Patents

Literature

66results about How to "Improve Manufacturing Tolerances" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

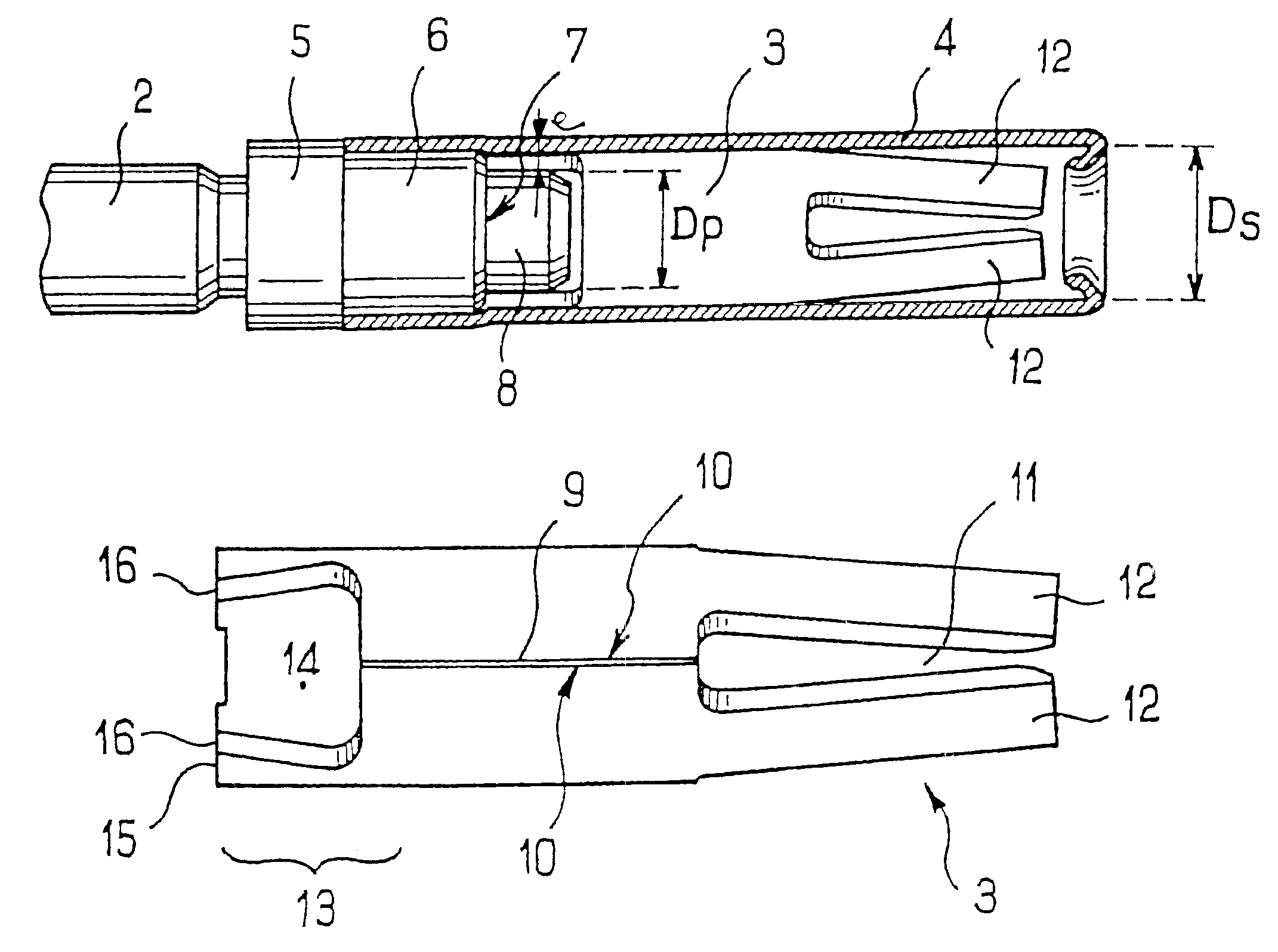

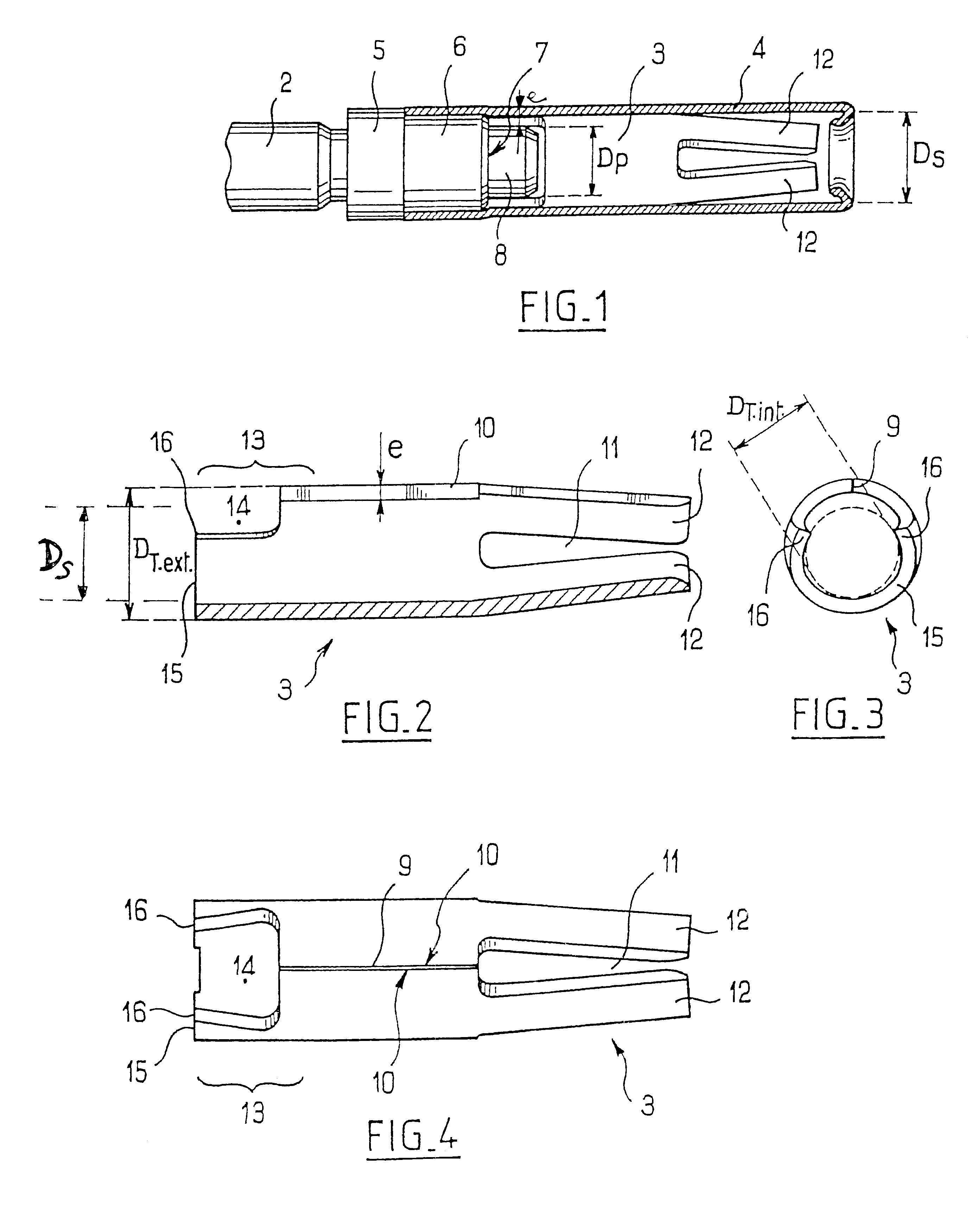

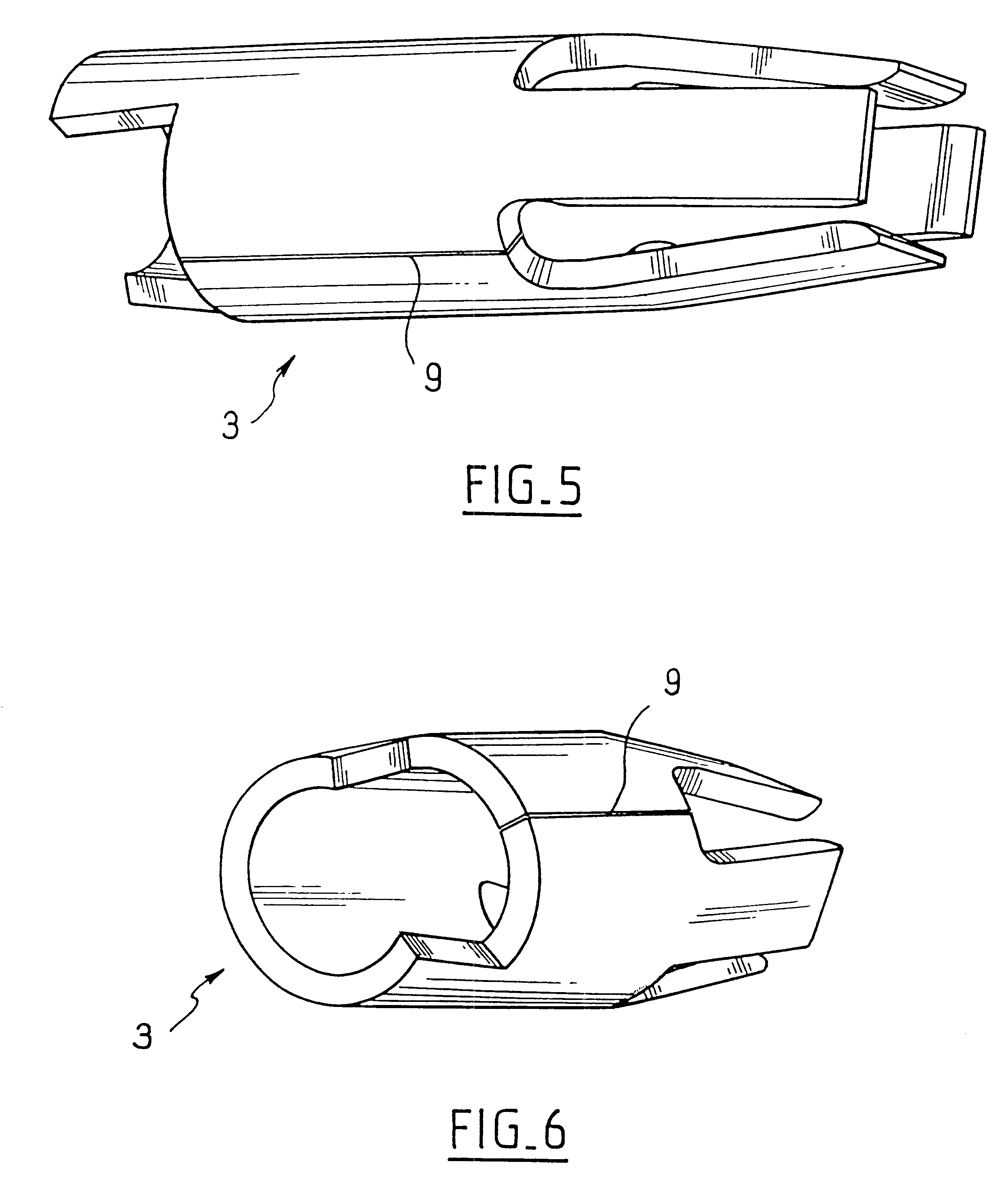

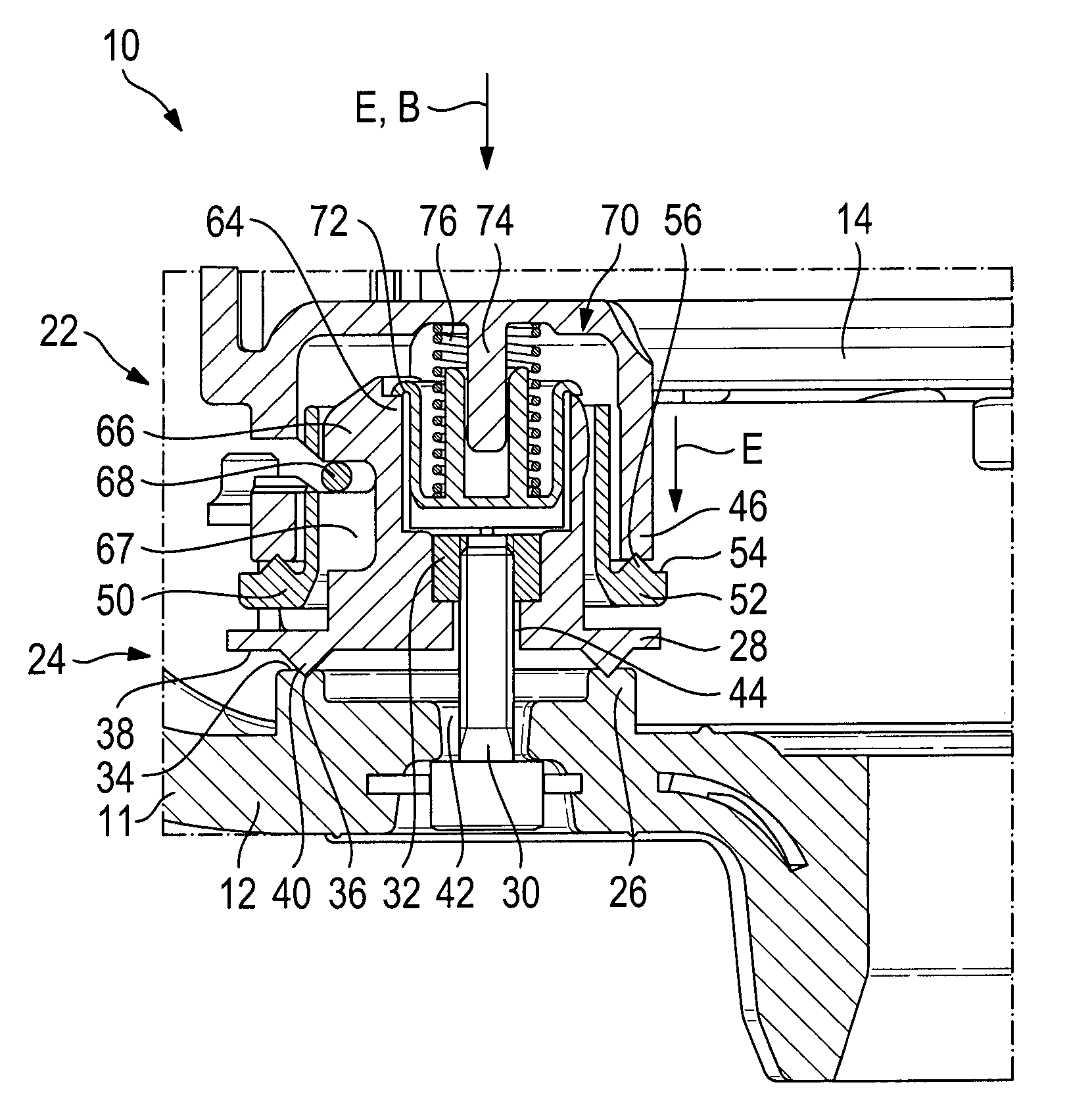

Electrical connector contact pin

InactiveUS6475039B1Little strengthImprove Manufacturing TolerancesContact member manufacturingCoupling contact membersCouplingEngineering

A contact pin for an electrical connector comprises a body, a connector element, and a sheath, the connector element being maintained in the extension of the body by being coupled with a peg projecting from the front face of the body, the sheath being disposed around the connector element and maintained on the body by clamping an annular portion of the latter. At the peg end, connector element comprises an end for coupling with said pin, conformed such that the pin cannot fit inside the cross section of said coupling end, the connector element being capable of deforming elastically to enable its coupling end to friction fit onto the pin, the thus deformed connector element being unable to fit inside the cross section of the sheath.

Owner:RADIALL SA

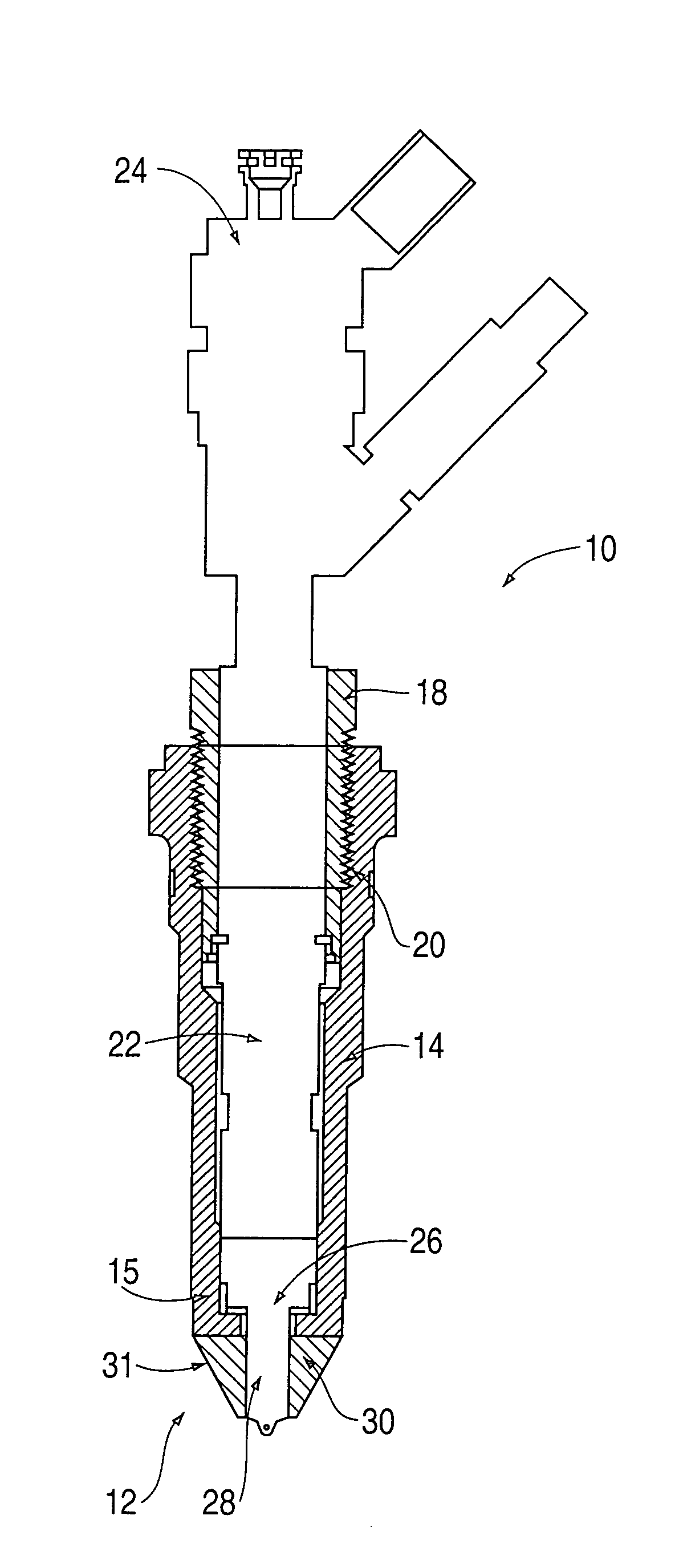

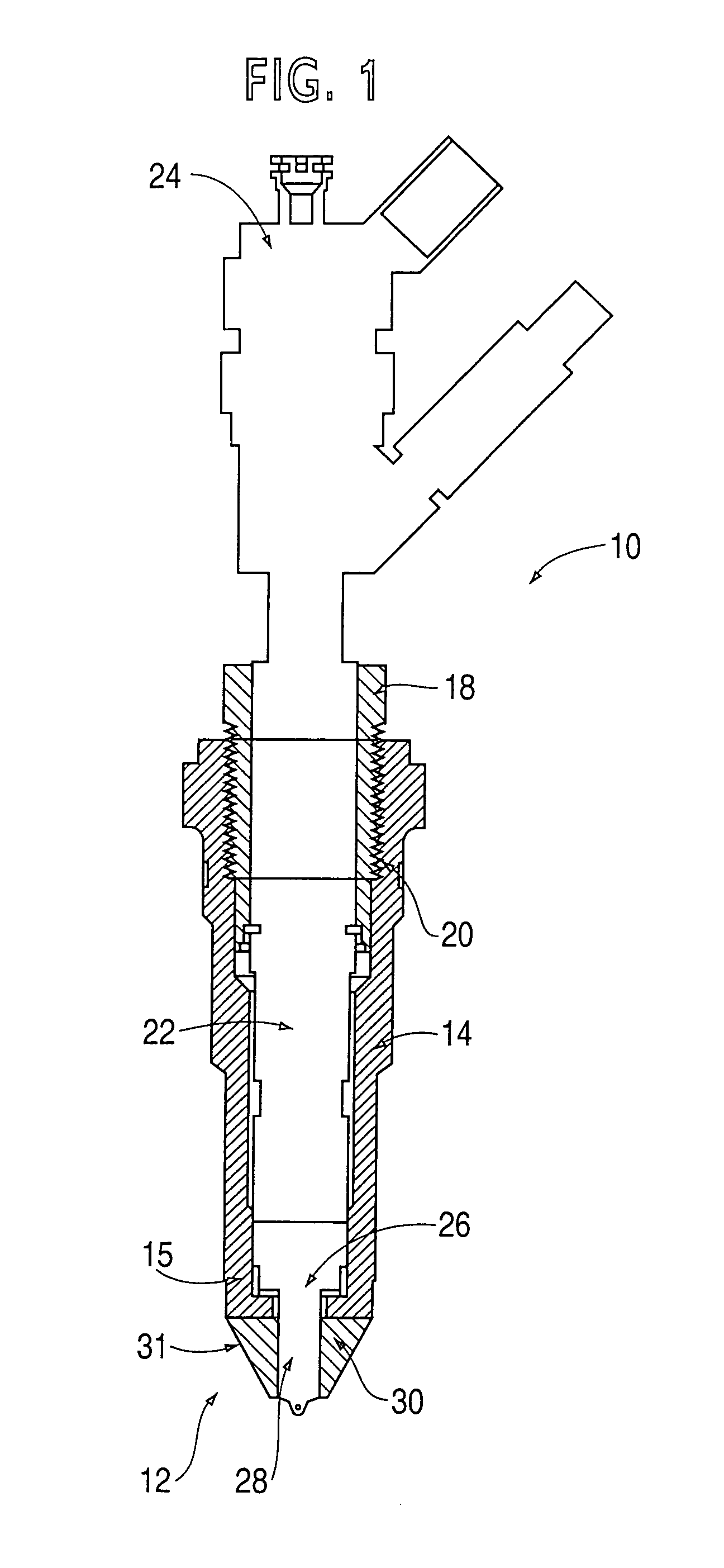

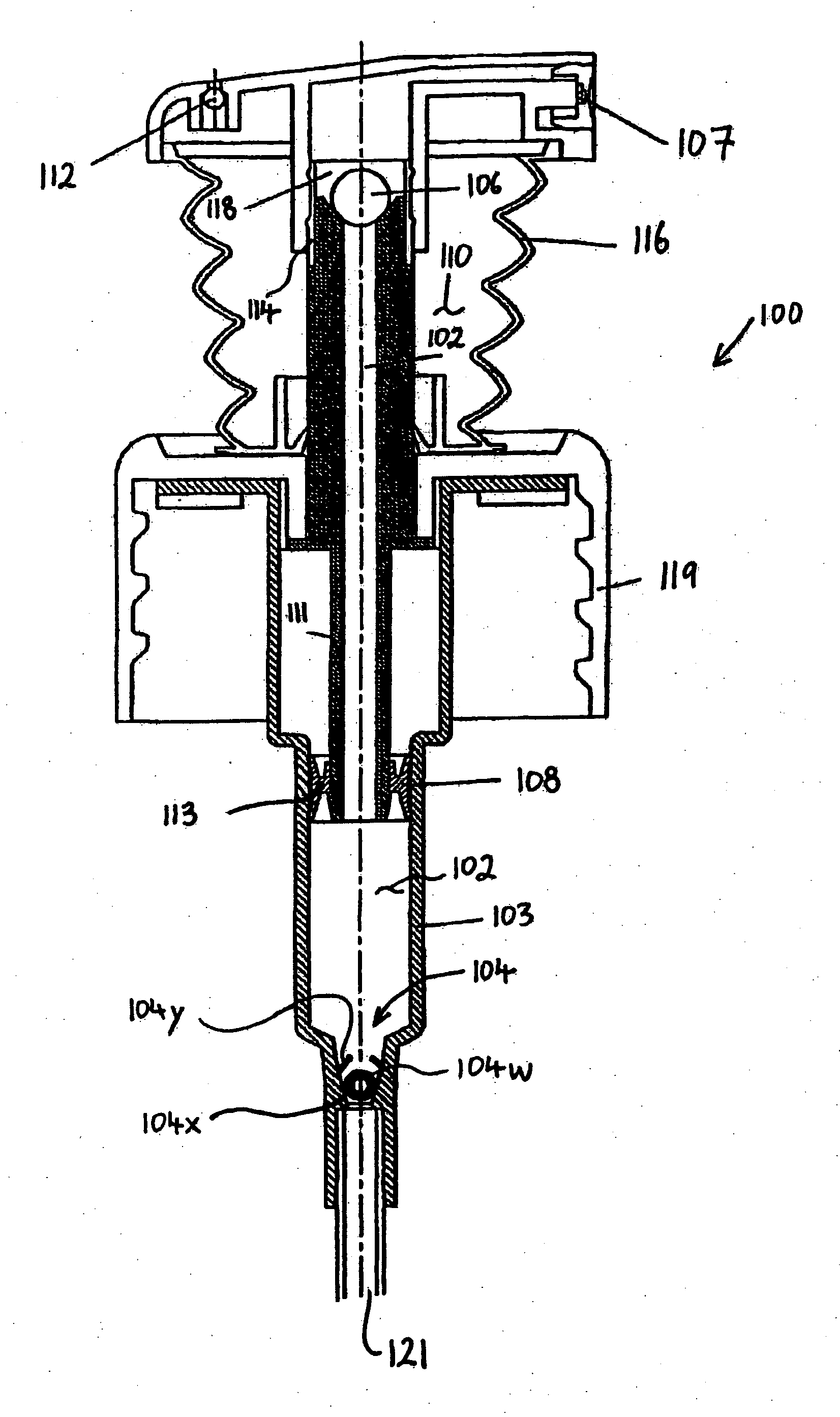

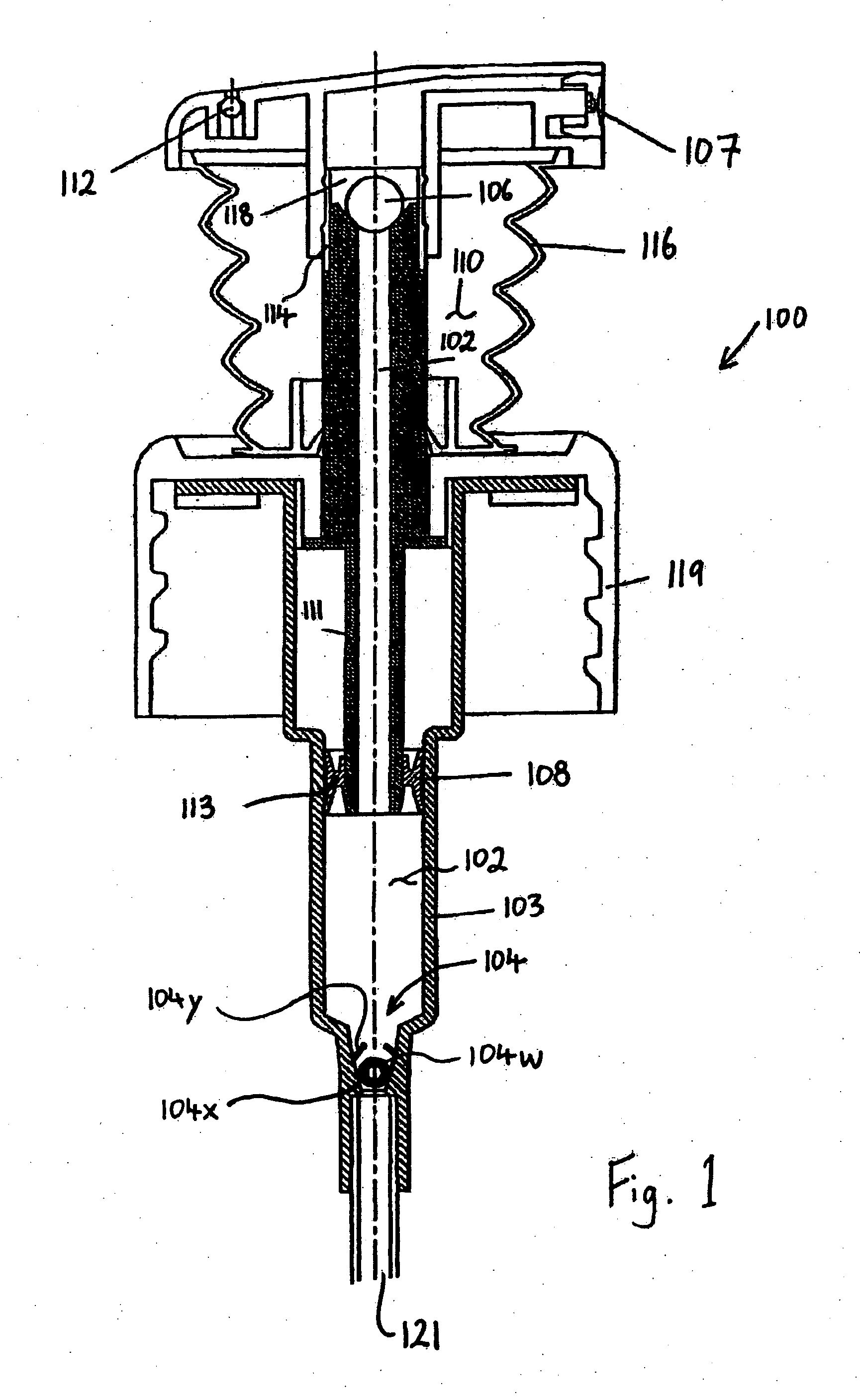

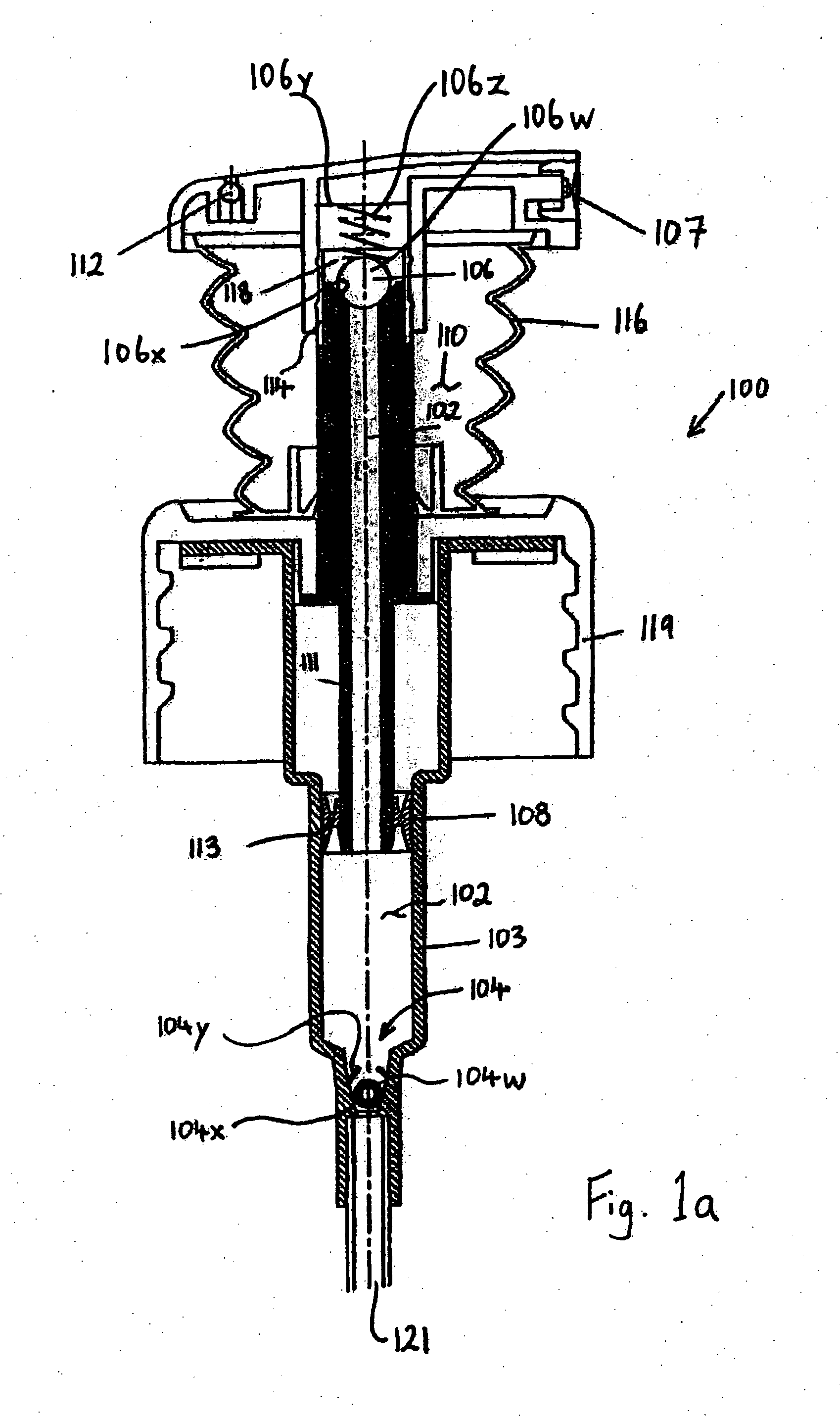

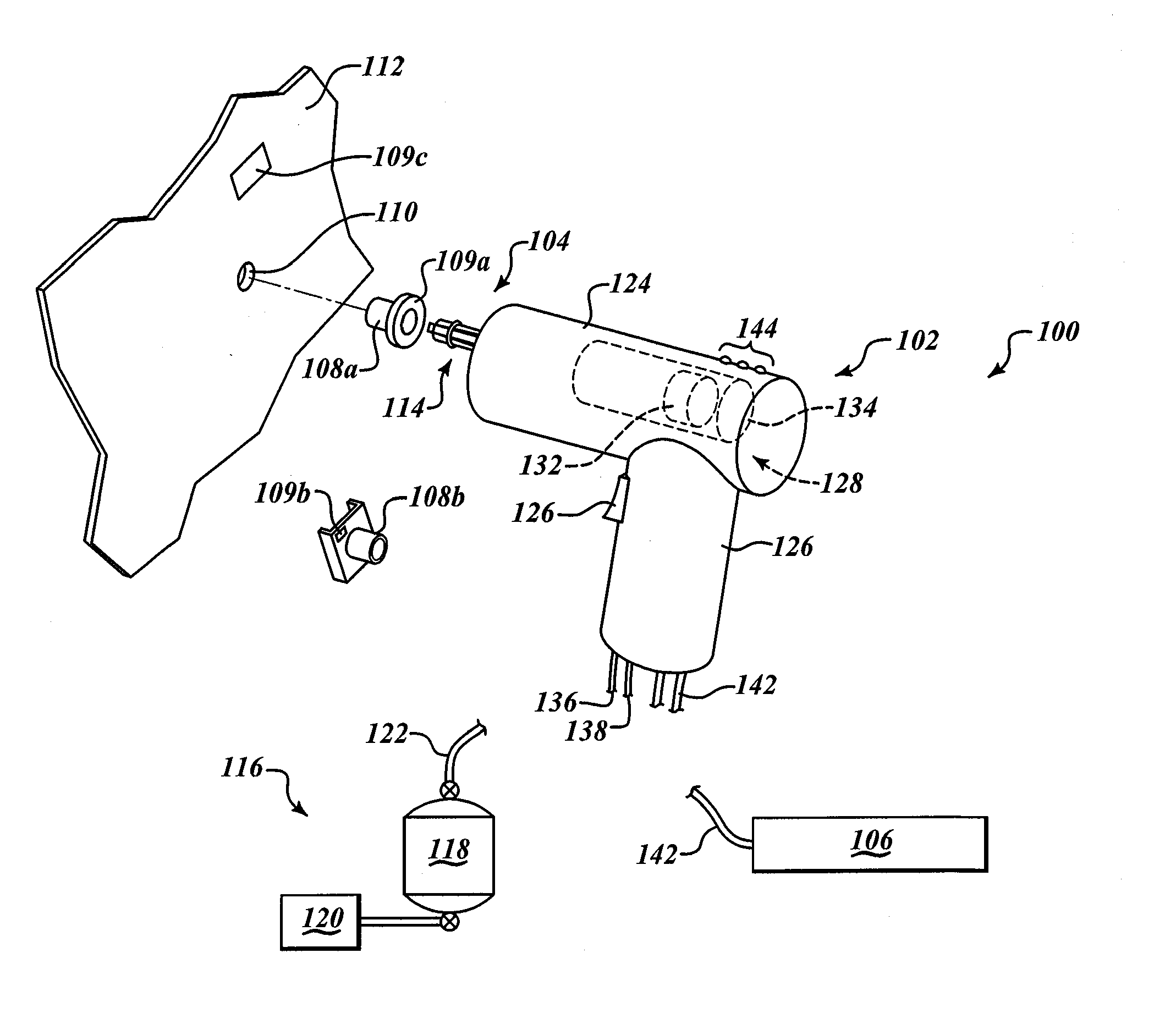

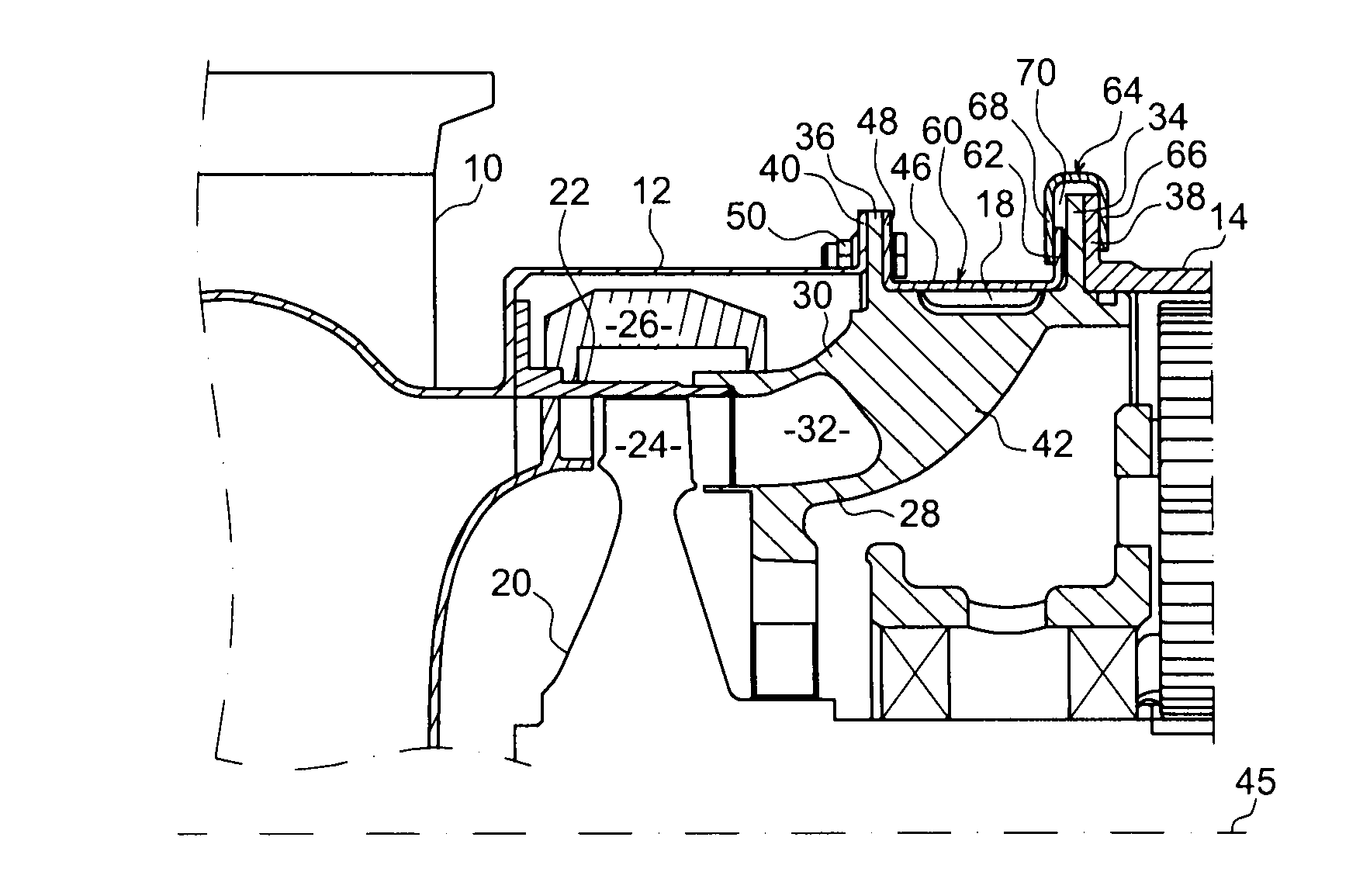

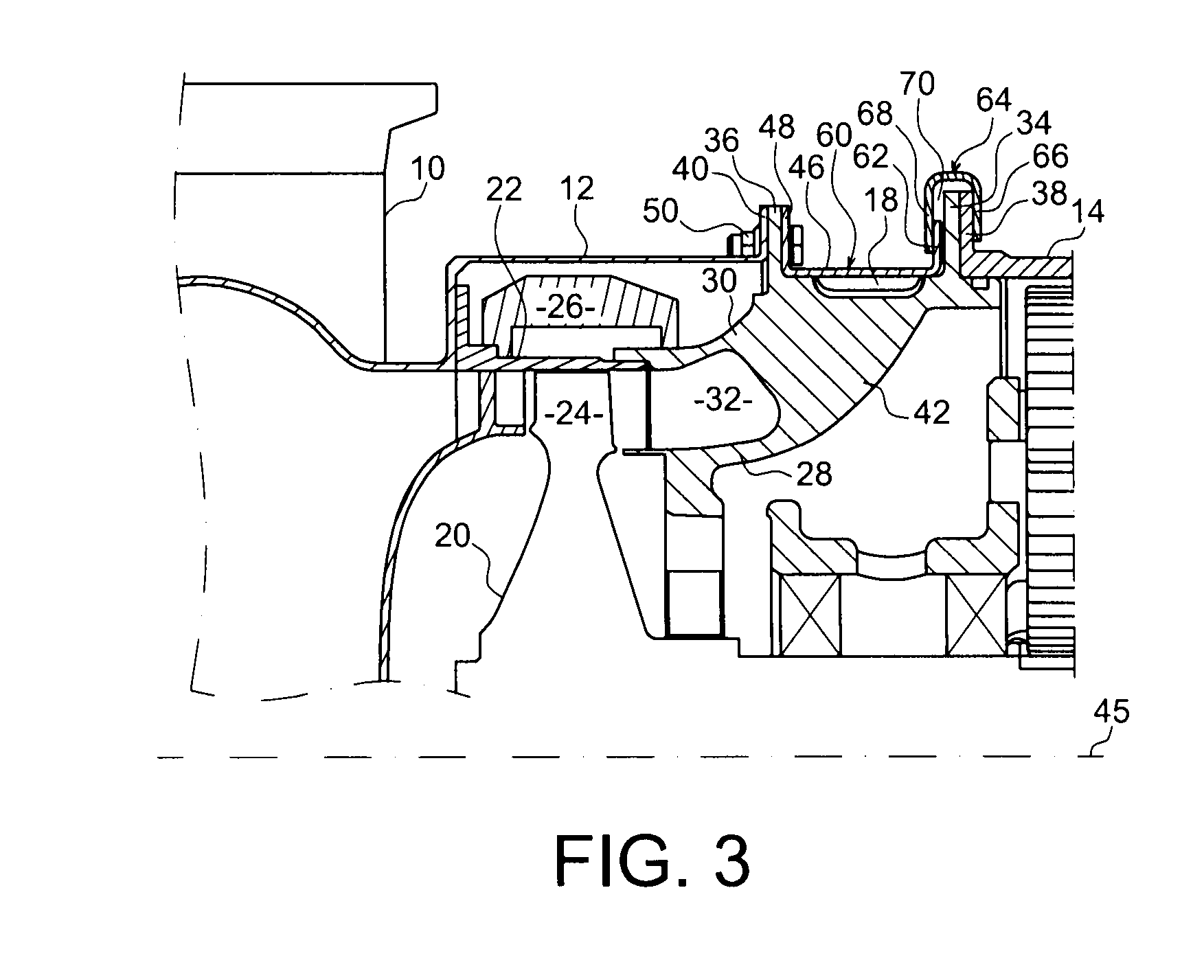

Fuel injector having a nozzle with improved cooling

InactiveUS7028918B2Improve reliabilityImprove performanceSpray nozzlesMachines/enginesInterference fitEngineering

A fuel injector having a nozzle with improved cooling including a retainer and a nozzle housing received therein. The nozzle housing includes a nozzle shank, an outer peripheral surface and at least one injection hole at a tip of the nozzle shank. The nozzle shank is positioned in a nozzle support portion of the retainer. In one embodiment, the outer peripheral surface of the nozzle shank is tapered, and the inner peripheral surface of the nozzle support portion is correspondingly tapered and sized to engage the outer peripheral surface of the nozzle shank along a tapered interface. In another embodiment, the inner peripheral surface of the nozzle support portion has a diameter smaller than a diameter of the outer peripheral surface of the nozzle shank so that an interference fit exists at a seal interface. In yet another embodiment, a nozzle seal seals an interface between the inner peripheral surface of the retainer and the outer peripheral surface of the nozzle shank to thereby prevent entry of hot gases into the interface. In another embodiment, the nozzle support portion is provided on a nozzle sleeve.

Owner:CUMMINS INC

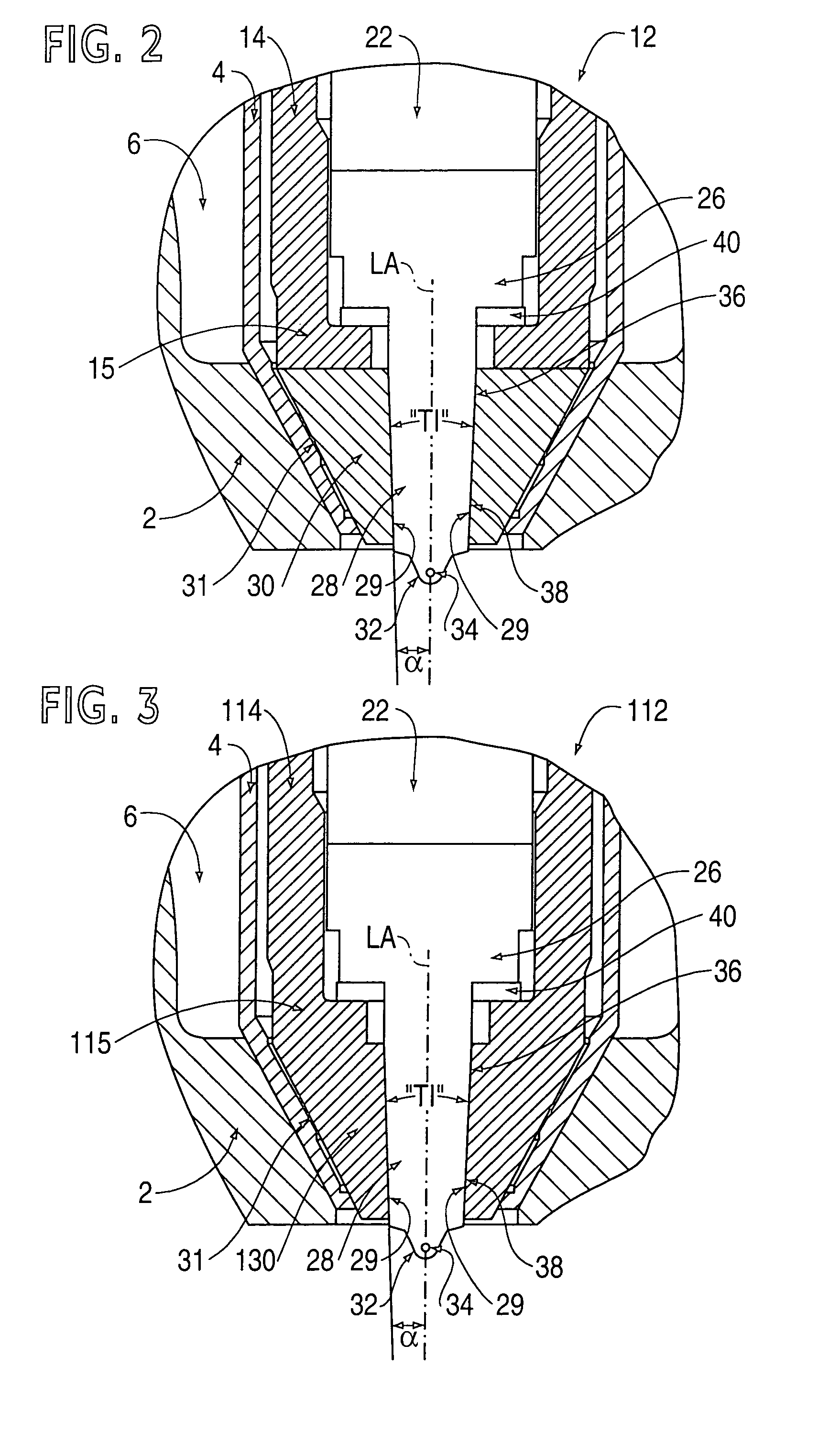

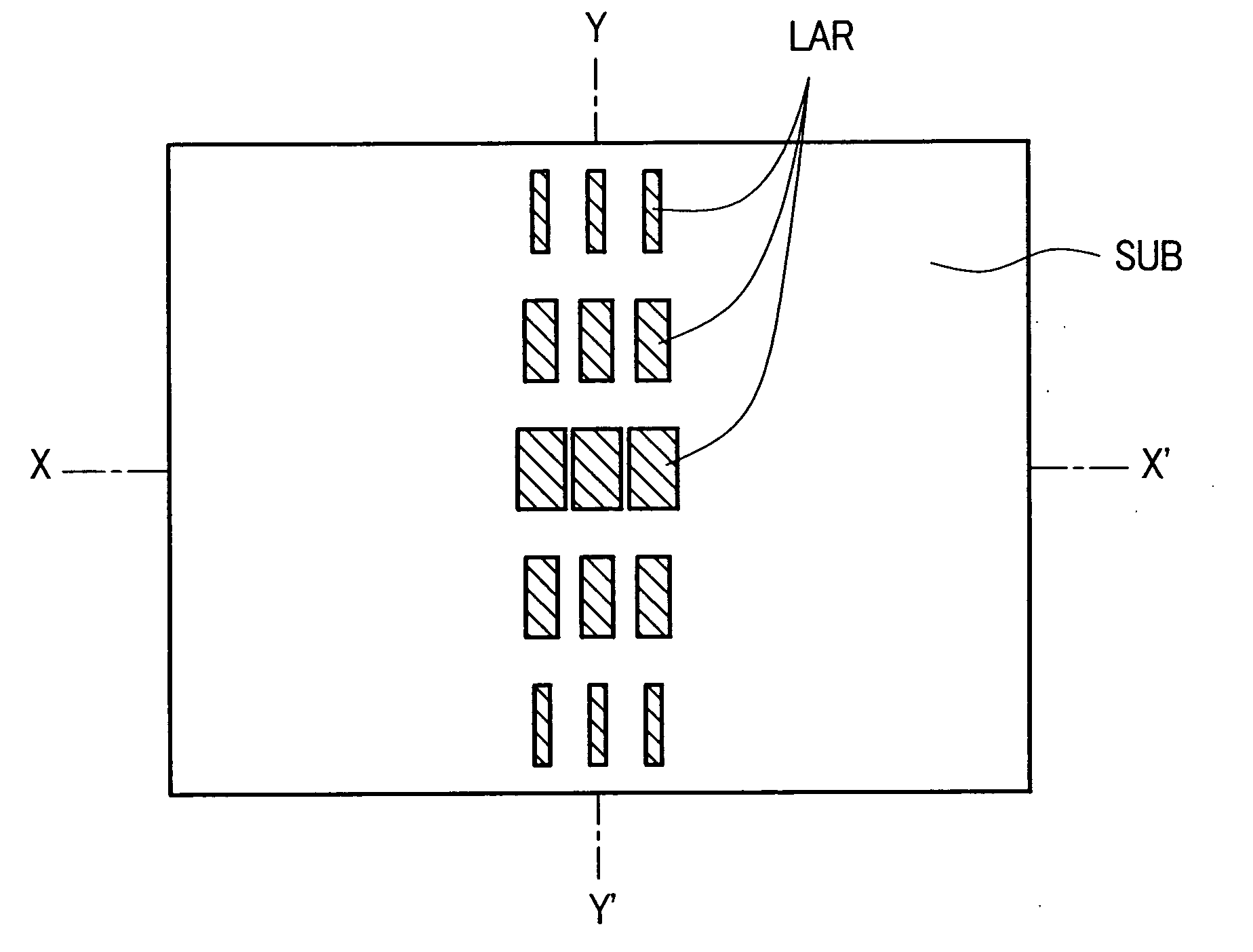

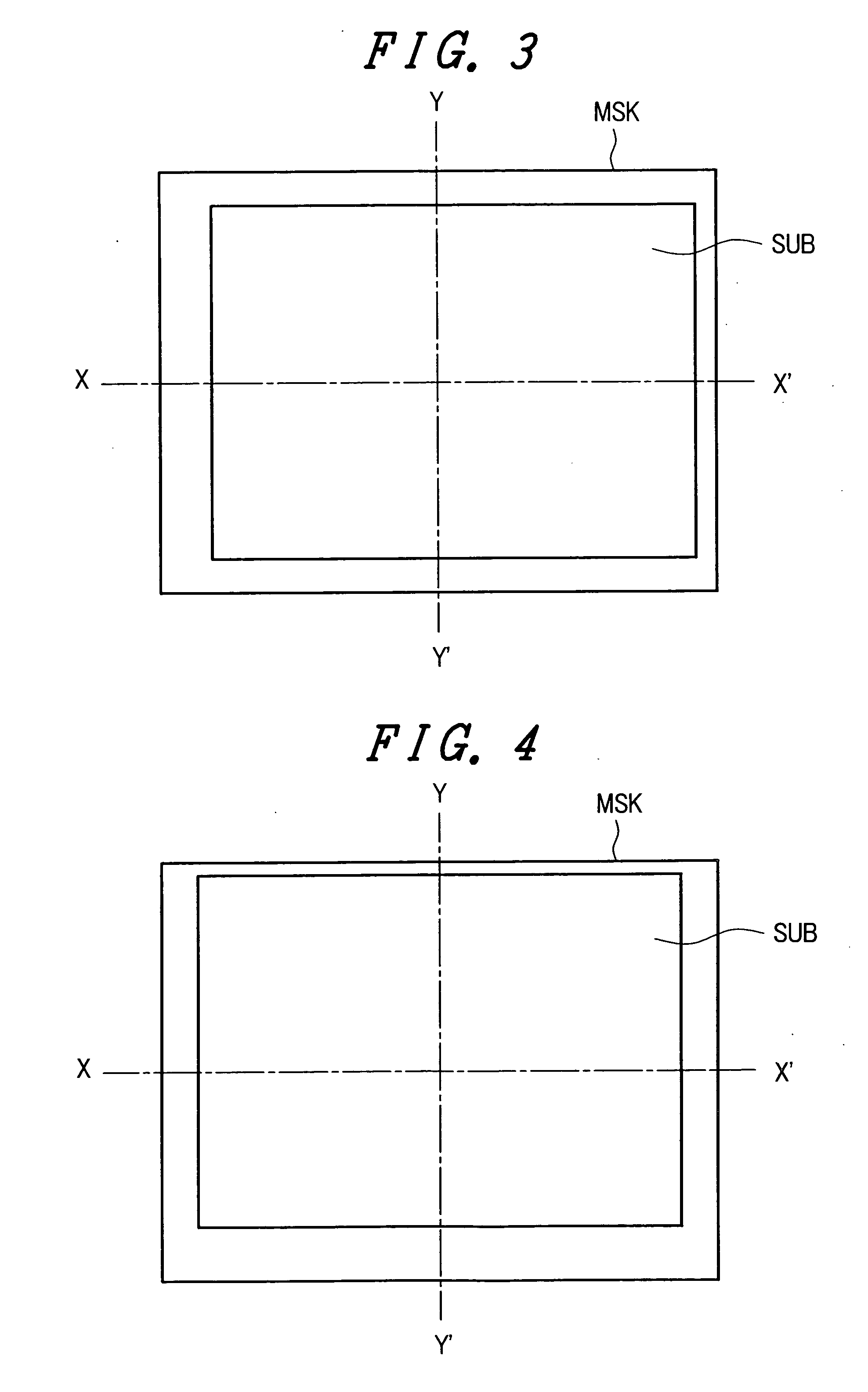

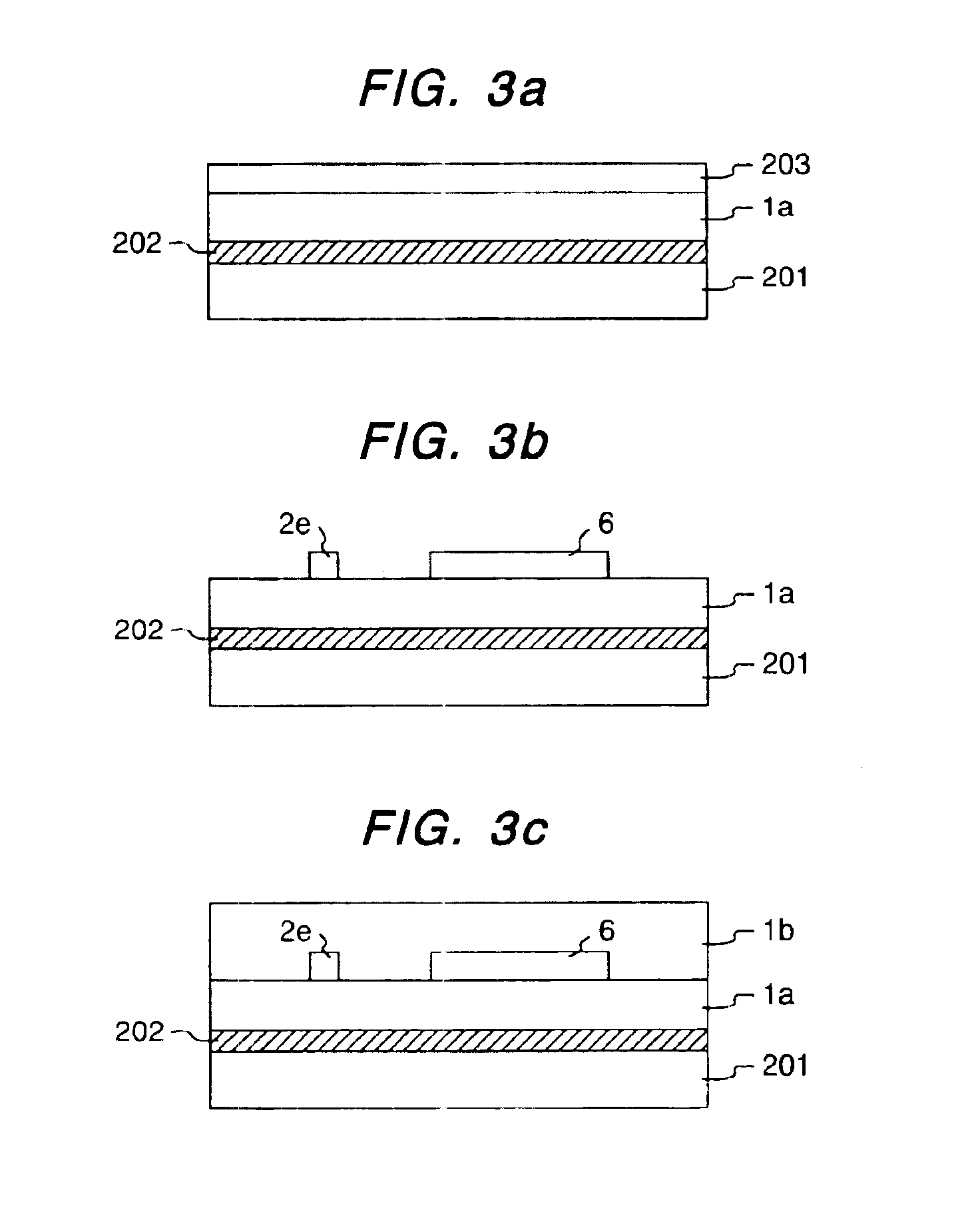

Self-emitting display

ActiveUS20050236970A1Good yieldImprove Manufacturing TolerancesDischarge tube luminescnet screensElectroluminescent light sourcesGas phaseEngineering

An aperture LAR of a light-emitting portion is changed in diameter (size) from the center portion of a screen to the peripheral portion thereof. In this manner, any displacement observed between the aperture LAR and a vapor deposition region VAR of an organic EL material is controlled. The aperture LAR is preferably larger in size at the center portion of the screen, and smaller in the peripheral portion thereof. As such, a light-emitting layer is vapor-deposited on a substrate correctly for every pixel so that a high-quality self-emitting display including organic EL display can de derived.

Owner:SAMSUNG DISPLAY CO LTD +1

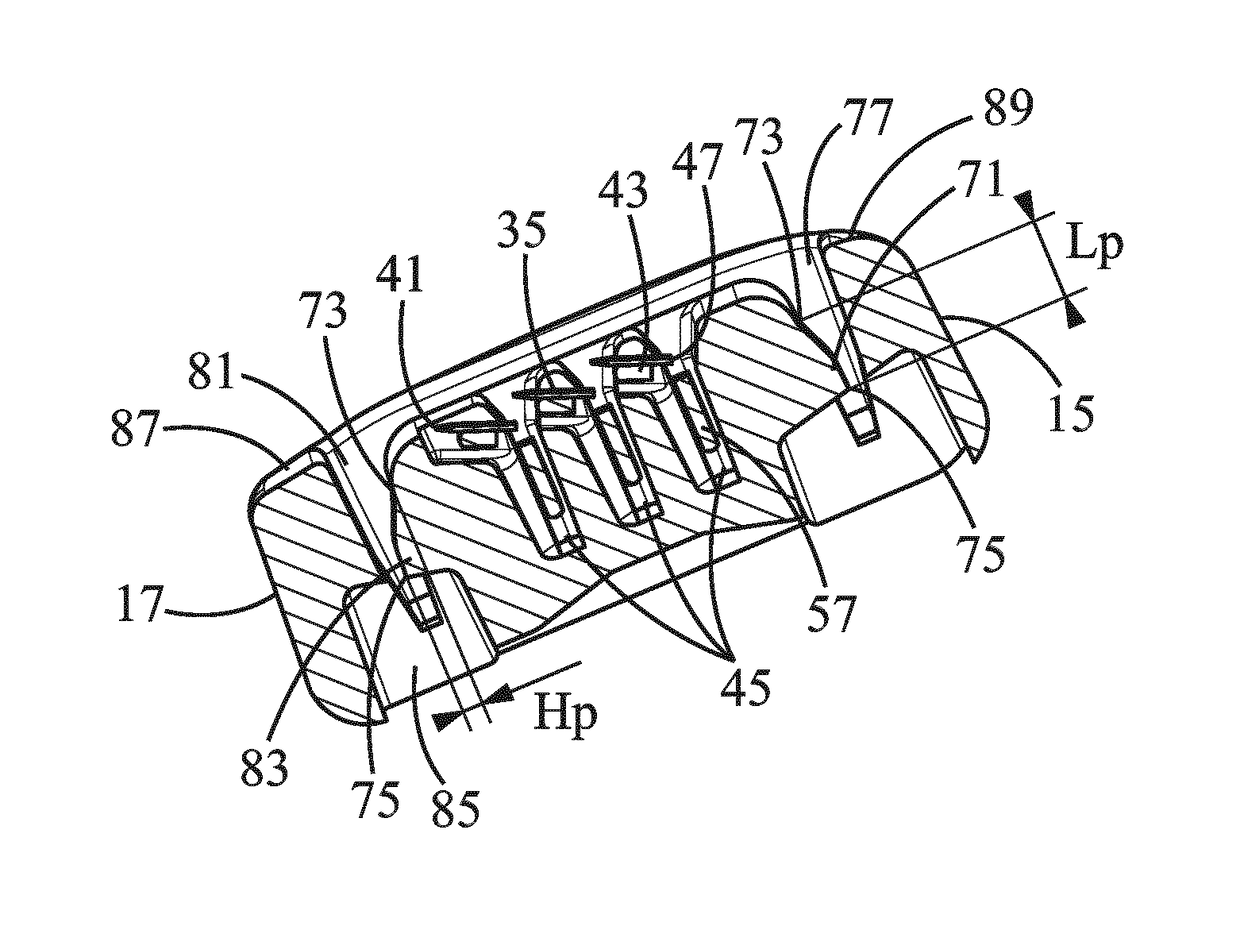

Cathode header optic for x-ray tube

ActiveUS7529345B2Reduced cross sectionImprove electronic efficiencyX-ray tube electrodesCathode ray concentrating/focusing/directingEngineeringElectron

A cathode header optic for an x-ray tube includes an elongate trench with opposite trench walls. A cup recess is formed in the trench between the opposite trench walls, and has a bounded perimeter. A cathode element is disposed in the trench at the cup recess. The cathode element is capable of heating and releasing electrons. A secondary cathode optic defining a cathode ring can be disposed about the header optic. The cathode optics can form part of an x-ray tube.

Owner:MOXTEK INC

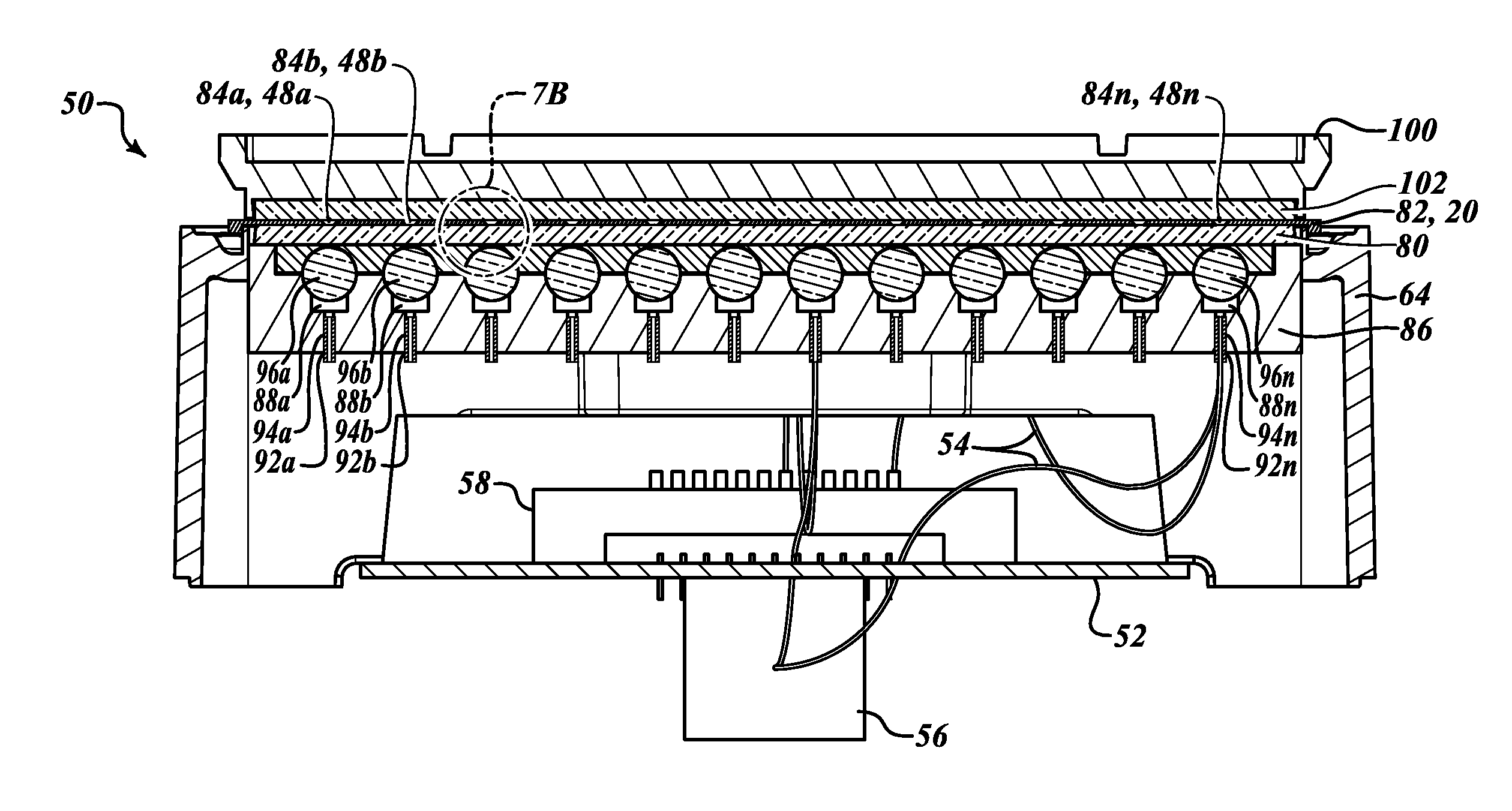

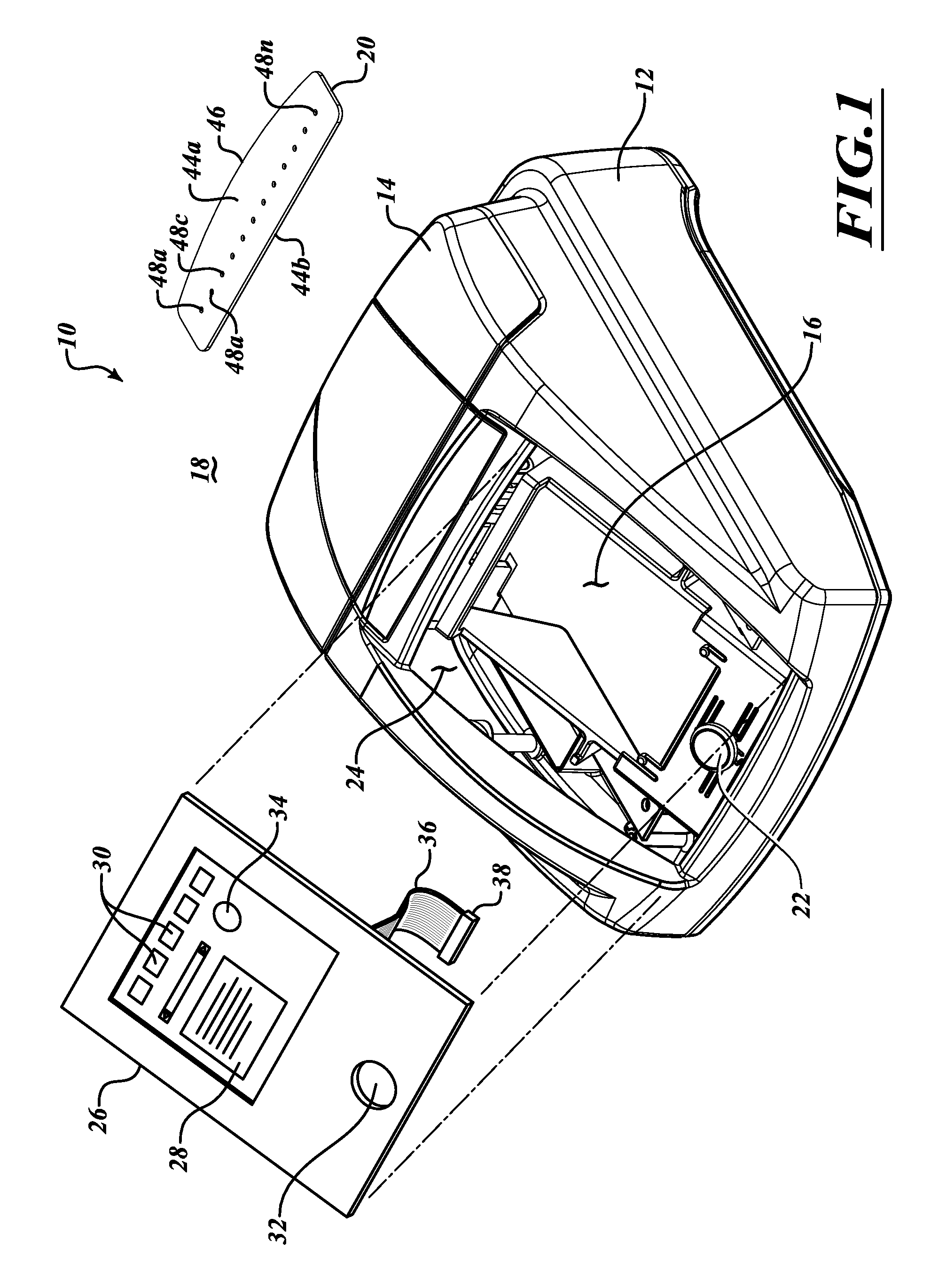

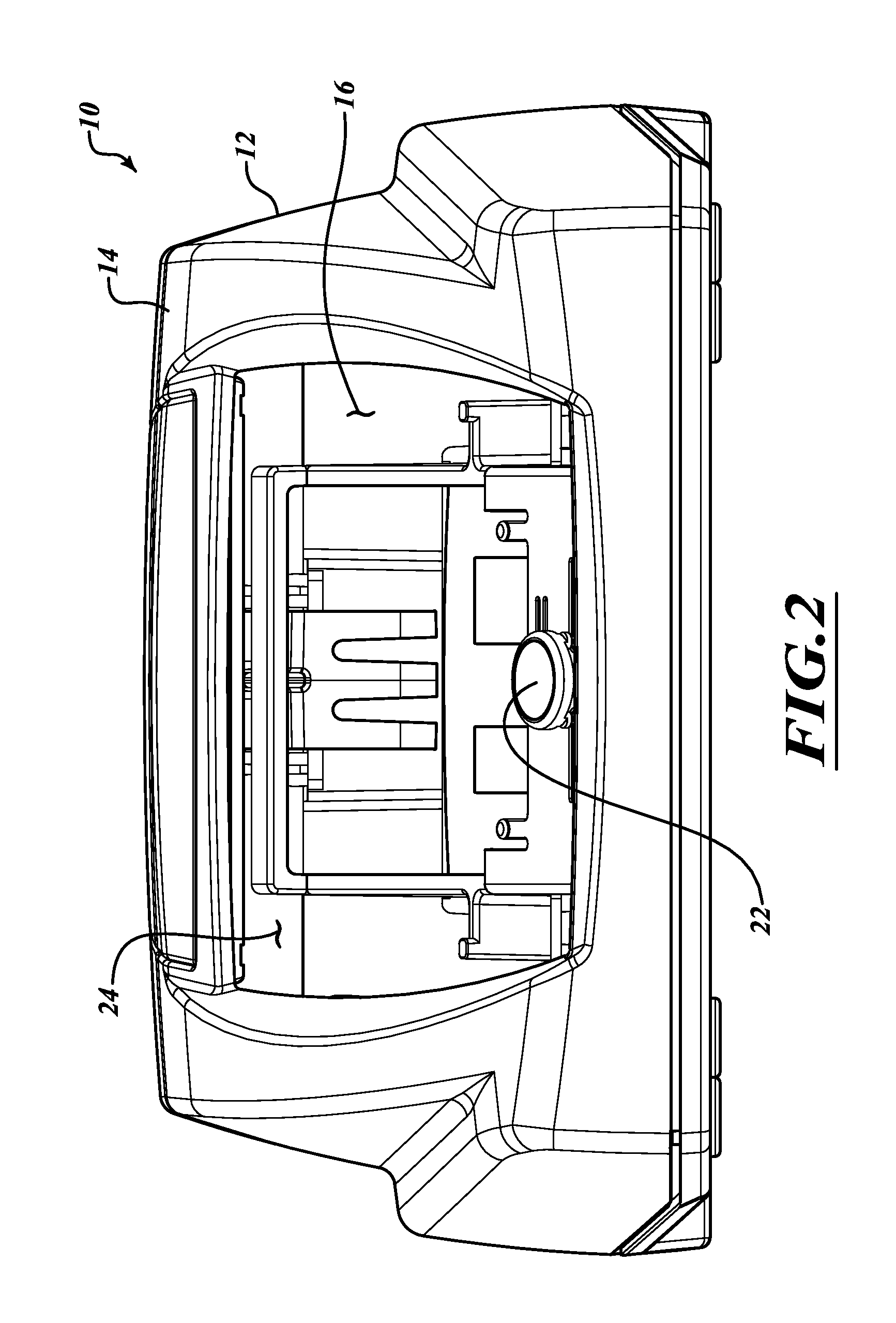

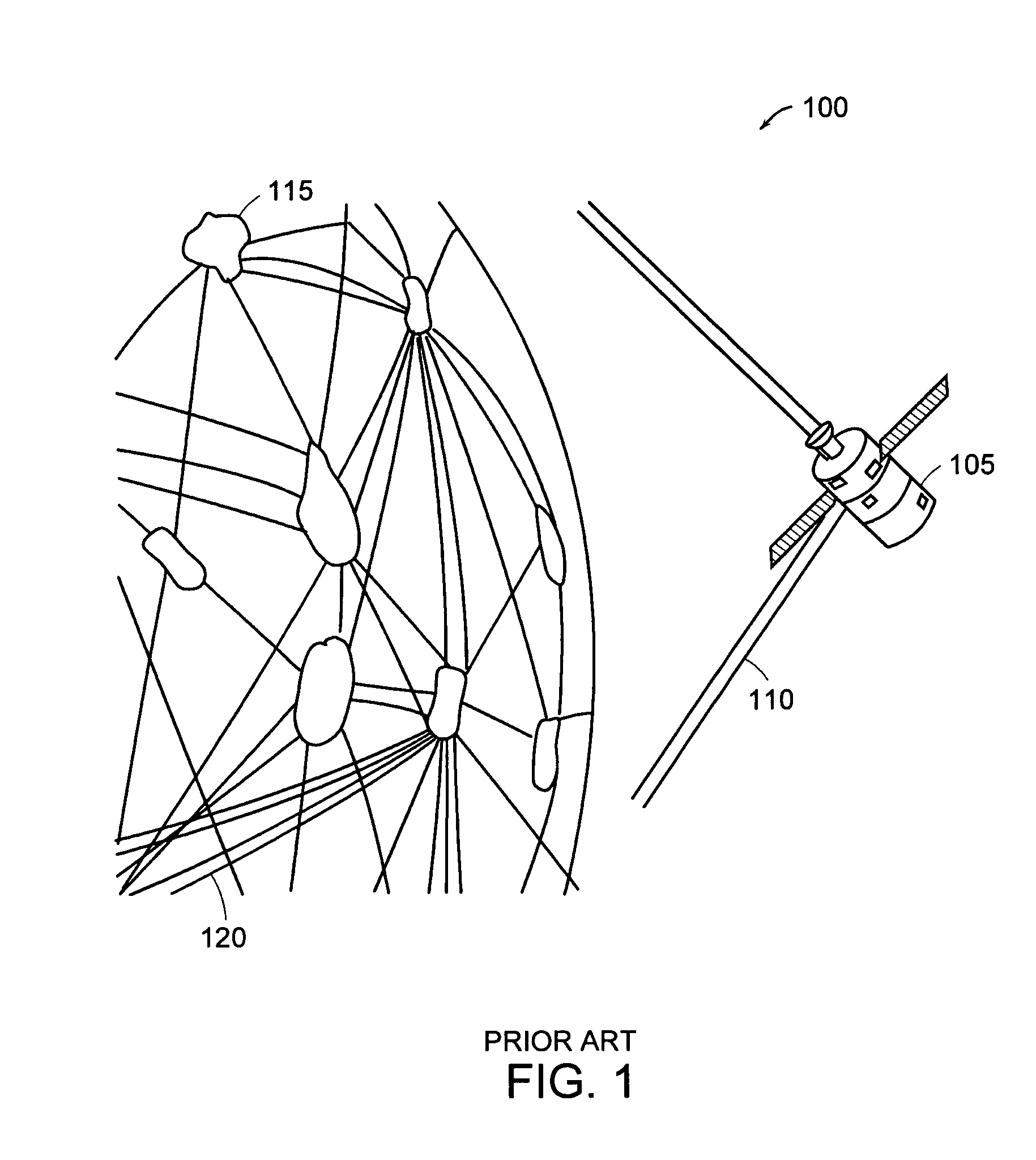

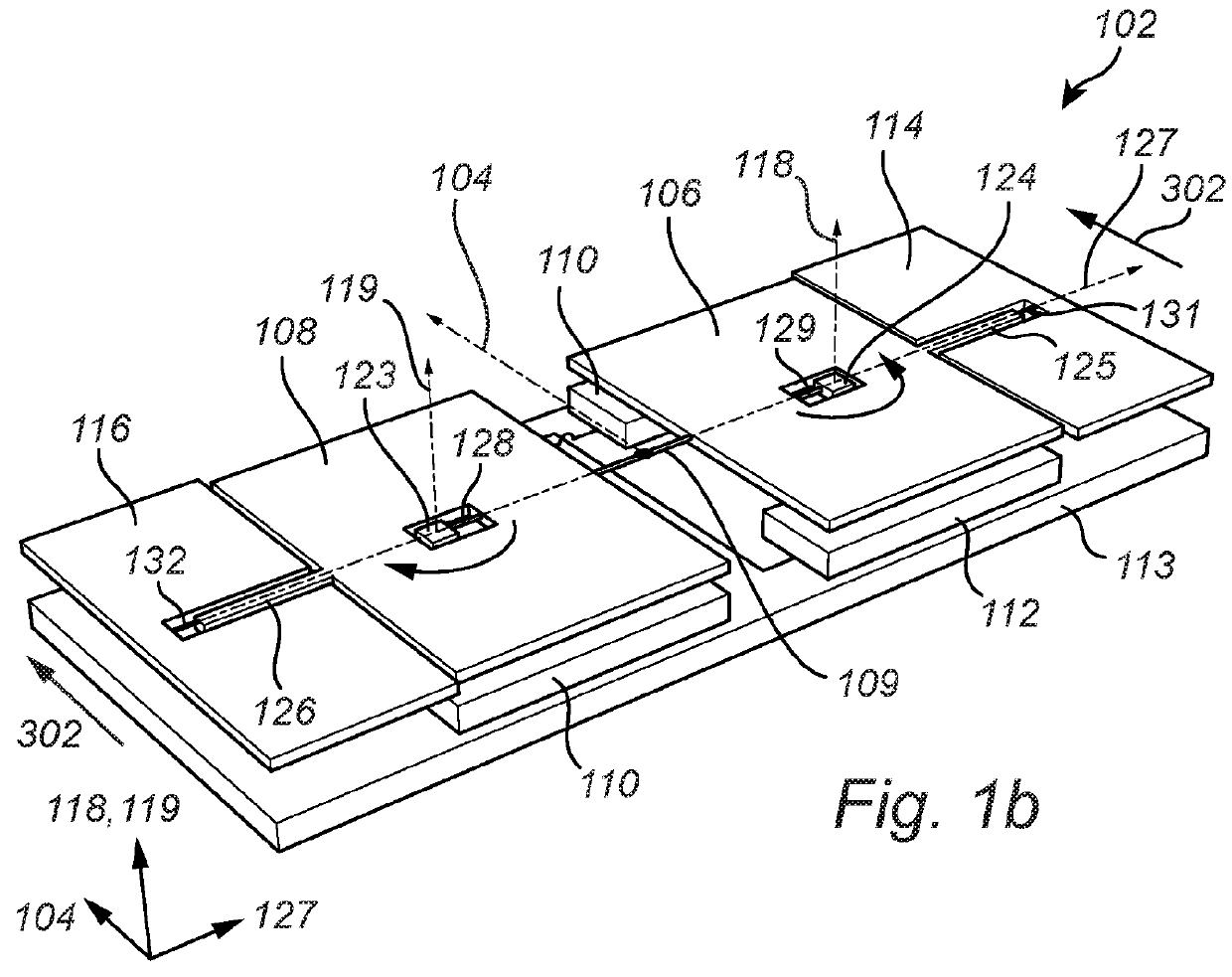

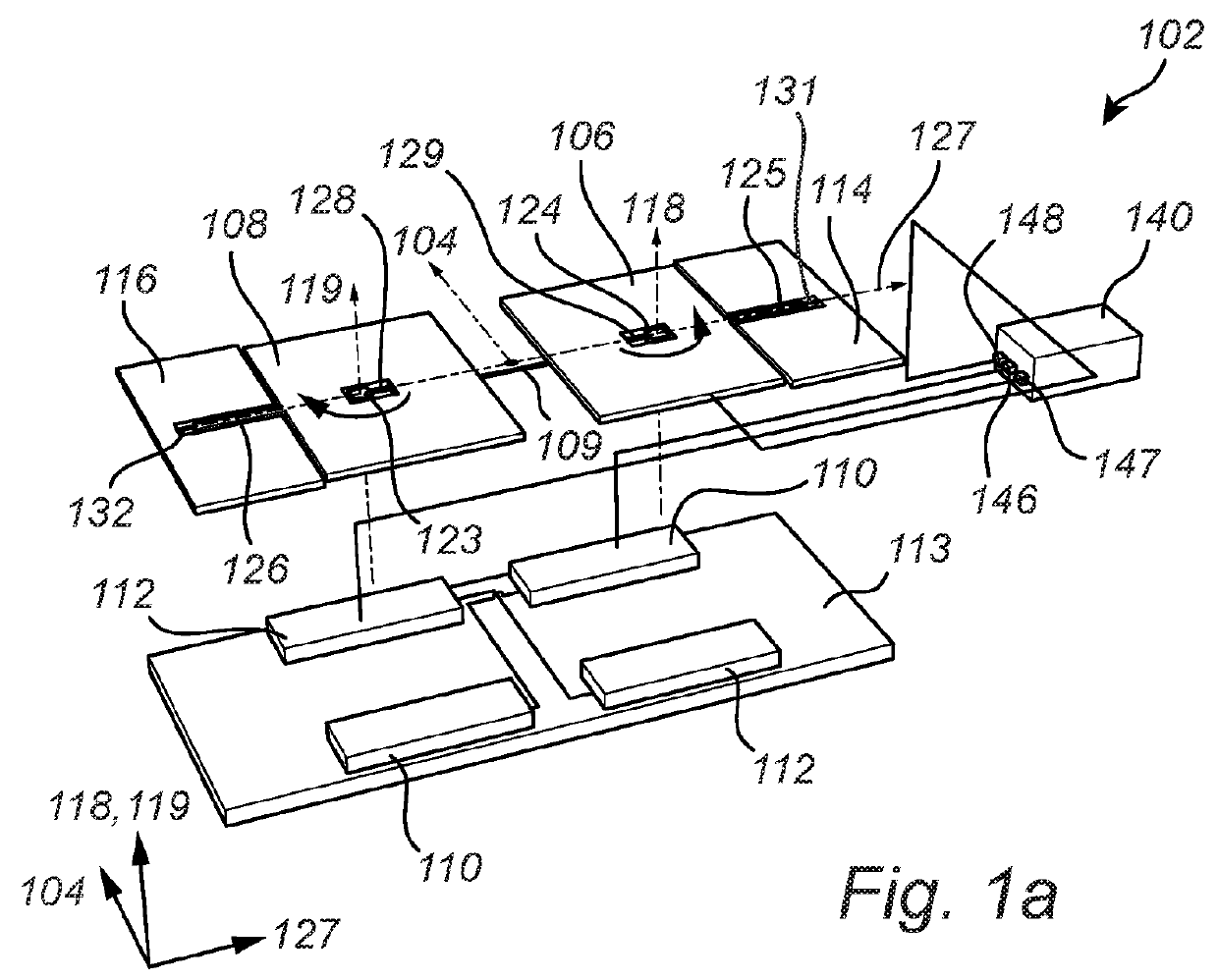

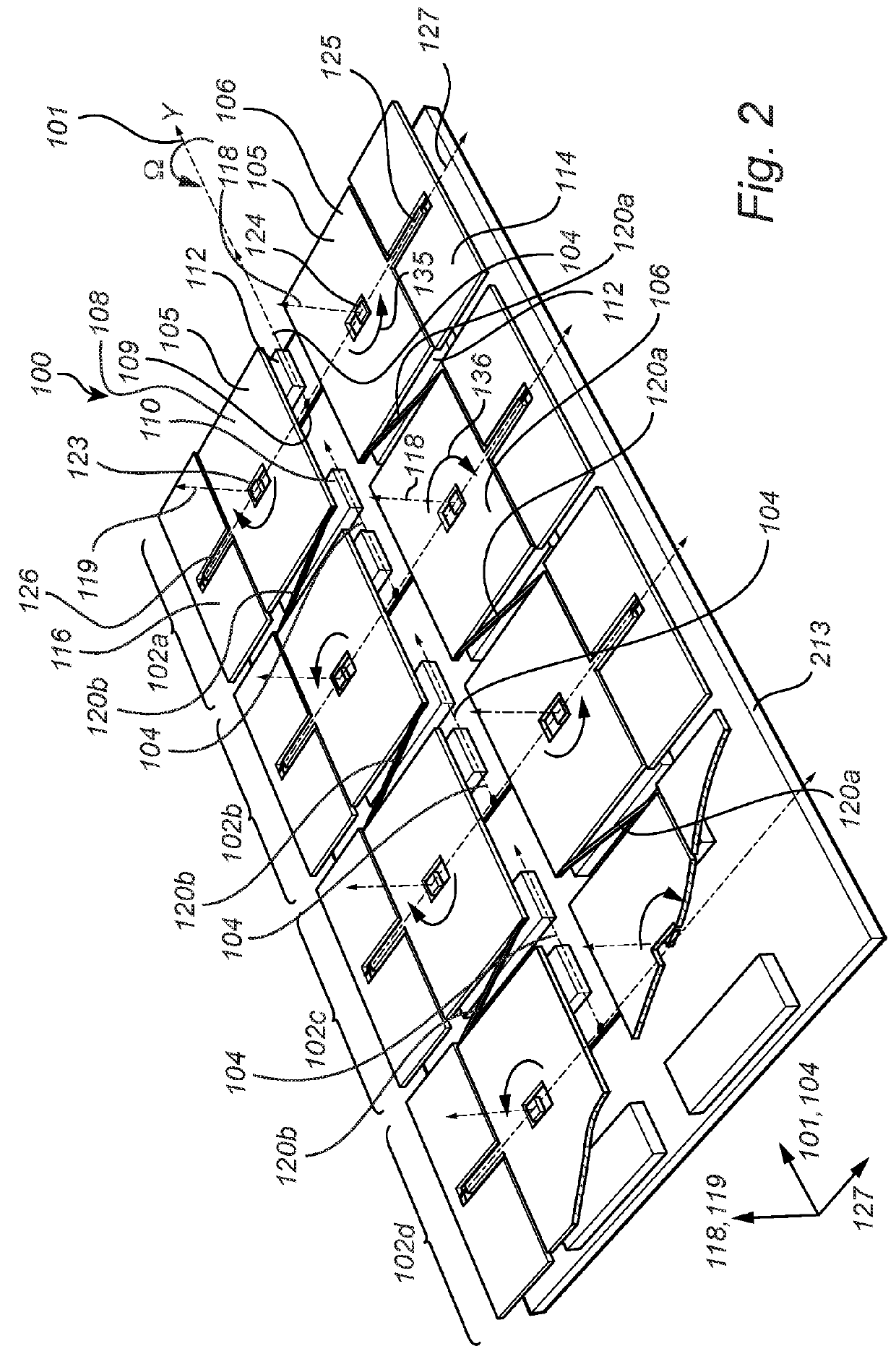

Multichannel analytical instruments for use with specimen holders

ActiveUS20130228675A1Well exposedImprove throughputRadiation pyrometryInvestigating moving fluids/granular solidsSensor arrayFiber

An analytical instrument may have multiple distinct channels. Such may include one or more illumination sources and sensors. Illumination may be delivered to specific locations of a specimen holder, and returned illumination may be delivered to specific locations of a sensor array. Illumination may first pass a specimen, and a mirror or reflector may then return the illumination past the specimen. Optical splitters may be employed to couple pairs of fiber optics proximate a specimen holder. Such channels may further include a plurality of illumination sources positioned on one side of a specimen holder and a plurality of sensors on the other side. The plurality of sensor may capture image of a specimen and a spectrophotometer may concurrently scan the specimen. A plurality of specimens may be imaged and scanned in a single pass of a plurality of passes. Spherical or ball lenses may be placed in an optical path of the illumination to achieve a desired illumination pattern.

Owner:LAXCO

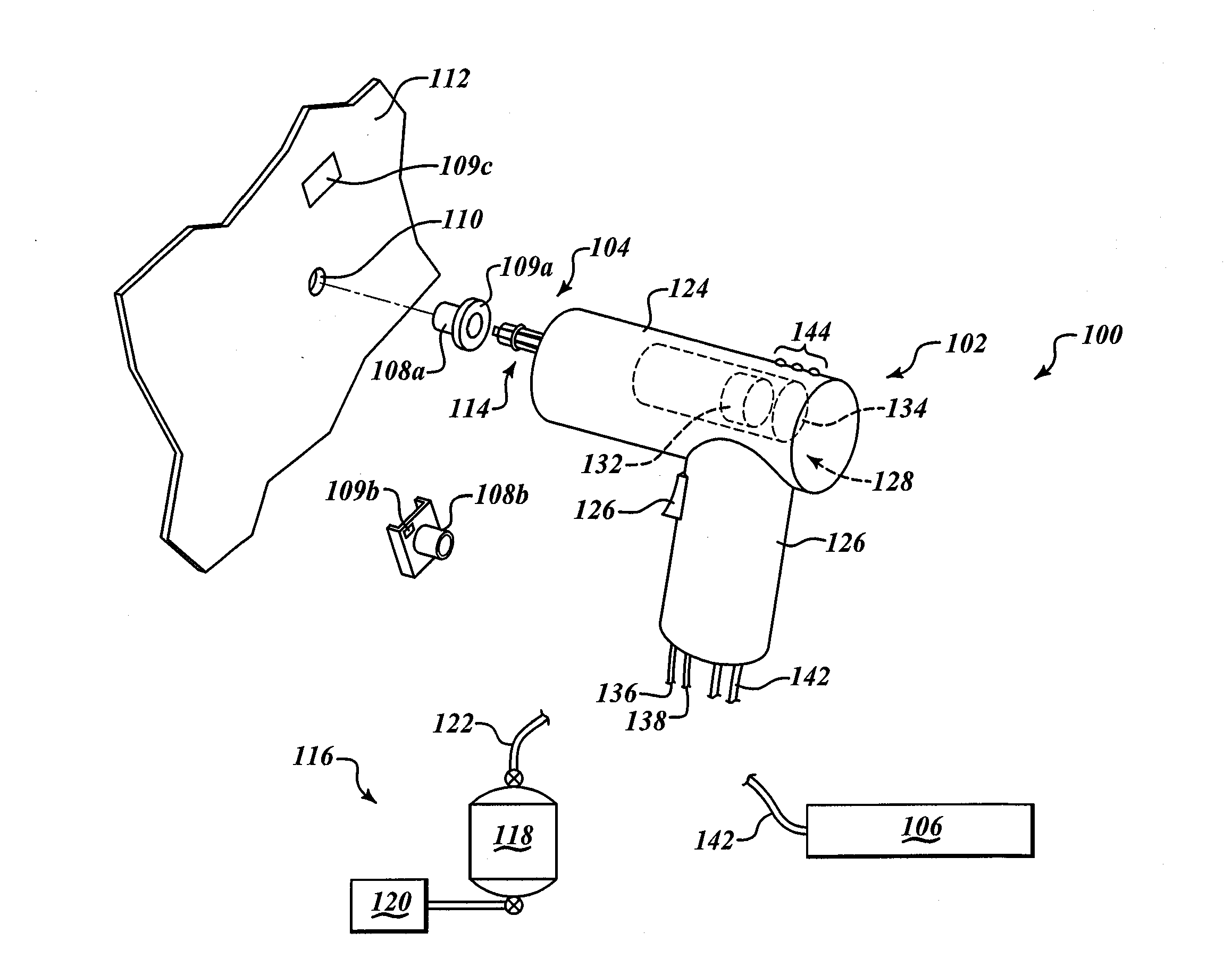

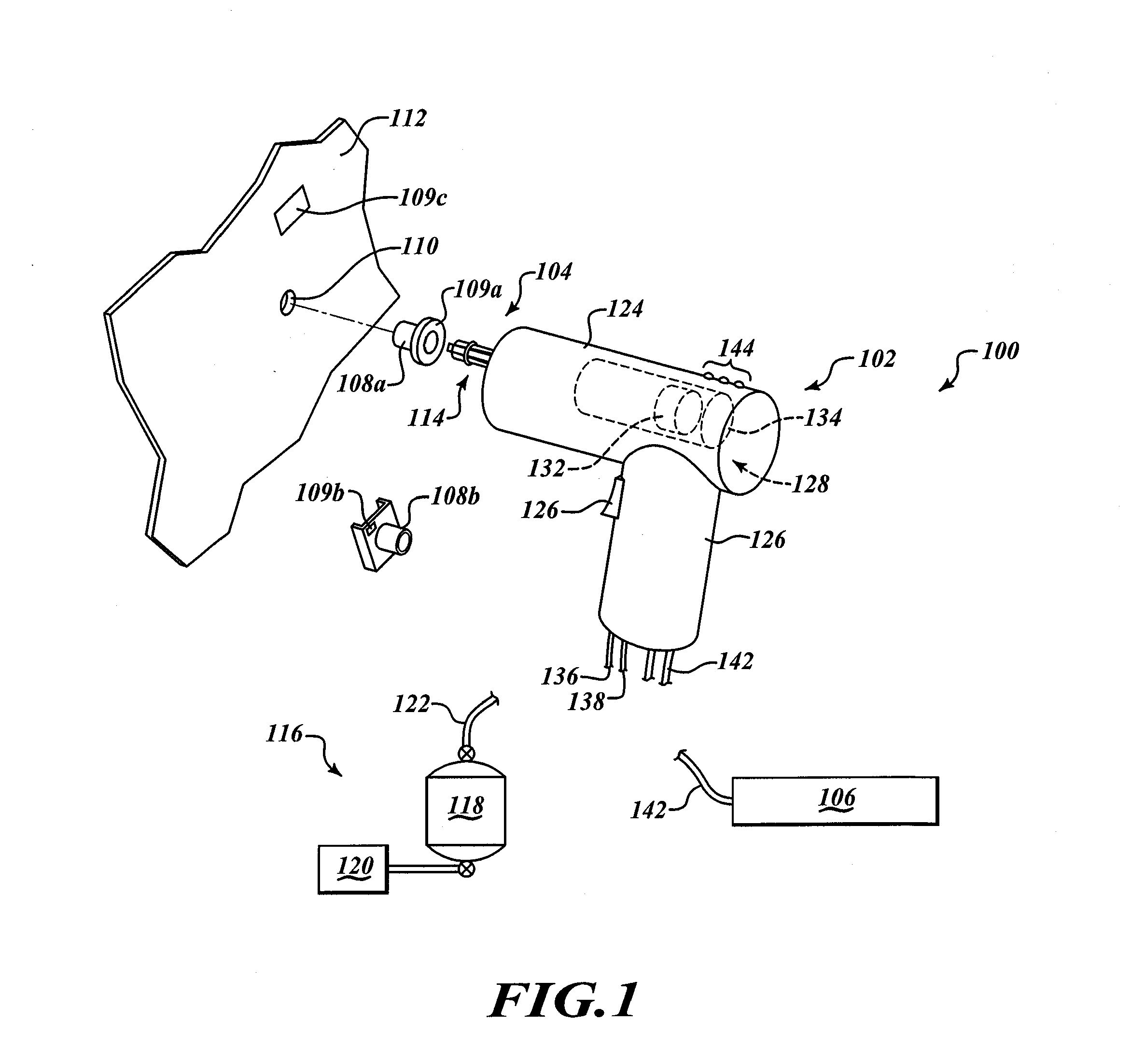

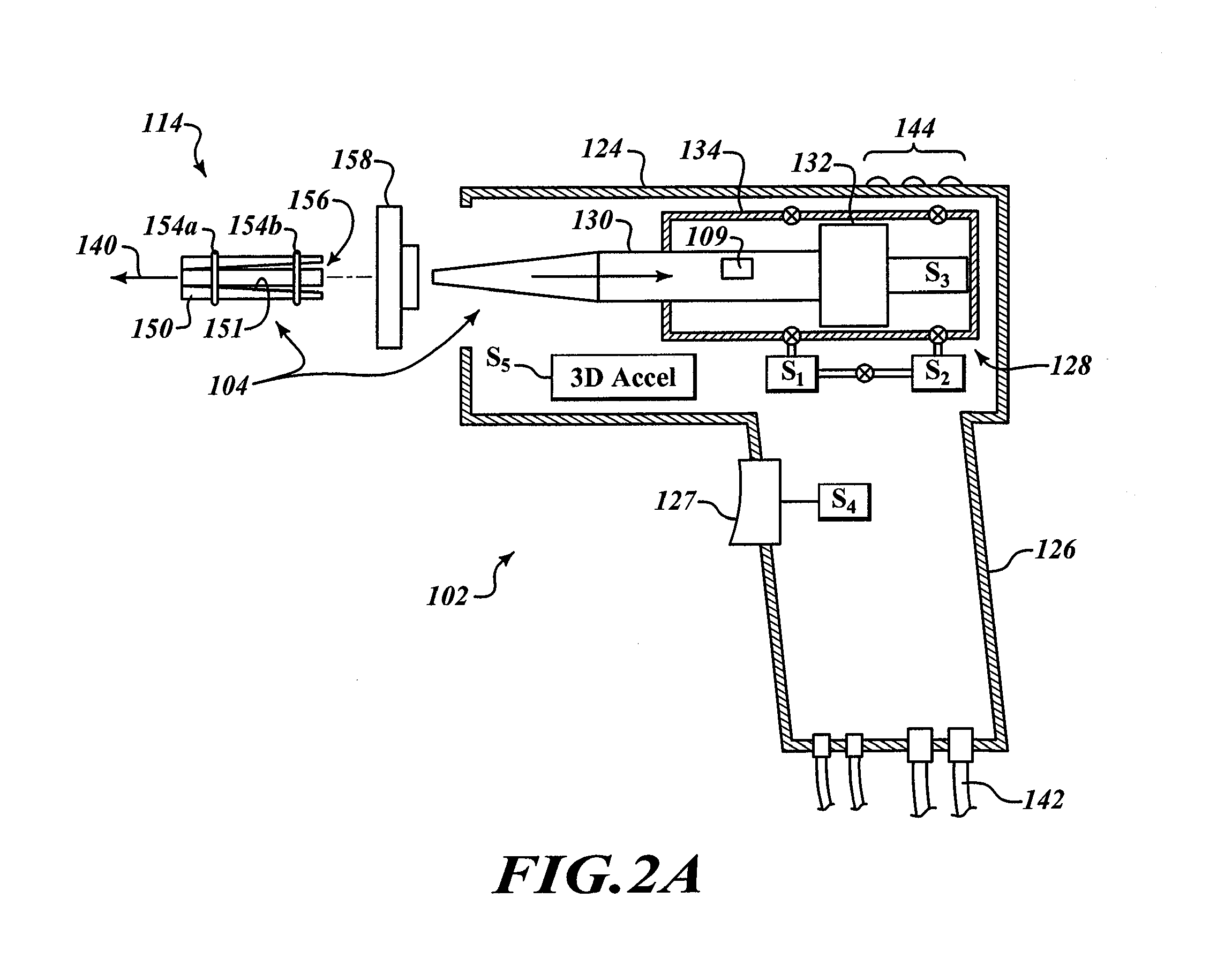

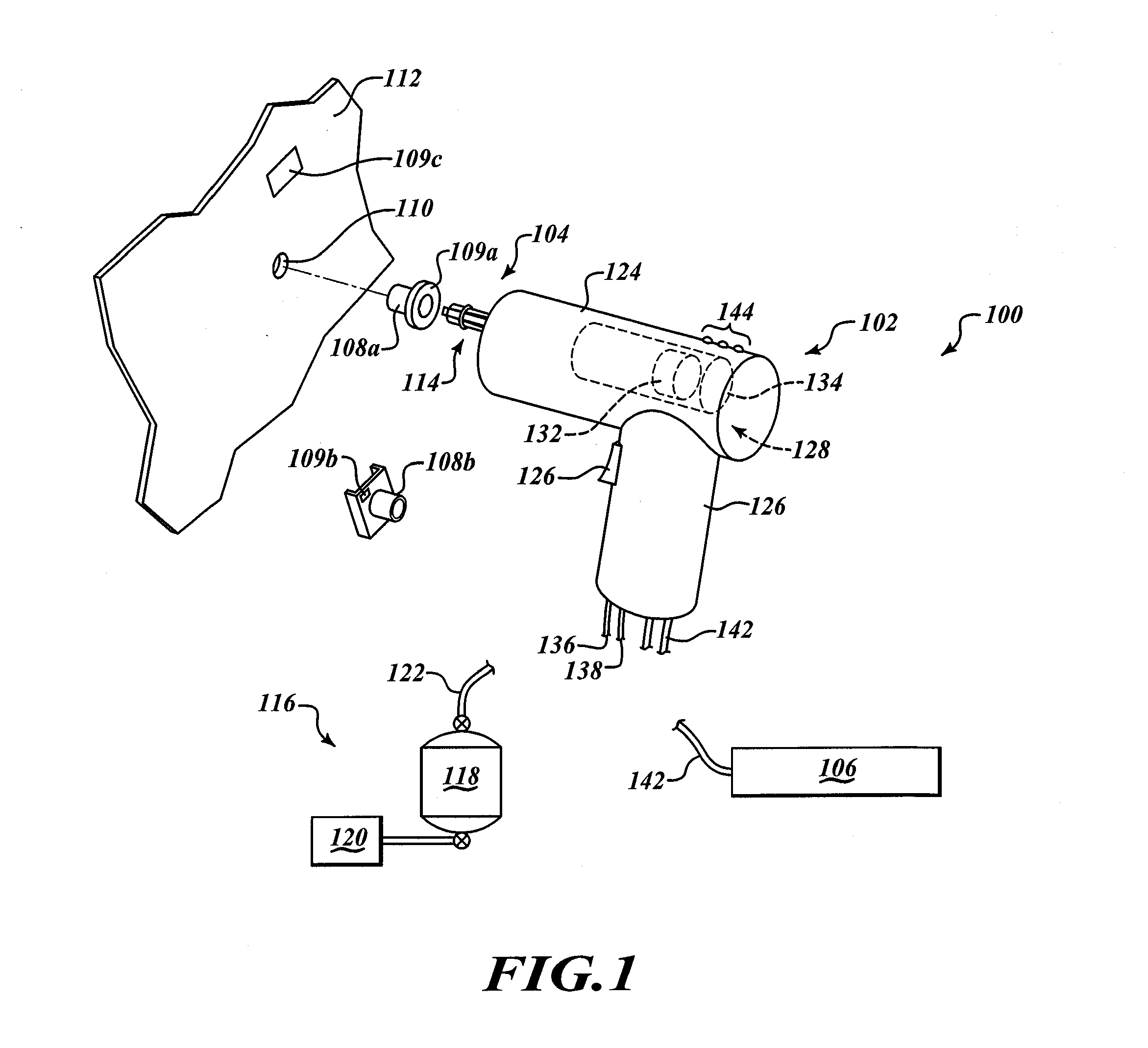

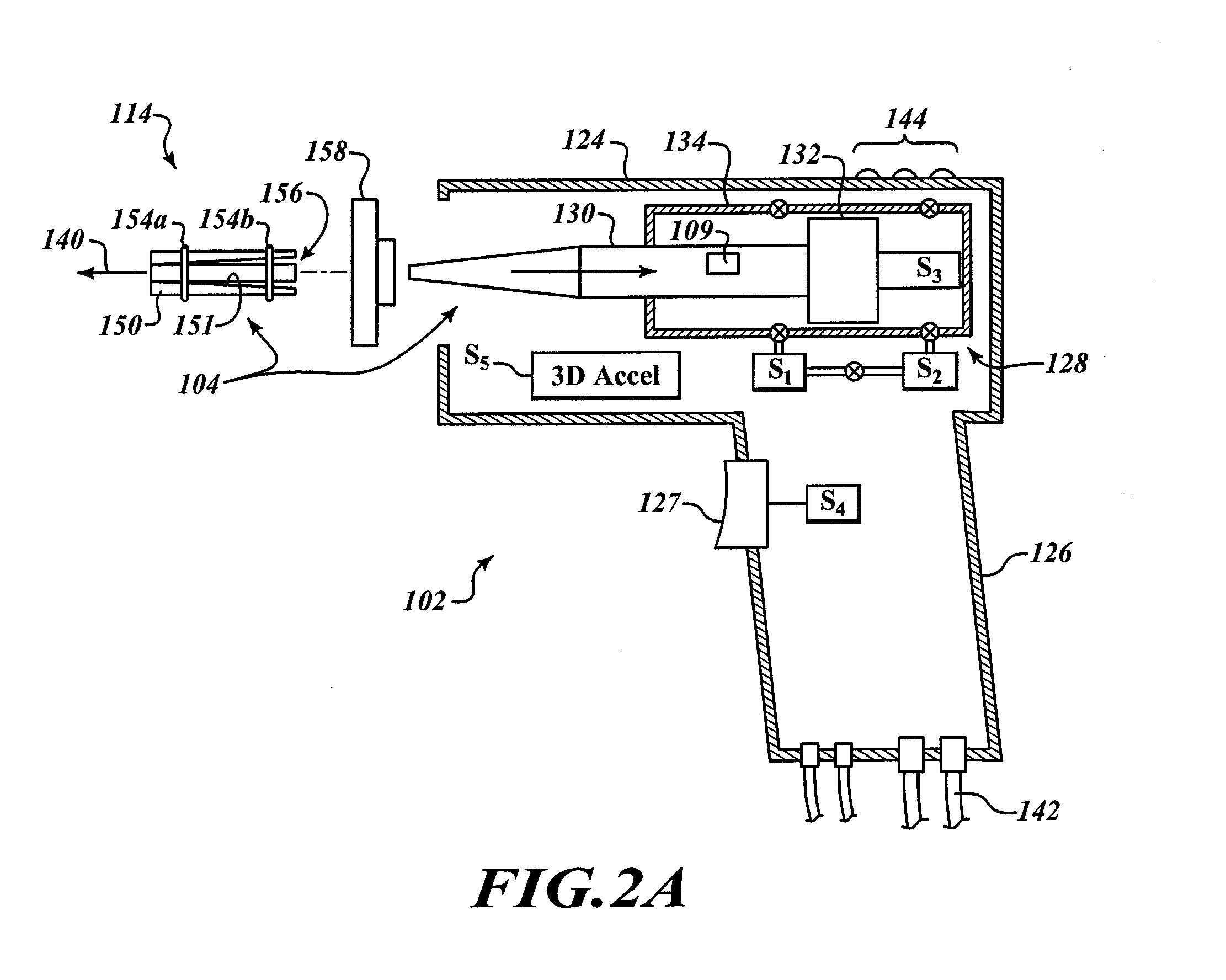

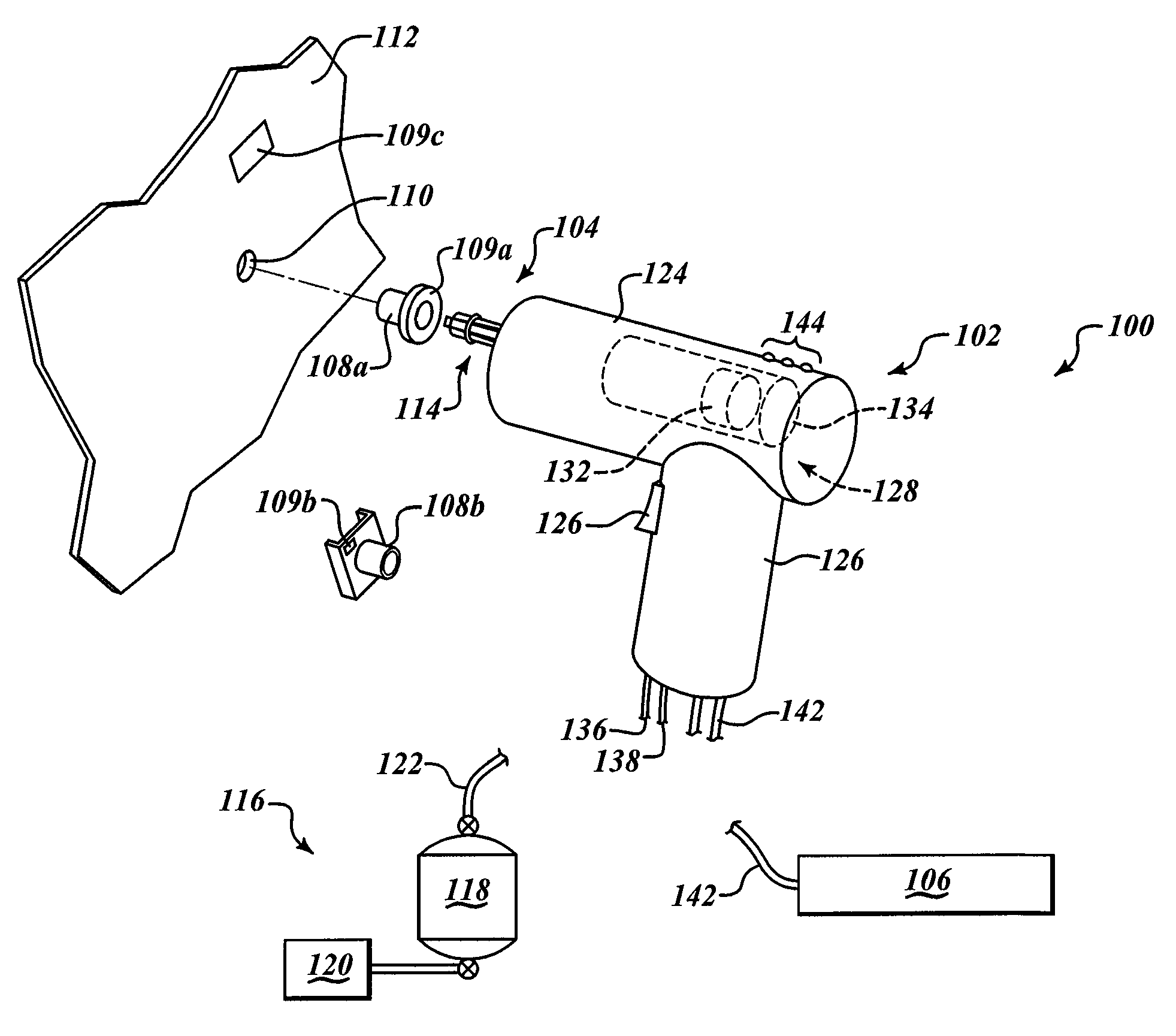

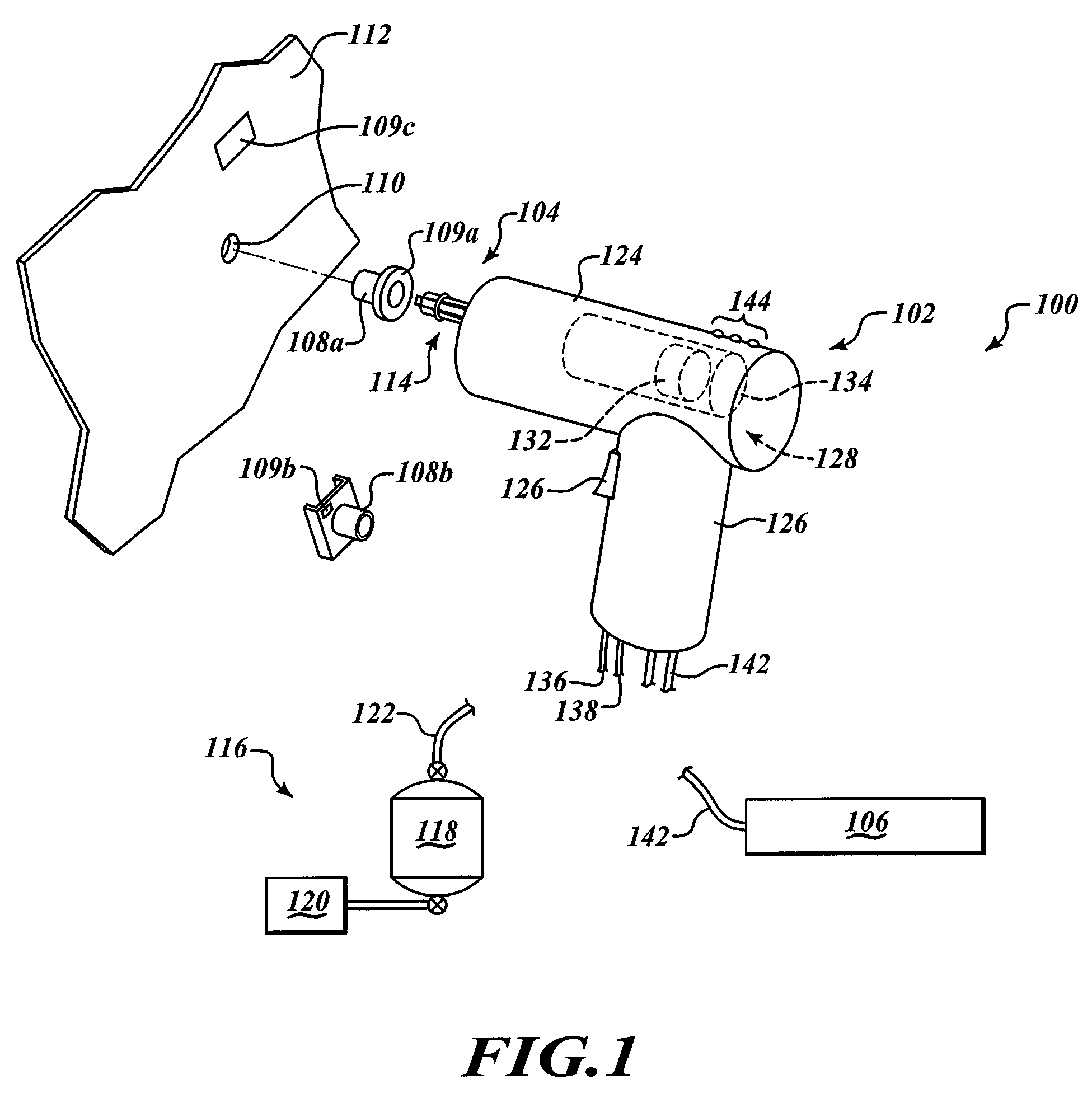

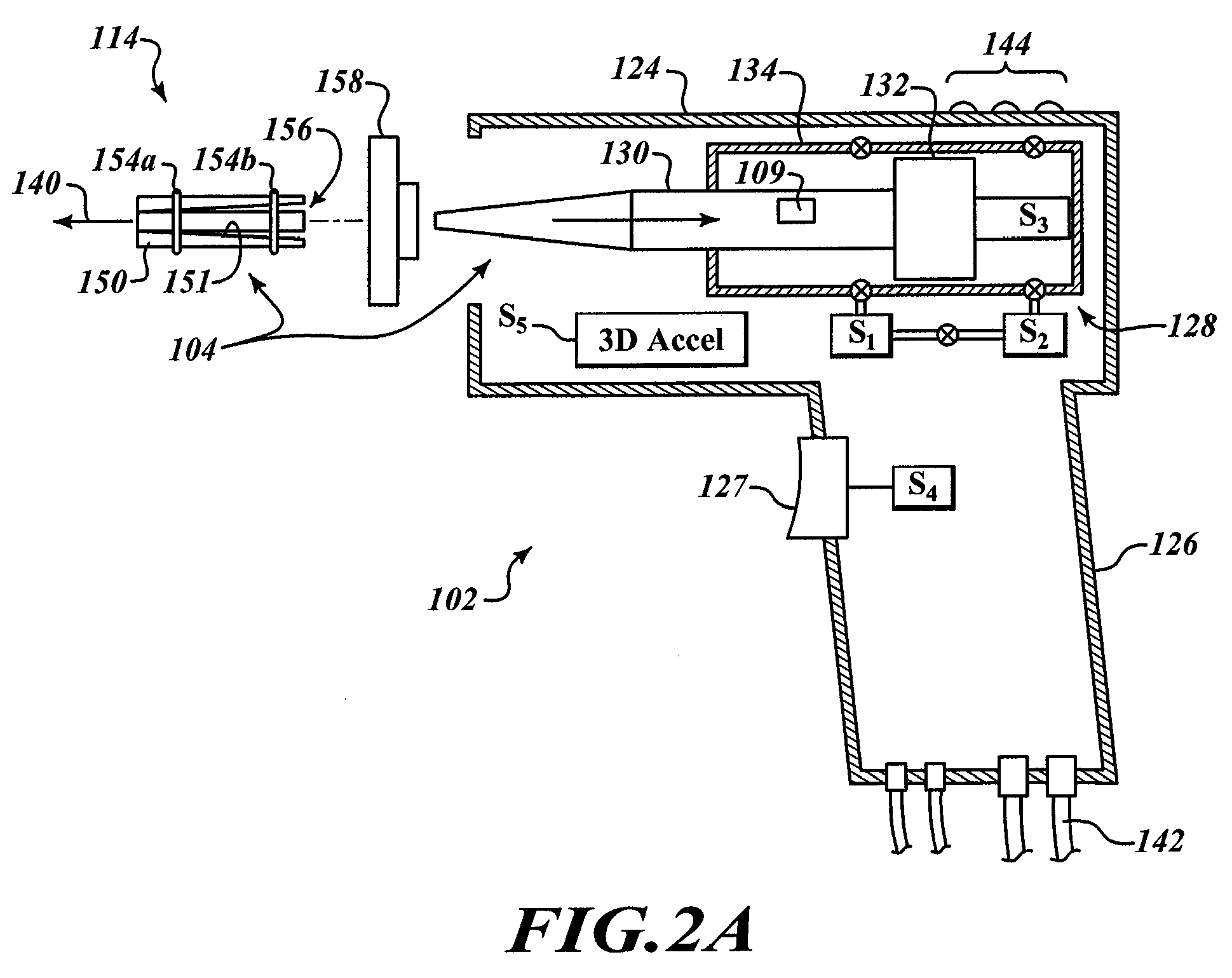

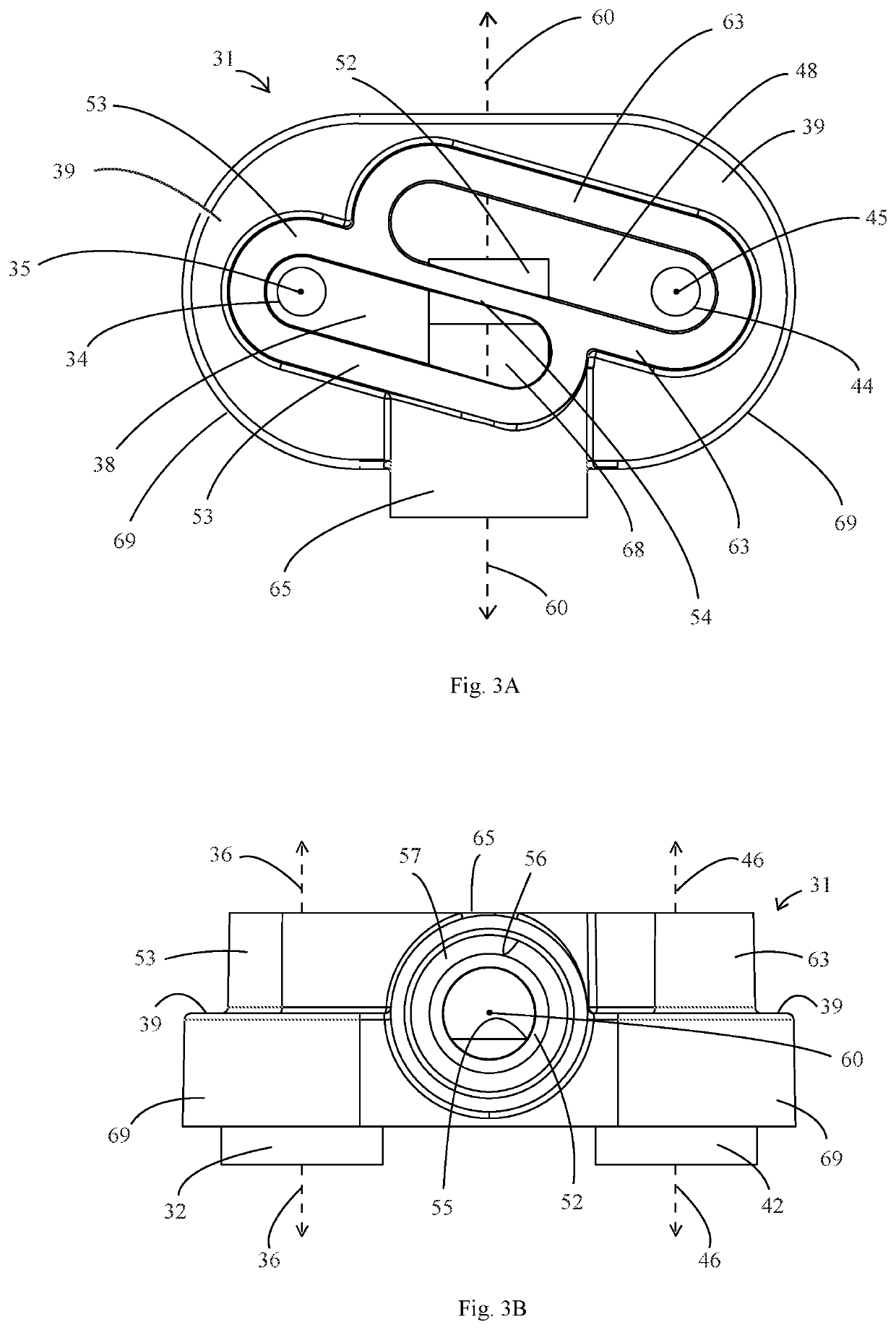

Smart installation/processing systems, components, and methods of operating the same

ActiveUS20130204422A1Less worryEliminate axial flow of materialProgramme controlUsing fluid meansEngineeringHandling system

A processing system employs a processing tool to process workpieces, for example cold working holes and / or installing expandable members into holes. Sensors sense various aspects of the processing. Information regarding performance of the process and / or materials may be stored, for example a hole-by-hole or a workpiece-by-workpiece basis, allowing validation of processing. Information also allows dynamic operation of the processing tool. Analysis of response relationships (e.g., pressure or force versus position or distance) may provide insights into the process and materials, and / or facilitate the real-time feedback including control, alerts, ordering replacement for consumable components.

Owner:FATIGUE TECH

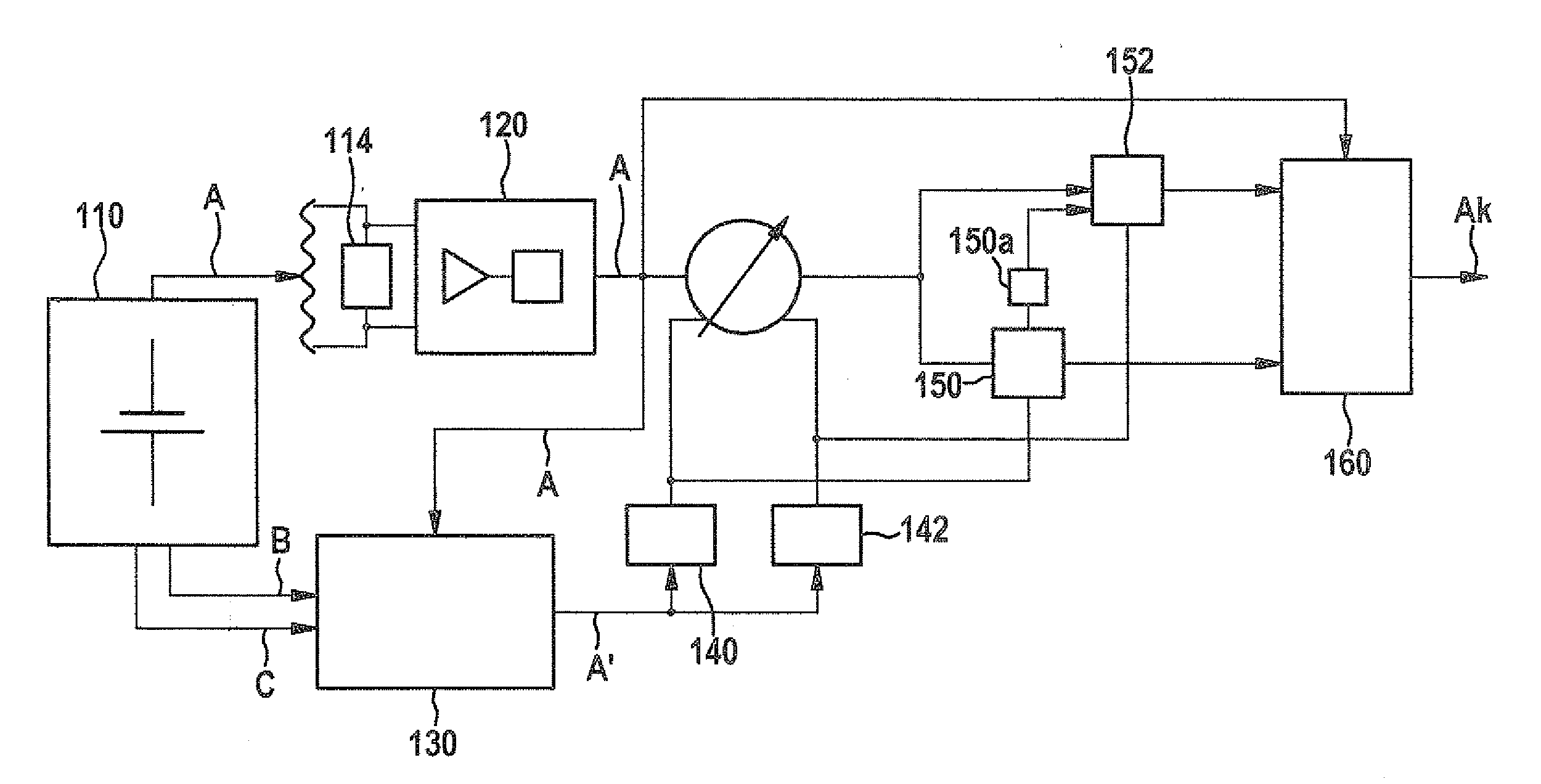

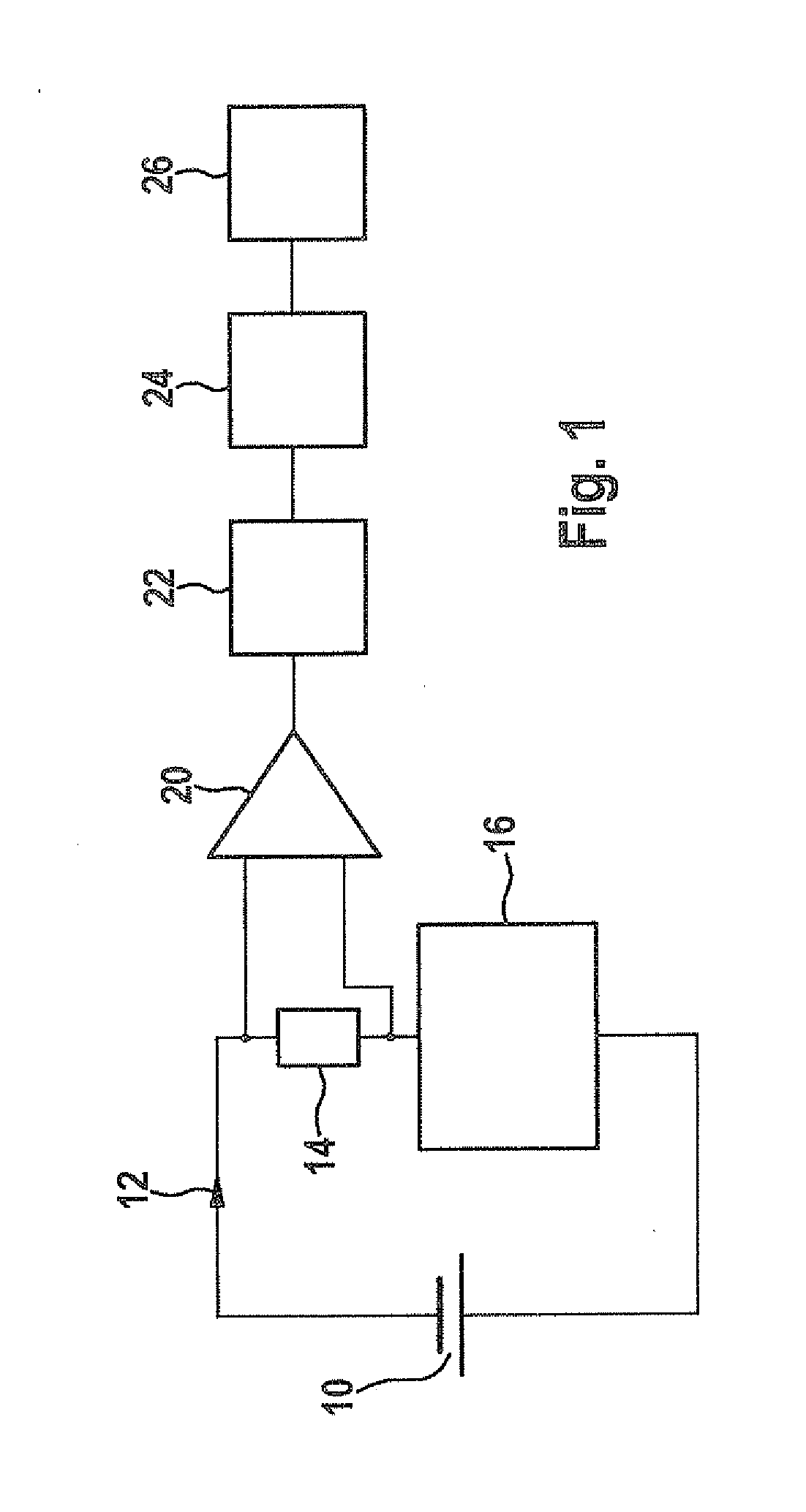

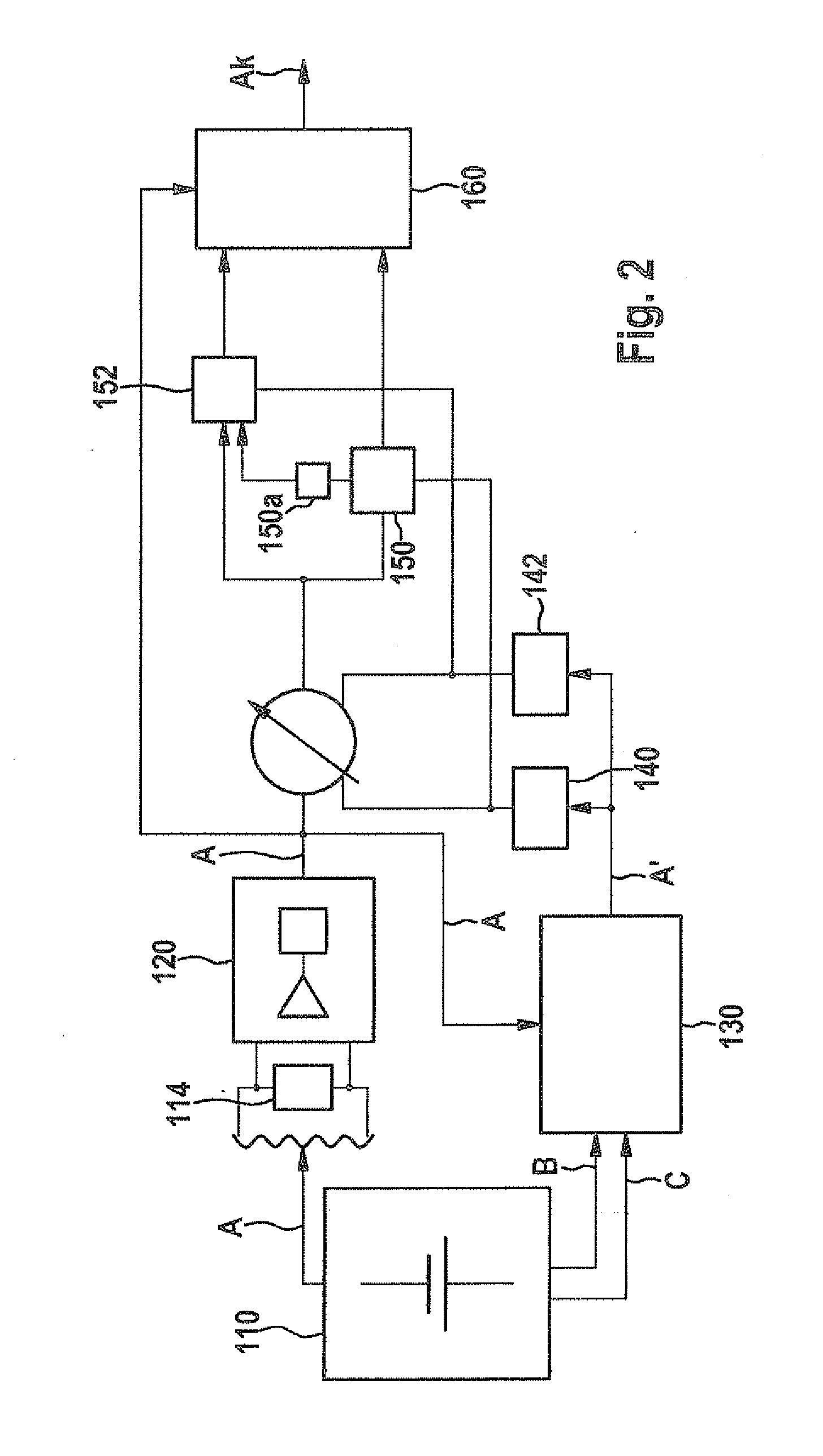

Method and device for error-compensated current measurement of an electrical accumulator

InactiveUS20120283970A1Improve Manufacturing TolerancesImprove accuracyElectrical testingCurrent measurements onlyEngineeringRelative maximum

A method for error-compensated current measurement of an electrical accumulator, including: providing a time window-related estimated charge ascertained by a model-based estimator from operating variables of the accumulator and reflecting the estimated charge that has been withdrawn from the accumulator and supplied to the accumulator within the time window; and detecting the accumulator current supplied to the accumulator and withdrawn from the accumulator during the time window, with a current detection sensor. A zero crossing point in time (estimated charge is essentially zero) and a maximum point in time (the absolute value of the estimated charge essentially has a relative maximum or has a value which is greater than a minimum charge difference) are detected. A current measurement offset error is ascertained at the zero crossing point in time by comparing the estimated charge to the detected accumulator current. The accumulator current is ascertained according to the current measurement offset error, and a current measurement scaling error is ascertained at the maximum point in time by comparing the estimated charge to the detected accumulator current. The ascertained current measurement offset error is subtracted from the comparison result thus obtained, and the accumulator current is compensated for based on the current measurement scaling error. A related device for error-compensated current measurement is also described.

Owner:ROBERT BOSCH GMBH

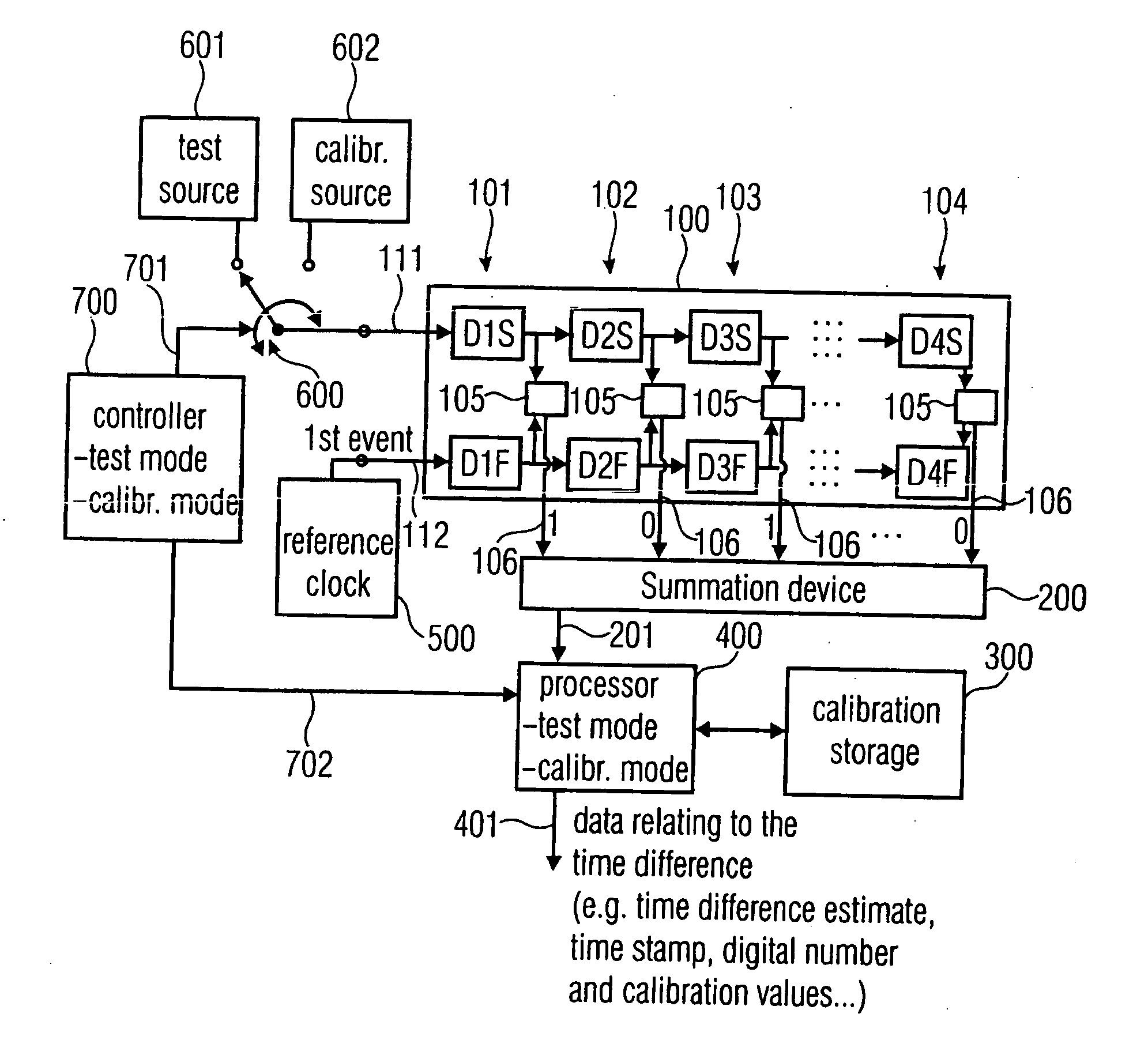

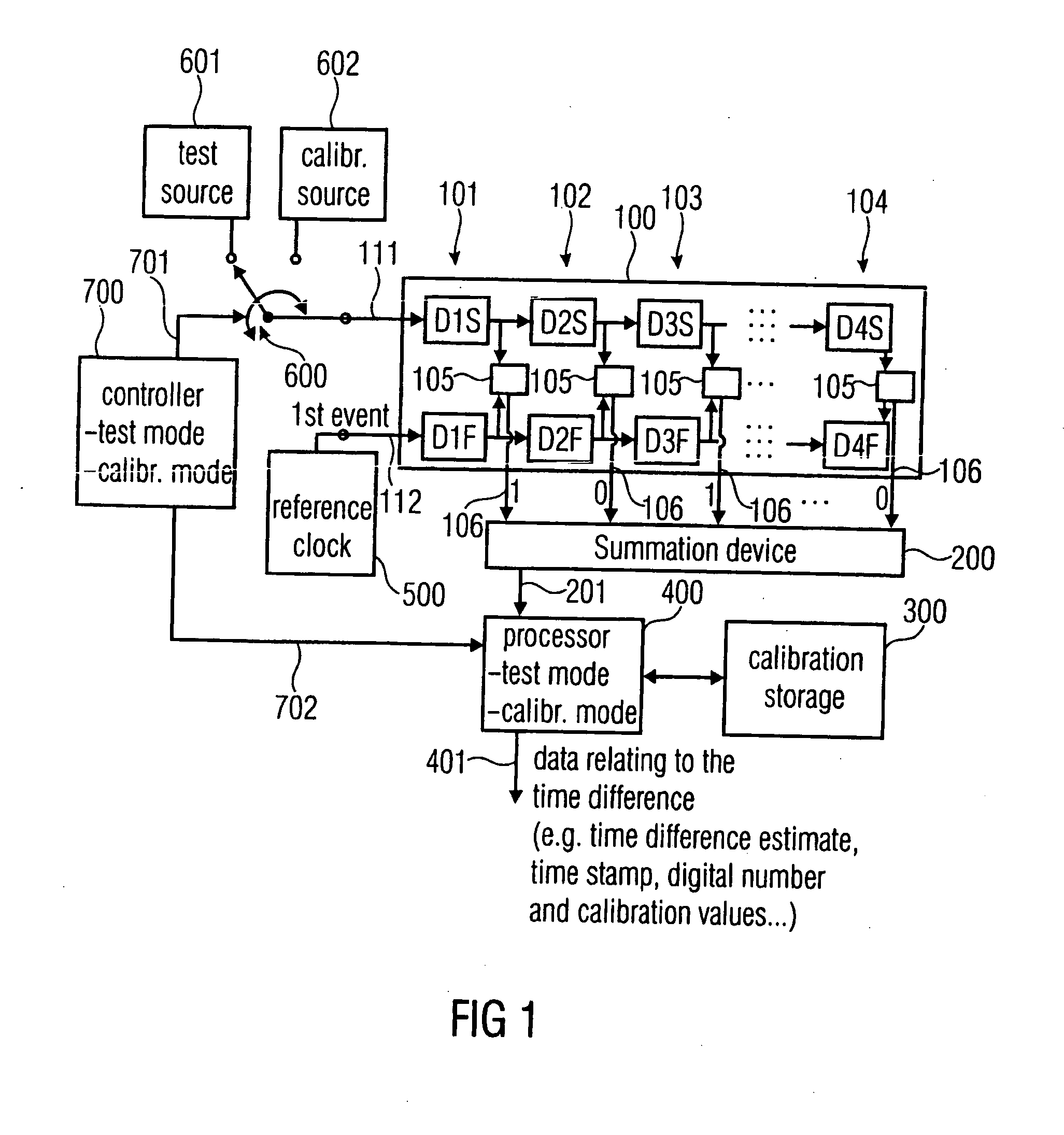

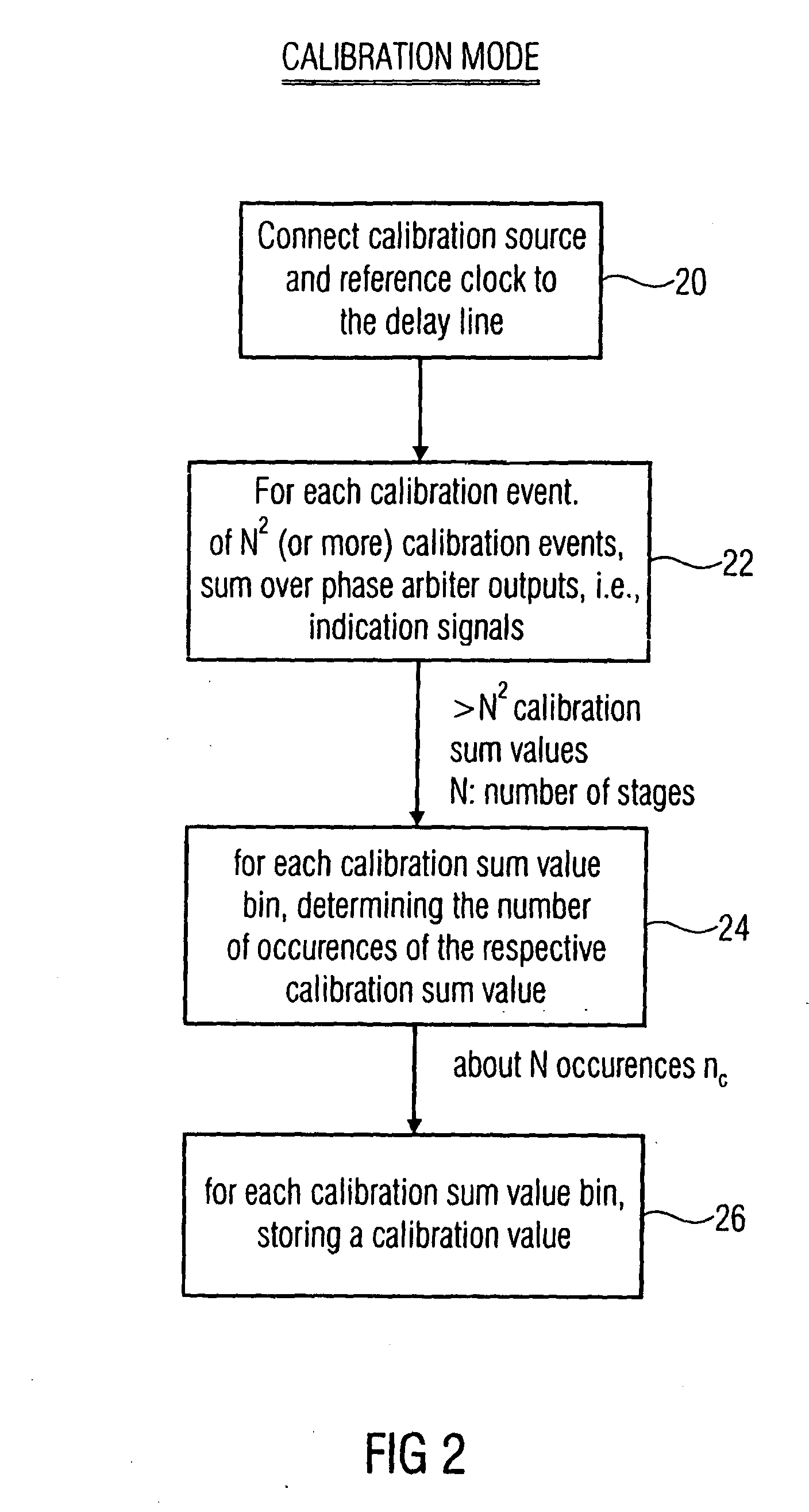

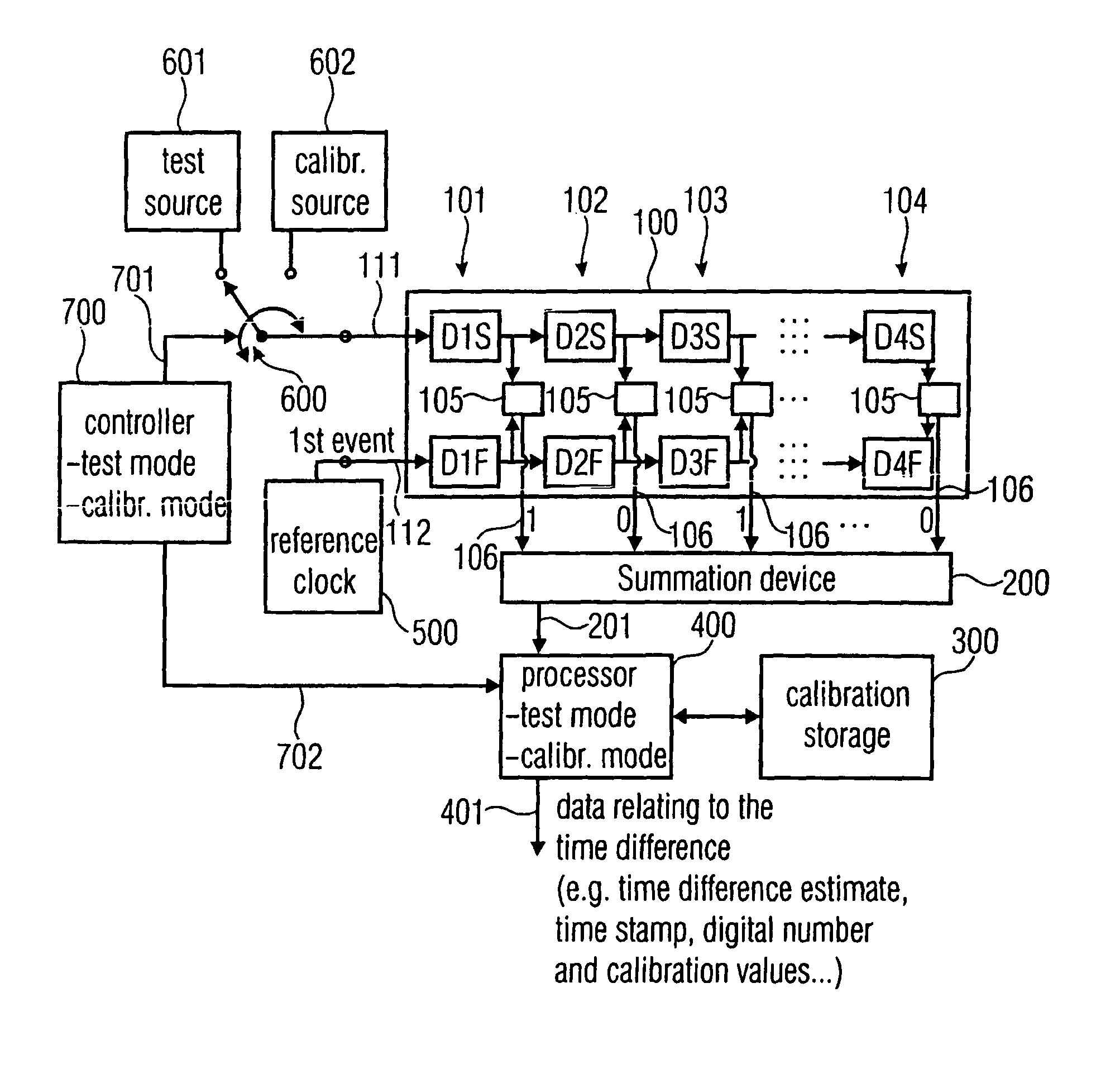

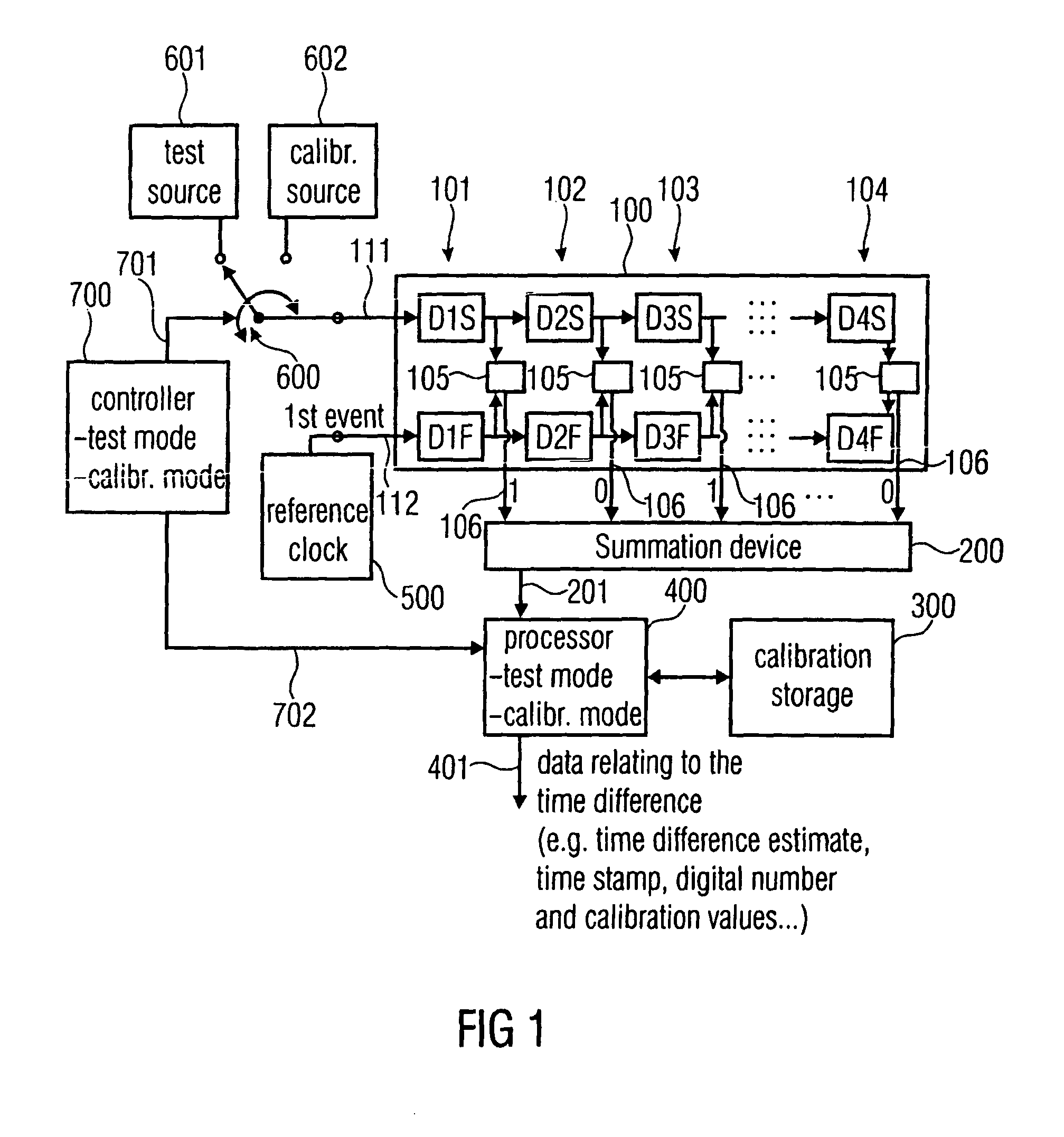

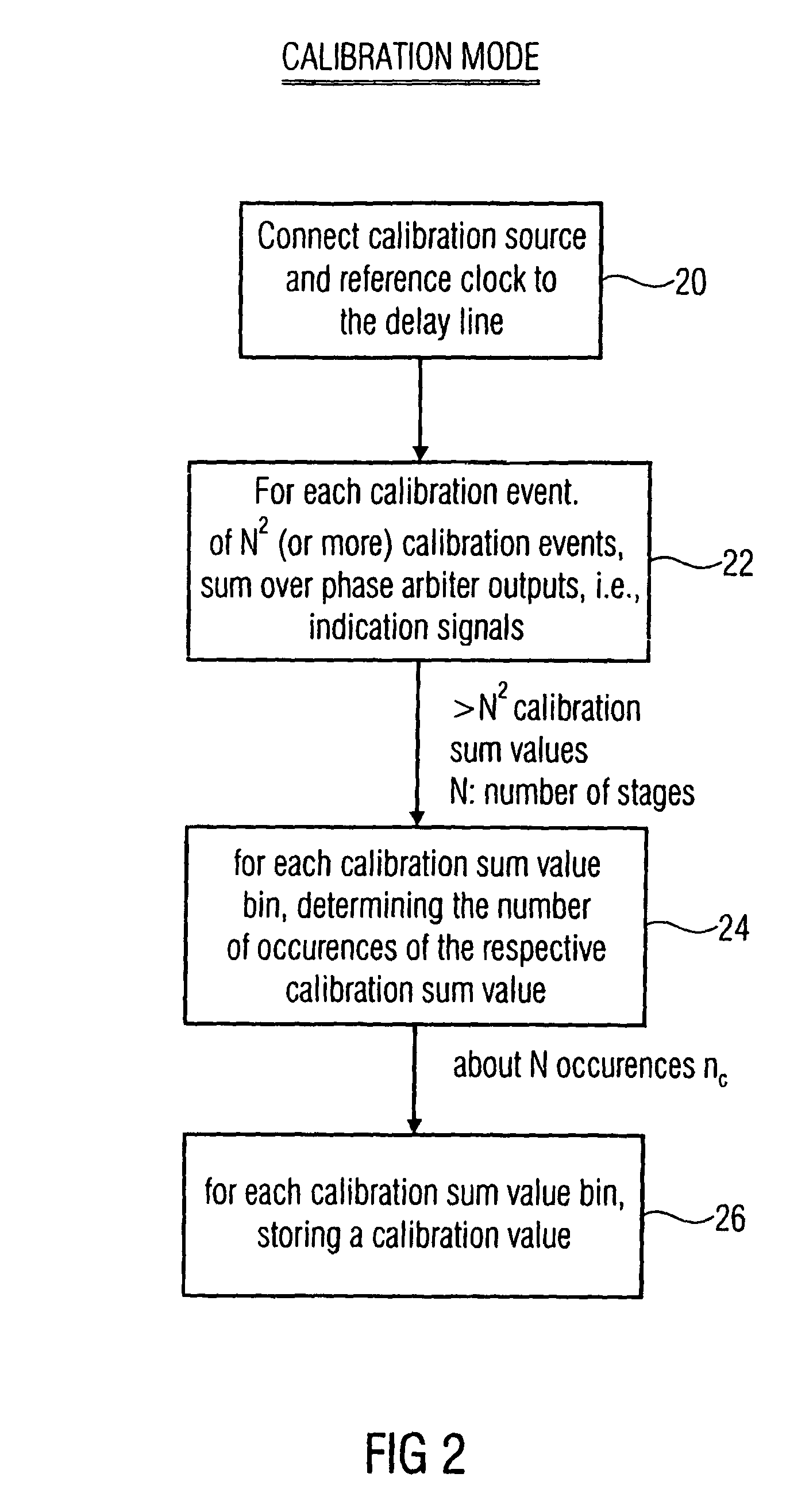

Apparatus and method for estimating data relating to a time difference and apparatus and method for calibrating a delay line

ActiveUS20110140737A1Increase product yieldImprove characteristicVoltage-current phase angleOscillations comparator circuitsTime differenceComputer science

An apparatus for estimating data relating to a time difference between two events includes a delay line having a plurality of stages. Each stage has a delay difference between a first delay in a first part and a second delay in a second part. This delay difference is measured by a phase arbiter in each stage, which outputs an indication signal indicating whether the first event of two events in the first part precedes or succeeds a second event of the two events in the second part. A summation device is provided for summing over the indication signals of the plurality of stages to obtain a sum value. The sum value indicates a time difference estimate.

Owner:ADVANTEST CORP

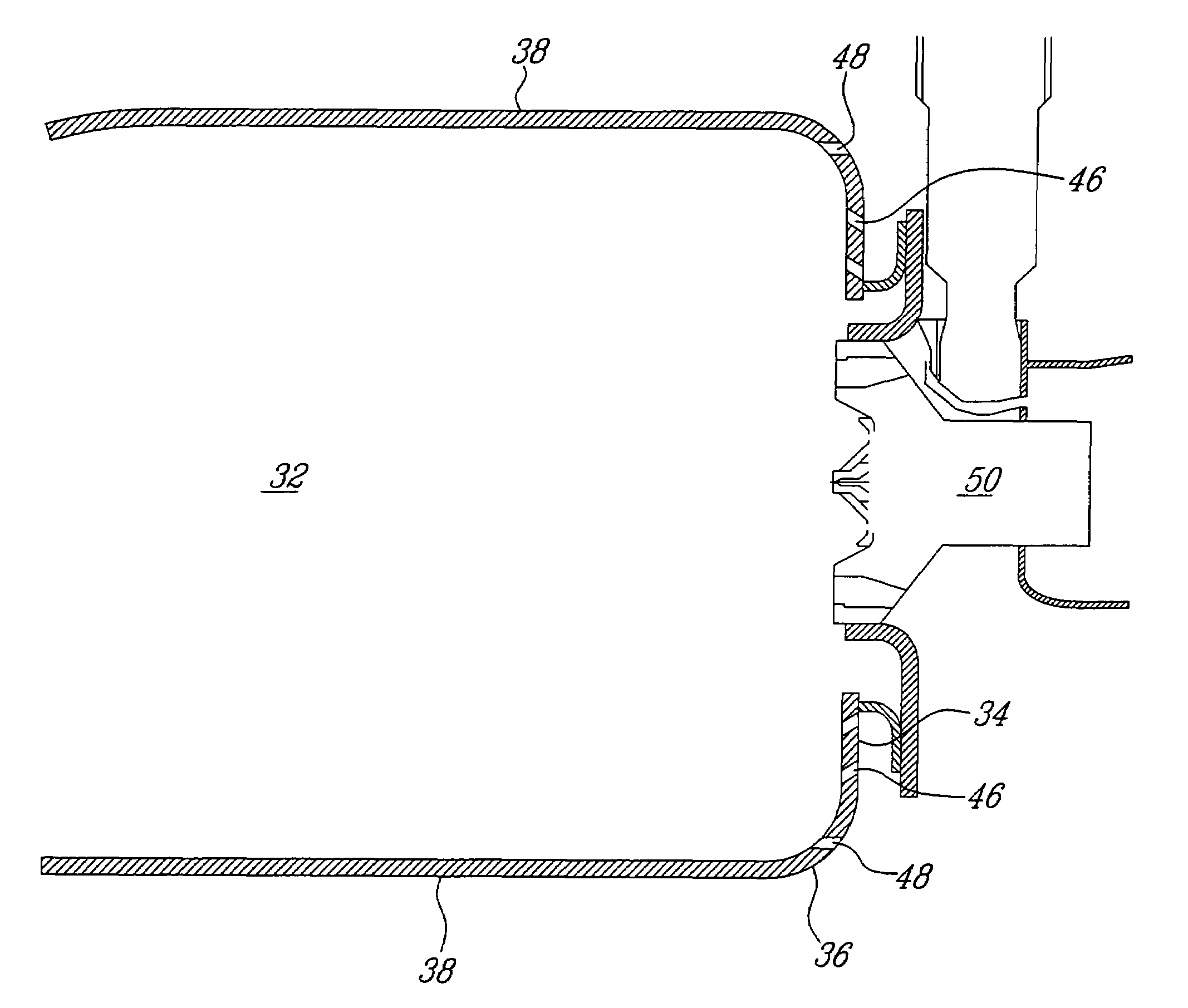

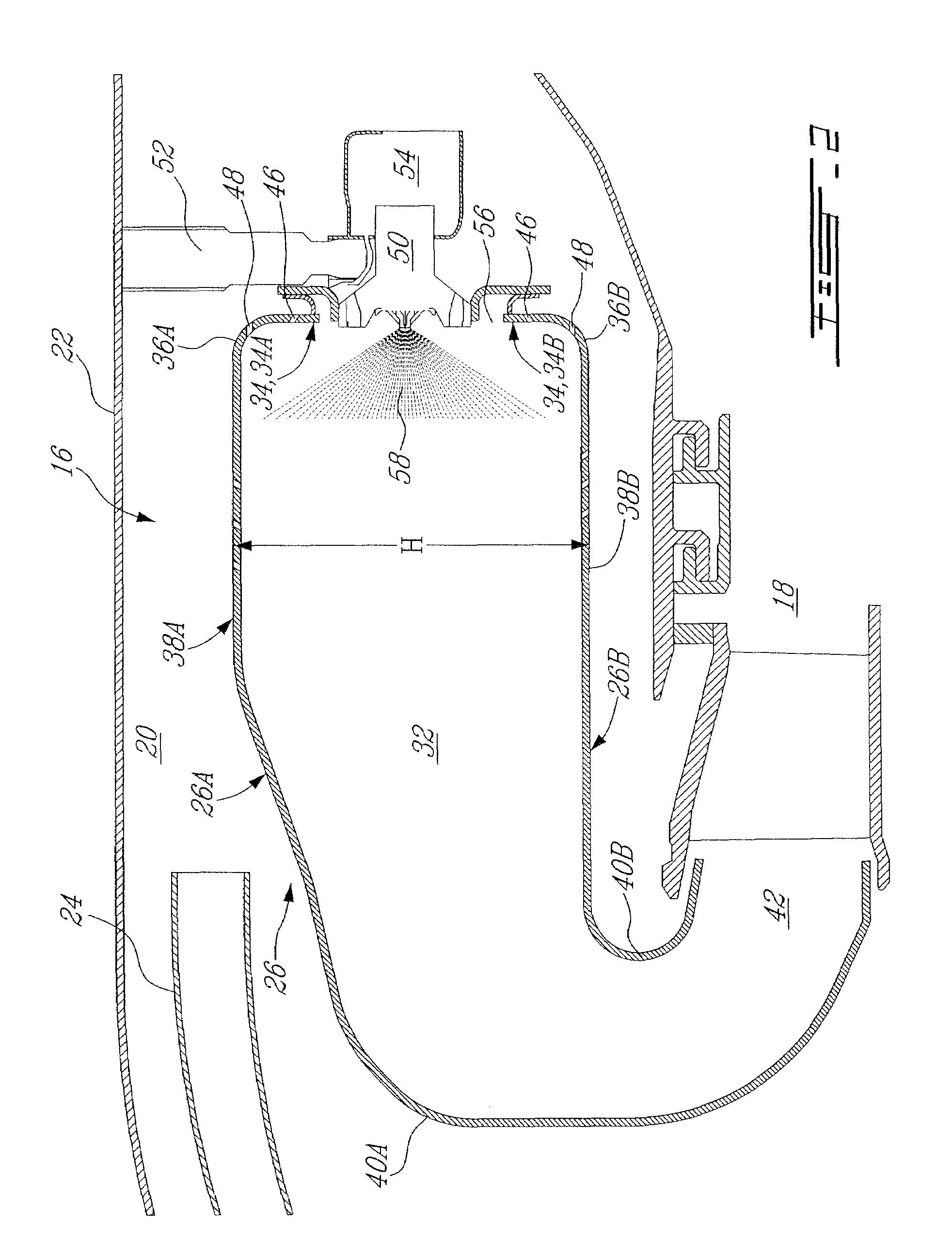

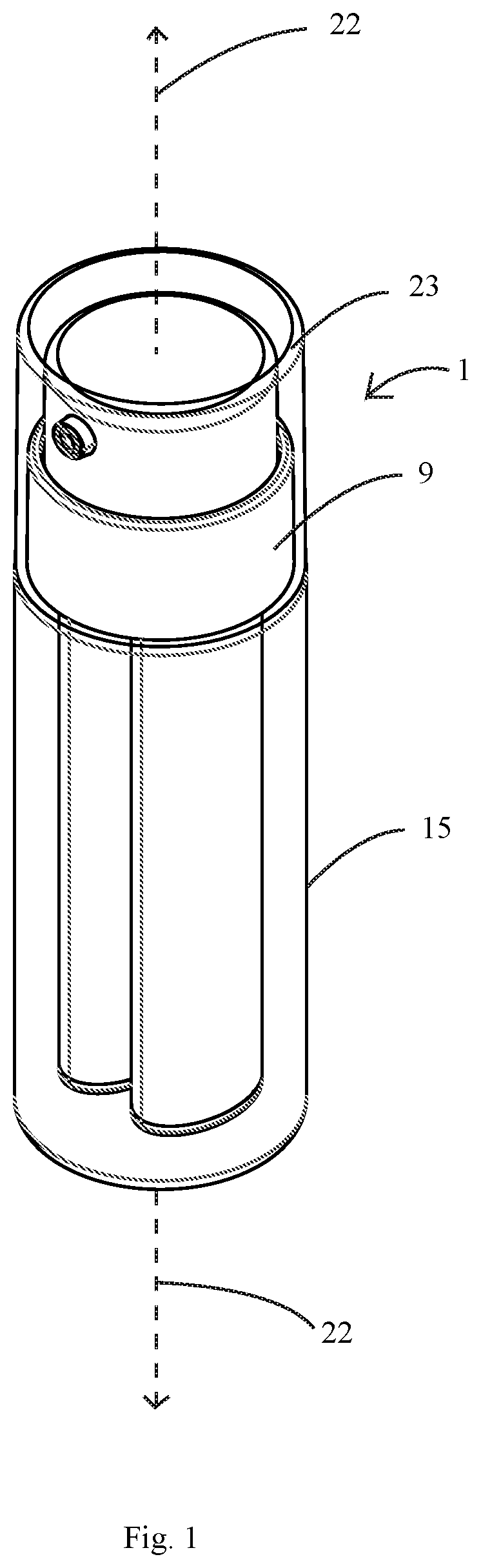

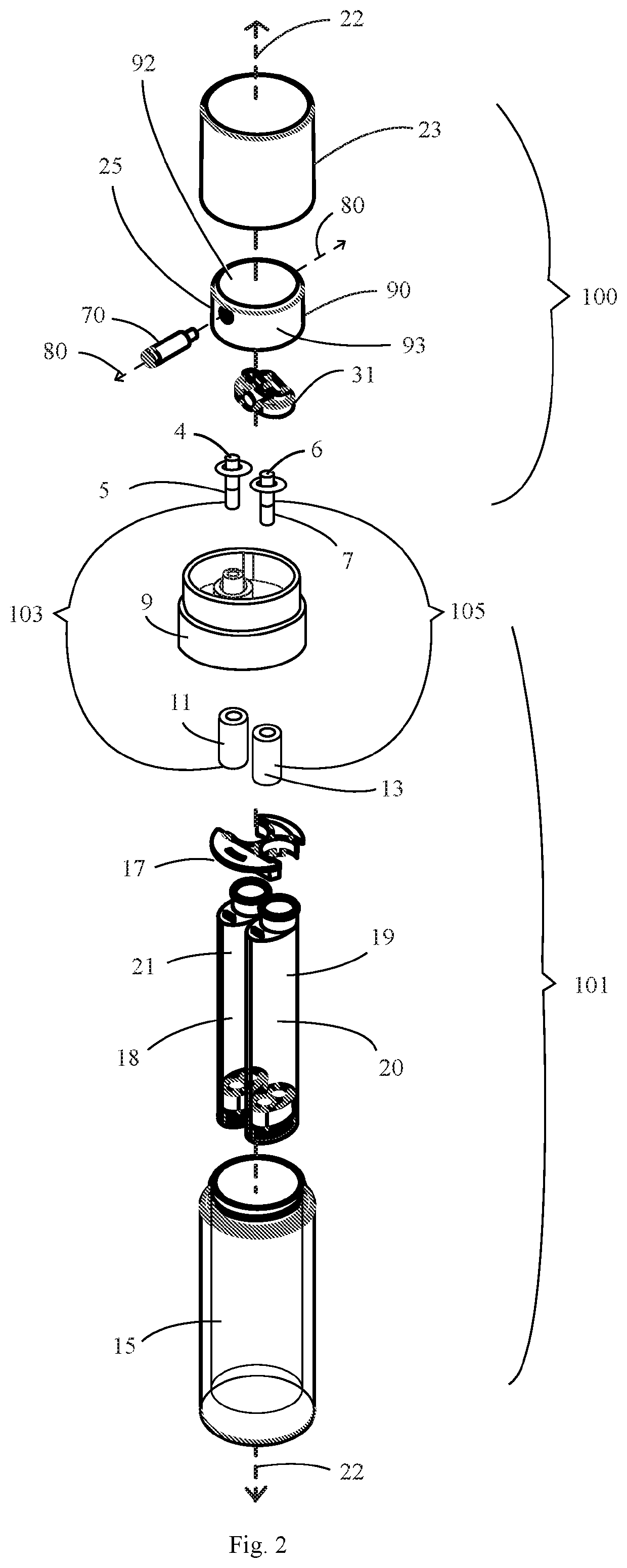

Fluid product dispenser

InactiveUS20070194054A1Easy to manufactureImprove Manufacturing TolerancesHolders and dispensersLiquid transferring devicesLiquid productEngineering

A dispenser for dispensing a fluid product includes a liquid reservoir for storing a liquid product and a pump that is connected to the liquid reservoir. The pump may include a liquid chamber for containing a dose of the liquid product, a liquid outlet valve for regulating passage of liquid product from the liquid chamber to a dispensing head, compression means for applying a compressional force to liquid product in the liquid chamber, thus forcing liquid product from the liquid chamber through the liquid outlet valve and through the dispensing head. The dispenser may also include a liquid inlet device for administering admission of liquid product into the liquid chamber from the liquid reservoir. The liquid inlet device may include a body of solid material in which at least one constrictive passage is provided. The constrictive passage may be constantly open and serve to allow passage of liquid product back and forth between the liquid reservoir and the liquid chamber.

Owner:TECHN CONCEPTS BENTFIELD

Smart installation/processing systems, components, and methods of operating the same

ActiveUS20130200543A1Reduce upsetImprove fatigue lifeProgramme controlUsing fluid meansEngineeringHandling system

A processing system employs a processing tool to process workpieces, for example cold working holes and / or installing expandable members into holes. Sensors sense various aspects of the processing. Information regarding performance of the process and / or materials may be stored, for example a hole-by-hole or a workpiece-by-workpiece basis, allowing validation of processing. Information also allows dynamic operation of the processing tool. Analysis of response relationships (e.g., pressure or force versus position or distance) may provide insights into the process and materials, and / or facilitate the real-time feedback including control, alerts, ordering replacement for consumable components.

Owner:FATIGUE TECH

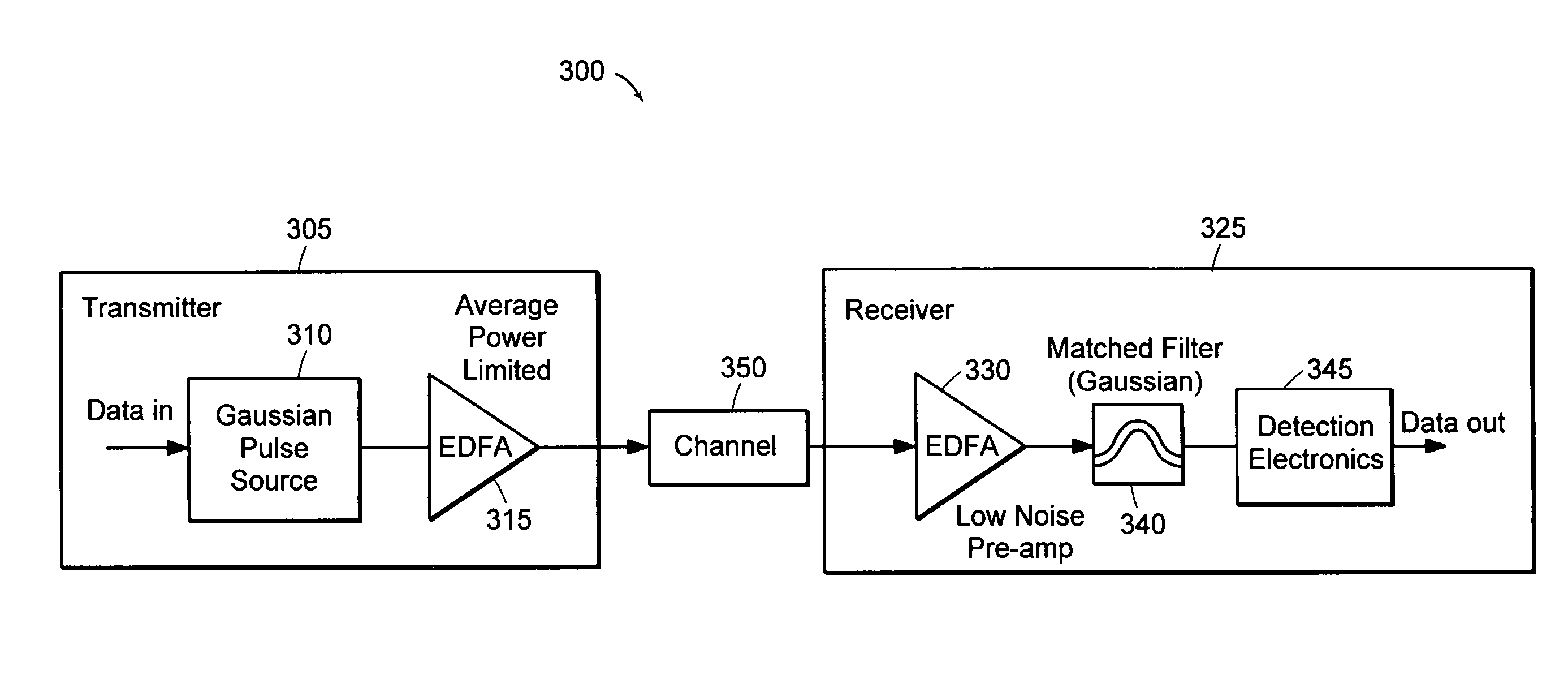

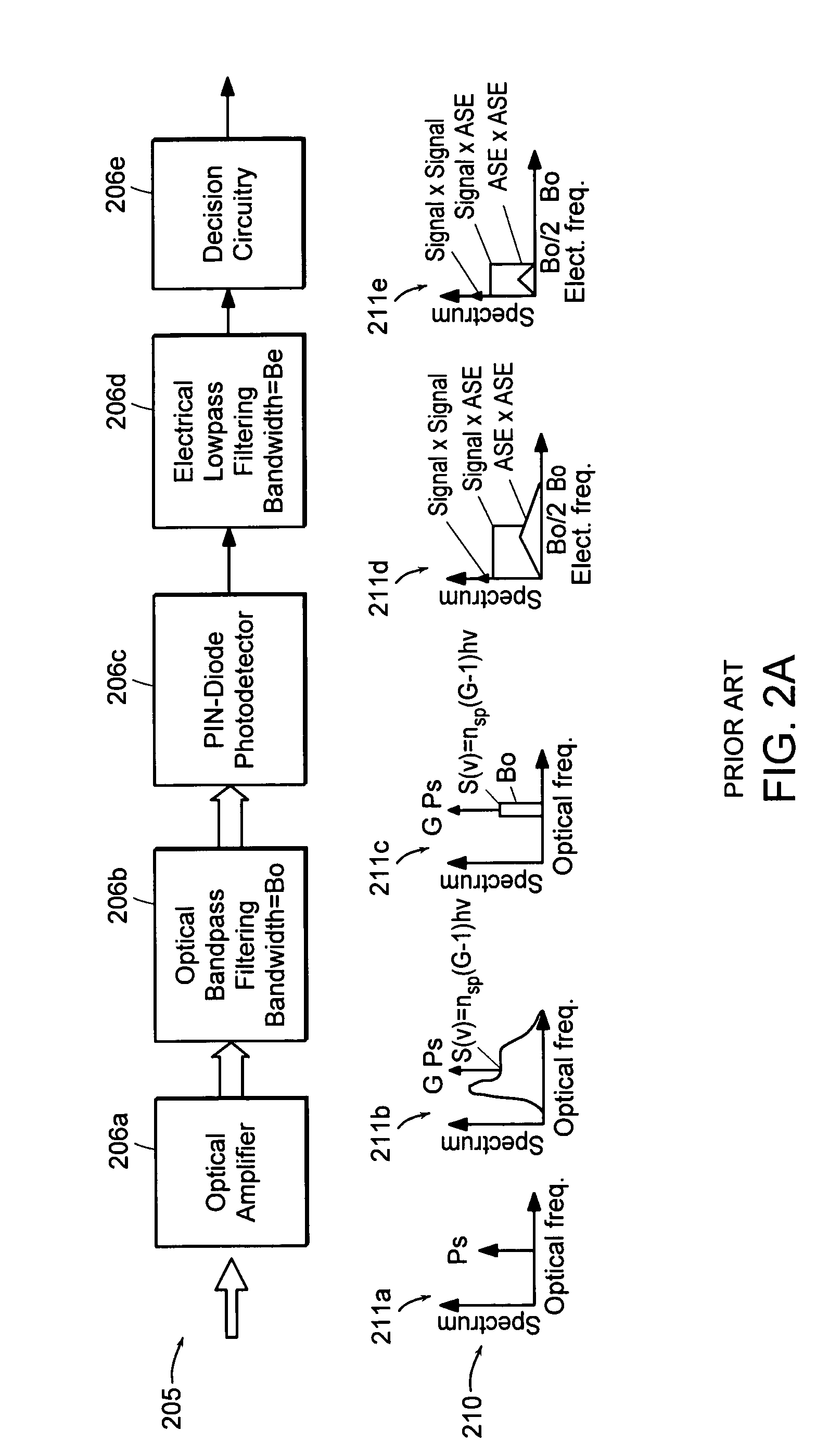

Methods of achieving optimal communications performance

InactiveUS7181097B2High bandwidthImprove measurement resolutionCoupling light guidesElectromagnetic transmissionErbium dopingPower limits

A system includes an optical transmitter that outputs an optical signal having a substantially Gaussian waveform and an optical receiver that is optically coupled to the optical transmitter and has an impulse response essentially matching the waveform. The impulse response and waveform preferably match in the time domain. The transmitter and receiver may be average-power-limited, using, for example, an erbium-doped fiber amplifier. To achieve a high signal-to-noise ratio, the waveform may be designed to minimize jitter, sample duration, matching parasitics, and inter-symbol interference (ISI). Such a waveform may be a return-to-zero (RZ) Gaussian or Gaussian-like waveform and may be transmitted in a variety of modulation formats. Further, the system may be used in WDM or TDM systems. A method for characterizing the time domain impulse response of an optical element used in the optical receiver is provided, where the method is optionally optimized using deconvolution and / or cross-correlation techniques.

Owner:MASSACHUSETTS INST OF TECH

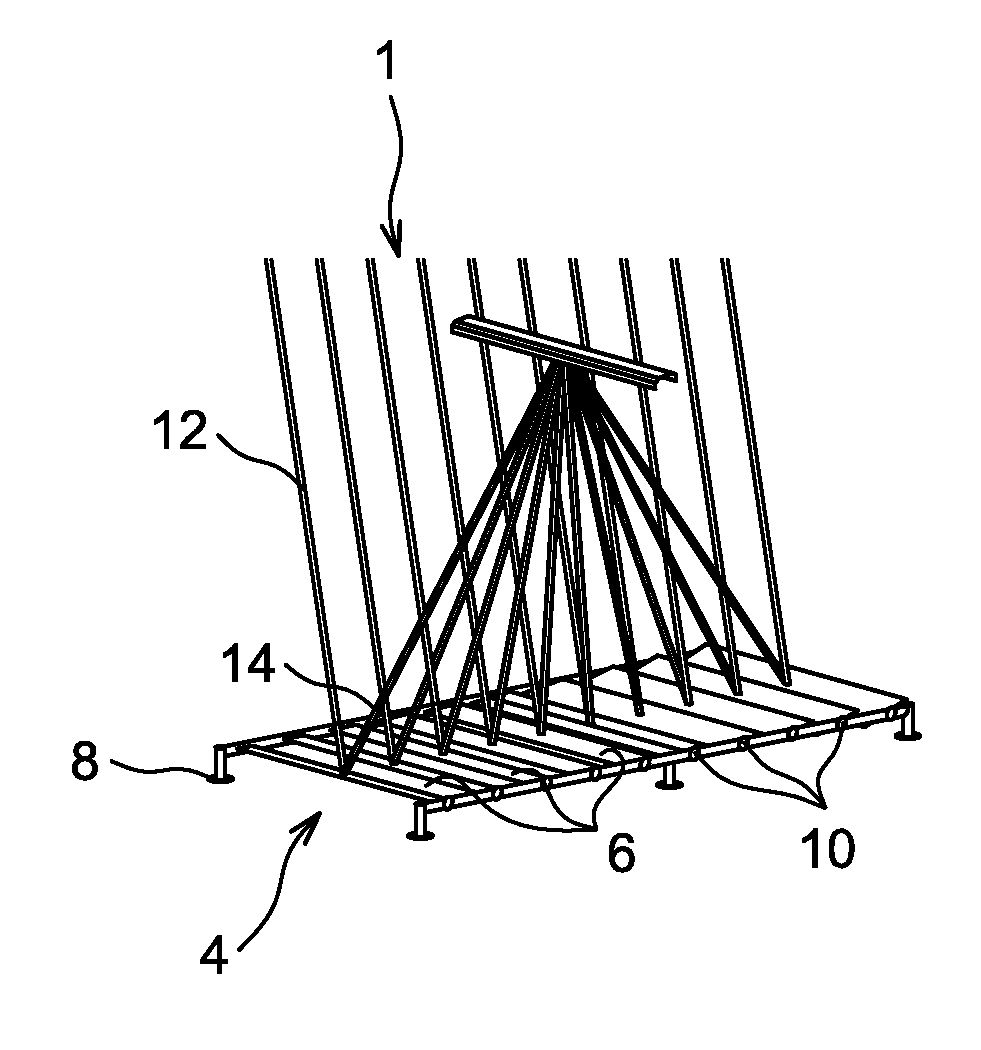

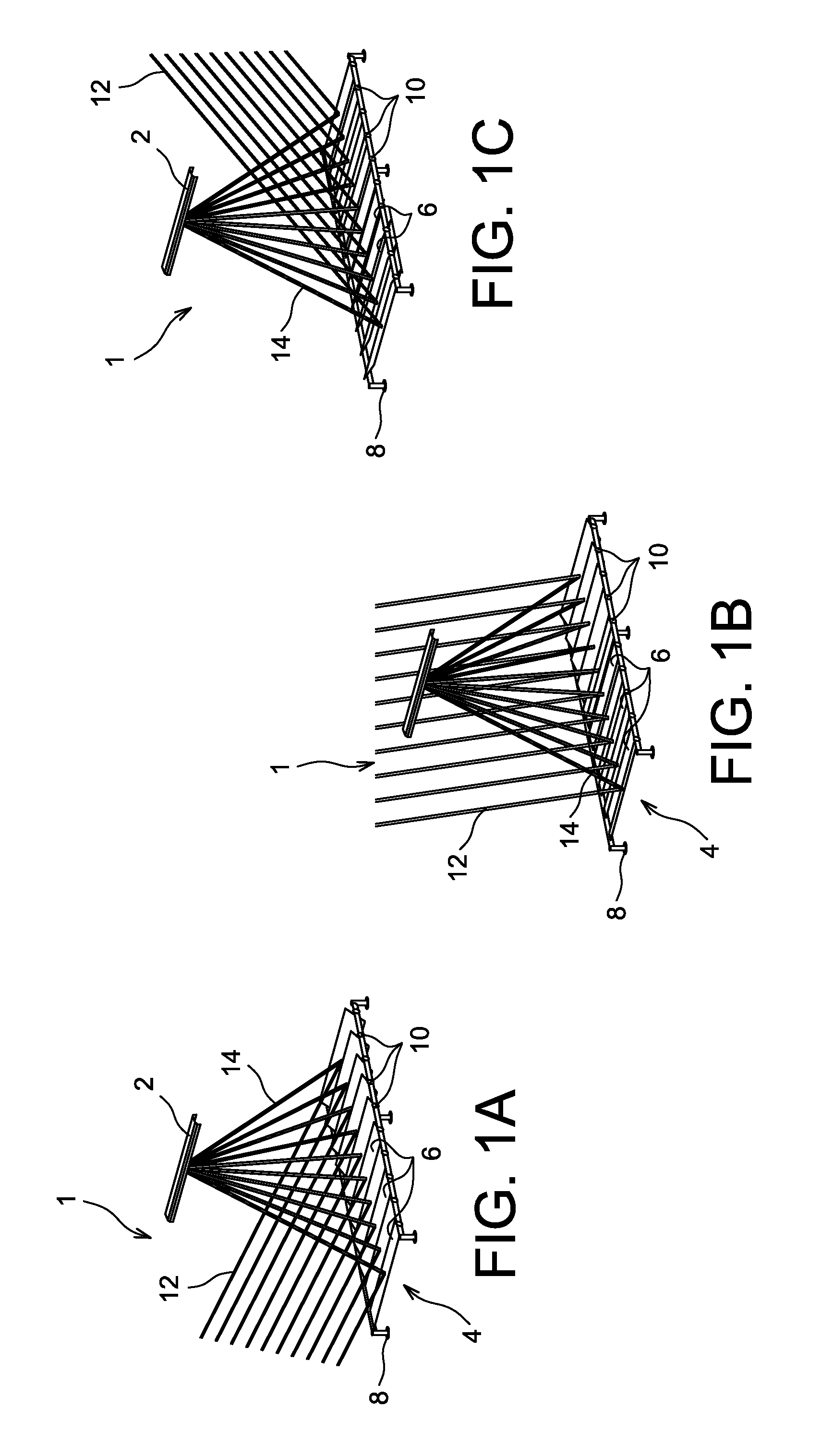

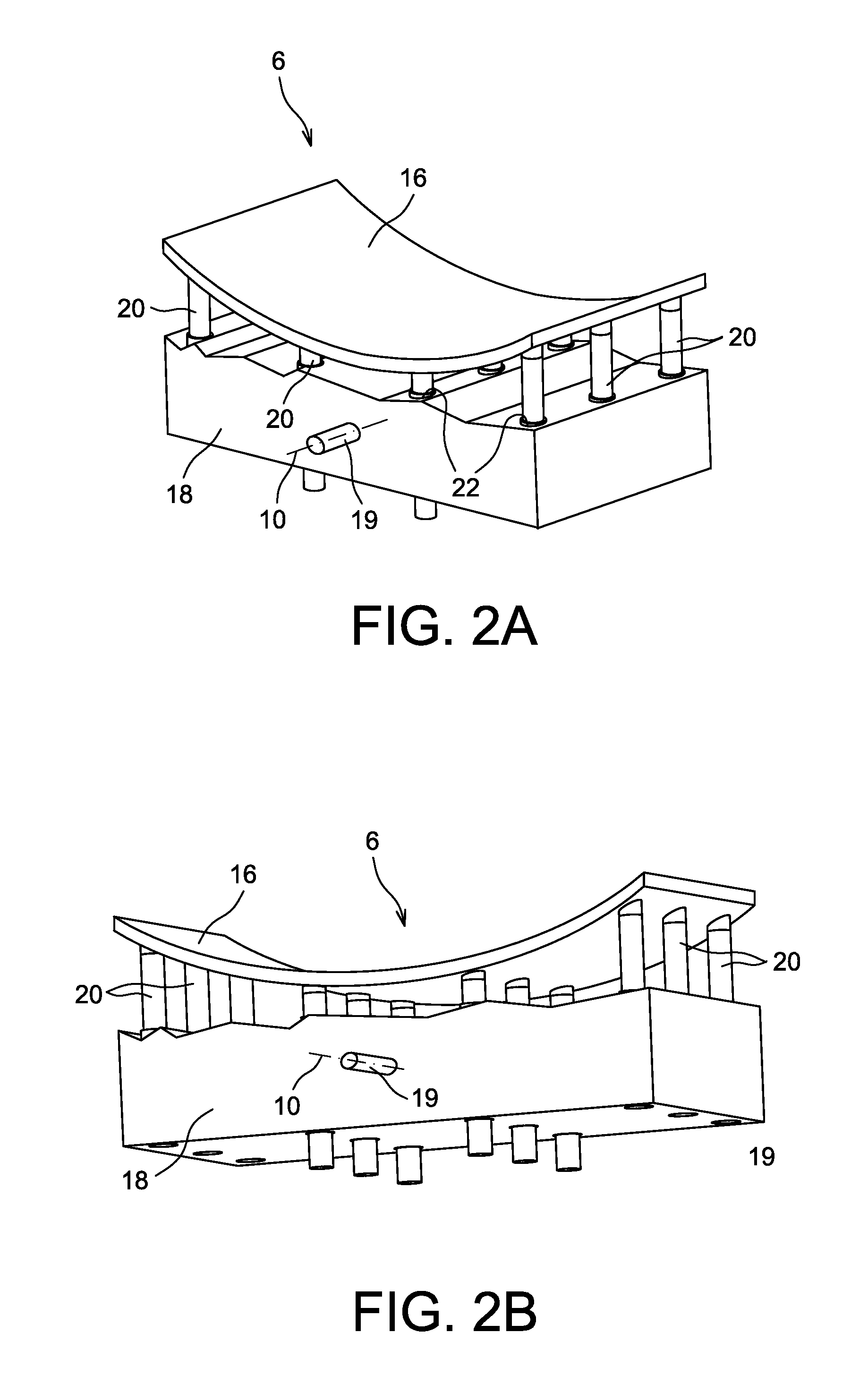

Method for Manufacturing a Reflector, Preferably for the Solar Energy Field

ActiveUS20130314813A1Improve Manufacturing TolerancesSupporting structureSolar heating energyMirrorsEngineeringSolar energy

Owner:COMMISSARIAT A LENERGIE ATOMIQUE ET AUX ENERGIES ALTERNATIVES

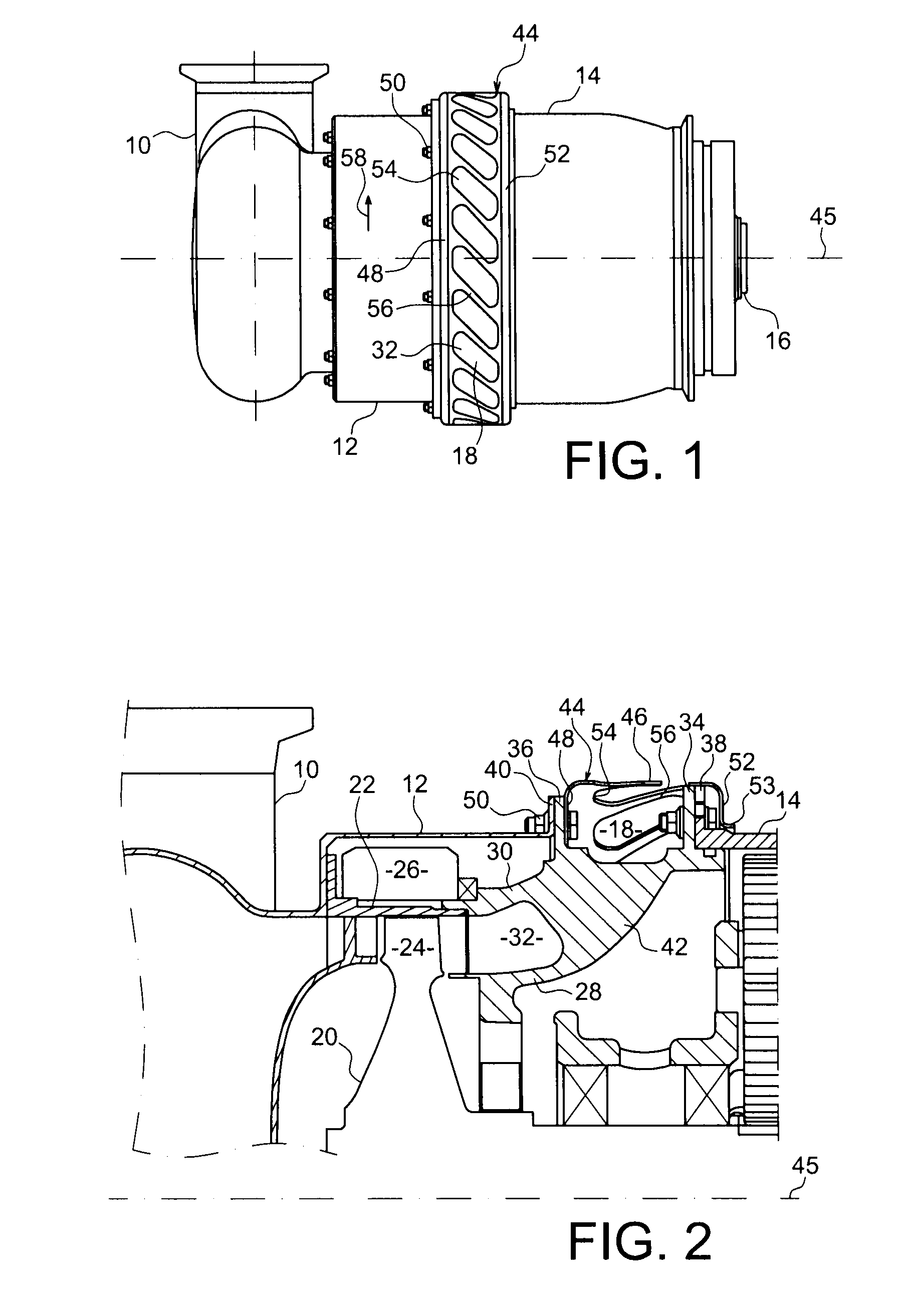

Combustor and method of improving manufacturing accuracy thereof

ActiveUS7308794B2Improve manufacturing precisionImprove Manufacturing TolerancesContinuous combustion chamberGas turbine plantsCombustorEffusion

Owner:PRATT & WHITNEY CANADA CORP

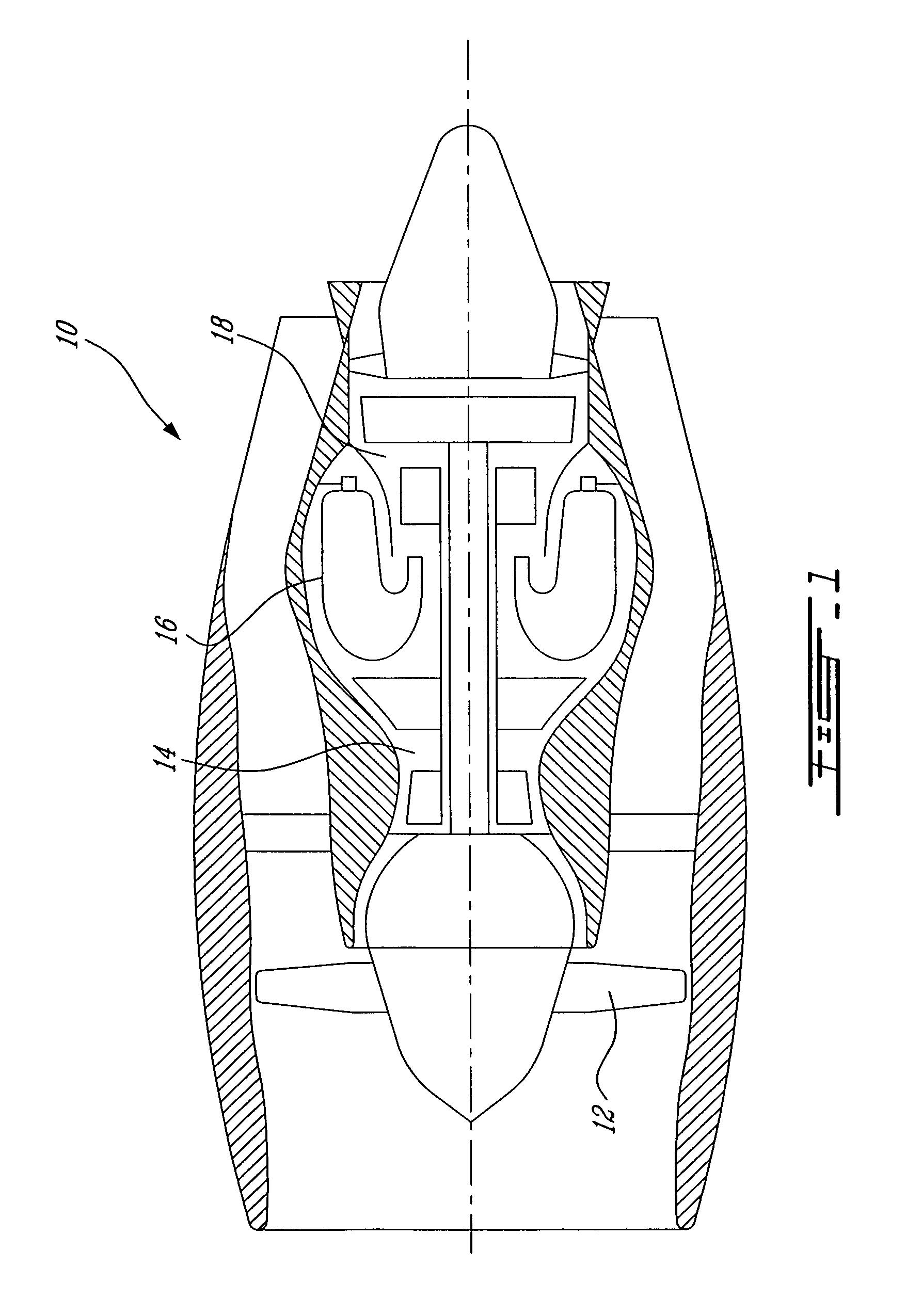

Compressed air starter for turbomachine

ActiveUS20100192594A1Light weightPrevent axial displacementPump componentsTurbine/propulsion engine ignitionFront and back endsCompressed air

Air starter for turbomachine, comprising a forward casing (12), an aft casing (14), an annular exhaust flow path (32) opening up between an aft end of the forward casing and a forward end of the aft casing, and a cylindrical outlet mesh (44) of the exhaust flow path (32) the forward and aft ends of which comprise means (48, 52) of axially retaining the forward casing (12) and the aft casing (14) respectively to the mesh (44), wherein at least said means (52) of axially retaining one (14) of the casings to the mesh (44) enable a relative rotation of the mesh (44) and this casing (14).

Owner:SAFRAN POWER UNITS

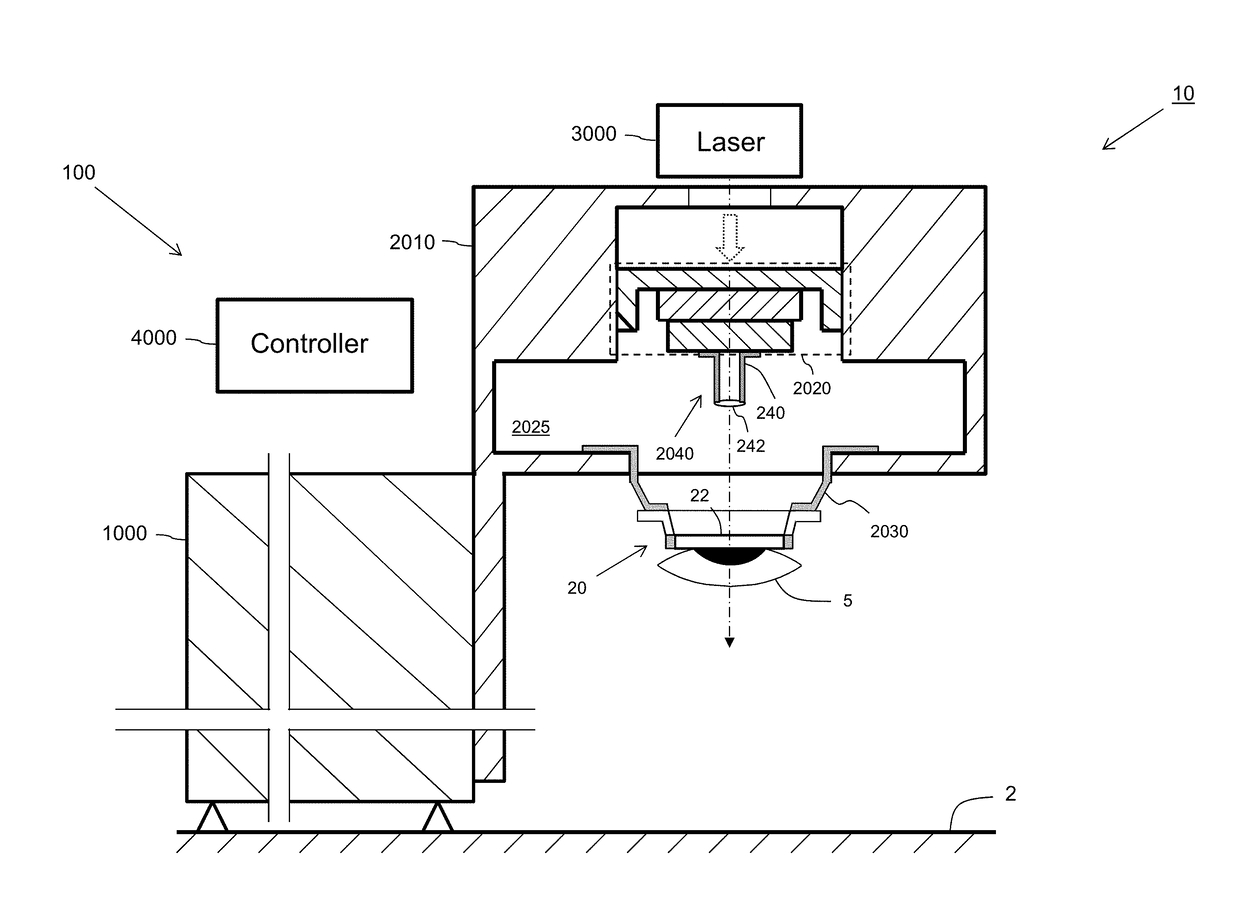

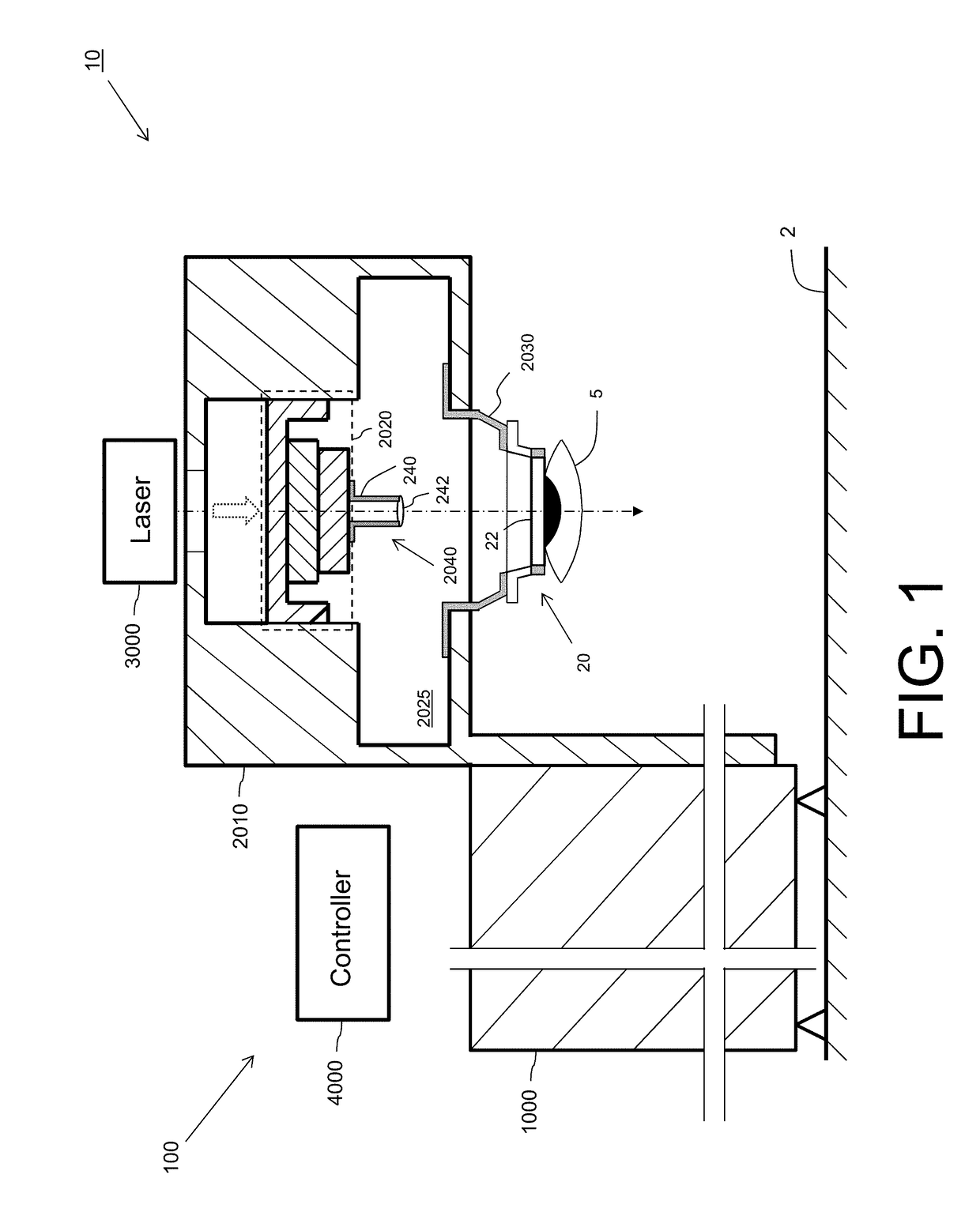

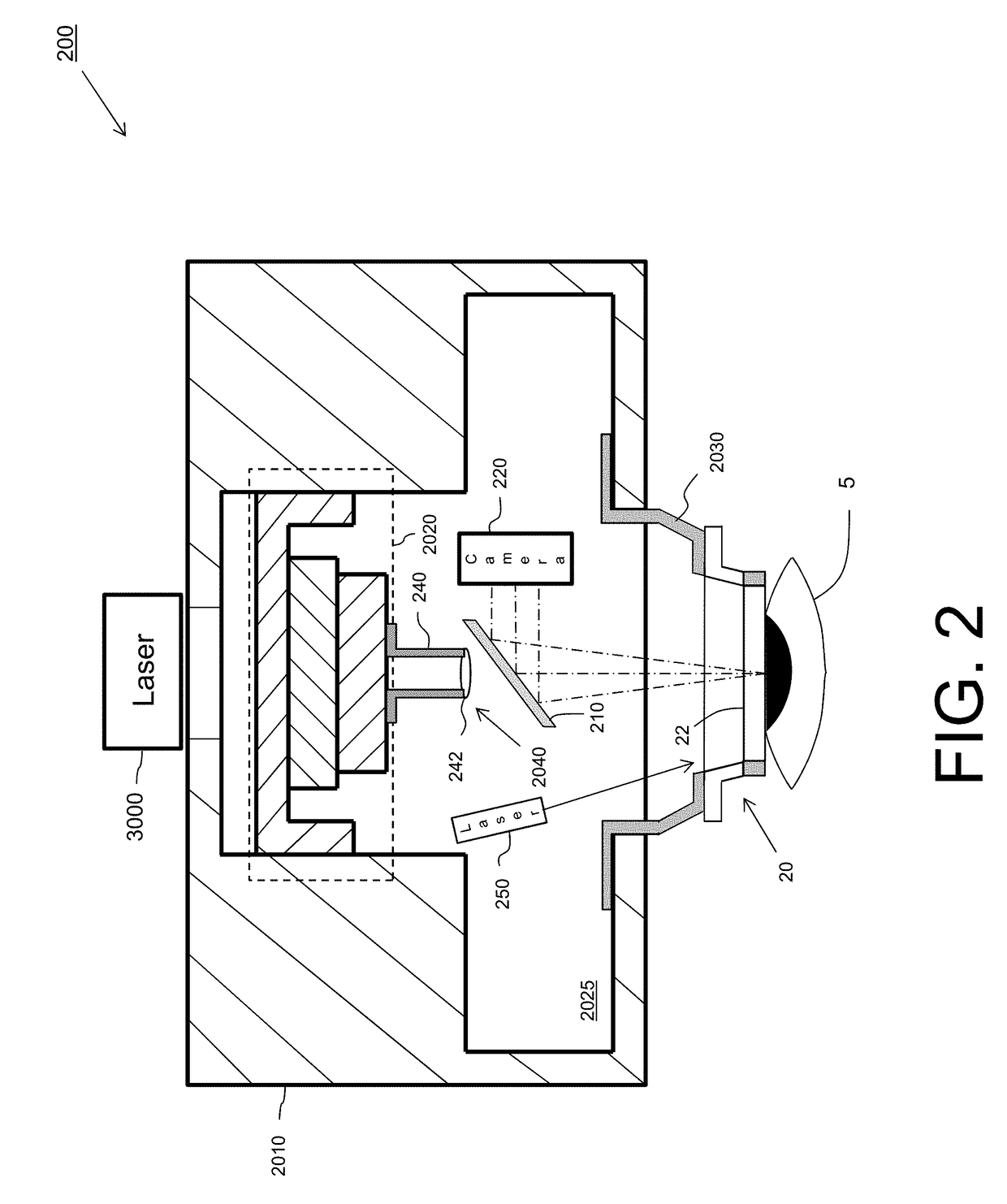

Patient interface device for laser eye surgery having light guiding structure for illuminating eye

ActiveUS20170281407A1High degree of parallelismImprove Manufacturing TolerancesLaser surgerySurgical instrument detailsLight guideLaser surgery

A patient interface device includes: a first interface port configured to be interfaced with a laser surgery apparatus; a second interface port configured to be interfaced with a patient's eye, the second interface port including an applanating lens for application to a patient's eye during a laser surgery procedure; a chamber extending between the first interface port and the second interface port and defining a chamber therein, wherein air may be evacuated from the chamber by the laser surgery apparatus via the first interface port; and a tubular light guiding structure having at a first end thereof a light receiving surface, configured to receive light, and having at a second end thereof a light-emitting surface, wherein the second surface is disposed adjacent the applanating lens and configured to provide the light in a vicinity of the patient's eye when the applanating lens is applied to the patient's eye.

Owner:AMO DEVMENT

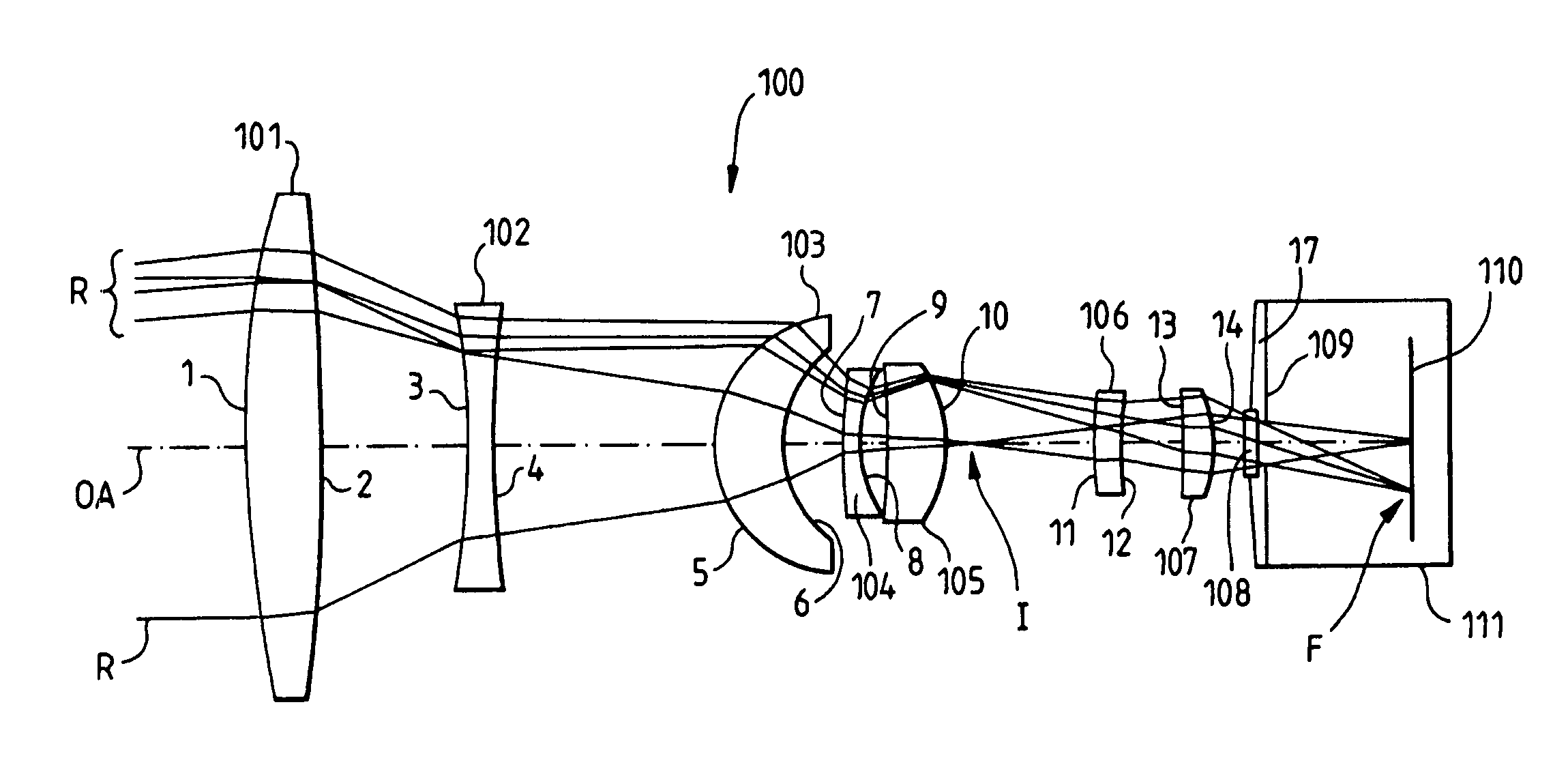

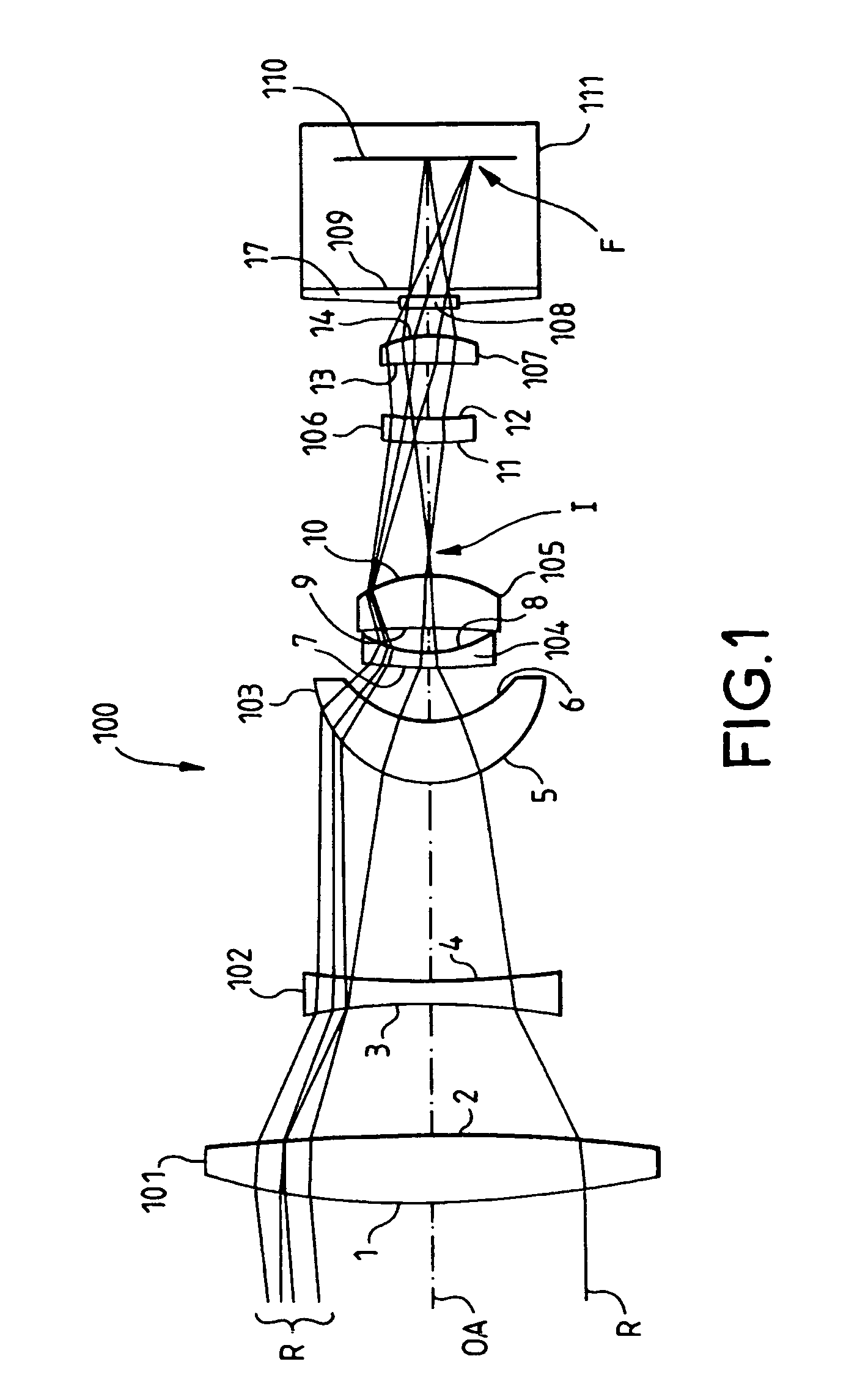

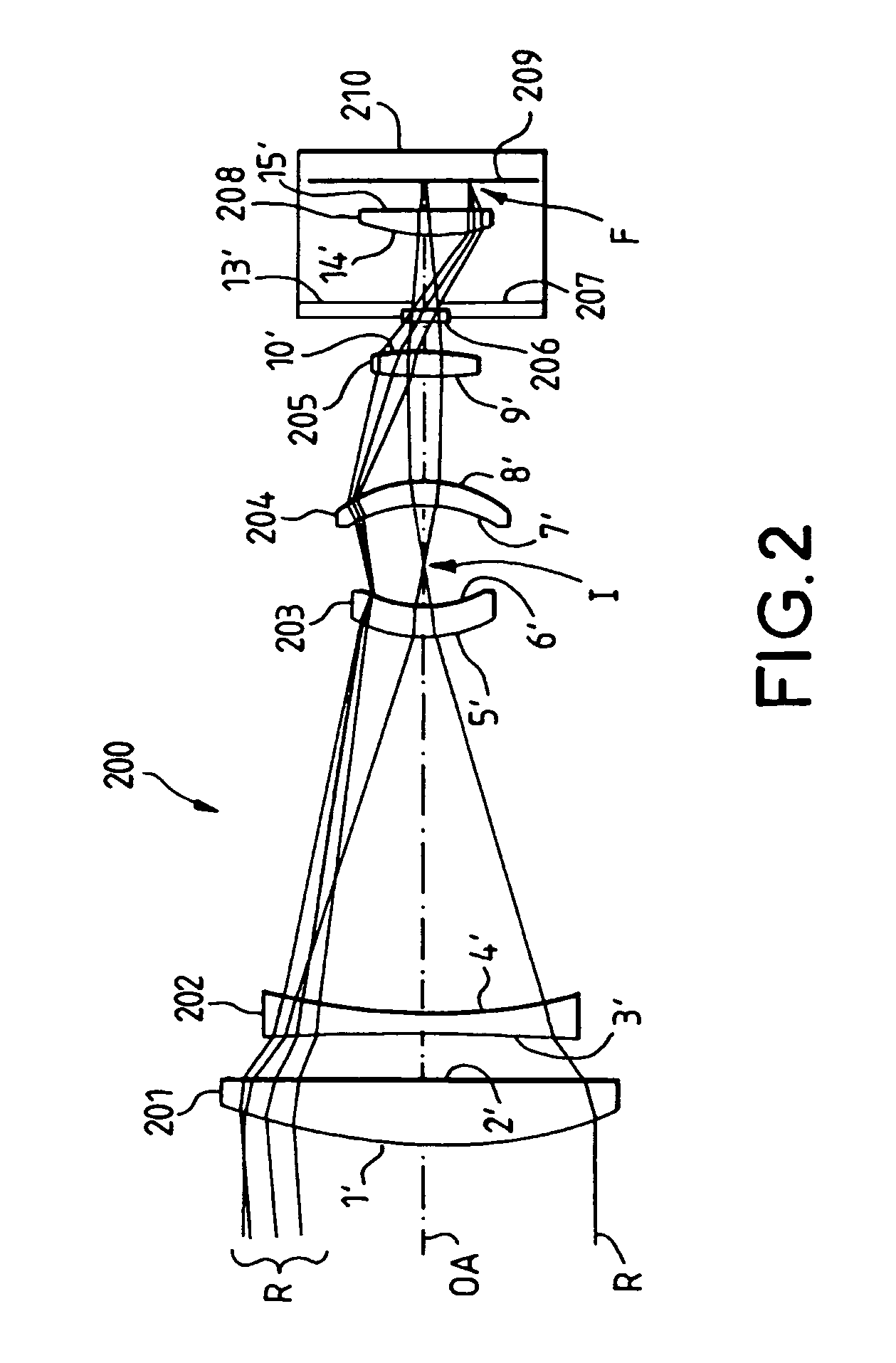

Optical apparatus

InactiveUS7136235B2Improve Manufacturing TolerancesHigh strengthOptical elementsOptical radiationIntermediate image

The present invention provides an optical apparatus including an objective lens system for focusing optical radiation from a scene or object into an intermediate image and has at least one lens element which imposes a substantial degree of negative distortion on the intermediate image. The invention also provides a second lens system for focusing optical radiation from the intermediate image into a final image and an aperture stop for limiting the optical radiation forming the final image. The aperture stop is located between the final image region in which the final image is formed or to be formed and the lens element of the second lens system most distant from the final image region.

Owner:THALES OPTICS

Cathode header optic for x-ray tube

ActiveUS20090022277A1Less affectedReduced cross sectionX-ray tube electrodesCathode ray concentrating/focusing/directingEngineeringElectron

A cathode header optic for an x-ray tube includes an elongate trench with opposite trench walls. A cup recess is formed in the trench between the opposite trench walls, and has a bounded perimeter. A cathode element is disposed in the trench at the cup recess. The cathode element is capable of heating and releasing electrons. A secondary cathode optic defining a cathode ring can be disposed about the header optic. The cathode optics can form part of an x-ray tube.

Owner:MOXTEK INC

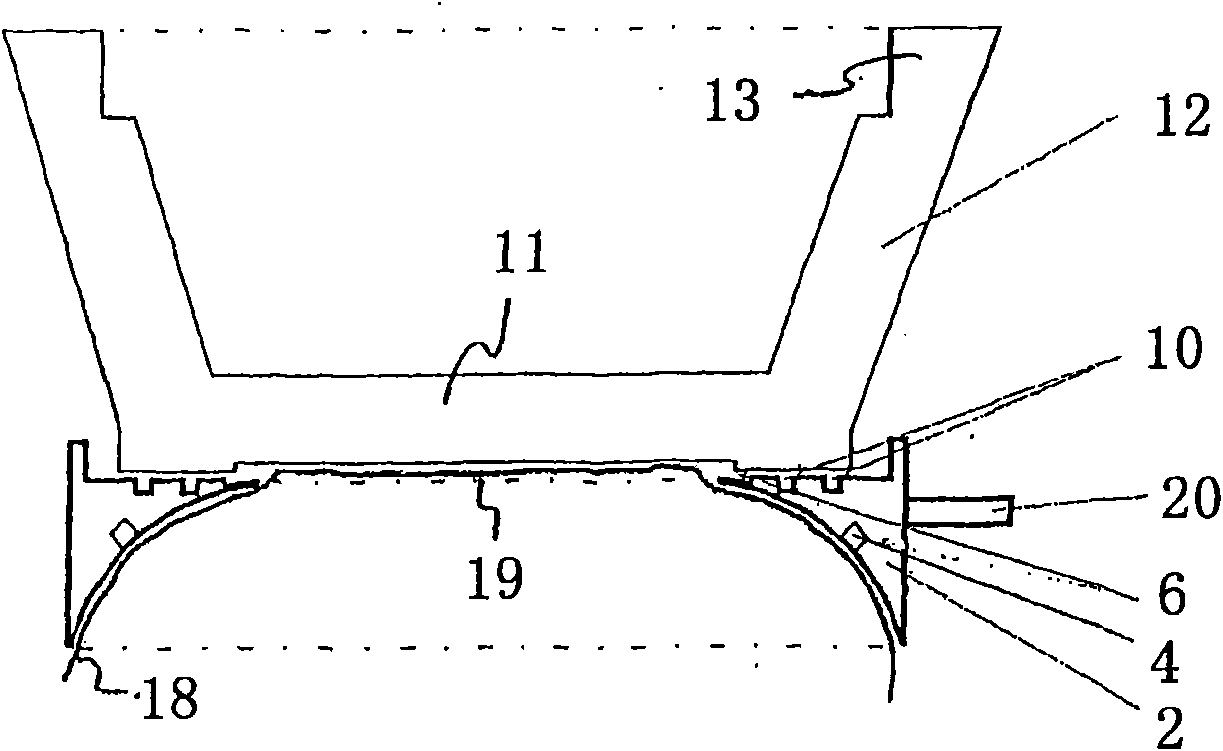

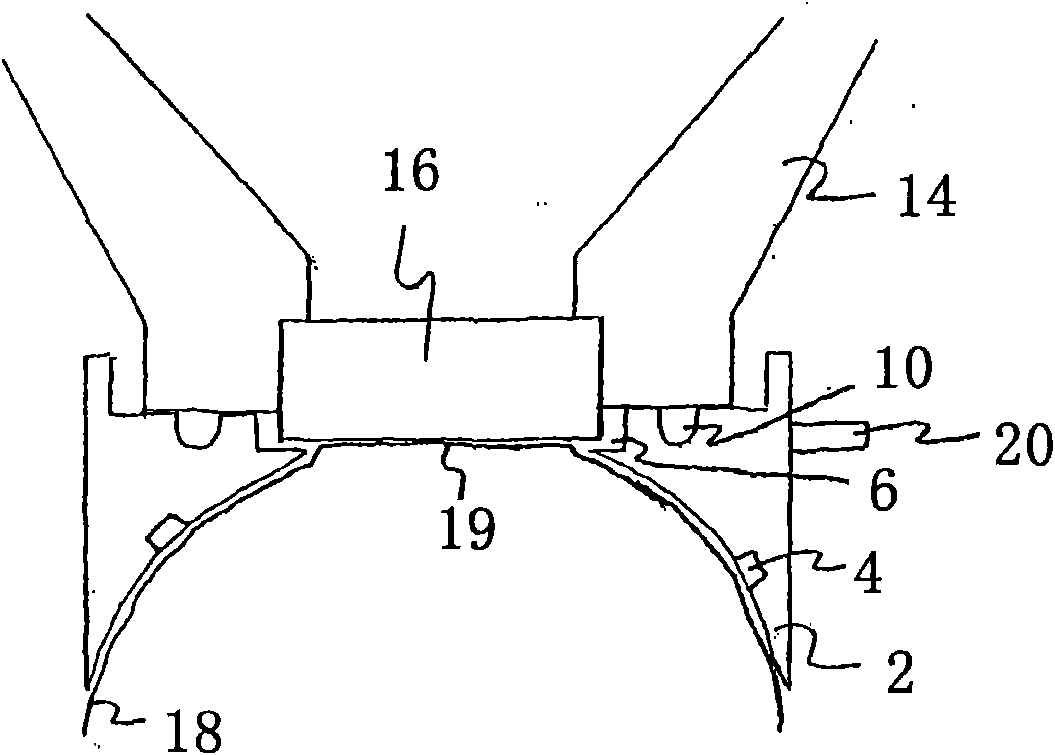

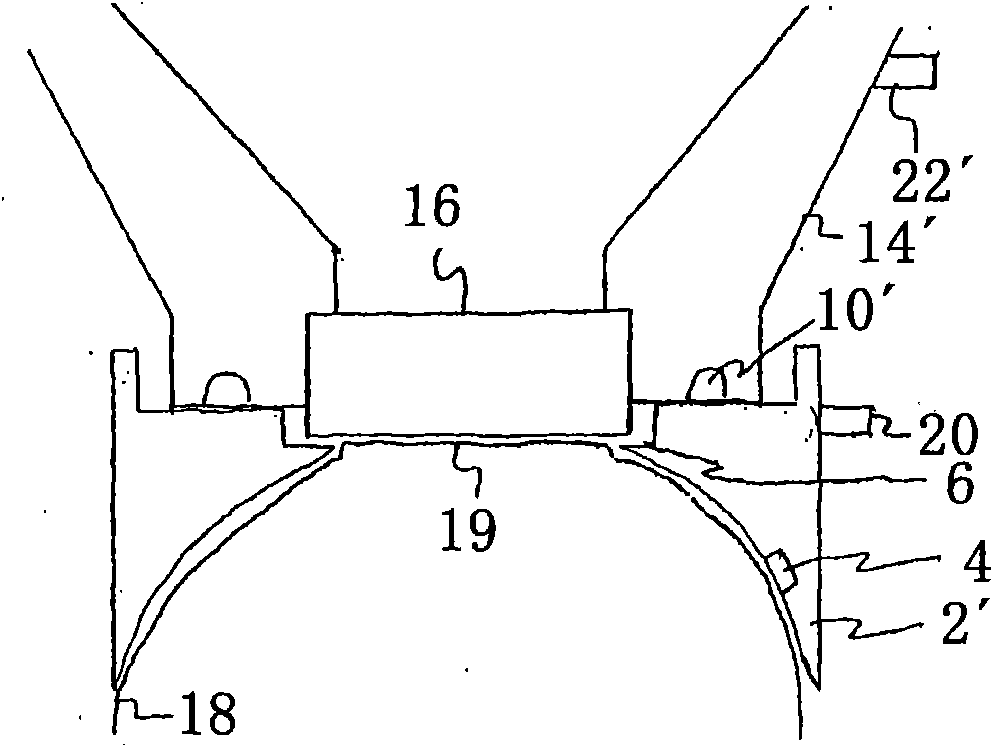

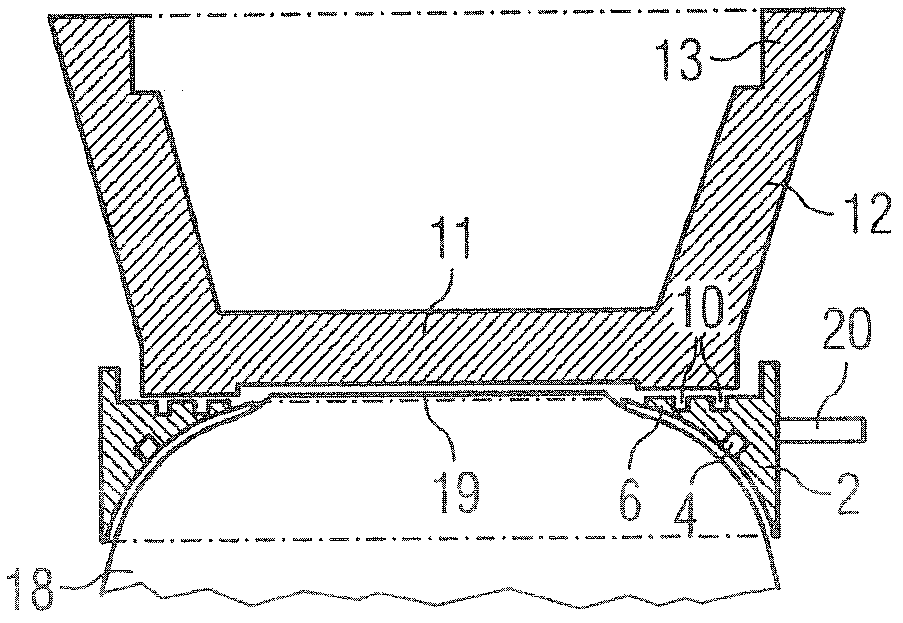

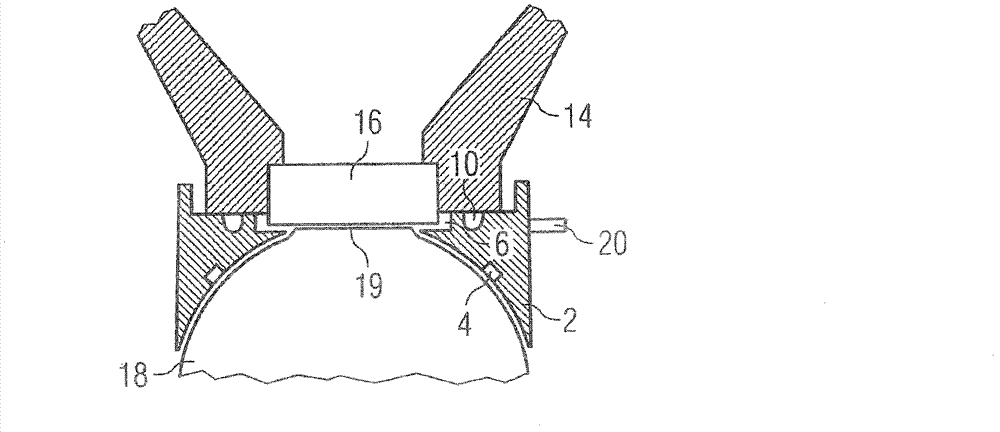

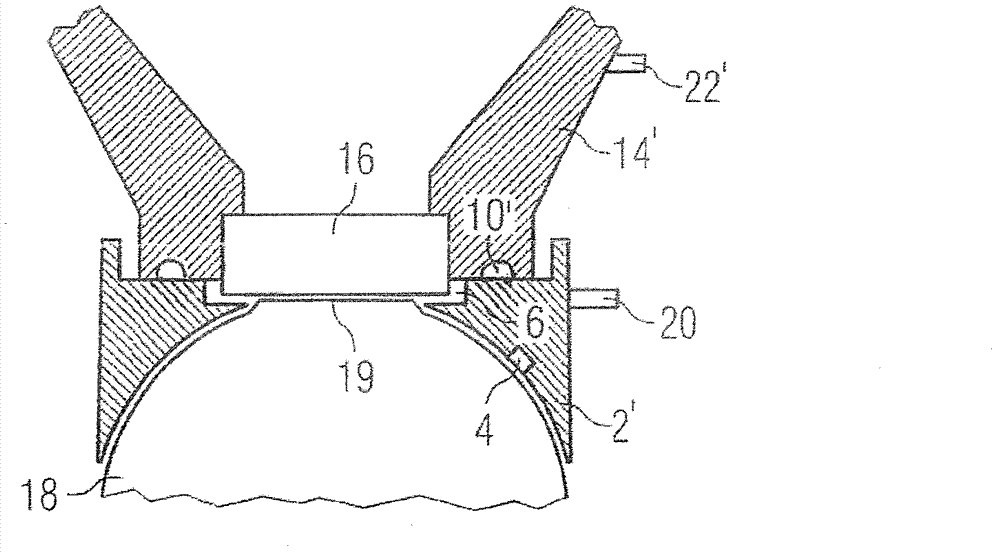

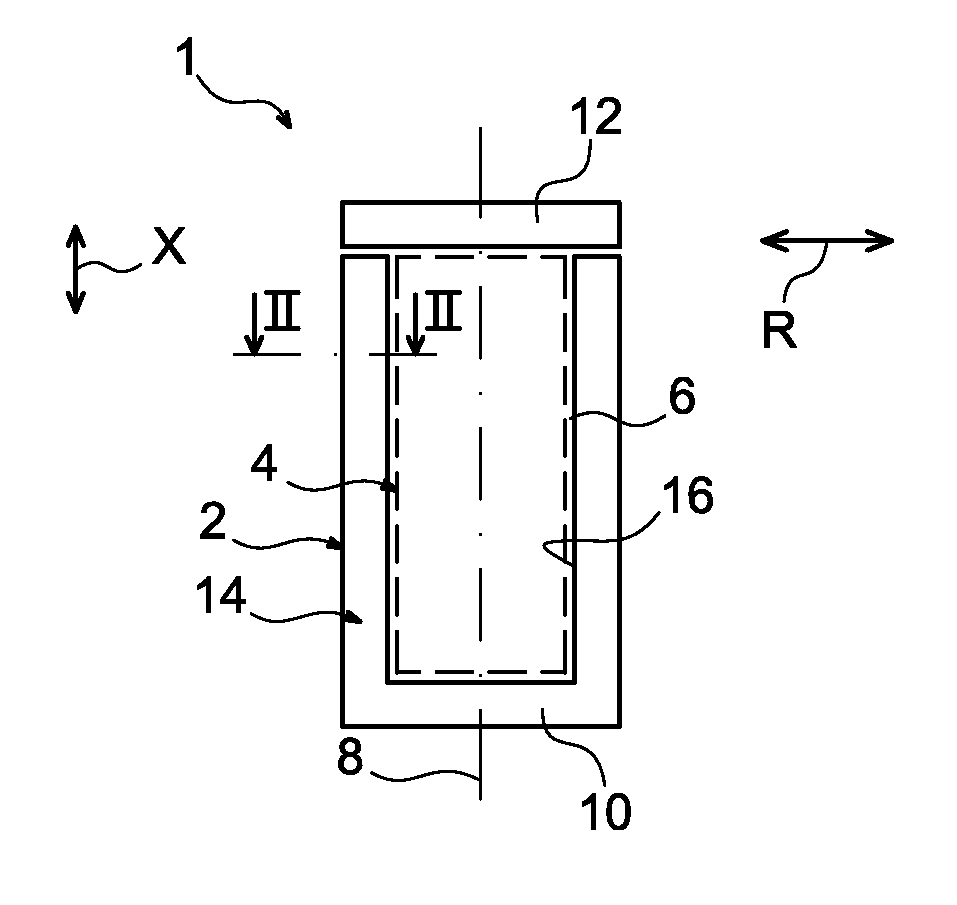

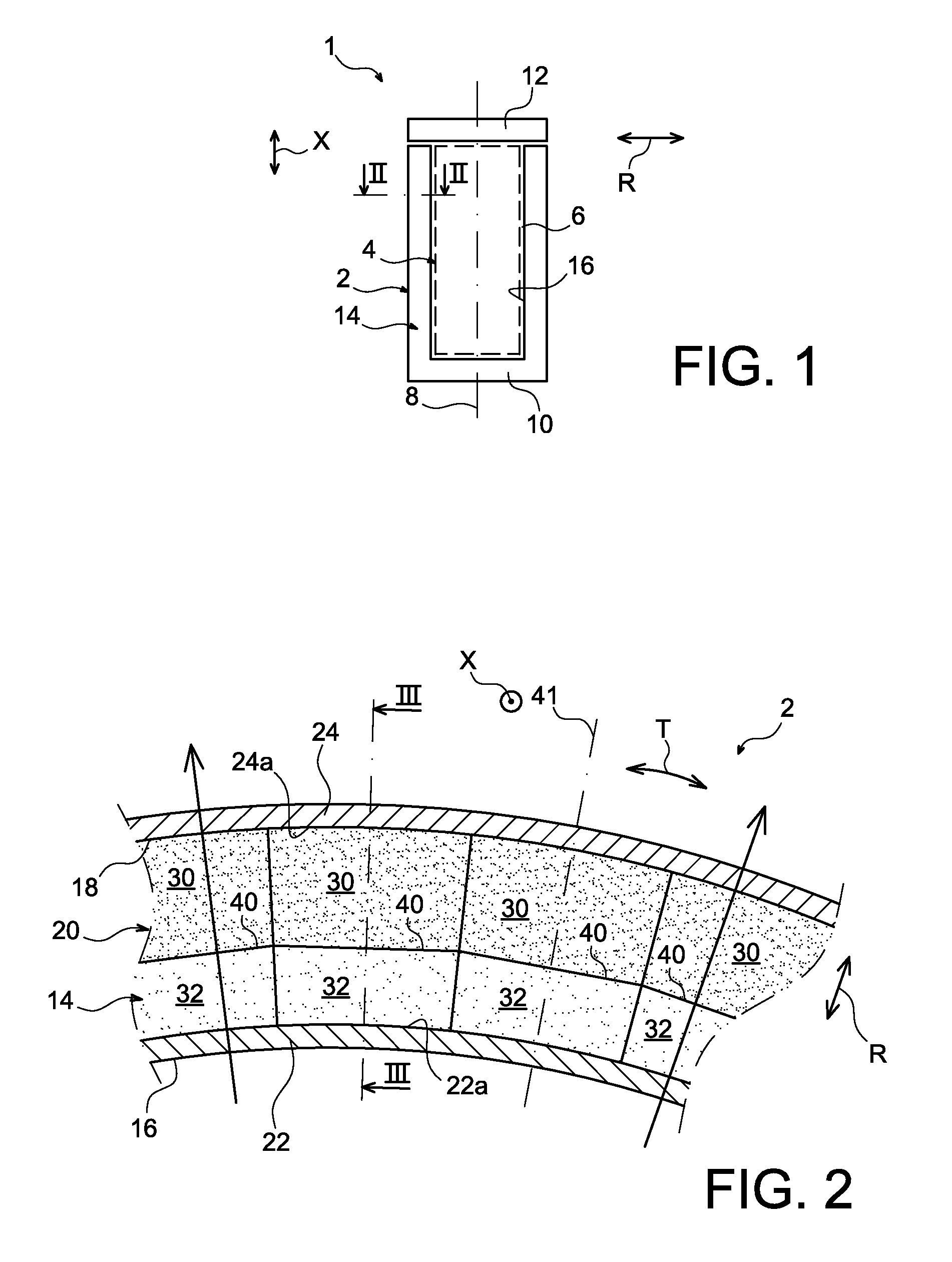

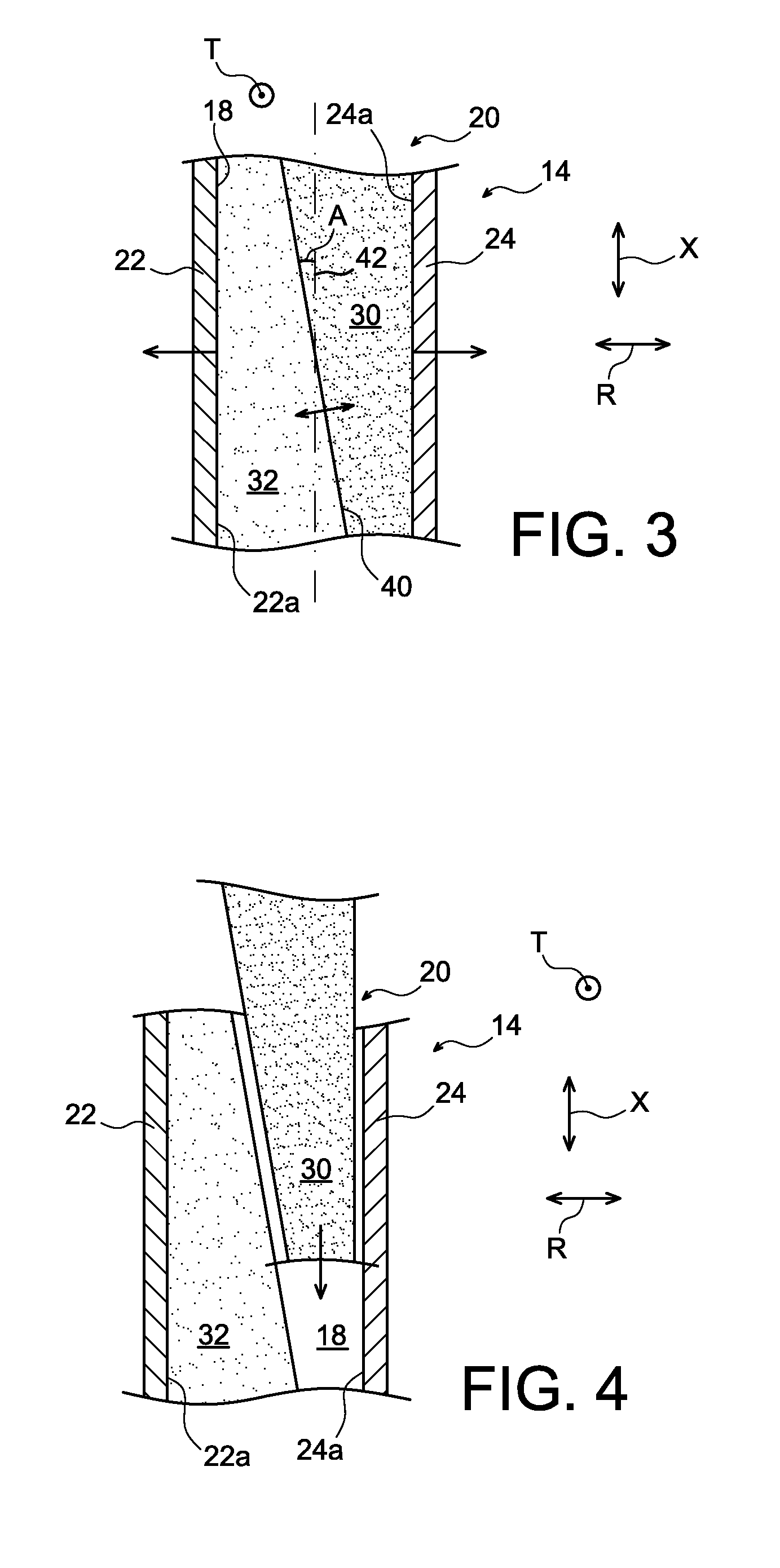

Apparatus for coupling an element to the eye

The invention relates to a suction ring (4) for ophthalmological surgery, having a first suction region (6) that is configured to suction the suction ring onto an eye (18), and having a second suction region (10) that is configured to suction on a functional element (13). The functional element, and / or or the suction ring may comprise a measuring means. The functional element may be configured inthe shape of a vessel such that it may receive a fluid that is located between cornea of the eye and a lens during use.

Owner:WAVELIGHT GMBH

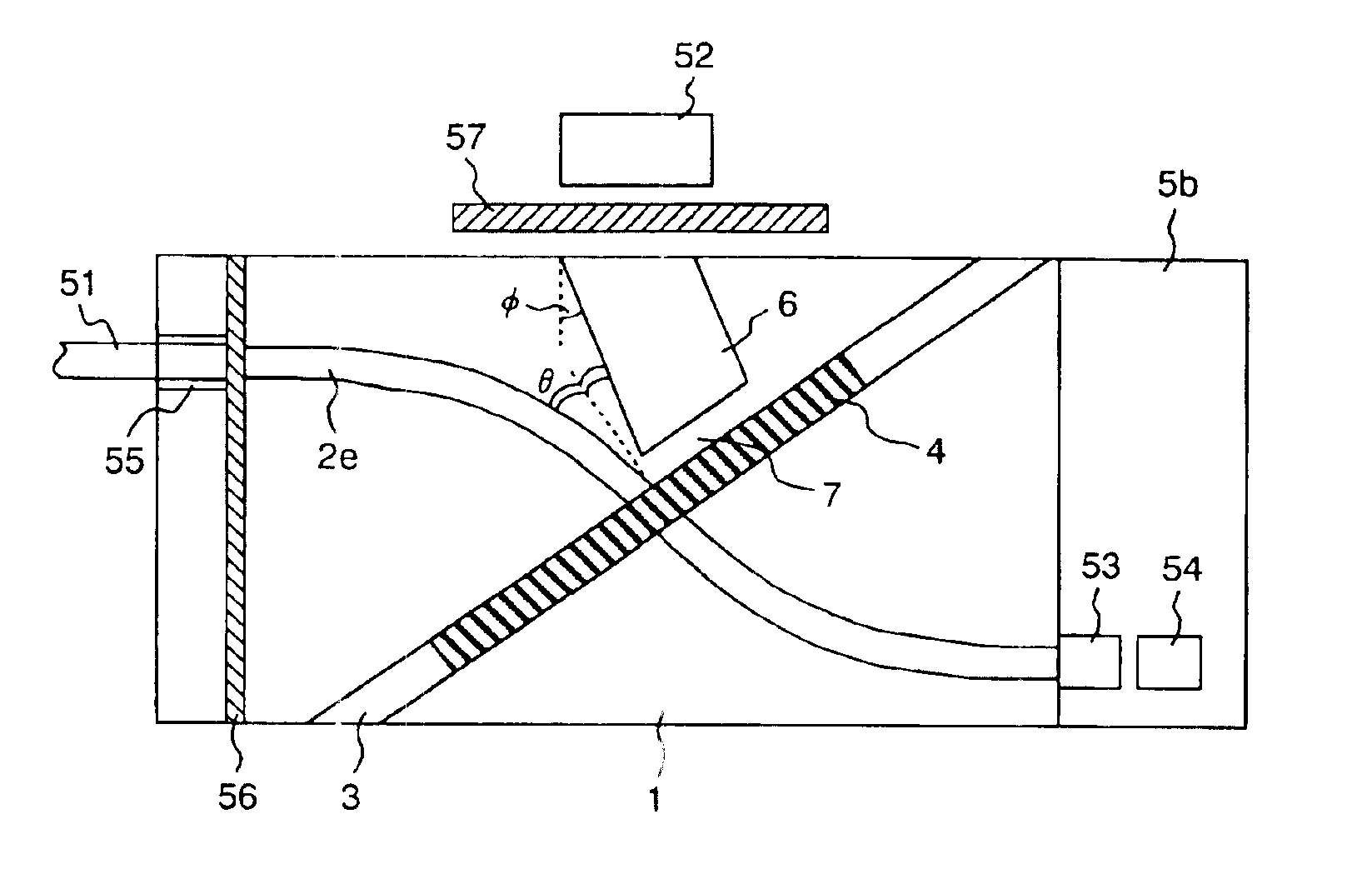

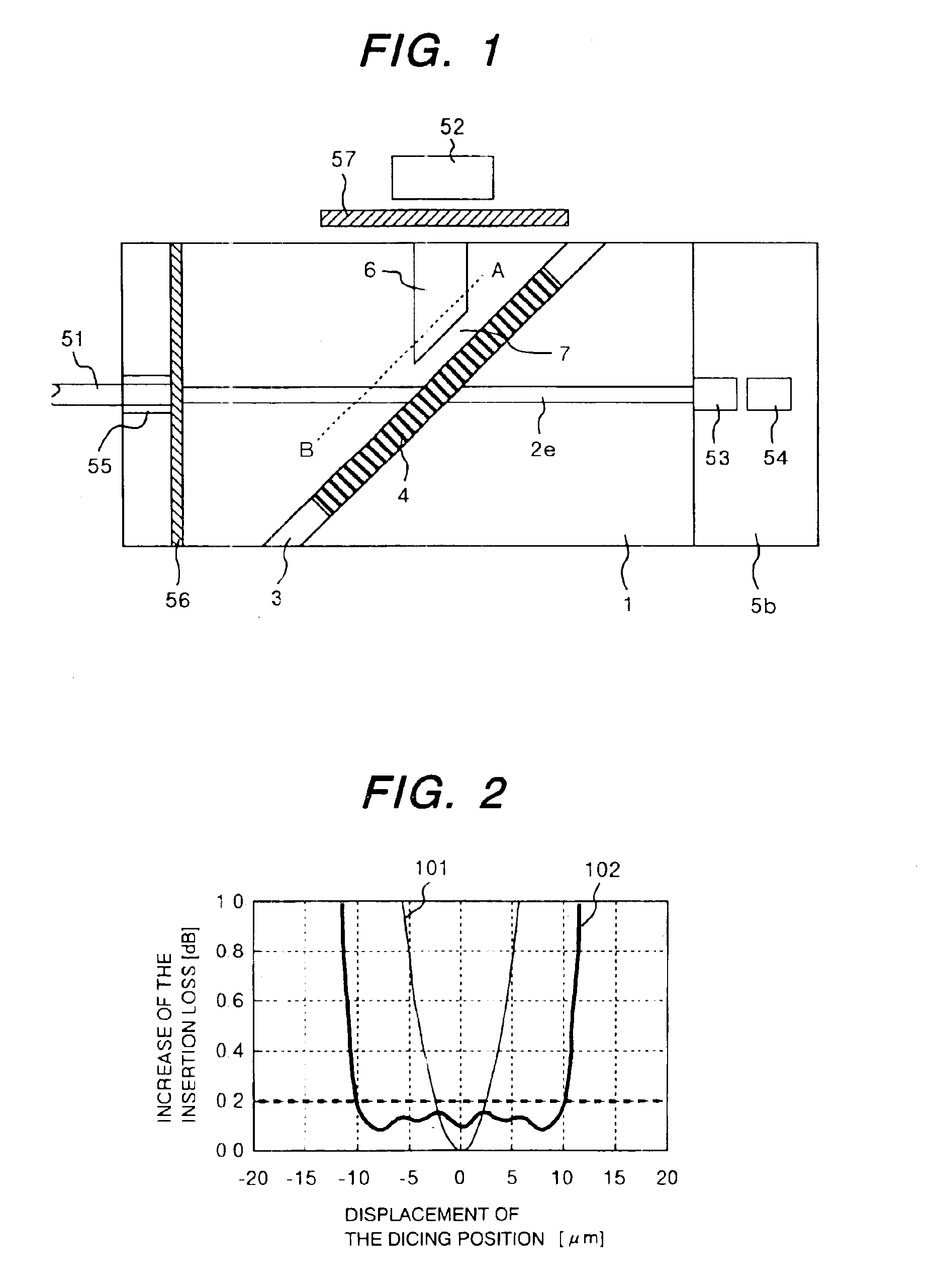

Optical waveguide and their application of the optical communication system

InactiveUS6868210B2Improve Manufacturing TolerancesImprove featuresCladded optical fibreCoupling light guidesCommunications systemOptical communication

An optical transmitter / receiver module of wavelength division multiplexing type which undergoes a reduced excess loss resulting from the displacement of a dicing position is fabricated with a high yield rate. An optical waveguide for guiding reflected light from a wavelength selection filter has a core substantially larger in size than the core of each of the other optical waveguides.

Owner:HITACHI LTD +1

Apparatus for coupling an element to the eye

Owner:WAVELIGHT GMBH

Smart installation/processing systems, components, and methods of operating the same

ActiveUS8938886B2Improve Manufacturing TolerancesAss qualityProgramme controlComputer controlEngineeringHandling system

A processing system employs a processing tool to process workpieces, for example cold working holes and / or installing expandable members into holes. Sensors sense various aspects of the processing. Information regarding performance of the process and / or materials may be stored, for example a hole-by-hole or a workpiece-by-workpiece basis, allowing validation of processing. Information also allows dynamic operation of the processing tool. Analysis of response relationships (e.g., pressure or force versus position or distance) may provide insights into the process and materials, and / or facilitate the real-time feedback including control, alerts, ordering replacement for consumable components.

Owner:FATIGUE TECH

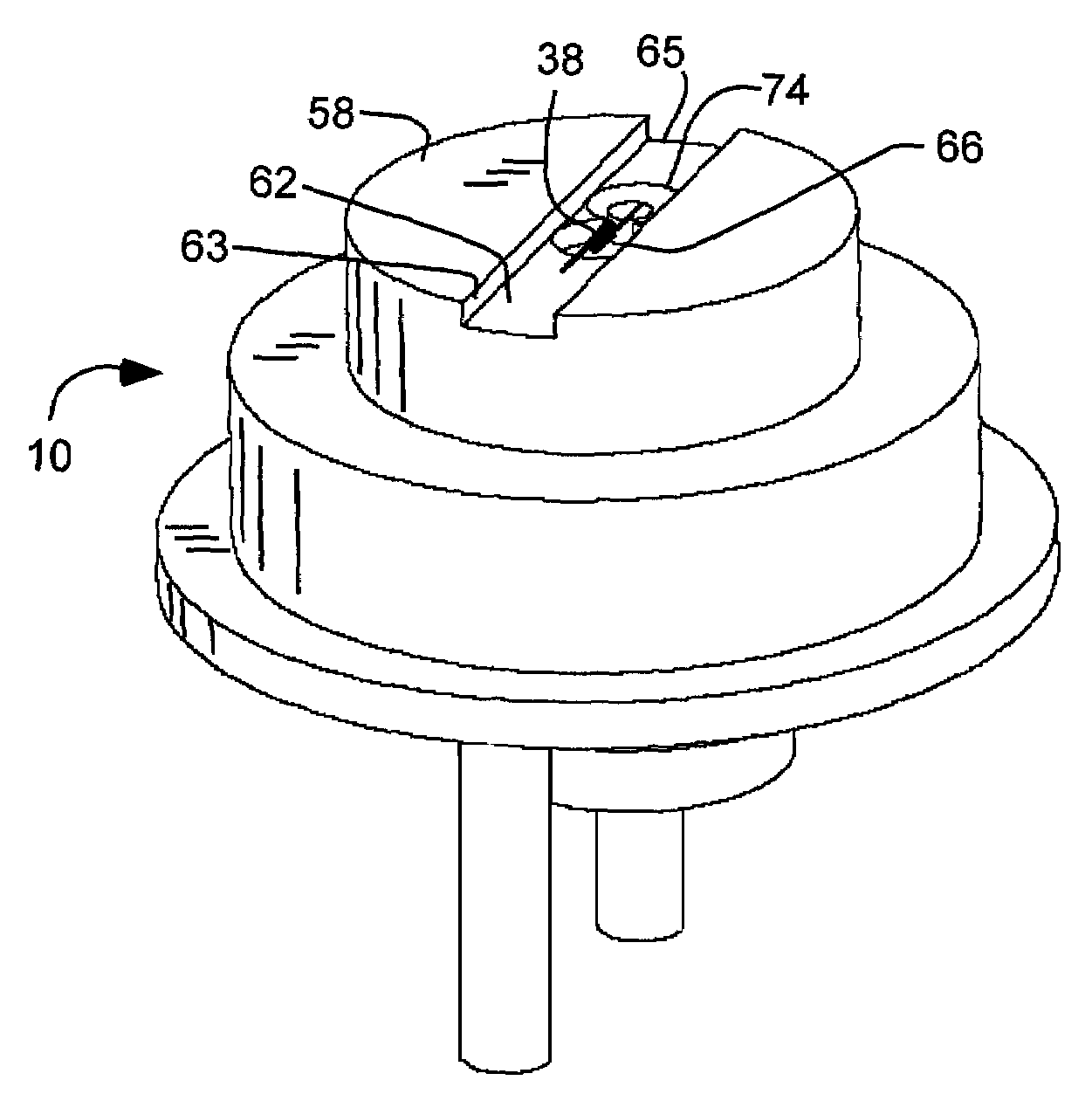

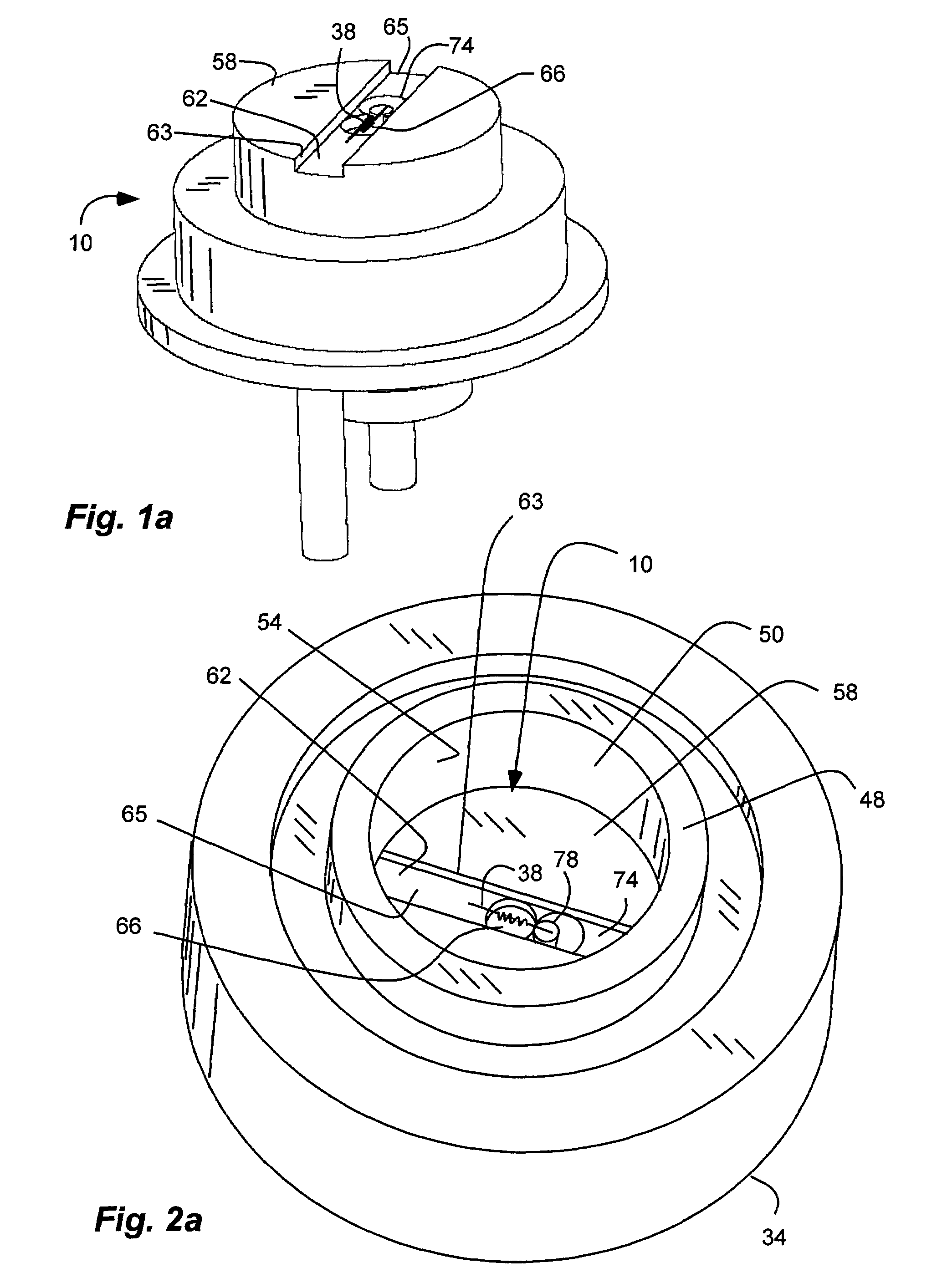

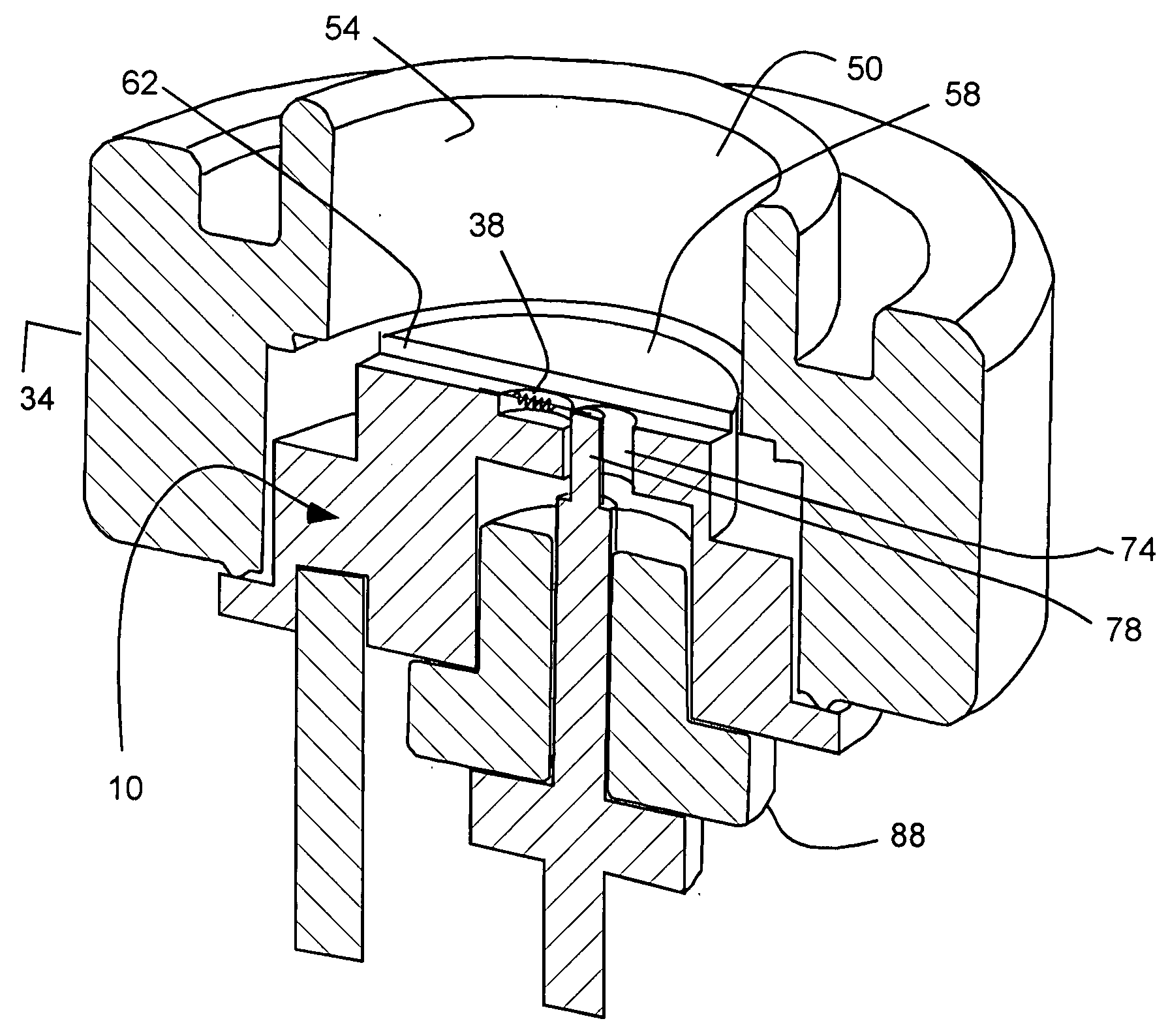

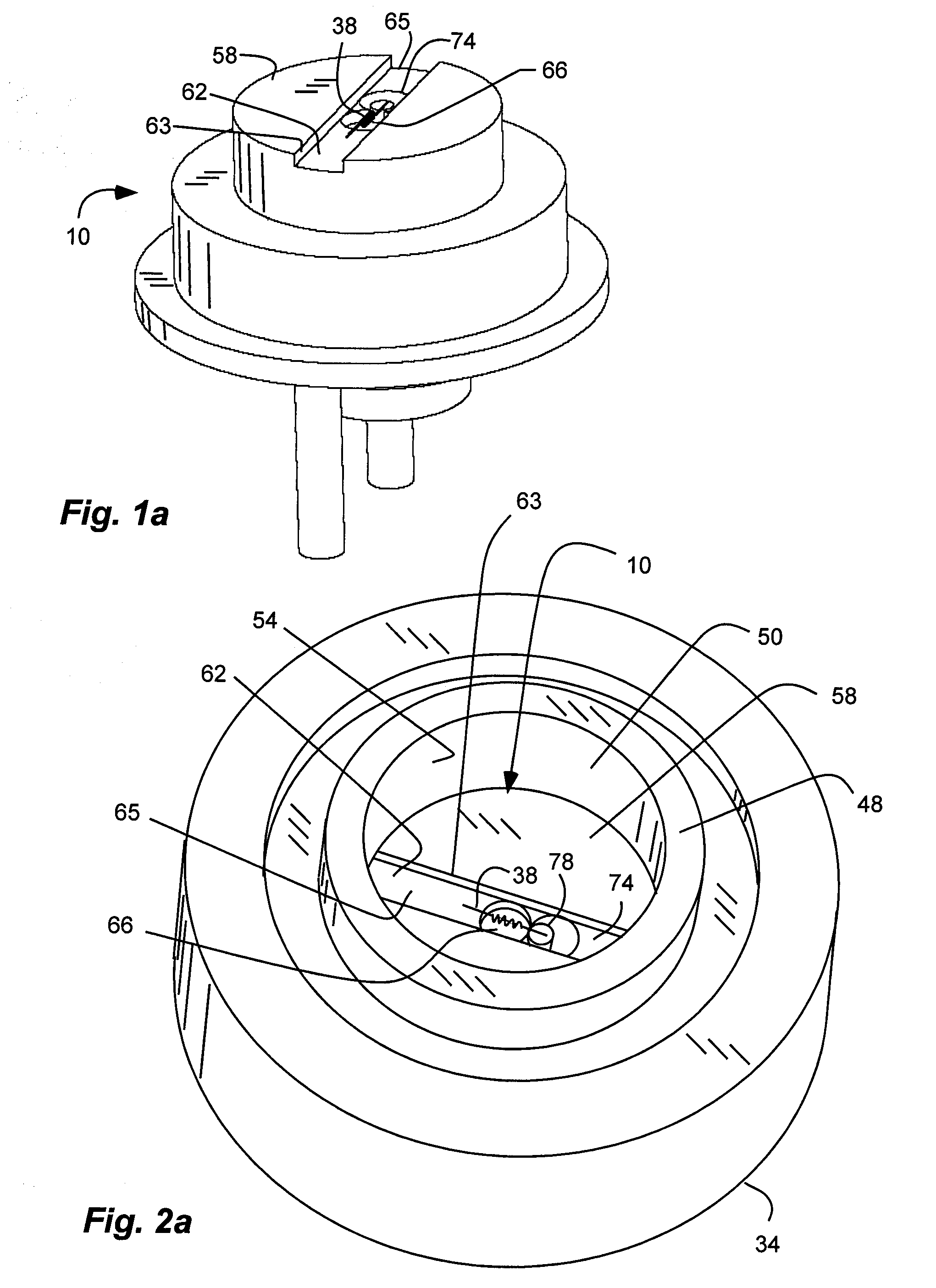

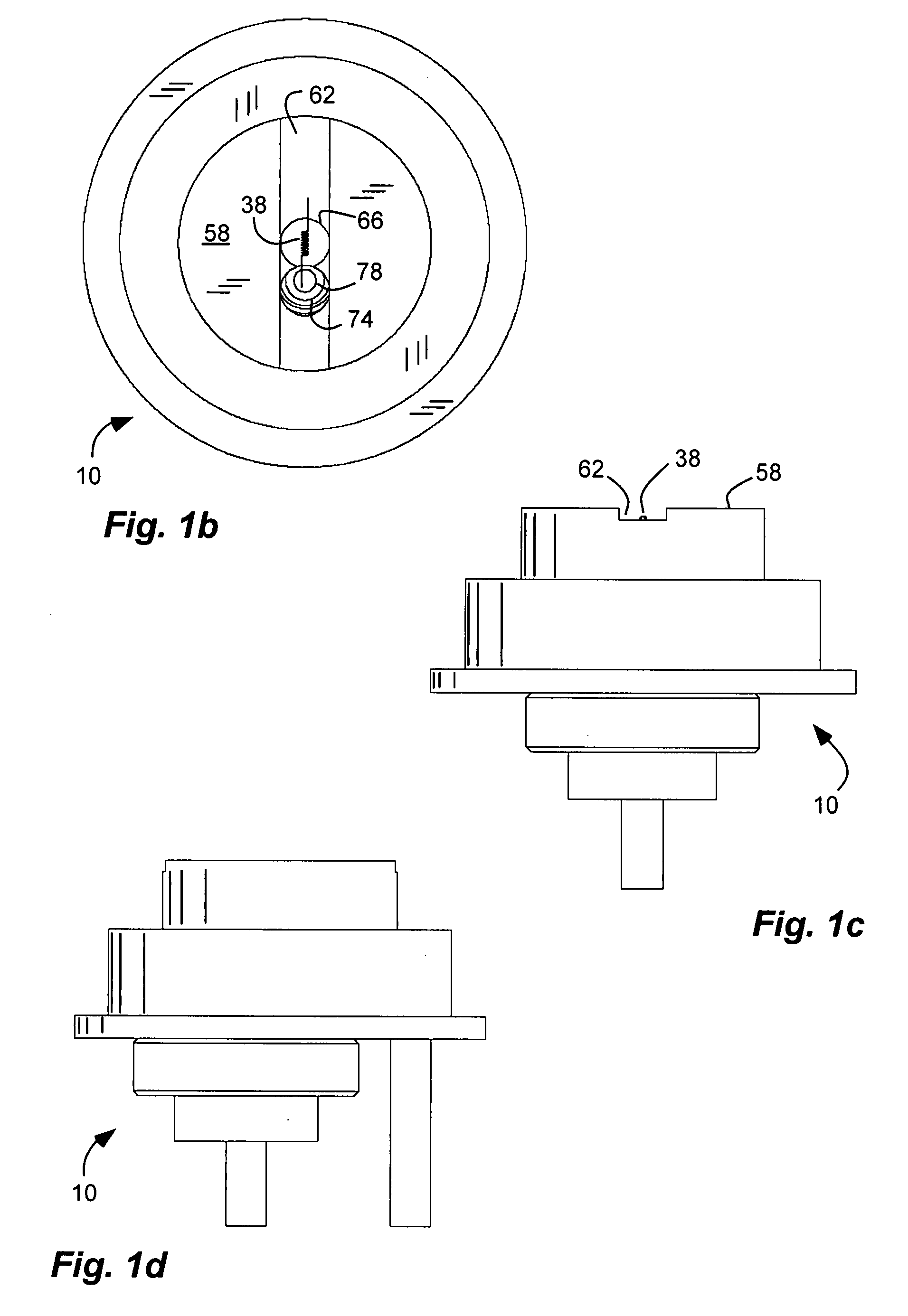

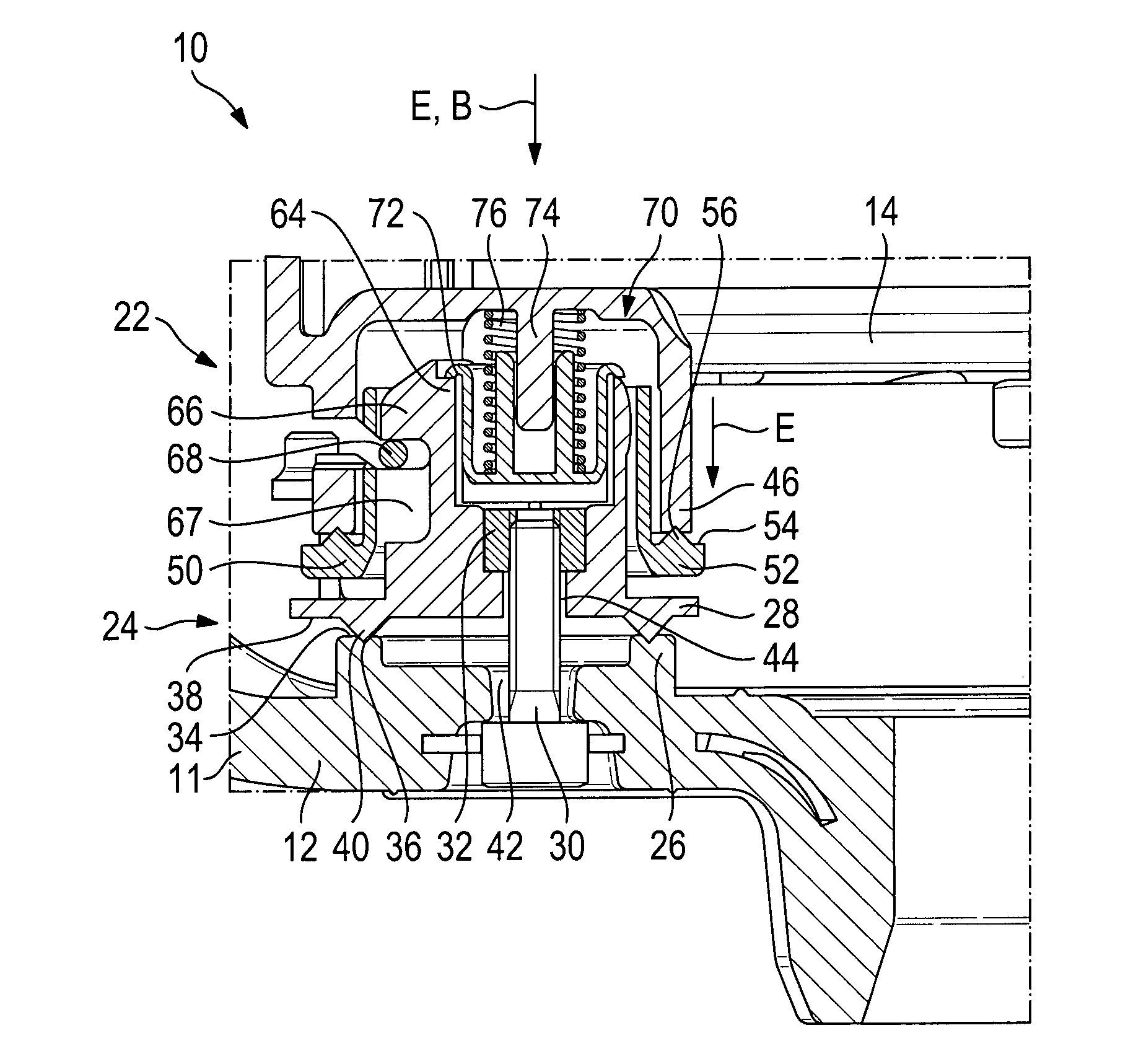

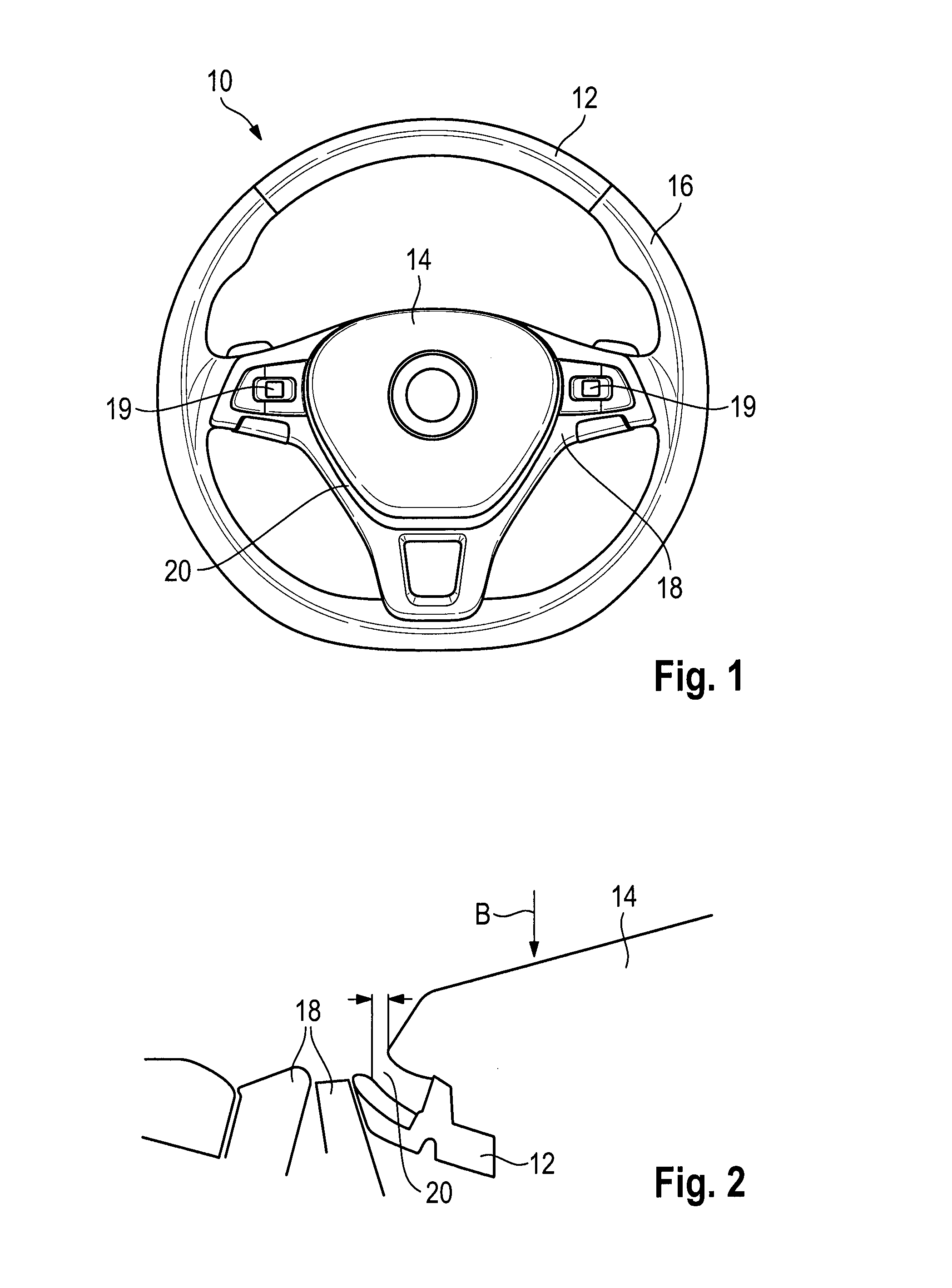

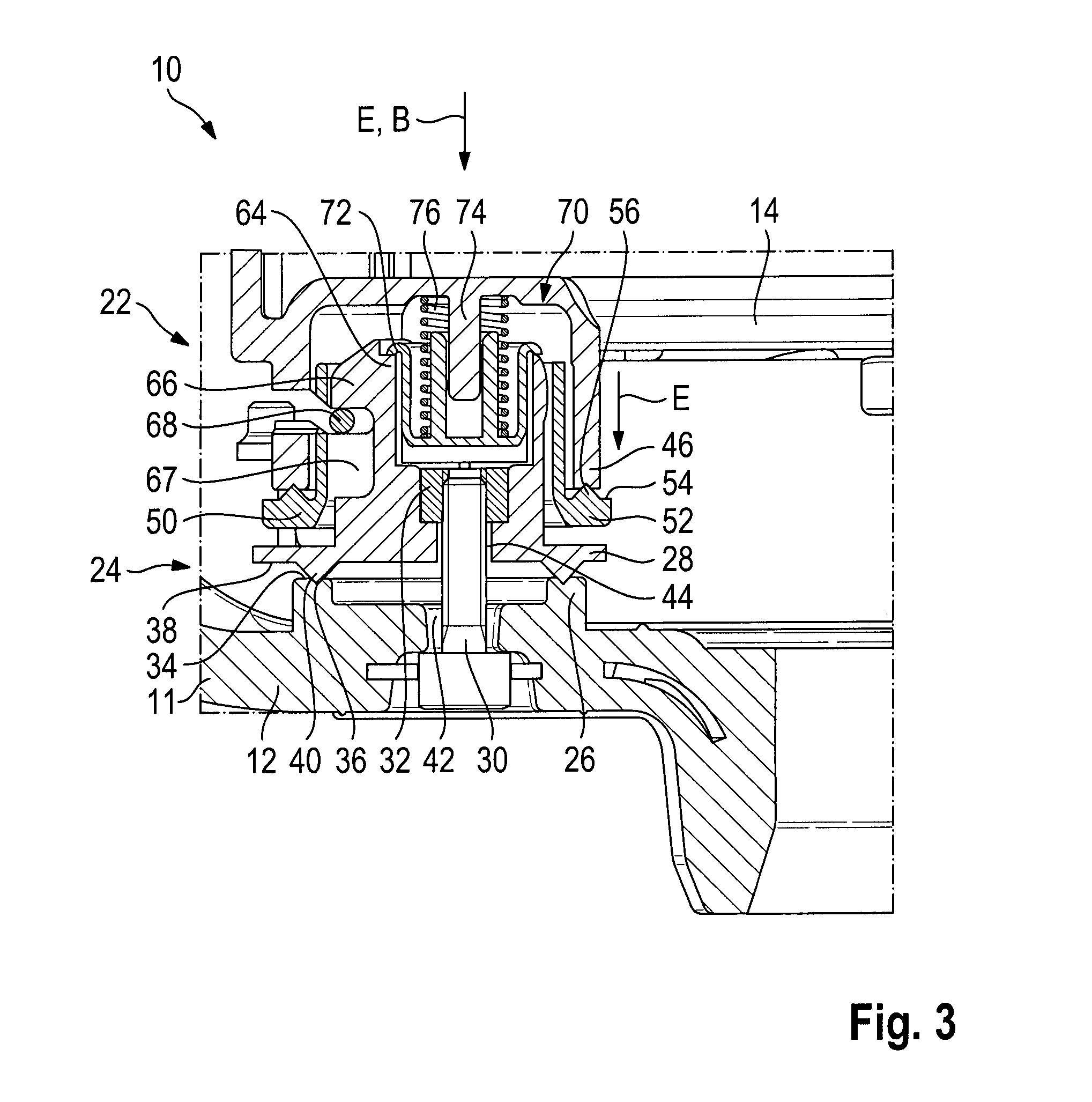

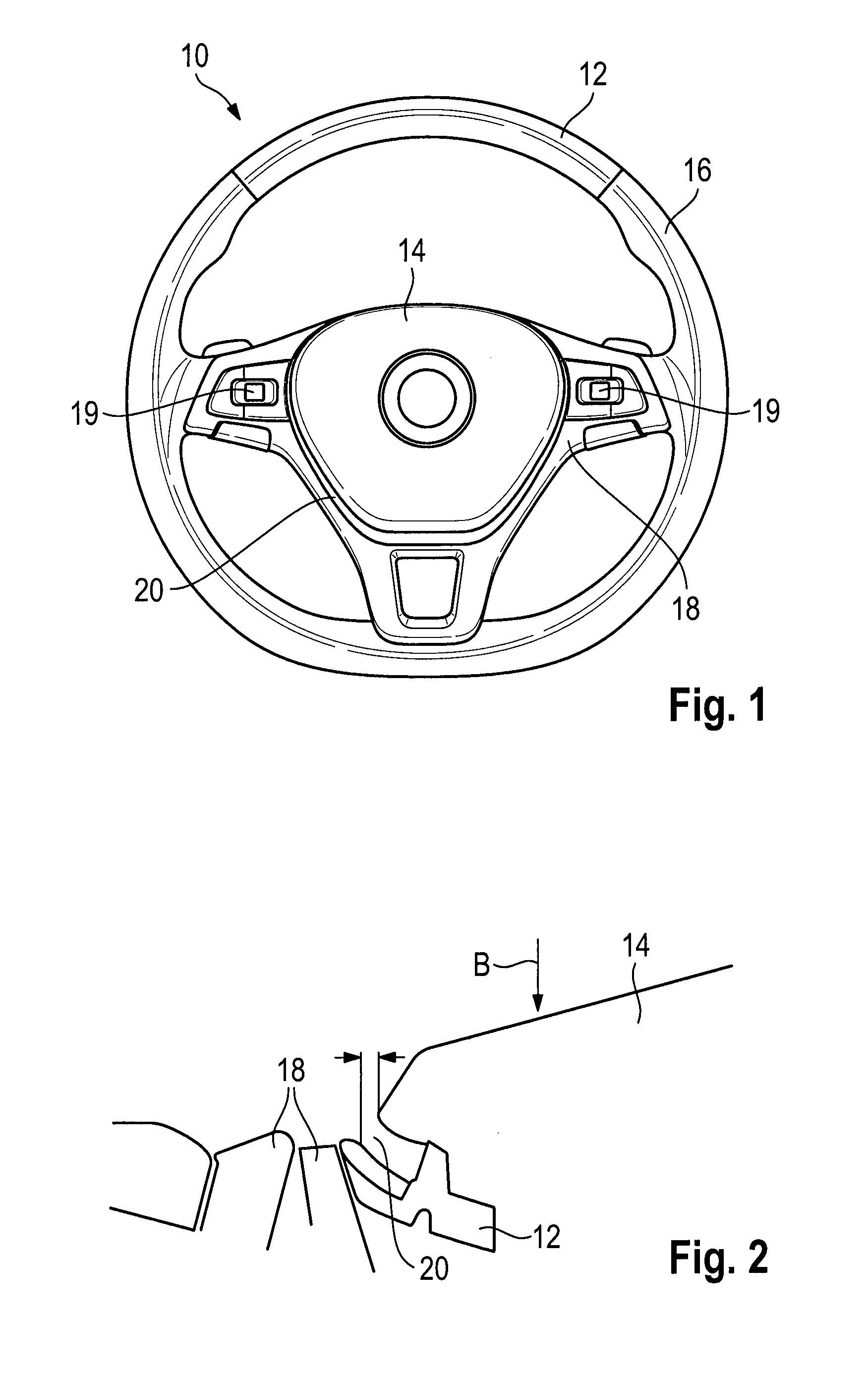

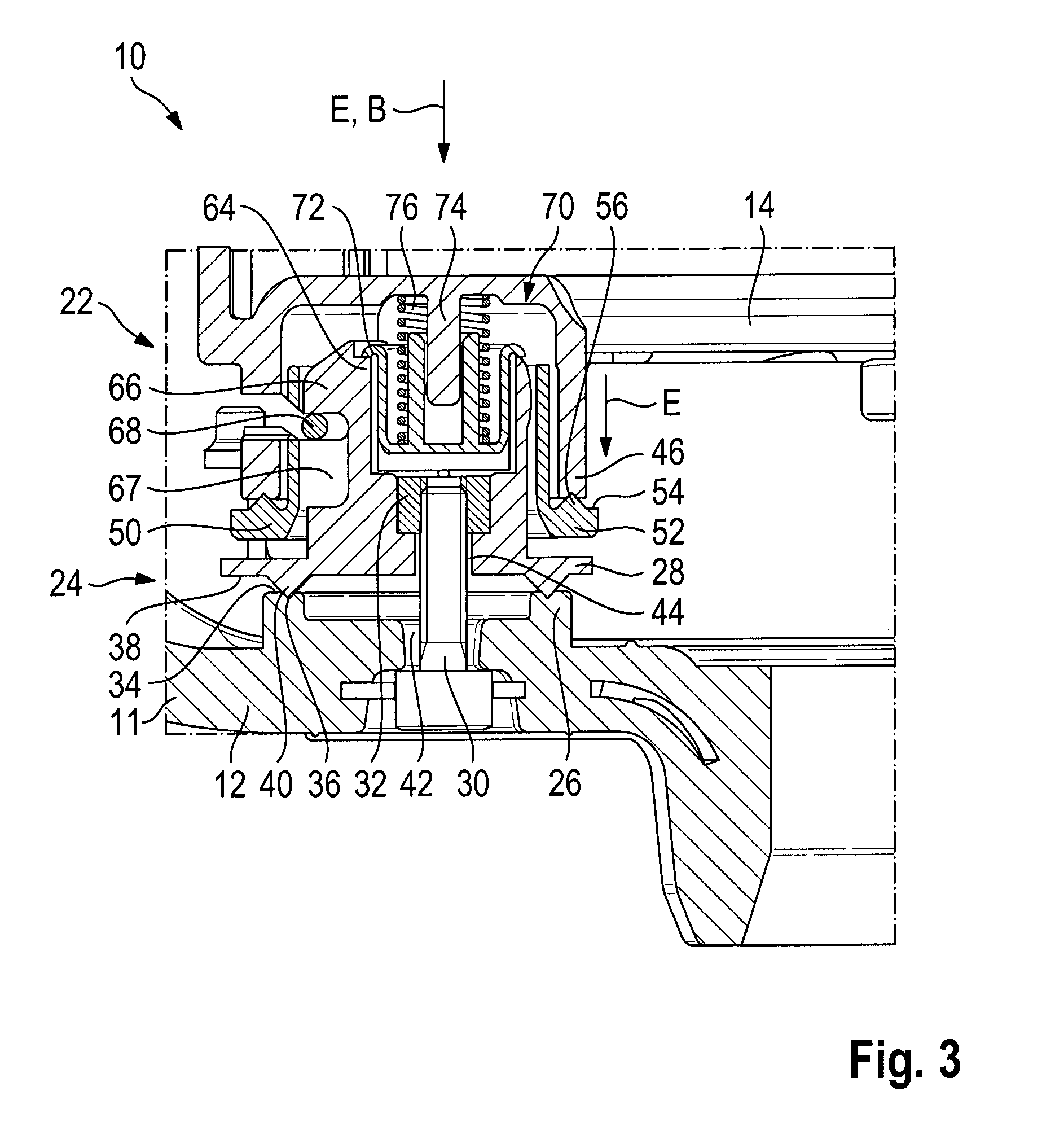

Method and device for the serial production of a vehicle assembly, bearing unit, vehicle steering wheel and horn module for a steering wheel assembly and steering wheel assembly

ActiveUS20140203539A1Simple mannerAccurate and simpler positioningAutomatic control devicesPedestrian/occupant safety arrangementBearing surfaceEngineering

A method for series production of a vehicle assembly, especially an interior assembly, including a vehicle-side support, especially a vehicle steering wheel (12), and a component to be fastened at the support, especially a horn module (14), wherein a module-side bearing unit (22) consisting of at least two bearing members (46, 50) is assigned to the component and / or a support-side bearing unit (24) consisting of at least two bearing members (26, 28) is assigned to the support, and wherein one of the bearing members (28, 50) of the respective bearing unit (22, 24) has a contact surface (34, 58) and the other one of the bearing members (26, 46) has at least one bearing surface (38, 54) includes the step of individually orientating the two bearing members (26, 28, 46, 50) of at least one bearing unit (22, 24) relative to each other as a function of the actual dimensions of the support installed and / or the component installed, fastening the two bearing members (26, 28, 46, 50) orientated relative to each other, and fastening the component to the support. The position of the support and the component relative to each other is defined by at least one bearing unit (22, 24).

Owner:TRW AUTOMOTIVE SAFETY SYST

MEMS gyro

ActiveUS20170268879A1Less sensitiveLess complicated mechanical layoutSpeed measurement using gyroscopic effectsGyroscopes/turn-sensitive devicesGyroscopeInertia

A sensor is disclosed for detecting a rotational motion about a resulting sensitivity axis. The sensor includes at least two dual mass gyroscope units, each of the gyroscope units are adapted to detect a rotational motion about a sensitivity axis of the respective gyroscope unit. The sensitivity axes being parallel to each other and to the resulting sensitivity axis. The gyroscope units are interconnected at the inertial masses of the gyroscope units which cause the gyroscope unit to operate synchronously.

Owner:RISE ACREO AB

Method for improving curing forming quality of L-shaped composite material laminated plate

The invention discloses a method for improving a curing forming quality of an L-shaped composite material laminated plate. The method comprises the following steps that (1), an elastomer material is selected, and an elastomer buffer flexible film is manufactured according to the contour dimension of a component; (2) vent holes are uniformly formed in the elastomer buffer flexible film in the thickness direction after the elastomer buffer flexible film is formed; and (3) the L-shaped composite material component is prepared, a prepreg laminated layer is paved on a rigid die according to the paving ratio, the outer surface of the laminated layer is covered with the prepared elastomer buffer flexible film, and a vacuum bag pressing method or a drying oven is adopted for curing and forming according to the set temperature and pressure curves. According to the method, the pressure borne by a part with the curvature of the composite material component in the forming process can be balanced through the introduction of the elastomer buffer flexible film, fibers can be prevented from generating micro-bending in the forming process, fiber wrinkles are prevented from being generated on the surface of the composite material laminated plate, and therefore the surface quality of the composite material laminated plate is improved, and the stability of the outer side dimension of the compositematerial component with the curvature is ensured.

Owner:WUHAN UNIV OF TECH

Method and device for the serial production of a vehicle assembly, bearing unit, vehicle steering wheel and horn module for a steering wheel assembly and steering wheel assembly

ActiveUS9365177B2Improve Manufacturing TolerancesPrecise positioningPedestrian/occupant safety arrangementHand wheelsSteering wheelEngineering

A method for series production of a vehicle assembly, especially an interior assembly, including a vehicle-side support, especially a vehicle steering wheel (12), and a component to be fastened at the support, especially a horn module (14), wherein a module-side bearing unit (22) consisting of at least two bearing members (46, 50) is assigned to the component and / or a support-side bearing unit (24) consisting of at least two bearing members (26, 28) is assigned to the support, and wherein one of the bearing members (28, 50) of the respective bearing unit (22, 24) has a contact surface (34, 58) and the other one of the bearing members (26, 46) has at least one bearing surface (38, 54) includes the step of individually orientating the two bearing members (26, 28, 46, 50) of at least one bearing unit (22, 24) relative to each other as a function of the actual dimensions of the support installed and / or the component installed, fastening the two bearing members (26, 28, 46, 50) orientated relative to each other, and fastening the component to the support. The position of the support and the component relative to each other is defined by at least one bearing unit (22, 24).

Owner:TRW AUTOMOTIVE SAFETY SYST

Multi-composition product dispenser

ActiveUS20210009336A1Avoid frustrationWell mixedClosuresSingle-unit apparatusProcess engineeringIndustrial engineering

Owner:THE PROCTER & GAMBLE COMPANY

Canister for transporting and/or storing radioactive materials comprising radially stacked radiological protection components

InactiveUS20120007004A1Satisfactory thermal conductivitySimple design and manufactureShieldingPortable shielded containersDevice formEngineering

A canister for transporting / storing radioactive materials, comprising two concentric shells between which is housed a radiological protection device forming a barrier against gamma radiation, comprising a first and a second metal radiological protection components superimposed along a radial direction of the canister, the first component being supported against the outer shell and the second component being supported against the inner shell. In addition, the components are in contact with each other along an interface taking, in section along any plane integrating the longitudinal axis, the form of a straight line segment inclined in relation to this axis.

Owner:TN INT (FR)

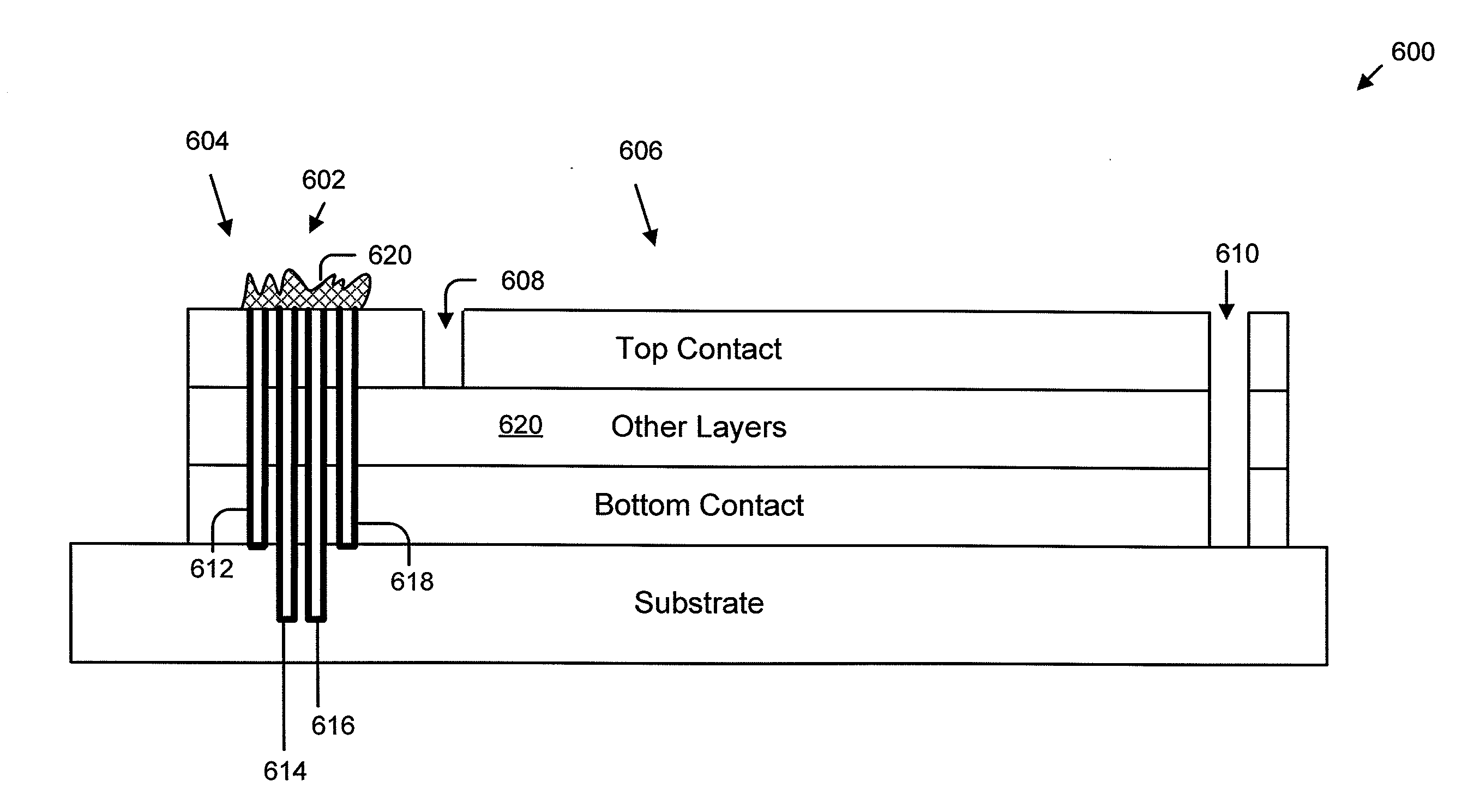

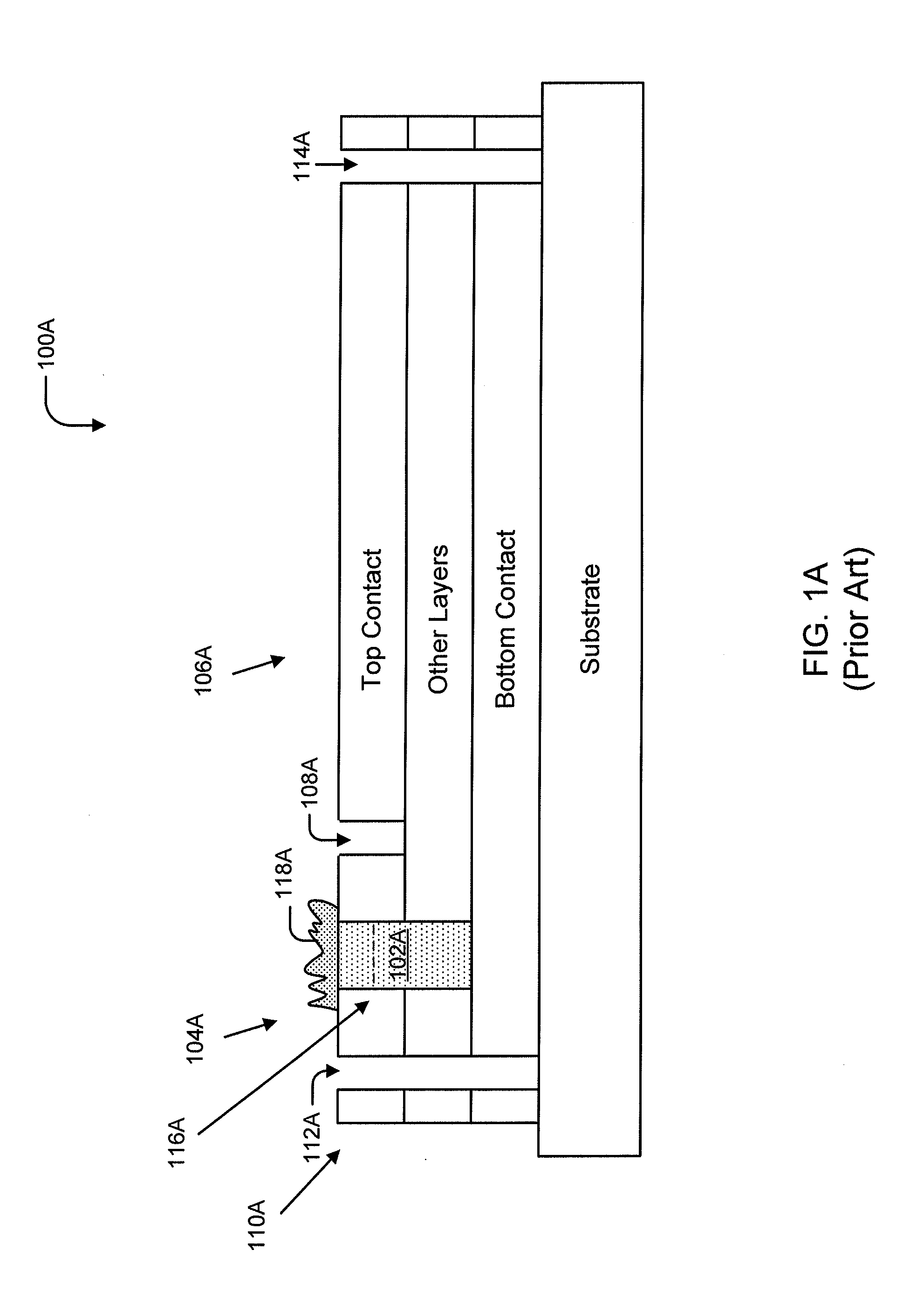

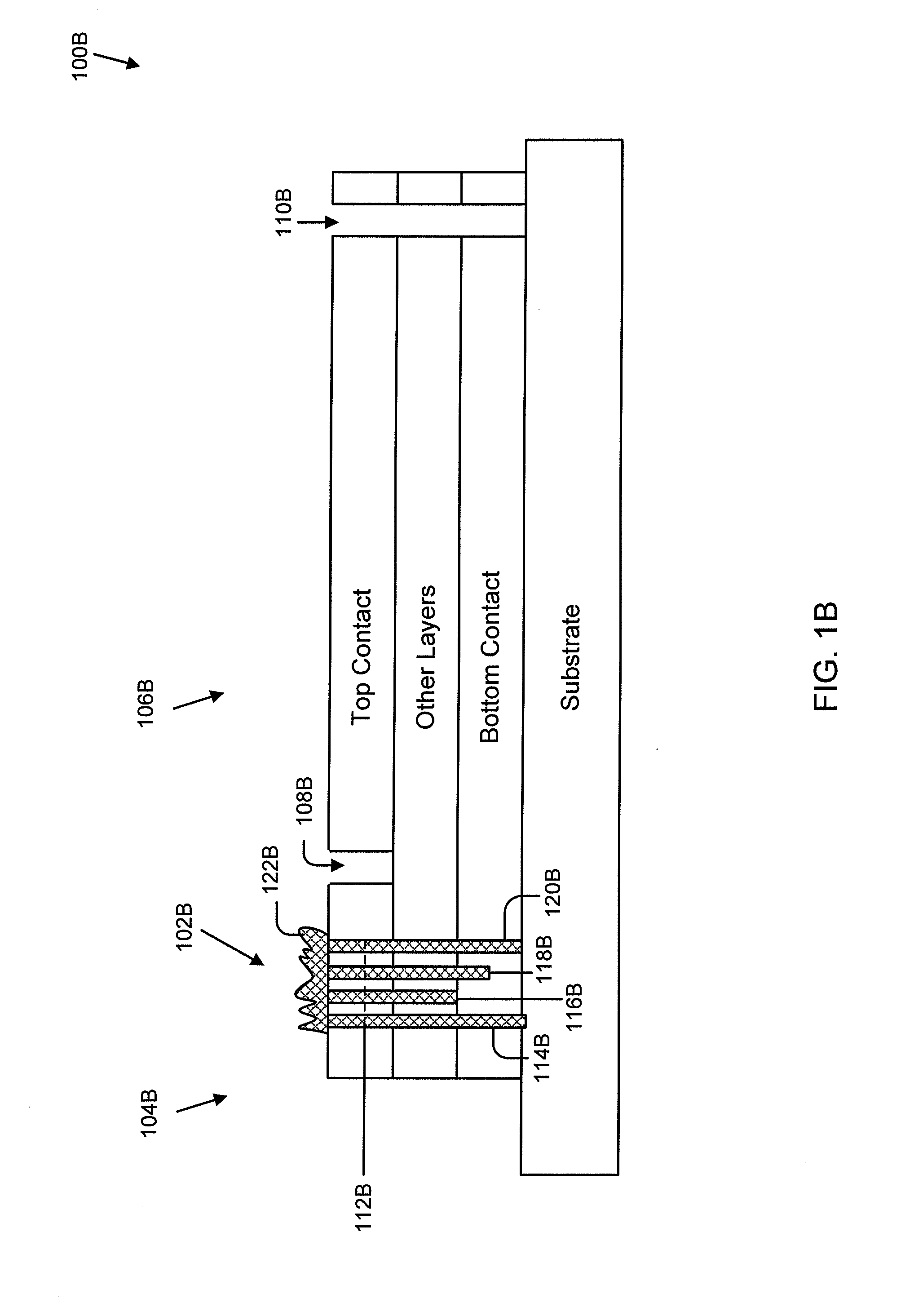

Perforation patterned electrical interconnects

InactiveUS20130154113A1Weight and size advantageReduce power lossSemiconductor/solid-state device detailsSolid-state devicesContact layerEngineering

This disclosure describes systems and methods for increasing the usable surface area of electrical contacts within a device, such as a thin film solid state device, through the implementation of electrically conductive interconnects. Embodiments described herein include the use of a plurality of electrically conductive interconnects that penetrate through a top contact layer, through one or more multiple layers, and into a bottom contact layer. The plurality of conductive interconnects may form horizontal and vertical cross-sectional patterns. The use of lasers to form the plurality of electrically conductive interconnects from reflowed layer material further aids in the manufacturing process of a device.

Owner:ITN ENERGY SYST INC

Apparatus and method for estimating data relating to a time difference and apparatus and method for calibrating a delay line

ActiveUS8825424B2Improve Manufacturing TolerancesHigh measurement accuracyElectromechanical unknown time interval measurementVoltage-current phase angleComputer scienceTime difference

An apparatus for estimating data relating to a time difference between two events includes a delay line having a plurality of stages. Each stage has a delay difference between a first delay in a first part and a second delay in a second part. This delay difference is measured by a phase arbiter in each stage, which outputs an indication signal indicating whether the first event of two events in the first part precedes or succeeds a second event of the two events in the second part. A summation device is provided for summing over the indication signals of the plurality of stages to obtain a sum value. The sum value indicates a time difference estimate.

Owner:ADVANTEST CORP

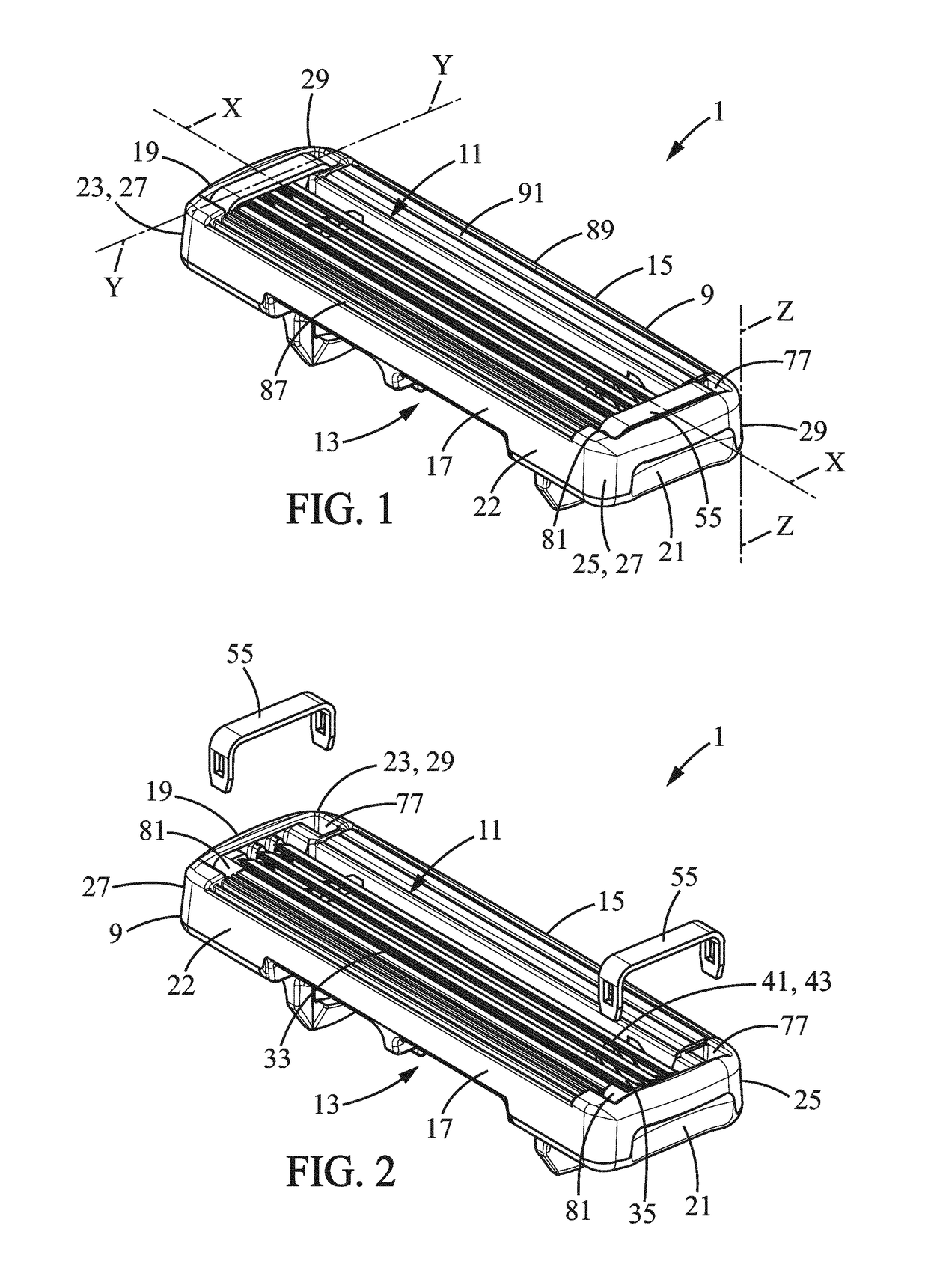

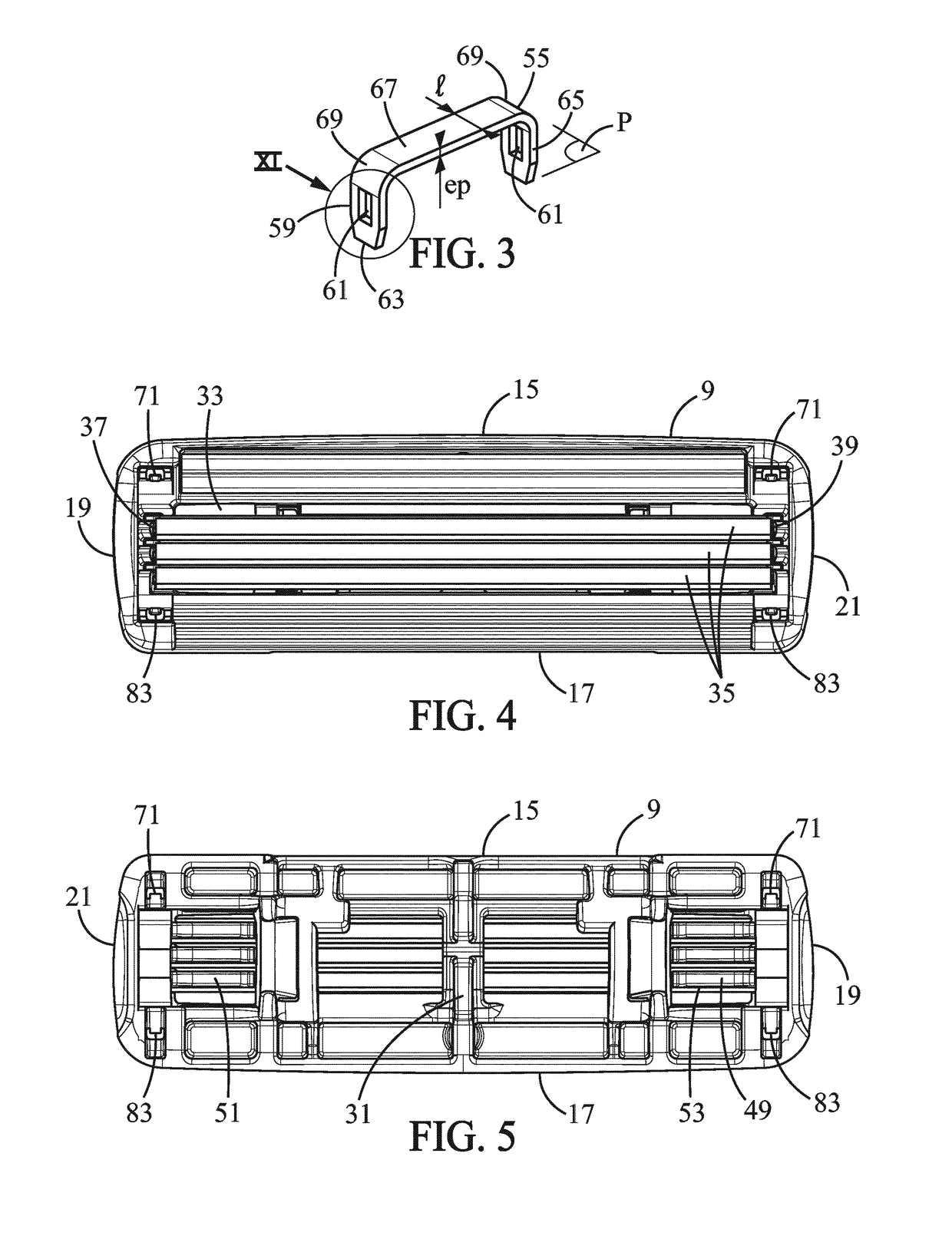

Shaving blade cartridge

ActiveUS10093030B2Reduce manufacturing stepsControlling the riskMetal working apparatusMechanical engineering

Owner:BIC VIOLEX SA

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com