Non-contact magnetic spinning apparatus

A non-contact, magnetic technology, used in magnetic separation, solid separation, dehydration/drying/concentrated sludge treatment, etc., can solve the problem of low shock load resistance, easy wear of pressure rollers and magnetic cylinders, and slag in filtrate. Large volume and other problems, to achieve the effect of strong shock load resistance, less magnet consumption, and high dehydration efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] Embodiments are given below in conjunction with the accompanying drawings to further illustrate the present invention.

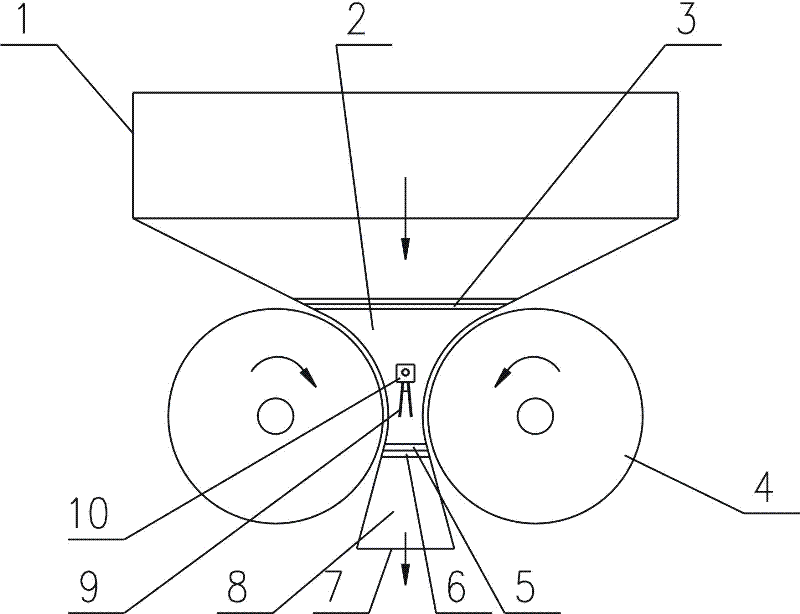

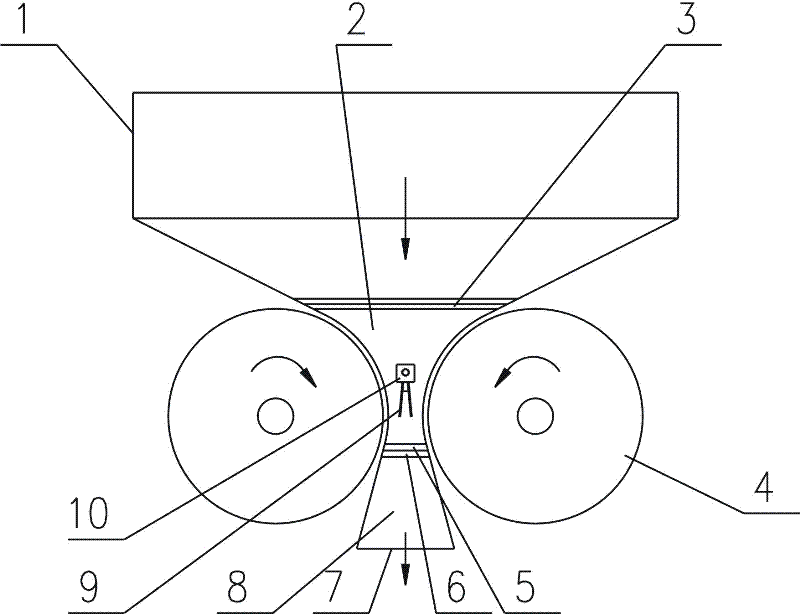

[0019] Such as figure 1 As shown, the non-contact magnetic spinning device provided in this embodiment includes a feeding chamber 1 , a magnetic acting chamber 2 , a permanent magnetic roller 4 , and a discharging chamber 8 .

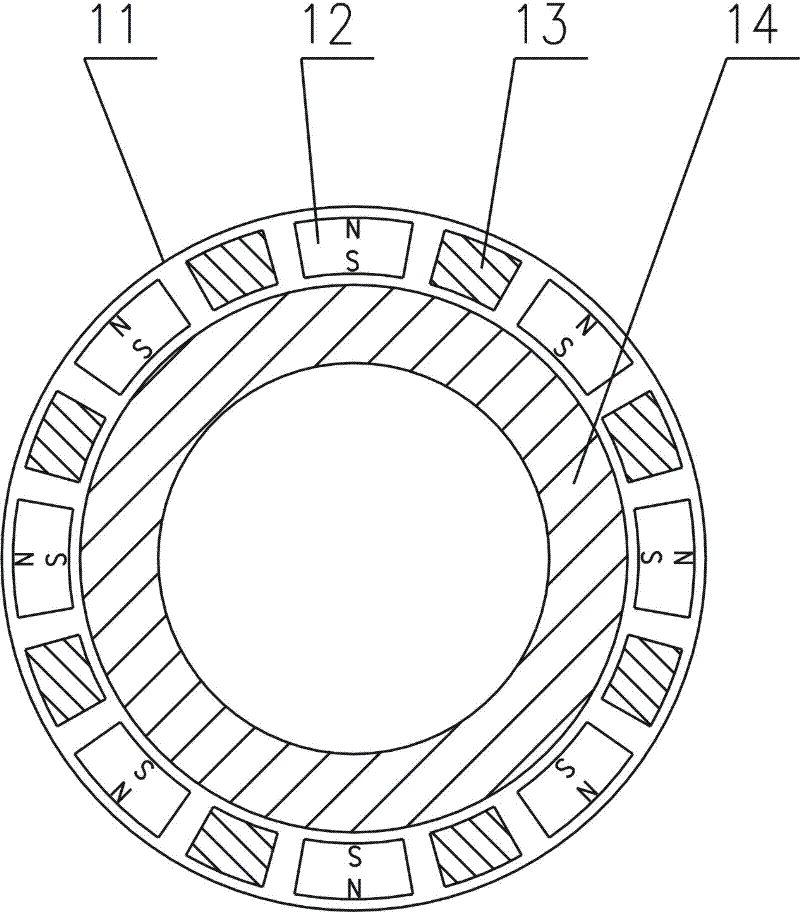

[0020] Such as figure 2 As shown, the permanent magnet roller 4 provided in this embodiment is composed of a roller shaft 14, magnets 12 and non-magnetic spacers 13 arranged at intervals on the circumference of the roller shaft 14, and a stainless steel sleeve 11; wherein the magnet 12 is made of Segment magnets made of ferrite or rare earth permanent magnets.

[0021] combine figure 1 and figure 2 , the permanent magnet rollers 4 are arranged in pairs close to the two side walls of the magnetic force action chamber 2, and the two permanent magnet rollers 4 are relatively rotated (the left permanent magnet roller rotates ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com