Magnetostriction longitudinal-tersional compound ultrasonic vibration transducer

A vibration transducer and composite ultrasonic technology, applied in the direction of fluid using vibration, can solve the problems of low energy conversion efficiency, difficulty in ensuring longitudinal vibration and torsional vibration resonance, etc., to improve processing quality and processing efficiency, and achieve small Design and reduce the effect of parts

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0039] (1) The preparation and processing of tangentially polarized piezoelectric ceramic sheets is difficult, and the power of the ultrasonic transducer made by combining tangentially polarized and longitudinally polarized piezoelectric ceramic sheets is small, and the torsional torque is lost during transmission larger.

[0040] (2) Mode-converting ultrasonic transducers mostly use a chute structure to achieve longitudinal-torsional conversion. The energy conversion efficiency of this device is low, and there are difficulties in the design, it is difficult to ensure the resonance of longitudinal vibration and torsional vibration.

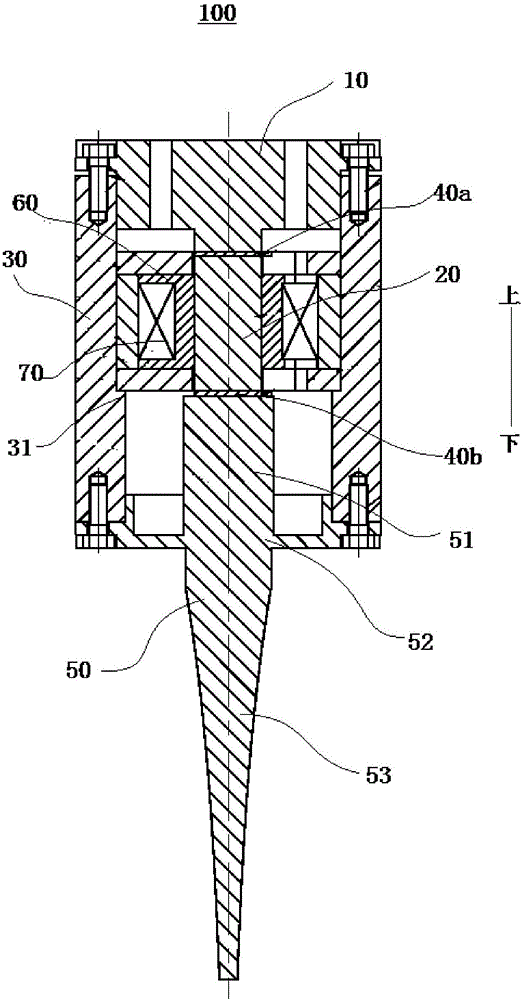

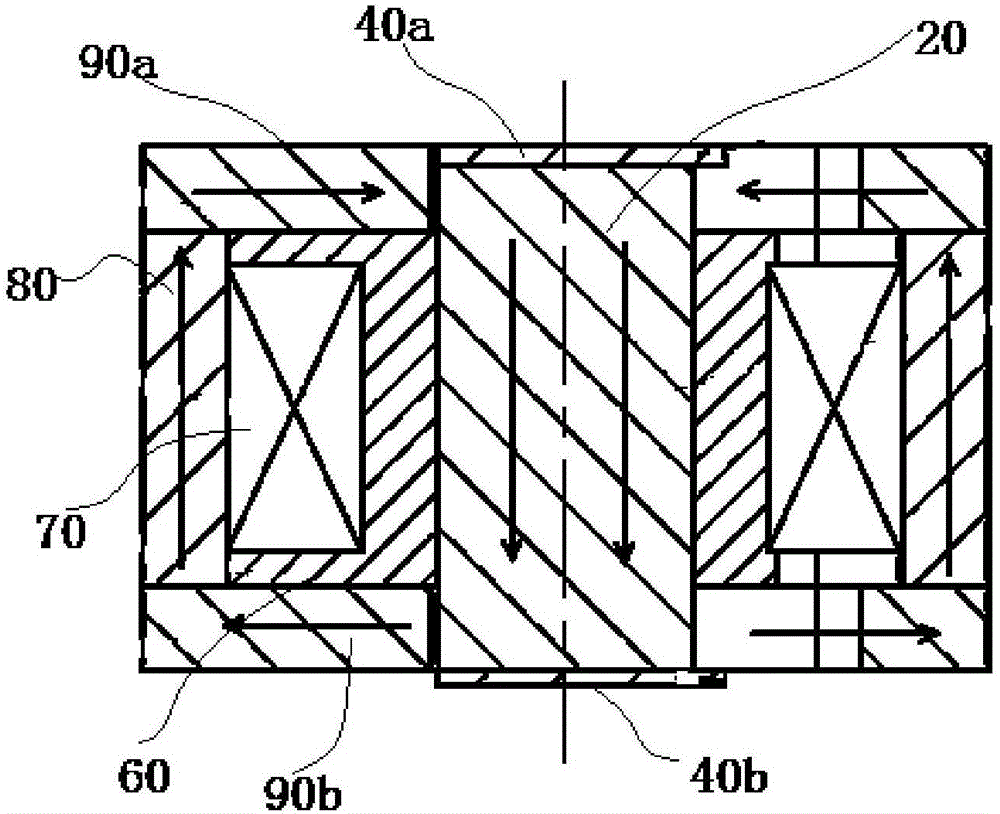

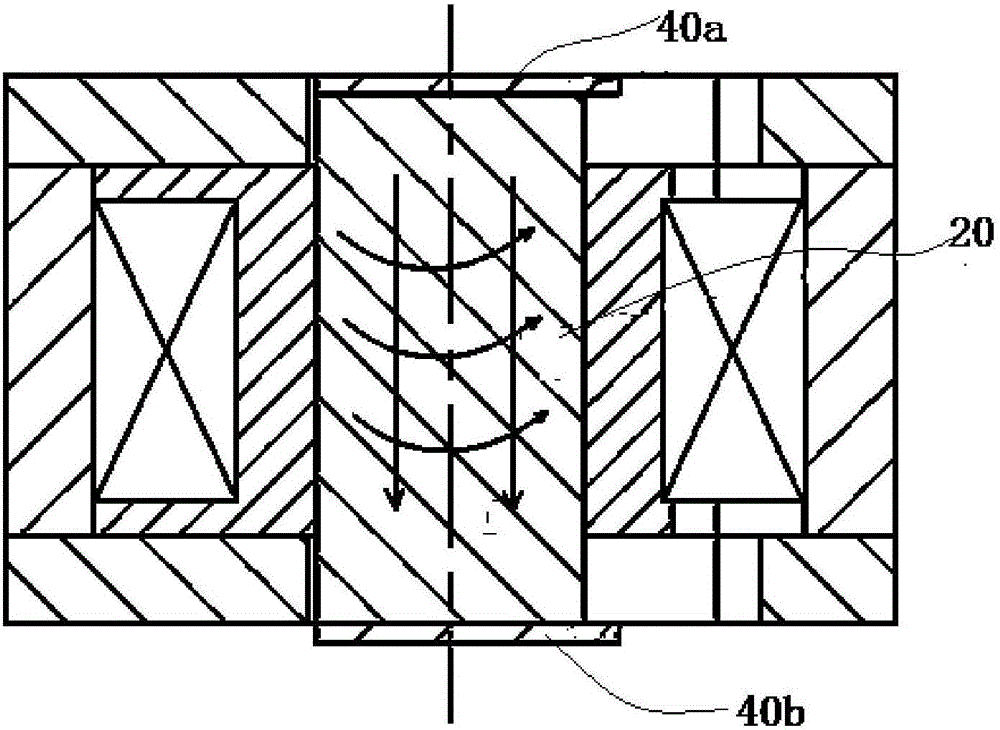

[0041] In view of some of the above-mentioned problems, the present invention proposes a new type of torsional vibration generation mode based on the Wiedemann effect of magnetostrictive material (Fe-Ga), and designs a high-power magnetostrictive longitudinal-torsional composite ultrasonic vibration transducer The magnetostrictive longitudinal-to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com