Moving field vacuum coating magnetron sputtering source

A vacuum coating and magnetron sputtering technology, applied in the field of metallurgy, can solve the problems of unsuitable small magnetron sputtering sources, low target utilization rate, poor sputtering uniformity, etc. Improved uniformity and uniform particle distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

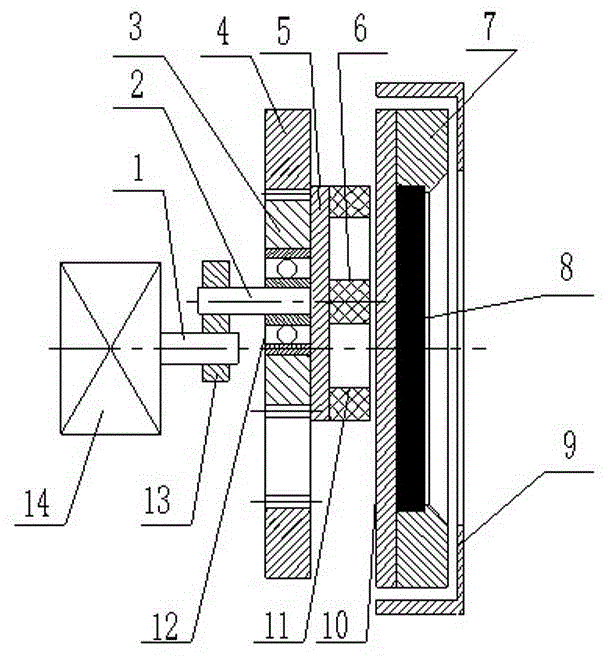

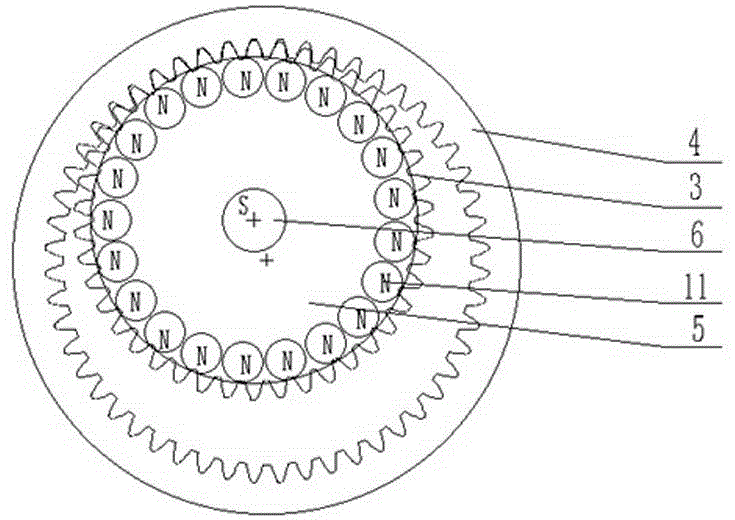

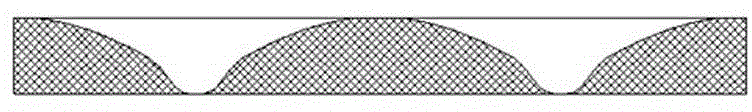

[0018] refer to figure 1 , figure 2 , the present invention includes a target substrate 10 with the front in a vacuum deposition chamber, a target pressure ring 7 connected to the target substrate, a sheet-shaped target material 8 welded or fixed on the front of the target substrate by a pressure ring, covering the circumferential side of the target substrate and The shielding ring 9 on the front of the target substrate other than the target material, the magnetic steel substrate 5 arranged on the back of the target substrate, the inner magnetic steel 6 installed on the magnetic steel substrate facing the center of the target substrate side, and the outer magnetic steel at the circumferential position 11. The outer magnet 11 and the inner magnet 6 are respectively composed of a plurality of magnet bodies, and the magnetic poles of the outer magnet 11 and the inner magnet 6 are opposite. The diameter of the magnetic steel substrate 5 is greater than the radius of the target m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com