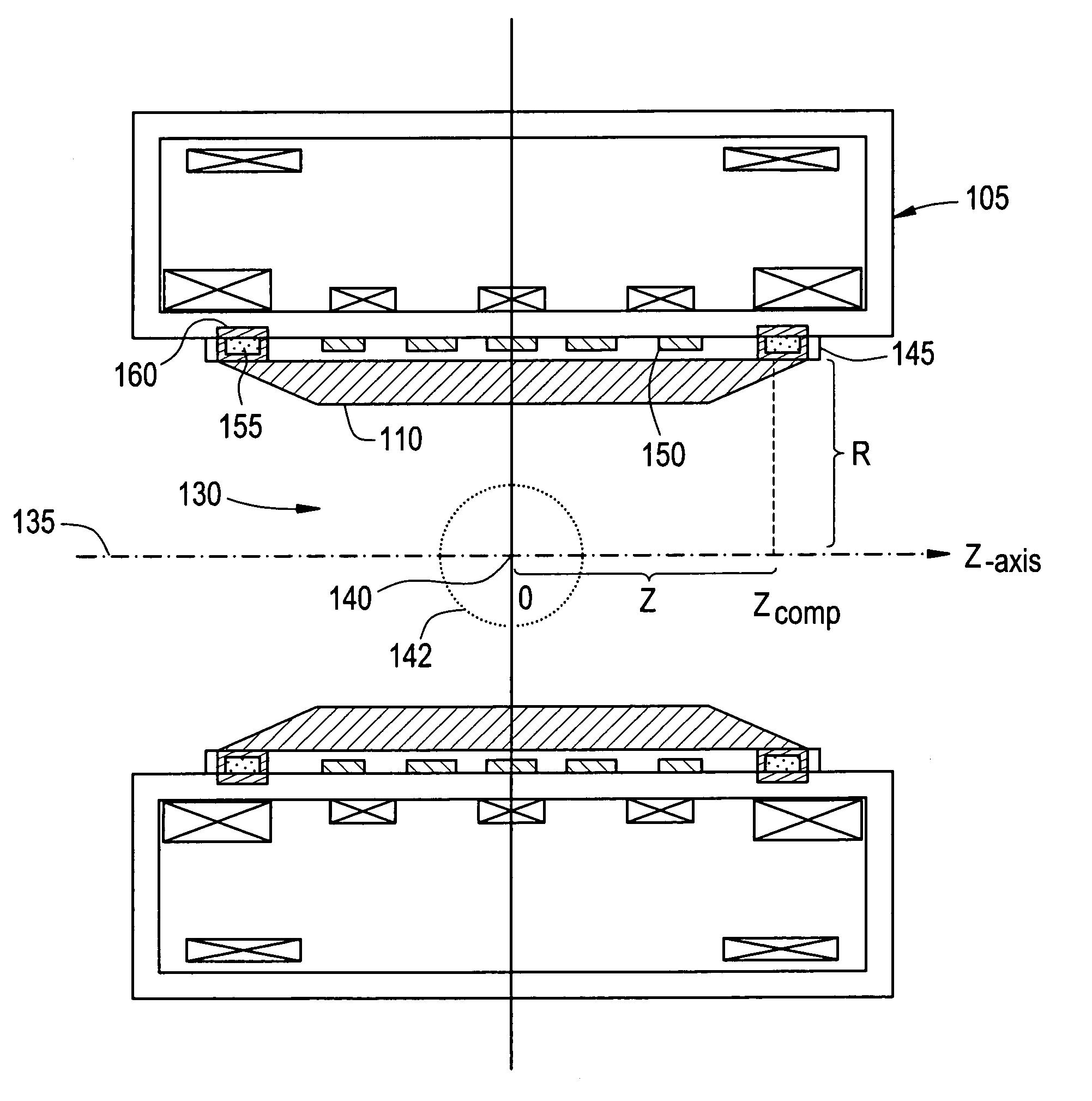

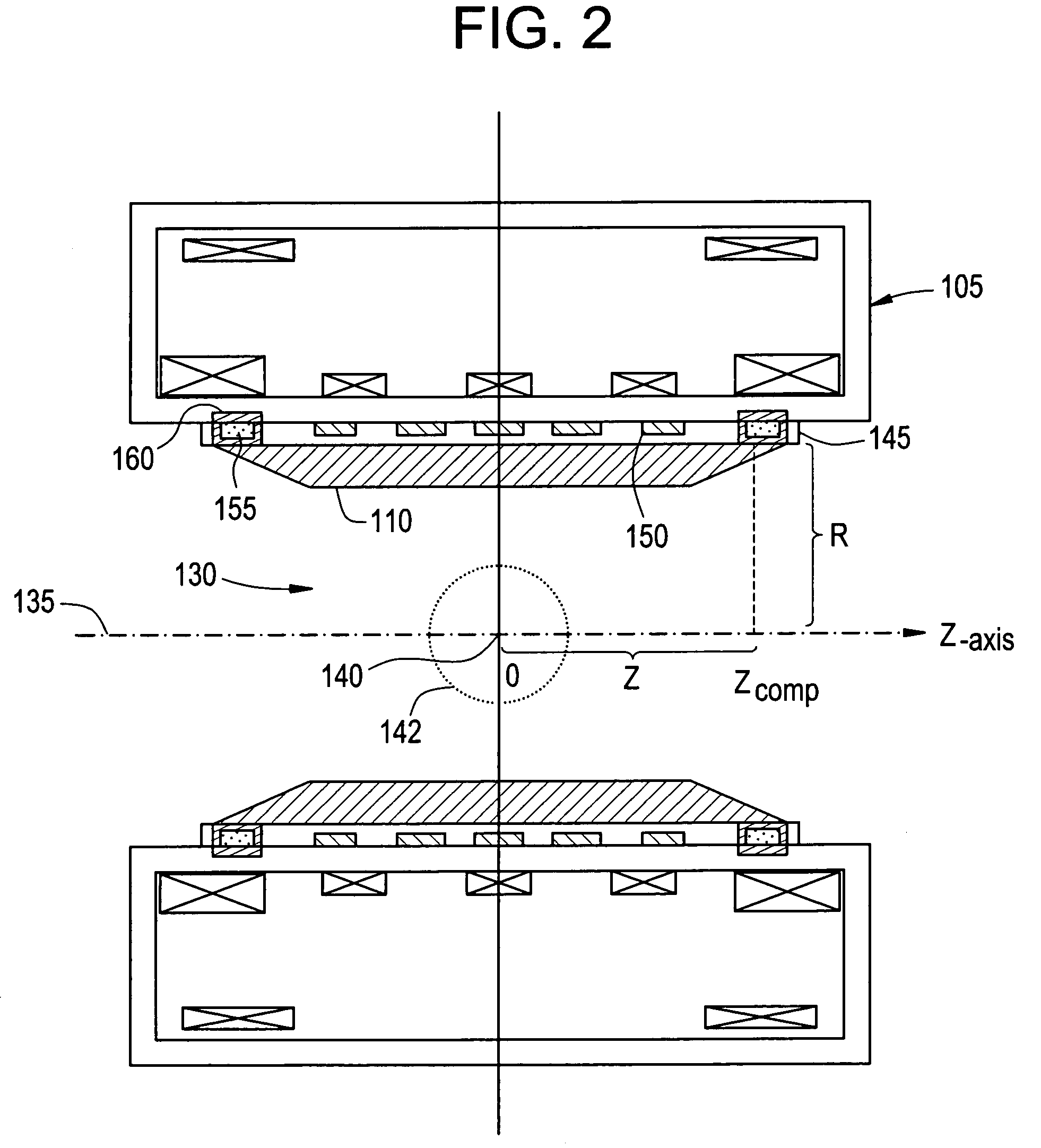

Magnetic field generating apparatus and method for magnetic resonance imaging

ActiveUS20060113995A1Magnetic measurementsElectric/magnetic detectionAxial distanceCondensed matter physics

A magnetic field generating apparatus for use in magnetic resonance imaging (MRI) is disclosed. The apparatus includes an annular magnet field generator defining a patient bore, a gradient coil disposed between the magnetic field generator and the patient bore, a first set of shim elements, and a second set of shim elements. The patient bore has an imaging volume, a z-axis, and an isocenter. The first set of shim elements are disposed at a region between the magnetic field generator and the imaging volume, and the second set of shim elements are disposed at the region at a location having equal to or greater than a specified Z / R ratio, where Z defines an axial distance from the isocenter and R defines a radial distance from the z-axis.

Owner:GENERAL ELECTRIC CO

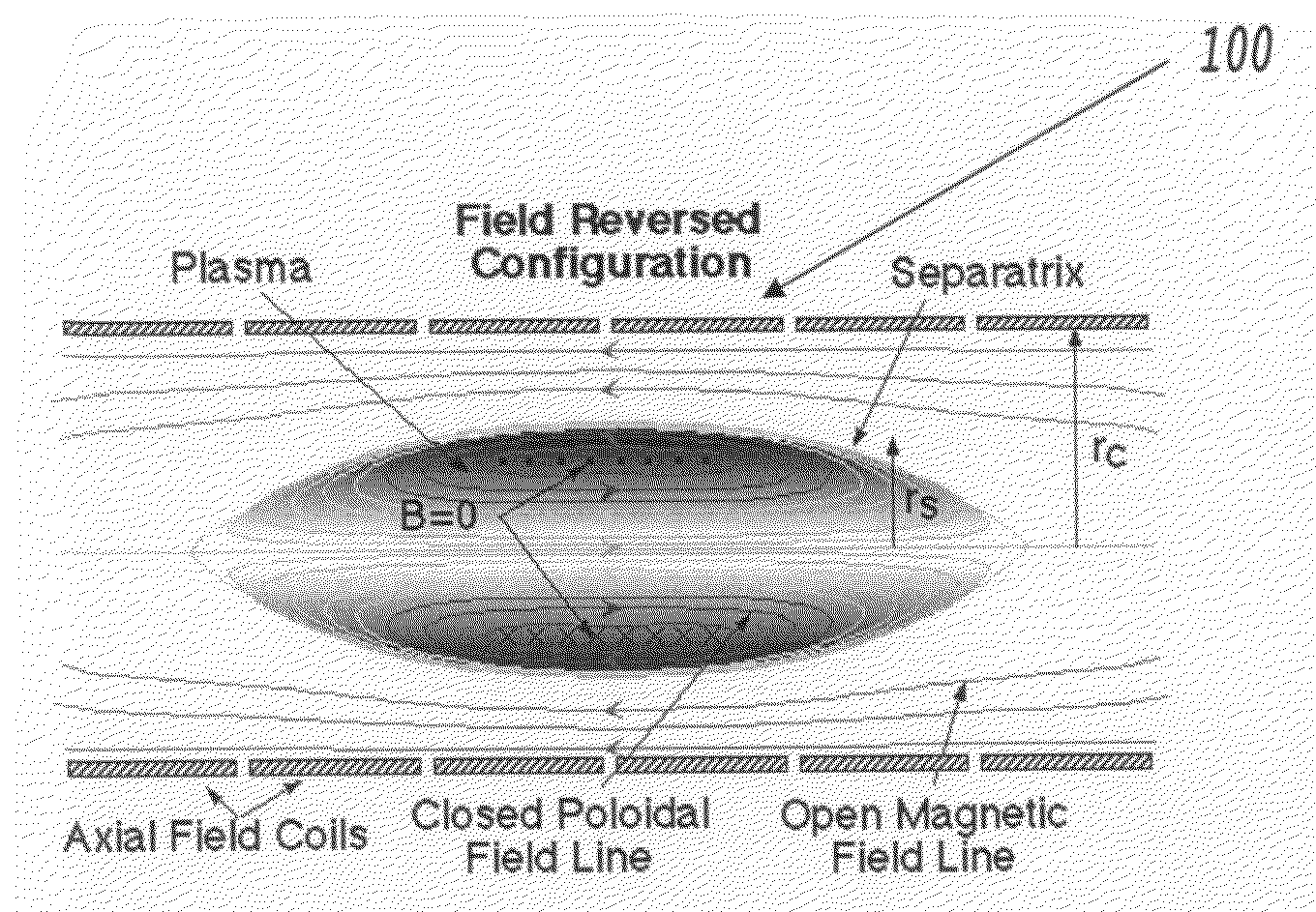

Method for obtainging plasma

A method for obtaining high temperature plasma in the Field Reversed Configuration (FRC) magnetic topology is described, allowing for compression, retention and heating plasma, which can be used for obtaining thermonuclear energy or laser pumping. The storage of the magnetic field energy is accomplished by creating a current in the winding of a solenoid over a working volume. In addition, a pulse toroidal magnetic field with force lines perpendicular to the magnetic field of the solenoid is created via the transmission of a current through the working volume. Then, the current is broken off in the solenoid winding when it reaches its maximum to excite a closed current loop in the plasma created in the working volume. The change of the direction of magnetic field outside the current-carrying loop in the plasma is achieved either by changing to the opposite direction of the current in the solenoid or transmitting the current in additional turns parallel to the turns of the solenoid.

Owner:MOZGOVOY ALEXANDER

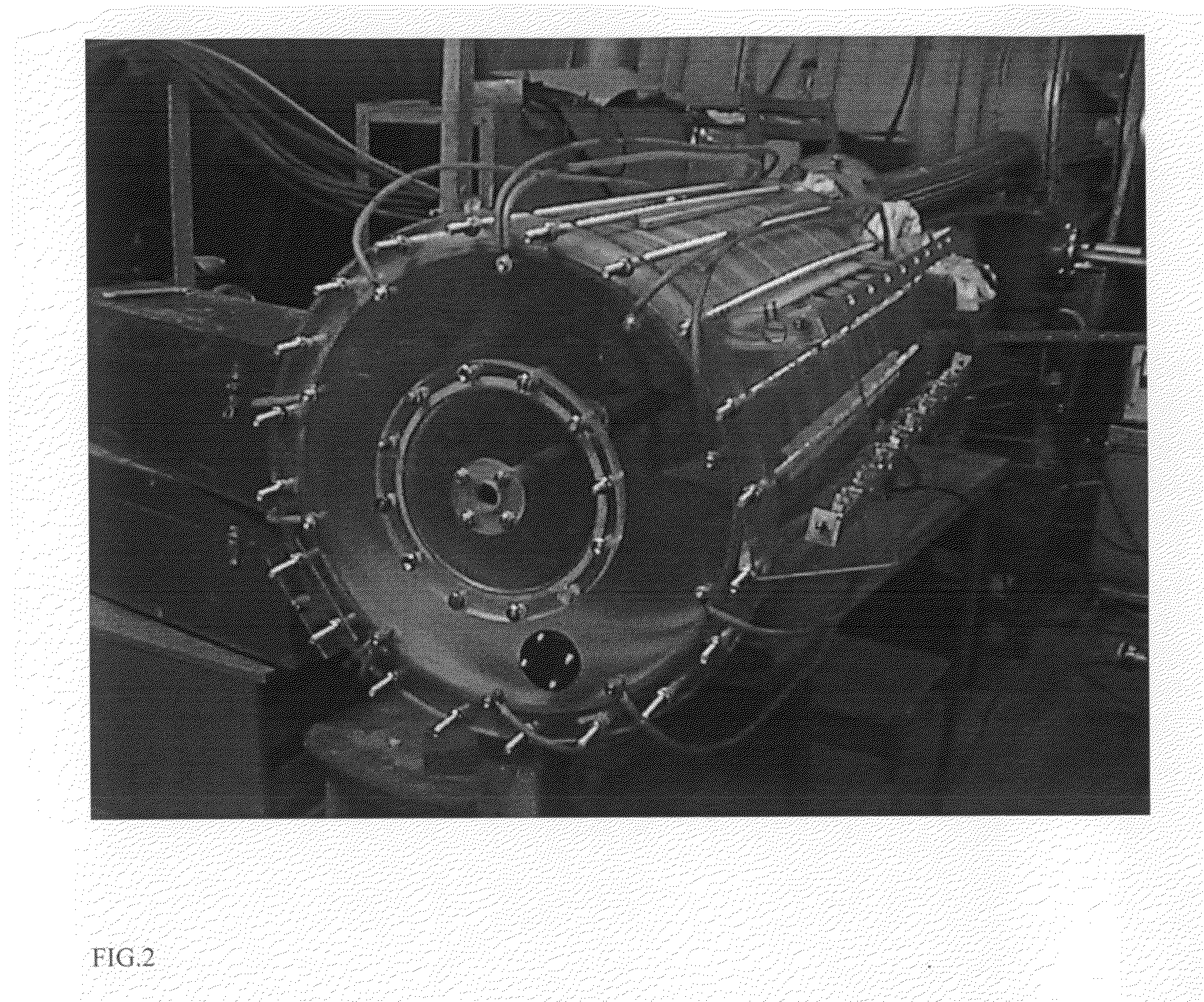

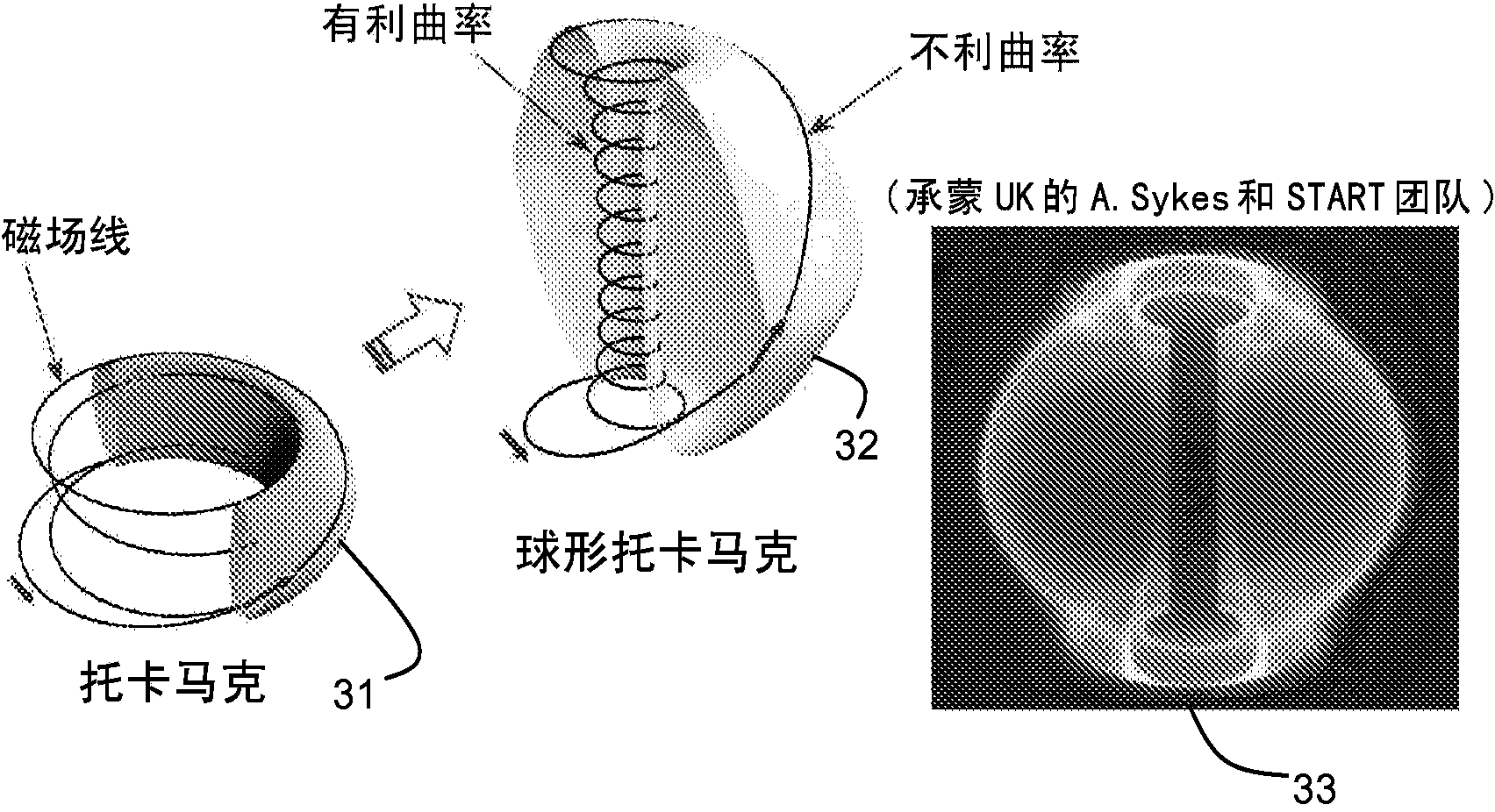

Efficient compact fusion reactor

An efficient compact nuclear fusion reactor for use as a neutron source or energy source is described. The reactor comprises a toroidal plasma chamber and a plasma confinement system arranged to generate a magnetic field for confining a plasma in the chamber. The plasma confinement system is configured so that a major radius of the confined plasma is 1.5m or less. The toroidal magnetic field is operated 5T or less and the plasma current is 5 MA or less. Despite this, [Alpha]-particles generated are confined in the plasma.

Owner:TOKAMAK ENERGY

Magnetic fishing tool and method

Owner:VENTURI OIL TOOLS

Efficient compact fusion reactor

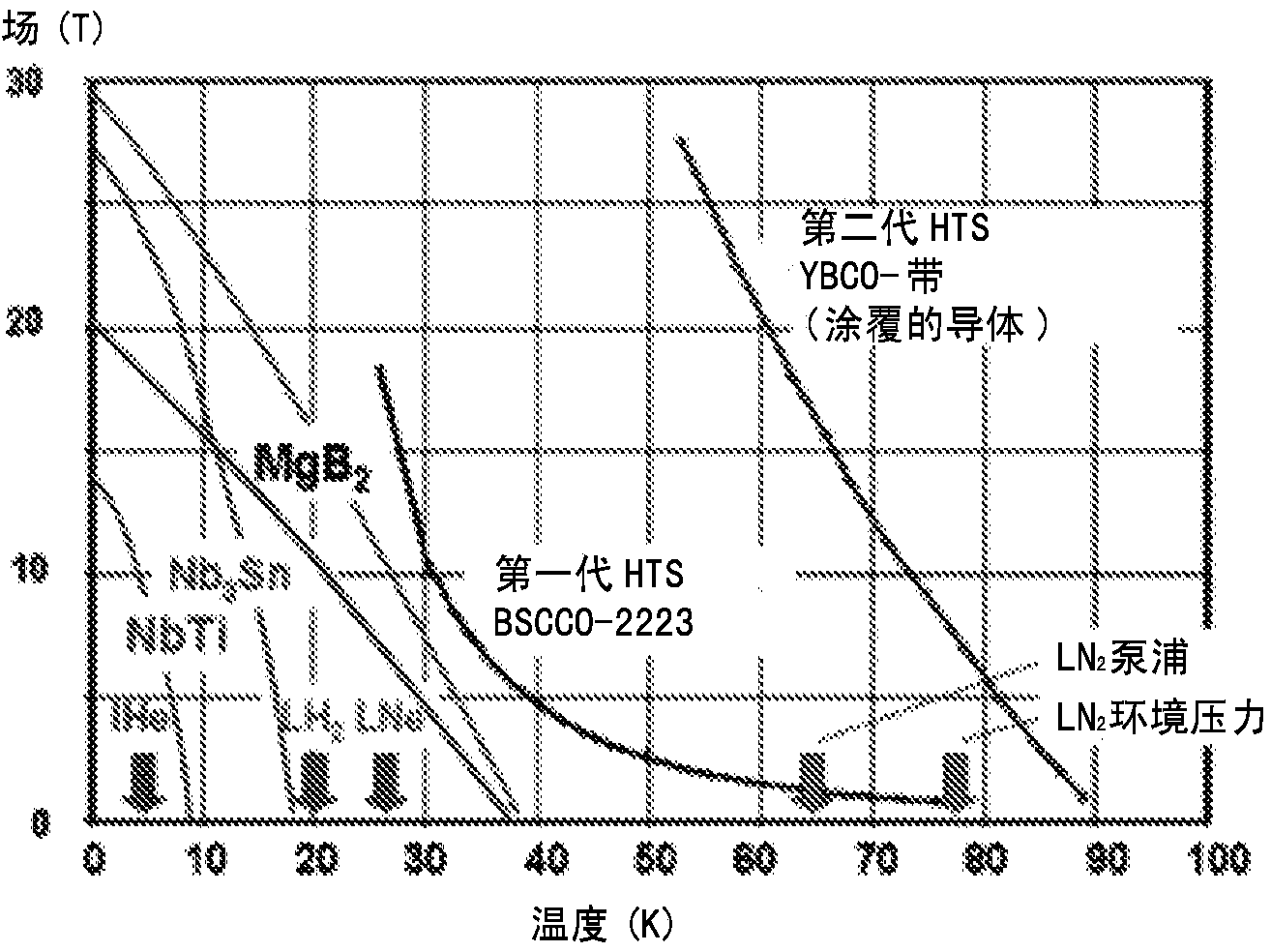

InactiveCN103765999AEfficient heatingNuclear energy generationSuperconducting magnets/coilsNuclear fusionHigh temperature superconducting

An efficient compact nuclear fusion reactor for use as a neutron source or energy source is described. The reactor comprises a toroidal plasma chamber and a plasma confinement system arranged to generate a magnetic field for confining a plasma in the chamber. The plasma confinement system is configured so that a major radius of the confined plasma is 1.5m or less. The reactor is constructed using high temperature superconducting toroidal magnets, which may be operated at low temperature (77K or lower) to provide enhanced performance. The toroidal magnetic field can be increased to 5T or more giving significant increases in fusion output, so that neutron output is very efficient and the reactor can produce a net output of energy.

Owner:TOKAMAK ENERGY

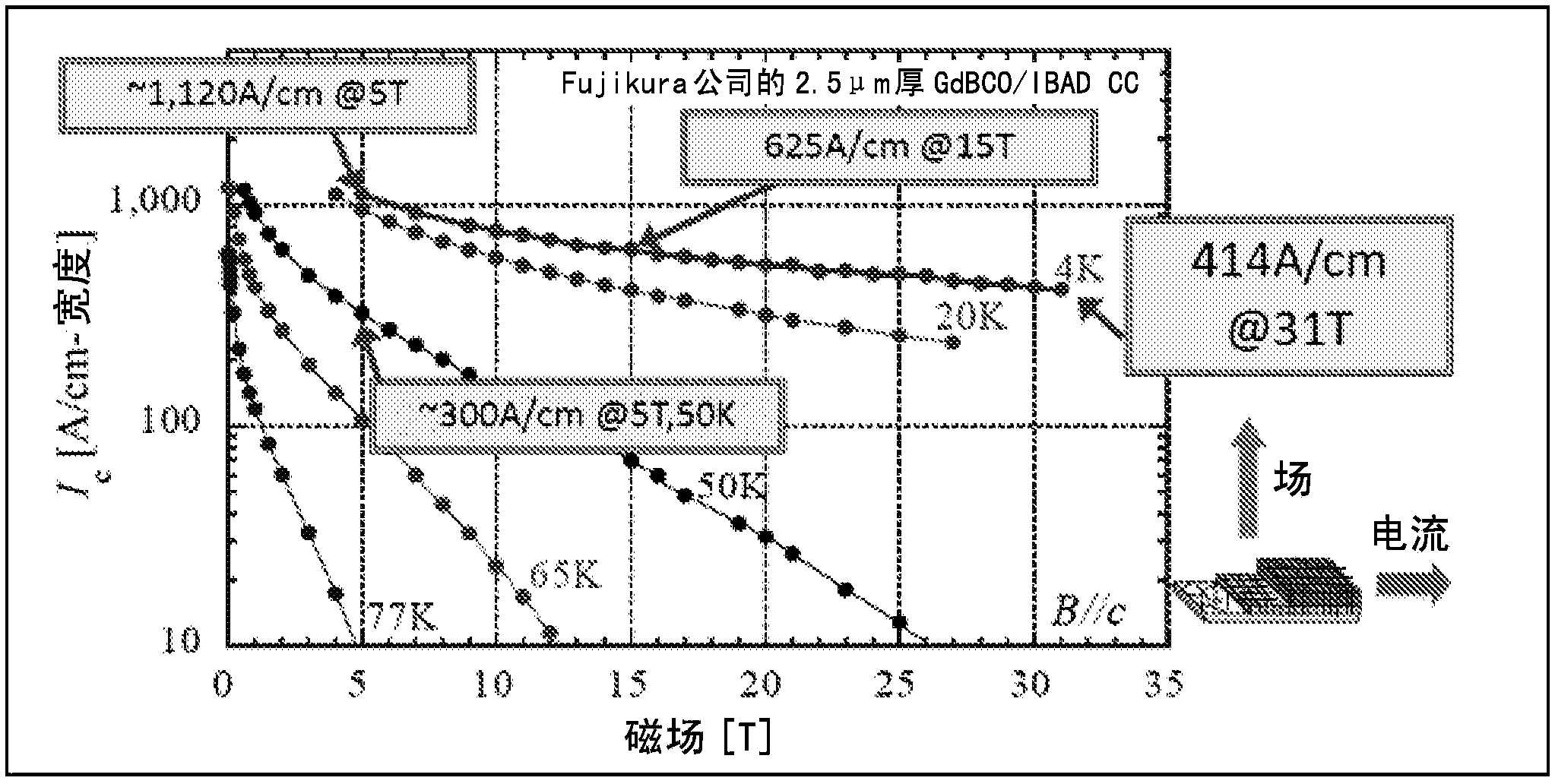

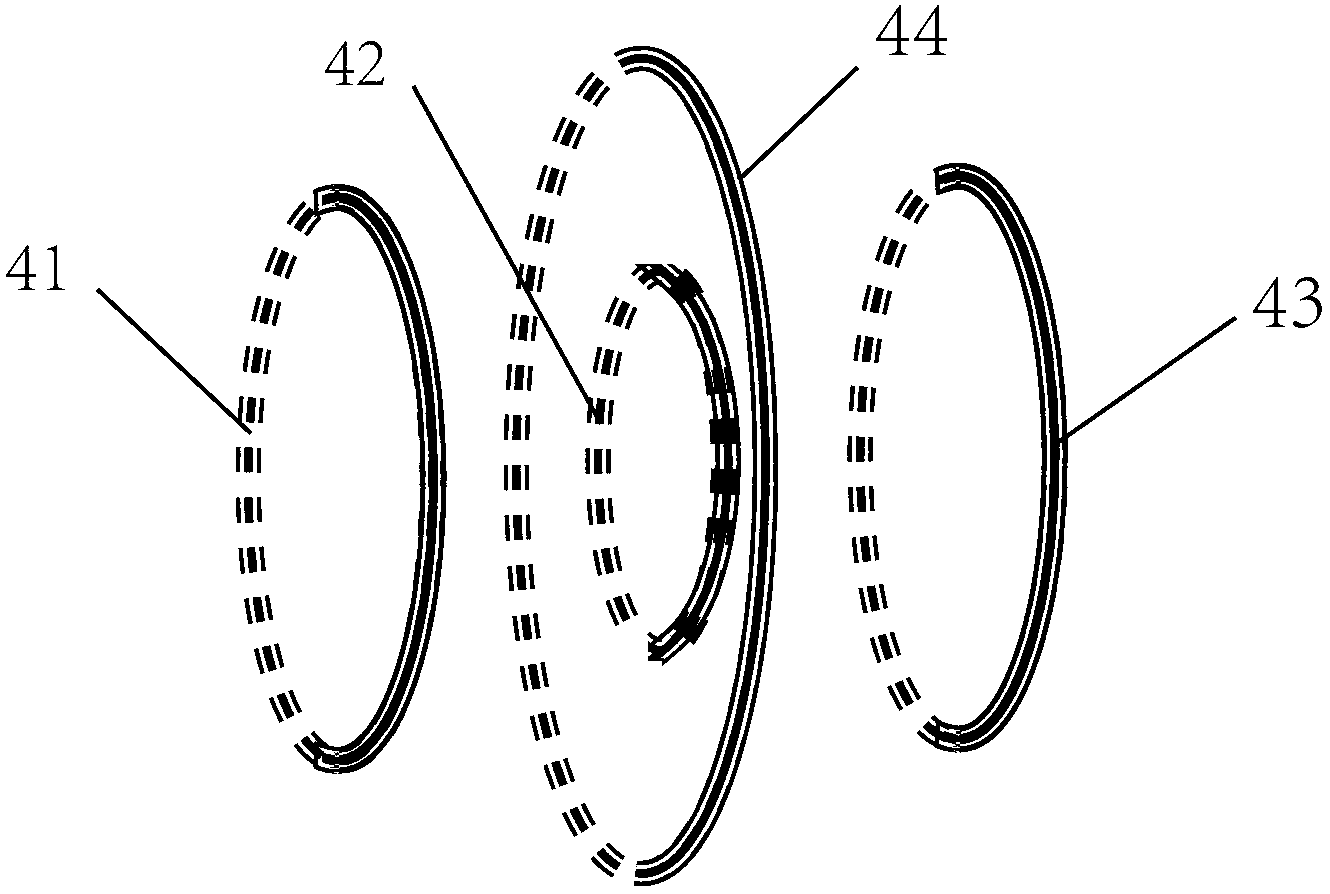

Toroidal field coil for use in a fusion reactor

ActiveCN105637592ANuclear energy generationSuperconducting magnets/coilsNuclear fusionConductor Coil

Disclosed herein is a toroidal field coil for generating a toroidal magnetic field in a nuclear fusion reactor comprising a toroidal plasma chamber having a central column, the toroidal field coil comprising a plurality of windings passing through the central column and around the outside of the plasma chamber. Each winding includes a cable comprising a plurality of stacked HTS tapes, each HTS tape including one or more layers of a high temperature superconductor material. The HTS tapes are arranged such that a face of each HTS tape is parallel to the toroidal magnetic field as the cable passes through the centre column.

Owner:TOKAMAK ENERGY

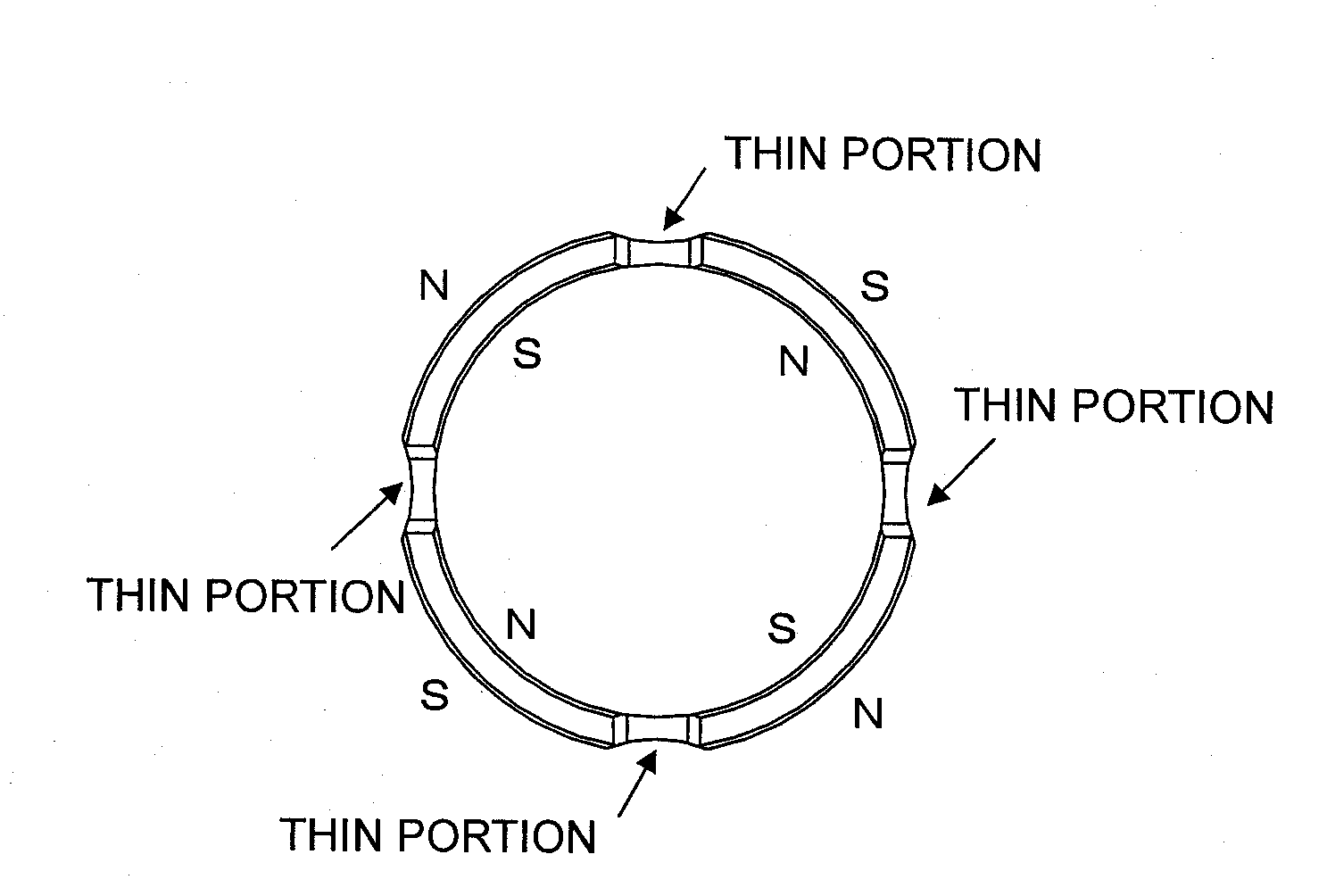

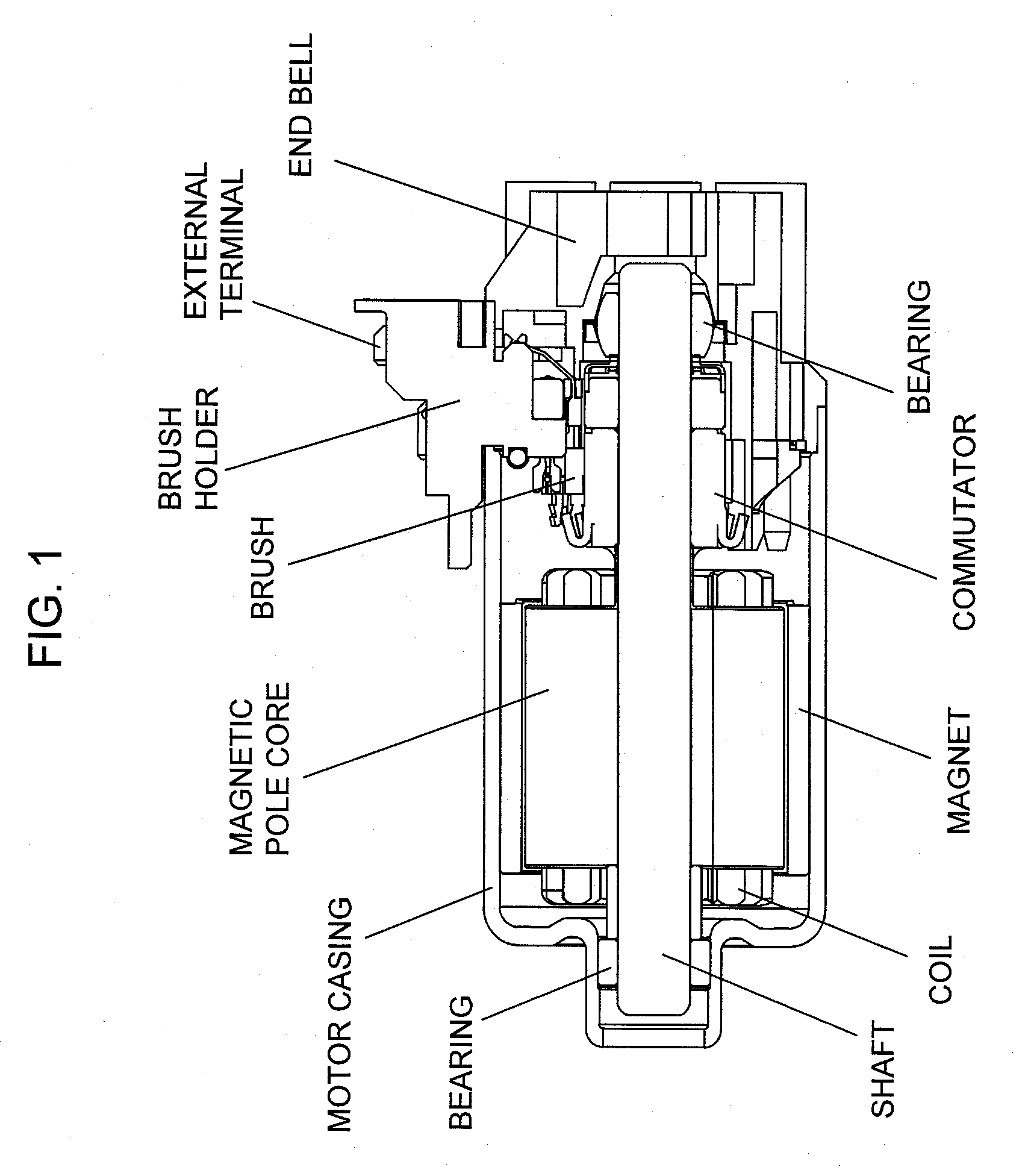

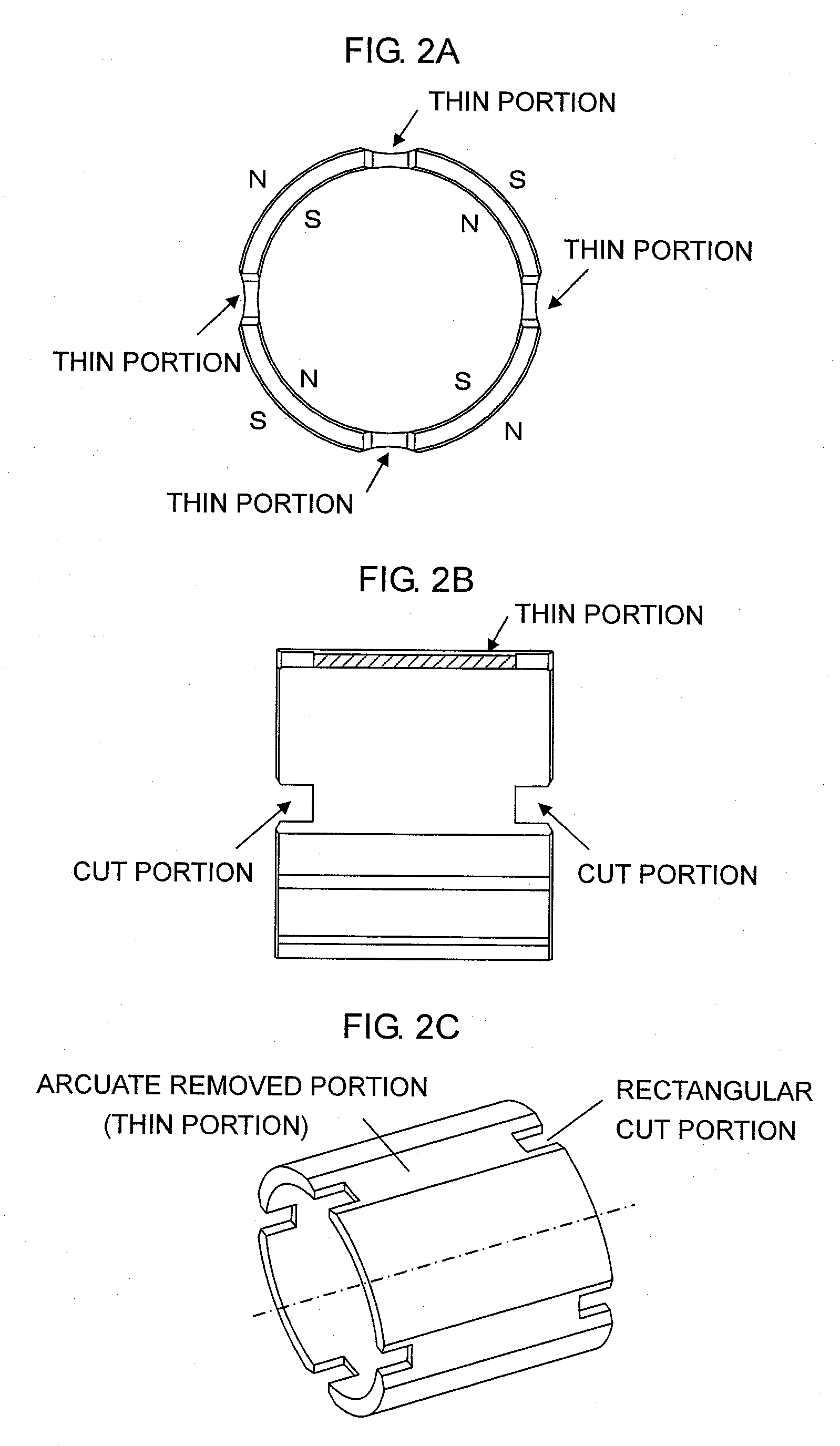

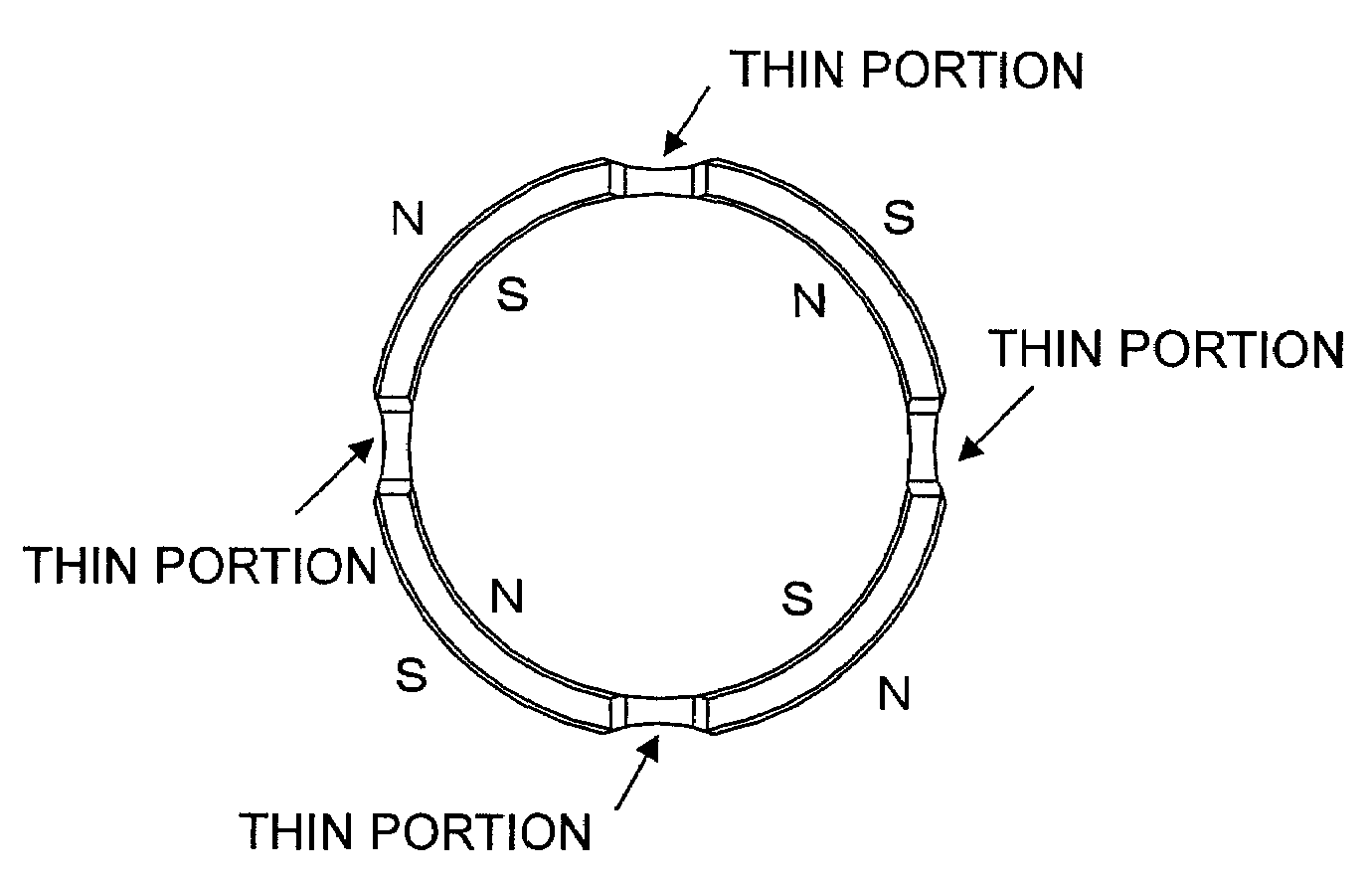

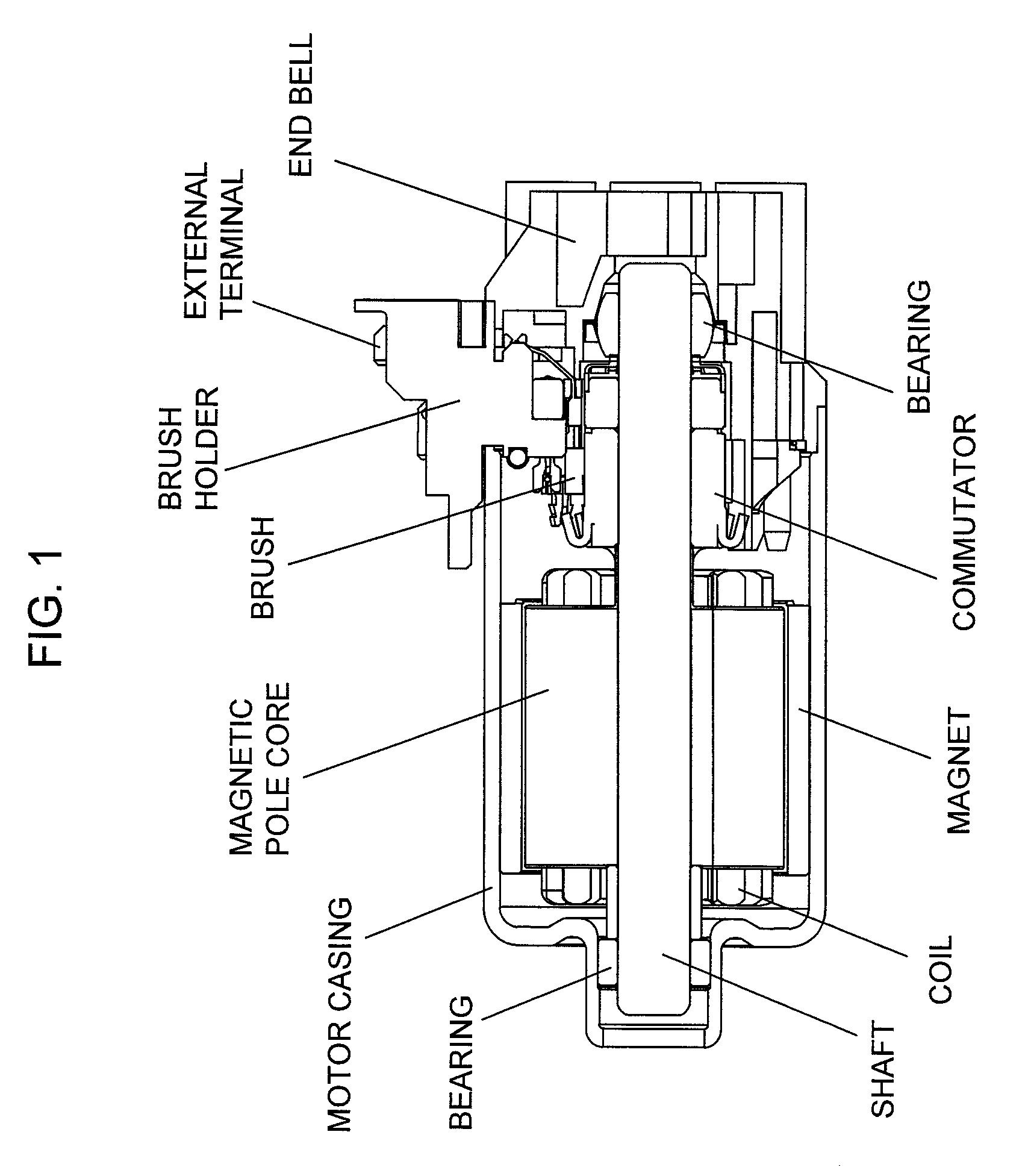

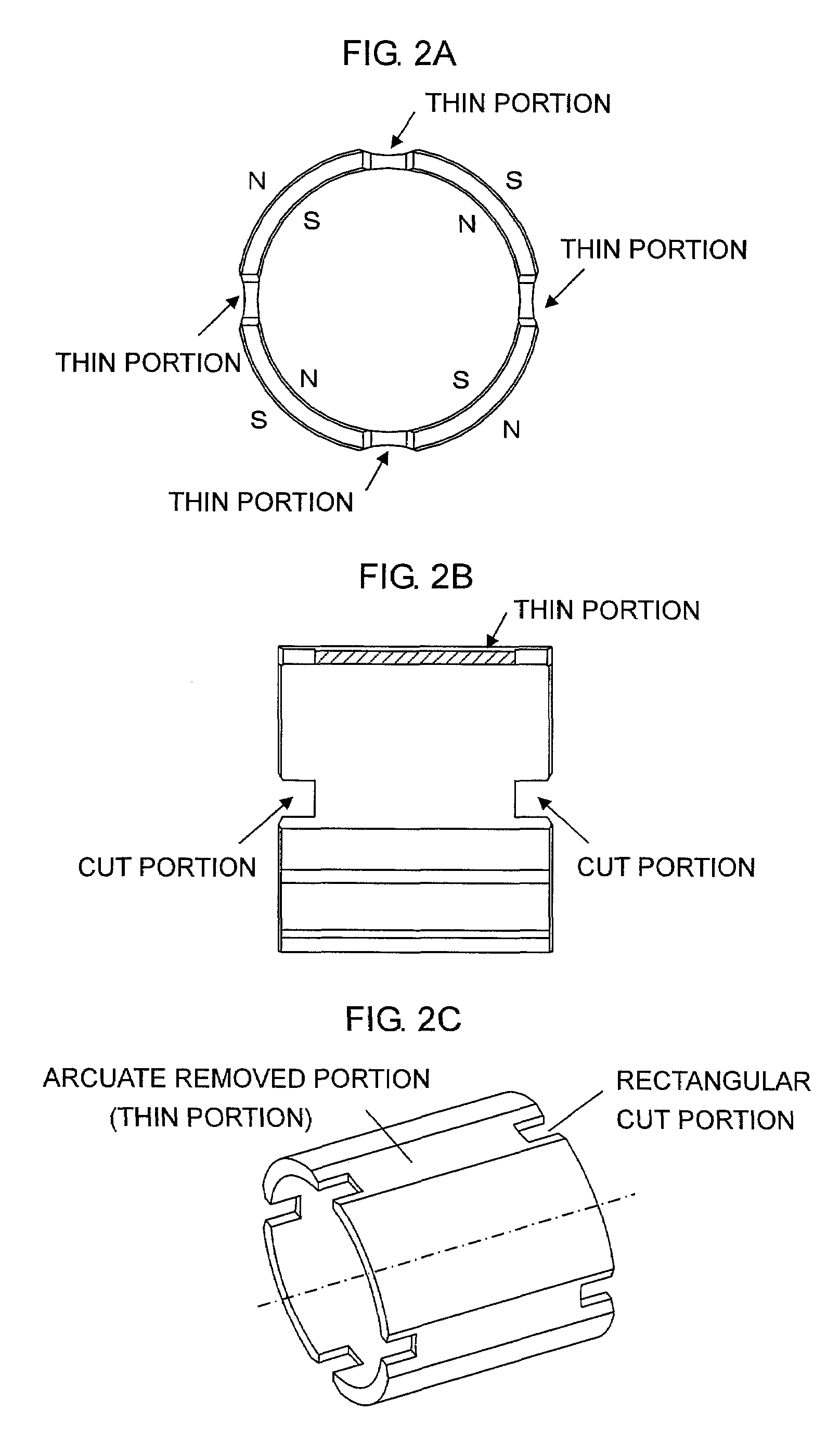

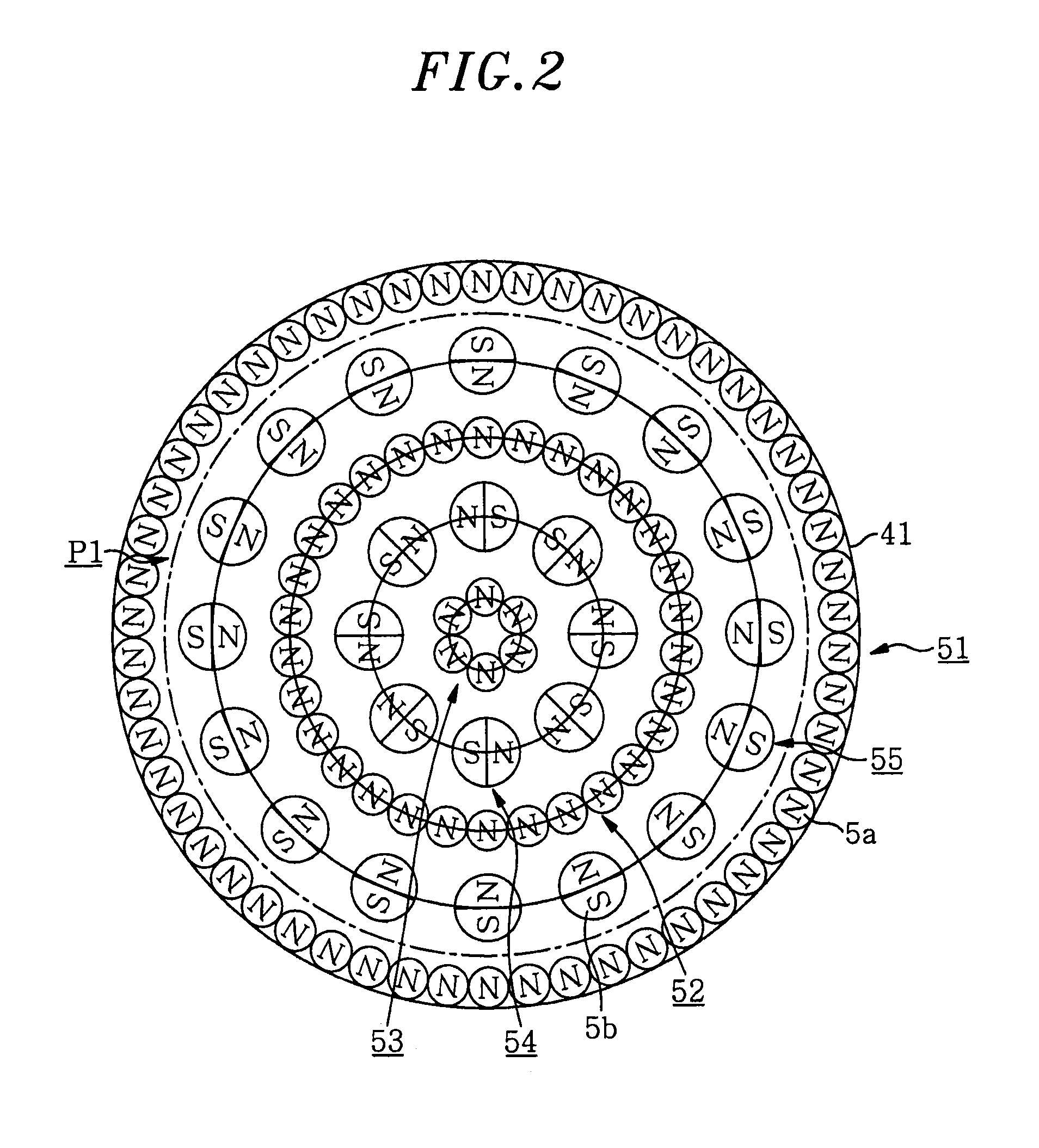

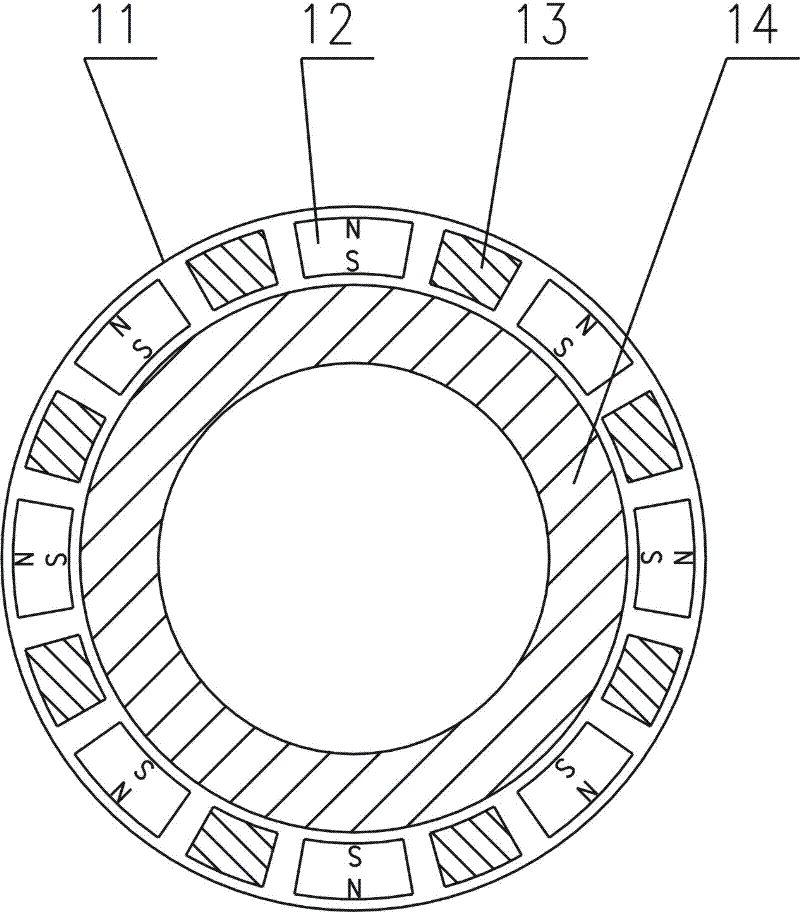

Small-sized motor having ring-shaped field magnet

ActiveUS20080030095A1Reduce volumeLow costMagnetic circuit rotating partsMagnetic circuit stationary partsMagnetic polesMagnetization

A small-sized motor includes a field magnet attached to an inner circumferential surface of a metallic motor casing and having four or more magnetic poles. The field magnet is formed of a single ring-shaped magnet member having a predetermined thickness with respect to the radial direction and a predetermined length with respect to the thrust direction. At each of portions between the magnetic poles formed through magnetization, the magnet member has a thin portion having a reduced thickness with respect to the radial direction, the thin portion being formed by cutting the magnet member from the radially outward side. The magnetization is performed in the radial direction so as to alternately form S poles and N poles in the circumferential direction. At each of portions between the magnetic poles, the magnet member may have cut portions formed at opposite end portions of the magnet member with respect to the thrust direction.

Owner:MABUCHI MOTOR

Magnetic field generating apparatus and method for magnetic resonance imaging

ActiveUS7224167B2Magnetic measurementsElectric/magnetic detectionAxial distanceCondensed matter physics

A magnetic field generating apparatus for use in magnetic resonance imaging (MRI) is disclosed. The apparatus includes an annular magnet field generator defining a patient bore, a gradient coil disposed between the magnetic field generator and the patient bore, a first set of shim elements, and a second set of shim elements. The patient bore has an imaging volume, a z-axis, and an isocenter. The first set of shim elements are disposed at a region between the magnetic field generator and the imaging volume, and the second set of shim elements are disposed at the region at a location having equal to or greater than a specified Z / R ratio, where Z defines an axial distance from the isocenter and R defines a radial distance from the z-axis.

Owner:GENERAL ELECTRIC CO

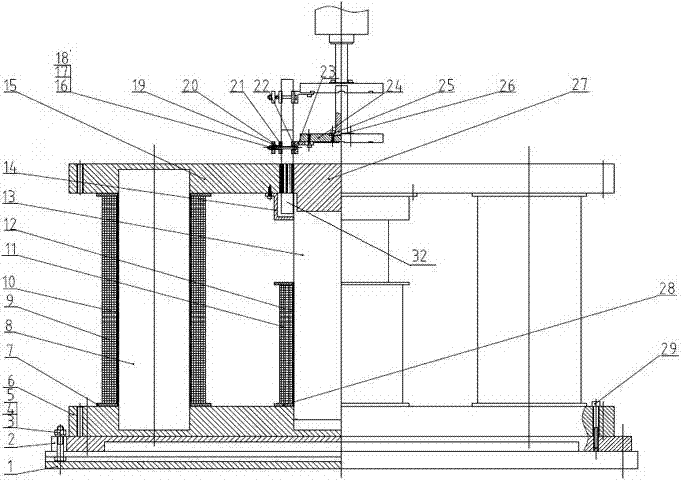

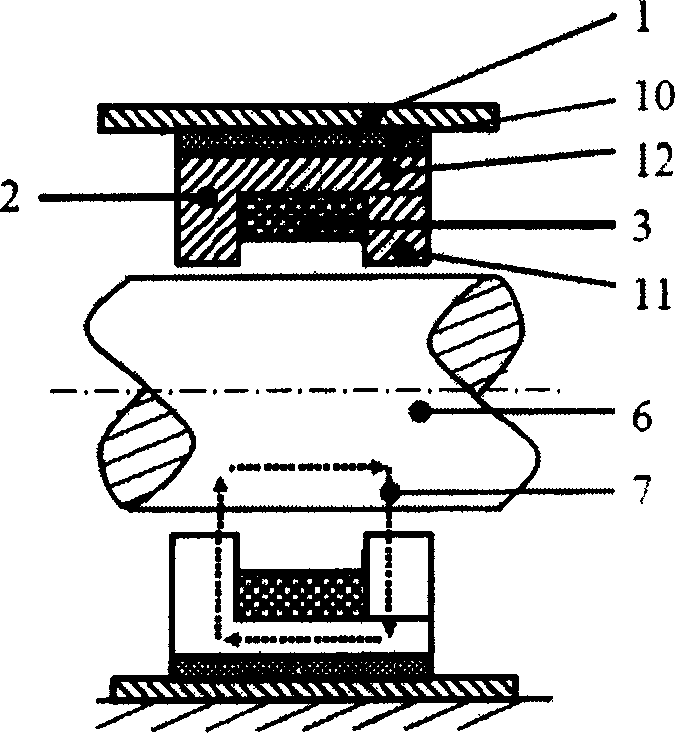

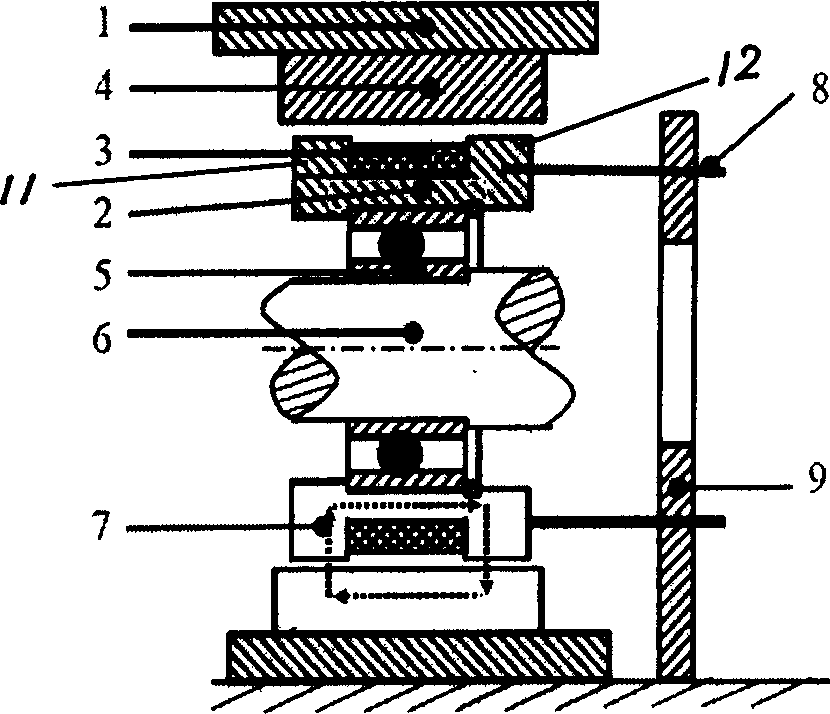

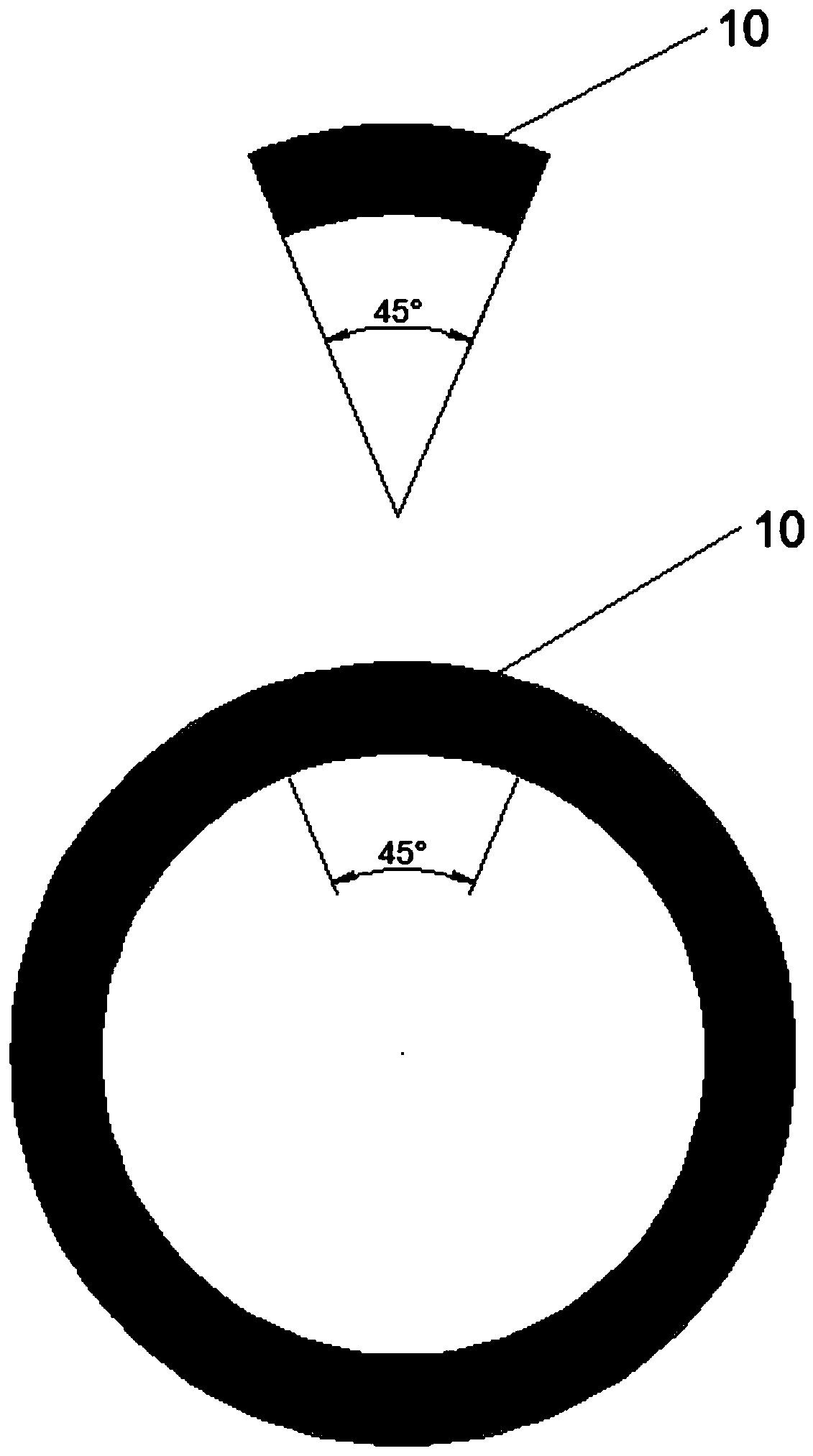

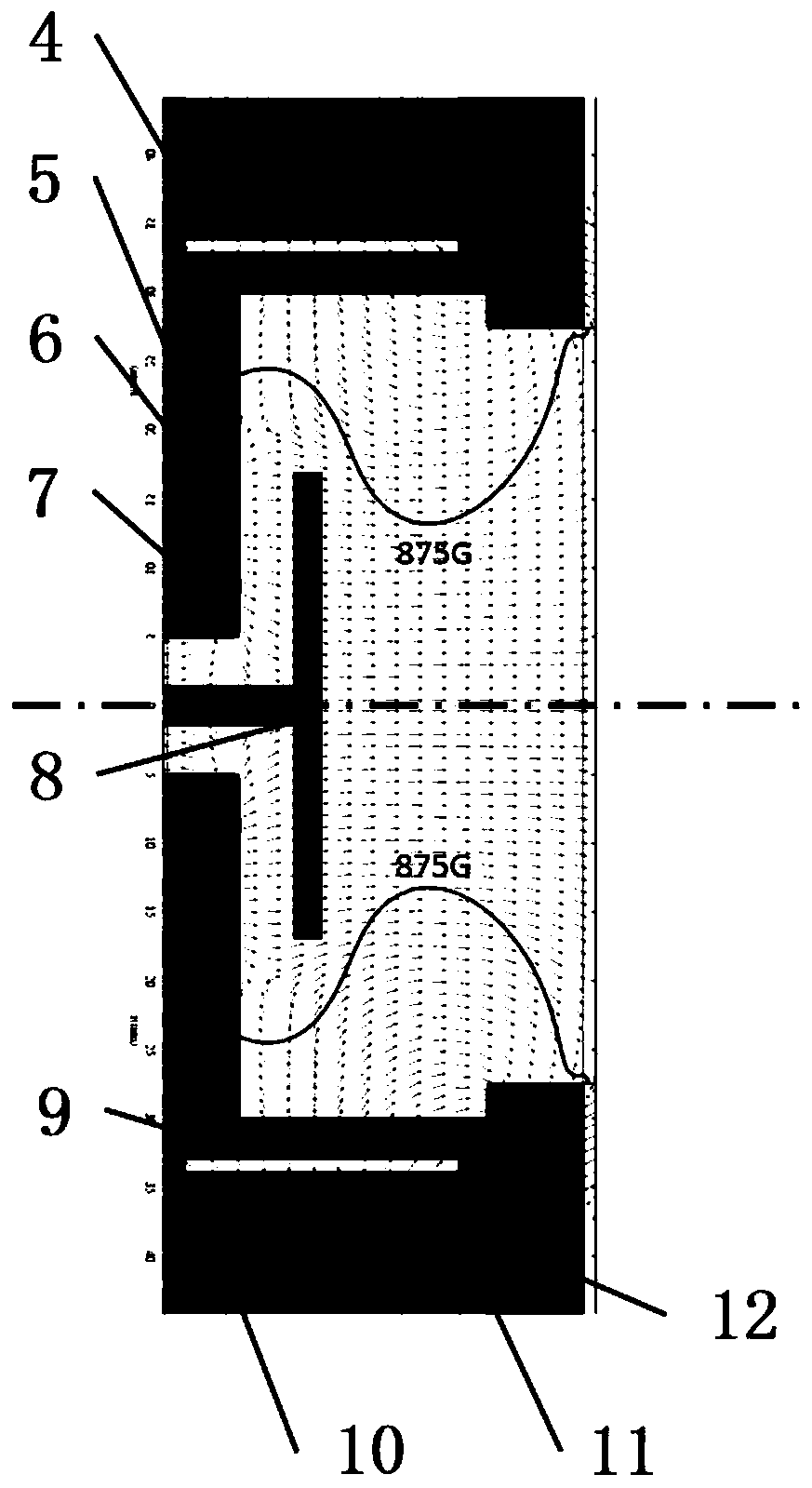

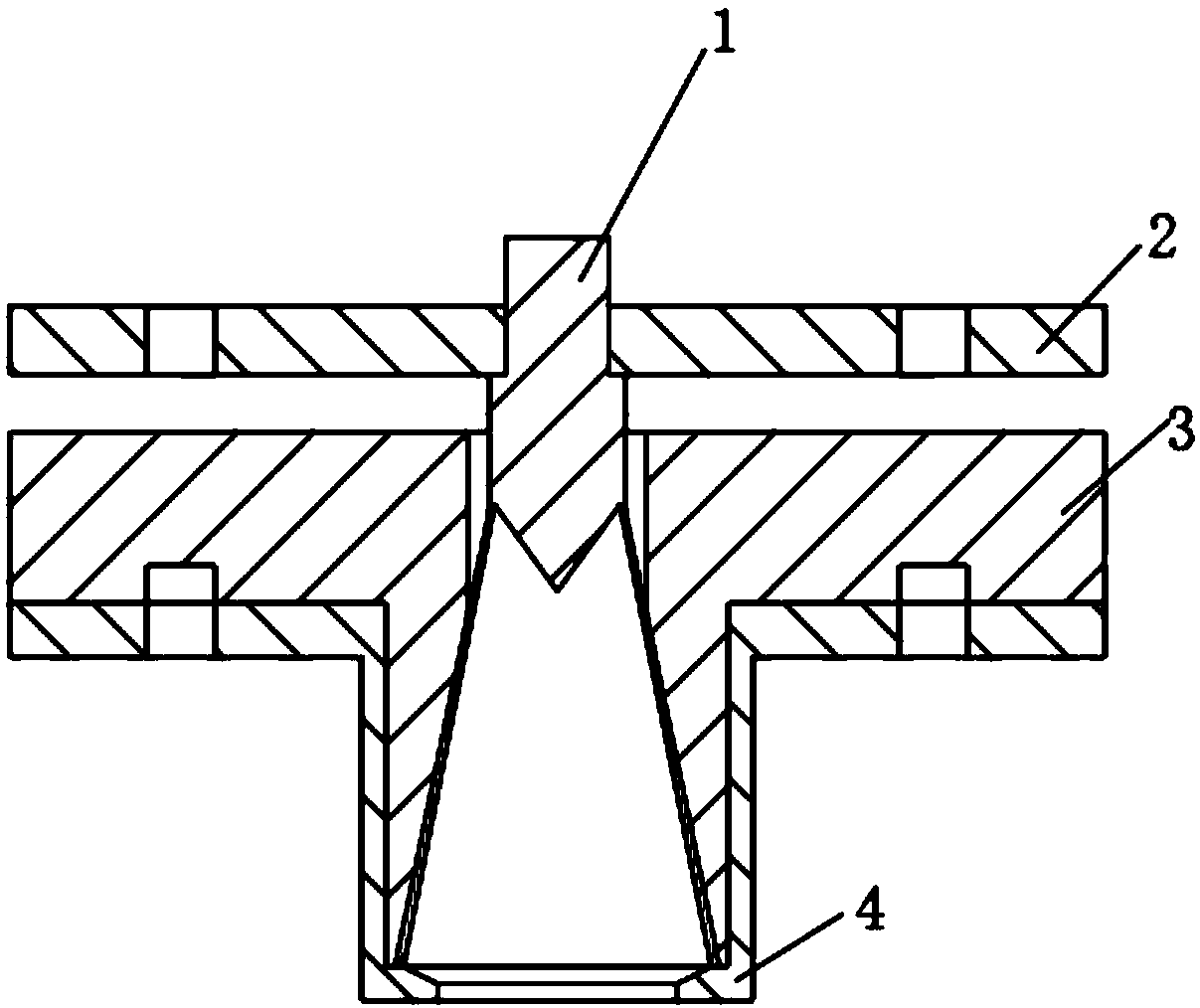

Magnetic abrasive finishing processing method and device of toroidal magnetic field excitation

ActiveCN103612195AImprove efficiencyQuality improvementLapping machinesWork carriersMagnetic polesNon magnetic

The invention discloses a magnetic abrasive finishing processing method and device of toroidal magnetic field excitation. The magnetic abrasive finishing device is mainly composed of an excitation system and a clamp body. The excitation system comprises an upper magnet yoke and a lower magnet yoke. An inner hole is formed in the center of the upper magnet yoke, a magnetic pole is arranged in the inner hole, an annular air gap is formed between the magnetic pole and the upper magnet yoke, and a non-magnetic grinding groove used for containing magnetic grinding materials is formed. The magnetic pole and the lower magnet yoke are connected through a middle iron core, and the middle iron core is sleeved with a middle coil. The upper magnet yoke and the lower magnet yoke are connected through outer iron cores, and each outer iron core is sleeved with an outer coil. After the middle coil and the outer coils are powered on, the magnetic grinding materials form an annular magnetic abrasive finishing brush under the action of magnetic force. A workpiece rotates relative to the magnetic abrasive finishing brush, and magnetic abrasive finishing can be achieved. Automatic precise finishing is achieved on various complex parts, and compared with manual processing, efficiency and quality are improved, and processing cost is lowered.

Owner:HUNAN UNIV

Small-sized motor having ring-shaped field magnet

ActiveUS7732963B2Reduce volumeLow costMagnetic circuit rotating partsMagnetic circuit stationary partsMagnetizationMagnetic poles

A small-sized motor includes a field magnet attached to an inner circumferential surface of a metallic motor casing and having four or more magnetic poles. The field magnet is formed of a single ring-shaped magnet member having a predetermined thickness with respect to the radial direction and a predetermined length with respect to the thrust direction. At each of portions between the magnetic poles formed through magnetization, the magnet member has a thin portion having a reduced thickness with respect to the radial direction, the thin portion being formed by cutting the magnet member from the radially outward side. The magnetization is performed in the radial direction so as to alternately form S poles and N poles in the circumferential direction. At each of portions between the magnetic poles, the magnet member may have cut portions formed at opposite end portions of the magnet member with respect to the thrust direction.

Owner:MABUCHI MOTOR

Electric eddy-current damping device for rotary machine rotor

InactiveCN1609471ASimple structureReduce volumeRotating vibration suppressionElectricityElectrical conductor

The electric eddy current damper of mechanical rotor operates on the principle that conductor moving in magnetic field will generate electric eddy current force proportional directly to the speed of the moving conductor. It includes mainly ring magnet and ring conductor coaxially on the rotor. Around the ring magnet surface, there is winding with some interval in between, and one of the ring magnet and the winding is fixed to the casing for producing non-rotation relative motion. When some current flows through the winding, a ring magnetic field will be established in the interval between the ring magnet and the ring conductor, and the object moving in the magnetic field will produce a damping force proportional to the motion speed to reduce vibration of the rotor system and raise the stability of the rotor system. Being simple and convenient, the electric eddy current damper may be applied in various kinds of mechanical rotor systems.

Owner:ZHEJIANG UNIV

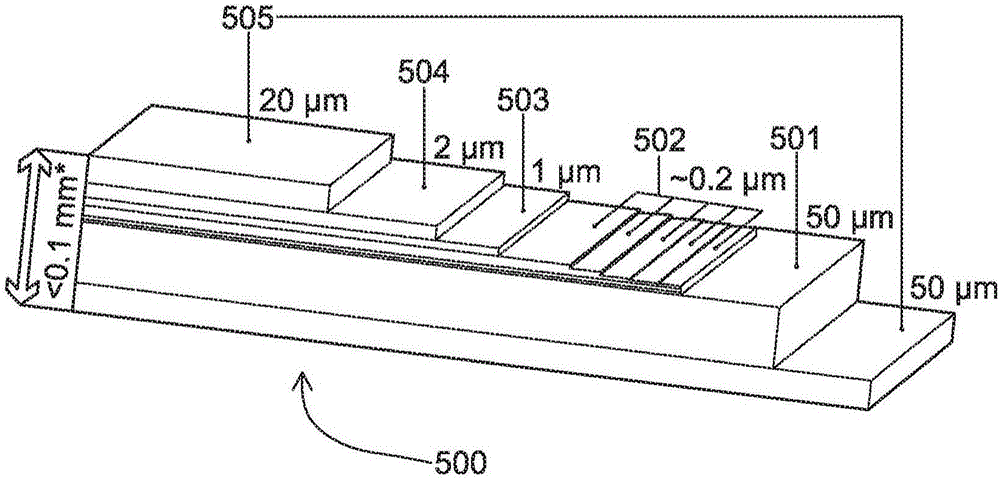

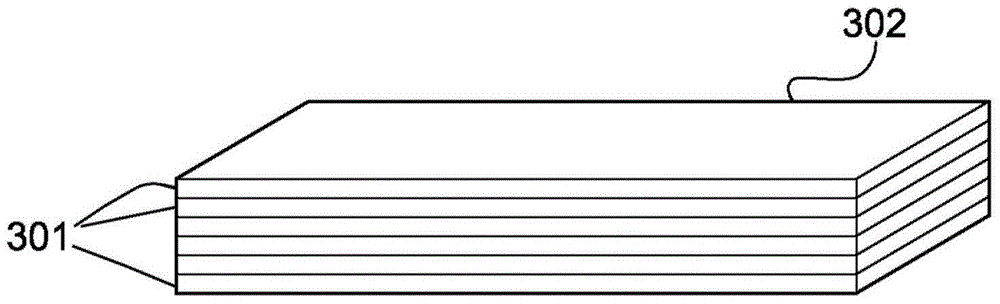

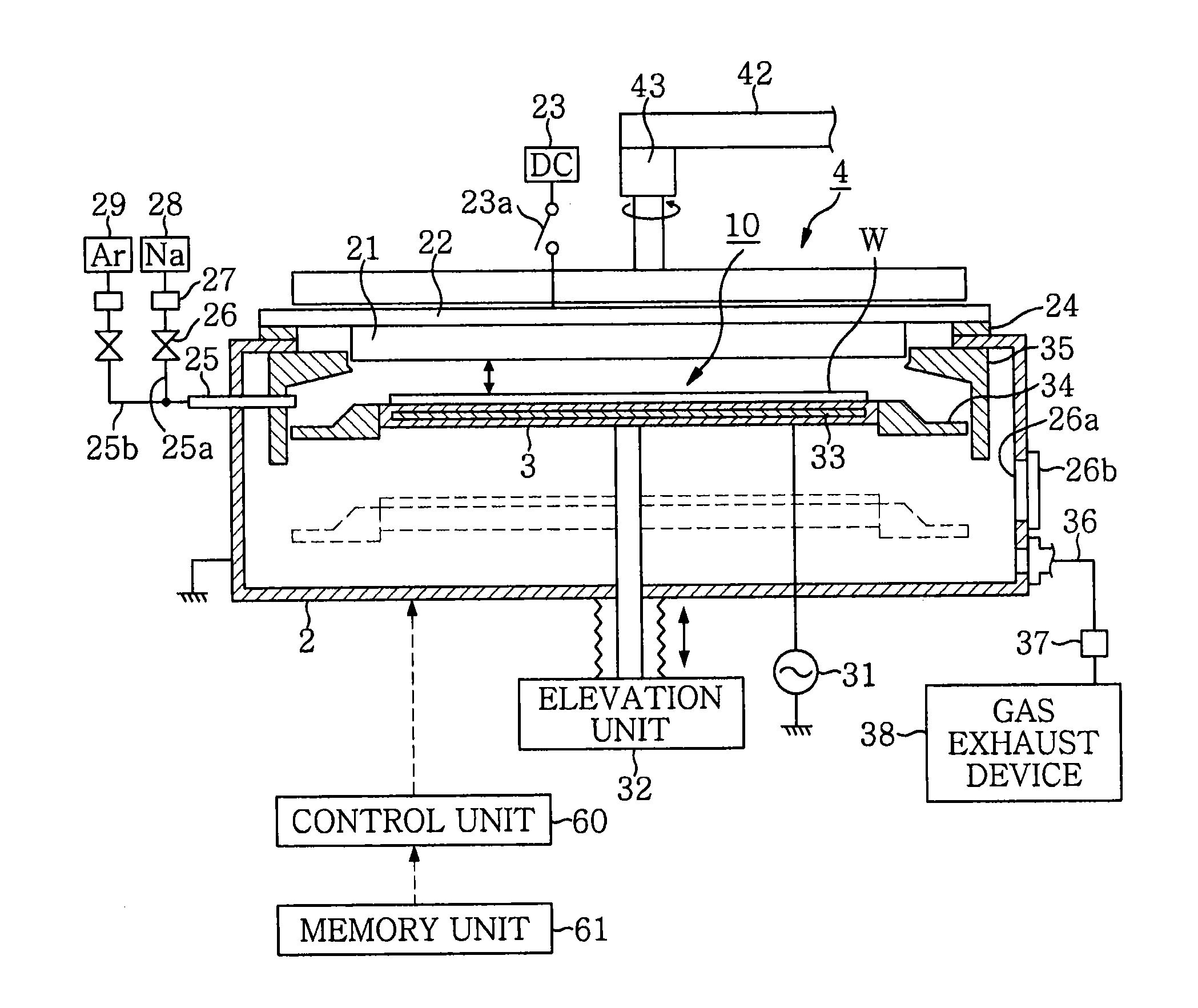

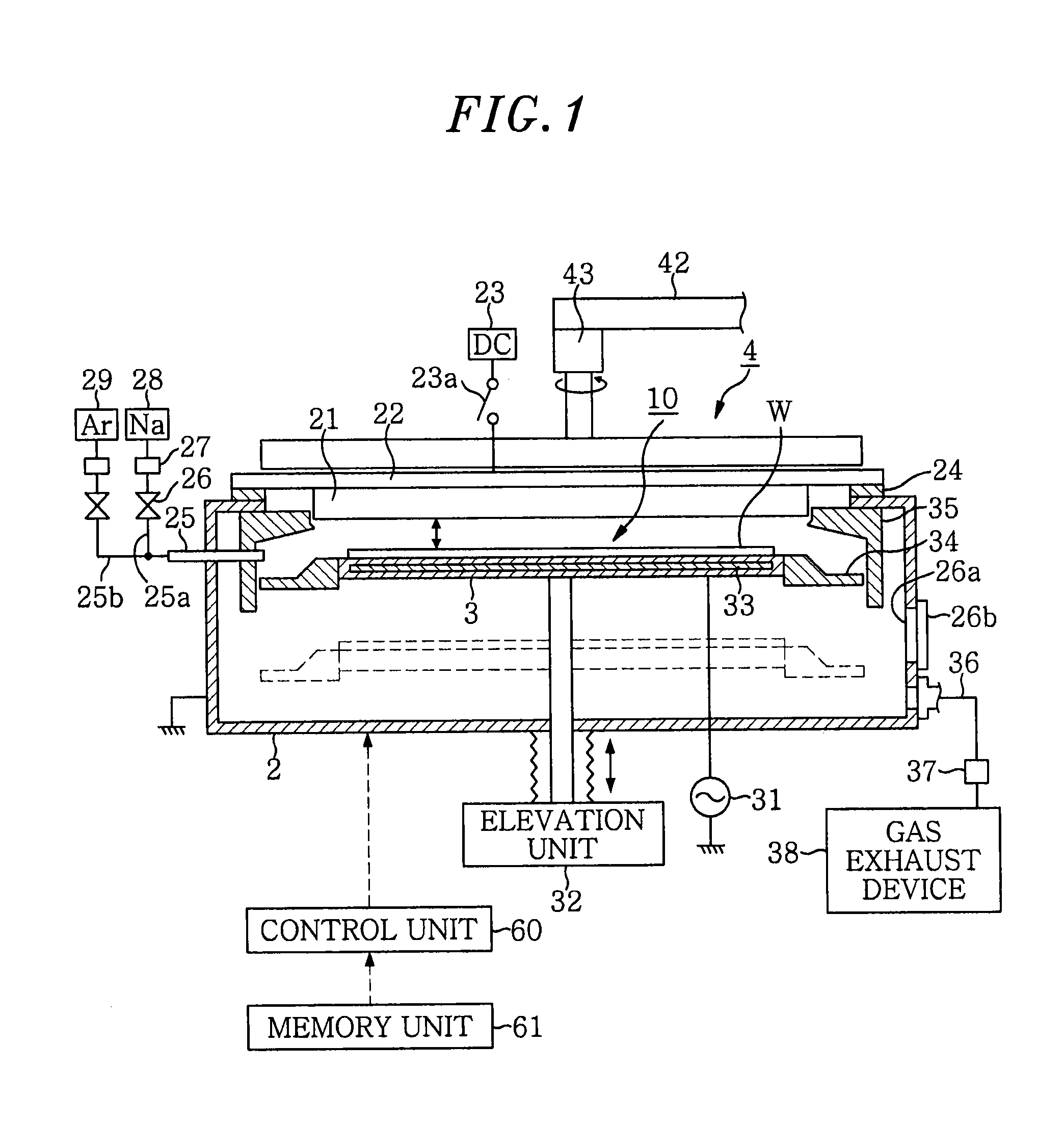

Magnetron sputtering apparatus and film forming method

A target is provided opposite to a wafer mounted on in a vacuum chamber, and a magnet array body is disposed above the target. In the magnet array body, ring-shaped magnet arrays are arranged to generate annular magnetic fields in the circumferential direction of the wafer, and a sputtering film formation is performed by switching between the magnetic fields.

Owner:TOKYO ELECTRON LTD

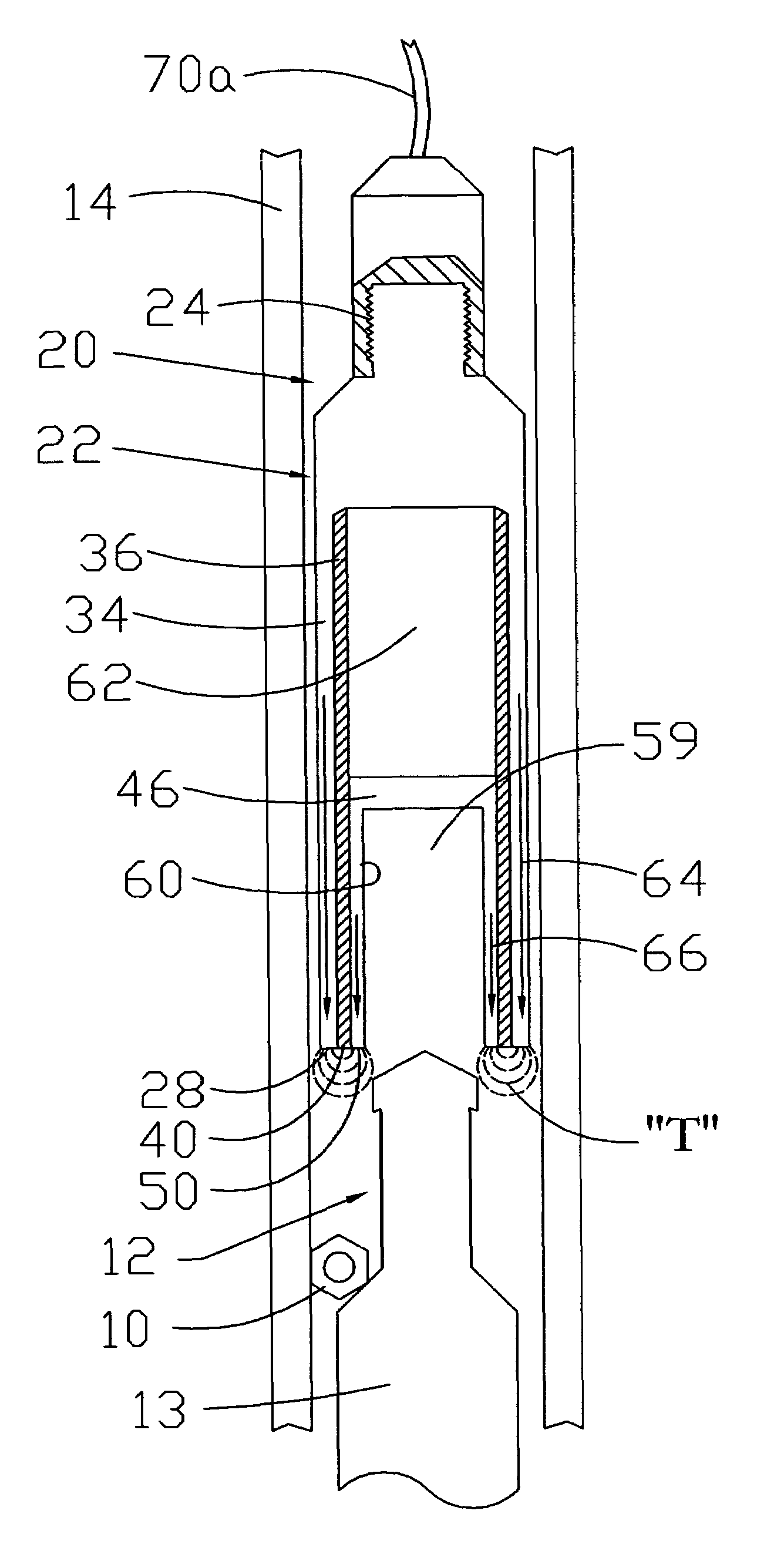

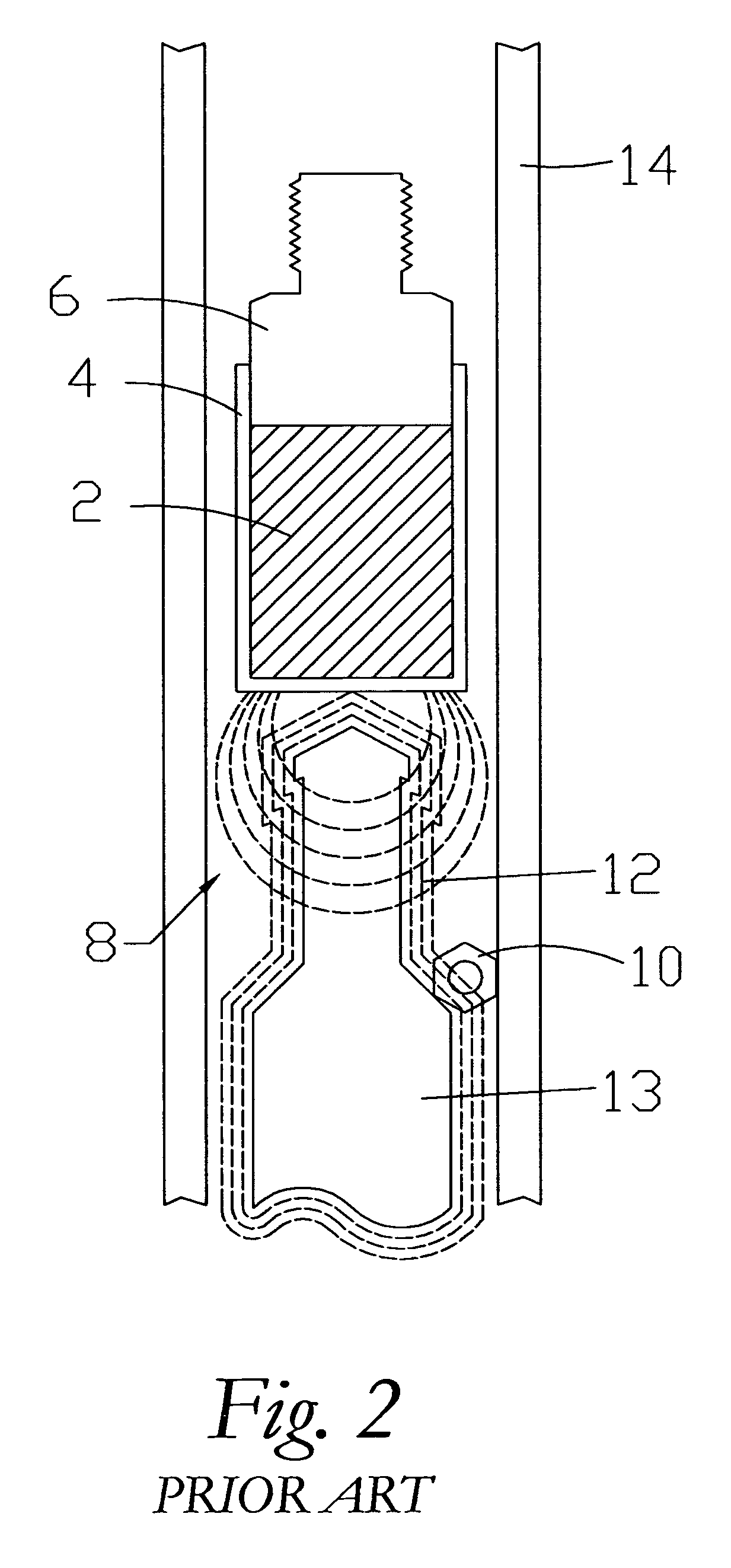

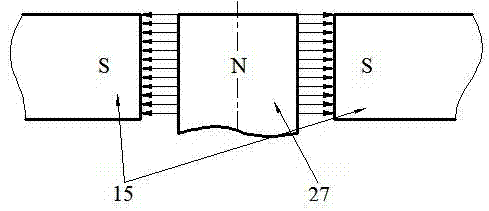

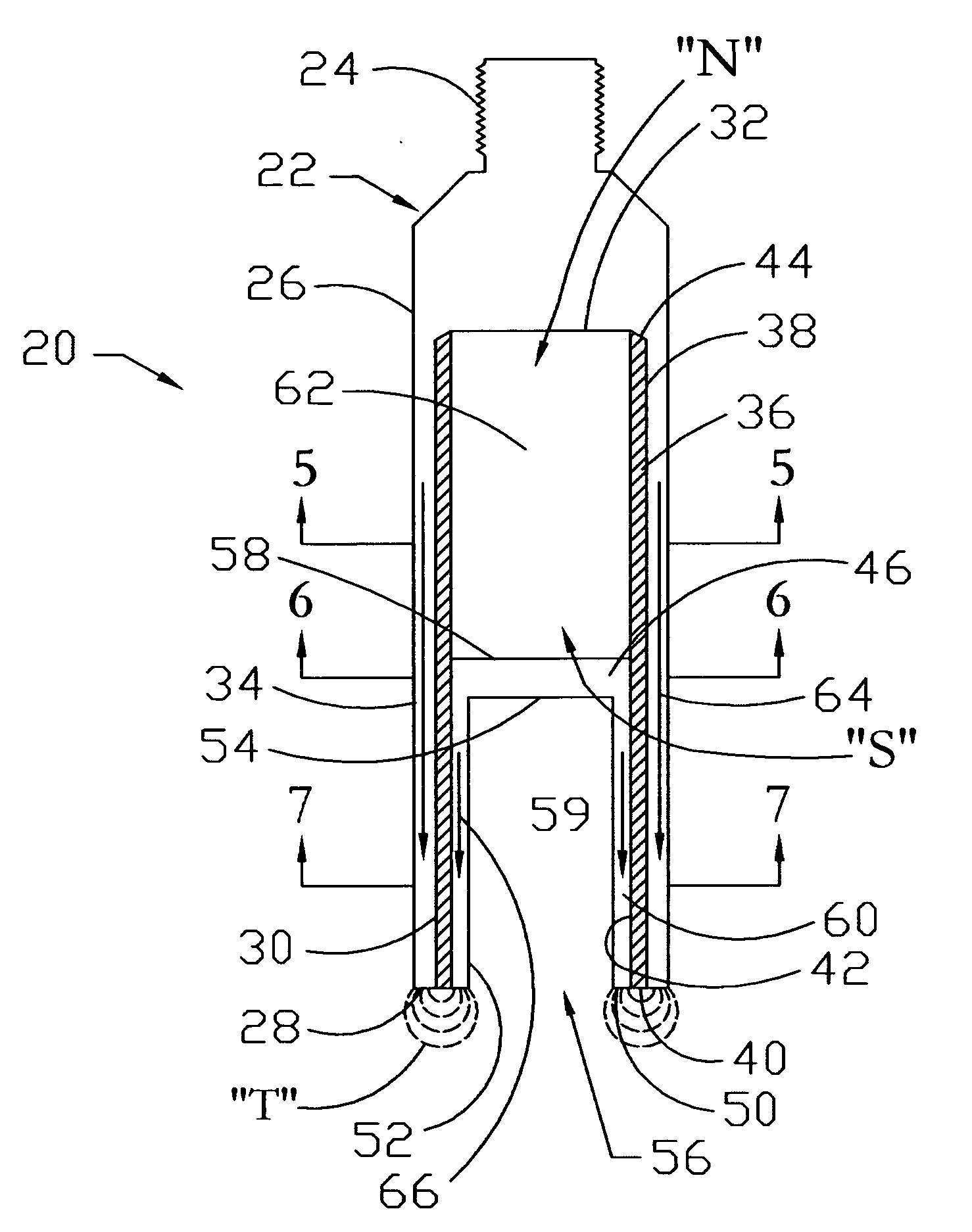

Magnetic fishing tool and method

An apparatus for retrieving metal objects. The apparatus includes a housing with an inner part, with the housing having a first wall. The apparatus further includes a sleeve disposed within the housing, with the sleeve being constructed of a non-magnetic conduction material. A magnet is disposed within the sleeve, with the magnet having a north pole and a south pole. The apparatus further includes a container disposed within the sleeve, the container having a second wall. In the most preferred embodiment, the first wall defines a first pathway for magnetic lines of flux for the north pole of the magnet and wherein the second wall defines a second pathway for magnetic lines of flux for the south pole of the magnet so that a toroidal magnetic field is formed about the distal end of the sleeve. A method of retrieving a metal object within a well bore is also disclosed.

Owner:VENTURI OIL TOOLS

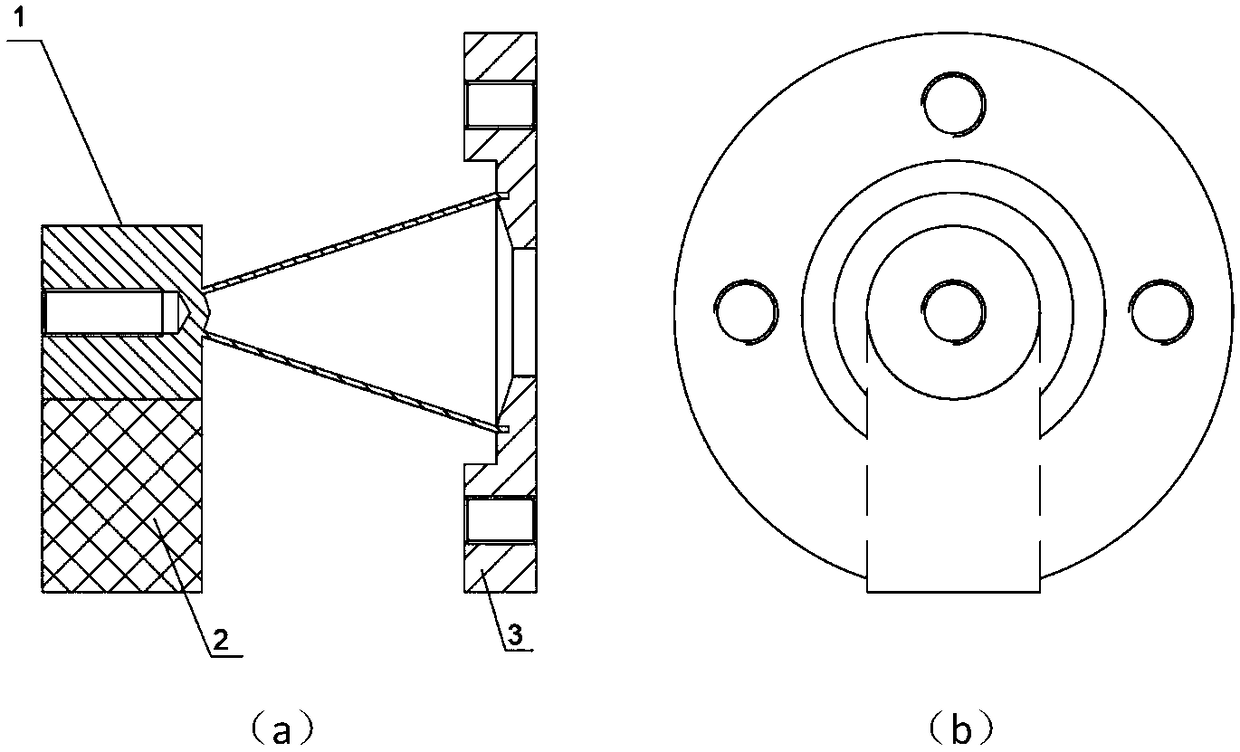

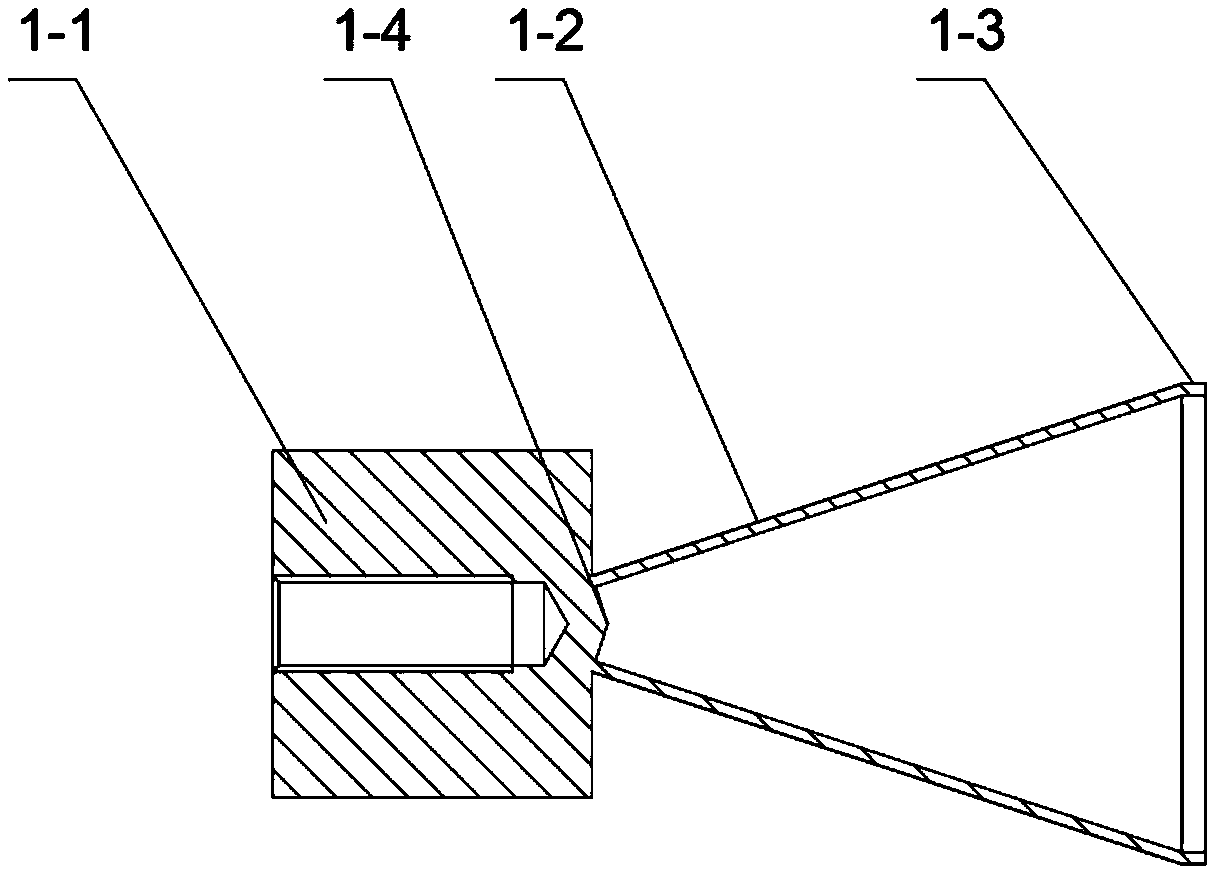

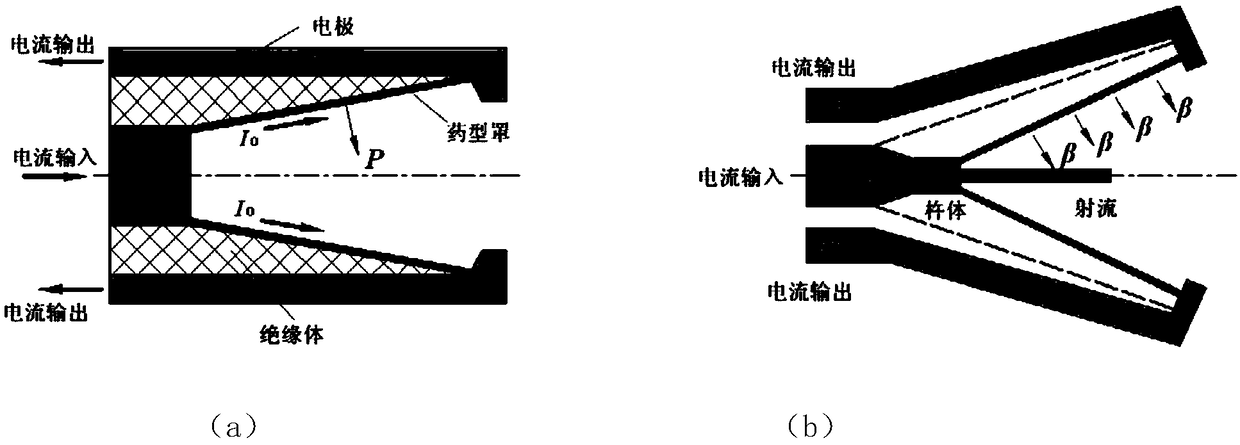

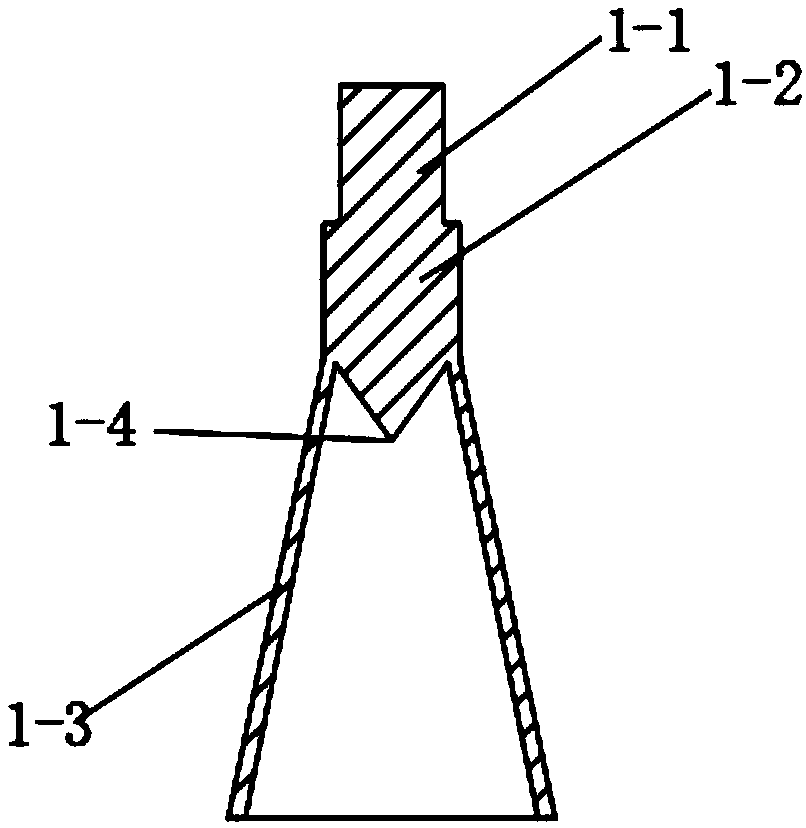

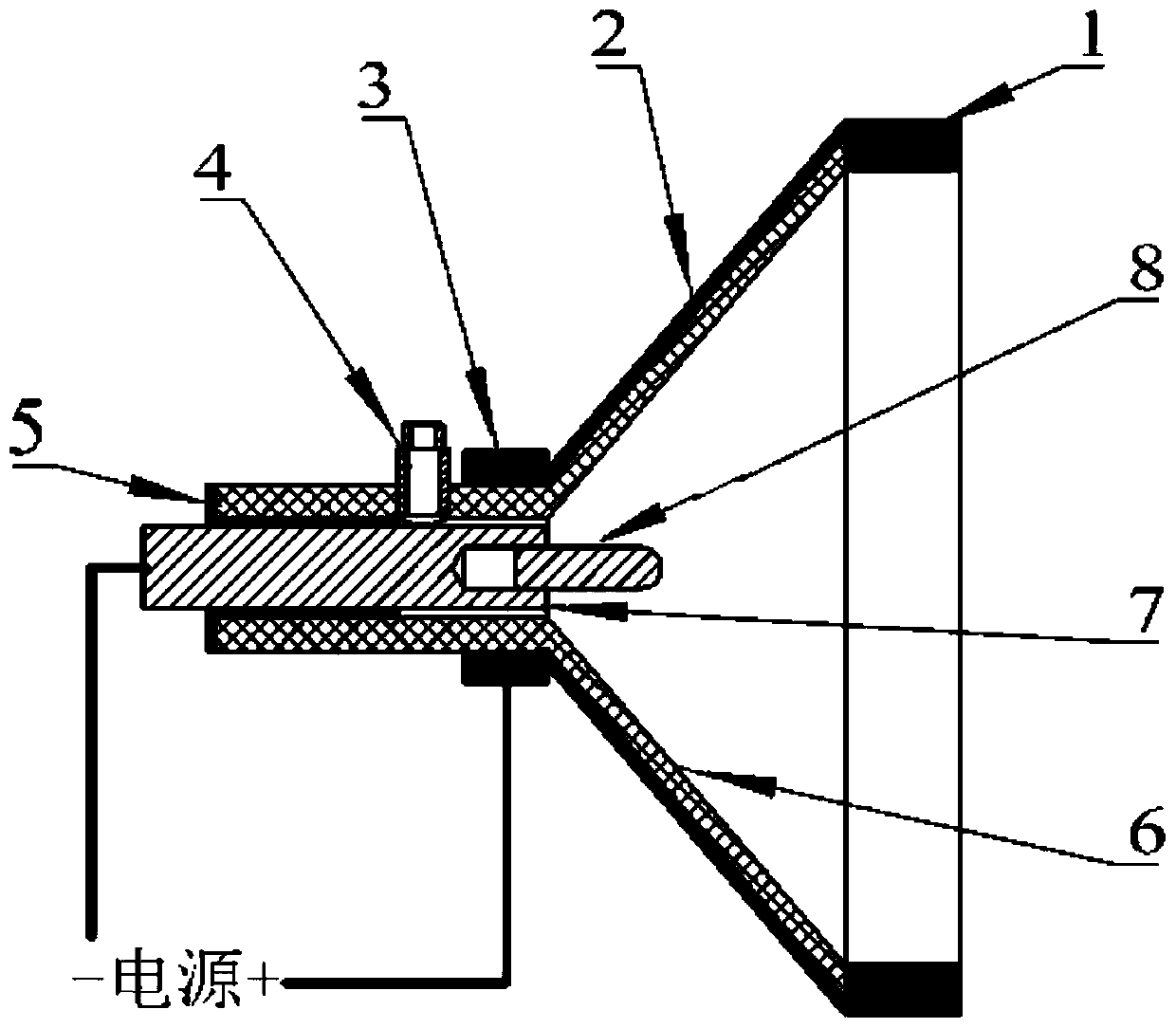

Jet flow forming device with strong magnetic driving

The invention discloses a jet flow forming device with strong magnetic driving. The jet flow forming device with strong magnetic driving comprises a liner device, a pedestal and an output end. A capacitor unit with high energy storage is used as an initial loading energy source to generate strong electric current of a megampere level, a strong magnetism loading manner is innovatively adopted to enable the electric current to flow through the surface of the metal liner and generate a toroidal magnetic field, and the metal liner stresses ampere force converging in the axial direction and then overwhelms the liner to form metal jet flow. The higher the electric current flowing through the liner, the higher overwhelming speed of the liner is, so that the speed of the head of jet flow is higher, and the penetration power of the jet flow is higher. With the jet flow forming device with strong magnetic driving, jet flow forming measures of new concepts and new principles can be enriched, thesingle mode, used for decades, of explosive driving forming jet flow is broken through, and the methods of driving jet flow forming are expanded. The jet flow forming device with strong magnetic driving can be applied to high-speed jet flow forming and hole forming power enhancement.

Owner:NANJING UNIV OF SCI & TECH

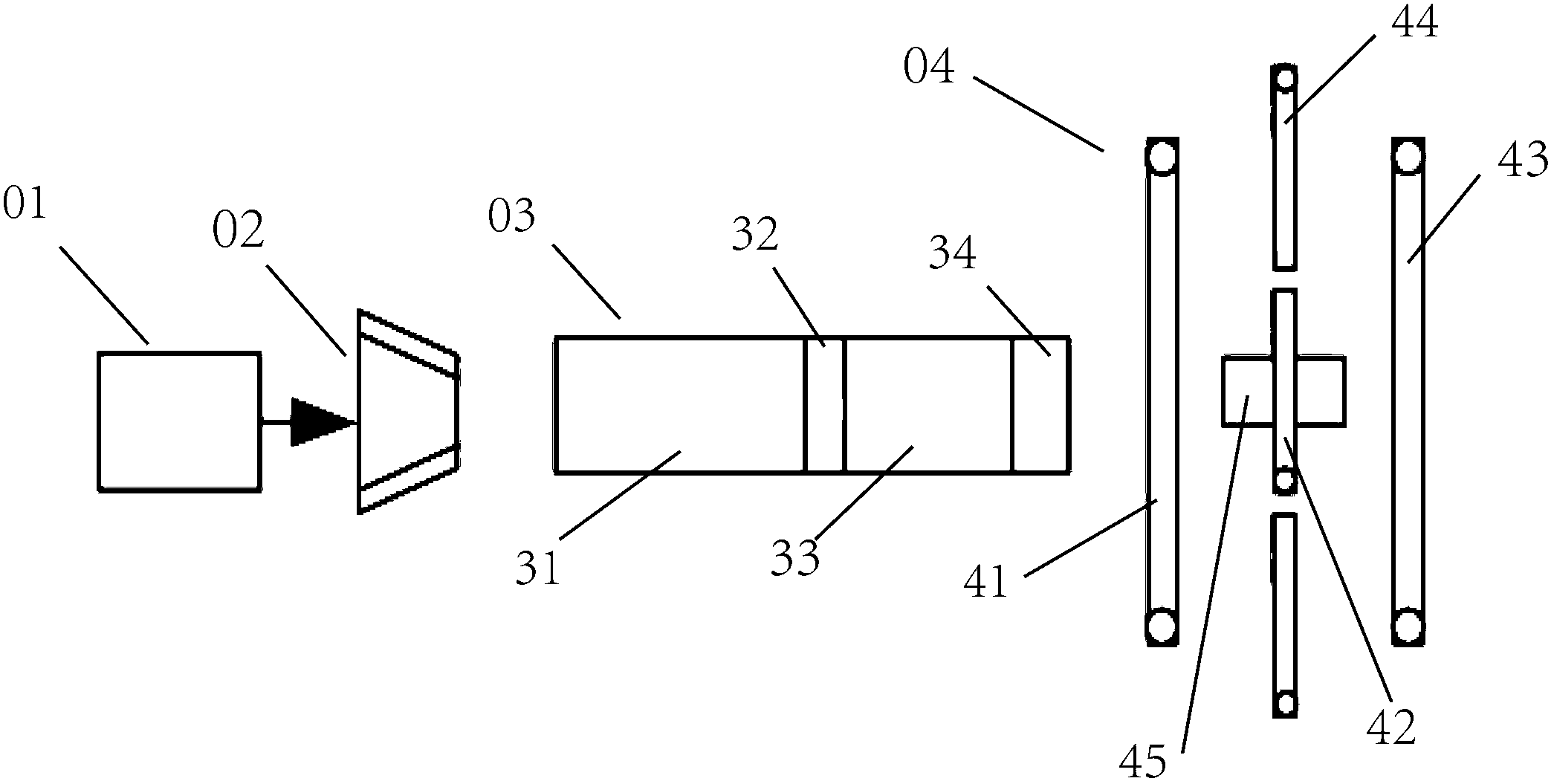

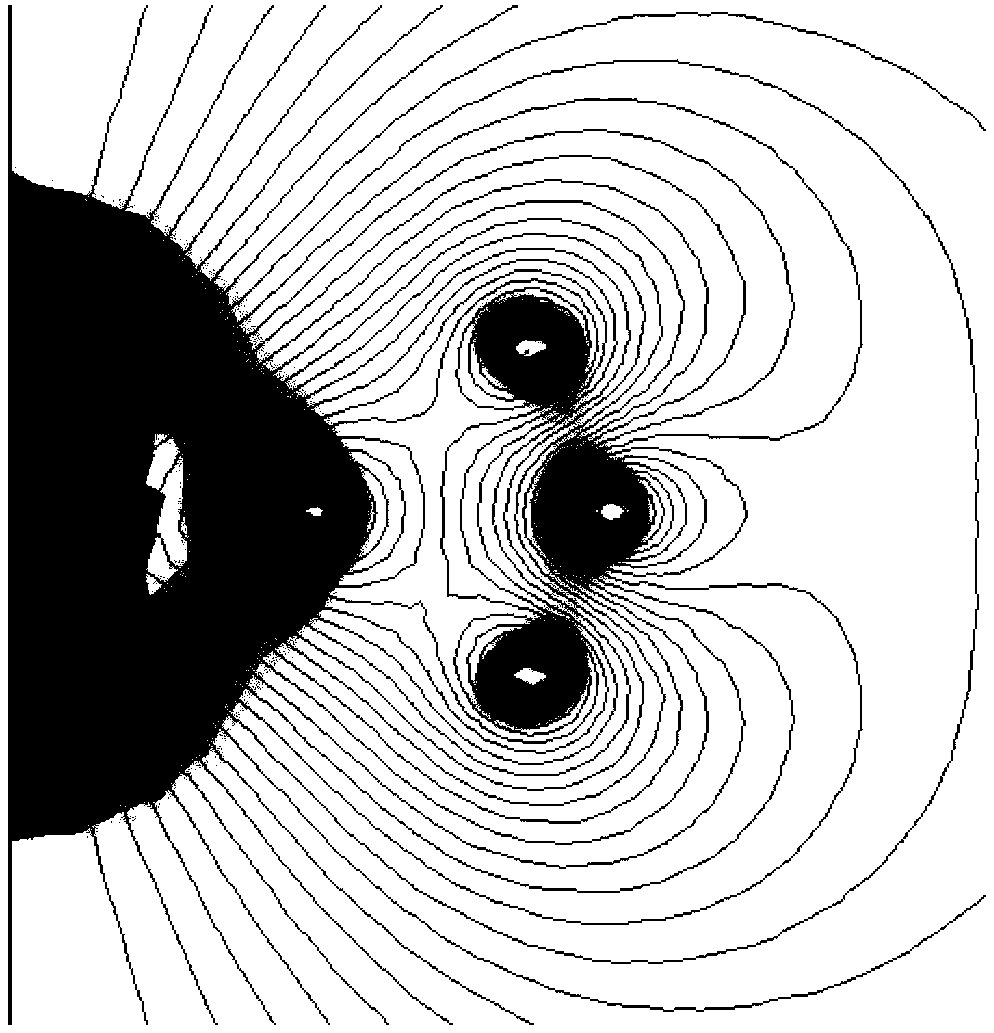

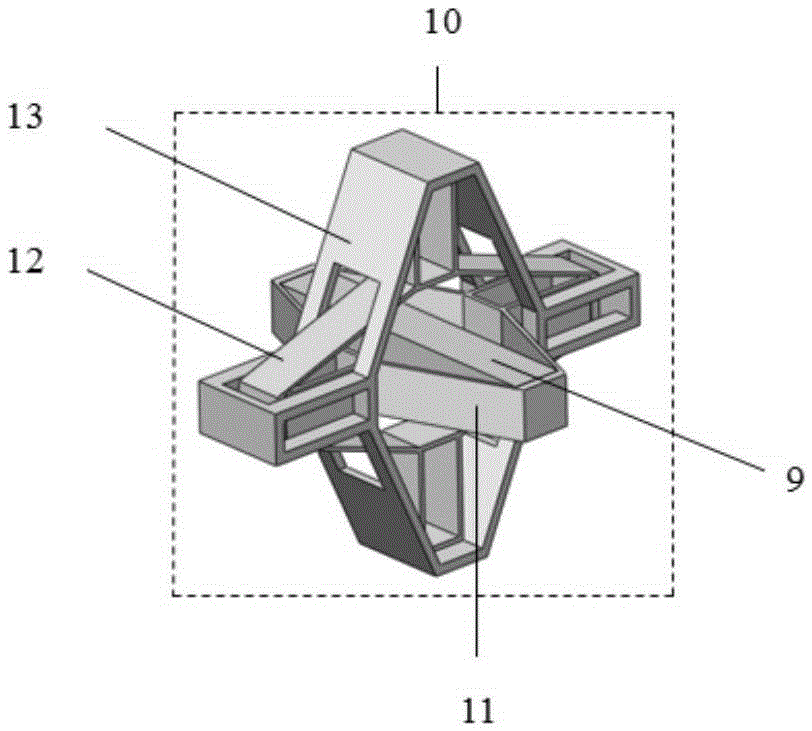

System and method using magnetic field configuration with zero magnetic field area to restrain high-temperature plasma

InactiveCN103269555ASwap Instability SuppressionIncrease the beta valueNuclear energy generationPlasma techniqueElectricityHigh voltage pulse

The invention discloses a system and method using a magnetic field configuration with a zero magnetic field area to restrain high-temperature plasma. The system using the magnetic field configuration with the zero magnetic field area to restrain the high-temperature plasma comprises a plasma gun, a high-voltage pulse power source, a full-plasma channel and a magnetic trap coil, wherein the plasma gun is filled with neutral gases, and is used for generating and transmitting plasma beams, the high-voltage pulse power source is used for providing electricity for the plasma gun, the full-plasma channel is arranged opposite to an outlet of the plasma gun, and is used for transporting the plasma beams transmitted by the plasma gun, and injecting the plasma beams into the magnetic trap coil, and the magnetic trap coil is arranged opposite to an outlet of the full-plasma channel, and is used for generating the ring-shaped magnetic field configuration. A ring-shaped area on the periphery of the ring-shaped magnetic field configuration is a barrier magnetic field, and the central area of the ring-shaped magnetic field configuration is a low-intensity magnetic field area with the zero magnetic field area. A chute coil is further arranged in the full-plasma channel. Due to the fact that the direction of a magnetic field generated by the chute coil and the direction of the barrier magnetic field are opposite, the plasma can easily enter the low-intensity magnetic field area, and then the plasma is stably restrained in the low-intensity magnetic field area.

Owner:哈工大(张家港)智能装备及新材料技术产业化研究院有限公司

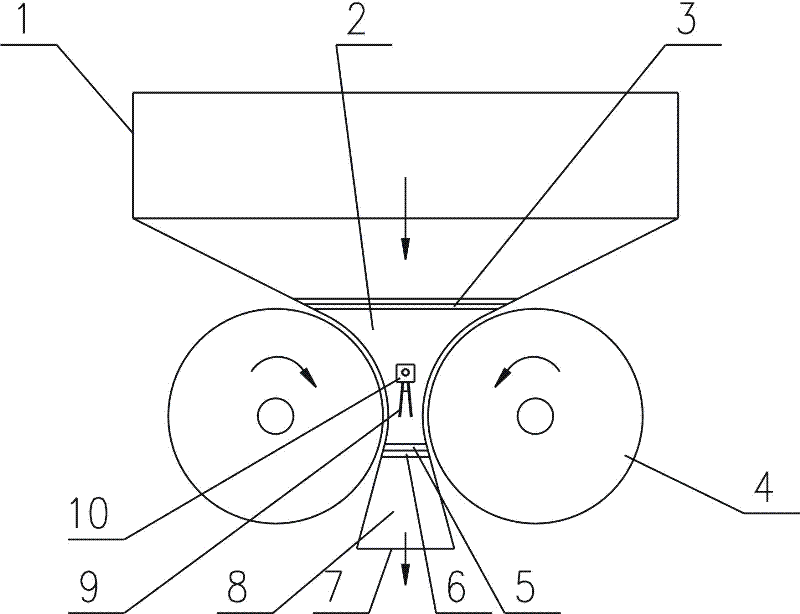

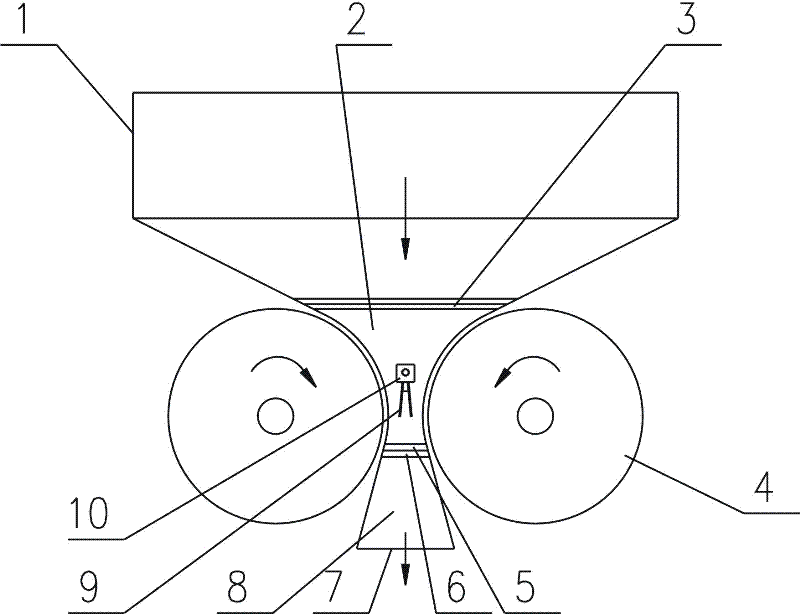

Non-contact magnetic spinning apparatus

ActiveCN102198424ANo wearSmooth dischargeSludge treatment by de-watering/drying/thickeningMagnetic separationMagnetic tension forceLoad resistance

The invention relates to a non-contact magnetic spinning apparatus, which allows condensation, dehydration and feeding to be realized through a manner that magnetic material particles or floccules are subjected to migration, aggregation, and extrusion by magnetic force of toroidal magnetic fields changing in a strong-weak alternation way. The apparatus is characterized in that: the apparatus comprises a charge cavity, a magnetomotive cavity, a discharge cavity and at least a pair of permanent magnetic rollers rotating reversely; the charge cavity is communicated with the magnetomotive cavity and the discharge cavity in sequence; and the paired permanent magnetic rollers, which are arranged on the outer of both side walls of the magnetomotive cavity, generate toroidal alternate magnetic force in the magnetomotive cavity. Non-contact condensation, dehydration and feeding are carried out on the magnetic materials through the toroidal alternate magnetic force, so the apparatus has the advantages of simple method, easy manufacture, low cost, strong impact load resistance and good processing effect.

Owner:CHENGDU YUANRONG ENVIRONMENTAL TECH +1

Circular plate antenna crossed magnetic field microwave electron cyclotron resonance ion propeller

ActiveCN110985323AReduced microwave power densityInhibit arcingMachines/enginesUsing plasmaMagnetic gradientElectron cyclotron resonance

The invention discloses a circular plate antenna crossed magnetic field microwave electron cyclotron resonance ion propeller, and belongs to the technical field of microsatellite electric propulsion.Microwave energy is fed by adopting a circular plate antenna, the microwave power density of the antenna is decreased, antenna arcing is inhibited, the cut-off power density is increased, the transverse microwave electric field intensity of a resonance region is increased, the breakdown power is reduced, the plasma generation efficiency is improved, and meanwhile the plasma radial uniformity is improved. A closed permanent magnet steel column body is composed of circular-arc-shaped magnet steel blocks and forms a crossed magnetic field with an end face annular magnetic field, therefore, ions are effectively constrained and driven through the radial and axial magnetic gradient force, and the ion generation efficiency is improved. Meanwhile, charged particle leakage at a weak magnetic fieldin a magnet steel clearance is reduced through the closed magnetic field. Under optimized resonance region distribution, an electron cyclotron resonance region on the front end face can be covered byadopting a thin aluminum plate, local strong discharge of the region is inhibited, the plasma generation efficiency is improved, and the performance of the propeller is further improved.

Owner:DALIAN UNIV OF TECH

Petroleum perforating bullet device through electromagnetic driving

Owner:NANJING UNIV OF SCI & TECH

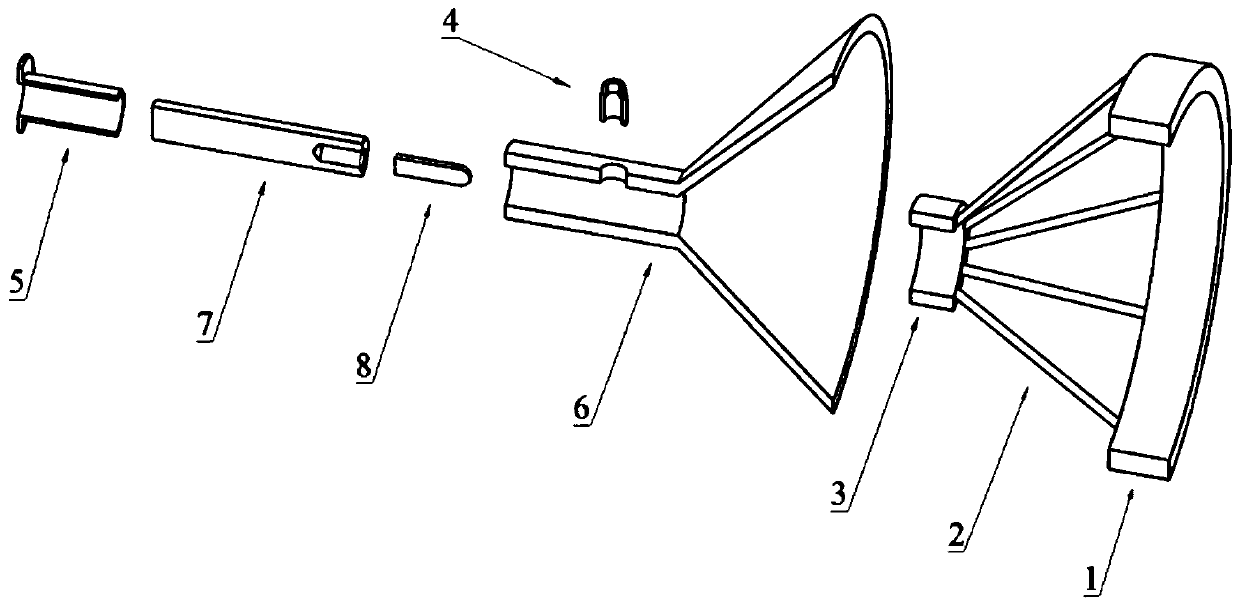

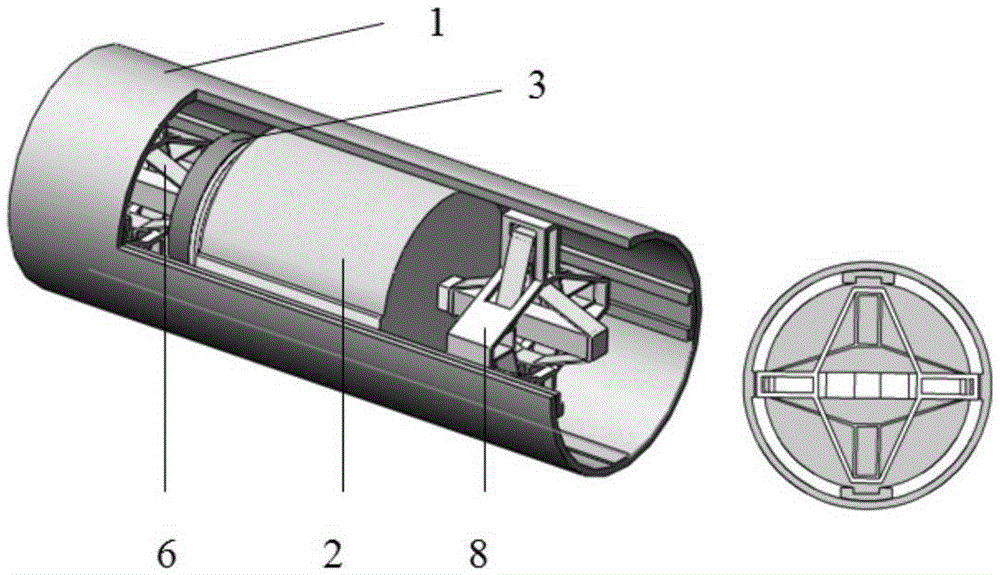

Expanding self-magnetic field magnetic plasma thruster

PendingCN110043436AImprove cooling efficiencyReduce the total massMachines/enginesUsing plasmaConoidDischarge current

An expanding self-magnetic field magnetic plasma thruster comprises a ceramic separator, a segmented expanding anode, a cathode and an air inlet joint; the ceramic separator comprises a hollow cylindrical section and a conical expanding section; the segmented expanding anode comprises an anode fixing ring, an anode discharge ring and a plurality of anode current transmission lines radially connected between the anode fixing ring and the anode discharge ring; the hollow cylindrical section is sleeved with the anode fixing ring; the anode discharge ring is fixed to the outer end of the expandingsection; the cathode is coaxially arranged in the hollow cylindrical section, and the top end of the cathode extends into the conical expanding section; the hollow cylindrical section is provided with the inlet joint; and a gas working medium enters an annular passage between the cathode and the ceramic separator from the air inlet joint and is uniformly injected into an expanding discharge cavity between the cathode and the segmented expanding anode on the outer circumference of the cathode. The acceleration effect of a toroidal magnetic field generated by anode discharge current on plasma is fully utilized, and the electromagnetic acceleration mechanism of the self-magnetic field magnetic plasma thruster is maximized.

Owner:NAT UNIV OF DEFENSE TECH

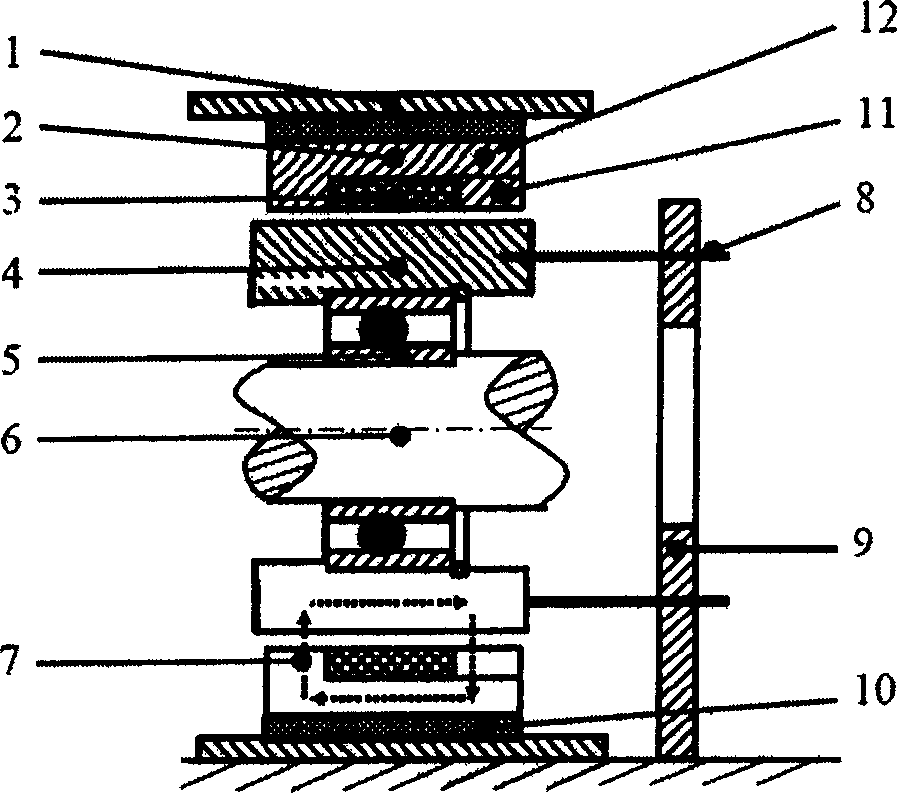

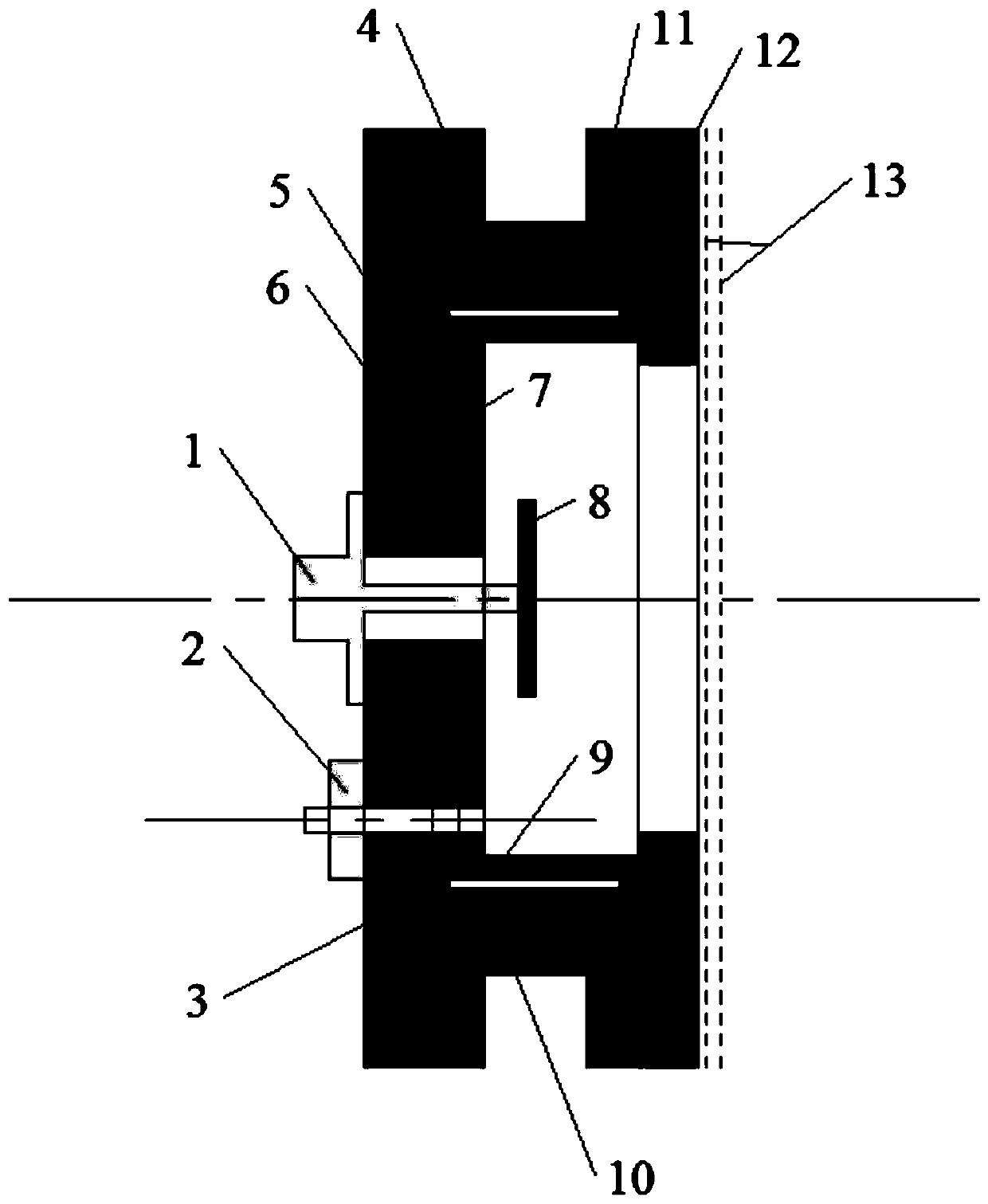

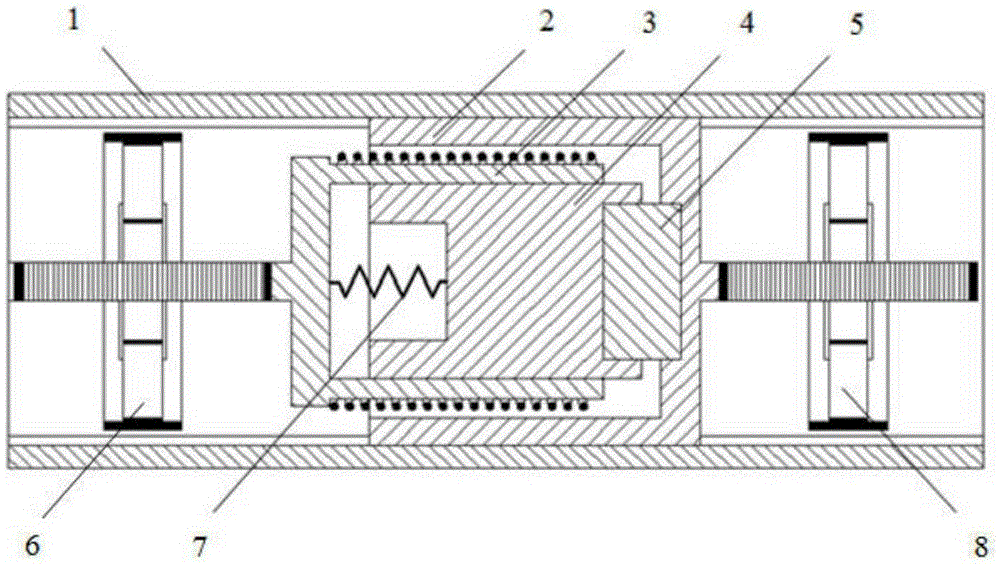

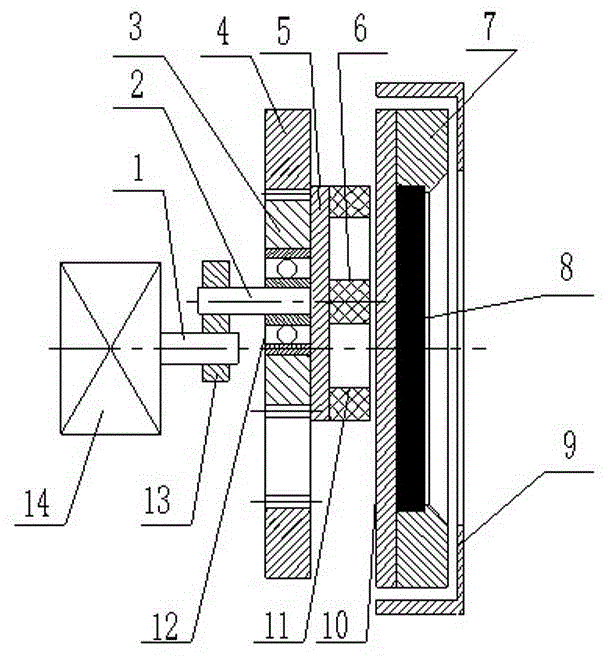

Magnetic-piezoelectric bidirectional stepping type large-displacement actuator and actuation method thereof

ActiveCN105391334AAny position lockReduce weightPiezoelectric/electrostriction/magnetostriction machinesElectricityActuator

A magnetic-piezoelectric stepping type large-displacement actuator and an actuation method thereof. The actuator consists of a housing, an external magnetizer, an internal magnetizer, a permanent magnet, a coil, a spring and piezoelectric amplification mechanisms. The process for realizing bidirectional stepping type actuation is as follows: a uniform toroidal magnetic field is generated between the internal and external magnetizers at two ends of the permanent magnet, the coil is located in the magnetic field, an outer end is connected with the first piezoelectric amplification mechanism, and the interior is connected with the internal magnetizer through the spring; the external magnetizer is connected with the second piezoelectric amplification mechanism; the piezoelectric amplification mechanisms are locked to an inner wall of the housing when not electrified; a first piezoelectric stack is electrified, and locking is released; then current is applied to the coil, and Ampere force is generated to push the first piezoelectric amplification mechanism to move; the first piezoelectric stack is powered off and locked, a second piezoelectric stack is electrified and locking is released, and spring restoration force pulls the coil and the second piezoelectric amplification mechanism to move, thereby realizing unidirectional movement; and if current of an opposite direction is applied to the coil, reverse movement is realized; and thus bidirectional stepping type output of large displacement and force is realized.

Owner:XI AN JIAOTONG UNIV

Diamond-like carbon coating preparation device with resultant field and application of device

ActiveCN108374154AQuality improvementIncrease free pathVacuum evaporation coatingSputtering coatingDiamond-like carbonTransverse magnetic field

The invention discloses a diamond-like carbon coating preparation device with a resultant field and application of the device. A diamond-like carbon coating mainly utilizes a central positive pole, onwhich a rotational magnetic core is assembled, or a vertical electromagnetic coil as well as a closed magnetic field formed by eight groups of process components assembled on a regular octagonal machine, plasmas below the formed composite magnetic field are used for preparing the diamond-like carbon coating, a closed toroidal magnetic field is formed by the eight groups of process components controlled by the magnetic field, eight magnetic boots are assembled on the rotational magnetic core of the central positive pole and can form a transverse magnetic field with corresponding process components, the vertical coil can form a vertical magnetic field in a vacuum chamber after being energized, a complicated resultant field can be formed in the vacuum chamber through interaction of two or three magnetic fields, the electronic free path can be increased, the ionization rate of particles is enhanced, so that the activity of carbon particles is increased, and the high-quality diamond-like carbon coating is obtained.

Owner:WENZHOU POLYTECHNIC

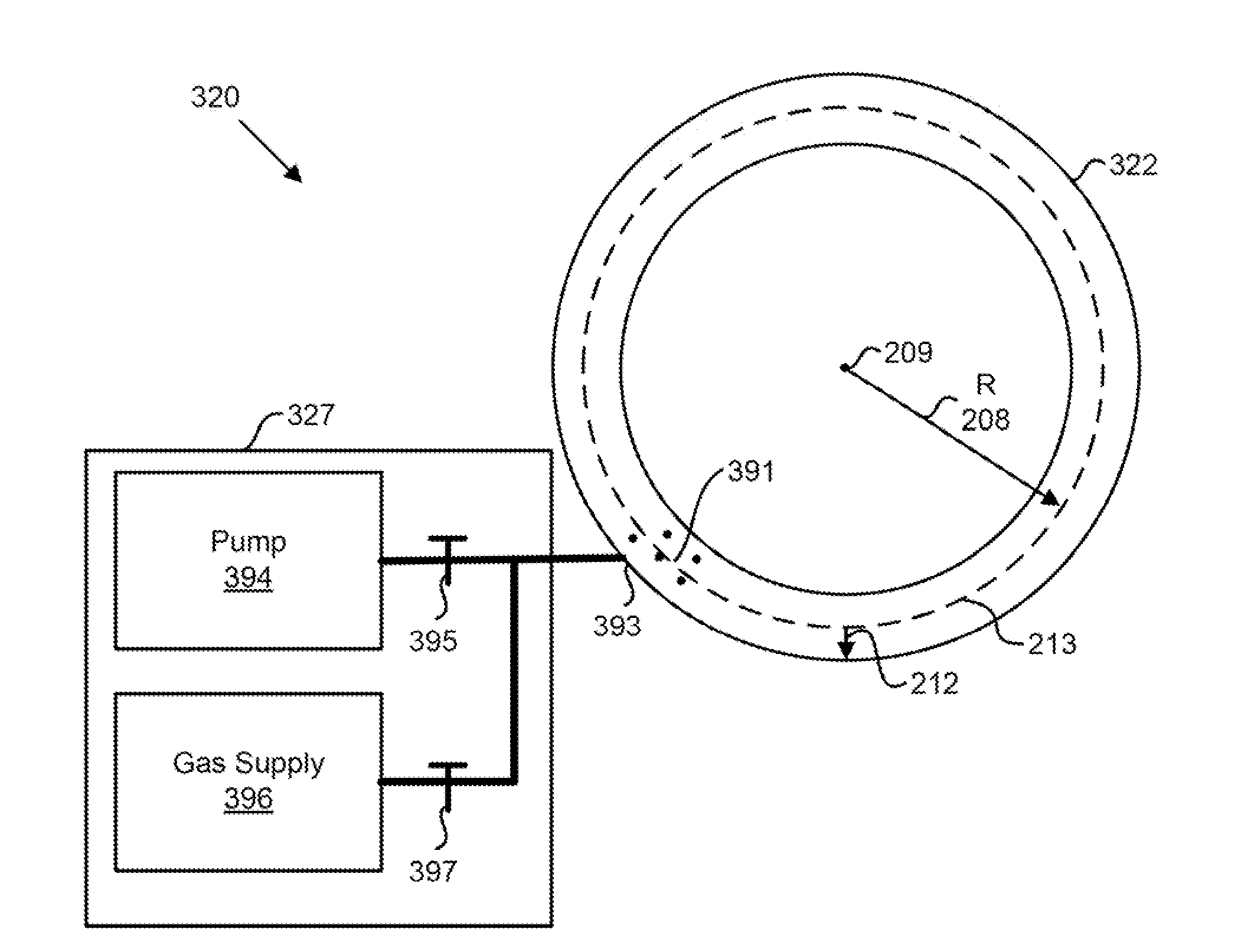

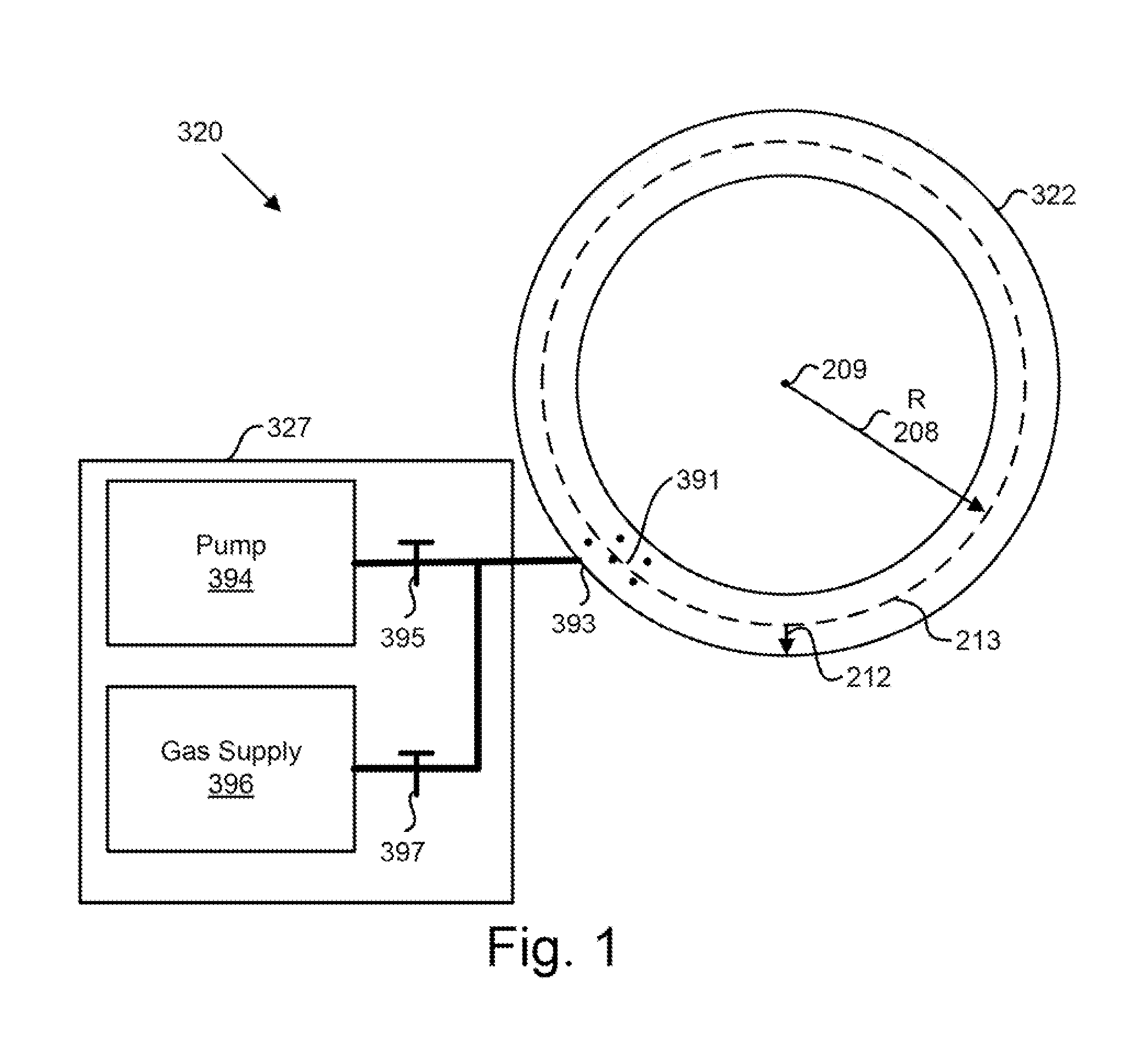

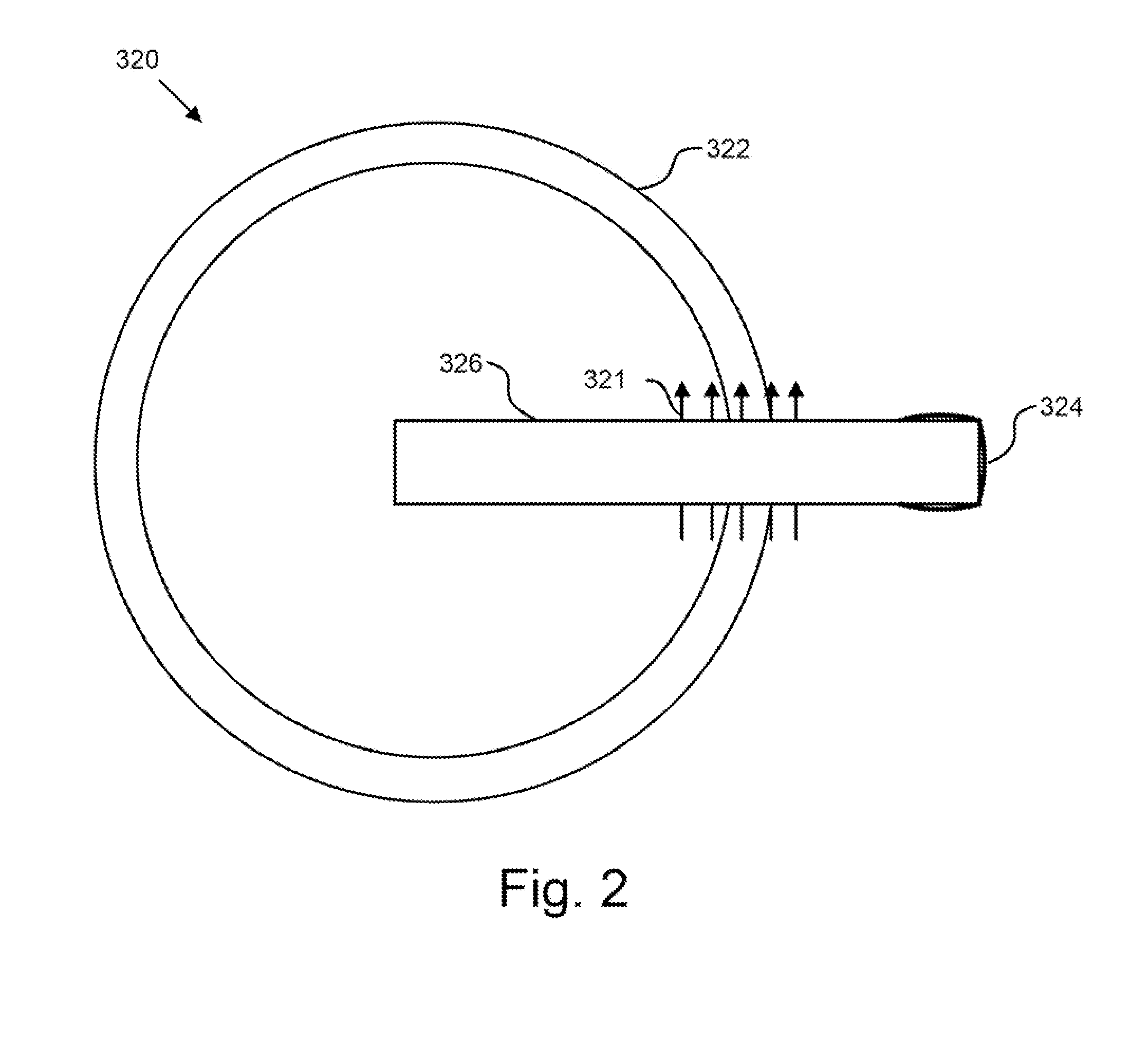

Ion-mode plasma containment

For ion-mode plasma containment, a toroidal vacuum vessel (322) has a major radius (208) and a minor radius (212). The toroidal vacuum vessel (322) is filled with a gas (391) having an initial particle density. An ionizing device (341) ionizes the gas (391) into a plasma (400). A transformer inductively (326) drives a toroidal particle current (332) comprising an ion current and an electron current about a toroidal axis. The toroidal particle current (322) heats the plasma (400) and generates a poloidal magnetic field (373). Field coils (414) wound poloidally about the toroidal vacuum vessel (322) generate a toroidal magnetic field (371). The toroidal magnetic field (371) at a wall of the toroidal vacuum vessel (322) is adjusted to satisfy a boundary condition for a minimum-energy. The plasma (400) is contained by the radial electric field, the poloidal magnetic field (373), and the toroidal magnetic field (371) within the toroidal vacuum vessel (322) in the minimum-energy state.

Owner:UTAH STATE UNIVERSITY

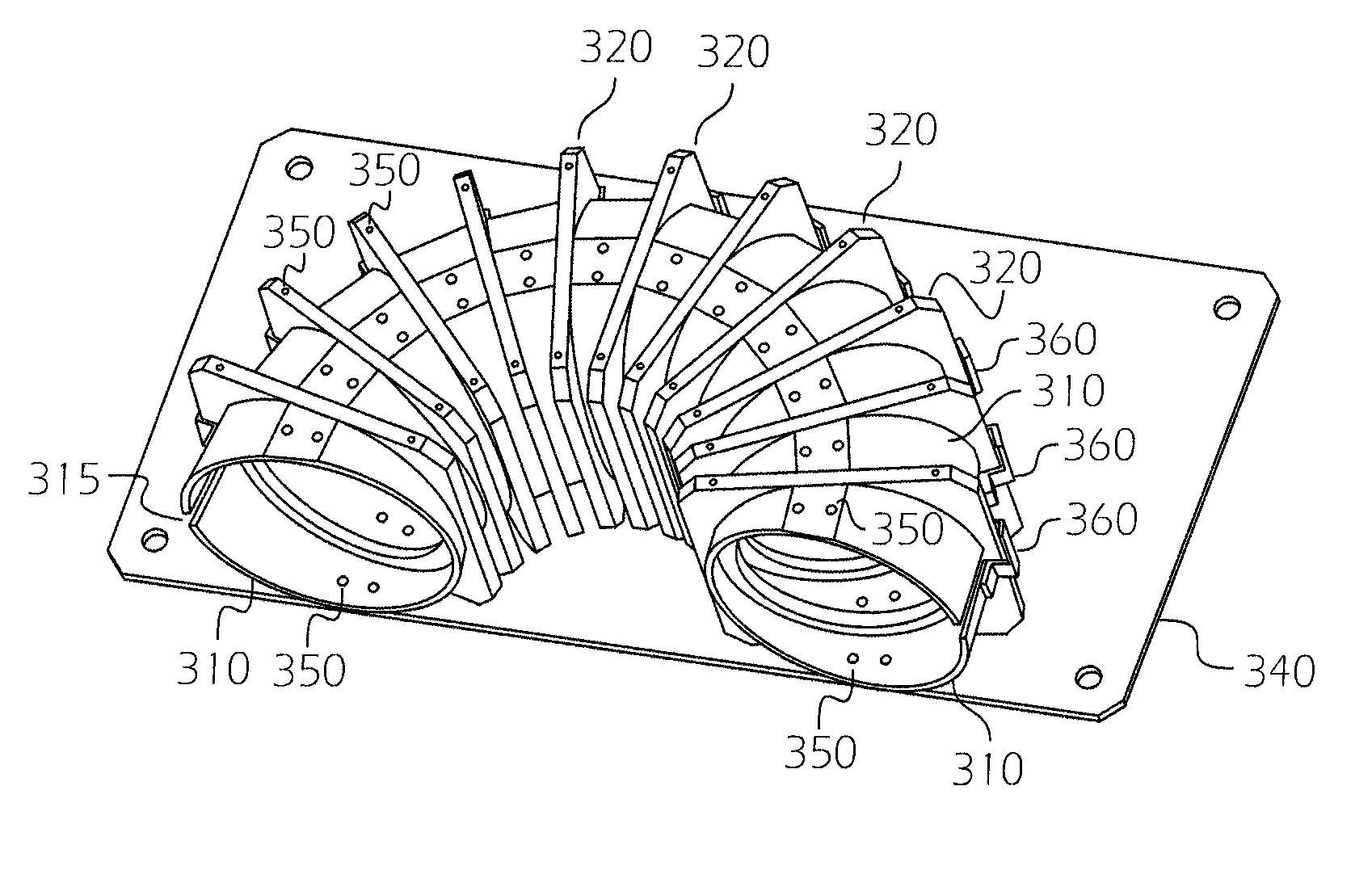

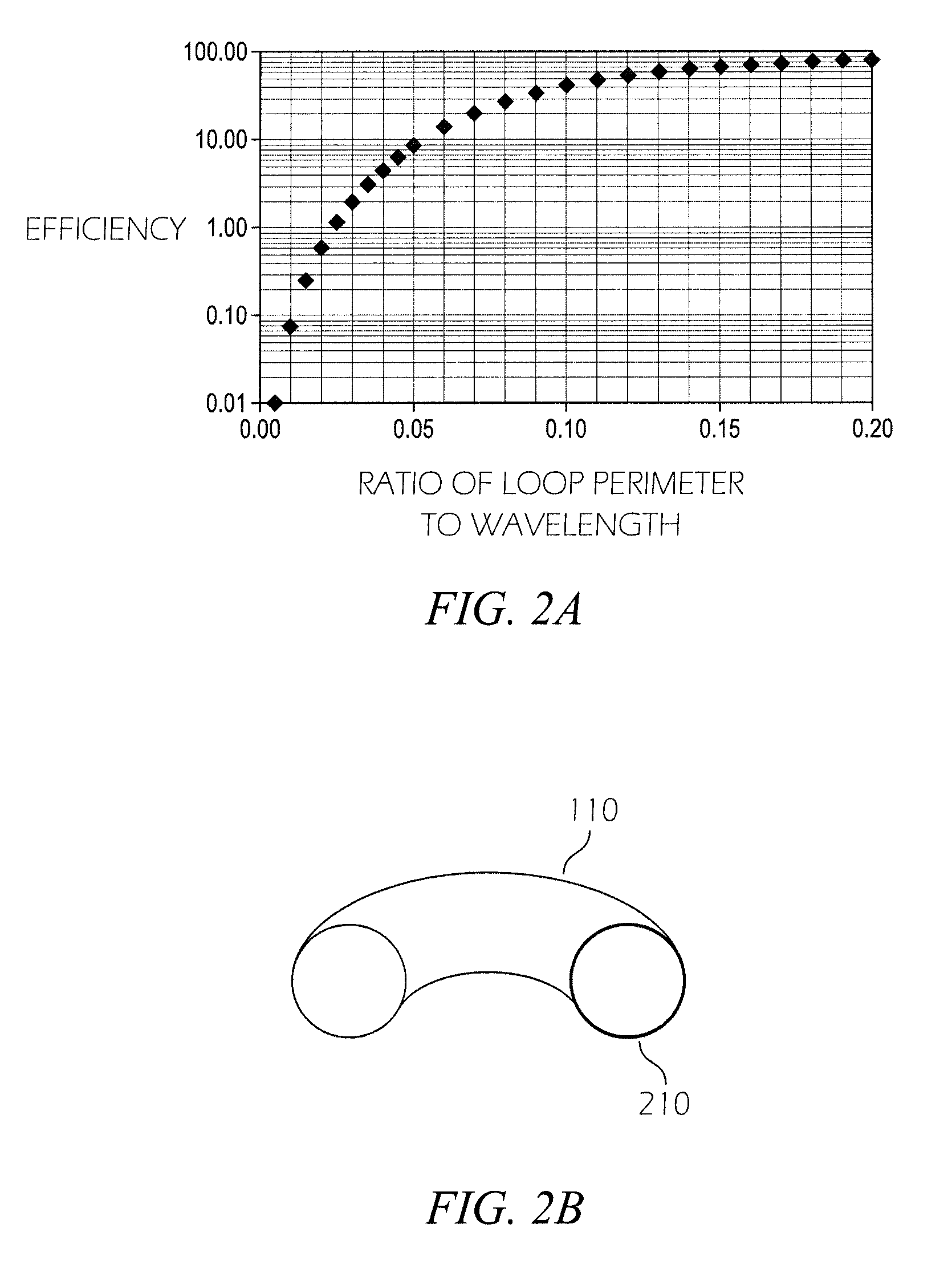

Multisegmented toroidal magnetic field projector

A system for triggering improvised explosive devices (IEDs) with an alternating magnetic field. In one embodiment, the magnetic field is produced by a magnetic field projector in the shape of one-half of a torus, the half-torus being composed of several conductive segments referred to as toroidal wedges. A poloidal current flows in each toroidal wedge, producing a magnetic field that is projected by the half-torus. The magnetic field may induce a current, producing heating, in a conductive loop in an IED and triggering the IED.

Owner:RAYTHEON CO

Magnetic heat treatment method applicable to annular devices

ActiveCN106319188AConvenient magnetic field heat treatmentStrong process controllabilityFurnace typesHeat treatment furnacesMagnetic polesShielding gas

The invention discloses a magnetic heat treatment method applicable to annular devices, and belongs to the technical field of material engineering. The magnetic heat treatment method applicable to annular devices comprises the steps of firstly, calculating the electric current I which flows through a linear heating element according to the needed magnetic field intensity H; then calculating the radical of the linear heating element further according to the total power of a heat treatment furnace; an annular device is arranged on the linear heating element in a sleeving manner, and placing the annular device and the linear heating element together into the furnace body; and at last, vacuumizing the furnace body, adding shielding gas, setting the heat treatment time, and carrying out magnetic heat treatment on the annular device in the furnace body. The heating treatment apparatus needed in the magnetic heat treatment method applicable to annular devices is composed of the furnace body and the linear heating element, no magnetic poles are needed, and a toroidal magnetic field is generated by the direct current carried by the linear heating element. With the magnetic heat treatment method applicable to annular devices, on one side, the problem that annular devices cannot be treated with a traditional method is solved, on the other side, the technological parameters of magnetic heat treatment can be accurately controlled, and therefore, to some extent, the efficiency can be improved, and energy consumption can be reduced.

Owner:马鞍山延隆新材料科技有限公司

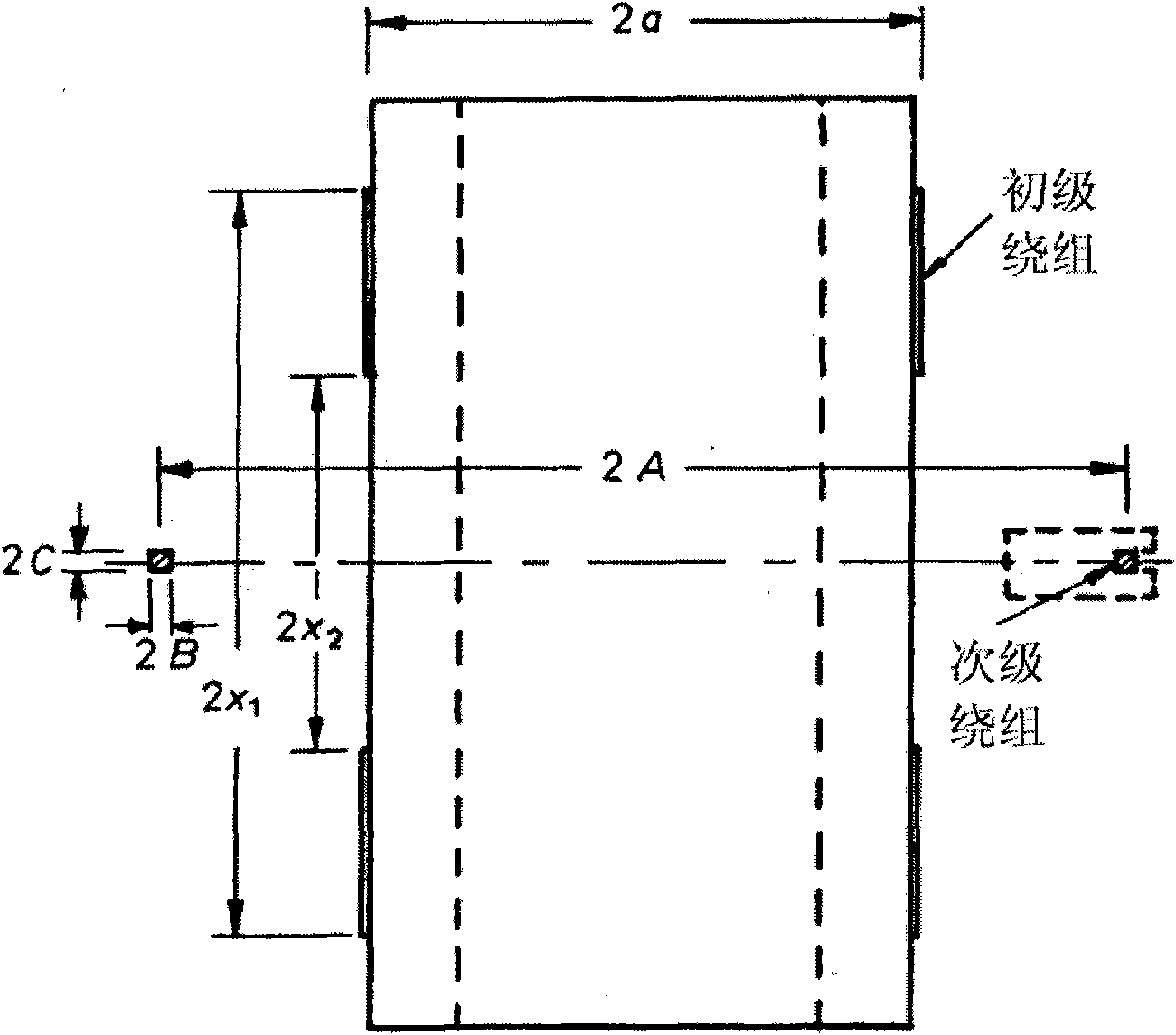

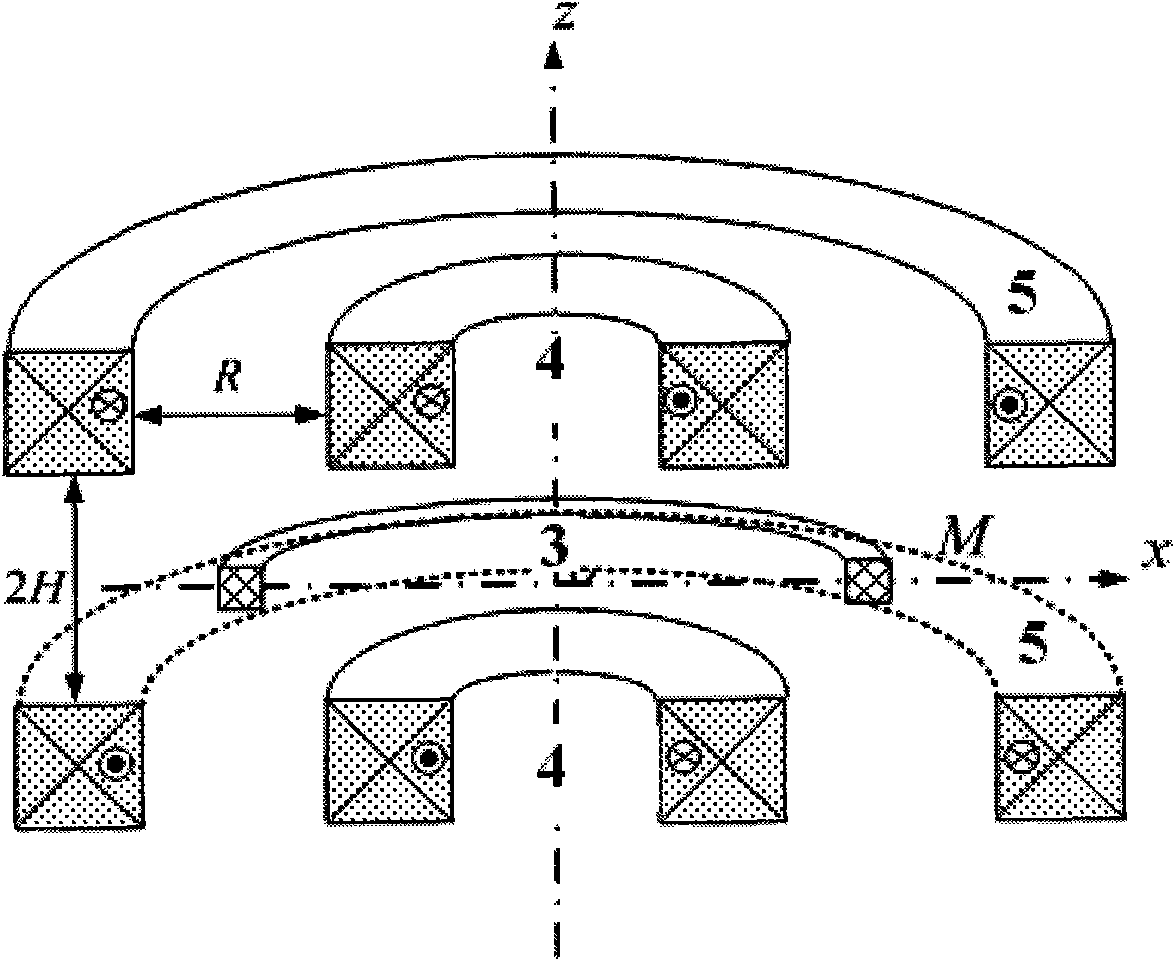

Mutual inductor measuring system and method for realizing uniform mutual inductance quantity vertical gradient

The invention relates to a novel mutual inductor system and method for realizing highly uniform mutual inductance quantity vertical gradient in an annular region of a mutual inductor. The novel mutual inductor system is different from the traditional mutual inductor system, and the parameters of the coil and the relative positions of a primary winding and a secondary winding of the mutual inductor are reasonably configured. When the space R between an internal excitation coil and an external excitation coil and the distance H between the excitation coils and a suspension coil meet the equation R2=4 / 3H2 and the turns ratio of the internal excitation coil to the external excitation coil to the suspension coil meets 10000:2700:430, a toroidal magnetic field uniform region with 2 cm axial length can be produced near the symmetrical plane of a Joule balance magnetic field, and the mutual induction parameters of the coil system in the uniform region have four-order uniformity.

Owner:NAT INST OF METROLOGY CHINA

Moving field vacuum coating magnetron sputtering source

InactiveCN103147056AIncrease profitEliminate wasteVacuum evaporation coatingSputtering coatingRADIUSVacuum coating

The invention discloses a moving field vacuum coating magnetron sputtering source which comprises a target base plate, a platy target welded or fixed on the front of the target base plate by a pressure ring, a shielding ring, a magnetic steel base plate and inner magnetic steel and outer magnetic steel mounted on the magnetic steel base plate. An improvement is as follows: the diameter of the magnetic steel base plate is greater than the radius of the target and less than the diameter of the target; the axis of the magnetic steel base plate deviates from the axis of the target base plate; the magnetic steel base plate is fixed on a side surface of a spur gear; a gear ring meshed with the spur gear is mounted on a rack of a coating machine; a motor located on the rear side of the spur gear is mounted on the rack; a crank handle is fixed on a power output shaft of the motor; a gear shaft is mounted on the crank handle; and the power output shaft of the motor and the gear ring are coaxially arranged with the target base plate. The moving field vacuum coating magnetron sputtering source disclosed by the invention has the positive effects that a toroidal magnetic field with revolution and autorotation is obtained and used for scanning each position of the target so that a larger area of the target is uniformly sputtered and etched. The utilization rate of the target is high, and the coating is uniform.

Owner:CHANGCHUN KENA OPTOELECTRONICS TECH

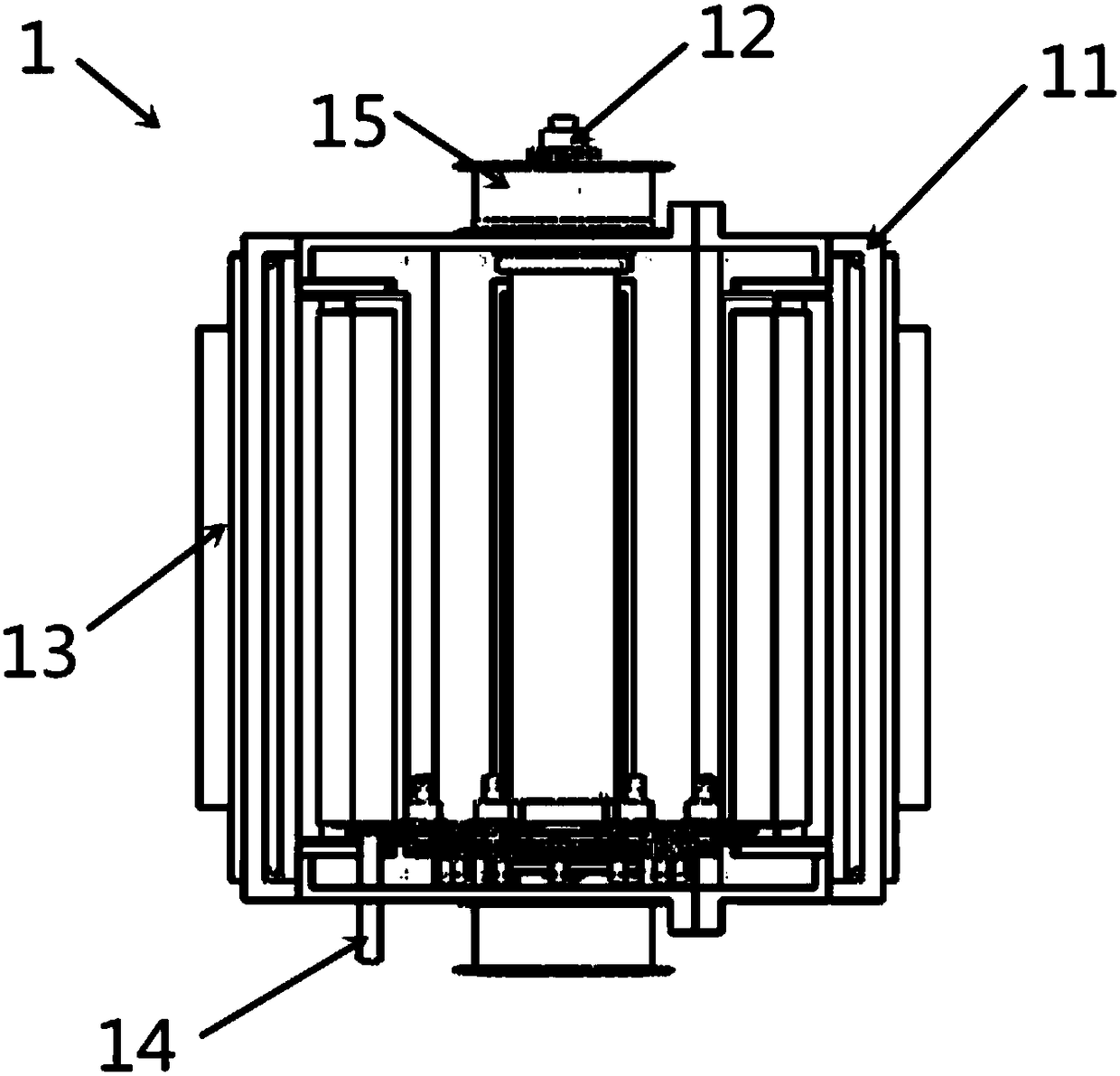

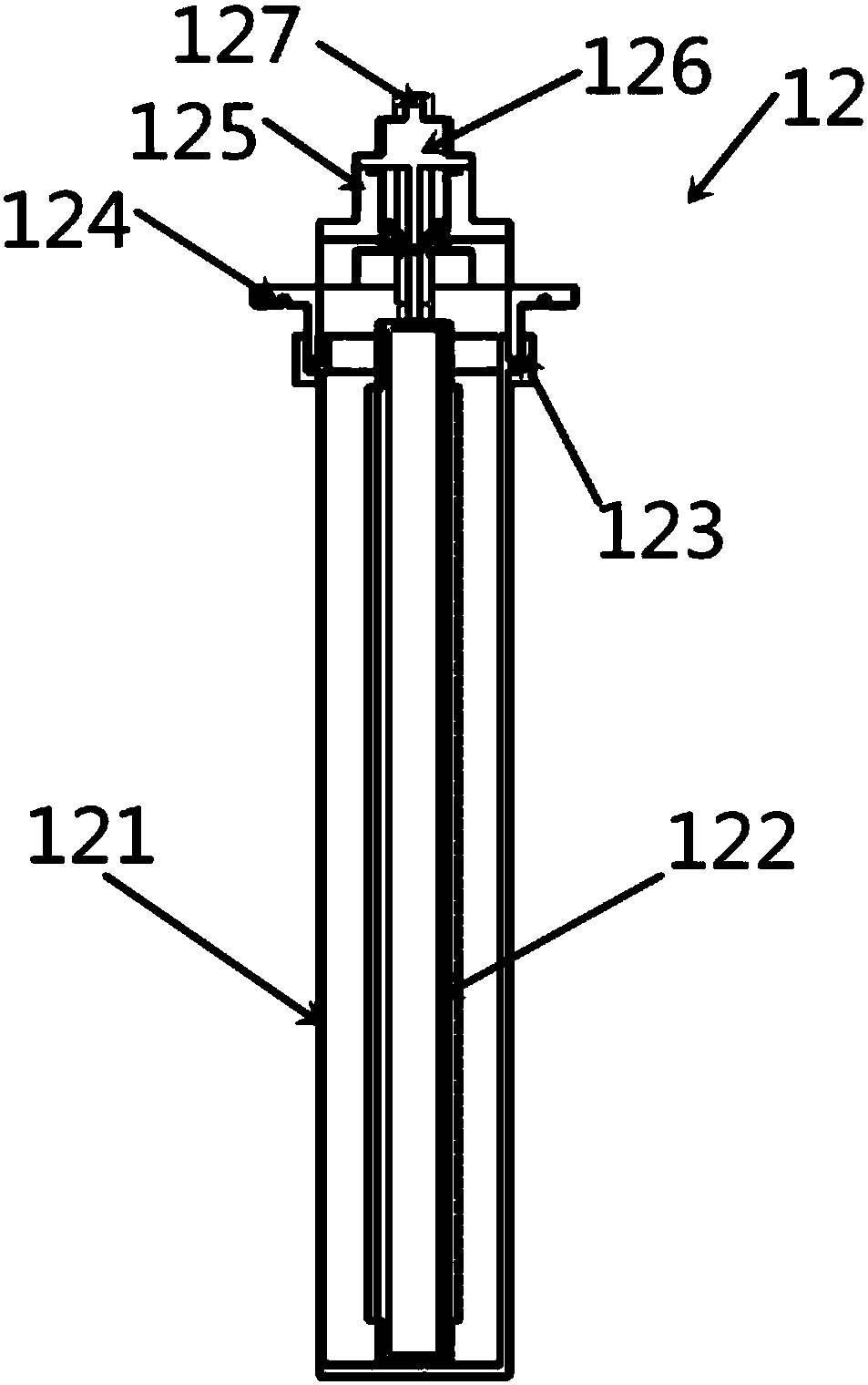

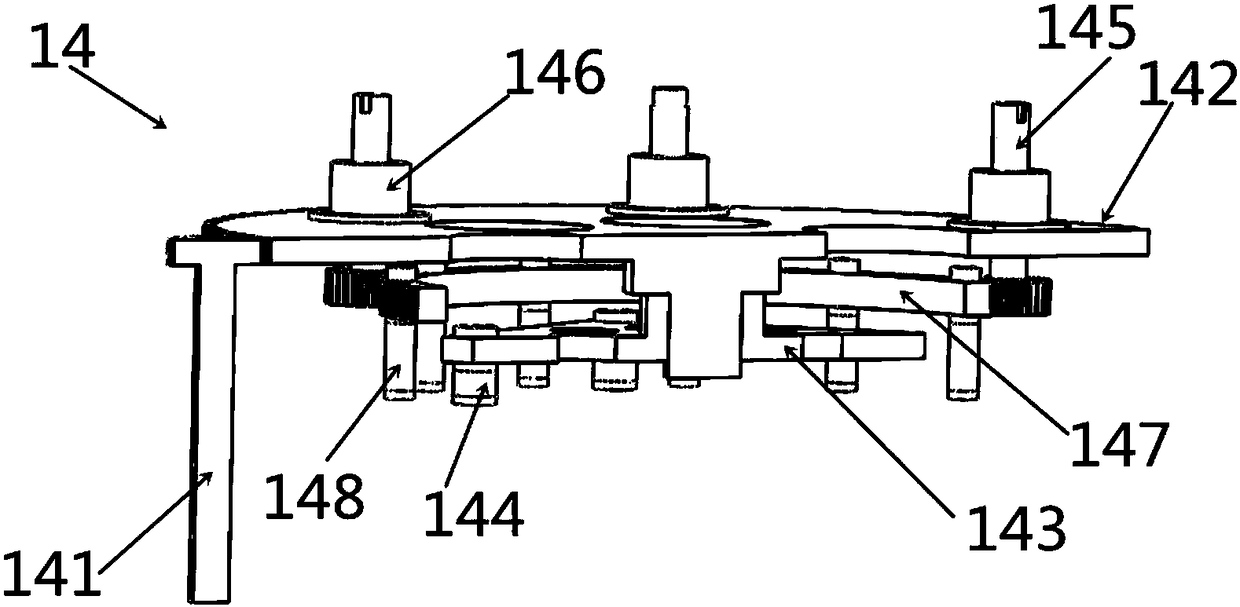

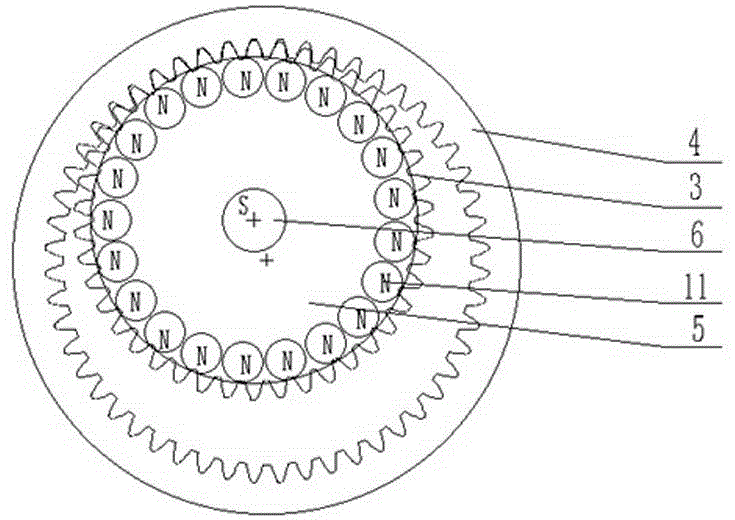

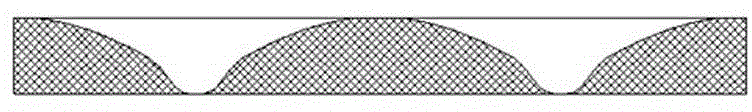

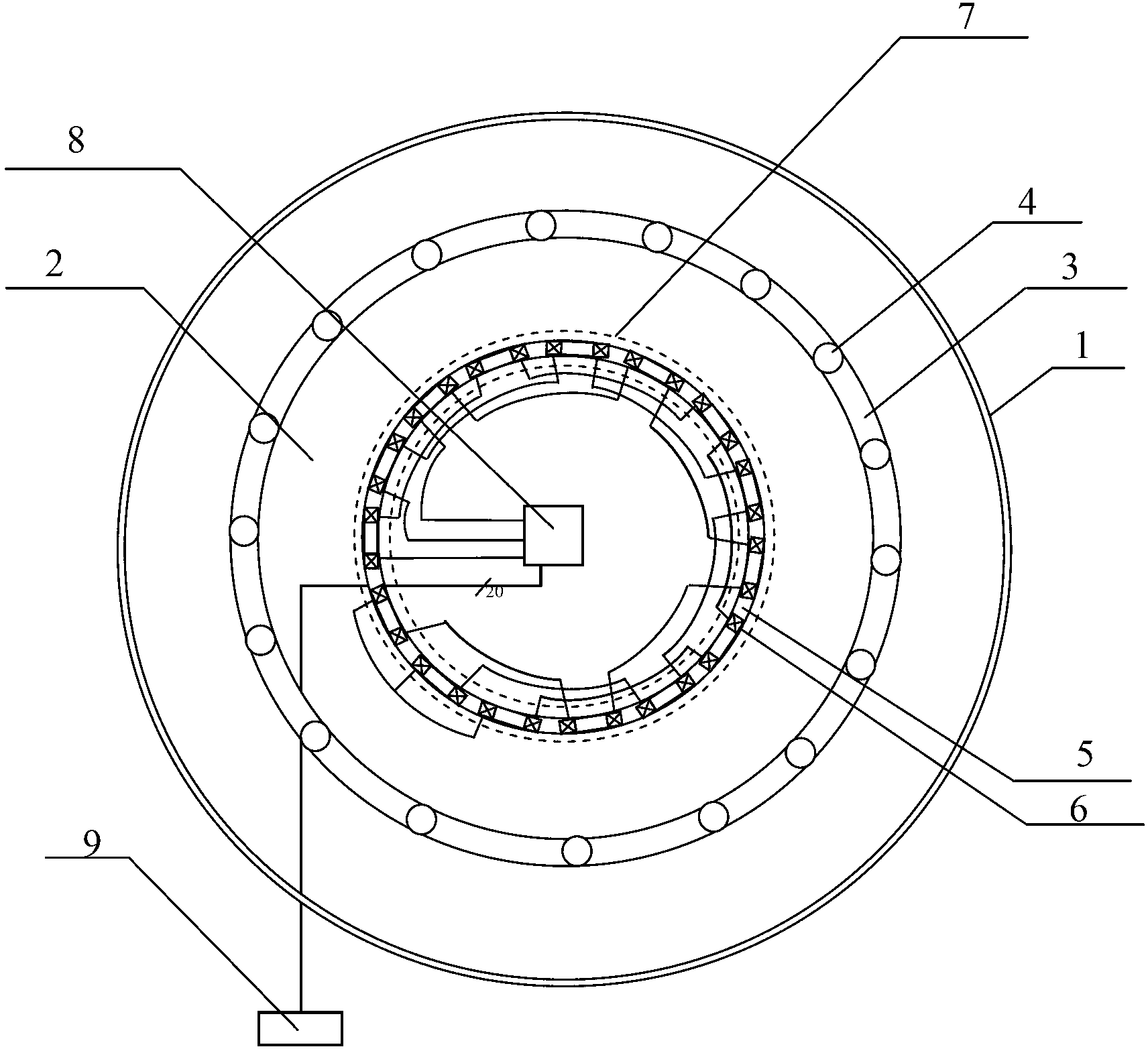

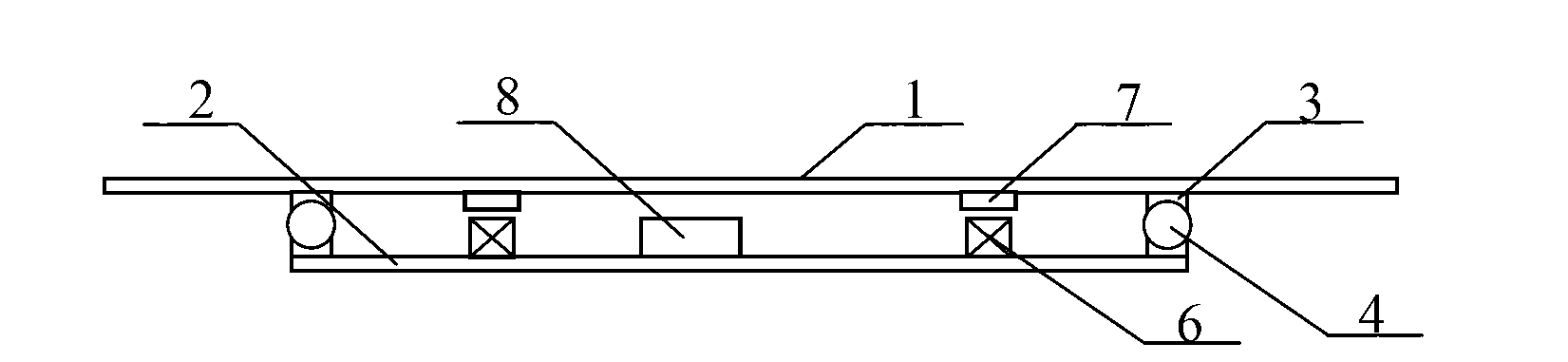

Dining table electric rotary disk based on driving of toroidal magnetic field

InactiveCN103211466ASmall structureSimple structureConversion without intermediate conversion to dcTable equipmentsElectricitySteel ball

The invention relates to a dining table electric rotary disk based on driving of a toroidal magnetic field. The dining table electric rotary disk comprises a base and a rotary disk body. A rail ring is arranged between the rotary disk body and the base. A plurality of evenly distributed steel balls are arranged on the rail ring. The rotary disk body is arranged above the base through the steel balls and can rotate on the base through the steel balls. A plurality of annular concave iron cores are arranged on the inner side of the rail ring and located on the base. Three-phase coil windings are embedded in the annular concave iron cores and are electrically connected with a rotary controller, and the rotary controller is electrically connected with a switch. A salient pole type permanent magnet with alternate N poles and S poles is arranged above the annular concave iron core and is fixedly installed on the lower surface of the rotary disk body. The rotary controller controls the conduction of the three-phase coil windings through on-off signals inputted through the switch so as to enable the applying force generated through matching between the three-phase coil windings and the permanent magnet to push the rotary disk body to rotate on the base. The dining table electric rotary disk is simple and compact in structure, low in using cost, high in rotating control accuracy, wide in application scope, safe, and reliable.

Owner:JIANGNAN UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com