Electric eddy-current damping device for rotary machine rotor

An eddy current damping, rotating machinery technology, applied in the direction of rotation vibration suppression, etc., can solve the problems of large size and weight of electromagnetic bearings, limited maximum operating speed, low system reliability, etc., to achieve short response time, easy power supply, volume small effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described below in conjunction with accompanying drawing.

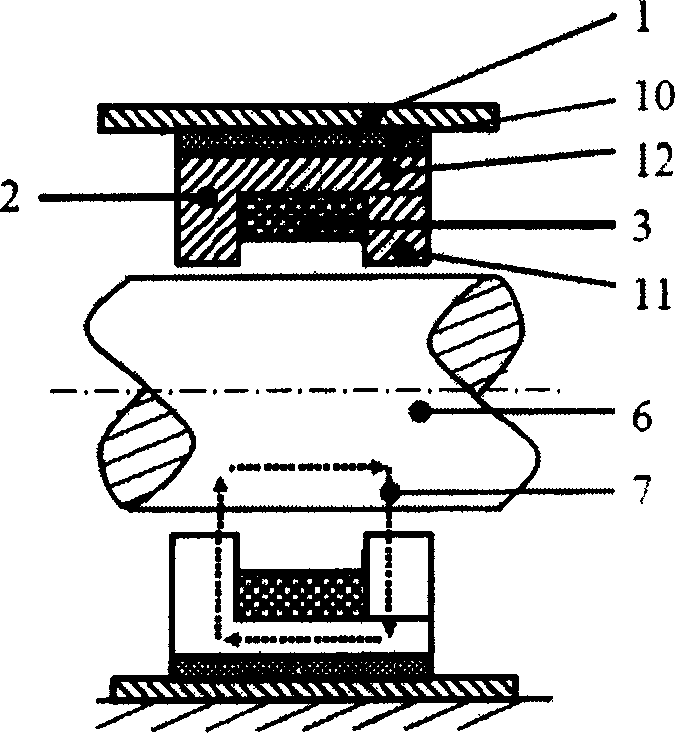

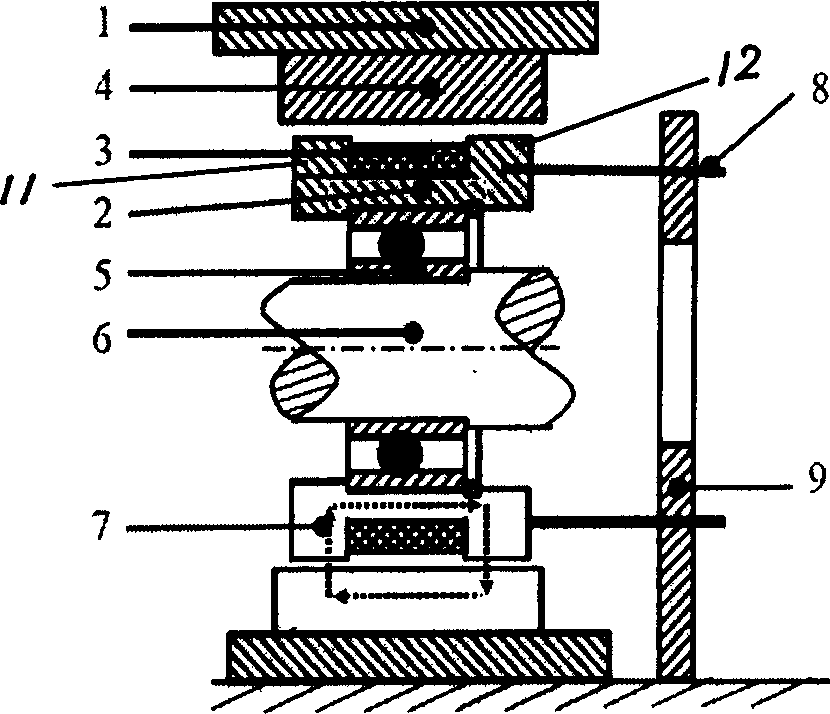

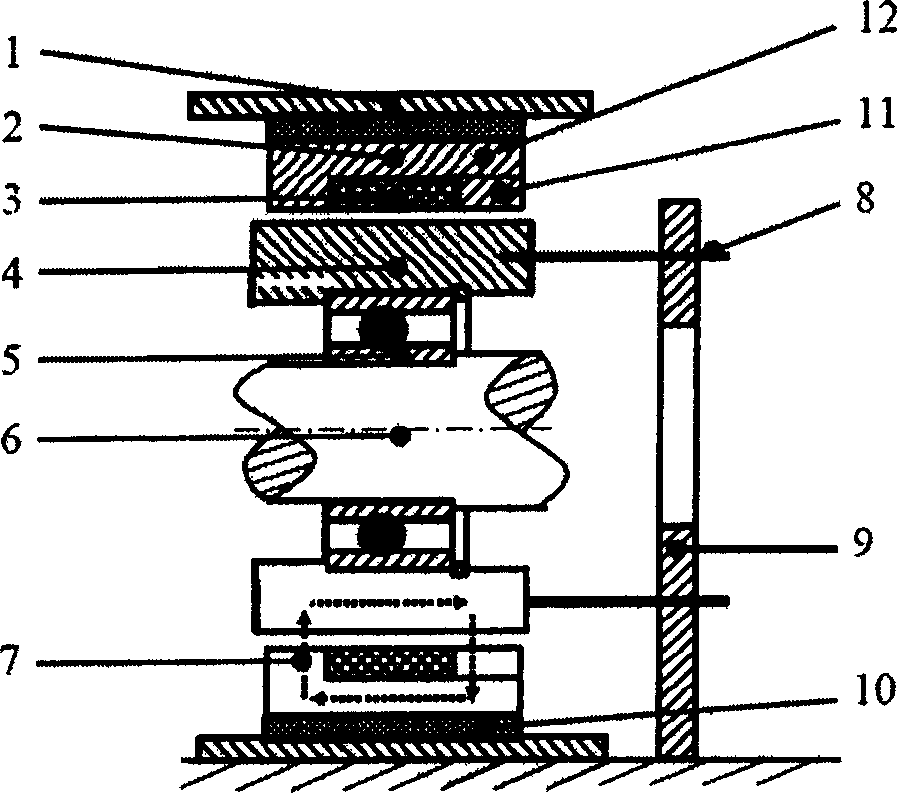

[0024] see figure 1 The eddy current damping device for rotating machinery of the present invention includes a ring magnet 2 coaxially sleeved on the rotor 6 from the inside to the outside, a magnetic isolation ring 10 and a casing 1, and there is a gap between the ring magnet 2 and the rotor 6. There is a gap, and the rotor 6 moves in the gap, and the inner circular surface of the ring magnet 2 is provided with a groove along the circumferential direction, and the coil 3 wound around the groove is arranged in the groove. The ring magnet 2 can be an integral structure, and for the convenience of processing, it can also be composed of a ring magnet 12 with an L-shaped cross section and a ring surface magnet 11. The casing 1 can be a magnetically conductive material, or a non-magnetically conductive material that separates the magnetic field. When the casing 1 is made of a n...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com