Diamond-like carbon coating preparation device with resultant field and application of device

A technology of diamond coating and preparation equipment, which is applied in the direction of metal material coating process, coating, ion implantation plating, etc., can solve the problems of small effective deposition area, affecting the quality of film formation, and low ionization rate of equipment, and achieves Improve the deposition rate, improve the surface activity, and improve the effect of ionization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

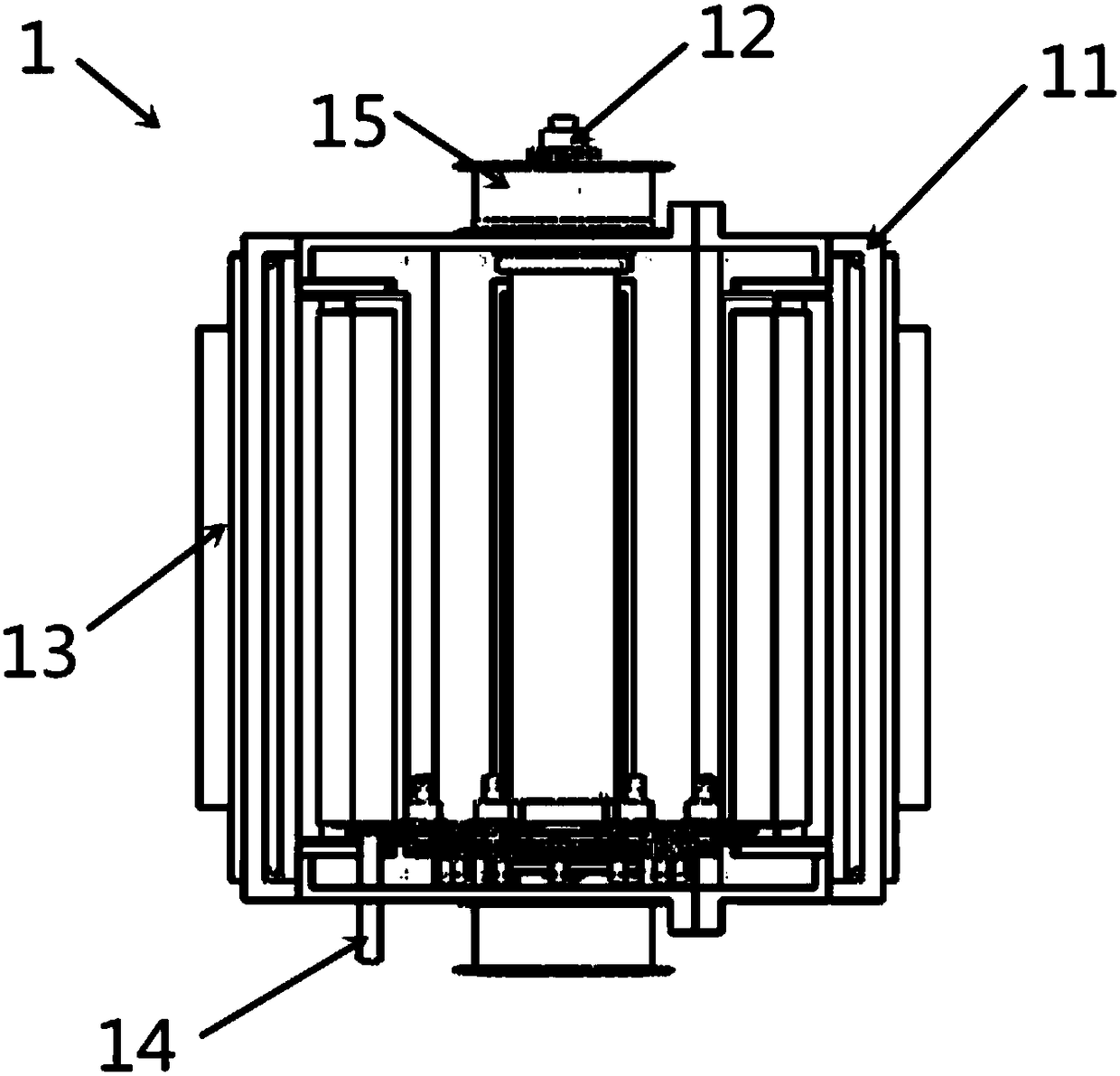

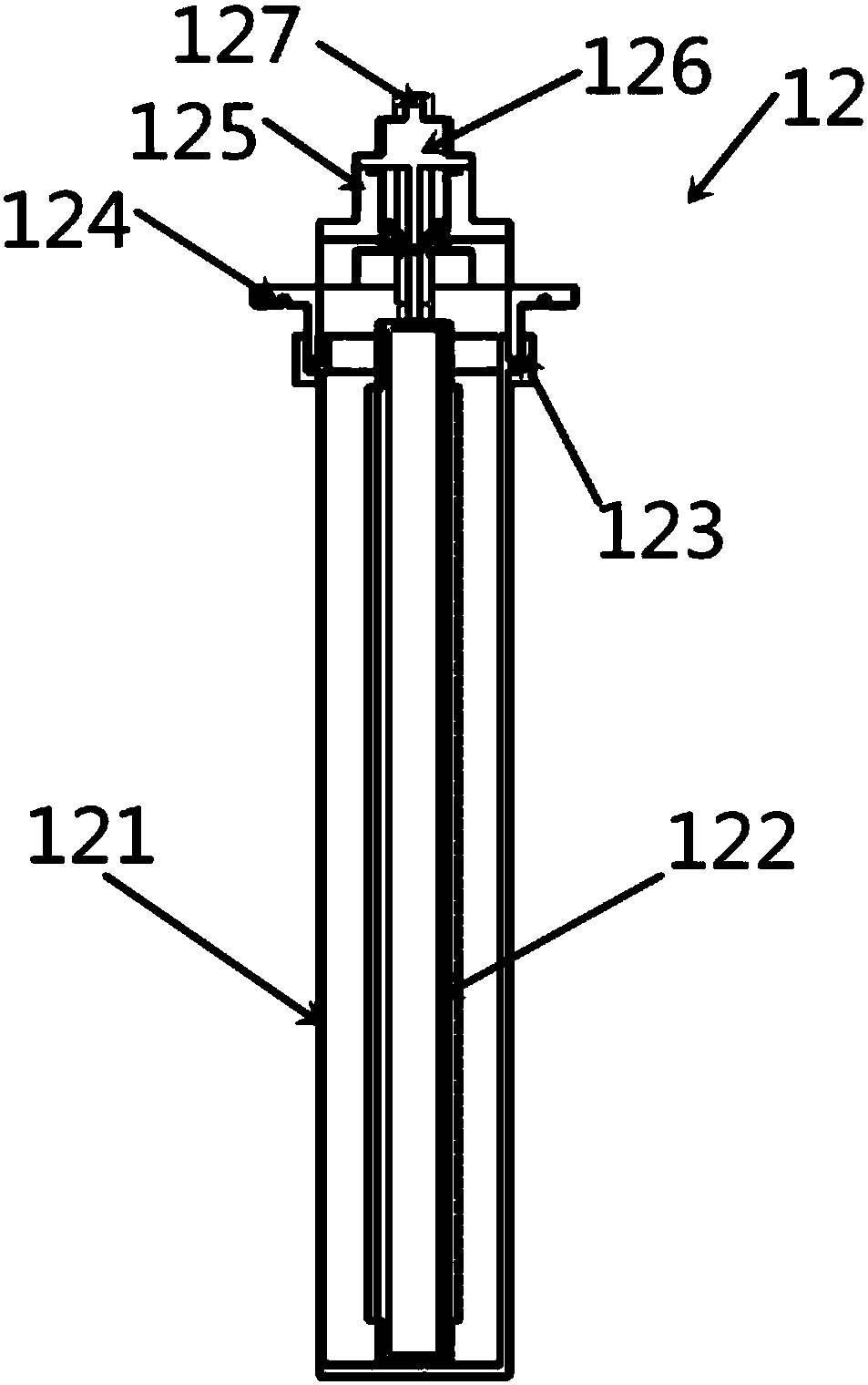

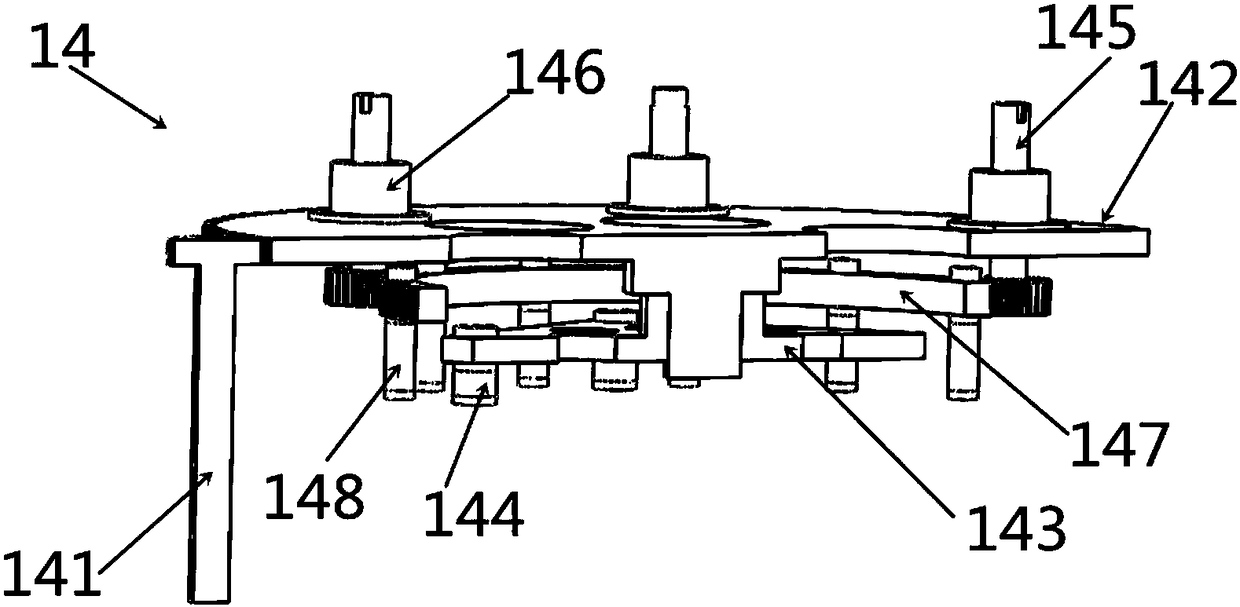

Embodiment 1

[0043] see Figure 4 As shown: the configuration of the composite magnetic field coating equipment for preparing hydrogen-containing diamond-like coatings is as follows, the process components 13 used are four sets of anode layer ion sources 131 and four sets of magnetron sputtering metal cathodes 132, and the two particle sources are arranged at intervals , eight groups of process components form a closed ring magnetic field, the center water-cooled anode 12 is equipped with a rotatable magnetic shoe, eight groups of magnets are assembled on the magnetic shoe, and the longitudinal electromagnetic coils 15 are respectively assembled at the upper and lower center positions. During the glow discharge process, Under the action of the magnetic field, the electrons under the compound magnetic field will be influenced by the electric field and attracted to the water-cooled anode. During the movement of the electrons, there will be collisions of hydrocarbon gas, thereby ionizing the g...

Embodiment 2

[0058] see Figure 5 As shown: the configuration of the composite magnetic field coating equipment for preparing doped diamond-like coatings is as follows, the process components 13 used are four sets of anode plates 133 with magnetic fields and four sets of arc sources 134 equipped with suspended gauze baffles. Arranged at intervals, during the arc source discharge process, the gauze baffle with suspended potential can filter out large particles. When the anode plate and the central anode with a magnetic field are connected, the electrons in the arc source discharge process will be controlled by the electric field. Attracted to the anode, during the movement of electrons, there will be hydrocarbon gas collisions, thereby ionizing the gas, and efficiently producing diamond-like coatings; in addition, the metal atoms filtered by the gauze can pass through the arc during the diamond-like deposition process. The adjustment of the current changes the ratio of the doped metal to fo...

Embodiment 3

[0074] see Image 6 As shown: the configuration of the composite magnetic field coating equipment for preparing hydrogen-free diamond-like coatings is as follows. The process components 13 used are four sets of graphite magnetron sputtering targets 135 and four sets of magnetron sputtering metal cathodes 136. The distance between the two particle sources is Arrangement, eight groups of process components form a closed circular magnetic field, the center water-cooled anode 12 is equipped with a rotatable magnetic shoe, eight groups of magnets are assembled on the magnetic shoe, and the longitudinal electromagnetic coils 15 are respectively assembled at the upper and lower center positions, during the glow discharge process In the process, the electrons under the compound magnetic field will be influenced by the electric field under the action of the magnetic field, and will be attracted to the water-cooled anode. During the movement of the electrons, there will be carbon particl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com