Nuclear fuel pellets, manufacturing method and nuclear reactor

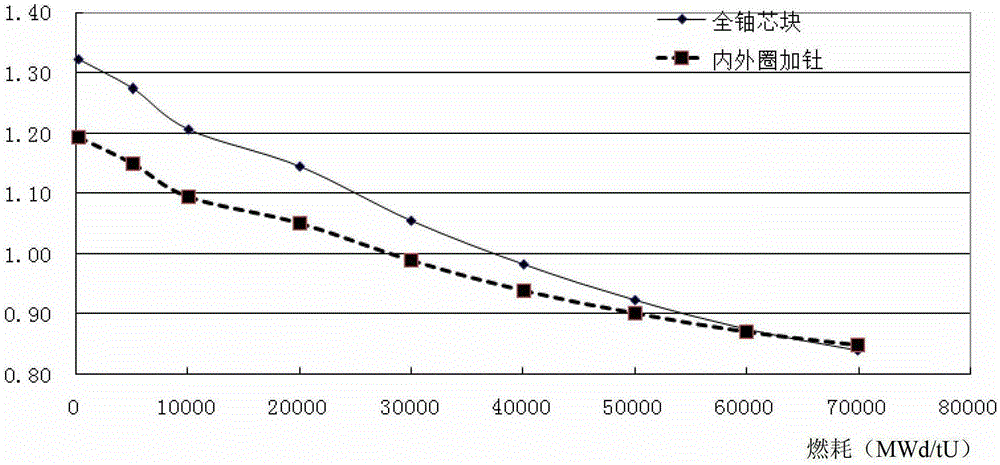

A technology for nuclear fuel and fuel, which is applied in the manufacture of reactors, reactors, and reactor fuel materials, etc., can solve the problems of low utilization rate and waste of nuclear fuel, and achieve the effects of avoiding waste, improving conversion ratio, and reducing initial excess reactivity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

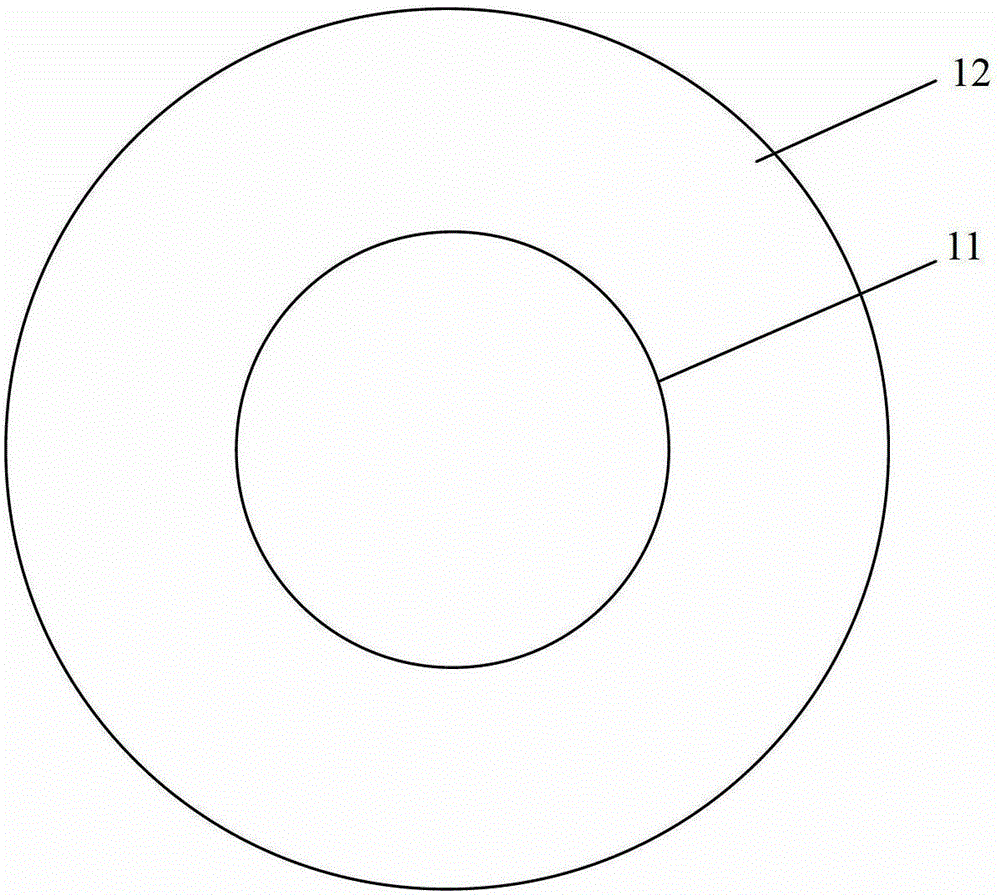

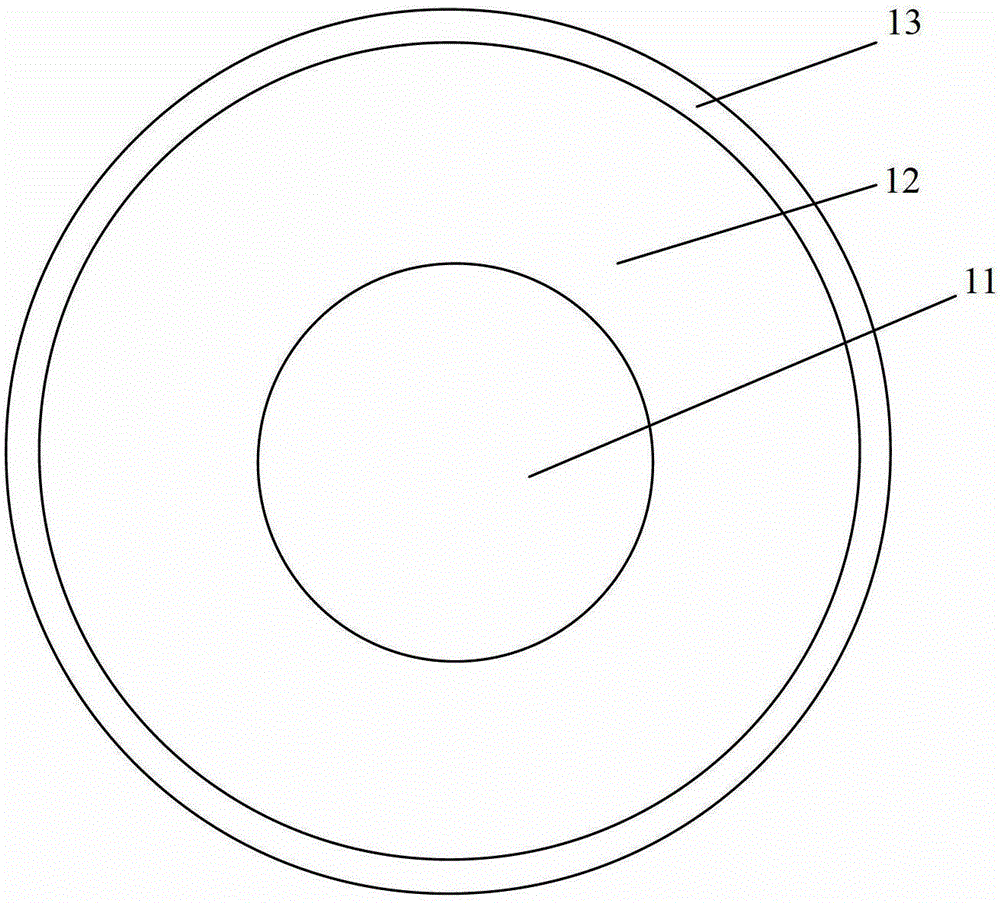

[0030] Such as figure 1 Shown is a first embodiment of the nuclear fuel pellet of the present invention, the nuclear fuel pellet includes nuclear fuel material.

[0031] The nuclear fuel pellet includes a first fuel region 11 and a second fuel region 12 arranged from inside to outside. In this embodiment, the nuclear fuel pellet is a cylindrical pellet, the first fuel region 11 and the second fuel region 12 are arranged non-uniformly along the radial direction, and the second fuel region 12 surrounds the periphery of the first fuel region 11 .

[0032] It can be understood that the nuclear fuel pellets may also be fuel pellets of other shapes, such as spherical pellets, flat pellets, and the like. When spherical pellets are used, the first fuel region 11 and the second fuel region 12 are distributed non-uniformly in the radial direction, ensuring that the second fuel region 12 wraps around the first fuel region 11; and when flat pellets are used, the first The fuel region 11...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com