Multi-type Pellet Mixed Loading Metal Cooling Reactor and Management Method

A metal cooling, multi-type technology, applied in the field of nuclear reactors, which can solve the problems of low utilization rate and large fuel loading

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

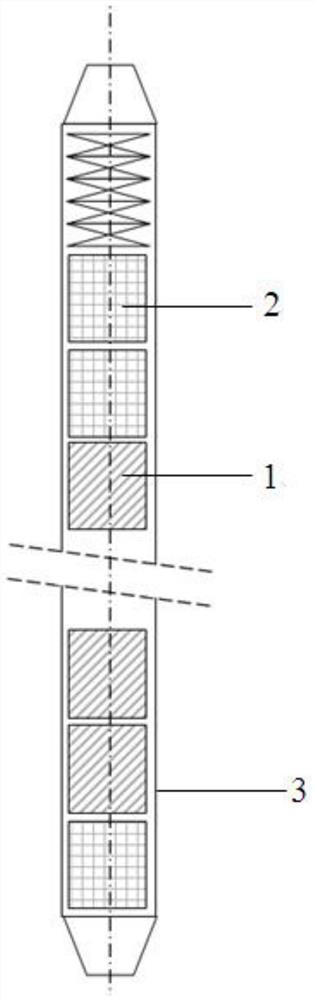

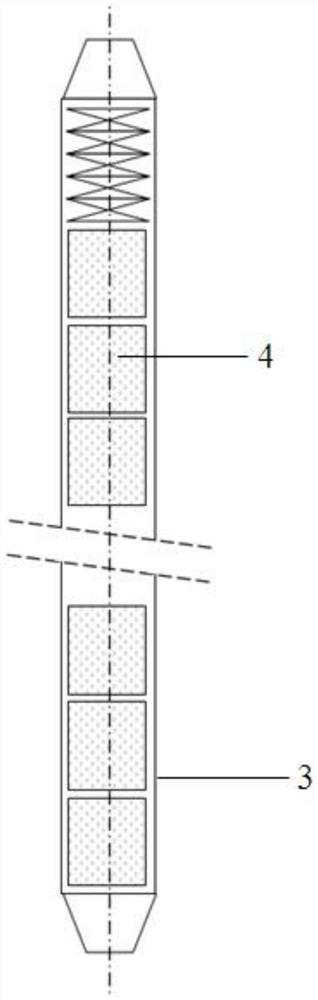

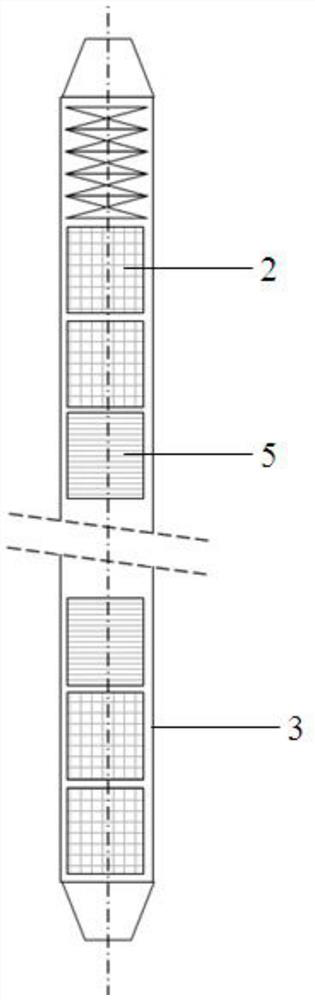

[0038] Such as Figure 1 to Figure 7As shown, a metal-cooled reactor is mixed with multiple types of pellets, and the reactor core is surrounded by a moderator assembly 11, a breeding type fuel assembly 12 is arranged on the sub-periphery, and a power type fuel assembly 13 is arranged in the inner area of the core. The moderating component 11 is composed of several moderating elements 6 arranged in a regular triangular grid, the moderating elements 6 include a cladding 3, and a zirconium hydride metal block 4 is arranged inside the cladding 3 of the moderating element 6, The moderator element 6 has a rod diameter of 9.0 mm, a cladding made of stainless steel, a thickness of 0.65 mm, and a pellet diameter of 7.5 mm. This type of element is fully loaded with zirconium hydride metal blocks 4, and the total height is 1000 mm; the multiplication type fuel The assembly 12 is composed of a number of multiplication fuel elements 7 arranged in a regular triangular grid. The multiplic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com