Magnetic heat treatment method applicable to annular devices

A heat treatment method and device technology, applied in heat treatment furnaces, heat treatment equipment, furnaces, etc., can solve the problems of uneven temperature field distribution, poor controllability of magnetic field, and difficult magnetic field heat treatment of annular devices, so as to shorten heat treatment time and reduce energy consumption. , Precisely control the effect of heating power

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments. However, the present invention is not limited to the following examples.

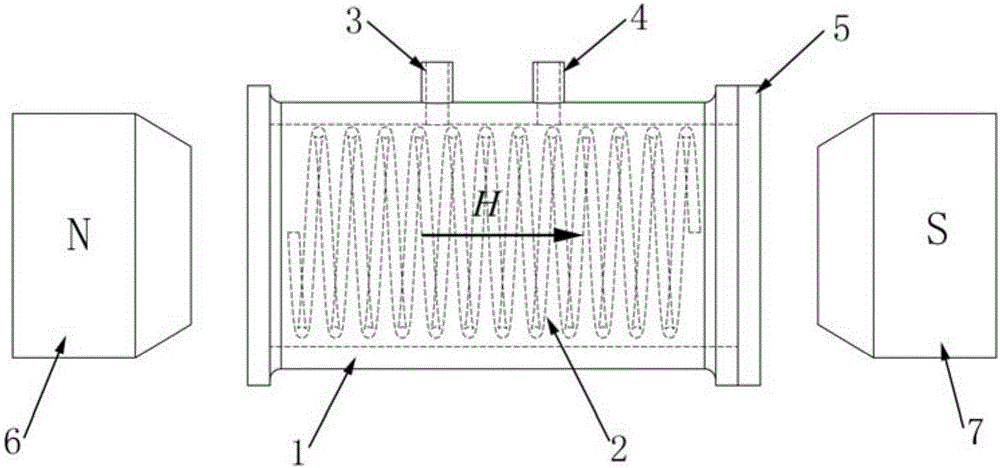

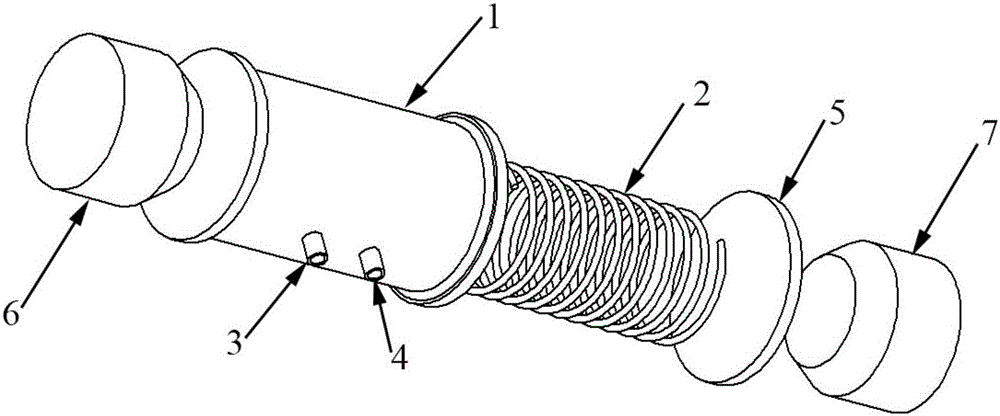

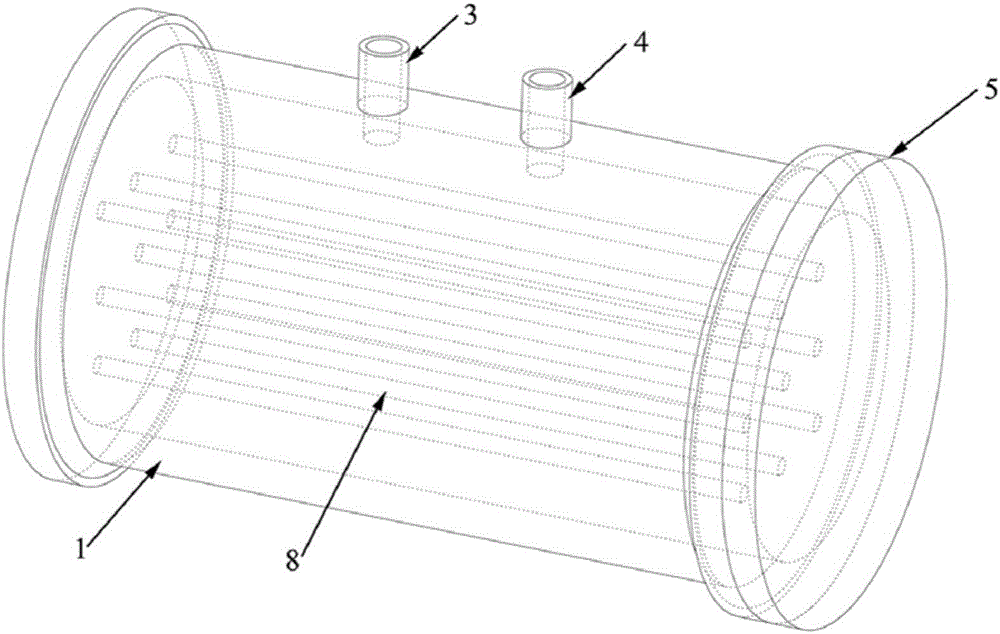

[0037] The present invention proposes a magnetic field heat treatment method for annular magnetic material devices, and the specific steps are as follows:

[0038] (1) Calculate the current I flowing through the linear heating element 8 according to the size of the required magnetic field strength H by the following (a),

[0039] I=2πR w H (a)

[0040] where R w is the outer radius of the ring device. It should be noted that the current I should not be less than 2πR w H, otherwise the magnetic field strength H at the outer radius of the ring device will be too small, which cannot meet the corresponding process requirements. However, at this time, the inner radius R of the ring device n The magnetic field strength will be significantly higher than the outer radius R ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com