Magnetic abrasive finishing processing method and device of toroidal magnetic field excitation

A technology of magnetic grinding and ring magnetic field, which is applied in the field of magnetic grinding processing, can solve the problems of difficulty in guaranteeing processing quality, high labor intensity, and low efficiency, and achieve strong adaptability, reduce processing costs, and improve efficiency and quality.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

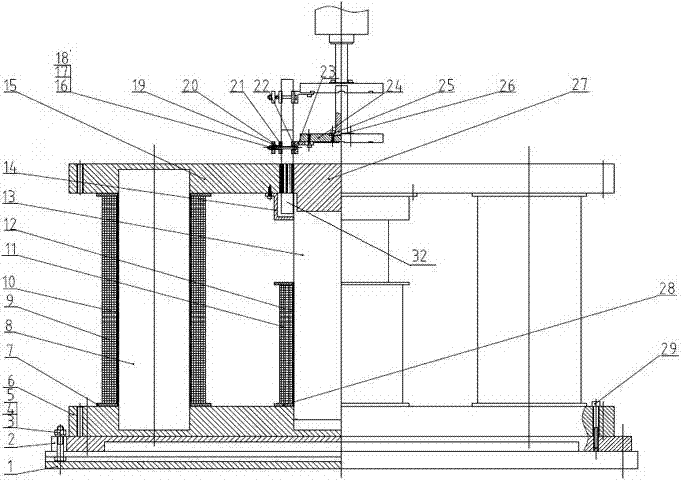

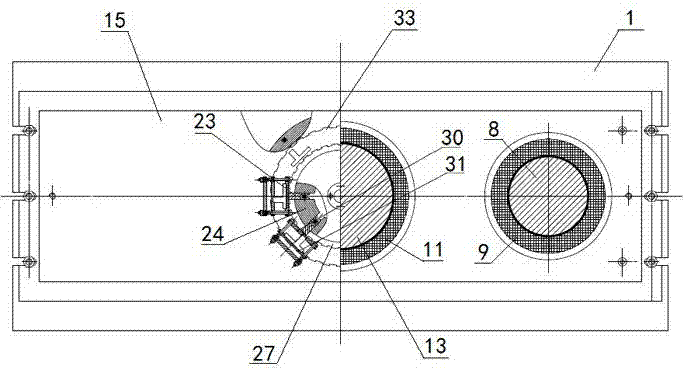

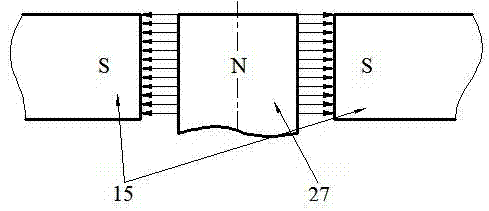

[0031] A magnetic grinding processing device excited by a ring magnetic field, such as figure 1 and 2 Shown, its flange shaft 25 can directly be connected with common vertical drill, milling machine main shaft, by fixture (by bolt 16,17,18, baffle plate 19, pressing plate 21,22,30,31, spring 20, adjustment block 23 , The clamp body 24 etc.) can realize that the workpiece is connected with the main shaft of the machine tool, and the workpiece is driven to make up and down feed motion and rotary motion, so that the workpiece moves relative to the annular magnetic grinding brush. Before processing, multiple workpieces are clamped to each station of the special fixture with different postures (the difference in loading angle is 180°), and then the clamp body is connected to the flange shaft 25, and the flange shaft 25 is then connected to the machine tool spindle; Magnetic abrasives are added to the grinding tank 14 . During processing, the spindle of the machine tool is fed ver...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com