Petroleum perforating bullet device through electromagnetic driving

An electromagnetic-driven, perforating charge technology, applied in the field of petroleum exploration, can solve the problems of secondary pollution and secondary damage, small perforation depth, difficult to control, etc., and achieve high energy utilization rate, increased perforation capacity, hole depth and Effects with easy size control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

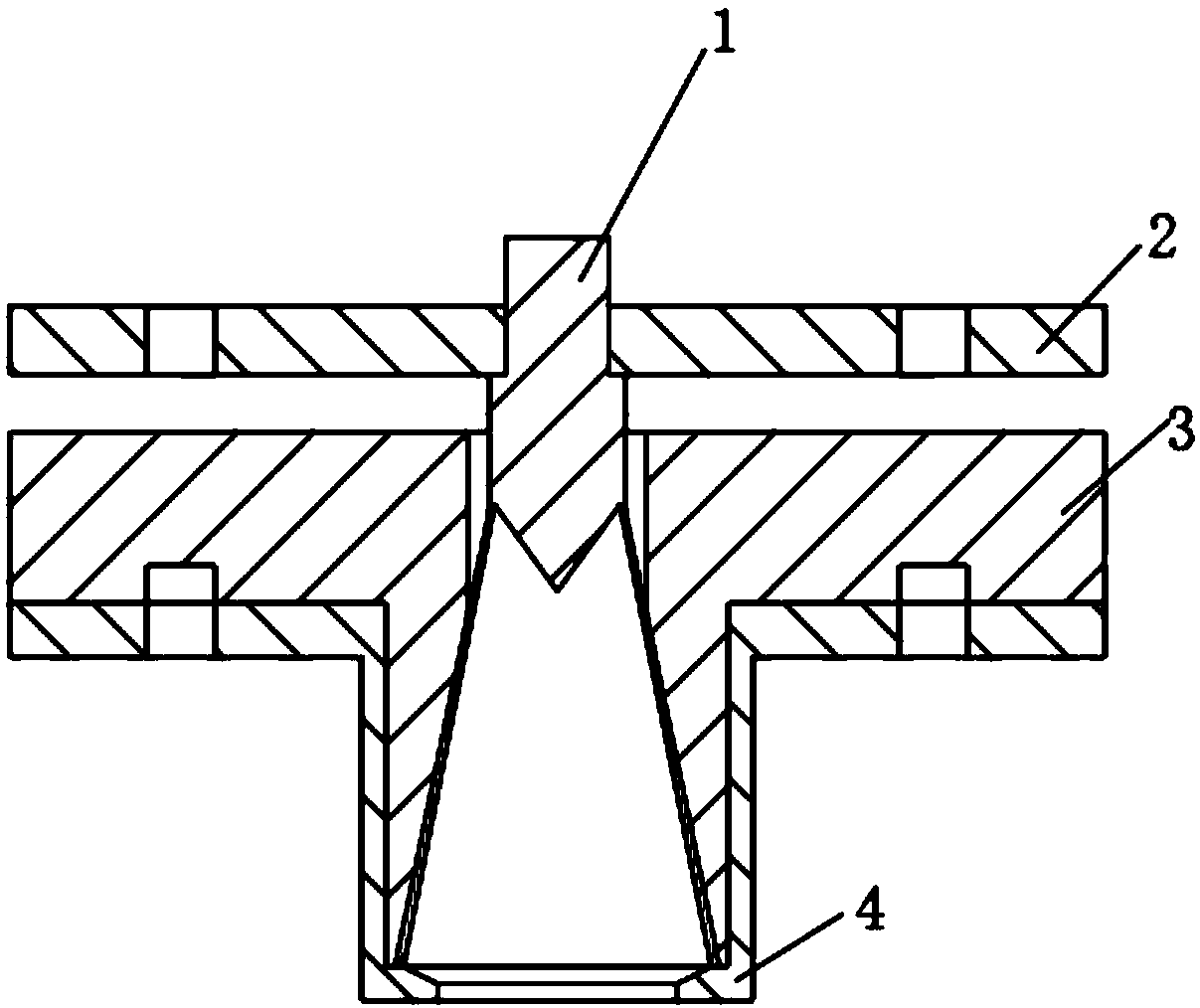

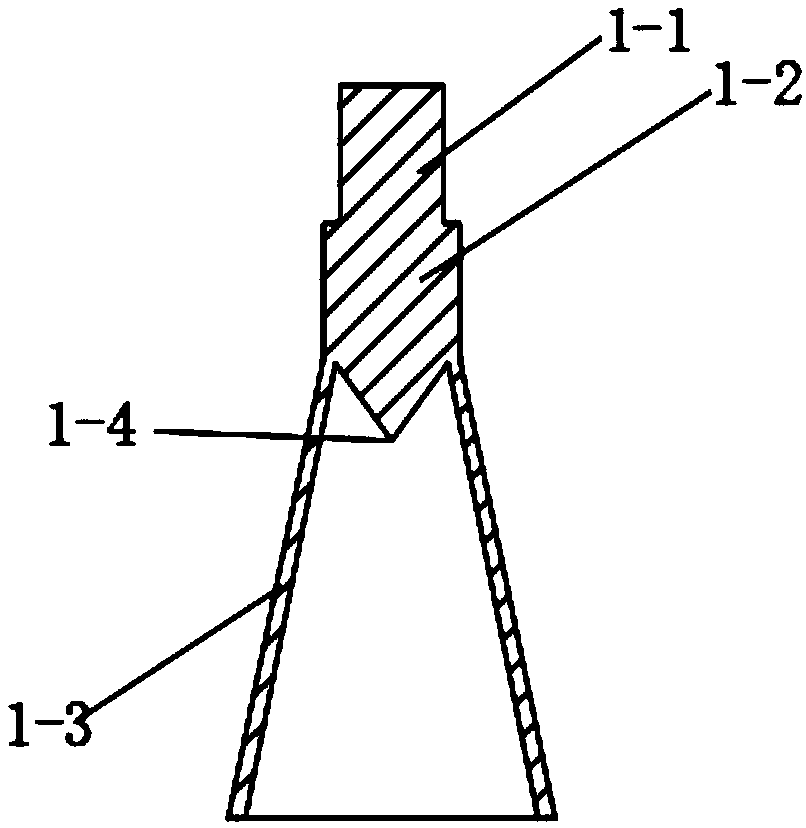

[0015] The present invention will be described in further detail below in conjunction with the accompanying drawings.

[0016] The present invention adopts the magnetic field coupling method that is easy to control, and utilizes the high-energy pulse capacitor group to produce the strong current of megaampere level, and strong current flows through the metal cover device 1 surface of the present invention and produces the hoop magnetic field, and metal cover device 1 is subjected to axial direction The concentrated ampere force further crushes the metal cover device 1 to form a metal jet. Theoretically speaking, the velocity difference between the head and the tail of the jet formed by the electromagnetic loading technology is small, and it still has a strong penetration ability at a large explosion height. The greater the current flowing through the metal cover device 1, the greater the crushing speed of the metal cover device 1, the higher the velocity of the jet head, and t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com